Abstract

Traditional concrete materials are expensive and ecologically detrimental, presenting significant challenges in balancing construction cost control with durability requirements for underground roads. To enable near-site, high-value utilization of bulk coal-based solid waste while optimizing coal mine roadway concrete performance, a fly ash-coal gangue concrete is developed in this study. In this material, natural crushed stone aggregates are substituted with coal gangue and cement is replaced with fly ash. Using coal gangue replacement rates (0%, 20%, 40%, 60%, 80%, 100%) and fly ash content (0%, 10%, 20%) as experimental variables, fresh concrete workability was assessed via slump tests; Strength characteristics and drying shrinkage behavior of hardened concrete were evaluated through compressive and flexural strength testing; Pore structure characteristics were analyzed using nuclear magnetic resonance (NMR); The optimization effect of triethanolamine dosages (0%, 0.01%, 0.03%, 0.05%) on drying shrinkage and mechanical properties was investigated in high-fly-ash-content concrete. The results demonstrate that concrete slump is significantly reduced by coal gangue content exceeding 40%, whereas workability is enhanced by appropriate fly ash addition; Concrete strength is diminished by elevated coal gangue content, necessitating a maximum dosage of 40%; Concrete compactness is improved and pore structure is refined by 10% fly ash content, while pore structure integrity is degraded by 20% fly ash; Drying shrinkage is increased by coal gangue but effectively mitigated by fly ash incorporation; Both drying shrinkage resistance and mechanical strength of fly ash-coal gangue concrete are substantially optimized by adding 0.03% triethanolamine.

Similar content being viewed by others

Introduction

Coal, as China’s primary energy source, remains a critical pillar for national energy security1,2,3. Against the backdrop of systemic energy transition toward sustainability, the coal industry must urgently advance industrial restructuring through digital transformation and sustainable operational models4,5,6.

In order to predict the stability of the roadway floor, Zhu et al. proposed a disaster warning method based on microseismic monitoring to predict the stability of the floor, but did not explore the path of using mining solid waste to improve support materials from the source to enhance stability. Especially for the loss of self stabilization ability in abandoned roadway, there is a lack of economically efficient reinforcement solutions7,8. Mo et al. focused on the macroscopic mechanical parameters of rock layers for the stability analysis of roadway floor, but did not analyze the influence of rock microstructure on floor heave9,10,11. However, the preparation of common concrete requires a large amount of cement, river sand and gravel, the production cost is higher and the ecological and environmental benefits are lower, the use of mass concrete for roadway floor hardening is not in line with the goal of green upgrading of coal industry, and also causes great economic pressure on coal mine operation12,13. Therefore, from the goal of roadway pavement construction cost and quality optimization, it is urgent to develop pavement concrete materials with both economic benefits and performance characteristics.

The industrial restructuring of the coal sector inevitably encompasses industrial solid waste management. Coal gangue and fly ash – byproducts of coal mining – exemplify persistent engineering challenges in mining regions regarding their large-scale utilization and value-added reprocessing14,15. Applying such coal-based solid wastes to roadway hardening projects in coal mines enables on-site resource recovery of bulk materials while generating substantial economic and environmental benefits16,17. However, owing to low quality grade and significant variability in physical properties18, rigorous assessment of their impact on concrete workability, mechanical characteristics, and volumetric stability is imperative prior to widespread adoption in pavement applications.

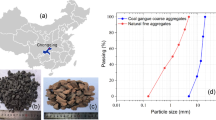

In view of this, this paper collected coal gangue from a coal mine in Ordos area and fly ash from a fossil-fuel power station nearby. Through controlled bivariate experimentation (coal gangue replacement rate for natural gravel aggregate: 0%, 20%, 40%, 60%, 80%, 100%; fly ash content: 0%, 10%, 20%), we systematically characterized concrete slump, mechanical properties, pore structure, and drying shrinkage behavior. Based on experimental observations, the optimal proportion of coal-based solid waste in the concrete matrix was determined. Performance optimization of solid-waste concrete was subsequently conducted using drying shrinkage rate and mechanical strength as primary control metrics. These findings establish practical guidelines for green and economical hardening engineering in coal mine roadway.

Raw materials and test scheme

Raw materials

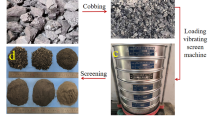

The cement is P·O 42.5 ordinary Portland cement, and its physical and mechanical properties are shown in Table 1. Fly Ash is grade I, with an apparent density of 2650 kg·m−3 and a specific surface area of 533 m2·kg−1. The chemical composition of cement and fly ash is given in Table 2. The fine aggregate is natural river sand with fineness modulus of 2.5, mud content of 2.1% and water content of 2.9%, bulk density of 1782 kg·m−3 and apparent density of 2653 kg·m−3. Natural crushed stone and coal gangue are used as coarse aggregates with particle sizes of 5–20 mm, in which the mass proportions of 5–10 mm and 10–20 mm aggregates are 40% and 60%, respectively. The coal gangue comes from a coal mine in Ordos City, and its water absorption and crushing value are 2.1% and 22.5% respectively. In order to improve the workability of concrete mixture, the high-efficiency polycarboxylate superplasticizer produced by kezhijie new materials group is adopted. In order to improve the effect of high-volume fly ash on the strength development of coal gangue concrete, analytically pure triethanolamine (TEA) produced by Sinopharm group was used to regulate the hydration reaction of cementitious system.

Mix proportion and test method

The reference mix for concrete is shown in Table 3. The amount of superplasticizer is fixed at 0.3% by mass of the cementitious material. When coal gangue or fly ash is incorporated into concrete, the corresponding concrete numbers are CG and F, respectively, and the following numbers indicate the percentage of incorporation, where the amount of coal gangue is 0%, 20%, 40%, 60%, 80% and 100%, respectively, 0%, 10%, and 20% fly ash. Concrete number CG20F10 indicates 20% coal gangue and 10% fly ash.

The raw materials were weighed and the concrete was prepared according to the mix proportion in Table 3. The slump of each group of concrete mixture was tested according to the standard of test methods for performance of ordinary concrete mixture (GB/T 50080 − 201619. Then each group of concrete was poured into the test formwork with the sizes of 100 mm×100 mm×100 mm and 100 mm×100 mm×400 mm, and the concrete specimens were cured with the formwork for 1 d before the formwork was removed, the mechanical properties were tested after the standard curing conditions (temperature 20 ± 2 °C, relative humidity 97%20 continued curing to the preset age. According to the standard of test method for mechanical properties of ordinary concrete (GB/T50081-201921, the compressive strength and flexural strength of concrete specimens with sizes of 100 mm×100 mm×100 mm and 100 mm×100 mm×400 mm were tested, the compressive strength and flexural strength of each group of concrete specimens were obtained by multiplying the test results by the size conversion coefficients of 0.95 and 0.85, respectively.

The drying shrinkage of concrete was tested according to the standard of test method for long-term properties and durability of ordinary concrete (GB/T 50082 − 202422. After the concrete specimen is prepared, dismantled and cured to 3D age according to the above process, a probe is fixed on the side of the concrete specimen and a dial indicator is arranged, after that, the concrete specimens were placed in a constant drying environment of 20 ± 2 °C and 60 ± 5% relative humidity23, and the drying age was calculated from then on. The drying shrinkage deformation and water loss mass of the specimens were regularly observed and recorded.

Mesomr-60 nuclear magnetic resonance (NMR)24 was used to analyze the pore structure of concrete. During the test, the temperature in the laboratory was controlled at 23 ± 1℃. Firstly, the concrete specimens at the age of 28 d were drilled and sampled, and the size of the core sample was 25 mm×50 mm. Then, all the specimens were placed in a vacuum saturation device. After 24 h of vacuum saturation, the specimens were fully wrapped with plastic wrap to prevent moisture loss, the specimens were tested by nuclear magnetic resonance. The CPMG sequence is used to test the transverse relaxation process of pore water in saturated specimens.The waiting time TW in the sequence parameters was set to 10,000 ms, the cumulative multiple NS was 16, the echo interval time TE was set to 0.12 ms, the echo number NECH was 2000, and the recovery times in the CPMG sequence were 20. Then the SIRT algorithm is used to invert the echo attenuation curve to obtain the transverse relaxation time (t 2) spectrum25, the pore size distribution of concrete is calculated from the surface relaxation rate of concrete.

Experimental results and discussion

Performance characteristics of coal-based solid waste concrete

Figure 1 shows the influence of the ratio of coal gangue to aggregate and the content of fly ash on the slump of fresh concrete. It can be seen from the figure that the slump of concrete decreases with the increase of coal gangue content when the content of fly ash is determined, but the influence of different content of coal gangue and fly ash on the slump of concrete is different. When the content of fly ash is 0%, the concrete is coal gangue concrete. When the content of coal gangue is 0%, the maximum slump of concrete is 93 mm, the concrete slump gradually decreased from 93 mm to 46 mm, which decreased by 11.83%, 19.36%, 32.26%, 44.09% and 50.54%, respectively, relative to the concrete slump when the coal gangue content was 0%, when the coal gangue content is greater than 40%, the concrete slump decreases rapidly. When fly ash is added into concrete, the change law of concrete slump is the same as that of the control group. When the content of coal gangue is determined, the slump of concrete increases with the increase of the content of fly ash. For ordinary concrete (coal gangue content of 0%), with the increase of fly ash content from 0 to 20%, the slump of concrete increased from 93 mm to 120 mm, compared with the control group, the slump increased by 29.03%. In summary, due to the differences in porosity, water absorption and morphology between coal gangue and natural gravel aggregate, replacing coarse aggregate in concrete with coal gangue26 will reduce the workability of fresh concrete to a certain extent, it is not conducive to the transportation and construction of concrete, but the incorporation of fly ash can better improve the fluidity of fresh concrete and make up for the defects caused by the incorporation of coal gangue aggregate, the performance of fresh concrete can be improved by using coal gangue and fly ash as two typical coal-based solid wastes.

Mechanical properties of coal-based solid waste concrete

Figure 2(a) shows the compressive strength of fly ash-coal gangue concrete cured for 7 d under standard curing conditions. As can be seen from the figure, with the increase of coal gangue content, the overall strength of concrete shows a downward trend. When the content of fly ash is 0%, the compressive strength of concrete gradually decreases from 30.0 MPa to 17.1 MPa with the increase of coal gangue content to 100%, and the strength reduction rate reaches 47.0%. When the content of coal gangue is certain, the compressive strength of 7 d age concrete decreases with the increase of the content of fly ash.

Figure 2(b) shows the test results of compressive strength of 28 d age concrete with different contents of coal gangue and fly ash. It can be seen from the figure that with the increase of coal gangue content, the compressive strength of concrete still shows a downward trend similar to the 7 d age. In the absence of fly ash, with the increase of coal gangue content, the compressive strength of concrete gradually decreased from 42.1 MPa to 27.3 MPa, and the decrease rate of concrete strength was 35.1%. When the content of coal gangue is not more than 40%, the decrease of concrete strength is not large, but with the increase of coal gangue content, the compressive strength of concrete decreases faster. When the coal gangue content is fixed, with the gradual increase of fly ash content to 20%, the compressive strength of concrete increases first and then decreases. Figure 3 shows the influence of coal gangue and fly ash on the flexural strength of 28 d concrete. It can be seen from the diagram that with the increase of coal gangue content, the flexural strength of coal-based solid waste concrete at 28 d decreases gradually, and with the increase of fly ash content from 0–20%, the flexural strength of coal-based solid waste concrete decreases gradually, the flexural strength of concrete increases first and then decreases, which is similar to its compressive strength.

According to the influence of coal-based solid waste on the compressive and flexural strength of concrete at different ages, it can be found that the effect of fly ash is related to the age of concrete, the reason is that fly ash in concrete mainly play filling, heterogeneous nucleation, chemical reaction and micro-aggregate effect27. In the early stage of hydration reaction, fly ash mainly plays the role of filler, its reaction degree is low and reduces the cement content in unit volume, so it is not conducive to the strength development of concrete28. With the increase of curing age, the degree of hydration reaction of cementitious materials increases. The secondary hydration reaction of fly ash and calcium hydroxide results in the filling of pores and the increase of matrix compactness, which promotes the strength growth However, when the content of fly ash is too high, the reaction activity of fly ash is relatively low and the generation of calcium hydroxide is limited, which in turn will adversely affect the strength29. The physical parameters of coal gangue are inferior to those of natural gravel30, so the increase of its content will cause a decrease in the strength of concrete31. In summary, it can be found that the content of coal gangue in concrete should not be higher than 40%, and adding appropriate amount of fly ash can improve the adverse effect of coal gangue on the mechanical properties of concrete, but the content of fly ash is greatly limited.

Pore structure characteristics of coal-based solid waste concrete

In NMR experiments, the radius of concrete pore structure is proportional to the transverse relaxation time32, so the transverse relaxation time spectrum distribution of concrete can be transformed into the corresponding concrete pore size distribution. Figure 4 is the T2 NMR spectrum of coal-based solid waste concrete at the age of 28d. It can be seen from the figure that the T2 spectrum shows a “Three-peak structure” as a whole, and the area of the three peaks decreases from left to right. When the fly ash content was 0, 10%, and 20%, the minimum transverse relaxation time was 2.967 ms, 1.382 ms, and 2.409 ms, and the first peak apex relaxation time was 11.097 ms, 6.368 ms, and 10.353 ms, respectively. The change of NMR T2 spectrum area can reflect the change of internal pore structure of concrete. When 10% fly ash is added, the signal peak of T2 spectrum shifts to the left, and the peak area decreases slightly, indicating that the pore volume and pore size of concrete decrease, the signal peak shifts to the right, and the signal peak area increases, indicating that excessive fly ash has an adverse effect on the matrix compactness and pore structure.

According to the T-2 nuclear magnetic resonance spectrum, the pore distribution of concrete is calculated33. With the increase of fly ash content from 0 to 20%, the porosity of concrete increases first and then decreases, 3.38%, 2.48%, and 2.73%, respectively. Further, the concrete pore size was divided into four intervals of 0.01 μm, 0.11 μm, 110 μm, and > 10 μm with 0.1 μm, 0.11 μm, and 10 μm as the boundaries, respectively, the percentage of pore volume in each of the four size ranges is calculated, as shown in Fig. 4(b). As can be seen from the figure, concrete has the highest percentage of voids in the 0.01 μm and 0.11 μm ranges. When the content of fly ash is 10%, the proportion of pores in the pore size range of 0.11 μm and > 10 μm increases, indicating that the volume content of fine pores increases and the content of coarse pores decreases, and the pore structure has been improved. When the content of fly ash continues to increase to 20%, the phenomenon of decrease in fine pore content and increase in coarse pore content can be observed, which is also consistent with the development trend of mechanical properties of concrete, this indicates the negative effect of excessive fly ash on the compactness of concrete microstructure.

Drying shrinkage properties of coal-based solid waste concrete

Figure 5 is the influence of different coal gangue on the replacement rate of natural macadam and fly ash content on the drying shrinkage of concrete. As can be seen from Fig. 5(a), the drying shrinkage strain of concrete develops rapidly during the first 15 d of the test and then gradually stabilizes. With the increase of coal gangue content, the growth rate and the final value of drying shrinkage increase gradually. Compared with natural gravel aggregate, coal gangue aggregate has lower strength and elastic modulus, while higher porosity, and therefore, the constraint ability of coal gangue aggregate on the shrinkage deformation of concrete matrix is weak34, and the effect of coal gangue aggregate on the shrinkage deformation of concrete matrix is not obvious, the drying shrinkage strain of concrete specimens with high coal gangue replacement ratio is greater. Figure 5(b) shows the effect of fly ash on the drying shrinkage of coal gangue concrete. It can be seen from the figure that the addition of fly ash does not change the overall development trend of drying shrinkage. With the increase of fly ash content, the drying shrinkage strain of concrete has been effectively inhibited. Because the reactivity of fly ash is lower than that of cement particles, the addition of fly ash can reduce the cement content in unit volume, reduce the water consumption of hydration reaction, and increase the free water content in pores, at the same time, unreacted fly ash particles as micro-aggregates play a role in stabilizing and inhibiting the matrix deformation of the skeleton, thus reducing the drying shrinkage deformation of concrete.

Combining the above research results of the influence of coal gangue and fly ash on the drying shrinkage of concrete, it can be found that the addition of fly ash can improve the adverse effect of coal gangue replacing natural gravel aggregate on the drying shrinkage of concrete. However, when the content of fly ash is 20%, its deterioration effect on the mechanical properties and pore structure of concrete can not be ignored. Therefore, it is necessary to carry out optimization research on coal-based solid waste concrete with higher content of fly ash. In this section, triethanolamine is used to improve the drying shrinkage and mechanical properties of coal-based solid waste concrete (CG40F20). The effects of different triethanolamine contents on the drying shrinkage and mechanical properties of concrete are shown in Figs. 6 and 7, respectively. It can be seen from Fig. 6 that with the increase of triethanolamine content to 0.05%, the drying shrinkage of concrete decreases first and then increases, and reaches the lowest value when the triethanolamine content is 0.03%, when the triethanolamine content is 0.05%, the final value of drying shrinkage has exceeded the reference group.

Triethanolamine is a cement early strength agent35, which can not only accelerate the early hydration reaction of cement, but also promote the dissolution of fly ash particles and pozzolanic reaction36. It can be seen from Fig. 7 that triethanolamine can effectively improve the compressive and flexural strength of coal-based solid waste concrete. With the increase of triethanolamine content, the compressive and flexural strength increase first and then decrease, and reach the highest value when the content is 0.03%. According to the influence of different dosage of triethanolamine on the drying shrinkage and mechanical properties of coal-based solid waste concrete, it can be determined that the optimum dosage of triethanolamine is 0.03%. The performance of coal-based solid waste concrete can be optimized by adding appropriate amount of triethanolamine37. On the one hand, triethanolamine improves the reaction degree of fly ash in coal-based solid waste concrete and enhances the compactness of microstructure, on the other hand, the high surface activity of triethanolamine can reduce the surface tension of the pore solution in the capillary pores and reduce the driving force of the drying shrinkage deformation, and then reduce the shrinkage deformation of concrete35.

Conclusions

In this paper, the properties and pore structure of fly ash-coal gangue concrete for roadway pavement are studied. The main conclusions are as follows:

(1) The addition of coal gangue will reduce the slump of fresh concrete, especially when the content is more than 40%, and the addition of fly ash can effectively improve the fluidity of concrete.

(2) The increase of coal gangue in concrete will reduce its strength, and the appropriate amount of fly ash can partially alleviate this effect. The amount of coal gangue should not exceed 40%, and the amount of fly ash should also be properly controlled to optimize the performance of concrete.

(3) Nuclear magnetic resonance test shows that 10% fly ash content can improve the compactness and fine pore structure of concrete, while 20% content leads to the increase of pore size and porosity, which has an adverse effect on concrete structure. This indicates that the content of fly ash needs to be finely controlled to optimize the microstructure of concrete.

(4) The study shows that although the coal gangue increases the drying shrinkage of concrete, the addition of fly ash effectively inhibits this effect and improves the microstructure of concrete. The appropriate use of triethanolamine (0.03% is the best dosage) further optimizes the drying shrinkage and mechanical properties of coal-based solid waste concrete.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Xu, J. et al. Coal utilization eco-paradigm towards an integrated energy system. Energy Policy. 109, 370–381 (2017).

Jing, Z. et al. Trade-off or synergy? The impacts of coal energy consumption on compound system vulnerability: A perspective from coal resource base assessment. Ecol. Ind. 170, 113124 (2025).

Amir Raza, M. et al. Global progress towards the coal: tracking coal reserves, coal prices, electricity from coal, carbon emissions and coal phase-out. Gondwana Res. 139, 43–72 (2024).

Tian, Y. et al. Evolution dynamic of intelligent construction strategy of coal mine enterprises in China. Heliyon, 8(10). (2022).

Miao, D. et al. Research on Coal Mine Hidden Danger Analysis and Risk Early Warning Technology Based on Data Mining in China1711–17 (Process Safety and Environmental Protection, 2022).

Wang, K., Bai, J. & Feng, G. Measurement of impact failure evolution of coal samples under in-situ water pressure environment: visualization SHPB experiment and damage model analysis. Measurement, : 117714. (2025).

Zhu, Y. et al. Study on the effect of rock stratum structure on the stability of weakly cemented layered floor and the floor control measures: A case study of Meihuajing mine. Energy Sci. Eng. 11 (7), 2238–2252 (2023).

Bai, J. et al. Deformation and Failure Behaviour of Coal-Backfilling Composite Structure Under Double Shearing579079–9096 (Rock Mechanics and Rock Engineering, 2024). 11.

Chen, D. H., Sun, R. & Yao, Z. Impacts of aggregate base on roadway pavement performances. Constr. Build. Mater. 48, 1017–1026 (2013).

Mo, S. et al. A numerical investigation into floor buckling mechanisms in underground coal mine roadways. Tunn. Undergr. Space Technol. 103, 103497 (2020).

Gai, Q. et al. Microseismic response difference and failure analysis of roof and floor strata under dynamic load impact. Eng. Fail. Anal. 143, 106874 (2022).

Liu, K. et al. Full-scale field test of early-age behaviour of partially continuous reinforced concrete pavement. Road. Mater. Pavement Des. 26 (5), 1065–1088 (2024).

Kazmi, R. & Chakraborty, M. Use of coal mining wastes in the construction industry to promote a circular economy: a systematic literature review. Circular Econ. Sustain., : 1–30. (2025).

Liu, X. Low-carbon utilization of coal gangue under the carbon neutralization strategy: a short review. J. Mater. Cycles Waste Manage. 25 (4), 1978–1987 (2023).

Das, D. & Rout, P. K. A review of coal fly Ash utilization to save the environment. Water Air Soil Pollut. 234 (2), 128 (2023).

Liu, B. et al. Analysis of damage and permeability evolution for mudstone material under coupled Stress-Seepage. Materials 13 (17), 3755 (2020).

Jin, J. et al. Insights into factors influencing coal gangue-filled backfill cemented by self-consolidating alkali-activated slag Grouts. Constr. Build. Mater. 411, 134422 (2023).

Jin, J. et al. Preparation of self-consolidating cemented backfill with tailings and alkali activated slurry: performance evaluation and environmental impact. Constr. Build. Mater. 438, 137088 (2024).

Ren, Z. et al. The flowability and high-temperature resistance of manufactured sand concrete: an exploration for high-rise buildings. Mater. Res. Express. 10 (11), 115509 (2023).

Jin, J. et al. Rheology control of self-consolidating cement-tailings Grout for the feasible use in coal gangue-filled backfill. Constr. Build. Mater. 316, 125836 (2022).

Wang, J. & Li, X. Hybrid Steel-Polyethylene Fiber-Reinforced iron ore tailing concrete: mechanical, sulfate Freeze–Thaw resistance, and microscopic characteristics. Buildings 14 (6), 1843 (2024).

Zhang, C. et al. Synergistic effect of PVA fiber and PTB emulsion on mechanical properties of cementitious composites for damage repair in operating tunnels. KSCE J. Civ. Eng. 26 (12), 5222–5239 (2022).

Rudić, O. et al. Drying shrinkage and carbonation of steel slag-metakaolin alkali-activated composites: effect of vegetable oil addition and slag aggregates. Cem. Concr. Res. 189, 107764 (2024).

Li, J. et al. Curing process and pore structure of metakaolin-based geopolymers: Liquid-state 1H NMR investigation. Cem. Concr. Res. 143, 106394 (2021).

Wang, W. et al. Compressive behavior deterioration mechanism of concrete under carbonization and freeze-thaw cycles and time-varying structural reliability evaluation. Constr. Build. Mater. 466, 140359 (2025).

Zhang, J. et al. Mechanical properties and Stress–Strain constitutive relations of Coal-Fired slag concrete. Buildings 14 (10), 3103 (2024).

Szcześniak, A. et al. The influence of the addition of Microsilica and fly Ash on the properties of Ultra-High-Performance concretes. Materials 18 (1), 28 (2024).

Zhu, Y. et al. Effect of decarbonization of high carbon fly Ash on workability, mechanical properties and durability of concrete. Mater. Struct. 56 (9), 171 (2023).

Bieliatynskyi, A. et al. Study of the possibility of using sulfur asphalt and sulfur concrete in road construction. Mater. Science-Poland. 41 (2), 244–262 (2023).

Li, Y., Liu, S. & Guan, X. Multitechnique investigation of concrete with coal gangue. Constr. Build. Mater. 301, 124114 (2021).

Liu, H. et al. The influence of coal gangue coarse aggregate on the mechanical properties of concrete columns. Case Stud. Constr. Mater. 17, e01315 (2022).

Liu, L. et al. Application of Low-Field NMR to the pore structure of concrete. Appl. Magn. Reson. 52 (1), 15–31 (2020).

Zhang, S. et al. Grey model study on strength and pore structure of self-compacting concrete with different aggregates based on NMR. J. Building Eng. 64, 105560 (2022).

Gao, W. C. et al. Shrinkage model for concrete incorporating coal gangue coarse and fine aggregates. J. Building Eng. 80, 107865 (2023).

Yaphary, Y. L. et al. Effect of triethanolamine on cement hydration toward initial setting time. Constr. Build. Mater. 141, 94–103 (2017).

He, Y. et al. Influence of triethanolamine on mechanical strength and hydration performance of blended cement containing fly ash, limestone and slag. J. Building Eng. 44, 102879 (2021).

Yang, X. et al. Effect of triethanolamine hydrochloride on the performance of cement paste. Constr. Build. Mater. 200, 218–225 (2018).

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China (contract Nos. 52404125, 52274084).

Funding

National Natural Science Foundation of China (contract Nos. 52404125, 52274084).

Author information

Authors and Affiliations

Contributions

J.W. and B.L.: Supervision, Project administration. B.L.: Conceptualization, Funding acquisition, Writing - review & editing. C.W.: Formal analysis, Investigation, Data curation, Writing - review & editing. L.Z.: Formal analysis, Investigation, Data curation, Writing - original draft. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, C., Zhang, L., Liang, B. et al. Study on the influence of coal-based solid waste on performance optimization of roadway pavement concrete. Sci Rep 15, 33133 (2025). https://doi.org/10.1038/s41598-025-18523-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-18523-8