Abstract

Accurate and efficient prediction of thermal radiant of hydrogen jet fire is important to schedule safety design and emergency rescue program for hydrogen pipelines. In response, this paper proposes a novel Optuna-improved back propagation neural network (Optuna-BPNN) to estimate hydrogen jet flame radiation. A linear integral approach incorporating leakage rate and jet flame length is theoretically derived to establish dataset for machine learning. Then the Optuna tool is employed to optimize the initial weights and thresholds of the BP neural network. Input matrix of the Optuna-BPNN model includes pipeline diameter, leakage aperture size and hydrogen pressure. 8 sets of experimental data are employed to verify its correctness. When the abnormal data is excluded, the predicted thermal radiation of hydrogen jet fire agrees quite well with experimental results, with average and maximum deviations being 12.4% and 24.4% respectively. Using the linear integral approach, 32,670 thermal radiation data points are generated to train and test the Optuna-BPNN model. The maximum deviation between predicted and theoretical radiant heat flux for training and testing sets are only 4.5% and 6.2%, respectively. Parallel comparison trials using 6 different machine learning algorithms show that the Optuna-BPNN model gives the best mean absolute error, root mean square error and determination coefficient, which proves the effectiveness and feasibility of the developed Optuna-BPNN model in predicting thermal radiation of hydrogen pipeline jet fires.

Similar content being viewed by others

As a clean and renewable energy, hydrogen has become an important component for the energy system to promote energy structure and address climate change. It is believed that hydrogen is a crucial contributor for energy transition and fulfillment of the 2050 net-zero target. Hydrogen delivery is a critical piece of the entire value chain of hydrogen economy1. High-pressure pipeline is widely employed for hydrogen transportation ascribing to its efficiency and economic benefit. Meanwhile, concomitant safety problem in pipeline transportation is brought to the forefront. Due to the low ignition energy (0.018 MJ), once compressed hydrogen leaks from the pipe, it easily forms jet fires that produces strong thermal radiation, which could damage nearby facilities and personnel. Astbury et al.2 investigated 81 hydrogen fire incidents and found that spontaneous combustion accounts for 86.3% of these accidents. It was reported that 65% of severe hydrogen accidents are involved with jet fires caused by equipment failures3. Predicting hydrogen jet fire radiation becomes a must for safe operation and emergency rescue of hydrogen pipeline transportation.

Intuitively, we easily understand that the size of jet fire is decisive for its radiant destructiveness. Early in 1978, Becker et al.4 analyzed jet fire length of hydrogen and other fuels based on Richardson number. However, data obtained from over 70 sets of experiments with nozzle diameter ranging from 1.08 mm to 10.1 mm that formed both subsonic and sonic hydrogen jet flames were all lower than the calculated length using Becher’s formula5. Shevyakov et al.6 proposed a Froude number-based correlation that agreed quite well with measured hydrogen jet flame length. Mogi et al.7 performed hydrogen jet fire experiments with release pressure ranging from 0.001 MPa to 40 MPa. It was found that jet flame length was positively correlated to spouting pressure in form of LF/D = 524.5P0.436, where LF is flame length in m, D is nozzle diameter in m and P is spouting pressure in MPa. Molkov et al.8 summarized experimental data from different research groups and proposed a fitted equation that incorporated nozzle exit diameter and mass flow rate. Henriksen et al.9 found that nozzle geometry presented dramatic impact on jet fire length. It could increase as much as 62% at different nozzle shapes with the same mass flow rate. However, as it is unpractical to determine the shape of leakage hole in real accidents, round-shaped nozzle is widely utilized in calculating gas flow rate and jet fire length.

Thermal radiation is the main hazard mode for jet fires on human and facilities. There are two classical mathematical models to calculate the thermal radiation of jet fires, i.e., point source model and solid flame model10. The point source model assumes that all the radiation energy stems from a single point located somewhere on the main axis of the flame. Since flame height and width are ignored, location of the point heat source is uncertain, which makes accuracy of the point source model unsatisfactory. To improve this, Technica et al.11 developed a multi-point heat source model that assumes flame combustion heat is concentrated on several point heat sources that uniformly distribute along the flame center line. Thermal radiation flux at a certain target is the synthesis of all point heat sources. Taking into account jet flame length, reliability of multi-point heat source model gets improved when compared with point source model. However, uncertainty in determination of point source number makes it a thumb rule to some extent. Another derived method from point source model for jet fire radiation calculation is weighted-multi-point-source model12. It takes into account the nonuniform distribution of flame heat along the center line by assuming that emissive power of each point is proportional to its location on the flame. Nevertheless, how to set the weighting coefficients makes it somewhat empirical with low practicability. Another jet flame radiation model is solid flame model13. It takes the jet flame geometry as cone, cylinder, or wall. Radiant thermal energy of the flame is emitted from the surface. Accuracy of this model heavily depends on jet flame shape and surface integral. As it is rather difficult to conduct exact mathematical description on the geometrical shape of jet fire and its surface, practicability of the solid flame model remains a problem.

The above models provide some theoretical foundations for hydrogen jet fire radiation prediction. But it remains challenging to take quick calculation in actual jet fire accidents using these models. In recent years, neural network, as one of the most popular machine learning method, rapidly develops. As a highly efficient tool, it is capable of making quick prediction with known data. Senthilraja et al.14 presented an artificial neural network to forecast the performance of a hydrogen generation system. Çolak15,16 employed neural network to ascertain the apparent viscosity of waxy crude oil in pipe and thermal energy storage properties of nanoencapsulated phase change materials in wavy enclosures. In fire accident investigation, He et al.17 adopted back propagation neural network (BPNN) to acquire heat release rate of tunnel fires from video data of the monitoring system. Hu et al.18 proposed a genetic algorithm back propagation neural network to predict the maximum ceiling temperature in longitudinally ventilation tunnels. Mashhadimoslem et al.19 employed vertical propane jet fire geometry as input and output data of a deep learning neural network. It presented satisfactory performance in predicting propane jet flame length and diameter. Gu et al.20 conducted experiments to get the extension characteristics and temperature profile of ceiling flame in a thermal impinging flow of hydrogen-blended methane jet fire. Neural network was then employed to conduct quick calculation of volume flow rate of gas leakage.

Although theoretical calculation and numerical simulation are capable of estimating hydrogen leakage and consequent jet fire, practical application of these traditional approaches remains challenging due to the complex and time-consuming implementation process. In recent years, machine learning has gained wide attention in combustion, fire and explosion, however scarcely can we find any works of this promising technology to achieve quick calculation of geometrical and radiant information of hydrogen jet fire, which is urgently need by the hydrogen piping industry. A tough problem faced by application of machine learning in hydrogen jet fire radiation prediction is to acquire effective data for model training and testing. In response, this paper proposes a linear integral approach for data generation and develops a novel Optuna-BPNN model for convenient calculation of hydrogen jet fire thermal radiation. By taking the flame as a linear heat source concentrated on its center line, it corresponds better with real jet flame than conventional point source and discrete multi-point source assumptions. Dataset for hydrogen jet fire radiation is then established. Verification against experimental data proves its reliability. Next, BP neural network is employed to estimate thermal radiation of hydrogen pipeline jet fire. A new and powerful Optuna tool is used to optimize the hyperparameters. The Optuna-BPNN model achieves fast and accurate prediction of thermal radiation of hydrogen jet fire. Predictive performance of the this model is verified by conducting parallel comparison trials. Future concerns to improve the current work are also discussed. Novelty of this work mainly lies in two aspects. For one thing, it proposes a more practical method to estimate thermal radiation of hydrogen jet fire than traditional point source and discrete multi-point source assumptions. For another, the Optuna-BPNN model achieves practical application of artificial intelligence in hydrogen fire estimation. It could be a powerful tool for fast and accurate prediction of thermal radiation of hydrogen jet fire for the hydrogen piping industry.

Theoretical basis

Gas leakage rate

Pipeline leakage can be divided into small hole leakage (leakage aperture smaller than 20 mm), large hole leakage (leakage aperture larger than 20 mm and less than pipe diameter) and full section rupture. Lydell et al.21 made a statistical analysis and found that small hole leakage accidents accounted for over 80% of pipeline leakage accidents. Therefore, we mainly focus on small hole leakage of hydrogen pipeline in this work.

Flow regime is decisive for gas flow rate at the leakage aperture. In small hole leakage model, gas flow state can be divided into sonic flow and subsonic flow based on flow velocity, among which sonic flow conforms to

where p0 is the ambient pressure, = 101.325 kPa in the open air; p is the gas pressure in pipe, Pa, k is the adiabatic index of hydrogen, = 1.41.

While subsonic flow conforms to

As the delivery pressure of hydrogen pipeline is generally higher than 1 MPa, sonic flow is dominant in hydrogen leakage incidents for most cases, where the leakage rate can be given by

where Q is the mass flow rate, kg/s; Cd is the discharge coefficient, = 1.0 when the leakage hole is round; A is the leakage area, m2; Mk is the molecular weight of the gas, kg/mol; R is the molar gas constant, = 8.314 J/(mol·K); T is the gas temperature in pipe, K.

More detailed information regarding hydrogen leakage rate could be found elsewhere22.

Hydrogen jet flame length

Calculating the length of jet fire has long been a hot topic for hydrogen jet research. Varieties of hydrogen jet flame length models has been proposed23,24,25,26. Most of these models are based on Froude number and involve complex calculation of parameters such as hydrogen density and velocity at different positions. This dramatically deteriorates utility and feasibility of these models. In repose, Molkov et al.8 proposed a new dimensional equation drawn from experimental data obtained by different research groups. The input parameters are actual leak diameter and mass flow rate. Determination of notional nozzle diameter, gas density and velocity are all excluded. More importantly, this correlation has been validated against subsonic, sonic, and supersonic hydrogen jet flames8.

where LF is hydrogen jet flame length, m; D is the actual nozzle exit diameter, m.

Experimental data from Schefer et al.23 is used for verification, where nozzle diameter is 5.08 mm, pipeline pressure is 10.48 MPa, temperature in pipe and in the open air are 231.4 K and 293 K respectively, ambient pressure is 101.325 kPa. Li et al.27 conducted numerical simulation on the experiment. The flame length was simulated to be 5.81 m (see Fig. 1), presenting a 13.3% deviation to the actual hydrogen jet flame length (6.7 m). Using Eq. (3), hydrogen leakage rate is calculated to be 0.127 kg/s, then Eq. (4) is employed to get the jet fire length. The calculated value is 5.94 m with deviation being 11.3%, which proves the error of Eq. (4) for large-scale hydrogen jet fire is within a reasonable bound.

Simulation and experimental flame length diagram27.

Linear integral model for thermal radiation of hydrogen pipeline jet fire

Zhou et al.22,28,29,30,31 conducted a number of theoretical works on thermal radiation on jet fires. Inspired by their insightful idea in calculating radiant heat flux, a linear integral model is estimated to predict the thermal radiation of hydrogen pipeline jet fire in this work. The flame is taken as a linear heat source concentrated on its center line, which corresponds better with real jet flame than point source and discrete multi-point source assumptions. As the actual jet flame geometry is uncertain, we ignore the flame width and assume that hydrogen combustion heat uniformly distributes along the center line. Moreover, due to the high pressure of hydrogen pipeline, the flame is momentum-dominated and thus its center line is simplified to be straight, which applies well to windless and breezy conditions. Figure 2 gives the schematic diagram of hydrogen pipeline jet flame.

The radiant heat flux received by nearby target from a single point heat source is31

where I is radiant heat flux, W/m2; \({\tau _{\text{a}}}\) is the atmospheric transmissivity for thermal radiation, = 1 in dry weather condition12; \(q=\eta Q{H_{\text{e}}}\) is the total radiation energy emitted from the source, W; \(\eta\) is radiative fraction, = 0.2; Q is hydrogen leakage rate, kg/s; He is the combustion heat of hydrogen, \(=1.43 \times {10^8}\) J/kg; d is the distance between the target and radiation source, m.

Determination of radiative fraction is complicated as it is affected by varieties of factors. In many cases, radiative fraction of hydrogen is lower than 0.129. But in some cases it reaches up to 0.2930. In this work, we tentatively take it to be 0.2, with which the calculated thermal radiation of hydrogen jet fire matches well with experimental results.

As hydrogen combustion heat uniformly distributes along the flame center line, density of hydrogen combustion heat along the linear heat source can be given by

where \({q_{\text{l}}}\) is the density of hydrogen combustion heat of the linear heat source, W/m.

For a micro segment on the center line, the emitted radiation energy is

For any nearby target located at (x, y, 0) on the ground, the radiant heat flux it receives from this micro segment of the flame center line is

When the jet velocity increases to some extent, the jet flame would be lift-off from the orifice exit, where the lift-off distance can be given by32

where S is the lift-off distance, m; C is the time constant, \(=2.65 \times {10^{ - 5}}\) s for hydrogen.

Through geometric analysis, the distance between the target point and the micro segment is31

where r is the pipeline radius, m.

Thus the whole radiant heat flux received by the target from the hydrogen jet flame can be calculated through integral

Verification

Acton et al.33 conducted large-scale hydrogen release experiments using high pressure tank buried in soil backfill. A 152.4-mm pipeline was set on the tank as nozzle for hydrogen leakage. Four wide-angle radiometers were installed 40-, 50-, 60- and 80-m away from the leakage point to measure the radiant heat flux of jet fire. Schematic of the experiment arrangement is given in Fig. 3.

The initial absolute pressure within the hydrogen tank is 6.1 MPa and its total volume is 163 m3. As gas leaks, the pressure inside the tank declines. Gas mass flow rate, jet flame length and radiant heat flux are measured. The linear integral model is used to calculate the radiant heat flux at different locations. Comparison between measurement and calculation is given in Table 1. For the 8 sets of data, average and maximum deviations between measured and calculated radiant heat fluxes are 16.1% and 42.3% respectively. Radiant heat flux of the 42.3% deviation case is 9.5 kW/m2, where the radiometer locates 40 m away from the leakage point. The thermal radiation is even lower than the measured value at the 50 m radiometer (9.8 kW/m2). Thus it is highly likely to be caused by measurement error. When the abnormal 42.3% deviation case is excluded, the average and maximum deviations of the remaining cases are 12.4% and 24.4% respectively. Given that the 152.4-mm leakage diameter could be considered as full-bore release30and it dose not apply to small hole leakage scenario quit well, this result should be deemed as satisfactory, which proves the feasibility of the linear integral model in predicting thermal radiation of hydrogen jet fires in vast variation of leakage diameters.

Optuna-improved BP neural network (Optuna-BPNN) for thermal radiation of hydrogen pipeline jet fire

BP neural network (BPNN)

BP neural network is one of the most important artificial neural networks (ANN) that has been widely used in varieties of fields34. It is a multi-layer feed-forward neural network with error back propagation ability. As shown in Fig. 4, input layer, hidden layer and output layer connected by weights and thresholds form the basic structure of BP neural network. The calculation process of BP neural network mainly consists of three steps, namely forward propagation, backward propagation and model test. Forward propagation obtains the prediction result based on input data. Weights and thresholds are key parameters in this process. They are continuously adjusted and updated through error reduction in backward propagation. Prediction accuracy is verified by the test model. In BP neural network implementation, its structure is determined based on the dimensions of input and output layers of the problem. After initialization of input and output data, and determination of initial weights and thresholds, output is obtained through weights, thresholds and activation functions. Then backward propagation of the error between actual and calculated output parameter is carried out to update the weights and thresholds until the error meets the precision requirements. Due to the strong self-adaptation, self-learning and nonlinear approximation ability, BP neural network is widely used in classification and function approximation.

A standard neuronal unit in the hidden layer of a neural network includes output variables, weights, and biases. The relationship between neuron input and output can be given by

where \(\overrightarrow {{w_j}} =[{w_{1j}},{w_{2j}},...,{w_{nj}}]\) is weight vector, bj is bias, f is transfer function, \(\overrightarrow p =[{x_1},{x_2},...,{x_n}]\) and yi are input and output variables respectively.

Hyperparameter optimization tool-Optuna

In traditional BP neural networks, most hyperparameters are randomly assigned based on experience, which causes significant uncertainty in the computational process and easily leads to converge at local optima. To enhance the performance of BP neural network, Optuna is employed to optimize its hyperparameters. Optuna is an emerging hyperparameter optimization framework that supports multiple algorithms including Bayesian optimization. It exhibits notable efficiency and performance advantages in hyperparameter adjustment. Optuna is capable of dynamically constructing the parameter searching space and efficiently performing the pruning and searching operations. Optuna selects the next hyperparameter combination based on existing historical operation data, then determines potential hyperparameter combination regions. Further search is conducted within these regions to obtain a better solution. As new results are constantly generated, Optuna updates the searching space and evaluates its effectiveness, thereby gradually optimizes the accuracy and reliability of hyperparameter combination.

Defining the optimization function is the first step in implementation of Optuna. The optimization function is in charge of sampling the hyperparameter combination. Optuna automatically selects hyperparameter combinations in the set searching space through its internal sampling mechanism, which has strong flexibility. In this work, the hyperparameters to be optimized include hidden layer number, neuron number in hidden layer, activation function, L2 regularization coefficient, learning rate and so on. The ranges of these hyperparameters are set through prior knowledge and experimental experience, covering common deep learning configuration intervals. To improve searching efficiency, Optuna introduces an pruning mechanism. In the optimization process, intermediate results are reported for each round of training. If the performance of a certain test at the current stage is significantly lower than the median historical performance, it will be terminated to save computing resources. Optuna manages the optimization process by constructing a Study object to set the optimization direction and pruning strategy. Multiple rounds of trials are conducted to search for the optimal hyperparameter combination by using the Tree-structured Parzen Estimator (TPE) algorithm, which has a good global optimization ability by constructing probability models of high-performance and low-performance regions and using the expected improvement criterion to select the hyperparameter points that are most likely to improve the performance.

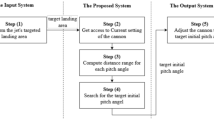

Implementation process of the optuna -BPNN

Implementation of the Optuna-BPNN model to predict thermal radiation of hydrogen pipeline jet flame is showcased in Fig. 5. Initially, the dataset is normalized and randomly split into training and testing sets at an 8:2 ratio. Next, set the search scope of hyperparameters. To optimize the scale of hidden layer, Optuna searches its neuron number with the upper limit of each training being 100 epochs. Cross-validation is adopted to evaluate the accuracy rate in the validation set. Low-performing trials are automatically terminated. Probabilistic model is built based on historical trial results, and potential combination of hidden layer and neuron number is explored. Then the combination with the highest accuracy rate is determined. The maximum coefficient of determination (R2 are taken as objective function of Optuna. In model verification stage, mean absolute error (MAE) and root mean square error (RMSE) are used as auxiliary evaluation indexes. The early stop mechanism is used to prevent overfitting, and the maximum number of iteration is dynamically adjusted to improve computational efficiency. Take the TPE algorithm as sampler, maximum R2 as optimization direction. The optimal configuration is obtained through 200 test iterations. After performing multiple tests, the combination of hyperparameters that produces the highest score is screened out. The optimal parameter combination is selected to build the final BP neural network. Lastly, predictive performance of the model is verified using the test data and the result is reverse-normalized to actual value of thermal radiation of hydrogen pipeline jet fire.

Prediction of radiant heat flux of hydrogen jet fire

Generation of dataset

Generating data samples for thermal radiation of hydrogen pipeline jet fire is the first step to train the proposed Optuna-BPNN model. The linear integral approach given by Eq. (11) is used to establish the dataset. As shown in Table 2, the calculation matrix includes six pipeline diameters, nine leakage aperture sizes and five hydrogen pressures. It generate 270 hydrogen jet fire scenarios (\(270=6 \times 9 \times 5\)). x = 5, 10, 20, 30, 40, 50, 60, 70, 80, 90, 100 m and y = 5, 10, 20, 30, 40, 50, 60, 70, 80, 90, 100 m form 121 monitoring locations, which provides 32,670 thermal radiation data points of hydrogen jet fire for the Optuna-BPNN model training and testing.

Data pre-processing

Thermal radiation of hydrogen jet flame is calculated using Eq. (11). Input parameters of the Optuna-BPNN model include hydrogen pressure, nozzle diameter, and monitoring point coordinate, while radiant heat flux is the only node in output layer. Input and output parameters in datset are at different properties and their numerical ranges vary greatly, where features with large absolute values tend to dominate the training process. This easily leads to insufficient learning of other parameters. To avoid numerical instability and speed up the training process, all data are normalized to the interval from 0 to 1.

where xn is the normalized parameter, xmax and xmin are maximum and minimum values of the input array.

Evaluation metrics

To precisely evaluate prediction ability of the developed model, three distinct evaluation metrics including mean absolute error (MAE), root mean square error (MSE) and determination coefficient (R2 are utilized35.

where n is the number of sample set, Yi,theo is theoretical data obtained from Eq. (11), Yi,pred is predicted data, \(\overline {Y}\) is average value of theoretical data.

For the MAE and MSE, the smaller they are, the better the predictive performance is. On the contrary, larger R2 means better fitting ability of the model.

Model configuration

Input and output neurons of BP neural network are connected by activation function. In this work, relu function is taken as the activation function due to its good performance in alleviating gradient depth loss with simple calculation, which improves the nonlinear approximation ability of the BP neural network.

Optimized by Optuna, key hyperparameters of the BP neural network are listed in Table 3.

Performance analysis of the Optuna-BPNN model

To evaluate the performance of the proposed Optuna-BPNN model, prediction of both training and test sets are compared with theoretical heat fluxes using Eq. (11). As showcased in Fig. 6, most data points are located on the x = y line with a determination coefficient (R2 reaching up to 0.999. The maximum deviation between predicted and theoretical radiant heat fluxes for training and test set are only 4.5% and 6.2% respectively, which proves that the Optuna-BPNN model is capable of fitting the nonlinear relationship between input and output variables quite well with satisfactory prediction accuracy.

Parallel comparison trial

Swarm intelligence algorithms including salp swarm algorithm (SSA)36genetic algorithm (GA)37grey wolf optimization (GWO)38 and bald eagle search algorithm (BES)39 are introduced to improve the BP neural network. Moreover, support vector machine (SVM) and random forest (RF) are also used for comparison.

Radar chart is a powerful visualization tool to compare and evaluate the performance of multiple models using various performance metrics. The predictive performance of above models is showcased in Fig. 7. In this figure, each axis corresponds to a performance index. The farther a point is from the center, the better the model performs on that metric. The indexes of Optuna-BP are used as benchmark for comparison.

The Optuna-BPNN model gives the largest determination coefficient (0.95), which implies that it has the best fitting performance on radiant heat flux of hydrogen pipeline jet fire. MAE and MSE of the developed Optuna-BPNN model also locate in the outermost circle, indicating the lowest discreteness and deviation among all these seven models. It proves effectiveness and feasibility of the developed Optuna-BPNN model in predicting thermal radiation of hydrogen pipeline jet fires.

Conclusions and future concerns

High-pressure hydrogen leakage severely threatens safety operation of hydrogen pipeline. It easily forms jet fires by self-ignition and generates strong thermal radiation to damage nearby facilities and personnel. Accurate and efficient prediction of radiant heat flux of hydrogen jet fire becomes a must to schedule safety design and emergency rescue programs. In response, this work proposes a novel Optuna-BPNN model based on machine learning for quick estimation of hydrogen jet flame radiation. A linear integral approach taking into account leakage rate and jet flame length is developed and its predictive performance is verified by experimental data from literature. The calculated radiate heat fluxes of hydrogen jet flames using the linear integral method agrees rather well with experiments. The average and maximum deviations are 12.4% and 24.4% respectively. Using the linear integral model, 32,670 sets of thermal radiation data points of hydrogen jet fire is generated for the Optuna-BPNN model training and testing. In machine learning, a new and powerful Optuna tool is utilized to optimize the initial weights and thresholds of BP neural network, which achieves accurate and quick prediction of thermal radiation of hydrogen pipeline jet fire. The maximum deviations between predicted and theoretical radiant heat fluxes for the training and test datasets are 4.5% and 6.2% respectively. Parallel comparison trial is conducted using SSA-BPNN, GA-BPNN, GWO-BPNN, BES-BPNN, SVM and RF algorithms. The radar chart shows that the Optuna-BPNN model gives the best MAE, MSE and R2 indexes, which proves its excellent predictive performance in estimating thermal radiation of hydrogen pipeline jet fires.

For traditional theoretical models in thermal radiation prediction of hydrogen jet fire, the implementation processes are usually complicated and time-consuming. Some parameters are hard to obtain. In comparison, the proposed Optuna-BPNN model is a practical and helpful tool with relatively convenient and accurate calculation of thermal radiation of hydrogen jet fires. The input parameters (pipeline diameter, leakage aperture size and hydrogen pressure) are all easy to get. Moreover, the 152.4-mm hydrogen leakage diameter in verification experiments proves its scalability.Nevertheless, as a preliminary investigation of machine learning in estimation of hydrogen pipeline jet flame radiation, the current work can be improved from several aspects. Initially, determination of radiative fraction in the linear integral model is somewhat empirical without solid theoretical foundation, and full-bore hydrogen release in model verification experiments does not apply to the small hole leakage scenario of the linear integral model quite well. Derivation strictness and application reliability of the theoretical model need further improvement. Secondly, apart from vertical, hydrogen could leak in different directions, the angle of jet fire should be considered in future work. Secondly, meteorological conditions including wind and rain are decisive for hydrogen jet fire radiation, but they are ignored in this work. Moreover, higher level of piping pressure and larger leakage aperture are expected to expand application of the proposed Optuna-BPNN model.

Data availability

The datasets used and analyzed during the current study available from the corresponding author on reasonable request.

References

Cheng, W. & Cheng, Y. F. A techno-economic study of the strategy for hydrogen transport by pipelines in Canada. J. Pipeline Sci. Eng. 3, 100112 (2023).

Astbury, G. R. & Hawksworth, S. J. Spontaneous ignition of hydrogen leaks: A review of postulated mechanisms. Int. J. Hydrogen Energ. 32, 2178–2185 (2007).

Gómez-Mares, M., Zárate, L. & Casa, J. Jet fires and the domino effect. Fire Saf. J. 8, 583–588 (2008).

Becker, H. A. & Liang, D. Visible length of vertical free turbulent diffusion flames. Combust. Flame. 32, 115–137 (1978).

Gautam, T. Lift-off heights and visible lengths of vertical turbulent jet diffusion flames in still air. Combust. Sci. Technol. 41, 17–29 (1984).

Shevyakov, G. G. & Komov, V. Effect of non-combustible admixtures on length of an axisymmetric on-port turbulent diffusion flame. Combust. Explo Shock+. 17, 563–566 (1977).

Mogi, T., Nishida, H. & Horiguchi, S. Flame characteristics of high-pressure hydrogen gas jet. Proceedings of the 1st International Conference on Hydrogen Safety. Pisa, Italy (2005).

Molkov, V. & Saffers, J. Hydrogen jet flames. Int. J. Hydrogen Energ. 19, 8141–8158 (2013).

Henriksen, M., Gaathaug, A. V. & Lundberg, J. Determination of underexpanded hydrogen jet flame length with a complex nozzle geometry. Int. J. Hydrogen Energ. 44, 8988–8996 (2019).

Raj, P. K. LNG fires: A review of experimental results, models and hazard prediction challenges. J. Hazard. Mater. 140, 444–464 (2007).

Technica, L. Techniques for Assessing Industrial hazards-A Manual (World Bank Technical Paper, 1988).

Miguel, R. B., Machado, I. M., Pereira, F. M., Pagot, P. R. & França, F. H.R. Application of inverse analysis to correlate the parameters of the weighted-multi-point-source model to compute radiation from flames. Int. J. Heat. Mass. Tran. 102, 816–825 (2016).

Palacios, A., Muñoz, M., Darbra, R. M. & Casal, J. Thermal radiation from vertical jet fires. Fire Saf. J. 51, 93–101 (2012).

Senthilraja, S., Çolak, A. B., Gangadevi, R., Baskaran, M. & Awad, M. Experimental investigation and artificial neural network modeling of performance of photovoltaic-Thermal solar collector based hydrogen production system with phase change material. Int. J. Hydrogen Energ. 109, 540–8550 (2025).

Çolak, A. B. Numerical investigation of thermal energy storage in wavy enclosures with nanoencapsulated phase change materials using deep learning. Energy 320, 135272 (2025).

Çolak, A. B. Investigating a machine learning algorithm’s applicability for simulating the apparent viscosity of waxy crude oil in a pipeline. Int. J. Oil Gas Coal T. 37, 321–337 (2025).

He, Q., Cao, Z., Tang, F., Gu, M. & Zhang, T. Experimental analysis and machine learning research on tunnel carriage fire spread and temperature evolution. Tunn. Undergr. Sp Tech. 133, 104940 (2023).

Hu, P., Peng, X. & Tang, F. Prediction of maximum ceiling temperature of rectangular fire against wall in longitudinally ventilation tunnels: experimental analysis and machine learning modeling. Tunn. Undergr. Sp Tech. 140, 105275 (2023).

Mashhadimoslem, H., Ghaemi, A. & Palacios, A. Analysis of deep learning neural network combined with experiments to develop predictive models for a propane vertical jet fire. Heliyon 6, e05511 (2020).

Gu, M., He, Q. & Tang, F. Experimental and machine learning studies of thermal impinging flow under ceiling induced by hydrogen-blended methane jet fire: temperature distribution and flame extension characteristics. Int. J. Heat. Mass. Tran. 215, 124502 (2023).

Lydell, B. O. Y. Pipe failure probability-the Thomas paper revisited. Reliab. Eng. Syst. Safe. 68, 207–217 (2000).

Zhou, B. et al. Prediction of state property, flow parameter and jet flame size during transient releases from hydrogen storage systems. Int. J. Hydrogen Energ. 27, 12565–12573 (2018).

Schefer, R. W., Houf, W. G., Williams, T. C., Bourne, B. & Colton, J. Characterization of high-pressure, underexpanded hydrogen-jet flames. Int. J. Hydrogen Energ. 32, 2081–2093 (2007).

Liu, S., Zhang, X., Fang, X. & Hu, L. Experimental study on tilting behavior and blow out of dual tandem jet flames under cross wind. Process. Saf. Environ. 158, 1–9 (2022).

Schefe, R. W., Houf, W. G., Bourne, B. & Colton, J. Spatial and radiative properties of an open-flame hydrogen plume. Int. J. Hydrogen Energ. 31, 1332–1340 (2006).

Vijayan, P., Sajeevan, A. C., Thampi, G. K. & Palacio, A. Experimental evaluation of subsonic-horizontal jet flames: impact of practical crack shapes. Fire Saf. J. 145, 104127 (2024).

Li, X. et al. Numerical simulation of leakage jet flame hazard of high-pressure hydrogen storage bottle in open space. Int. J. Hydrogen Energ. 62, 706–721 (2024).

Zhou, B. & Jiang, J. Thermal radiation from vertical turbulent jet flame: line source model. J. Heat. Trans. 138, 042701 (2016).

Zhou, B., Qin, X., Wang, Z., Pan, X. & Jiang, J. Generalization of the radiative fraction correlation for hydrogen and hydrocarbon jet fires in subsonic and chocked flow regimes. Int. J. Hydrogen Energ. 43, 9870–9876 (2018).

Zhou, B., Wang, X., Liu, M. & Liu, J. A theoretical framework for calculating full-scale jet fires induced by high-pressure hydrogen/natural gas transient leakage. Int. J. Hydrogen Energ. 43, 22765–22775 (2018).

Zhou, B., Liu, J. & Jiang, J. Prediction of radiant heat flux from horizontal propane jet fire. Appl. Therm. Eng. 106, 634–639 (2016).

Liu, J., Fan, Y., Zhou, K. & Jiang, J. Prediction of flame length of horizontal hydrogen jet fire during high-pressure leakage process. Procedia Eng. 211, 471–478 (2018).

Acton, M. R., Allason, D., Creitz, L. W. & Lowesmith, B. J. Large scale experiments to study hydrogen pipeline fires. Proceedings of the 8th International Pipeline Conference, Calgary, Alberta, Canada, September 27-October 1, (2010).

Xu, L. et al. Corrosion failure prediction in natural gas pipelines using an interpretable XGBoost model: insights and applications. Energy 325, 136157 (2025).

Yin, P., Xie, L., Zhang, H., Li, W. & Wang, W. Modelling wax deposition of diesel in sequential transportation of product oil pipeline using optimized back propagation neural network. Can. J. Chem. Eng. 102, 1764–1776 (2024).

Mirjalili, S., Gandomi, A. H., Mirjalili, S. Z., Saremi., Faris, S. H. & Mirjalili, S. M. Salp swarm algorithm: A bio-inspired optimizer for engineering design problems. Adv. Eng. Softw. 114, 163–191 (2017).

Liu, Z., Liu, A., Wang, C. & Niu, Z. Evolving neural network using real coded genetic algorithm (GA) for multispectral image classification. Future Gener Comp. Sy. 20, 1119–1129 (2004).

Mirjalili, S., Mirjalili, S. M. & Lewis, A. Grey Wolf optimizer. Adv. Eng. Softw. 69, 46–61 (2014).

Alsattar, H. A., Zaidan, A. A. & Zaidan, B. B. Novel meta-heuristic bald eagle search optimisation algorithm. Artif. Intell. Rev. 53, 2237–2264 (2020).

Acknowledgements

The authors gratefully acknowledge the support from the National Natural Science Foundation of China (No. 52071338), the Provincial Science Foundation for Distinguished Young Scholars of Shaanxi (No. 2022JC-34), the Science and Technology Development Project of CNPC (No. 2022DQ0527), the Basic Research and Strategic Reserve Technology Research Fund Project of CNPC (No. 2023DQ03-04).

Funding

This article is funded by the National Natural Science Foundation of China (No. 52071338), the Provincial Science Foundation for Distinguished Young Scholars of Shaanxi (No. 2022JC-34), the Science and Technology Development Project of CNPC (No. 2022DQ0527), the Basic Research and Strategic Reserve Technology Research Fund Project of CNPC (No. 2023DQ03-04).

Author information

Authors and Affiliations

Contributions

Anqing Fu developed the concept, wrote the original draft and received funding. Weidong Li and Mingxing Li were involved in data analysis and algorithm development. Hang Su conducted data acquirement and analysis. Chaoming Wang made contributions to the study supervision and funding acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Fu, A., Li, W., Li, M. et al. Estimating thermal radiation of vertical jet fires of hydrogen pipeline based on linear integral and machine learning. Sci Rep 15, 34423 (2025). https://doi.org/10.1038/s41598-025-17462-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-17462-8