Abstract

The Loos-Manas-Zloczower model has been simplified and developed for conductivity predicting in polymer carbon nanofiber (CNF) systems (PCNFs). Herein, CNFs surrounded by interphase and tunneling distance (λ) are considered as extended CNFs, and their resistance is calculated to determine the PCNF conductivity. The developed model is analyzed across various factors, and its predictions are compared to the actual conductivity of different samples. For instance, when λ > 8 nm, the PCNF conductivity is minimized to 0.01 S/m, whereas with a λ of 1 nm and a polymer tunnel resistivity of 50 Ω.m, the nanocomposite conductivity increases to 0.79 S/m. Thus, both tunneling space and polymer resistivity conversely manage the conductivity. Furthermore, the conductivity of the nanocomposite maximizes at 0.75 S/m with a minimum CNF radius of 30 nm and a supreme CNF length of 60 μm, which indicates that the thinnest and longest CNFs provide the uppermost PCNF conductivity. The predictions of the developed method show a good agreement with the real conductivity of various samples, confirming its validity.

Similar content being viewed by others

Introduction

Carbon nanofiber (CNF) exhibits excellent electrical conductivity and appropriate stiffness1,2,3,4. Consequently, CNF has significant potential to enrich the toughness and thermal/electrical conduction of polymer composites5,6,7. Kumar et al.8 prepared a polycarbonate (PC)/oxidized CNF composite and found that its DC conductivity augmented from about 10−14 S/m for PC to 100 S/m for the composite containing only 3 wt% of CNF. Additionally, it was reported that the composite storage modulus improved with increasing CNF loading, with the storage modulus of a nanocomposite with 5 wt% CNF showing a remarkable 282% increase at 165 °C compared to pure PC.

Tunneling of electrons primarily manages the conduction in polymer composites of CNF (PCNFs)9,10, due to the electron moving through narrow tunnels between adjacent particles. Generally, small tunnels can enhance electron movement, though large tunnels produce high resistance to electron current11,12,13,14. The tunneling features were studied in the nanocomposites of graphene15,16, silver nanowires17 and carbon nanotubes (CNTs)18, but they have been overlooked in the conductivity of PCNFs. Consequently, it is significant to investigate the tunneling impacts on the PCNF conductivity.

In PCNFs, the interphase zone is created owing to the huge interfacial area and strong interfacial contacts between CNFs and polymers5,19,20,21. The strengthening role of the interphase in nanocomposites has been reported in many studies22,23,24,25,26,27. Additionally, the interphase can assimilate into the filler net, significantly influencing the onset of percolation and network dimensions28,29,30,31. The percolation of the interphase and its power on the nanocomposite stiffness and conduction were documented in the literature32,33. However, the percolation of the interphase has not been studied in the CNF-filled materials.

From a modeling perspective, the power-law model has been used to predict the nanocomposite conductivity34,35,36. It considers the percolation onset, filler conduction, and filler concentration to calculate conductivity37. Although the outputs of this model have fine arrangement with the measured numbers, the power-law model does not account for the filler dimensions, tunnels, and interphase. Additionally, few conductivity models have been advanced for the samples comprising CNT38,39 and graphene11,13,14 by considering interphase depth and tunneling effects, but models specifically for the conductivity of PCNFs are limited. Previous research has mainly focused on the experimental measurement of conductivity in PCNFs. Therefore, it is valuable to analyze the conductivity of PCNFs from a modeling perspective to identify effective parameters for optimization.

Takayanagi equation was advanced by Loos and Manas-Zloczower for the modulus of CNT-polymer composites, supposing dispersed/networked CNT after the percolation onset40. However, their model does not consider the interphase in nanocomposites. Meanwhile both stiffness and conductivity of nanocomposites exhibit percolating trend and are affected by the features of the nanofiller network and interphase, advanced Takayanagi equation can be more progressed for the conductivity of PCNFs. Actually, the existing models commonly disregarded the interphase percolation in the nanocomposite conductivity. As mentioned, the power-law model does not consider the CNF dimensions, tunnels, and interphase, which is insufficient for conductivity prediction. Also, Takayanagi model was suggested for the modulus of CNT-polymer composites, ignoring the interphase network.

This article presents a novel development and application of the Loos-Manas-Zloczower equation for the PCNF electrical conductivity. Unlike the past models that chiefly focused on experimental measurements, this work incorporates detailed considerations of interphase size, tunneling effects, and the extended CNF concept. By participating these critical terms, the model offers a more inclusive and precise calculation of PCNF conductivity. The innovative approach of treating CNFs surrounded by interphase and tunneling distances as extended CNFs enables a better understanding of the characters of many factors, such as CNF twistiness, interphase thickness, and tunneling resistance, in influencing conductivity. This model’s ability to align closely with experimental data from various samples underscores its robustness and practical applicability. The findings that specific configurations of CNF dimensions, percolation onset, interphase characteristics, and tunneling properties can optimize conductivity provide valuable insights for designing high-performance PCNF composites, marking a significant advancement in the field of polymer nanocomposites.

Theory

The Takayanagi model was modified and developed by Loos and Manas-Zloczower40 using the network of CNT after the onset of percolation. They proposed two arrangements (Fig. 1), nonetheless only Form II is appropriate for the modulus of nanocomposites40.

The adjusted model according to Form II is stated by the volumetric portions of the filler (\({\varphi _f}\)) and network (\({\varphi _N}\))40 as:

Ed, EN, and Em are the moduli of the dispersed filler, network and polymer media, in that order.

Equation 1 can be utilized for the PCNF conductivity, because the PCNF includes the networked and dispersed particles after percolation onset. Both the conductivity and modulus in nanocomposites reveal percolating trend depending on the physical appearance of the nanofiller, network, and interphase.

The modulus in Eq. 1 can be substituted with conductivity. Since the dispersed CNFs do not significantly contribute to conductivity, it is assumed that both Em and Ed are replaced by the conductivity of the polymer matrix (σm). Since the charge transferring occurs through the continuous network of CNFs, the dispersed nanofibers in the matrix cannot transfer the electrons. So, it is assumed that the dispersed CNFs cannot contribute to the conductivity of nanocomposites. Equation 1 is adjusted for the system’s conductivity as:

σN is the conductivity of CNF. Too minor values of \({\varphi _N}\), \({\varphi _f}\)and σm simplify Eq. 2 to:

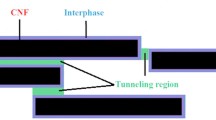

Equation 3 commonly overestimates the PCNF conductivity, because the conductivity of CNF is 104 S/m41,42,43. Moreover, Eq. 3 ignores the tunneling effect, even though electron tunneling plays a vigorous role in the conductivity of PCNFs. The tunneling distance among neighboring CNFs can be assumed by the extension of CNF, as seen in Fig. 2. The extended CNF includes the CNF, interphase, and tunnels simultaneously.

The conductivity of the stretched CNF (σext) is approximated and replaced into Eq. 3 to forecast the PCNF conductivity as:

The resistance for a stretched CNF is calculated as:

Rf and Rtun mean the intrinsic resistance of CNF and tunnels, correspondingly.

Rf can be estimated as44:

R and l represent the CNF radius and length, correspondingly.

Nonetheless, the twistiness of CNF reduces its operative size and conduction. The minimum length among the two tops of CNF is the operative length (leff), signifying the twistiness parameter as:

where a higher u indicates more curliness, although a straight CNF represents u = 1. Twistiness diminishes the conductivity as44:

leff = l/u and CNF conductivity are reflected in Eq. 6 to express Rf by:

The resistance of tunnels includes the CNF (R1) and the polymer film (R2) resistances at tunnels as44:

R1 is given by contact diameter (d) as44:

Additionally, R2 is expressed by the tunnel resistivity of polymer (ρ), contact area (S ≈ d2) and tunneling length (λ)44 as:

Exchanging Eqs. 11 and 12 into Eq. 10 presents the tunnel resistance as:

Now, substituting Eqs. 13 and 9 into Eq. 5 predicts the total resistance of protracted CNF (Ω) as:

which can be used to suggest the conductivity of the extended CNF (S/m) as:

Moreover, \({\varphi _N}\) is stated by the share of networked CNF (f) in the PCNF as:

The interphase can cultivate the net in nanocomposites, so its concentration should be considered in the network volume fraction. The interphase volume portion is assessed as:

t represents the depth of interphase.

The operative volume portion of the filler comprises both interphase and CNF as:

Additionally, thinner and longer CNFs can provide more connections in the PCNFs. Also, a denser interphase can reduce the space among nanofibers to yield the lower percolation onset and bigger network. So, the percolation onset in PCNF is recommended44 as:

However, waviness unpleasantly affects the ϕp by leff = l/u, since more waviness decreases the effective length of nanofibers in the network. Actually, the waviness shortens the efficient nanofibers increasing the percolation onset. So, u as waviness parameter affects the ϕp (Eq. 19) as:

The network percentage in the PCNF is designed as45:

which is protracted by Eqs. 18 and 20 as:

Now, \({\varphi _N}\) (Eq. 16) can be derived from Eqs. 22 and 18 as:

When \({\varphi _N}\) (Eq. 23) and σext (Eq. 15) are considered in Eq. 4, the PCNF conductivity can be assessed as:

determining the CNF/interphase/tunnel influences on the PCNF conductivity. It is important to note that polymer chemistry (e.g., polarity, crystallinity) may control the interactions at polymer CNF interface, which affect the interphase size and tunneling characteristics. For example, the strong bonding among the polymer chains and CNFs produces a denser interphase, which widens the network and improves the nanocomposite conductivity.

Results and discussion

Checking of factors

The inspirations of all parameters on the sample conductivity are surveyed by the progressive technique at the typical values of u = 1.2, t = 20 nm, ϕf = 0.02, R = 50 nm, λ = 5 nm, l = 30 μm, d = 40 nm, and ρ = 150 Ω.m. Three-dimensional and contour schemes are employed to adjust the conductivity of PCNF (summarized as conductivity here) and to understand the key parameters.

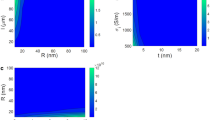

Figure 3 presents the conductivity drawings in relation to ϕf and ϕp, representing the CNF volume fraction and percolation onset, respectively. The lowest conductivity, approximately 0, is witnessed at ϕf = 0.01 and ϕp = 0.03, although the ultimate result of 0.185 S/m is realized at the uppermost ϕf = 0.04 and the smallest ϕp = 0.003. Thus, a higher CNF quantity and a lower onset of percolation improve the conductivity, with the optimized level observed at the peak CNF concentration and the lowest percolation onset.

A higher quantity of conductive nanofibers significantly enhances charge transfer because it results in a larger network after the percolation onset. A higher CNF concentration surges the conductive points in the samples, as the polymer matrices are insulative, with conductivities ranging from 10−14−10−16 S/m. Contrariwise, a little volume of CNFs leads to a smaller network, deteriorating conductivity owing to insufficient electron transport. Moreover, a very low quantity of CNFs may not even touch the percolation onset compulsory to produce a network. Numerous models have described a same relationship between the nanocomposite conductivity and filler concentration11,17. Therefore, it is reasonable to establish a right relation between composite conductivity and CNF concentration.

An inferior onset of percolation definitely increases both the portion (Eq. 21) and concentration (Eq. 23) of networked CNFs, thereby improving conductivity. In fact, a lower onset of percolation enhances the extent and density of the network, thereby cultivating electron transport. Conversely, a higher inception of percolation reduces the volume of CNF net in the system, deteriorating electron transport. Thus, there is an opposite association between ϕp and conductivity, corroborating the developed attitude.

Figure 4 exemplifies the conductivity by the CNF curliness and the depth of interphase. The slightest value of 0.005 S/m is observed at u > 1.3 and t < 13 nm, whereas the maximum extent of 0.2 S/m is realized by u = 1 and t = 40 nm. These results reveal that less waviness and a denser interphase yield higher conductivity. However, waved CNFs and a thin interphase only slightly improve conductivity. Therefore, straight CNFs and a thick interphase are essential for optimizing conductivity.

Straight CNFs (with less waviness) minimize the percolation onset (Eq. 20) and exhibit high conductivity (Eq. 8), because straight CNFs surge both the dimensions and conduction of the net in the samples, improving charge transfer. Actually, straighter CNFs provide more connections in the system, which facilitate the network formation. In contrast, higher waviness of CNFs shortens their effective size, which adversely affects percolation onset and conduction. The waved CNFs reduce the network size and conduction (Eq. 8), which in turn lowers conductivity. Consequently, waved CNFs weaken conductivity, confirming the calculations of the suggested technique.

The interphase can donate to the development of the network in the system. A thicker interphase lessens the onset of percolation and expands the network, increasing the charge transfer. In fact, a thicker interphase increases the concentration of the conductive phase in the PCNF, thus improving conductivity. On the contrary, a thinner interphase negatively impacts the conductivity of PCNF because it cannot effectively join and expand the CNF network. Accordingly, the proposed model precisely predicts conductivity at numerous interphase depth ranges. A better adhesion at polymer - CNF interface can provide a thicker interphase, which produces a lower percolation onset, bigger network and thus higher conductivity.

Figure 5 displays the predicted conductivity at different ranges of CNF dimensions. An insulative material is detected at R > 80 nm and l < 20 μm, nevertheless the conductivity maximizes to 0.75 S/m at the least R = 30 nm and the extreme l = 60 μm. Thick and short CNFs do not increase conductivity, whereas the thinnest and longest CNFs yield super-conductive samples. Generally, CNF dimensions are the most effective factors, with thinner and larger CNFs being desirable to enhance conductivity.

Thinner and longer CNFs reduce the ϕp (Eq. 20) and augment the size of the interphase (Eq. 17). Accordingly, thinner and longer CNFs build a larger net, enriching the charge transfer. Generally, thinner and extended nanoparticles provide a bigger aspect ratio, which grows the conductivity of composites, due to its positive effect on network dimensions13,14. However, thicker and shorter CNFs upsurge the ϕp and reduce the interphase concentration, leading to a smaller network in PCNFs. Thick and short CNFs form a small network that limits charge transfer. Hence, the developed model produces accurate outputs across various CNF dimensions.

Figure 6 reveals the impressions of λ and ρ as tunneling properties on conductivity. λ > 8 nm results in a minimized conductivity of 0.01 S/m, whereas the extreme conductivity of 0.79 S/m is noted at the tiniest levels of λ = 1 nm and ρ = 50 Ω.m. Thus, both tunneling length and polymer resistance adversely affect the electron transfer, and optimal conductivity is achieved with the slimmest tunnels and the least polymer resistivity. Conversely, big tunnels with high polymer resistance result in poor conductivity.

Slimmer tunnels with lower polymer resistivity reduce resistance to electron transfer, enhancing the tunneling effect44,46,47. Slim tunnels with low polymer resistivity allow more electron transfer, increasing the conductivity of PCNFs. Conversely, large tunnels with high polymer resistivity contain a thick and insulative polymer layer, causing high tunneling resistance and restricting electron transfer. It can be concluded that large tunnels with higher polymer resistivity are undesirable for charge transfer, worsening conductivity. Consequently, the proposed model realistically connects nanocomposite conductivity to these tunneling features.

Figure 7 displays the estimations of conductivity by d and f as tunneling/contact diameter and network fraction. d < 26 nm significantly reduces conductivity to nearly zero, while the maximum levels of d = 80 nm and f = 0.4 optimize conductivity to 0.43 S/m. A very low tunneling diameter cannot advance conductivity, but the broadest tunnels and uppermost network percentage provide the most conductivity. Both tunneling wideness and network percentage directly control conductivity, verifying the model.

Equation 13 reveals that d as contact diameter inversely governs the resistance of tunneling area. A high contact diameter reduces tunneling resistance, enhancing the conductivity. A wider tunnel facilitates charge transfer, producing higher conductivity. Conversely, a lower contact diameter surges tunnel resistance, limiting the charge transfer. Small tunnel diameters cannot transfer charges, and thus the new model appropriately associates conductivity to contact diameter.

An upper f grows the volume of the interphase/CNF net, because f determines the amount of both CNFs and interphase in the network according to Eq. 23. Thus, greater f results in higher conductivity because it produces a larger network, augmenting conductivity. On the other hand, a lower f results in a smaller concentration of the CNF/interphase network, reducing charge transfer. Therefore, f directly manages conductivity, validating the developed model.

Experiential facts legalizing the planned model

In this section, the real conductivity of various PCNFs is used to evaluate the developed model. Table 1 illustrates the prepared PCNFs and their features based on references. Initially, the percolation onset of examples is fitted to Eq. 20 for determination of interphase depth. Actually, t is extracted from fitting the measurements of percolation onset to Eq. (20). The varying interphase depths reveal different levels of interfacial adhesion among the CNFs and polymer matrices. The thickest interphase of 35.4 nm is perceived in the HDPE sample, though the PMMA system shows the thinnest interphase (5 nm). The interphase depth of samples changes at nanoscale, which is logical and meaningful, because the interphase depth is smaller than gyration radius of polymer macromolecules.

The progressive model is then applied to approximate the samples’ conductivity. The experimental and theoretical data are presented in Fig. 8. It is demonstrated that the experimental and theoretical conductivity values show acceptable agreement in all samples. This satisfactory fit indicates that the developed model is a reliable technique for estimating the PCNF conductivity. This model can also calculate the tunneling characteristics for the samples, as exposed in Table 1. The tunnel size (λ) sorts from 3 to 15 nm, revealing the variable tunneling distances in the samples. These results are meaningful because they are on the nanoscale. Additionally, the ρ varies from 70 to 450 Ω.m. The topmost and lowermost points of ρ are created in the EMA and PMMA samples, correspondingly.

The contact width (d) lies between 5 nm and 60 nm, with the PMMA sample showing the largest contact width and the EMA composite the smallest. These results demonstrate the highest and lowest tunneling resistance values in the EMA and PMM systems, correspondingly, according to Eq. 14. Since the tunneling mechanism meaningfully affects the PCNF conductivity, it is expected that the EMA and PMMA composites exhibit the minimum and maximum conductivity ranges among the studied samples. Figure 8 confirms this, emphasizing the crucial role of tunneling in the PCNFs. These results also validate the assumption of tunneling resistance in the developed model.

Conclusions

The Loos-Manas-Zloczower theory was expanded for the PCNF conductivity, supposing an extended CNF by interphase and tunnels. The analysis of this model across several factors is suitable and reasonable. Besides, the real conductivity of various samples shows good agreement with the model estimates. The lowest conductivity, approximately 0 (insulative sample), is realized at ϕf = 0.01 and ϕp = 0.03 or R > 80 nm and l < 20 μm or d < 26 nm. Nevertheless, the extreme range of 0.185 S/m is realized at the peak ϕf = 0.04 and the slightest ϕp = 0.003. Additionally, the value of 0.75 S/m is reached by a minimum R = 30 nm and maximum l = 60 μm. The lowest levels of λ = 1 nm and ρ = 50 Ω.m increase the conduction to 0.79 S/m, while the maximum levels of d = 80 nm and f = 0.4 optimize the conductivity to 0.43 S/m. These results demonstrate that the highest amount of the straightest CNFs (the least waviness), the thinnest and longest CNFs, the lowest percolation onset, the thickest interphase, the narrowest and widest tunnels, the lowest polymer tunneling resistivity, and the highest network percentage provide the highest conductivity. Besides, the lowermost level of tunnel resistance is obtained for the samples with the highest conductivity, corroborating the developed model.

Data availability

The data that support the findings of this study are available on a request from corresponding author.

References

Ahmad, S., Tyagi, S., Joshi, M. & Ali, S. W. Effect of synthesized copper oxide nanorods on electrical and thermal properties of compatibilized high-density polyethylene/carbon nanofiber nanocomposite films. Polym. Compos. 45 (15), 14036–14051 (2024).

Luo, Y., Li, J., Chen, C., Liu, W. & Yan, X. MnO2-decorated flexible carbon nanofibers with controllable hierarchical porous nanostructures for high energy density supercapacitors. Surf. Interfaces. 55, 105248 (2024).

Mallah, D., Mirjalili, B. B. F. & Bamoniri, A. Carbon nanofiber/taurine-catalyzed synthesis of coumarin and 1, 2, 4, 5-tetra-substituted imidazole derivatives under metal-free conditions. Sci. Rep. 14 (1), 10677 (2024).

Yan, T. et al. Highly dispersed g-C3N4 on one-dimensional W18O49/carbon nanofibers for constructing well-connected S-scheme heterojunctions with synchronous H2 evolution and pollutant degradation performance. Surf. Interfaces. 54, 105122 (2024).

Chanda, A., Sinha, S. K. & Datla, N. V. The influence of fiber alignment, structure and concentration on mechanical behavior of carbon nanofiber/epoxy composites: experimental and numerical study. Polym. Compos. 42 (3), 1155–1173 (2021).

Goto, T. et al. Fabrication of flexible porous slide-ring polymer/carbon nanofiber composite elastomer by simultaneous freeze-casting and cross-linking reaction with dimethyl sulfoxide. Compos. Sci. Technol. 215, 109028 (2021).

Santos, P., Silva, A. P. & Reis, P. N. The effect of carbon nanofibers on the mechanical performance of epoxy-based composites: a review. Polymers 16 (15), 2152 (2024).

Kumar, S., Lively, B., Sun, L., Li, B. & Zhong, W. Highly dispersed and electrically conductive polycarbonate/oxidized carbon nanofiber composites for electrostatic dissipation applications. Carbon 48 (13), 3846–3857 (2010).

Haghgoo, M., Ansari, R., Hassanzadeh-Aghdam, M. & Nankali, M. Analytical formulation for electrical conductivity and percolation threshold of epoxy multiscale nanocomposites reinforced with chopped carbon fibers and wavy carbon nanotubes considering tunneling resistivity. Compos. Part A: Appl. Sci. Manufac. 126, 105616 (2019).

Tallman, T. N. & Hassan, H. A computational exploration of the effect of alignment and aspect ratio on alternating current conductivity in carbon nanofiber–modified epoxy. J. Intell. Mater. Syst. Struct. 31 (5), 756–770 (2020).

Vatani, M., Zare, Y., Gharib, N., Rhee, K. Y. & Park, S-J. Simulating of effective conductivity for graphene–polymer nanocomposites. Sci. Rep. 13 (1), 5907 (2023).

Zare, Y., Kim, T-H., Gharib, N. & Chang, Y-W. Effect of contact number among graphene nanosheets on the conductivities of tunnels and polymer composites. Sci. Rep. 13 (1), 9506 (2023).

Zare, Y., Munir, M. T. & Rhee, K. Y. Assessment of electrical conductivity of polymer nanocomposites containing a deficient interphase around graphene nanosheet. Sci. Rep. 14 (1), 8737 (2024).

Zare, Y., Munir, M. T. & Rhee, K. Y. A novel approach to predict the electrical conductivity of nanocomposites by a weak interphase around graphene network. Sci. Rep. 14 (1), 21514 (2024).

Payandehpeyman, J., Mazaheri, M. & Khamehchi, M. Prediction of electrical conductivity of polymer-graphene nanocomposites by developing an analytical model considering interphase, tunneling and geometry effects. Compos. Commun. 21, 100364 (2020).

Zare, Y., Rhee, K. Y. & Park, S-J. Progressing of a power model for electrical conductivity of graphene-based composites. Sci. Rep. 13 (1), 1596 (2023).

Mohammadpour-Haratbar, A., Zare, Y. & Rhee, K. Y. Simulation of electrical conductivity for polymer silver nanowires systems. Sci. Rep. 13 (1), 5 (2023).

Alidoust, A., Haghgoo, M., Ansari, R., Hassanzadeh-Aghdam, M. K. & Jang, S-H. A finite element percolation tunneling approach on the electrical properties of carbon nanotube elastomer nanocomposite pressure sensors. Compos. Part A: Appl. Sci. Manufac. 180, 108111 (2024).

Nouranian, S. et al. Molecular dynamics simulations of vinyl ester resin monomer interactions with a pristine vapor-grown carbon nanofiber and their implications for composite interphase formation. Carbon 49 (10), 3219–3232 (2011).

Khan, S. U. & Kim, J-K. Improved interlaminar shear properties of multiscale carbon fiber composites with Bucky paper interleaves made from carbon nanofibers. Carbon 50 (14), 5265–5277 (2012).

Aribou, N., Paleo, A. J., da Silva, J. O., Tavares, C. J. & Achour, M. E. Variation of the general mixing rule to explore the interphase in the AC electrical conductivity of polypropylene melt-mixed with as-grown carbon nanofiber composites. Phys. B: Condens. Matter 714,417420. (2025).

Farajifard, M., Yeganeh, J. K., Zare, Y., Munir, M. T. & Rhee, K. Y. Simulation of tensile strength for polymer hydroxyapatite nanocomposites by interphase and nanofiller dimensions. Polym. Compos. 45 (11), 10234–10245 (2024).

Zare, Y. & Garmabi, H. Modeling of interfacial bonding between two nanofillers (montmorillonite and CaCO3) and a polymer matrix (PP) in a ternary polymer nanocomposite. Appl. Surf. Sci. 321, 219–225 (2014).

Zare, Y. A simple technique for determination of interphase properties in polymer nanocomposites reinforced with spherical nanoparticles. Polymer 72, 93–97 (2015).

Zare, Y. & Rhee, K. Y. Multistep modeling of young’s modulus in polymer/clay nanocomposites assuming the intercalation/exfoliation of clay layers and the interphase between polymer matrix and nanoparticles. Compos. Part A: Appl. Sci. Manufac. 102, 137–144 (2017).

Zare, Y. & Rhee, K. Y. Dependence of Z parameter for tensile strength of multi-layered interphase in polymer nanocomposites to material and interphase properties. Nanoscale Res. Lett. 12 (1), 1–7 (2017).

Fallahi, H., Kaynan, O. & Asadi, A. Insights into the effect of fiber–matrix interphase physiochemical-mechanical properties on delamination resistance and fracture toughness of hybrid composites. Compos. Part A: Appl. Sci. Manufac. 166, 107390 (2023).

Aribou, N. et al. Prediction of filler/matrix interphase effects on AC and DC electrical properties of carbon reinforced polymer composites. Polym. Compos. 40 (1), 346–352 (2019).

Zare, Y. & Rhee, K. Y. Evaluation of the tensile strength in carbon nanotube-reinforced nanocomposites using the expanded Takayanagi model. JOM 71 (11), 3980–3988 (2019).

Hadi, Z., Yeganeh, J. K., Zare, Y., Munir, M. T. & Rhee, K. Y. Predicting of electrical conductivity for Polymer-MXene nanocomposites. J. Mater. Res. Technol. 28, 4229–4238 (2024).

Paleo, A. J. et al. Electrical properties of melt-mixed polypropylene and as-grown carbon nanofiber composites: analysis of their interphase via the AC conductivity modeling. J. Compos. Mater. 56 (12), 1879–1889 (2022).

Hadi, Z., Yeganeh, J. K., Munir, M. T., Zare, Y. & Rhee, K. Y. An innovative model for electrical conductivity of MXene polymer nanocomposites by interphase and tunneling characteristics. Compos. Part A: Appl. Sci. Manufac. 186, 108422 (2024).

Zare, Y., Munir, M. T., Rhee, K. Y. & Park, S-J. Multi-scale prediction of effective conductivity for carbon nanofiber polymer composites. J. Mater. Res. Technol. 33, 8895–8902 (2024).

Wang, S. et al. Evaluation and modeling of electrical conductivity in conductive polymer nanocomposite foams with multiwalled carbon nanotube networks. Chem. Eng. J. 411, 128382 (2021).

Xiang, D. et al. 3D printed high-performance flexible strain sensors based on carbon nanotube and graphene nanoplatelet filled polymer composites. J. Mater. Sci. 55, 15769–15786 (2020).

Shin, B. et al. Flexible thermoplastic polyurethane-carbon nanotube composites for electromagnetic interference shielding and thermal management. Chem. Eng. J. 418, 129282 (2021).

Maiti, S., Shrivastava, N. K. & Khatua, B. Reduction of percolation threshold through double percolation in melt-blended polycarbonate/acrylonitrile butadiene styrene/multiwall carbon nanotubes elastomer nanocomposites. Polym. Compos. 34 (4), 570–579 (2013).

Zare, Y. & Rhee, K. Y. Correlation of tunneling diameter between neighboring carbon nanotubes in polymer nanocomposites to interphase depth, tunneling factors and the percentage of networked nanoparticles. J. Phys. Chem. Solids. 142, 109467 (2020).

Saberi, M., Moradi, A., Ansari, R., Hassanzadeh-Aghdam, M. K. & Jamali, J. Developing an efficient analytical model for predicting the electrical conductivity of polymeric nanocomposites containing hybrid carbon nanotube/carbon black nanofillers. Compos. Part A: Appl. Sci. Manufac. 185, 108374 (2024).

Loos, M. & Manas-Zloczower, I. Micromechanical models for carbon nanotube and cellulose nanowhisker reinforced composites. Polym. Eng. Sci. 53 (4), 882–887 (2013).

Tibbetts, G. G., Lake, M. L., Strong, K. L. & Rice, B. P. A review of the fabrication and properties of vapor-grown carbon nanofiber/polymer composites. Compos. Sci. Technol. 67 (7–8), 1709–1718 (2007).

Panapoy, M., Dankeaw, A. & Ksapabutr, B. Electrical conductivity of PAN-based carbon nanofibers prepared by electrospinning method. Thammasat Int. J. Sc Tech. 13, 11–17 (2008).

Inagaki, M., Yang, Y. & Kang, F. Carbon nanofibers prepared via electrospinning. Adv. Mater. 24 (19), 2547–2566 (2012).

Arjmandi, S. K., Khademzadeh Yeganeh, J., Zare, Y. & Rhee, K. Y. Development of Kovacs model for electrical conductivity of carbon nanofiber–polymer systems. Sci. Rep. 13 (1), 7 (2023).

Feng, C. & Jiang, L. Micromechanics modeling of bi-axial stretching effects on the electrical conductivity of CNT-polymer composites. Int. J. Appl. Mech. 7 (01), 1550005 (2015).

Zare, Y., Munir, M. T., Rhee, K. Y. & Park, S-J. Effects of a deficient interface, tunneling size and interphase depth on the percolation inception, percentage of graphene in the Nets and conductivity of nanocomposites. Diam. Relat. Mater. 142, 110791 (2024).

Fang, C., Zhang, J., Chen, X. & Weng, G. J. A Monte Carlo model with equipotential approximation and tunneling resistance for the electrical conductivity of carbon nanotube polymer composites. Carbon 146, 125–138 (2019).

Bhawal, P. et al. A comparative study of physico-mechanical and electrical properties of polymer-carbon nanofiber in wet and melt mixing methods. Mater. Sci. Engineering: B. 245, 95–106 (2019).

Ladani, R. B. et al. Improving the toughness and electrical conductivity of epoxy nanocomposites by using aligned carbon nanofibres. Compos. Sci. Technol. 117, 146–158 (2015).

Jimenez, G. A. & Jana, S. C. Electrically conductive polymer nanocomposites of polymethylmethacrylate and carbon nanofibers prepared by chaotic mixing. Compos. Part A: Appl. Sci. Manufac. 38 (3), 983–993 (2007).

He, L-X. & Tjong, S-C. Internal field emission and conductivity relaxation in carbon nanofiber filled polymer system. Synth. Met. 160 (19–20), 2085–2088 (2010).

Author information

Authors and Affiliations

Contributions

Y.Z. and M.N. wrote the main manuscript text and K.Y.R. and S.J.P. revised the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zare, Y., Naqvi, M., Rhee, K.Y. et al. Simulation of electrical conductivity for polymer carbon nanofiber composites assuming an extended nanofiber by interphase depth and tunneling distance. Sci Rep 15, 31623 (2025). https://doi.org/10.1038/s41598-025-17613-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-17613-x

Keywords

This article is cited by

-

Modeling of conductivity for carbon black nanocomposites incorporating network concentration, interphase conductivity and tunneling dimensions

Scientific Reports (2026)

-

Predictive modeling of conductivity for carbon black nanocomposites: influence of filler features, interfacial effects and network portion

Scientific Reports (2026)

-

Degree of conduction transfer through incomplete interphases controlling the conductivity of carbon nanofiber composites

Scientific Reports (2026)