Abstract

Cement-based materials are widely used in infrastructure but are inherently electrically insulating, limiting their application in smart and multifunctional systems. Enhancing their electrical conductivity without compromising mechanical strength is crucial for emerging applications such as structural health monitoring and energy-efficient infrastructure. This study examines the influence of acetylene carbon black (ACB) addition on the electrical and mechanical properties of cement-based materials, including cement paste, mortar, and concrete. The primary objective is to enhance the electrical conductivity of these composites while maintaining acceptable compressive strength for structural applications. Comprehensive evaluations were conducted using scanning electron microscopy (SEM), electrical resistivity measurements, and compressive strength tests. The findings revealed that ACB significantly improved the electrical properties of all composites. At 28 days, the resistivity of cement paste without ACB decreased from 80.65 to 40.69 Ω·m with ACB addition. Mortar exhibited a significant reduction from 193.57 to 33.11 Ω·m. Concrete showed a substantial decrease from 919.53 to 344.00 Ω·m. The ball milling method for cement paste + ACB improved dispersion and further enhanced conductivity. Overall, ACB incorporation offers a balanced approach to developing multifunctional cement composites with enhanced electrical and mechanical properties. These materials show promise for applications in self-sensing, de-icing, and electromagnetic interference shielding in infrastructure.

Similar content being viewed by others

Introduction

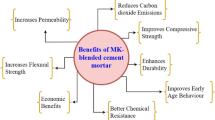

Cement concrete is a crucial material in the construction industry and is the most widely used element in both building and infrastructure projects. It is easy and affordable to manufacture, offers good durability when properly executed, and has remarkable structural capabilities, making it the most consumed material worldwide1,2,3. However, the inherent properties of cement-based materials limit the development of highly customizable features with added electrical functionalities4,5. Conductive cement composites have emerged as a promising area of research due to their potential applications in structural health monitoring, electromagnetic interference (EMI) shielding, energy storage systems, self-heating pavements, and de-icing surfaces6,7,8,9,10. These composites can be used to create self-sensing concrete that monitors structural integrity in real time, leading to safer and more resilient infrastructure. Incorporating conductive fillers into the cement matrix is a common approach to achieve conductivity in cement-based materials. Among the various conductive fillers, carbon-based materials such as carbon black, carbon nanotubes, and graphene have shown significant promise due to their excellent electrical conductivity11,12,13.

Carbon black (CB) is widely used due to its fine particle size, ability to form conductive networks within the cement matrix, and relatively low cost. Previous studies have demonstrated that the addition of carbon black can significantly enhance the electrical conductivity of cement composites14,15. For instance, it was shown that the inclusion of carbon black improved the piezoresistive behavior of cement paste, enabling it to serve as a sensor for stress and strain16. CB’s nanostructure enables conductive networks, significantly reducing resistivity crucial for self-sensing concrete. Additionally, CB acts as a nano-filler, improving mechanical properties by enhancing particle packing, reducing porosity, and increasing bond strength between hydration products17. Due to its high thermal stability and ability to absorb electromagnetic waves, CB is also used in electromagnetic interference (EMI) shielding applications in infrastructure projects18. Furthermore, CB-modified cement composites exhibit enhanced moisture retention, leading to improved hydration reactions and durability over time. In construction materials, carbon black has been incorporated into self-sensing and smart concrete for real-time structural health monitoring. It is also explored for de-icing pavements, conductive coatings, and energy-efficient building components. In addition, it was reported that nano carbon black improved electrical and thermal conductivities of cement composites, which can be beneficial for applications requiring efficient heat dissipation19.

The acetylene carbon black (ACB) produced through the thermal decomposition of acetylene gas, offers superior properties compared to conventional carbon black20. Compared to other carbon black types such as furnace black and thermal black, ACB possesses superior electrical conductivity, higher BET surface area, and finer particle size, which facilitate better dispersion and enhance the formation of conductive pathways in cementitious composites. Due to its high purity and superior electrical conductivity, ACB has been proven in previous studies to markedly enhance electrode performance in batteries and improve the conductivity of rubber, plastics, and coatings21,22,23,24. Additionally, its fine particle size makes it an ideal candidate for forming efficient conductive networks within the cement matrix25. The high specific surface area of ACB facilitates better dispersion and interaction with the cement particles, resulting in more uniform and reliable electrical properties. Studies have demonstrated that the integration of ACB into cement composites significantly enhances their electrical conductivity, mechanical performance, and thermal conductivity. These characteristics make ACB a valuable additive for developing advanced cement-based materials for applications.

However, the hydrophobic nature of ACB makes it difficult to mix uniformly with the aqueous cement slurry, further complicating the dispersion process26. Adding a surfactant can help improve the mixing and dispersion of ACB in the slurry. On the other hand, surfactants may also negatively impact the strength of the cement by interfering with the formation of key binding phases, potentially reducing its overall mechanical performance27,28. This issue necessitates the exploration of alternative mixing methods that can further enhance the dispersion and integration of ACB into the cement matrix. Another interesting method is the ball milling technique, which is widely used for improving the dispersion, morphology, and functionality of conductive additives in cement-based composites. Previous studies have demonstrated that ball milling effectively reduces the particle size of carbon nanotubes (CNTs), graphene, and conventional carbon black, leading to enhanced electrical conductivity and mechanical reinforcement in cementitious systems. For example, ball-milled CNTs have shown improved dispersion and a significant decrease in electrical resistivity when incorporated into cement pastes29,30. Similarly, graphene nanoplatelets processed through ball milling exhibited enhanced interfacial bonding with the cement matrix, leading to superior mechanical performance. In the case of conventional carbon black, ball milling aids in breaking down agglomerates, thereby increasing the available surface area and improving electrochemical performance31,32.

This research investigates the efficacy of different methods for producing conductive cement-based composites using ACB. Cement paste composites were prepared using two dispersion strategies: surfactant-assisted mixing and ball milling. Although ACB shows strong potential as a conductive filler, few studies have systematically compared the effects of different dispersion techniques on the performance of cementitious composites. Moreover, most existing research focuses primarily on cement paste, with limited exploration of ACB’s effectiveness in mortar and concrete, which are inherently more challenging due to their heterogeneous composition and lower conductivity. To address these gaps, this work provides a comprehensive evaluation of both dispersion methods and composite scales—ranging from paste to mortar and concrete. The novelty of this study lies in its systematic approach to optimizing ACB dispersion across multiple cement-based systems, offering new insights into the formation of conductive networks in otherwise insulating matrices. By balancing improved electrical conductivity with mechanical integrity, the findings contribute to the development of multifunctional cement-based materials. This research not only establishes performance thresholds for ACB incorporation but also offers a mechanistic framework for designing high-performance, electrically conductive cement composites for advanced infrastructure applications.

Experimental

Materials

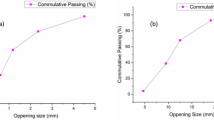

In this research, acetylene carbon black (ACB) was utilized as the primary conductive filler to enhance the electrical properties of cement-based materials, including cement paste, mortar, and concrete. ACB was supplied by IRPC Public Company Limited, Thailand. Its chemical and physical properties are presented in Table 1. Ordinary Portland Cement (OPC) was used as the primary binder in all cement-based materials. The OPC conformed to the ASTM C150 Type I standard with a specific surface area of 3360 cm²/g, ensuring consistency and reliability in the experimental results. A commercial sodium naphthalene sulfonate formaldehyde (SNF, SIKA Limited, Thailand) superplasticizer was employed to aid in the dispersion of ACB particles within the cement paste, mortar, and concrete. Hydroxyethyl cellulose (HEC, Chemipan Corporation Co., LTD.), was used as a surfactant to assist in dissolving ACB in water. Natural river sand, with a maximum particle size of 1 mm, corresponding to particles passing through a No. 18 sieve (1 mm openings), was used in the mortar and concrete formulations. Crushed granite with a maximum size of 9.5 mm, passing through a No. 3/8 sieve (9.5 mm openings), was used in the concrete mix to provide structural integrity. Reverse Osmosis water (RO, Prima 60, Elga) was used in all mixing and preparation processes to ensure minimal contamination and consistent hydration reactions.

Sample preparation

In this study, four distinct series of cementitious materials were systematically developed to explore their properties. The mixing ratios of cement-based composites are presented in Table 2. Each set was carefully formulated with specific objectives and methods to investigate how different additives and preparation techniques influence the material characteristics. The four series include: (1) Cement paste + ACB (surfactant), (2) Cement paste + ACB (ball milling), (3) Mortar + ACB, and (4) Concrete + ACB. A schematic diagram for the preparation processes of all samples is shown in Fig. 1, and the details for each sample set are summarized below.

Cement paste + ACB (surfactant)

The HEC was added at a ratio of HEC/ACB = 0.5. Superplasticizer (SP) at a ratio of SP/ACB = 0.8, and ACB was used in varying concentrations of 0.25, 0.5, 0.75, and 1.0 wt.% of OPC powder, with water mixed at a water-to-cement ratio (W/C) of 0.5. To ensure consistency in our approach, we added HEC to the pure cement sample in the same amount as the sample containing 0.25 wt.% ACB. The preparation steps included mixing HEC, SP, and water with ACB, followed by 5 min of stirring and 20 min of sonication using a bath-type ultrasonic cleaner (GT SONIC-D3, JEDTO) operating at a frequency of 40 kHz to ensure proper dispersion. The well-mixed and sonicated mixture was then blended with OPC using a mortar mixer according to ASTM C305-06 standards33. The prepared cement paste composites are poured into 5 × 5 × 5 cm33 acrylic molds to form samples for mechanical testing. The electrical properties samples were cast into 2.5 × 2.5 × 10 cm³ acrylic molds, with four brass sheets installed on the samples to serve as electrodes. The electrical resistivity was measured using a four-point probe method34,35. Then, the mixture was kept in the mold for 1 h, wrapping it with clear plastic sheets to prevent the water in the mixture from evaporating. This ensures that the water continues to react with the cement, increasing the structural strength. After 24 h, it was removed from the mold and cured in saturated lime water for 7, 14, and 27 days before mechanical testing. For electrical testing samples, they were cured in a curing chamber at a controlled temperature of 25 °C and 50% RH before being tested at 7, 14, and 28 days.

Cement paste + ACB (ball milling)

The cement paste + ACB (ball milling) was prepared by thoroughly mixing cement powder and ACB raw materials using the ball milling technique. The pure cement sample was also subjected to ball milling to ensure uniform cement dispersion under the same conditions. Yttria-stabilized zirconia (YSZ) grinding balls, with a diameter of 5 mm, were used in a milling chamber with a diameter of 90 mm. The weight ratio of the grinding balls to the combined weight of the cement and ACB powder was set at 1:1, with ACB used in varying concentrations of 0.25, 0.5, 0.75, and 1.0 wt.% of OPC powder. The milling chamber was rotated at a speed of 250 rpm for 4 h. After milling, the grinding balls were filtered out to collect well-dispersed ACB powder within the cement powder. Following the ball milling process, the hydrophobic properties of the ACB powder were reduced, making it more compatible with water as the cement particles surrounded the ACB particles. This facilitated better interaction with water during mixing and formation, preventing the ACB powder from floating to the top of the mixture. The mixing process was carried out according to ASTM C305-06 standards. The entire mixture was then poured into molds for mechanical and electrical testing, similar to the preparation method described above.

Mortar + ACB

The mortar samples were reinforced with carbon fibers (CF) and ACB to enhance electrical conductivity. The CF morphology was observed using SEM, which estimated the diameter to be 7 μm, as shown in Fig. S1 (Supplementary Information). CF was added into the mortar to improve its highly insulative nature. The CF content was fixed at 0.3 wt.% of OPC powder, as it was the optimized concentration for best performance36. The W/C ratio of 0.6 and superplasticizer (SP) at a ratio of SP/ACB = 0.8. ACB was added in varying concentrations (0.25, 0.5, 0.75, and 1.0 wt.%). Initially, CF and natural river sand were combined in a mixing bowl at a sand-to-OPC ratio of 2:1 and mixed at 285 rpm for 5 min using a mortar mixer to ensure uniform dispersion of CF. Next, water and SP were added to the bowl, with SP aiding in the dispersion of ACB in water. This was followed by the addition of ACB, and OPC powder. The entire mixture was then stirred at 285 rpm for an additional 3 min to achieve homogeneity37. The prepared mixture was poured into molds for mechanical and electrical testing. The samples remained in the molds and were cured following the same procedure used for cement paste preparation.

Concrete + ACB

The concrete + ACB samples were prepared by incorporating ACB following ASTM C192/C192M standards for mixing and curing38. The OPC, sand, coarse aggregates, and ACB were used as the primary materials, with ACB added in varying concentrations (0.25, 0.5, 0.75, and 1.0 wt.%). The sand was mixed with OPC at a ratio of 2:1, and the coarse aggregates were mixed with OPC at a ratio of 3:1. The W/C ratio was adjusted 0.6, SP at a ratio of SP/ACB = 0.8. The prepared Concrete + ACB mixture was poured into 5 × 5 × 5 cm33 acrylic molds for compressive strength testing, according to ASTM C109/C190M – 20a39. The prepared mixture was then poured into molds for electrical testing and left to cure as previously described.

Characterization techniques

The morphology and size of the raw ACB were observed using a transmission electron microscope, field emission type (FE-TEM, Talos F200X G2, Thermo Fisher Scientific, USA). High-resolution images, energy dispersive X-ray (EDX) mapping images, and selected area electron diffraction (SAED) patterns were also recorded. The morphology and microstructure of the raw ACB, the raw OPC and the fractured surface specimens were examined using an environmental scanning electron microscope (e-SEM, Quattro, Thermo Fisher Scientific, USA) operating in high vacuum mode (3.3 × 10⁻³ Pa). Before SEM imaging, the samples were sputter-coated with gold to enhance conductivity. The X-ray diffraction (XRD) analysis with Cu-Kα radiation (MiniFlex, Rigaku, Japan) was employed over a 2θ range of 10–90° to investigate the crystal structure and phase information of the raw ACB and the cement paste containing ACB.

The workability at the early age of cement paste, mortar, and concrete samples was assessed using various standardized tests. The flowability was evaluated using a miniature slump cone test, following ASTM C14340. The spread diameter of the cement paste, mortar, and concrete was recorded after measuring the vertical displacement of a paste cone after lifting the mold. Afterward, the paste was permitted to spread, and the diameter was measured at one-minute intervals for a total of five minutes. The workability (%W) was calculated as:

where d is the spread-out diameter of cement paste, and d0 is the original diameter.

The density of the cement paste, mortar, and concrete samples was determined using a standard procedure. For each condition, samples were prepared and cured for 7 days, with six samples used for measurement. This procedure was conducted according to ASTM C642 for determining the density41.

The compressive strength was evaluated using a universal testing machine (UTM, CY-6040A12, Chun Yen Testing Machine Co., Ltd., Taiwan). The machine applied force at a rate of 50 kN/min until the specimens fractured, with a maximum load capacity of 50 tons. For the compressive strength tests, 50 mm cube samples were utilized in accordance with ASTM C109/C109M-20a standards39, applicable to paste, mortar, and concrete.

Electrical resistivity of the specimens cured for 7, 14, and 28 days was measured using the electrical transport option (ETO) mode in a VersaLab instrument (Quantum Design, USA) with a maximum applied current of 0.2 mA. The four-point probe method was employed to measure the I-V curve by connecting four brass electrodes embedded in the samples. Figure S2 (Supplementary Information) shows the samples cast for the electrical resistivity test.

For compressive strength and electrical resistivity testing, separate sets of specimens were prepared for each condition. Specifically, six independently cast samples were used for compressive strength measurements, and another six specimens were prepared for electrical resistivity testing. The results reported represent the average values from these six samples, and the standard deviations are shown as error bars to indicate measurement reliability and reproducibility. All tests were conducted under ambient conditions (25 ± 1 °C, 50 ± 5% RH).

Results and discussion

Microstructural analysis of ACB particles

The high-resolution TEM analysis was used to study the ACB powders, as shown in Fig. 2. The TEM image in Fig. 2a reveals that individual ACB particles are not totally isolated but rather cluster into a grape-like bunch. This agglomeration is attributed to the van der Waals interactions between nanoparticles, which results in a strong tendency for ACB particles to form secondary structures. Such clustering can affect dispersion in cement-based composites, necessitating the use of surfactants or ball milling to achieve uniform distribution. The energy-dispersive X-ray (EDX) mapping in Fig. 2b shows the elemental composition of the ACB, indicating the presence of carbon (C), a crucial component for enhancing the electrical conductivity of the composite. Further structural analysis through selected area electron diffraction (SAED), depicted in Fig. 2c, suggests that the ACB exhibits low crystallinity. The diffraction pattern indicates a lack of long-range atomic order, characteristic of amorphous phase materials.

The amorphous nature of ACB indicates its potential interaction with the cementitious composites, which may influence both the physical and chemical behavior of the system. This observation is further corroborated by XRD analysis (Fig. S3, Supplementary Information), where the raw ACB exhibits a broad hump rather than distinct peaks, confirming its amorphous nature. Moreover, the XRD patterns of cement paste samples containing ACB show no additional crystalline phases, indicating that the incorporation of ACB does not disrupt the hydrated cement phase assemblage. The particle size distribution, presented in Fig. 2d, shows that the average particle size of the raw ACB is 43.0 nm. Small particle sizes infer the large surface area available for interaction with the cement particles, thereby improving the dispersion, leading to enhanced electrical conductivity and mechanical strength.

Density and workability of ACB-added Cement-based composites

The density and workability of ACB/cement-based composites were evaluated and are presented in Fig. 3. Figure 3a shows the density of ACB/cement-based composites with varying ACB contents of 0.00, 0.25, 0.50, 0.75, and 1.00 wt.%. The density of the composites decreases slightly with increasing ACB content for all series. This is because ACB has a lower density than the cementitious materials, leading to a reduction in the overall density of the composites as its content increases14. Among the composites, Concrete + ACB showed the highest density, followed by Mortar + ACB, and then Cement paste + ACB. This trend is observed across all ACB concentrations and can be attributed to the composition and structure of each material. The observed density reduction can be further explained by the interactions between ACB and the cementitious matrix. The incorporation of ACB could introduce additional void spaces, leading to an overall decrease in density. Furthermore, the hydrophobic nature of ACB may affect the dispersion of cement particles, influencing the microstructure and packing density of the composite. These interactions suggest that the incorporation of ACB modifies both the physical and chemical characteristics of the cementitious system, warranting further investigation into its long-term stability and mechanical performance.

Figure 3b illustrates the workability (%) of the composites. The results indicate that the workability of Cement paste + ACB (surfactant) increases with higher ACB content, suggesting improved dispersion and fluidity due to the surfactant method. HEC and SP improve flowability by reducing agglomeration and forming a hydration film around ACB particles42. This results in the highest workability across all ACB concentrations. In contrast, Cement paste + ACB (ball milling) exhibits the second-highest workability, as the ball milling improves ACB dispersion but lacks the additional fluidity provided by surfactant, leading to higher water demand due to capillary forces. Mortar + ACB and Concrete + ACB show a decline in workability, as ACB and solid components absorb free water, reducing lubrication within the mix. Mortar + ACB demonstrates the lowest workability due to the highly absorptive nature of carbon fibers (CF), which further restricts flowability43,44. Moreover, for Cement paste + ACB (ball milling), Mortar + ACB, and Concrete + ACB, workability decreases with increasing ACB content due to the absorptive nature of ACB, which limits the available water for flow and lubrication.

Electrical resistivity and compressive strength of ACB-added cement-based composites

The electrical resistivity of the cement paste, mortar, and concrete composites with varying ACB contents was measured at 7, 14, and 28 days of curing, as shown in Fig. 4a-c, with all the datapoint listed in Table 3. Note that the Y-axis for the resistivity is on a logarithmic scale, thus, the resistivity values vary significantly among samples from each series. Additionally, the addition of ACB consistently results in a reduction in resistivity across all series. The primary reason for this reduction is the inherently low electrical resistivity of ACB (~ 2.5 × 10− 3 Ω·m), which is approximately 103 times lower than that of ordinary cement paste. The incorporation of ACB into the cement paste structure facilitates the formation of interconnected conductive pathways, consistent with percolation theory. This theory describes the critical filler concentration (percolation threshold) at which a continuous conductive network forms, resulting in a significant drop in electrical resistivity5,7. At this threshold, ACB particles enable electron hopping, thereby sharply reducing resistivity once a continuous conductive network is formed16,45. In this study, the percolation threshold for establishing a conductive network via ACB addition was determined to be approximately 1.0 wt.% in cement paste. As shown in Fig. S4 (Supplementary Information), electrical resistivity decreases progressively with increasing ACB content up to 1 wt.%. Beyond this concentration, further addition of ACB does not significantly reduce resistivity but leads to noticeable degradation in compressive strength. Based on this observation, 1.0 wt% was selected as the upper limit for ACB content in other cementitious matrices.

The electrical resistivity of the Cement paste + ACB (surfactant) composites decreased significantly with increasing ACB content, from 25.60 ± 1.28 Ω·m for the control sample (0.00 wt.% ACB) to 19.52 ± 1.46 Ω·m for the sample with 0.25 wt.% ACB at 7 days of curing. This trend continued with prolonged curing times and higher ACB contents. At 14 days of curing, the electrical resistivity of the control sample increased to 30.51 ± 1.53 Ω·m, while the sample with 0.25 wt.% ACB showed a reduced electrical resistivity of 23.20 ± 1.20 Ω·m. Furthermore, with 1.00 wt.% ACB, the electrical resistivity dropped significantly to 16.72 ± 0.27 Ω·m at 14 days. This indicates that the surfactant method effectively enhances ACB dispersion within the cement matrix and the formation of conductive pathways. Enhanced dispersion of ACB increases the likelihood of forming continuous networks, essential for creating conductive pathways that allow efficient electron transfer through the material46,47. The formation of these conductive pathways follows a percolation mechanism, where at low ACB concentrations, discrete ACB particles act as electron hopping sites. As the ACB content increases, these discrete conductive particles form interconnected networks, significantly reducing resistivity45,48.

Cement paste + ACB (ball milling), similar to the surfactant method, increasing ACB content led to a decrease in electrical resistivity. The control sample exhibited an electrical resistivity of 31.01 ± 1.55 Ω·m at 7 days, which decreased to 16.35 ± 0.82 Ω·m with 0.25 wt.% ACB addition. The ball milling technique aids in the homogeneous distribution of ACB by mechanically breaking down agglomerates and enhancing particle contact, thus improving the electrical conductivity of the cement paste49. Compared to the surfactant method, the preparation of ACB mixed with OPC using ball milling simplifies the mixing process. Scaling this method to industrial production can reduce both costs and processing steps.

Mortar + ACB specimen acts as an insulator due to its high sand content, but the inclusion of ACB helps to significantly reduce its electrical resistivity. In addition, the presence of carbon fibers (CF) and ACB significantly reduces electrical resistivity by creating a conductive network within the mortar matrix. ACB particles adhere to the CF and integrate into the cement matrix, enhancing electrical conduction more effectively than direct transmission between CF and the cement matrix. Concrete + ACB contains sand and aggregate, which are highly insulating materials that contribute to its overall high electrical resistivity. In contrast, the incorporation of conductive fillers such as ACB can significantly alter these properties. The substantial reduction in electrical resistivity with ACB addition highlights its potential to enhance the electrical properties of concrete. ACB fills interstitial voids between aggregates and cement paste, functioning as an interfacial conductive medium. The high surface area and nanoscale morphology of ACB contribute to the formation of efficient multi-scale networks, improving macroscopic conductivity despite the inherently insulating nature of the aggregate phase25,45. These pathways facilitate electron transfer across the composite material, effectively reducing the overall electrical resistivity50.

In addition, in every sample, longer curing times lead to increased electrical resistance value, due to hydration reaction of the cement powder to form calcium silicate hydrate (C-S-H) phase51,52. The formation of C-S-H introduces additional insulating barriers between conductive ACB particles, which may slightly offset the percolation effect at later curing stages. However, despite this natural increase in resistivity with curing, the overall effect of ACB incorporation remains beneficial in maintaining enhanced electrical conductivity. These findings demonstrate that incorporating ACB into cementitious materials can effectively enhance their electrical properties.

To evaluate the mechanical performance, the compressive strength of cement paste, mortar, and concrete composites with varying ACB contents was assessed at curing intervals of 7, 14, and 28 days, as illustrated in Fig. 4d-f, with all the datapoint listed in Table 3. Cement paste + ACB (surfactant) composites showed that a low concentration of ACB slightly increased compressive strength by filling voids within the cement matrix, enhancing the material’s density and structural integrity. However, increasing ACB to higher levels decreased strength due to diminished OPC cohesion, which continued to decrease with curing time. In addition to agglomeration, the use of surfactants during ACB dispersion may have influenced the cement hydration process and contributed to the observed reduction in compressive strength. Surfactants are known to adsorb onto cement particle surfaces, potentially hindering water penetration and delaying early-stage nucleation of C–S–H. This phenomenon may lead to reduced matrix cohesion and mechanical integrity, particularly at higher ACB contents where more surfactants are required to maintain dispersion stability. In contrast, the ball milling improved the compressive strength compared to the surfactant method by avoiding surfactants that can interfere with OPC hydration. Higher ACB levels, however, still reduced strength, highlighting the need for careful management of ACB concentrations in commercial scaling.

A direct comparison of the two dispersion methods reveals that ball milling offers superior overall performance. Cement paste + ACB composites prepared by ball milling exhibited notably lower electrical resistivity than those produced using surfactant-assisted mixing, indicating more effective formation of conductive networks due to finer and more uniform ACB dispersion. In terms of mechanical performance, the compressive strength of the ball-milled samples was better retained, suggesting minimal disruption to cement hydration. By contrast, the surfactant-assisted method resulted in slightly higher porosity and a moderate decline in compressive strength, likely due to interference with hydration processes. These findings underscore the advantage of ball milling in achieving a balanced enhancement of both electrical and mechanical properties in ACB-modified cementitious systems.

Mortar + ACB composites maintained their compressive strength within acceptable standards despite slight reductions caused by ACB. The strength of the mortar was supported by CF, which reinforced the microstructure and enabled better stress distribution. A number of studies have demonstrated that CF enhances the mechanical properties of cement-based materials by bridging microcracks, improving stress transfer, and increasing toughness. CF effectively reduces crack propagation by forming an interconnected network within the cement matrix, thereby enhancing the overall compressive and flexural strength of cementitious composites53,54. The addition of ACB and CF together enhanced the electrical conductivity of the composites, making them suitable for structural applications requiring both strength and conductivity. The incorporation of ACB at an appropriate concentration range (0.25–1.00 wt.%) in mortar did not significantly reduce compressive strength at any curing age (7, 14, and 28 days). The compressive strength values remained within acceptable structural standards, indicating that ACB, when properly dispersed, does not severely compromise the mechanical integrity of the mortar matrix. It should be noted that the inclusion of both ACB and CFs in the mortar mixtures may complicate the evaluation of ACB’s isolated effect. While both components contribute to conductivity enhancement, their potential synergistic or overlapping roles may obscure the individual impact of ACB.

Concrete + ACB composites exhibited an initial increase in compressive strength with moderate ACB addition, attributed to improved void filling around aggregates. However, excessive ACB led to clustering that disrupted the bonding of OPC, crucial for aggregate cohesion, leading to decreased compressive strength over time. Moderate ACB levels contribute to densification of the matrix and more uniform load distribution through void filling and improved interparticle bonding. However, exceeding the optimal concentration leads to agglomerate formation that weakens the matrix by acting as stress concentrators17,32.

Overall, the addition of ACB to cement paste, mortar, and concrete resulted in a slight decrease in compressive strength. However, the compressive strengths of all samples remained within acceptable standards for structural applications, according to ACI 318 and Eurocode 2 (EN 1992-1-1), cement-based composites used in structural elements should achieve a minimum compressive strength of approximately 20–25 MPa at 28 days55,56. Therefore, the incorporation of ACB provides a balance between improved electrical conductivity and adequate mechanical strength, making these composites suitable for multifunctional applications where both properties are desired. Compared to other conductive fillers, ACB offers a practical balance between performance, cost, and processability. Multi-walled carbon nanotubes (MWCNTs), provide excellent conductivity but often require advanced dispersion techniques and incur high material costs57. In contrast, industrial fillers such as slag, waste iron chips, or carbon-based blends offer lower conductivity but are more compatible with conventional cement processing58. ACB lies between these approaches its conductivity is moderate, but it offers easy dispersion (especially with ball milling) and is suitable for large-scale applications without the need for functionalization or high dosages.

Microstructure of ACB-added cement-based composites

Scanning Electron Microscopy (SEM) images were employed to investigate the presence and distribution of ACB within the microstructure of cement paste. The description of raw OPC particles, as shown in Fig. 5a, displays irregularly shaped particles of various sizes59. The raw ACB particles, shown in Fig. 5b, are much finer and form agglomerates due to their high surface area and low bulk density. The ACB agglomerate size distribution is shown in the inset of Fig. 5b, with an average agglomerate size of approximately 43.3 ± 7.9 nm. Figure 5c, d illustrate the microstructure of cement paste prepared using the surfactant method. Figure 5c, which does not contain ACB, shows well-hydrated OPC particles and the formation of hydration products (C-S-H phase). The blue circles highlight unreacted OPC particles, which were identified based on their irregular shape, distinguishing them from ACB clusters. The incomplete reaction between cement and water is attributed to the interference of the surfactant with the hydration process, reducing the formation of the C-S-H phase. In Fig. 5d, the addition of 1 wt.% ACB is highlighted by red circles, indicating dispersed ACB particles within the cement matrix. These particles are well-distributed due to the surfactant, enhancing the electrical performance by forming conductive pathways. The ACB particles were identified based on their distinctive morphology, typically appearing as agglomerates of fine spherical particles, as illustrated in the high-magnification image in Fig. S5 (Supplementary Information). Figure 5e, f depict the microstructure using the ball milling method. Figure 5e, without ACB, features a microstructure dominated by C-S-H phase (yellow text) and fewer unreacted OPC particles (blue circles) compared to the surfactant method. This suggests a more complete hydration process, contributing to higher compressive strength. The C-S-H phase is the primary phase in the cement structure, and is characterized by a homogeneous, continuous, and dense microstructure. Figure 5f, with 1 wt% ACB, shows uniformly dispersed ACB particles (red circles), where ball milling breaks down agglomerates and promotes homogeneous distribution, enhancing both mechanical and electrical properties. Moreover, as noted in prior studies, carbon black additives have been shown to improve hydration reactions and reduce permeability in cementitious matrices17,18.

These SEM images illustrate how different preparation methods and ACB additions impact the microstructure. While the surfactant method effectively disperses ACB and results in less agglomeration compared to the ball milling method due to the presence of dispersing agents, some localized ACB clustering may still occur, which could influence hydration and compressive strength. Conversely, ball milling achieves a more uniform ACB distribution, enhancing overall performance by ensuring more complete hydration and better integration of ACB into the cement matrix. Moreover, the addition of ACB could have a positive effect on durability of the cement matrix. Previous studies on carbon black additives have been shown improvements in hydration reactions and reductions in permeability within cementitious matrices17,18. As such, incorporating ACB may lead to reduced porosity and enhanced moisture retention, both of which could contribute to prolonged material durability.

SEM images of (a) Raw OPC, (b) Raw ACB, microstructure of cement paste after curing at 28 days; Cement paste + ACB (surfactant) (c) without ACB (d) adding 1 wt.% ACB, Cement paste + ACB (ball milling) (e) without ACB (f) adding 1 wt.% ACB. Red circles identify ACB particles, blue circles indicate unreacted OPC particles, and yellow text labels C–S–H phase.

Figure 6 presents SEM images illustrating the microstructure of Mortar + ACB and Concrete + ACB specimens after curing for 28 days. The microstructure of Mortar without ACB as shown in Fig. 6a and c. Figure 6a shows the presence of CF well distributed within the mortar matrix. The CF appears as long cylindrical structure with smooth and continuous surfaces, contrasting with the rough texture of the surrounding cementitious phases. Figure 6c displays a higher magnification of the sample, highlighting the microstructure around the CFs. The blue circles indicate remaining unreacted OPC particles, while the yellow circles highlight the C-S-H phase, which is responsible for the strength and durability of the cementitious matrix. Figure 6b and d illustrate the microstructure of Mortar + ACB with the addition of 1 wt.% ACB. In Fig. 6b, the orange text indicates CFs, while the red circles highlight the dispersed ACB particles within the mortar matrix. The addition of ACB forms a conductive network that enhances connectivity between CF strands, contributing to improved electrical properties. To aid in this explanation, SEM images were taken at high magnification of the CF surface, as shown in Fig. S6 (Supplementary Information). These images reveal ACB particles adhering to the CF surface. Moreover, Fig. S7 (Supplementary Information) presents EDX mapping analysis of Mortar + ACB, providing further insights into the distribution of carbon within the matrix. Table S1 (Supplementary Information) provides a quantitative analysis of the chemical composition of CF/mortar from EDX mapping analysis. The data shows that the carbon content increases from 15.39 ± 0.2 at.% in the sample without ACB to 18.84 ± 0.1 at.% in the sample with 1 wt.% ACB, confirming the successful incorporation of ACB into the mortar matrix.

Figure 6e, f illustrate the bulk structures of concrete samples with and without ACB, with higher-magnification images provided in Fig. S8 (Supplementary Information). Figure 6e shows a control sample post-compressive testing, and Fig. 6f highlights a sample with 1 wt.% ACB, identifying ACB agglomerates that potentially enhance conductive pathways within the matrix. SEM images in Figs. 6g-h detail the microstructures of these samples. The coarse aggregates in the concrete specimens were identified by their large, fractured surfaces and irregular texture, which are distinctly different from the finer cementitious phases. Their identification was based on morphological characteristics commonly observed in concrete microstructures. Figure 6g focuses on ACB-free concrete, emphasizing the critical calcium-silicate-hydrate (C-S-H) phase and its role in mechanical strength by binding aggregates. Figure 6h, on the other hand, shows concrete with 1 wt.% ACB, where well-dispersed ACB particles fill voids and create additional conductive pathways, improving electrical conductivity. While ACB enhances electrical properties and structural integrity, excessive ACB can weaken mechanical strength by disrupting bonding within the matrix. However, compressive strengths remain within acceptable limits for structural applications.

SEM images of microstructure (a, c) Mortar without ACB (b, d) Mortar adding 1 wt.% ACB (g) Concrete without ACB (h) Concrete adding 1 wt.% ACB. Observed macrostructure of concrete (e) without ACB (f) adding 1 wt.%ACB. Red circles identify dispersed ACB particles, blue circles mark remaining unreacted OPC grains, yellow circles highlight the C–S–H phase, and orange text denotes carbon fibers (CFs).

Based on the observed electrical and mechanical properties, along with SEM results, we developed a microstructural model to illustrate the effects of ACB incorporation in cement-based composites, as presented in Fig. 7. In the Cement paste + ACB (surfactant) composite, the ACB particles are uniformly dispersed due to the action of the surfactant, which reduces surface tension and ensures even distribution throughout the cement matrix. The diagram highlights the presence of some agglomerates alongside unreacted cement particles and moisture. This uniform distribution of ACB promotes the formation of continuous conductive pathways, significantly enhancing the electrical conductivity of the paste. In contrast, the Cement paste + ACB (ball milling) composite benefits from the milling process, which breaks down ACB clusters into smaller particles. This results in a more homogeneous ACB distribution. Furthermore, this method could preserve the strength of the cement paste better than mixing it with a surfactant. In Mortar + ACB composites, the presence of CF introduces additional conductive pathways, while ACB particles are well-dispersed among fine sand particles. The combination of ACB and CF creates a robust interconnected network that enhances both the electrical conductivity and mechanical strength of the mortar. The minimized agglomeration ensures effective interaction between the conductive components and the cement matrix, optimizing performance. Lastly, in the Concrete + ACB composite, the schematic reflects the heterogeneous nature of concrete, with coarse aggregates embedded in the cement matrix. ACB particles and agglomerates are dispersed among these aggregates, with their distribution affected by the aggregate size. This results in regions with varying ACB concentration, but the inclusion of ACB still forms a conductive network that lowers electrical resistivity. Additionally, ACB aids in electron transfer and contributes to improved bonding between aggregates, maintaining structural integrity despite the composite’s heterogeneity.

Lastly, to illustrate a potential application of the ACB/cement-based composite, a block sample was connected to brass electrodes and powered by an alternating current (AC) source with a temperature controller (Fig. S9, Supplementary Information). Upon switching on, the conductive network formed by ACB allowed electrical current to flow through the sample, generating heat via Ohmic heating. The surface temperature could go up to 45 °C, indicating the feasibility of using such composites for self-heating or de-icing infrastructure during winter conditions.

Conclusions

The incorporation of acetylene carbon black (ACB) effectively enhanced the electrical conductivity of cement-based composites while maintaining acceptable mechanical strength. Among the dispersion methods evaluated for cement paste/ACB composites, ball milling produced finer and more homogeneous ACB distribution, resulting in superior performance compared to surfactant-assisted mixing, which caused incomplete cement hydration and higher porosity. Specifically, ball milling reduced the electrical resistivity of cement paste by approximately 50% – from 80.65 to 40.69 Ω·m. In mortar and concrete, ACB addition led to reductions in resistivity of up to 82%, accompanied by modest strength improvements. The electrical conductivity followed the trend: cement paste + ACB (ball milling) > cement paste + ACB (surfactant) > mortar + ACB > concrete + ACB. Moderate ACB levels were beneficial, while excessive amounts led to agglomeration and slight strength reduction. Although some findings are consistent with existing literature, this work provides new insights through a systematic comparison of dispersion methods and a multi-scale material investigation. The findings offer a practical framework for designing multifunctional cement-based materials with tunable electrical and mechanical performance.

Nevertheless, this study focused primarily on short-term performance. Future investigations should evaluate long-term durability, including resistance to moisture, chemical exposure, and sustained electrical stability. Additionally, further assessments of cost-effectiveness, material scalability, and environmental impact—such as life cycle analysis—are crucial for enabling the practical deployment of ACB-modified cement composites in real-world infrastructure applications.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Abdelhamid, T., El-Gafy, M. & Mitropoulos, P. Selection of roof casting formwork systems for the bird Island project: case study. Pract. Period Struct. Des. Constr. 14, 224–241 (2009).

Tupý, M. et al. Exposure of mortars modified with rubber aggregates and polymer admixtures to acid environments and elevated temperature conditions. J. Mater. Civ. Eng. 28, 04015171 (2016).

Hossain, M. U., Cai, R., Ng, S. T., Xuan, D. & Ye, H. Sustainable natural Pozzolana concrete–A comparative study on its environmental performance against concretes with other industrial by-products. Constr. Build. Mater. 270, 121429 (2021).

Honorio, T., Carasek, H. & Cascudo, O. Electrical properties of cement-based materials: multiscale modeling and quantification of the variability. Constr. Build. Mater. 245, 118461 (2020).

Lübeck, A., Gastaldini, A., Barin, D. & Siqueira, H. Compressive strength and electrical properties of concrete with white Portland cement and blast-furnace slag. Cem. Concr Compos. 34, 392–399 (2012).

Chanut, N. et al. Carbon–cement supercapacitors as a scalable bulk energy storage solution. Proc. Natl. Acad. Sci. U S A. 120, e2304318120 (2023).

Farcas, C. et al. Heating and de-icing function in conductive concrete and cement paste with the hybrid addition of carbon nanotubes and graphite products. Smart Mater. Struct. 30, 045010 (2021).

Gwon, S., Moon, J. & Shin, M. Self-heating capacity of electrically conductive cement composites: effects of curing conditions. Constr. Build. Mater. 353, 129087 (2022).

Jiang, X., Lu, D., Yin, B. & Leng, Z. Advancing carbon nanomaterials-engineered self-sensing cement composites for structural health monitoring: A state-of-the-art review. J Build. Eng, 87, 109129 (2024).

Wanasinghe, D., Aslani, F., Ma, G. & Habibi, D. Advancements in electromagnetic interference shielding cementitious composites. Constr. Build. Mater. 231, 117116 (2020).

Bai, S., Jiang, L., Xu, N., Jin, M. & Jiang, S. Enhancement of mechanical and electrical properties of graphene/cement composite due to improved dispersion of graphene by addition of silica fume. Constr. Build. Mater. 164, 433–441 (2018).

Kim, H., Nam, I. W. & Lee, H. K. Enhanced effect of carbon nanotube on mechanical and electrical properties of cement composites by incorporation of silica fume. Compos. Struct. 107, 60–69 (2014).

Gwon, S., Kim, H. & Shin, M. Self-heating characteristics of electrically conductive cement composites with carbon black and carbon fiber. Cem. Concr. Compos. 137, 104942 (2023).

Chen, B. et al. Investigation on electrically conductive aggregates produced by incorporating carbon fiber and carbon black. Constr. Build. Mater. 144, 106–114 (2017).

Wen, S. & Chung, D. Partial replacement of carbon fiber by carbon black in multifunctional cement–matrix composites. Carbon 45, 505–513 (2007).

Chung, D. Piezoresistive cement-based materials for strain sensing. J. Intell. Mater. Syst. Struct. 13, 599–609 (2002).

Lima, G. E. S. et al. Microstructural investigation of the effects of carbon black nanoparticles on hydration mechanisms, mechanical and piezoresistive properties of cement mortars. Mater. Res. 24, e20200539 (2021).

Dai, Y., Sun, M., Liu, C. & Li, Z. Electromagnetic wave absorbing characteristics of carbon black cement-based composites. Cem. Concr. Compos. 32, 508–513 (2010).

Abolhasani, A., Pachenari, A., Razavian, S. M. & Abolhasani, M. M. Towards new generation of electrode-free conductive cement composites utilizing nano carbon black. Constr. Build. Mater. 323, 126576 (2022).

Shtertser, A. A. et al. Production of hydrogen and carbon black by detonation of fuel-rich acetylene-oxygen mixtures. Int. J. Hydrogen Energy. 47, 14039–14043 (2022).

Shin, H. C., Cho, W. I. & Jang, H. Electrochemical properties of carbon-coated LiFePO4 cathode using graphite, carbon black, and acetylene black. Electrochim. Acta. 52, 1472–1476 (2006).

Huang, J. C. Carbon black filled conducting polymers and polymer blends. Adv. Poly Technol. 21, 299–313 (2002).

Song, J., Tian, K., Ma, L., Li, W. & Yao, S. -c. The effect of carbon black morphology to the thermal conductivity of natural rubber composites. Int. J. Heat. Mass. Transf. 137, 184–191 (2019).

Spahr, M. E., Goers, D., Leone, A., Stallone, S. & Grivei, E. Development of carbon conductive additives for advanced lithium ion batteries. J. Power Sources. 196, 3404–3413 (2011).

Dinesh, A., Saravanakumar, P., Prasad, B. R. & Raj, S. K. Carbon black based self-sensing cement composite for structural health monitoring–A review on strength and conductive characteristics. Mater. Today: Proc. 661, 2214–7853 (2023).

Terayama, Y. et al. Carbon black/ptfe composite hydrophobic gas diffusion layers for a water-absorbing porous electrolyte electrolysis cell. Int J. Hydrogen Energy 43, 2018–2025 (2018).

Chuah, S., Li, W., Chen, S. J., Sanjayan, J. G. & Duan, W. H. Investigation on dispersion of graphene oxide in cement composite using different surfactant treatments. Constr. Build. Mater. 161, 519–527 (2018).

Feneuil, B., Pitois, O. & Roussel, N. Effect of surfactants on the yield stress of cement paste. Cem. Concr Res. 100, 32–39 (2017).

Gao, Z. et al. Dispersion of carbon nanotubes improved by ball milling to prepare functional epoxy nanocomposites. Coatings 13, 649 (2023).

Li, B. et al. Nanoscale dispersion of carbon nanotubes in a metal matrix to boost thermal and electrical conductivity via facile ball milling techniques. Nanomater 13, 2815 (2023).

Zhang, N., Mao, Y., Wu, S. & Xu, W. Effects of the ball milling process on the particle size of graphene oxide and its application in enhancing the thermal conductivity of wood. Forests 13, 1325 (2022).

Zhang, S. et al. Control of graphitization degree and defects of carbon Blacks through ball-milling. RSC Adv. 4, 505–509 (2014).

Committee, C. Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency. In ASTM International: West Conshohocken, PA, USA (2014).

Chuewangkam, N., Payakaniti, P., Chindaprasirt, P. & Pinitsoontorn, S. Ohmic heating as an effective path to rapidly cure and strengthen alkali activated material. Constr. Build. Mater. 322, 126425 (2022).

Liang, S., Du, H., Zou, N., Chen, Y. & Liu, Y. Measurement and simulation of electrical resistivity of cement-based materials by using embedded four-probe method. Constr. Build. Mater. 357, 129344 (2022).

Payakaniti, P., Pinitsoontorn, S., Thongbai, P., Amornkitbamrung, V. & Chindaprasirt, P. Electrical conductivity and compressive strength of carbon fiber reinforced fly Ash geopolymeric composites. Constr. Build. Mater. 135, 164–176 (2017).

Yu, H. et al. Enhancing the mechanical and functional performance of carbon fiber reinforced cement mortar by the inclusion of a cost-effective graphene nanofluid additive. Cem. Concr. Compos. 134, 104777 (2022).

C192/C192M. A. Standard practice for making and curing concrete test specimens in the laboratory. ASTM, 4–9 (2016).

Testing, A. S. & Cement, M. C. C.-o. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. Or [50-mm] Cube Specimens). (ASTM International, (2013).

Mebrouki, A., Belas, N. & Bendani, K. Bouhamou, N. A self-compacting cement paste formulation using mixture design. J. Appl. Sci. 9, 4127–4136 (2009).

ASTM, C. Standard Test Method for Density, Absorption, and Voids in Hardened Concrete (American Society for Testing and Material. ASTM., 2013).

Barbhuiya, S. & Das, B. B. Water-soluble polymers in cementitious materials: A comprehensive review of roles, mechanisms and applications. Case Stud. Constr. Materials 19, e02312 (2023).

Sun, M., Li, J., Wang, Y. & Zhang, X. Preparation of carbon fiber reinforced cement-based composites using self-made carbon fiber mat. Constr. Build. Mater. 79, 283–289 (2015).

Zhu, H., Zhou, H. & Gou, H. Evaluation of carbon fiber dispersion in cement-based materials using mechanical properties, conductivity, mass variation coefficient, and microstructure. Constr. Build. Mater. 266, 120891 (2021).

Chang, E. et al. Percolation mechanism and effective conductivity of mechanically deformed 3-dimensional composite networks: computational modeling and experimental verification. Compos. Part. B: Eng. 207, 108552 (2021).

Baranek, S., Cerny, V., Drochytka, R., Meszarosova, L. & Melichar, J. Electrically conductive composite materials with incorporated waste and secondary Raw materials. Sci. Rep. 13, 9023 (2023).

Lim, K. M. & Lee, J. H. Electrical conductivity and compressive strength of cement paste with multiwalled carbon nanotubes and graphene nanoplatelets. Appl. Sci. 12, 1160 (2022).

Cruz, H. & Son, Y. Effect of aspect ratio on electrical, rheological and glass transition properties of PC/MWCNT nanocomposites. J. Nanosci. Nanotechnol. 18, 943–950 (2018).

Mendes, J. C. et al. On the relationship between morphology and thermal conductivity of cement-based composites. Cem. Concr. Compos. 104, 103365 (2019).

Milone, G., Vlachakis, C. & Tulliani, J. M. & Al-Tabbaa, A. in Structures 106789 (Elsevier). (2024)

John, E. & Lothenbach, B. Cement hydration mechanisms through time–a review. J. Mater. Sci. 58, 9805–9833 (2023).

Narattha, C. & Chaipanich, A. Effect of curing time on the hydration and material properties of cold-bonded high-calcium fly ash–Portland cement lightweight aggregate. J. Therm. Anal. Calorim. 145, 2277–2286 (2021).

Chuang, W. et al. Dispersion of carbon fibers and conductivity of carbon fiber-reinforced cement-based composites. Ceram. Int. 43, 15122–15132 (2017).

Wang, Y., Li, A., Zhang, S., Guo, B. & Niu, D. A review on new methods of recycling waste carbon fiber and its application in construction and industry. Constr. Build. Mater. 367, 130301 (2023).

European Committee for Standardization. Eurocode 2: Design of concrete structures–Part 1–1: General rules and rules for buildings. Brussels. EN 1992-1-1. (2004).

American Concrete Institute. Building Code Requirements for Structural Concrete (ACI 318 – 19). Farmington Hills. (2019).

Filazi, A., Yılmazel, R. & Pul, M. Developing geopolymer composites with structural damage control potential: utilization of blast furnace slag, calcined clay, and MWCNT. Iran. J. Sci. Technol. - Trans. Civ. Eng. 49, 1293–1315 (2025).

Filazi, A., Yilmazel, R. & Pul, M. Investigation of electrical conductivity in cement mortars with waste iron chips. Int. J. Eng. Res. 15, 82–91 (2023).

Huo, W. et al. Utilization of OPC and FA to enhance reclaimed lime-fly Ash macadam based geopolymers cured at ambient temperature. Constr. Build. Mater. 303, 124378 (2021).

Acknowledgements

This research has received funding support from the Research and Innovation of Khon Kaen University, and the NSRF via the Program Management Unit for Human Resources & Institutional Development, Research and Innovation (B13F660126). The author would like to thank Integrated Refinery & Petrochemical Complex (IRPC) Public Company Limited for supporting the grant and providing materials.

Author information

Authors and Affiliations

Contributions

Nattapong Chuewangkam—Conceptualization; Data curation; Formal analysis; Investigation; Methodology; Visualization; Writing—original draft Ploychanok Iadrat—Supervision; Writing—review & editing Tarabordin Yurata—Resources; Supervision; Validation; Writing—review & editingChuchawin Changtong—Funding acquisition; Resources; Supervision; Writing—review & editingSupree Pinitsoontorn—Conceptualization; Funding acquisition; Project administration; Supervision; Writing—review & editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chuewangkam, N., Iadrat, P., Yurata, T. et al. Enhancing electrical performance of cement-based materials with acetylene carbon black for paste, mortar and concrete applications. Sci Rep 15, 33552 (2025). https://doi.org/10.1038/s41598-025-18414-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-18414-y