Abstract

In this study, Hempseed protein isolates (HPI) and concentrates (HPC) were prepared via bis(2-ethylhexyl) ester sodium salt (AOT) reverse micelle (RMS) and alkaline extraction–isoelectric precipitation (AE) processes, respectively. And their functional properties, structure and nutritional value were compared. RMS-HPI presented a greater protein content but worse protein extraction and recovery rates than AE-HPC did. SDS‒PAGE indicated that AE-HPC dissociated during the separation process, whereas RMS-HPI remained in the natural state. The RMS-HPI was mainly composed of albumin, whereas the AE-HPC was mainly composed of edestin. Moreover, the RMS significantly improved the color of the HPI. RMS-HPI has higher solubility, foaming ability, oil holding capacity, and emulsification ability, whereas AE-HPC has higher foam stability, water holding capacity, emulsification stability, and decomposition temperature. The FTIR results revealed that a fat absorption peak was observed in AE-HPC, and the number, position and intensity of the absorption peaks of RMS-HPI and AE-HPC were different, which was related to the change in secondary structure. The CD results revealed that the main secondary structures of RMS-HPI and AE-HPC were β-sheets and α-helices, respectively. The large differences in shape, number and type between the AE-HPC and RMS-HPI were observed via SEM, which may be related to their functional characteristics and structure. In addition, the RMS-HPI has advantages in terms of amino acid composition and nutritional profile. These results indicated that reverse micelles could improve the functional and nutritional properties of hemp seed protein, which is helpful for the application of hemp seed protein in food.

Similar content being viewed by others

Introduction

By 2050 the world’s population is estimated to reach 9 billion, resulting in increased demand for food protein. The supply of animal protein has difficulties meeting the rapid growth of the population1. The consumption of more plant protein is an effective measure to address these problems. However, compared with that of animal protein, the application of plant protein sources is limited because their amino acid distribution and the presence of antinutrients lead to lower nutritional value, which may impair protein digestion and increase consumption toxicity2. In addition, plant proteins exhibit poor physicochemical and sensory properties, such as solubility, bitterness, off-flavors, and unattractive colors3. For the above reasons, high-quality plant proteins and economical and efficient acquisition methods have attracted increasing attention.

Hemp (Cannabis sativa L.) is an herbaceous annual belonging to the Cannabinaceae family. Globally, the hemp protein market grew at a compound annual growth rate (CAGR) of 15.2% from 2019 to 20244. Hempseed protein is composed of 65% high-quality edestin protein, the most potent protein of any plant source, with the remaining 35% provided by albumin protein and essential amino acids5. Hemp protein is considered ‘perfect protein’ as it contains all 20 amino acids along with nine essential amino acids6. Hemp protein is sufficient for the Food and Agriculture Organization (FAO)/World Health Organization (WHO) suggested requirements for 2- to 5-year-old children7. The Arg/Lys ratio of hemp protein is in the range of 4.7– to 6.1, which is much higher than that of many well-known protein sources (e.g., soy protein and casein). These findings suggest the potent role of hemp protein as a valuable ingredient in promoting cardiovascular health8. The ratio of essential amino acids to total amino acids in hemp protein was significantly greater than that in soybean protein, which indicated that the nutritional amino acid pattern of hemp protein was better. During characterization, amino acid composition and in vitro digestibility analyses of hemp protein, hempseed protein was found to have high digestibility and be nonallergenic9. In the food industry, beverages, functional ingredients, nutritional supplements and personal care products have been developed from hempseed protein10.

Although hempseed protein has high nutritional value, its application is limited by several functional properties, such as poor solubility, emulsifying ability and stability11. In general, the important functions and nutrients of proteins are affected by various factors. The structural changes of proteins are closely related to the preparation method, which results in changes in the functional characteristics of the proteins12,13. Alkaline extraction–isoelectric precipitation (AE‒IEP) has been the most commonly used method to extract protein from plant foods. Many studies have been conducted on the extraction of hempseed protein via the alkali extraction‒isoelectric precipitation method14,15,16,17. The alkali extraction‒isoelectric precipitation method has a high recovery rate and simple operation, but it has the disadvantages of being time-consuming, being unfriendly to the environment by using acid and alkali, resulting in protein denaturation caused by strong alkaline conditions, reducing protein digestibility as a result of extracting polyphenols and pigments, and having an unattractive protein color18. Therefore, an alternative process of extracting hempseed protein is beneficial for the utilization of hempseed protein.

Reverse micelles (RMS) have become more popular during the last decade due to their wide range of applications, such as the extraction of food proteins, simultaneous extraction of oils/proteins, purification and/or extraction of enzymes, and enrichment of components such as amino acids for analysis18. RMS are nanometer-sized aggregates of surfactants containing encapsulated water molecules as inner cores within a bulk nonpolar solvent19. The surfactant molecules consist of a polar head and a nonpolar tail structure. Being hydrophilic, the polar heads orient themselves toward the water content at the inner core, whereas the apolar or hydrophobic tails orient themselves toward the organic solvent. As a novel method for protein recovery from plant sources20, RMS offers multiple advantages over AE-IEP: maintaining native protein conformation; enabling simultaneous oil-protein co-extraction; producing whiter protein color better suited for food industry requirements; eliminating the need for strong acid/alkali conditions, reducing wastewater treatment; and allowing solvents/surfactants to be evaporated or precipitated for recovery and reuse, thereby providing both environmental and economic benefits21,22. Some studies have reported the application of reverse micelles in the extraction of protein from soybean, wheat, walnut and other plants12,23,24. Zhao et al.12 reported that, compared with protein extracted via the AE‒IEP method, soybean protein extracted via the RMS extraction method presented greater solubility, oil absorption, foaming, and emulsifying stability; a lower water holding capacity; a greater total amino acid content, essential amino acid content, amino acid score and biological value; and a lower content of volatile odor substances. These results showed that RMS extraction can affect protein structure and improve protein function and nutritional characteristics.

Currently, there are no systematic studies on reverse micellar extraction of hempseed protein. Using reverse micellar extraction for hempseed protein is expected to simultaneously achieve: maintaining structural integrity of hempseed protein, producing white-colored and odor-free products, improving functional properties, enabling co-extraction of protein and oil, and reducing environmental pollution. In a previous study, we optimized the process of reverse micelle extraction of hempseed protein. In brief, we analyzed the effects of different conditions on the extraction of hemp seed protein. Then, the response surface optimization of some key conditions was carried out to obtain the best extraction conditions. Specific research details can be referred to in our previous report25. The objective of this research was to evaluate the effects of reverse micelle extraction on the structure, function and nutritional status of hempseed protein (RMS-HPI). Compared with hempseed protein extracted by alkaline extraction–isoelectric precipitation (AE–HPC), the advantages and disadvantages of the two methods were identified, which will contribute to the application of hempseed protein in the food industry.

Materials and methods

Materials

Hempseed was purchased from a local marker. Sulfosuccinic acid bis(2-ethylhexyl) ester sodium salt (AOT) was purchased from the Sigma Chemical Co. (St. Louis, MO, USA). A bicinchoninic acid (BCA) protein assay kit was purchased from Nanjing Jiancheng Biotechnology (Nanjing, China). All other chemicals used in the experiments were of analytical grade or the highest purity.

Preparation of hemp protein (HP) from hempseed

Dehulling process

The hempseed was milled via a high-speed grinder (1000Y, Boou Co., Zhejiang, China). Hempseed powder was defatted in 25 w/v% hexane under constant stirring. The hexane was refreshed several times during the period, with an interval of 30 min, until no oil was put forward in hexane. The hempseed powder was dried at 40 °C for 24 h to ensure the removal of residual hexane, and the hexane used was recovered. Defatted hempseed protein meal (HPM) was sieved through an 80x screen and stored at 4 °C until protein extraction. The protein content of the HPM was 53.16%.

Preparation of AE-HPC

AE-HPC were prepared via a previously reported method26, with slight modifications. As shown in Fig. 1a, The HPM was mixed with distilled water at a weight/volume ratio of 1:20, and the pH was adjusted to 10.0 with 1 M NaOH. The extraction process was conducted at 35 °C, and the mixture was stirred with an electric stirrer for 2 h. The pH was adjusted every 20 min to maintain a pH of 10. The dispersions were then centrifuged at 8000 × g for 20 min at room temperature. The bottom layer was discarded, the supernatant was collected and vacuum-filtered, and the filtrate was subjected to acidic precipitation at pH = 5 with 1 M HCl. The suspension was subsequently centrifuged at 6000 × g for 20 min at 4 °C. The precipitate was then redispersed in deionized water, and the pH was adjusted to 7.0 using 1 M NaOH and lyophilized for 48 h to obtain the AE-HPC powder.

Preparation of RMS-HPI

RMS-HPI were prepared on the basis of our previous optimized method25. As shown in Fig. 1b, This process can be divided into two processes: forward extraction and backward extraction. Forward extraction: AOT was dissolved in isooctane to prepare a solvent solution with a concentration of 0.09 g/mL. Then, 100 mM phosphate buffer (pH = 6.54) containing 0.05 M KCl was mixed with the AOT/isooctane solution, and a volume of 0.106 mL/mL was added. The solutions were subjected to ultrasonic treatment at 30 °C for 30 min via an ultrasonic machine (KQ-800DE, Ultrasound Instrument Co., Kunshan, China). The mixture was incubated overnight to obtain a clear and transparent reverse micelle solution. Afterward, HPM was mixed with the reverse micelles at a ratio of 1:15 (w/v). The forward extraction mixture was stirred at 150 rpm for 80 min at 50 °C. The mixture was then centrifuged (TD KZ-WS, CenLee Co., Hunan, China) at 3500 × g for 10 min at room temperature. The precipitate was discarded, and the organic phase (upper layer) collected from the forward extraction was subjected to backward extraction. Backward extraction: The stripping phase was prepared with 100 mM phosphate buffer (pH = 7.5) containing 1.0 M KCl. The collected organic phase from the forward extraction was mixed with an equal volume of the stripping phase, followed by stirring at 150 rpm for 45 min at 27 °C. The reaction mixture was centrifuged at 3500 × g at room temperature for 10 min, which formed three distinct layers. The lower aqueous phase was collected and dialyzed at 4 °C for 48 h to remove impurities, salts, and excess surfactant. The water was changed four times daily. After dialysis, the protein mixture was frozen at −20 °C overnight and then freeze-dried for 48 h to obtain the RMS-HPIs. The RMS-HPIs were stored at 4 °C for further analyses.

Exaction performance

The extraction yield (%) and protein recovery yield (%) were calculated according to the methods of Shen et al.14:

Proximate chemical composition analysis

The crude protein content of HPI/HPC was determined via the Kjeldahl method via a protein conversion factor (N × 6.25). The lipid content was determined via gravimetric measurement after extraction with petroleum ether via Soxhlet extraction. The moisture and ash contents were determined via AOAC official methods27.

Sodium dodecyl sulfate‒polyacrylamide gel electrophoresis (SDS‒PAGE)

The freeze-dried RMS-HPI and AE-HPC were subjected to SDS‒PAGE (reducing and nonreducing) according to the methods of Malomo et al.17 with some modifications. The protein samples were dispersed (10 mg/mL) in Tris/HCl buffer (pH = 8.0). Each loading sample was prepared by mixing 1 mL of the above prepared HP solution with 4 mL of 5 × Laemmli sample buffer. Next, 10% β-mercaptoethanol (β-ME) was added to the mixed solution for reduction. The diluted samples were subsequently heated at 100 °C for 5 min to denature the protein, followed by cooling at room temperature and centrifugation (8000 × g, 10 min). The electrophoresis mixture was processed by loading 5 µL of the supernatant into the gel, which was run at 80 V within a 5% stacking gel and then changed to 120 V for separation when the samples were run on a 12% separating gel. After electrophoresis, the gel was stained with 0.125% (w/v) Coomassie Brilliant Blue R-250 solution for 1 h and destained in destaining solution (30% (v/v) methanol and 10% (v/v) acetic acid) at room temperature until the gel was completely decolorized. Image acquisition was performed via a gel imaging system (GelView 6000Plus, Biolight Biotechnology Co., Guangzhou, China), and the band intensity was analyzed via ImageJ for semiquantification of different proteins.

Color

The color values (L*, a* and b*) of HPIs were measured with a colorimeter (SC-80C, KangGuang Co., Beijing, China). L* indicates the brightness/darkness index (0 to 100/black to white), a* indicates redness/greenness (‘+’ values for red, ‘−’ values for green), and b* indicates yellowness/blueness (‘+’ values for yellow, ‘−’ values for blue). ΔE indicates the total color difference between the AE-HPC and RMS-HPI. ΔE < 1 indicates that the color difference cannot be distinguished by the human eye, and 1 < ΔE < 3 indicates that the inconspicuous color difference can be distinguished by the human eye. ΔE > 3 indicates that there are significant color differences that can be distinguished by the human eye. ΔE is calculated via the following equation:

Functional properties of hemp protein isolates

Solubility

The percent protein solubility (PPS) of HPI/HPC was measured at pH values in the range of 2–10 according to the method described by Lan et al.28 with some modifications. Briefly, 100 mg of HPI was dispersed in 10 mL of distilled water. The pH of the HPI solution was adjusted from 2 to 10 with 1 N HCl solution or 1 M NaOH and then vortexed at room temperature for 2 min. The pH was adjusted again, and the mixture was vortexed. The mixture was then centrifuged at 8000 × g for 10 minutes at room temperature, and the protein concentration of the supernatant was measured with a BCA protein assay kit. To determine the total protein content, HPI/HPC were dissolved in 0.2 M NaOH at 1.0 wt%. Protein solubility was expressed as the percentage ratio of the protein content of the supernatant to the total protein content.

Water holding capacity and oil holding capacity

The water holding capacity (WHC) and oil holding capacity (OHC) were determined according to the methods of Liu et al.29. Five hundred milligrams of HPI/HPC was suspended in 5.0 mL of deionized water or corn oil and placed in a centrifuge tube. After vortexing for 1 min, the samples were allowed to stand for 30 min, and after centrifugation at 7000 × g for 25 min, the supernatant was drained by inverting the tube for 15 min. The remaining mass was weighed, and the WHC/OHC was calculated by dividing the additional weight of the pellet by the original protein isolate mass. The equation is as follows:

where W1 is the weight of HPI/HPC, W2 is the weight of the tube and HPI/HPC, and W3 is the weight of the tube and HPI/HPC after centrifugation.

Emulsifying capacity and stability

The emulsifying activity index (EAI) and emulsifying stability index (ESI) of the HPI samples were measured via the turbidimetric method according to the method of Fang et al.30 with some modifications. Thirty-two milliliters of a sample dispersion (0.10, wt%) in 0.05 M phosphate buffer (pH = 7.0) was mixed with 8 mL of corn oil and then homogenized via a high-speed blender at 15000 rpm for 1 min. Subsequently, 100 μL of the resulting emulsion was pipetted from the bottom of the mixture at 0 and 10 min and diluted to a total of 10 mL using 0.1% SDS solution (1.0 mg/mL). The absorbance at 500 nm was measured with a UV-3100PC spectrophotometer (VWR International, LLC, Radnor, PA) using 0.1% SDS solution as a blank. The emulsifying activity index (EAI) and emulsifying stability index (ESI) were calculated via the following equations:

where A0 and A10 are the absorbances of the diluted emulsion at 0 min and 10 min, respectively. D is the dilution factor, c is the concentration of HPI/HPC solution, φ is the volume fraction of corn oil (φ = 0.20), and t is the time interval (in our case, 10 min).

Foaming capacity and stability

The foaming capacity (FC) and foaming stability (FS) were determined according to the methods of Zhu et al.23 with some modifications. Fifty milliliters of a sample dispersion (2%, w/v) in 0.05 M phosphate buffer (pH = 7.0) was homogenized in a homogenizer (FSH-2A, JingFei Co., Zhejiang, China) at 22,000 rpm for 1 min at room temperature. The blend was then immediately transferred to a 100 mL graduated cylinder, and the total volume was recorded after 0, 2, 5, 8, 10, 20, 30, 40, 50 and 60 min. The FC and FS were calculated via the following equations:

where V0 is the original volume of the sample (50 mL), Vt is the total volume after different times (mL), and FC0 is the FC at 0 min.

Thermal stability

The thermal decomposition of HPI/HPC was examined via differential scanning calorimetry (DSC) according to the method of Zhu et al.23 with some modifications. The HPI/HPC were directly weighed into aluminum pans, and a sealed empty pan was used as a reference. Scanning was performed at 30–120 °C at a heating rate of 5 °C/min. Indium standards were used for temperature and energy calibrations. The onset temperature (To), thermal decomposition temperature (Td) and decomposition enthalpy (∆H) were calculated from the thermograms.

Structure of hemp protein isolates

Fourier transform infrared (FTIR) spectroscopy analysis

The structures of HPI/HPC extracted via different methods were examined via a Fourier transform infrared spectrometer (Perkin Elmer Spectrum RX I, USA). The final samples were prepared via the potassium bromide (KBr) pellet method31. The reference blank sample was pure KBr. Each spectrum interferogram was collected with a resolution of 4 cm−1 with 32 scans and 2 cm−1 intervals from 4000 to 400 cm−1.

Circular dichroism (CD) spectrum analysis

The secondary structures (α-helix, β-sheet, β-turn, and random coil) of HPI/HPC were measured with a CD spectrometer (Chirascan plus, Applied Photophysics, Skipton, UK). The HPI solution was diluted with deionized water to 0.3 mg/mL and then transferred into a quartz cell. The wavelength was scanned from 190 nm to 260 nm with a bandwidth of 1 nm, and each spectrogram was an average of three spectra accumulations. The secondary structure was analyzed via the CD tool (http://dichroweb.cryst.bbk.ac.uk).

Characterization of the microstructure of HPI

A scanning electron microscope (SEM) (JEOL Model JSM-6490LV, Peabody, MA, USA) was used to study the morphological properties of the powder samples. A speck of sample was attached to an adhesive carbon tab on a cylindrical aluminum mount, and the excess was blown off with a stream of nitrogen gas. The sample was then sputter-coated with gold and examined at an accelerating voltage of 10 kV. The appropriate magnification image was selected as the representative of each sample.

Amino acid and nutritional profile analysis

Analysis of amino acids and nutrients was performed according to the methods of Shen et al.14.

Protein Efficiency Ratio (PER)

The PER was calculated from the amino acid composition of both HPI and HPC via the following equations:

Essential Amino Acid Index (EAAI)

The essential amino acid (EAA) score and % EAAI were calculated via the following equations:

where n is the number of essential amino acids.

Predicted Biological Value (p-BV)

The p-BV was calculated via the following equation:

Nutritional Index (NI)

The NI was calculated as a function of EAAI and total protein:

Amino Acid Score (AAS)

The amino acid score (AAS) was calculated via the method of FAO/WHO32 as shown below:

Statistical analysis

Experiments were carried out in triplicate and the mean values with standard deviation (SD) were reported. Analysis of variance (ANOVA) was performed via SPSS 20.0 statistical software. Differences between groups were assessed with Tukey’s multiple-range test. Different lowercase (a–b) letters indicate markedly differences. The significance of differences was defined at the P < 0.05 level. Protein preparation was performed three times for all assays.

Results and discussion

Exaction performance and proximate chemical composition

The extraction yield, protein recovery yield, and proximate chemical composition of HPI/HPC as affected by the extraction method are summarized in Table 1. Compared with the reverse micelle method, the alkali extraction isoelectric precipitation method resulted in significantly greater extraction and protein recovery yields. A higher pH promotes the cleavage of disulfide bonds, so the alkaline extraction isoelectric precipitation method results in a high protein recovery yield and causes protein denaturation18. The extraction yield and recovery rate of AE-HPC exceed the ranges reported by Shen et al., Hadnadev et al., and Fang et al.14,30,33, primarily due to the high protein content of HPM (52.16%), which significantly reduces lipid interference and establishes fundamental conditions for efficient alkaline extraction. Zhu at al. and Hu et al.13,23 reported a greater protein extraction yield via the reverse micelle method than via the alkali extraction isoelectric precipitation method. The low extraction yield and recovery yield of the reverse micelle method in this work may be attributed to the process conditions. The volume of the reverse micelle molecules limits the extraction of macromolecular proteins, which is affected by the type and concentration of surfactant molecules, the type and structure of solvents and other parameters. Example: AOT represents the predominant anionic surfactant utilized in reverse micelle systems. The AOT/isooctane system forms structurally simple and stable reverse micelles without requiring co-surfactants, facilitating straightforward preparation. This system exhibits broad compatibility for the solubilization of diverse proteins. However, the inherently constrained aqueous core volume imposes limitations on the extraction efficiency of high-molecular-weight proteins19. As per the Codex Alimentarius Standard (2023) and widely accepted in food science, protein isolates are defined as products containing ≥90% protein by weight, while concentrates contain 50-90% protein. In this context: AE-HP product (86% protein) falls under the category of hemp seed protein concentrates (HPC). RMS-HP product (94.44% protein) meets the criteria for classification as hemp seed protein isolates (HPI). The protein content of RMS-HPI was significantly greater than that of AE-HPC, which may be attributed to the high selectivity of reverse micelles for proteins. To enhance the industrial scalability of reverse micelle extraction for hempseed protein production, yield-boosting measures can be implemented including: surfactant replacement, cosurfactant addition (e.g., ethanol), utilization of mixed surfactant systems (such as AOT-Tween 80, AOT-OPE 4, and AOT-DOLPA), systematic optimization of process parameters, and modifications to extraction conditions (e.g., ultrasonication)34.

Data are presented as the mean ± standard deviation (SD) of triplicate experiments. AE-HPC and RMS-HPI represent hempseed protein isolated by alkaline extraction–isoelectric precipitation and reverse micelle method, respectively. * indicates that the component has not been detected or the value is zero. Different lowercase (a–b) letters indicate markedly differences in the extraction performance and proximate chemical composition of AE-HPC and RMS-HPI, respectively (P < 0.05).

Sodium Dodecyl Sulfate-Polyacrylamide Gel Electrophoresis (SDS-PAGE)

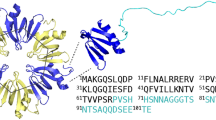

The SDS–PAGE profiles of AE-HPC and RMS-HPI under both nonreducing and reducing conditions are shown in Fig. 2a. The bands at ~50 kDa and 10–15 kDa under both conditions could be attributed to the edestin and albumin subunits, respectively. The band at ~33 kDa could be attributed to the acidic subunit (AS), whereas the 20- and 18-kDa bands could be attributed to the basic subunit (BS) of the edestin monomer, which is linked by a disulfide bond14,15. There were obvious differences between the AE-HPC and RMS-HPI bands under reducing and nonreducing conditions. The AS and BS bands appeared under nonreducing conditions, indicating that some of the edestin of AE-HPC was dissociated in the absence of β-ME. Under reducing conditions, the edestin and albumin subunit bands of AE-HPC disappeared. However, no dissociation of edestin was observed in RMS-HPI under nonreducing conditions; only inconspicuous AS and BS bands appeared under reducing conditions, and edestin and albumin did not disappear. Extraction–isoelectric precipitation is generally believed to lead to protein denaturation18. We reasoned that Strong alkaline conditions can cause breakage of hydrogen, amide, and disulfide bonds, resulting in partial dissociation of AE-HPC35; therefore, AE-HPC is completely dissociated in the presence of β-ME. However, the mild environment in the reverse micelles retained the natural structure of the protein; thus, no dissociation or only a small amount of dissociation occurred in the presence of β-ME.

(a) Electrophoresis profiles of RMS-HPI and AE-HPC under nonreducing and reducing conditions. (b) Contents of globulin and albumin of RMS-HPI and AE-HPC analyzed via ImageJ. Different lowercase (a–b) letters indicate markedly differences in the edestin content and albumin content of AE-HPC and RMS-HPI, respectively (P < 0.05).

The semiquantitative protein content from Image-J is shown in Fig. 2b. The AE-HPC contained 90.18% edestin and 9.82% albumin, whereas the RMS-HPI contained 8.38% edestin and 92.88% albumin. The results revealed that the main extraction object of the AE method is edestin, whereas the main extraction object of the RMS method is albumin. This difference stems from the different mechanisms of the extraction methods used. HPI contains water-soluble albumin and salt-soluble edestin36. After isoelectric precipitation, the albumin remaining in the supernatant was discarded. Therefore, the AE-HPC is dominated by edestin. The efficiency of protein extraction by RMS is affected by the size and shape of the reverse micelles, ionic strength, charge, temperature and other parameters. Our optimized method limiting the size of the reverse micelles is not conducive to the extraction of high-molecular-weight edestin. However, a larger size leads to instability of the reverse micelles. The phenomenon of extracting a small amount of edestin via the RMS method is expected to be overcome by adding cosurfactants and other methods22.

Color

According to the protein color data summarized in Table 2, the RMS-HPI presented higher L* (whiteness) and lower a* (redness) and b* (yellowness) values than did the AE-HPC. In addition, the ΔE value was 11.55, indicating that the degree of total color difference between the two samples was significant for the human eye (as shown in Fig. 3a). The L*, a*, and b* values of the AE-HPC are similar to those reported in other studies14,30. Compared with the HMI reported by Hadnadev et al.33, the RMS-HPI has a higher L* value and lower a* and b* values. According to other studies, native hempseed protein is tight and may be integrated with other components, such as phenolic compounds and phytic acid. The deep color of the AE-HPC is due to the alkaline conditions of the HPI extraction process, which is conducive to the coextraction of phenols from the HPM. The phenolic compounds are oxidized to form benzoquinones that can bind to the protein and thus bind to the protein as a complex14,30,37. During the experiment, we observed that the forward extraction solution was still green after the back extraction, whereas the back extraction solution did not appear green (as shown in Fig. 3b). We reasoned that the high selectivity of the stripping solution for the protein results in separation of the protein from the colored substance, which may be due to different forces between the protein and the interface (chemical, electrostatic, hydrophobic and flux dynamics interactions)38. The light color of the RMS-HPI potentially contributes to consumer acceptability in a variety of food applications.

Data are presented as the mean ± standard deviation (SD) of triplicate experiments. AE-HPC and RMS-HPI represent hempseed protein isolated by alkaline extraction–isoelectric precipitation and reverse micelle method, respectively. Different lowercase (a–b) letters indicate markedly differences in the L*, a*,b* values of AE-HPC and RMS-HPI, respectively (P < 0.05).

Functional properties of hemp protein isolates

The most common nonnutritive function of protein is known technofunctionality, which refers to the ability of protein to provide and/or stabilize the characteristic structure of foods during preparation, processing, storage and consumption, thereby contributing to the overall quality of food, sensory attributes and consumer acceptance39. One possible reason for the difference between proteins is that different protein extraction procedures lead to different ratios of edestin to albumin and different protein configurations40.

Solubility

Protein solubility is an important property in protein dispersion and influences other functional properties of proteins, such as the water and oil holding capacity, foaming, emulsification, and gelation39. Classic U-shaped solubility profiles were obtained for AE-HPC and RMS-HPI, with minimums at pH 5.0 (3.83%) and 6.0 (13.17%), respectively (as shown in Fig. 4a). The maximum solubility occurs at a pH of 2.0, which is in agreement with the findings of Fang et al.41. Previous studies have reported that HPI, which is mainly composed of edestin, has the minimum solubility in the range of pH 4–6. The difference in pH reported in different studies may be caused by many factors, such as the extraction process, hempseed variety, and origin17,39,41,42,43. The solubility of RMS-HPI in the pH range of 5–7 is almost unchanged. Fang reported that the isoelectric points of AE-HPC and SE-HPI (protein by salt extraction) were 5.7 and 6.4, respectively, and attributed this change in solubility to the two different extraction methods that changed the amino acid composition and protein composition of HPI30.

Analysis of the functional properties and structure of the AE-HPC and RMS-HPI. (a) Solubility; (b) Foaming capacity and stability; (c) Water holding capacity and oil holding capacity; (d) Emulsifying capacity and stability; (e) Thermal stability; (f) Secondary structure composition. Different lowercase (a–b) letters indicate markedly differences in the foaming capacity and stability, water/oil holding capacity, emulsifying capacity and stability, and secondary structure composition of AE-HPC and RMS-HPI, respectively (P < 0.05).

Compared with AE-HPC, RMS-HPI had greater solubility at all the pH values used in this work, which agreed with the findings of studies of soybean, wheat, walnut and other plant proteins extracted via the reverse micelle process. These authors suggested that this phenomenon might be due to the effect of extraction methods on the degree of protein denaturation. The environment of the polar core in reverse micelles approaches physiological environments, and proteins were solubilized in reverse micelles without damaging their native conformation, whereas the proteins obtained through AE-IP easily denature in acidic or alkaline media12,13,23. We postulated that the higher solubility of RMS-HPI than AE-HPC can be attributed to the higher proportion of albumin, which agreed with the findings of Nasrollahzadeh et al.4. In general, hemp edestin is less soluble than other vegetable proteins are, which is attributed to the high free sulfhydryl content of sulfur-containing amino acids that favors the formation of covalent disulfide bonds between individual proteins and subsequent aggregation at neutral or acidic pH values39. Albumin has almost no dense structure at different pH values, which prevents the extensive folding of proteins; hence, most residues are in contact with the environment. Therefore, albumin has greater flexibility and a less compact structure than edestin does, and albumin contains an ordered secondary structure. These characteristics may explain why albumin has higher solubility than more compact or aggregated globulin does9.

Water and oil holding capacities

The water/oil holding capacity of proteins is their ability to retain water/oil against gravity. The WHC is important for the quality of meat analogs and bakery products. The oil absorption capacity is an important property in fat and flavor retention. The high OHC of protein could be utilized in the food industry for the formulation of meat substitutes, ground meat, baked goods, extenders, and soups. The WHC and OHC values of hemp proteins have been reported by different authors and are in the ranges of 0.80–12.01 g/g and 1.05–13.70 g/g, respectively, suggesting that both the protein isolation procedure and method used determine the WHC influence values16,17,29,30,44. The WHC of the AE-HPC and RMS-HPI measured in this study were 0.70 and 0.39 g/g, respectively (as shown in Fig. 4b), which were lower than those reported previously. Tang et al. reported that the WHC of HPI was significantly lower than that of SPI, and the relatively poor WHC may be attributed to the fact that the polar groups of the protein are buried inside the aggregates due to protein aggregation16. Teh et al. reported that, compared with flaxseed protein, hemp and rapeseed meal, hemp protein isolate presented the highest WHC and OHC values, indicating that alkali or acid extraction could lead to changes in the conformation of hemp and rapeseed protein, resulting in a more pronounced hydrophilic surface than that of the raw material44. According to an investigation by Liu et al. and Ajibola et al., the WHC of albumin has not been reported due to its complete solubility in water29,39. Therefore, protein conformational changes induced by alkaline or acid extraction, combined with the low albumin content in AE-HPC, may contribute to its higher water holding capacity compared to RMS-HPI. The WHC of RMS-HPI is also lower than that of RMS-extracted soybean and walnut proteins. This phenomenon may be attributable to both the inherently poor WHC of HPI and the higher water solubility of RMS-HPI12,24. The OHC of the RMS-HPI was significantly greater than that of the AE-HPC, probably due to the greater albumin content of the RMS-HPI, which was supported by the report that the albumin OHC was greater than the edestin OHC39. Furthermore, the OHC of RMS-HPI significantly exceeds that of RMS-extracted proteins from soybean, walnut, wheat, and other sources. This phenomenon likely stems from the influence of multiple parameters governing protein OHC, including the physical entrapment of oil, protein surface area, particle size, charge distribution, and hydrophobicity. Critically, extraction methodsalter both the protein composition (albumin/globulin ratio) and conformational states of proteins. These modifications collectively contribute to the enhanced OHC observed in RMS-HPI relative to AE-HPC and other RMS-extracted plant proteins12,23,24.

Emulsifying capacity and stability

Compared with the AE-HPC, the RMS-HPI had a greater EAI but a lower ESI (as shown in Fig. 4c). A higher ALB content may be the main reason why the RMS-HPI has better EAI. Ajibola et al. reported that albumin protein has better emulsifying properties (smaller oil droplet size) than edestin and HPI do at all pH values and concentrations because a small size (larger surface area) indicates good interfacial properties of the emulsifier39. Many studies have reported a positive correlation between surface hydrophobicity, better solubility and emulsion properties, and when the solubility of a protein is high, surface hydrophobicity has a greater impact on the emulsification properties, whereas when protein solubility is low (<50%), solubility has a greater impact on emulsification properties14,16,45. A greater protein-solvent interaction promotes faster diffusion of protein molecules to the interface and rearranges them, forming an elastic film at the oil‒water interface. In addition, proteins with small molecular weights and flexible conformations have faster absorption rates at the oil‒water interface, so a higher EAI was observed for RMS-HPI. Some studies have reported the irrelevance between the solubility of ESI and EAI14,46. The stability of emulsions depends on the delicate balance of intramolecular and oil/water interface repulsion, which is affected by many factors, such as pH, ionic strength, protein composition and amino acid polarity30. The differences in the EAI and ESI between AE-HPC and RMS-HPI may be attributed to the following factors: the size of the reverse micelles limits the molecular weight of the proteins, resulting in low efficiency in reducing the interfacial tension23; AE-HPC can resist flocculation via stronger protein‒protein interactions; and under neutral pH conditions, the negatively charged AE-HPC at the interface away from the isoelectric point results in a strong repulsive force between the oil droplets, increasing the stability of the interface film37,47.

Foaming capacity and stability

The foaming capacity of a protein is its ability to form a foam under specific conditions, while the foam stability indicates how well such a protein maintains the foam volume over a specific period39. Foaming ability is necessary for many foods that require rheology, such as bread, cakes, and raw cream. In general, significant differences in the FC and FS were found between the RMS-HPI and AE-HPC. Compared with the AE-HPC, the RMS-HPI has a greater FC and lower FS (as shown in Fig. 4d). The negative correlation between the FC and FS is in agreement with investigations of Fang et al. and Chang et al.41,48; but differs from the data reported in a previous work that revealed a positive correlation between the FC and FS13,23. The reason was probably that the protein obtained through RMS had a greater proportion of albumin, which is supported by the results of the investigation of Ajibola et al. and Malomo et al.39,42, who reported that the FS of edestin was greater than that of albumin and that the FC of edestin was lower than that of albumin. The FC is affected by solubility, molecular flexibility and protein molecular weight. Previous studies have reported a positive correlation between the FC and solubility. The decrease in protein molecular weight and increase in flexibility of protein chains can cause the protein to unfold more effectively at the air/water interface, resulting in the encapsulation of air particles and increasing the FC12. The high solubility, low molecular weight and high flexibility of albumin are necessary conditions for good foaming properties. AE-HPC mainly contains edestin, and the greater FS properties of edestin may be attributed to higher content of hydrophobic amino acids, which increase the strength of protein interactions and the formation of a strong interfacial membrane at the air–water interface. The hydrophilicity of albumin leads to the formation of weaker interfacial membranes40. Albumin also has a much lower Molecular weight than edestin, which makes its exchange rate with the medium (interfacial film-medium) much higher, contributing to lower foam stability. Therefore, the edestin interfacial membrane is better able to withstand air bubble coalescence than are the albumin-stabilized foams.

Thermal stability

Response to temperature changes is an important characteristic of proteins. Changes in protein structure caused by high temperatures affect the function and nutritional properties of proteins49. In this study, the thermal stability of hemp seed protein isolates/concentrates was evaluated using solid-state differential scanning calorimetry (DSC) (Fig. 4e). It is important to note that solid-state DSC detects internal structural changes (e.g., hexamer dissociation or changes in secondary structures), whereas solution-state DSC reflects the overall denaturation process in hydrated states. Water molecules stabilize the native conformation via hydrogen bonding and hydrophilic/hydrophobic interactions, while simultaneously enabling bond rearrangements and exposure of hydrophobic regions to promote denaturation. The absence of water in solid-state systems may lead to higher decomposition temperatures (Td) due to restricted molecular mobility. Although Td and ΔH values from solid- and solution-state DSC are not directly comparable, solid-state DSC provides insights into structural stability under desiccated conditions. The results showed that AE-HPC exhibited a higher Td (96.72°C) compared to RMS-HPI (89.14°C), likely attributed to its protein composition and structural features: Protein composition: AE-HPC contains a higher proportion of edestin, whose 11S hexameric subunits exhibit greater thermal stability during dissociation compared to the 2S subunits predominant in RMS-HPI (rich in albumins). Structural characteristics: AE-HPC demonstrated a denser conformation and a higher ratio of α-helix and β-sheet structures (supported by CD spectroscopy, Fig. 4f), which enhance thermal stability. Notably, a higher decomposition temperature does not necessarily correlate with greater enthalpy change. RMS-HPI displayed a larger ΔH due to heterogeneous interactions within its complex (e.g., cooperative dissociation of 11S globulin hexamers) and a higher proportion of α-helical structures. These findings highlight the interplay between protein composition, structural organization, and thermal stability mechanisms.

Structure of hemp protein isolates

FITIR

Alterations in the AE-HPC and RMS-HPI structures were investigated by analyzing the changes in the peak position of the amide region. N–H stretching vibrations dominate the amide A region (3500–3200 cm−1). The amide 1 region occurs in the wavenumber range of 1700–1600 cm−1, where C=O (70–85%) and C–N stretching vibrations (10–20%) play predominant roles in protein linkages. The amide 2 region (1580–1480 cm−1) mainly contains N–H (40–60%), C–N (18–40%) and C–C (10%) stretching vibrations. The three regions (1450–1300 cm−1) contain complex vibration modes. The amide 1 region is most sensitive to changes in protein secondary structure. The different regions of amide 1 were assigned to specific protein secondary structures with β-sheets at 1610–1627 cm−1 and 1628–1642 cm−1, α-helices at 1650–1659 cm−1, β-turns at 1660–1699 cm−1 and random coils at 1643–1650 cm−1. In the amide 2 region, the 1545–1551 cm−1 and 1521–1525 cm−1 peaks represent α-helix and β-sheet conformations, respectively50,51.

As shown in Fig. 5a, the AE-HPC bands are similar to those reported by Karabulut et al. and El-Sohaimy et al.50,51. Compared with the AE-HPC, the RMS-HPI demonstrated changes in the number, position and intensity of peaks. AE-HPC had additional peaks at 1745 cm−1 and 1165 cm−1, indicating the presence of lipids in AE-HPC, whereas no lipids were present in RMS-HPI52. Compared with that of AE-HPC, the RMS-HPI peak in the amide 1 region shifted from 1655 cm−1 to 1653 cm−1, which corresponded to the α-helix structure. The peak in the amide 2 region shifted from 1541 cm−1 to 1539 cm−1. This shift may be due to the tendency of the RMS-HPI structure to form random coils50. AE-HPC showed a strong absorption band at 1238 cm−1, suggesting that β-sheets are the predominant secondary structures53. The stronger absorption band near 2928 cm−1 indicates that, compared with RMS-HPI, AE-HPC has more C–H stretching vibrations. The shift of the absorption peak of RMS-HPI in the amide A band to a higher wave numbers may be due to the presence of more hydrogen bonds, which may be related to its high solubility53.

CD

As shown in Fig. 4f, according to the CD spectrum image shown in Fig. 5b, the AE-HPC is composed of 13.88% α-helix, 42.71% β-sheet, 17.15% β-turn and 28.22% random coil, and the secondary structure estimation of the RMS-HPI revealed 26.93% α-helix, 19.90% β-sheet, 22.57% β-turn and 30.43% random coil. The difference between the AE-HPC and RMS-HPI was related to the extraction process and protein composition. The proportion of random coil of RMS-HPI is lower than the 47.05% of 2S protein and 36.15% of HPI reported by Ajibola et al.39, which may be attributed to the protective effect of the mild extraction environment of RMS on the protein structure. The water-surfactant-organic solvent three-phase system of reverse micelles protects the solubilized biomolecules within polar water pools from organic solvent damage54. Additionally, the anionic gemini surfactant AOT exhibits a high interfacial curvature due to its dual-chain structure, facilitating the formation of more spacious aqueous cores in reverse micelles. This structural feature effectively mitigates conformational distortion of encapsulated proteins caused by spatial confinement. AOT electrostatically captures proteins via ionic interactions between its sulfonate groupsm and positively charged residues on protein surfaces, thereby restricting protein flip-flop motions and stabilizing their dynamic behavior. Within the aqueous core, water molecules adopt a gradient arrangement: near the micellar interface, they form a rigid, "ice-like structured layer" through a hydrogen-bonding network, which anchors hydrophilic domains of proteins; meanwhile, the central region retains liquid-like fluidity to maintain protein flexibility. The system maintains a mild pH environment (near-neutral) and low ionic strength, which collectively suppress protein aggregation and inhibit intermolecular hydrophobic association by maintaining electrostatic repulsion and reducing salt-induced shielding effects. This preserves protein structural integrity and functional activity.

In the AE-HPC, only the proportion of β-sheet structures is greater than that in the RMS-HPI, which may be due to the greater proportion of edestin in the AE-HPC. Edestin has been reported to be dominated by a β-sheet secondary structure, whereas albumin usually has a greater percentage of α-helix structure14,30. The rigid structure caused by the high proportion of β-sheets and the low content of disordered structures lead to an increase in structural tightness, resulting in the poor solubility of edestin, which may be the main reason for the difference in functional properties between the AE-HPC and RMS-HPI. In addition, Eckhardt et al. and Yao et al. reported that an alkaline environment and ultrasonic treatment may lead to the transformation of α-helix to β-sheet structures, indicating that the alkaline extraction–isoelectric precipitation process may lead to protein denaturation and affect protein structure26,45.

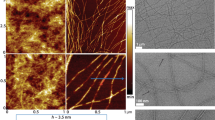

HPI microstructure characterization

Micrographs of AE-HPC and RMS-HPI, obtained by scanning electron microscopy at different magnifications, are shown in Fig. 6. Clear differences were observed in the morphological characteristics and sizes of the AE-HPC and RMI-HPI. A plate-shaped morphology with a smooth lamellar surface was observed in the AE-HPC, with a uniform size and small pores on the surface (As indicated by the red arrow). The RMS-HPI was observed at a greater magnification (× 5000) than the AE-HPC (× 1300). The proteins of RMS-HPI are densely distributed and stacked, with various forms, such as rods, strips, blocks, and circles. Some proteins are uneven in surface area, mostly three-dimensional in shape, and occasionally have a porous plate shape. A comparison of images a and b at the same magnification reveals that the size of the RMS-HPI is significantly smaller than that of the AE-HPC. In addition, the RMS-HPI has a smoother surface. The different morphological characteristics of the HPI/HPC might be related to their structure and contribute to their different functional properties. The plate-shaped morphology of the HPC may be due to the change in secondary structure caused by alkali, and the porosity may be due to destruction of the protein by the mechanical force during the extraction process. The small size of RMS-HPI due to the limitation of the reverse micelle size may be the reason for the high solubility of RMS-HPI.

Amino acid and nutritional profile analysis

The amino acid and nutrition profiles of AE-HPC and RMS-HPI are shown in Table 3. In this work, tryptophan was not reported due to its hydrolysis during the acid hydrolysis process48. Both AE-HPC and RMS-HPI contain nine essential amino acids required by the human body and are rich in glutamic acid, followed by arginine and aspartic acid, which is in line with previous studies14,30. Compared with AE-HPC, RMS-HPI contained high levels of methionine, histidine, cysteine, aspartic acid, serine, glutamic acid, glycine, tyrosine, and arginine, but lower levels of proline, while the compositions of the other amino acids were similar. This difference may be due to the different protein compositions and the destruction of amino acid residues under alkaline conditions. Albumin includes more sulfur-containing amino acids (cysteine and methionine), which allows RMS-HPI with a high albumin proportion to serve as a rich thiol resource to prepare highly nutritional foods and increase the antioxidant capacity of the human body36. Cysteine, arginine, and serine may be damaged in the alkaline extraction process24. The Arg/Lys ratio of RMS-HPI (4.81) is higher than that of AE-HPC (3.98) and significantly exceeds those of other plant proteins extracted via RMS (e.g., 0.65 for pigeon pea seed protein, 1.04 for tea protein, 1.03 for soy protein)12,55,56. The elevated Arg/Lys ratio in RMS-HPI confers cardiovascular protective advantages, as higher dietary Arg/Lys ratios have been demonstrated to reduce cholesterol levels and promote cardiovascular health. Specifically, arginine serves as a precursor to nitric oxide (NO), which mediates cardiovascular protection through:vasodilation; inhibition of leukocyte adhesion; reduction of platelet aggregation, and prevention of plaque formation. Conversely, lysine exhibits an antagonistic relationship with arginine and may induce hypercholesterolemia57,58. Moreover, the presence of leucine, isoleucine and valine in HPIs may contribute to human protein metabolism and muscle tissue formation14.

The PER has been recognized as an index of protein quality, and protein sources with PER values above 2 are considered high-quality proteins59. The PER values of the AE-HPC and RMS-HPI are similar and less than 2, which is different from the data reported by Shen et al.14. The PER is dominated by leucine, and the low leucine content of the HPI/HPC in this work led to a low PER. In addition, the EAAI can be used to evaluate the protein quality of samples on the basis of comparisons with reference proteins, such as egg protein. High EAAI values represent balanced amino acid compositions and good nutritional quality. Food materials with an EAAI value above 90 are classified as high-quality proteins14. The results revealed that the EAAI values of the AE-HPC (130.15) and RMS-HPI (139.38) were above 90, indicating that both the AE-HPC and RMS-HPI were high-quality proteins. The biological value (p-BV) is a measure of the ability of the human body to absorb protein efficiently. Protein-rich foods with good nutritional quality have a p-BV value above 70. The high predicted biological values of AE-HPC (130.16) and RMS-HPI (140.22) indicate that these compounds are high-quality proteins that are beneficial for human absorption. The nutritional index (NI) is a function of the essential amino index and protein content of a sample and is used to measure the nutritional value of food59. Compared with the AE-HPC (111.93), the RMS-HPI has a greater NI value (131.63) because of its higher protein content and EAAI value, indicating that the RMS-HPI has greater nutritional value. The amino acid score (AAS) results revealed that lysine was the first limiting amino acid of AE-HPC and RMS-HPI, followed by leucine and valine. Histidine, phenylalanine, tyrosine, methionine and cysteine were sufficient for the FAO/WHO-suggested requirements for infants or children. The remaining amino acids were close to the FAO/WHO amino acid requirement pattern32. Moreover, the dietary protein quality of RMS-HPI might be greater than that of AE-HPC according to the histidine, methionine and cysteine, phenylalanine and tyrosine scores.

Conclusions

Protein extraction methods affect the function, conformation and amino acid nutrition profile of hempseed protein isolates. The extraction of macromolecular proteins may be limited by the size of the reverse micelles, resulting in a low HPI extraction yield and recovery yield. The RMS-HPI protein content is relatively high because of the high selectivity of reverse micelles for proteins, thus reducing the effect of phenols and resulting in a relatively good color. The difference in HPI/HPC caused by the AE and RMS processes is related to changes in protein composition and the influence of protein structure. Compared with AE-HPC, RMS-HPI has greater solubility, foaming capacity, oil retention capacity and emulsifying capacity because of the mild extraction environment of RMS and the high albumin content. In contrast, AE-HPC has higher foam stability, water holding capacity, emulsification stability, and decomposition temperature due to its higher edestin content. The difference in function and composition between RMS-HPI and AE-HPC is reflected in structural changes and microstructures. The difference between the number, position and intensity of the infrared absorption peaks and that the RMS-HPI secondary structure is mainly α-helix while the AE-HPC secondary structure is mainly the β-sheet indicate that the protein compositions of AE-HPC and RMS-HPI differ. The diverse shapes and sizes of RMS-HPI may be attributed to the fact that RMS is mainly based on protein molecular weight for protein extraction. In addition, RMS-HPI has more advantages in terms of amino acid composition and nutritional profile because of its high amino acid content. A high Arg/Lys ratio increases the potential of the RMS-HPI for the prevention of cardiovascular disease.

In summary, reverse micelles and alkaline extraction-isoelectric point precipitation method have their own advantages. As distinct food matrices, RMS-HPI is suitable for applications in beverages, lightly baked goods, sauces/condiments, and functional foods, while AE-HPC demonstrates optimal compatibility with high-temperature processed products, meat products, frozen foods, and gel-based products. Although the yield of RMS-HPI is relatively low in this study, this limitation is counterbalanced by its enhanced functional properties, which render it suitable for diverse product formulations. The efficient exclusion of phenolic compounds during AOT-mediated reverse micelles extraction better preserves the native flavor profile of hempseed protein-based products. Furthermore, its superior nutritional value—particularly the high arginine/lysine ratio and cardioprotective potential—supports applications in value-added functional foods, such as cardiovascular health formulations targeting hypertension and oxidative stress mitigation. Further research on reverse micelle technology to improve protein yield is necessary for the application of reverse micelles in food.

Data availability

All data generated or analysed during this study are included in this published article.

References

Karabulut, G., Kahraman, O., Pandalaneni, K., Kapoor, R. & Feng, H. A comprehensive review on hempseed protein: Production, functional and nutritional properties, novel modification methods, applications, and limitations. Int .J. Biol. Macromol. 253, 127240. https://doi.org/10.1016/j.ijbiomac.2023.127240 (2023).

Pihlanto, A., Mattila, P., Mäkinen, S. & Pajari, A. M. Bioactivities of alternative protein sources and their potential health benefits. Food Funct. 8(10), 3443–3458. https://doi.org/10.1039/c7fo00302a (2017).

Hadnađev, M. S. et al. Progress in vegetable proteins isolation techniques: A review. Food Feed Res. 44(1), 11–22. https://doi.org/10.5937/ffr1701011h (2017).

Nasrollahzadeh, F., et al. 2022 Hemp (Cannabis sativa L.) protein concentrates from wet and dry industrial fractionation: Molecular properties, nutritional composition, and anisotropic structuring. Food Hydrocolloids, 131, 107755

Vahanvaty, U. S. Hemp seed and hemp milk: the new super foods?[J]. ICAN: Infant, Child, & Adolescent Nutrition, 1(4), 232-234 (2009). https://doi.org/10.1177/1941406409342121

Thakur, S., Pandey, A. K., Verma, K., Shrivastava, A. & Singh, N. Plant-based protein as an alternative to animal proteins: A review of sources, extraction methods and applications. Int. J. Food Sci. Technol. 59(1), 488–497. https://doi.org/10.1111/ijfs.16663 (2024).

Zhang, X., Zhou, W., Qin, X., Hou, C., & Yang, X. Preparation, Modification, Food Application, and Health Effects of Protein and Peptide from Hemp (Cannabis sativa L.) Seed: A Review of the Recent Literature. Foods, 14(7), 1149 (2025). 10.3390/foods14071149

Shen, P., Gao, Z., Fang, B., Rao, J. & Chen, B. Ferreting out the secrets of industrial hemp protein as emerging functional food ingredients. Trends Food Sci. Technol. 112, 1–15. https://doi.org/10.1016/j.tifs.2021.03.022 (2021).

Aluko, R. E. Hemp seed (Cannabis sativa L.) proteins: composition, structure, enzymatic modification, and functional or bioactive properties. In Sustainable protein sources 121-132 (2017). Academic Press. https://doi.org/10.1016/B978-0-12-802778-3.00007-X

Wang, Q. & Xiong, Y. L. Processing, nutrition, and functionality of hempseed protein: A review. Comprehensive Reviews in Food Science and Food Safety 18(4), 936–952. https://doi.org/10.1111/1541-4337.12450 (2019).

Barretto, R. et al. Hempseed protein is a potential alternative source for plant protein-based adhesives. Int. J. Adhes. Adhes. 133, 103740. https://doi.org/10.1016/j.ijadhadh.2024.103740 (2024).

Zhao, X., Zhang, X., Liu, H., Zhang, G. & Ao, Q. Functional, nutritional and flavor characteristic of soybean proteins obtained through reverse micelles. Food Hydrocolloids 74, 358–366. https://doi.org/10.1016/j.foodhyd.2017.08.024 (2018).

Hu, H. et al. Functional and conformational characterisation of walnut protein obtained through AOT reverse micelles. Int. J. Food Sci. Technol. 50(11), 2351–2359. https://doi.org/10.1111/ijfs.12900 (2015).

Shen, P., Gao, Z., Xu, M., Rao, J. & Chen, B. Physicochemical and structural properties of proteins extracted from dehulled industrial hempseeds: Role of defatting process and precipitation pH. Food Hydrocolloids 108, 106065. https://doi.org/10.1016/j.foodhyd.2020.106065 (2020).

Wang, X. S., Tang, C. H., Yang, X. Q., & Gao, W. R. Characterization, amino acid composition and in vitro digestibility of hemp (Cannabis sativa L.) proteins. Food Chemistry, 107(1), 11-18 (2008). https://doi.org/10.1016/j.foodchem.2007.06.064

Tang, C. H., Ten, Z., Wang, X. S., & Yang, X. Q. Physicochemical and functional properties of hemp (Cannabis sativa L.) protein isolate. Journal of agricultural and food chemistry, 54(23), 8945-8950 (2006). https://doi.org/10.1021/jf0619176

Malomo, S. A., He, R. & Aluko, R. E. Structural and functional properties of hemp seed protein products. J. Food Sci. 79(8), 1512–1521. https://doi.org/10.1111/1750-3841.12537 (2014).

Hernández-Álvarez, A. J., Mondor, M. & Nosworthy, M. G. Green protein processing technologies from plants. Green protein processing technologies from plants https://doi.org/10.1007/978-3-031-16968-7 (2023).

Sun, X. & Bandara, N. Applications of reverse micelles technique in food science: A comprehensive review. Trends Food Sci. Technol. 91, 106–115. https://doi.org/10.1016/j.tifs.2019.07.001 (2019).

Manzanilla-Valdez, M. L., Ma, Z., Mondor, M. & Hernández-Álvarez, A. J. Decoding the duality of Antinutrients: Assessing the impact of protein extraction methods on plant-based protein sources. J. Agric. Food Chem. 72(22), 12319–12339. https://doi.org/10.1021/acs.jafc.4c00380 (2024).

Rashwan, A. K., Osman, A. I., Abdelshafy, A. M., Mo, J. & Chen, W. Plant-based proteins: advanced extraction technologies, interactions, physicochemical and functional properties, food and related applications, and health benefits. Crit. Rev. Food Sci. Nutr. 65(4), 667–694. https://doi.org/10.1080/10408398.2023.2279696 (2025).

Sánchez-Velázquez, O. A., Manzanilla-Valdez, M. L., Wang, Y., Mondor, M., & Hernández-Álvarez, A. J. Micellar precipitation and reverse micelle extraction of plant proteins. In Green protein processing technologies from plants: Novel extraction and purification methods for product development 237-263 (2023). https://doi.org/10.1007/978-3-031-16968-7_10

Zhu, K. X. et al. Comparison of functional properties and secondary structures of defatted wheat germ proteins separated by reverse micelles and alkaline extraction and isoelectric precipitation. Food Chem. 123(4), 1163–1169. https://doi.org/10.1016/j.foodchem.2010.05.081 (2010).

Zhao, X., Liu, H., Zhang, X. & Zhu, H. Comparison of structures of walnut protein fractions obtained through reverse micelles and alkaline extraction with isoelectric precipitation. Int. J. Biol. Macromol. 125, 1214–1220. https://doi.org/10.1016/j.ijbiomac.2018.09.095 (2019).

Li, Y. F., et al. Optimization of extraction process of hemp seed protein by reverse micelle method and study on its physicochemical properties and digestibility. Food and Machinery, 40(10), 195-203 (2025). https://doi.org/10.13652/j.spjx.1003.5788.2023.81201

Yao, S., Li, W., Wu, Y., Martin, G. J. & Ashokkumar, M. The impact of high-intensity ultrasound-assisted extraction on the structural and functional properties of hempseed protein isolate (HPI). Foods 12(2), 348. https://doi.org/10.3390/foods12020348 (2023).

AOAC. Official methods of analysis. Association of Official Analytical Chemists International (2016).

Lan, Y., Xu, M., Ohm, J. B., Chen, B. & Rao, J. Solid dispersion-based spray-drying improves solubility and mitigates beany flavour of pea protein isolate. Food Chem. 278, 665–673. https://doi.org/10.1016/j.foodchem.2018.11.074 (2019).

Liu, M. et al. The effects of germination on the composition and functional properties of hemp seed protein isolate. Food Hydrocolloids 134, 108085. https://doi.org/10.1016/j.foodhyd.2022.108085 (2023).

Fang, B., Chang, L., Ohm, J. B., Chen, B. & Rao, J. Structural, functional properties, and volatile profile of hemp protein isolate as affected by extraction method: Alkaline extraction–isoelectric precipitation vs salt extraction. Food Chem. 405, 135001. https://doi.org/10.1016/j.foodchem.2022.135001 (2023).

Du, Y., Zhang, Q., Zhao, X. & Chen, F. Effect of reverse micelle on physicochemical properties of soybean 7S globulins. J. Food Eng. 282, 110026. https://doi.org/10.1016/j.jfoodeng.2020.110026 (2020).

FAO Expert Consultation. Dietary protein quality evaluation in human nutrition. Food and Nutrition Paper 92, 1–66 (2013).

Hadnađev, M. et al. Hempseed meal protein isolates prepared by different isolation techniques. Part I. physicochemical properties. Food Hydrocolloids 79, 526–533. https://doi.org/10.1016/j.foodhyd.2017.12.015 (2018).

Sankaran, R. et al. Reverse micellar system in protein recovery-A review of the latest developments. Curr. Protein Pept. Sci. 20(10), 1012–1026. https://doi.org/10.2174/1389203720666190628142203 (2019).

Alarape, K. et al. Extraction and Nutritional Value of Soybean Meal Protein Isolate. Nutraceuticals 4(4), 503–521. https://doi.org/10.3390/nutraceuticals4040029 (2024).

Xu, Y. et al. Hempseed as a nutritious and healthy human food or animal feed source: a review. Int. J. Food Sci. Technol. 56(2), 530–543. https://doi.org/10.1111/ijfs.14755 (2021).

Potin, F., Goure, E., Lubbers, S., Husson, F. & Saurel, R. Functional properties of hemp protein concentrate obtained by alkaline extraction and successive ultrafiltration and spray-drying. Int. J. Food Sci. Technol. 57(1), 436–446. https://doi.org/10.1111/ijfs.15425 (2022).

Melo, E. P., Aires-Barros, M. R. & Cabral, J. M. S. Reverse micelles and protein biotechnology. Biotechnol. Annu. Rev. 7, 87–129. https://doi.org/10.1016/S1387-2656(01)07034-X (2001).

Ajibola, C. F. & Aluko, R. E. Physicochemical and functional properties of 2S, 7S, and 11S enriched hemp seed protein fractions. Molecules 27(3), 1059. https://doi.org/10.3390/molecules27031059 (2022).

Pihlanto, A., Nurmi, M., & Mäkinen, S. Industrial hemp proteins: Processing and properties. In Industrial Hemp 125-146 (2022). https://doi.org/10.1016/B978-0-323-90910-5.00014-2

Fang, B., Gu, Z., Ohm, J. B., Chen, B. & Rao, J. Reverse micelles extraction of hemp protein isolate: Impact of defatting process on protein structure, functionality, and aromatic profile. Food Hydrocolloids 135, 108158. https://doi.org/10.1016/j.foodhyd.2022.108158 (2023).

Malomo, S. A., & Aluko, R. E. A comparative study of the structural and functional properties of isolated hemp seed (Cannabis sativa L.) albumin and globulin fractions. Food Hydrocolloids, 43, 743-752 (2015). https://doi.org/10.1016/j.foodhyd.2014.08.001

Liu, M., Toth, J. A., Childs, M., Smart, L. B. & Abbaspourrad, A. Composition and functional properties of hemp seed protein isolates from various hemp cultivars. J. Food Sci. 88(3), 942–951. https://doi.org/10.1111/1750-3841.16467 (2023).

Teh, S. S., Bekhit, A. E. D., Carne, A. & Birch, J. Effect of the defatting process, acid and alkali extraction on the physicochemical and functional properties of hemp, flax and canola seed cake protein isolates. Journal of Food Measurement and Characterization 8, 92–104. https://doi.org/10.1007/s11694-013-9168-x (2014).

Eckhardt, L., Bu, F., Franczyk, A., Michaels, T., & Ismail, B. P. Hemp (Cannabis sativa L.) protein: Impact of extraction method and cultivar on structure, function, and nutritional quality. Current Research in Food Science, 8, 100746 (2024). https://doi.org/10.1016/j.crfs.2024.100746

Cui, L. et al. Functionality and structure of yellow pea protein isolate as affected by cultivars and extraction pH. Food Hydrocolloids 108, 106008. https://doi.org/10.1016/j.foodhyd.2020.106008 (2020).

Dapčević-Hadnađev, T. et al. Emulsifying properties of hemp proteins: Effect of isolation technique. Food Hydrocolloids 89, 912–920. https://doi.org/10.1016/j.foodhyd.2018.12.002 (2019).

Chang, L. et al. Plant proteins from green pea and chickpea: Extraction, fractionation, structural characterization and functional properties. Food Hydrocolloids 123, 107165. https://doi.org/10.1016/j.foodhyd.2021.107165 (2022).

Tănase Apetroaei, V., Pricop, E. M., Istrati, D. I., & Vizireanu, C. Hemp seeds (Cannabis sativa L.) as a valuable source of natural ingredients for functional foods—A review. Molecules, 29(9), 2097 (2024). https://doi.org/10.3390/molecules29092097

Karabulut, G., Feng, H. & Yemiş, O. Physicochemical and antioxidant properties of industrial hemp seed protein isolate treated by high-intensity ultrasound. Plant Foods Hum. Nutr. 77(4), 577–583. https://doi.org/10.1007/s11130-022-01017-7 (2022).

El-Sohaimy, S. A., Androsova, N. V., Toshev, A. D., & El Enshasy, H. A. Nutritional quality, chemical, and functional characteristics of hemp (Cannabis sativa ssp. sativa) protein Isolate. Plants, 11(21), 2825 (2022). https://doi.org/10.3390/plants11212825

Hernández-Castillo, J. B. E. et al. Modifications of the protein characteristics of pacaya caused by thermal treatment: a spectroscopic, electrophoretic and morphological study. Polymers 12(5), 1016. https://doi.org/10.3390/polym12051016 (2020).

Nazari, B., Mohammadifar, M. A., Shojaee-Aliabadi, S., Feizollahi, E. & Mirmoghtadaie, L. Effect of ultrasound treatments on functional properties and structure of millet protein concentrate. Ultrason. Sonochem. 41, 382–388. https://doi.org/10.1016/j.ultsonch.2017.10.002 (2018).

Phogat, Riya., et al. Exploring plant-based approaches: A review of protein extraction, characterization, food and pharmacological application from fruit pulps. Food Chemistry, 492, 145251 (2025). https://doi.org/10.1016/j.foodchem.2025.145251

Wang, X., et al. Ultrasound‐Assisted Reverse Micelle Simultaneous Extraction of Protein and Oil From Pigeon Pea Seeds: Optimization and Analyses of Physicochemical and Functional Properties. Asia-Pacific Journal of Chemical Engineering, e70038 (2025). https://doi.org/10.1002/apj.70038

Qiu, M. et al. Ultrasoundâ-assisted reverse micelle extraction and characterization of tea protein from tea residue. J. Sci. Food Agric. 103(8), 4068–4407. https://doi.org/10.1002/jsfa.12381 (2023).

Vallabha, V. S., Tapal, A., Sukhdeo, S. V. & Tiku, P. K. Effect of arginine: lysine ratio in free amino acid and protein form on l-NAME induced hypertension in hypercholesterolemic Wistar rats. RSC Adv. 6(77), 73388–73398. https://doi.org/10.1039/C6RA13632J (2016).

Yu, E. et al. Plasma arginine/asymmetric dimethylarginine ratio and incidence of cardiovascular events: a case-cohort study. J. Clin. Endocrinol. Metab. 102(6), 1879–1888. https://doi.org/10.1210/jc.2016-3569 (2017).

Mir, N. A., Riar, C. S. & Singh, S. Effect of pH and holding time on the characteristics of protein isolates from Chenopodium seeds and study of their amino acid profile and scoring. Food Chem. 272, 165–173. https://doi.org/10.1016/j.foodchem.2018.08.048 (2019).

Acknowledgements

This study was supported by the Project of Shanxi University of Chinese Medicine (grant number 202304051001043; 2024PY-JL-14-02; 2024PY-CXY-007; 2024XKJS-27).

Author information

Authors and Affiliations

Contributions

N.Q. designed the research content and revised the original manuscript. Y.L. has carried out all the research and wrote the original manuscript text. L.S. contributed to the results analysis. R.X carried out the analysis of the data obtained. X.L drew all figures. G. Z made all the tables. J.P assisted in the research. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Qin, N., Li, Y., Song, L. et al. Differences in hempseed protein separated from AOT reverse micelles and alkaline extraction–isoelectric precipitation. Sci Rep 15, 34760 (2025). https://doi.org/10.1038/s41598-025-18526-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-18526-5