Abstract

Wettability is crucial to enhanced oil recovery (EOR) techniques and reservoir efficiency because it improves the EOR process’s performance. The objective of this research is to investigate the impact of synthesized Fe3O4/gelatin nanocomposite (Fe/G NC) and compare it with nanoparticles (NPs), salt ions, and gelatin biopolymer on the wettability change of sandstone (quartz) rock. Furthermore, the impact of sodium dodecyl sulfate (SDS) surfactant, the advantages of mixing iron oxide (Fe3O4) NPs with the SDS, and aging time were investigated. First, the pure quartz contact angle was 50°. Then the contact angle measured for the quartz after aging (22 days) with crude oil was 107°. The adsorption of polar and heavy elements in oil leads to an increase in the contact angle. The contact angle of the quartz after 11 days of aging in silica (SiO2), Fe3O4 nanofluids, and SDS surfactant decreased from 107° to 51.38°, 46.21°, and 41.67°, respectively. SDS, via a hydrophobic reaction with the oil phase, leads to the quartz becoming water-wet. The wettability reformation mechanism by NPs is disjoining pressure. Afterward, the contact angle of aged quartz in gelatin and Fe/G NC decreased from 107° to 33.9° and 25.13°, respectively. Since gelatin contains both hydrophilic and hydrophobic amino acids, it can function as a biosurfactant. The creation of new interactions with polymer chains by NPs in synthesized nanocomposite led to a substantial reduction of the contact angle. Increasing the aging time causes more decreases in the contact angle. Also, the synergistic effect of combining Fe3O4 NPs with SDS led to a considerable reduction in the contact angle. Thus, Fe3O4/SDS solution treatment reduced the quartz contact angle to 32.64°, indicating water-wet conditions.

Similar content being viewed by others

Introduction

Due to the world’s population growth and the rapid depletion of hydrocarbon reservoirs, there is a significant increase in both global energy demand and consumption1,2,3. The recovery of hydrocarbons from tight oil reservoirs and low-porosity, low-permeability shale has lately emerged as a promising solution for the rising energy demand4,5. The oil recovery techniques are categorized into three phases: primary, secondary, and tertiary6. The primary and secondary steps of oil extraction are known as conventional techniques in the petroleum industry7. Significant amounts of crude oil are still unrecovered after the primary and secondary steps of oil recovery. Because of this, enhanced oil recovery (EOR), a tertiary recovery technique, has been employed to increase oil reservoir recovery7,8.

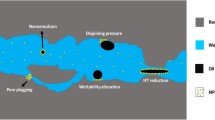

Capillary forces that cause “oil entrapment” and “oil bypass” during secondary recovery are the main reasons that reservoirs have residual oil saturation. Changing the wettability of rock formations is one technique to increase or improve oil recovery from such formations9. Figure 1 illustrates the obstacles and problems during the oil recovery methods. Therefore, the main focus of the present research, according to Fig. 1, is the topic of wettability.

EOR methods can be broadly categorized as follows: thermal EOR (in situ combustion and steam injection), gas injection (miscible and immiscible), chemical EOR (alkali, surfactant, polymer, and nanofluid), and other EOR methods like foaming, microbial, and low salinity water (LSW) flooding10,11,12. Modifying wettability, decreasing interfacial tension (IFT), and increasing injection fluid viscosity are the principal factors contributing to the successful implementation of EOR techniques13. Wettability is a key indicator of the physical characteristics of the reservoir, which has a considerable impact on oil recovery during the EOR methods14,15. Changes in wettability allow water to permeate the porous media more readily, which leads to the extraction of oil16. Research on the potential for wettability change to increase production in sandstones and carbonate reservoirs has been conducted extensively, and the results have been published17,18,19,20,21. The number of articles published in the context of wettability modification between 2000 and May 26, 2024 is depicted in Fig. 2, which illustrates the increasing trend and demand for sandstone and carbonate reservoirs’ wettability reformation.

Wettability change of sandstone and carbonate reservoirs22, and from the scholar.google.com.

Due to the significant number of papers, the contribution of various countries to this subject’s growth may not be fully reflected. Thus, we carried out a co-authorship analysis that better demonstrates the role played by different countries in the field of wettability. Countries such as Iran, the United States, China, the United Kingdom, Australia, Canada, Iraq, and South Africa have played a significant role (Fig. 3). Figure 3 also shows that countries like Egypt, Nigeria, Indonesia, Pakistan, and Kazakhstan (in the bottom-left corner of Fig. 3, which is indicated with a yellow color) have made little progress in wettability studies, and more efforts are needed to reduce this gap. The clusters in Fig. 3 indicate more studies between countries. The size of the nodes indicated the number of published articles. The density of links and various colors indicate the connection between countries.

The phrase “propensity of one fluid to spread on or stick to a solid surface in the presence of another immiscible fluid” defines wettability23, and has scientific significance in numerous domains, including fluid flow, corrosion control, dentistry, and the extraction of hydrocarbon from oil reservoirs22. The location, flow, and distribution of fluids in a reservoir are mainly controlled by wettability. Therefore, knowledge of the correct in-situ wettability conditions of a reservoir is crucial for both log and core analysis24. Overall, the oil recovery factor is influenced by capillary pressure and relative permeability curves, both of which are impacted by wettability13. The absorption of water into an oil-wet matrix and the wettability of the rock matrix are the two factors that determine the capillary pressure25. The intricate phenomena of wettability and flow via porous media create difficulties for reservoir operations. Because of formation heterogeneity, they can be classified as water-wet, oil-wet, or intermediate-wet26. Due to the oil-polar ingredients accumulating on the rock surface and precipitating onto it, rock wettability can alter from water-wet to intermediate or oil-wet27. Although many reservoirs have succeeded with traditional EOR techniques, they might no longer be efficient in intricate reservoir conditions28.

More recently, focus has been given to the development of nanotechnology and its applications to increase the effectiveness of different processes in the domains of metallurgy, medicine, catalysis, and the oil industry29,30. Nanofluids have been used extensively in EOR methods since the 1980s. The composition, concentration, size, and form of the NPs all play important roles in enhancing recovery rates28. Nanoparticles typically have sizes less than 100 nm, smaller than pore throat sizes in an oil reservoir. Consequently, they can easily move via the porous medium without significantly reducing relative permeability13. Studies on nanotechnology have appeared as a potential substitute for tertiary oil recovery processes31,32. Nanoparticles have been indicated to increase residual oil recovery through wettability modification. Nanoparticles could interact with a fluid in the pore space and create suitable conditions for wettability modification, IFT, and oil viscosity reduction29,33. The wettability reformation might not be the only fundamental mechanism, as various mechanisms for EOR have been proposed9. Since nanoparticles have high surface energy, their adsorption on the surface of rocks leads to surface energy alteration, which improves wettability modification16. Nanoparticles can be added to wetting agents such as salt ions, polymers, and surfactants to improve their efficiency in altering wettability34,35,36,37. The unique features of Fe3O4 NPs, such as their super-paramagnetic nature, facile preparation, low toxicity, and environmental friendliness, have attracted much attention38.

Literature review

In the field of wettability alteration in oil reservoirs for enhanced oil recovery, academic researchers have conducted extensive investigations over many years, the most significant of which are briefly listed below.

Jafari et al.39 published a study on using natural surfactants (cedar) instead of synthetic surfactants in EOR techniques. This research showed that cedar effectively modifies the wettability of sandstone and carbonate rocks, similar to synthetic surfactants.

Zhang et al.40 examined the factors and influencing mechanisms of EOR using surfactants. They observed that calcite’s wettability could change from intermediate wet to water-wet when an alkaline surfactant is used.

Hendraningrat and Torsæter41 employed hydrophilic silica as an EOR agent to improve oil displacement in the porous media, resulting in a 4.9% enhancement in oil recovery through the wettability modification of quartz rocks.

Shahrabadi et al.42 declared that increased oil recovery and improved rock surface wettability can be obtained by utilizing a nanofluid made from hydrophobic silica dispersed in brine.

Jadhunandan and Morrow’s43 studies on brine, crude oil, and rock indicated that the highest oil recovery through water flooding happens near neutral wettability.

Morrow44 examined the impact of reservoir wettability on water flooding recovery. Consequently, he showed that the maximum oil recoveries were for the neutral-wet systems.

Ziaraty et al.45 investigated NPs’ impact on wettability modification and asphaltene absorption. They created SiO2, Fe3O4 nanoparticles, and Fe3O4/SiO2 nanocomposite with different ratios. The study found that optimal nanofluid concentration and temperature led to decreased contact angles and water-wet conditions, indicating nanoparticles’ effectiveness in reservoir conditions.

Recently, in our previous study46, we investigated the wettability of carbonate reservoir rocks (calcite and dolomite) using Fe3O4/gelatin nanocomposite at different aging times (7 and 11 days). In this regard, the wettability of oil-wet dolomite and calcite samples aged in the nanocomposite solution for 11 days was significantly reduced from 107.7° and 104° to 26° and 24.1°, respectively.

Reservoirs are oil-wet structures that are extremely at holding the oil in the rock porous medium26. Therefore, a significant question emerges: how could we increase crude oil recovery by altering the wetting condition of these formations to a water-wet state? According to the type of rock, reservoirs are often classified into sandstone and carbonate reservoirs16.

In the current research, the wettability of sandstone (quartz) rock is examined. To investigate the chemical components and chemistry of the surface of the sandstone rock both with and without aging in oil, various assessments are performed using Fourier transform infrared spectroscopy (FT-IR), energy dispersive X-ray (EDX), and X-ray fluorescence (XRF). The characterization of nanocomposite (NC) is performed by using field emission scanning electron microscopy (FE-SEM) and transmission electron microscopy (TEM). Also, the impact of aging time on the wettability alteration is studied. In this study, we used gelatin as a modifying substance for surface modification of Fe3O4 nanoparticles. Gelatin is a suitable choice for surface reformation of nanoparticles to use in nano-flooding due to its special properties, such as biodegradability, biocompatibility, nontoxicity, low cost, easy availability, presence of functional groups (like amino groups (NH2) and carboxyl groups (COOH)), and surface activity47,48. Despite extensive studies on wettability alteration using synthetic surfactants, nanoparticles, and biopolymers, limited research has addressed the combined effect of magnetic nanoparticles and biocompatible polymers-particularly Fe3O4/gelatin nanocomposites-on sandstone reservoirs. Most prior works have focused on carbonate rocks or used either inorganic nanoparticles or surfactants independently. The unique contribution of this study lies in the synthesis and application of a biopolymer-modified magnetic nanocomposite (Fe3O4/gelatin), which is evaluated for the first time for wettability alteration of quartz rock surfaces. The current tests were conducted at ambient conditions; in our upcoming investigations, we will examine the impact of temperature and pressure. The research provides new mechanistic insights into how core-shell nanocomposites (e.g., Fe3O4/gelatin) interact with quartz surfaces to induce water-wet conditions, filling a critical gap in nanoparticle-assisted EOR for sandstone reservoirs.

Experimental section

Figure 4 illustrates the test steps used to examine the effects of Fe3O4 and SiO2 nanofluids, Fe/G NC, SDS surfactant, Fe3O4-SDS, NaCl, and CaCl2 solutions, seawater (i.e., Persian Gulf water (PGW)), and gelatin on wettability change. As shown in Fig. 4, cutting and cleaning quartz rock and aging of quartz rock with crude oil at various times are demonstrated. The aging of quartz samples with crude oil was performed by immersing the samples in crude oil at ambient temperature and pressure for 5, 11, and 22 days. The process was conducted in a sealed chamber to minimize evaporation and ensure consistent environmental conditions throughout the aging period. In this research, all test was conducted at ambient temperature and pressure. It should be noted that we used the same materials employed in our previous study46. Therefore, in this study, following our previous research46, the synthesized nanocomposite effect and the applications of these materials are studied to investigate the wettability of quartz rock.

Materials

Sodium dodecyl sulfate (SDS) was the anionic surfactant employed in this study. The selection of this surfactant was based on oilfield applications. SDS (density of 1.1 (g/cm3), pH of 7–9 (10 g/l), and purity of ≥ 86 (%)) was bought from the Merck Company. The concentration at which micelle formation is observable is called the critical micelle concentration (CMC)49. Electrical conductivity and surface tension are commonly used methods to determine CMC50. In this research, the amount of CMC was determined by the electrical conductivity procedure to be approximately 2450 ppm. Utilizing a magnetic stirrer, surfactant solutions were prepared in distilled water at a concentration of 2000 ppm. The properties of the utilized seawater (i.e., Persian Gulf water (PGW)) are indicated in Table 1.

The properties of the crude oil used in this study are shown in Table 2.

Rock sample

The sandstone (quartz) rock was selected as the rock substrate to examine the alteration of the wetting properties. To identify the composition of the rock, an X-ray fluorescence (XRF) test of the quartz sample was carried out. Table 3 depicts the XRF outcomes for the rock specimen. The rock’s measured wettability can be considerably influenced by its surface roughness52. Therefore, to measure contact angles, quartz rock was initially cut through a cutting machine into small slabs (4 × 4 × 0.5 cm) and then polished to create a smooth and flat surface. An increase in surface roughness leads to a decrease in the contact angle because water is retained in the grooves of the rough surface, thus resulting in increased hydrophilicity52. Using toluene (Merck, with a purity of 99 wt%) and the Soxhlet extraction procedure, all specimens were cleaned for 5 h. Subsequently, the specimens were maintained at 40 °C for 1 h in the oven. After that, the rock specimens were cleaned with distilled water for 6 h and kept in an oven at 40 °C for 8 h. Due to the organic pollution on the surface, this method was utilized to prevent significant errors in the measurements of wettability and face cleaning49. After that, the slices were treated in crude oil for different aging times (5, 11, and 22 days). The specimens aged with crude oil were dried at ambient temperature and immersed in the prepared solutions for 7 and 11 days. After the final specimens were dried for approximately 72 h at ambient temperature, contact angle measurements were conducted on the dried slabs.

Preparation of surfactant solution

To improve mixing, magnetic stirrers were used for preparing surfactant solutions. Finally, the slices were immersed in the surfactant solution at various aging times (7 and 11 days). It should be noted that distilled water was used as the base fluid in all tests.

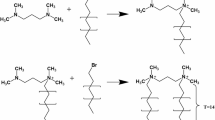

Synthesis of Fe3O4/gelatin nanocomposite and NPs characteristics

Fe/G NC was synthesized by an easy, affordable method and with the single-step chemical co-precipitation53 technique. We purchased ferrous chloride tetrahydrate (FeCl2.4H2O) and ferric chloride anhydrous (FeCl3) from Sigma-Aldrich. To change the pH amount, ammonium hydroxide (NH4OH at 25 w.t% in water) was used. To create a gelatin solution, 0.5 g of gelatin was added to 100 ml of distilled water and stirred continuously for 5 h at 50 °C. Afterward, the gelatin solution was cooled at ambient temperature. The next step included adding FeCl2.4H2O (Fe2+; 1.5 g) and FeCl3 (Fe3+; 3.0 g) to the gelatin solution. Afterward, it was stirred for 1 h at ambient temperature. Ultimately, NH4OH was added progressively while the solution was continuously stirred until the solution pH attained 10, after which the suspension became black. After being continuously stirred at ambient temperature for 4 h, the suspension was centrifuged for 10 min at 3000 rpm. Using distilled water and ethanol, the deposited particles were washed three times to remove the remaining chemical reagents. Finally, they were dried for 12 h in an oven at 70 °C. Figure 5 illustrates the synthesis and formation process of Fe/G NC.

Table 4 displays the characteristics of the NPs.

Nanofluid preparation

In this part, to make nanofluids, the amounts of Fe3O4, SiO2 NPs, and synthesized Fe/G NC (0.3 wt%) were progressively added to distilled water. Finally, it was mixed with a magnetic stirrer at 2000 rpm for 40 min and then put inside an ultrasonic apparatus. The ultrasonic device leads to increased nanofluid stability by decreasing the aggregation of NPs46. The solution was sonicated for 40 min at 20–25 °C using an ultrasonic device with high power (20 kHz, 200 watts). Remarkably, no stabilizer was used to stabilize the nanofluid. In this study, the optimized concentration for nanoparticles is 3000 ppm. In this research, we observed that after the concentration of 3000 ppm, the wettability does not change significantly with the increase of NPs concentration.

Gelatin biopolymer

This research investigates the wettability reformation of oil-wet quartz samples using gelatin (Sigma Aldrich) as a biosurfactant. Because SDS and gelatin act as surfactants, for better comparison between these two substances in wettability alteration, the optimized concentration for gelatin is 2000 ppm same as the optimized concentration of SDS (2000 ppm). In order to make a 2000 ppm gelatin solution, 0.5 g of gelatin was added to 250 ml of distilled water and stirred for 1 h using a magnetic stirrer. Then, oil-wet rock samples were aged for 7 and 11 days in gelatin solutions.

Salts

To perform an exhaustive investigation, two varieties of salts were examined. Using NaCl (≥ 99.5%) and CaCl2 (≥ 99.5%), which were purchased from the Merck Corporation, the effects of salinity on the wettability behavior were examined. The brine solution was created using distilled water as the base fluid, adding different amounts of salt. After that, the solutions were mixed for 30 min using a magnetic stirrer.

FT-IR

The Bruker TENSOR 27 Spectroscopy device was utilized to measure the FT-IR spectrum of the solid specimens in the 400–4000 cm− 1 range. Averaging 32 scans with a resolution of 4 cm− 1 was used to obtain all spectra. To conduct the FTIR test, dry quartz powder and oil sample were mixed with potassium bromide at a 100:1 ratio. After compressing the mixture into a pellet, the specimen’s moisture content was eliminated by placing the pellet in a desiccator54. The FT-IR analysis was carried out on the dried and treated specimens. This test is one of the qualitative techniques for determining functional groups54,55,56.

Contact angle

Measurements of the contact angle between oil and nanofluids on the surface of sandstone rock were performed using the sessile drop procedure. The oil-wet substrates for different soaking times (7 and 11 days) were aged in the nanofluids. Using the Krüss G2 contact angle measurement apparatus, the contact angle was determined. was utilized for measuring the contact angle with a syringe that had a distilled water-filled needle. A droplet of distilled water was cautiously placed on the rock surface that was placed horizontally on the device chamber. When the droplet water was completely constant on the surface, a high-resolution camera was employed to take an image. Ultimately, the contact angle was measured using the “Image j” software (version 1.54d; https://imagej.net/ij/). The contact angle of both sides of the droplet was measured, and the difference was less than 0.2°. The contact angle measurements were repeated twice; the second set of measurements showed a maximum alter of less than ± 2.5° between tests.

Results and discussion

Measuring the contact angle is a crucial factor in determining wettability because it improves the EOR process’s performance. The reservoir rocks are typically naturally water-wet, but after being exposed to crude oil for a longer period, the heavy hydrocarbons on the rock surface cause the rocks to become oil-wet. Therefore, in this study, we intend to change the oil-wet quartz surface wettability to water-wet conditions to improve oil recovery. Based on the three-phase contact angle (θ), wettability could be divided into three groups: water-wet (0° ≤ θ < 75°); intermediate-wet (75° ≤ θ ≤ 105°); and oil-wet (105° < θ ≤ 180°)57. Initially, the contact angle of the pure quartz surface was measured. In this step, drops of distilled water (three drops) were gently placed on the quartz surface, and then the contact angle between the rock surface and the distilled water droplets was determined. After that, the average of the data was considered. Image J software was used to analyze the images of the drops. The quartz surface’s initial contact angle was 50°, which shows that the rock specimen is water-wet.

Characterization of the synthesized fe/g NC

Utilizing TEM (Fig. 6) and FE-SEM (Fig. 7), the nanocomposite (NC) morphology and particle size distribution were determined. Also, the nature of the interaction between gelatin and Fe3O4 NPs was determined using FT-IR spectroscopy (Fig. 8).

TEM analysis

Two characteristics must be demonstrated when a core/shell nanocomposite is claimed to be created: (1) the particles are nanosized, and (2) the formation of a core/shell nanocomposite. The TEM analysis can be used to demonstrate these two characteristics. Figure 6 illustrates the synthesized NC’s TEM picture. According to the TEM analysis, gelatin was well coated on the exterior surface of Fe3O4 NPs with an almost spherical shape46. The spherical shape of nanoparticles leads to their high mobility and increased performance in oil reservoirs58. Additionally, it facilitates their facile transmission via porous media59,60. The average size of the synthesized NC was 30–80 nm. This size of nanoparticles is appropriate for injection into porous media. Gelatin causes the Fe3O4 nanoparticles’ aggregation to decrease because it surrounds the nanoparticles’ nucleus and prevents excessive nuclei expansion61. Smaller nanoparticles are more favorable because they will have excellent suspension stability in the dispersed solutions13. Finally, the TEM analysis of the Fe3O4/gelatin nanocomposite particles confirmed the formation of a core-shell structure, and the particles are nanosized.

FE-SEM analysis

Figure 7 illustrates high-quality and magnified FE-SEM images of the NC. Based on the FE-SEM analysis, the morphology of the synthesized NC is almost spherical. It should be noted that the FE-SEM analysis was taken from the quartz surface after the adsorption of the NC on the quartz surface. FE-SEM images demonstrate Fe3O4 NPs well coated with gelatin, as confirmed below using FT-IR analysis (Fig. 8).

FT-IR analysis

The functional group composition of the target product could be identified using FT-IR analysis. Figure 8 illustrates the FT-IR test of gelatin, Fe3O4 NPs, and Fe/G NC. In the band of pure gelatin, the absorption at peak 3425.4 cm− 1 is associated with the stretching vibrations of the N-H bond62. The amide I and II bonds are allocated by the peaks located at 1644.3 and 1552.6 cm− 1, respectively62. The spectra of the Fe3O4 NPs are illustrated by the peaks at 574.3 and 445.5 cm− 1, which are related to the Fe-O bond63. The spectrum of Fe/G NC displays the distinctive peaks of gelatin and Fe3O4 NPs, confirming that gelatin was successfully coated onto the Fe3O4 NPs’ surface. In addition, the N-H bond in the Fe/G NC spectrum changes to a lower wave number, and its band broadness becomes larger, indicating that Fe3O4 NPs and gelatin interact well through electrostatic attraction64.

Detection of rock type

To ascertain the nature of the rock, an EDX test was taken on pure quartz (Fig. 9). The EDX results suggest the presence of oxygen, silica, and carbon as the most dominant constituents in the quartz sample. Pure quartz comprised 53.77 wt%, 44.07 wt%, and 2.17 wt% of oxygen, silica, and carbon, respectively. The ingredients Si and O are characteristic of quartz25.

Wettability alteration

Oil and aging time’s effects on wettability

To evaluate the impact and aging time of oil, cut quartz specimens were treated in crude oil at various aging times (5, 11, and 22 days). The contact angle of the samples measured for 5, 11, and 22 days was 66°, 85°, and 107°, respectively. Images of distilled water droplets on quartz samples aged with oil for 5, 11, and 22 days are shown in Fig. 10.

Subsequently, the impact of aging time on the wettability of quartz samples was examined. The quartz contact angle increases as the aging time increases (Fig. 11). Therefore, aging time considerably affects wettability65. Sandstone reservoirs are typically negatively charged in neutral conditions14. Crude oil comprises polar compounds like asphaltenes and resin, which can be absorbed through surface deposition and polar interactions on negatively charged sandstone surfaces14. Additionally, crude oil amides could cause wettability changes51. In other words, the oil’s acidic ingredients can be adsorbed onto the rock’s surface and alter its wettability66. Various studies have shown that carboxylic acids adsorb onto rock surfaces irreversibly67,68. Therefore, the contact angle of the quartz sample increased significantly from 50° to 107° after being aged in crude oil for 22 days. The increase in the contact angle may be due to the increased adsorption of polar molecules and acidic substances in crude oil. Remarkably, the treated rock specimens with crude oil for 22 days were employed for analysis and subsequent experiments.

FE-SEM determination

By observing alterations in the morphology of the rock surfaces, it is possible to investigate the mechanism of the wettability change of the quartz surface treated with oil. The microscopic morphology of rock surfaces treated with crude oil was determined in this study using FE-SEM analysis. Figure 12 shows the FE-SEM images of pure quartz and quartz surfaces treated with crude oil. According to Fig. 12(a), the quartz rock surface is not entirely smooth before aging with oil. As can be seen from Fig. 12(b), in comparison to the pure quartz surface, the morphology of the aged quartz surface with oil has altered considerably due to asphaltenes of the oil phase being precipitated on the surface through polar interactions and ion binding69. FE-SEM analysis nicely reveals the mechanism of the wettability change from a water-wet quartz surface to an oil-wet quartz surface using crude oil.

EDX analysis

The specimens examined in elementary form are analyzed using the EDX analytical procedure70. The EDX analysis was utilized to compare the precipitation of the oil elements on the quartz surfaces before and after treatment with oil. Table 5 illustrates the elemental composition of the quartz surface before and after aging with oil. Also, the EDX test of the quartz sample aged with oil is shown in Fig. 13. S and C atoms, which are oil ingredients, are visible in the quartz aged with crude oil, whereas their presence was approximately zero before aging. Therefore, the rise in C atoms and the appearance of the S atom are the outcomes of oil adsorption on the quartz specimen surface, which leads to the wettability alteration.

FT-IR test

Functional groups of pure quartz and quartz aged with oil could be identified in Fig. 14. The absorption band at 468.07 cm− 1 is related to the asymmetric bending vibration of the Si-O bond26. The Si-O bond’s symmetric and asymmetric vibrations are represented by the peaks located at 785.47 cm− 1 and 1082.5 cm− 1, respectively71. Therefore, the rock used contains pure silica as the main element of quartz rock. The spectra of the oil-treated quartz illustrate a peak at 1880.5 cm− 1, which is related to the stretching vibration of the C = O bond26,72. Peaks at 2858.37 cm− 1 and 2926.3 cm− 1 are assigned to the alkyl C-H bond72. The peaks of pure quartz can be found in the spectrum of quartz aged in crude oil. Therefore, the FT-IR spectra confirm that the crude oil was successfully adsorbing onto the quartz surface.

Wettability alteration by seawater

After aging oil-wet quartz specimens in seawater (for 7 and 11 days), we placed them in an oven, and when they cooled, their contact angle was examined. The contact angle values for seawater at various aging times are demonstrated in Fig. 15. After aging for 7 days in seawater, the contact angle of the oil-wet quartz surface reduced from 107° to 99.6°. With rising aging times (for 11 days), it reduced from 107° to 88°. Ca2+ and Mg2+ ions in seawater could reduce the contact angle due to the formation of a complex structure with fatty acids, which leads to the separation of fatty acids from the rock’s surface73. Additionally, the separation of the oil phase from the rock surface may be caused by a reaction between Ca2+ and adsorbed carboxylic groups. Mg2+ concentration in seawater is approximately four times higher than Ca2+ concentration; therefore, Mg2+ could, using a replacement reaction as a determining ion, displace Ca2+ from the quartz surface74. Therefore, Mg2+ could be active in the wettability reformation process in seawater74. The contact angle will increase with increasing Na+ concentration in seawater. The increase in Na+ concentration causes a reduction in the activity of divalent ions and hinders their availability to the double layer, so the contact angle is increased. Na+ is an inactive ion; thus, its presence in the double layer does not have sufficient power to change the contact angle75. Additionally, since seawater has a high salinity, fewer carboxylic substances’ can dissolve in the aqueous phase, and the salting-out effect takes place65.

Effect of type of salt on the wettability

Two kinds of salts, sodium chloride (NaCl) and calcium chloride (CaCl2), were employed in a wide range of brine concentrations to test the wettability. Brine concentrations were changed to be between 1000 and 200,000 ppm. Quartz samples were aged in brine solutions for 11 days. As displayed in Fig. 16(a) and (b), the wettability of crude oil and brine decreases quickly as the concentration of salt increases and then gradually increases when more salt is added, but less rapidly. The optimal salinity of the NaCl and CaCl2 solutions was around 10,000 and 25,000 ppm, respectively.

Acidic substances exiting from the rock surface and dissolving in the aqueous phase are the mechanisms responsible for wettability reformation. Increases in the electrical double layer can be another mechanism responsible for the change in wettability during low salinity water. The electrical double layers increase as the Debye layer length rises, reducing the contact angle because of increased electrostatic repulsion at the interfaces. The ionic strength decreases with decreasing salinity. Hence, variations in ionic strength cause a considerable alteration in the surface charge of sandstone. Thus, LSW can shift the quartz surface to a water-wet condition76,77. In this work, at salt concentrations higher than 10,000 (NaCl) and 25,000 (CaCl2) ppm, the contact angle increased. Most likely, the exchange of ions between the positive and negative charges increases the contact angle78. At high concentrations of salt, the impact of the salt prevails over the cation valence. Therefore, according to Fig. 16, hydrocarbons’ propensity to dissolve in the aqueous phase reduces as brine salinity increases. In other words, the high salinity of brine minimizes the electrostatic forces, so oil can stick to the rock surface79. As the salinity increases, the salting-out effect causes more organic materials to remain in the oil phase76. In comparison to NaCl, CaCl2 exhibited superior interaction with the crude oil, leading to a higher decrease in wettability. Divalent cations demonstrate a stronger rate of repulsion and hydration at the interface than monovalent ions80. Consequently, divalent ions have a considerable impact on wettability reformation due to their high electrical charge density81. Conversely, the repulsive forces between anions and acidic substances partially hinder their solubility in water82. Understanding how oil sticks to the surface of rocks depends on the difference in surface potential between the two materials. For example, increased CaCl2 concentration causes a greater amount of calcium absorption on rock surfaces and oil, which causes both surfaces to have a greater positive electrostatic potential. Hence, reduced contact angles and more rock and oil repelling are caused by small variations in surface potential amounts83. As the concentration of NaCl rises, sodium is only absorbed on the rock surface, which leads to the surface-potential difference between rock and oil decreasing. Figure 16 depicts that the oil-wet quartz surface contact angle reduction is impossible using the high salinity of the NaCl and CaCl2 solutions.

Impact of NPs and surfactant on wettability

Fe3O4 and SiO2 NPs

In this part, Fe3O4 and SiO2-based nanofluids are employed to determine the contact angle of the oil-wet quartz specimen. In this regard, the quartz samples immersed in nanofluids were dried at ambient temperature, and their contact angle was determined. After 7 days of immersing quartz samples in SiO2 and Fe3O4 nanofluids, their contact angles decreased from 107° to 62.16° and from 107° to 52.13°, respectively (Fig. 17).

With increasing aging time (for 11 days) of quartz specimens in SiO2 and Fe3O4 nanofluids, the contact angle of quartz reduced from 107° to 51.38° and from 107° to 46.21°, respectively. The reason for this contact angle reduction is wedge film creation, a thin layer of nanoparticles that gradually apply disjoining pressure to the oil phase (see Fig. 18(a))26. The propensity of nanoparticles to arrange in a wedge-like shape is defined as a wettability modification mechanism during nanoparticle flooding84. In this procedure, a water layer with nanoparticles would provide force to reduce the system’s free energy, or disjoining pressure, and ultimately remove the oil that was adhered to the rock surface85.

Depending on the nanoparticles’ surface groups, they could encounter a wide range of chemical interactions86,87,88. For instance, SiO2 and Fe3O4 nanoparticles are hydrophilic and protected by hydroxyl groups89,90. Electrostatic repulsion and Brownian motion among nanoparticles are the primary driving forces of the disjoining pressure57. With the adsorption of NPs on the rock surface, the disjoining pressure mechanism leads to the wettability change of the rock surface from an oil-wet to a water-wet state. The primary mechanism of wettability reformation by nanofluids could be attributed to the NPs’ physisorption on the rock surface. In other words, layers of NPs are absorbed by the rock (or oil), which causes wettability modification of the rock surface91,92. Nanoparticles absorb acidic substances due to their small size and extremely high surface area, based on their surface energy93,94. Hence, nanoparticles could decrease the precipitated asphaltene molecules and change the wettability of the solid surface95,96. Destabilizing the oil layer(s) on oil-wet surfaces with nanoparticles could assist in the desorption of the oleic phase46. Therefore, oil layers exit the rock surface, and the wettability of the rock surface changes to a water-wet condition97. Besides, Nanoparticles could influence the roughness of the rock surface, which causes the rock’s surface to become more water-wet34,98,99.

Disjoining pressure arises from interactions between the solid surface, liquid, and nanoparticles, and it can significantly influence the stability and thickness of thin liquid films at the solid-liquid interface, thereby affecting wettability26,84,85. In our study, the effect of disjoining pressure was primarily considered from a theoretical standpoint. We accounted for its role in modifying the effective interaction forces at the solid-liquid interface, especially in the presence of nanoparticles that can adsorb onto surfaces or create structured layers at the solid-liquid interface. While we did not directly measure disjoining pressure experimentally, our wettability tests (e.g., contact angle measurements) indirectly reflect its influence, particularly when comparing treated vs. untreated surfaces.

SDS and Fe3O4/SDS

Using NPs to increase oil recovery has been considered, particularly when mixed with surfactants100,101. The loss of surfactants through adsorption into rocks could be considerably decreased by adding NPs to a surfactant solution46. Therefore, in the next section of the experiment, the quartz contact angle was measured for concentrations of SDS and Fe3O4/SDS (2000 and 3000/2000 ppm). It is clear that before treatment, all rock surfaces were oil-wet (θ = 107°). Oil-wet quartz samples were aged for 7 and 11 days in surfactant and Fe3O4/SDS solutions. As seen in Fig. 17, the quartz contact angle in the SDS solution was reduced from 107° to 46.53° and in the Fe3O4/SDS solution from 107° to 38° after 7 days of treatment. With an increasing aging time (for 11 days), the rock sample contact angle in SDS and Fe3O4/SDS solutions decreased from 107° to 41.67° and 32.64°, respectively. Nanoparticles of Fe3O4 improve the wettability reformation mechanism due to synergistic effects with SDS102. This synergy arises from the complementary surface-active properties of both components, leading to improved interfacial interactions with the rock surface and the crude oil103. Fe3O4 nanoparticles possess a high surface area and surface energy, enabling them to adsorb effectively at the oil-water and rock-fluid interfaces46. However, their tendency to aggregate can limit their efficiency in porous media. SDS, an anionic surfactant, reduces interfacial tension (IFT) and provides electrostatic stabilization to the nanoparticles, preventing aggregation by imparting a negative surface charge, thereby improving nanoparticle dispersion and mobility46. Additionally, the dual presence of Fe3O4 and SDS enhances disjoining pressure at the oil-rock interface and facilitates structural disjoining pressure film formation, which further promotes oil detachment from the rock surface84. The result is a more pronounced and stable wettability alteration than that achieved by either agent alone.

The optimum concentration of surfactant is important for wettability reformation. The surfactant molecules appear as monomers at concentrations below the CMC. Hence, the monomers can contact absorbed organic substances on rock surfaces to change their wettability and become more water-wet104. (It should be noted that the concentration used for the SDS in this study is 2000 ppm, i.e., < CMC.). Through the hydrophobic interactions between the absorbed acidic compounds and the surfactant tail, SDS adsorbs on the surface, causing the surface to become water-wet56. There is electrostatic repulsion between negatively charged SDS molecules and the quartz specimen; thus, just the hydrophobic effects and van der Waals forces can lead SDS to absorb onto the surface. Surfactants create ion pairs with the polar ingredients of oil, and then the ion pairs are separated from the rock surface, which causes a decreased contact angle27. Therefore, the two principal mechanisms that alter the wettability of rocks toward a more water-wet condition are ion-pair creation and the adsorption of surfactant molecules via interactions with the adsorbed crude oil elements on the rock surface20,22,27. Ion pair creation may remove the adsorbed layer of crude oil ingredients from the rock surface, causing the rock surface to become water-wet46. The ion pairs created during the process would no longer be water soluble and therefore would move easily across the oil/water interface into the oil phase, leaving the free surfactant molecules in the water phase to associate with the adsorbed crude oil elements near the oil/water interface22. Consequently, the surfactants can gradually alter the rock surface’s wettability to a more water-wet condition20.

Surfactants, through the formation of a surfactant monolayer on the oil-wet rock surfaces, cause a reduction in the contact angle20. The synergistic effects of Fe3O4 nanoparticles with positive charge and SDS cause a substantial reduction in the contact angle57. Single-layer absorption of SDS molecules onto Fe3O4 nanoparticles causes the hydrophobic tail of surfactants to be placed in the solution. Consequently, nanoparticles become hydrophobic and are absorbed at the interface of oil and water, causing a decrease in wettability (see Fig. 18(b)).

EDX analysis

Figure 19 displays the EDX analysis for quartz specimens after treatment with SiO2 and Fe3O4 nanofluids. According to EDX analysis, the silica amount of the quartz sample before treatment with SiO2 nanofluid was 9.88 wt%. After aging the quartz specimen in a solution containing SiO2 NPs, the silica amount increased to 14.02 wt%. Also, no iron was observed in the quartz rock before aging, whereas iron amounts were 45.43 wt% after treatment with Fe3O4 nanofluids.

For better understanding, the silica and iron absorption behavior on the quartz surface is depicted in Fig. 20 before and after aging.

Effect of gelatin and fe/g NC on wettability

Gelatin is a protein that dissolves in water and is obtained from the bones and skin of animals through thermal denaturation105. Gelatin, due to having functional groups such as carboxyl and amine, is an excellent choice for surface reformation of nanoparticles for utilization in nano flooding47,105. Gelatin is a natural polymer and has excellent biocompatibility. Moreover, gelatin is cheap and readily accessible47,106. Swelling ratio has been widely used as a simple method to characterize water absorption and stability of biomaterials106. Therefore, gelatin can swell after being adsorbed to the rock surface, and the oil phase adsorbed to the rock surface is separated from the rock surface along with the swelling of the gelatin. Divalent metal ions, including Cu2+, Ca2+, and Fe2+, are present in trace amounts in gelatin107,108,109. These ions stick to the carboxylic acid groups on the chains of the gelatin molecules and create ionic bonds (Fig. 21(a)). Through electrostatic interactions, negatively charged carboxylic acid groups can absorb positively charged amine groups (Fig. 21(a)). Due to the high hydrophilicity of the gelatin, water is absorbed by the gelatin through hydrogen bonds that are created between water molecules and amino and carboxylic acid groups (Fig. 21(b))106.

One of the other possible mechanisms of wettability reformation by gelatin is the creation of capillary forces through the hydrophobic interaction between the hydrophobic amino acids of gelatin and the oil phase106,110. Figure 22 illustrates the proposed mechanism of wettability reformation by gelatin. In general, gelatin can reduce the contact angle of the oil-wet surface, which behavior is attributed to the fact that gelatin tends to enhance the hydrophilic characteristics of the rock surface by having even more hydrophilic groups that can interact with water111.

The contact angles of quartz samples were measured after various aging times (7 and 11 days) in gelatin and NC solutions. As seen in Fig. 23, the contact angle of quartz specimens in gelatin and Fe/G NC solutions decreased from 107° to 39° and 27.4° in 7 days of aging. By rising the aging time of quartz samples in gelatin and Fe/G NC solution (for 11 days), the contact angles of quartz samples reduced from 107° to 33.9° and 25.13°, respectively. Hence, the Fe/G NC contact angle was dramatically less than the bare gelatin. While the results may not fully replicate reservoir conditions, the observed wettability behavior under ambient conditions provides valuable preliminary insight into the surface-fluid interactions. Future work will aim to extend this study by conducting measurements under temperature and pressure conditions representative of the reservoir to more directly assess field applicability.

Core-shell structured NPs are desirable for different applications due to their high stability under reaction conditions112. Their uniform size, morphology, and tunable chemical compositions also make them valuable in various applications113. Active mechanisms in the wettability change of a rock surface by NC are the same as those of NPs, except that the synergistic effect of Fe/G NC has significant performance114. Therefore, the rock surface becomes coated with Fe/G NC, creating a hydrophilic layer on the surface and reducing the contact angle114. By raising the disjoining pressure on the rock surface, nanocomposites could weaken the force of adhesion between the oleic phase and the rock surface and remove the oleic phase from the rock surface115,116. The physical and chemical characteristics of a material are enhanced by their combination111. Therefore, the Fe/G NC has better performance than bare iron and gelatin. Ensuring the oil-wet nature of the formation before flooding in the laboratory is necessary to study the efficiency of the EOR process, which targets recovery via wettability reformation. However, wettability reformation is dependent on various factors, including oil characteristics, aging temperature, aging time, etc117. Therefore, the effects of the mentioned parameters on the wettability of oil reservoir rocks assist our insight into reaching the desirable result.

The synthesized Fe/G NC demonstrates significant potential for large-scale implementation in EOR applications due to its effective wettability alteration performance and environmental compatibility. The Fe/G NC reduced the contact angle of oil-aged quartz from 107° to 25.13°, indicating a strong shift toward water-wet conditions, which is favorable for improved oil displacement efficiency. The use of gelatin (a biodegradable and surface-active biopolymer) may reduce nanoparticle aggregation and enhance transport through porous media, limiting nanomaterial retention and pore-blocking risks. Fe3O4 NPs are relatively inexpensive, chemically stable, and can be synthesized in bulk via established co-precipitation. In field scenarios, fluid-rock interactions will be influenced by mineralogical heterogeneity and reservoir temperature and pressure. However, further studies on core flooding performance, long-term stability under reservoir conditions (e.g., high salinity and temperature), and cost-benefit analysis are necessary to fully validate its field-scale application. Nevertheless, the synthesized Fe/G NC also faces challenges in EOR applications. Achieving stable dispersion of Fe3O4 NPs within the gelatin matrix and in reservoir fluids is challenging. Precise control over nanoparticle size, distribution, and loading within gelatin is necessary to optimize properties but can be difficult to achieve consistently. Efficient separation or recycling of NPs post-EOR is still a challenge.

Sandstone reservoirs present specific challenges in EOR processes due to their inherent surface wettability characteristics. A major issue is the tendency of quartz surfaces to become oil-wet over time as a result of the adsorption of heavy and polar components from crude oil118. This wettability alteration severely reduces EOR efficiency, as the displacement of oil becomes more difficult in oil-wet conditions. The main factors of sandstones’ wettability change by crude oil are their API, asphaltene, and clay contents119. Brine decreases the negative electrical charge on the clay surface in high-salinity reservoirs, which reduces the repulsive force19. Then, the surface-active material in the crude oil is adsorbed onto the clay surface, which leads to it being oil-wet119. Sandstone becomes more oil-wet when the clay content increases120. The wettability of sandstone is influenced by high temperature, pH, and brine composition119. Various opinions have been reported in the literature about the impact of high temperature on the wettability of sandstone and carbonate121. At high temperatures, sandstone can become either water-wet or oil-wet, whereas carbonate becomes water-wet as the temperature rises119.

By targeting the specific problem of oil-wet conditions in sandstone reservoirs, our study offers a comprehensive approach for wettability reformation using a variety of agents, including synthesized Fe/G NC, individual NPs, gelatin, salt ions, and SDS. This not only improves EOR efficiency but also provides insights into designing tailored nanofluids for complex sandstone reservoirs.

Conclusions

In this research, Fe3O4/gelatin nanocomposite was synthesized in the laboratory and investigated for EOR applications. This study included different static (i.e., characterizations, nanocomposite synthesis, and measuring contact angles) experiments. The wettability change of quartz by NPs, SDS surfactant, salt solutions, gelatin biopolymer, and seawater, and the impact of treatment time on wettability, were examined. The following is a summary of the important results:

-

1.

In the first step, the hydrophilic quartz surface was changed to an oil-wet state after treatment with crude oil (for 22 days). Therefore, the contact angle of pure quartz increased from 50° to 107°.

-

2.

This study used a facile procedure to synthesize the Fe/G NC, which was evaluated using FE-SEM, TEM, and FT-IR tests.

-

3.

Oil-wet quartz surface after aging (for 11 days) in SiO2 and Fe3O4 nanofluids and Fe3O4/gelatin nanocomposite decreased from 107° to 51.38°, 46.21°, and 25.13°, respectively.

-

4.

With the increasing treatment time, the ability of the contact angle to alter the wettability to the water-wet condition increases.

-

5.

Seawater exhibited the least change in contact angle because of its high salinity and the salting-out effect.

-

6.

First, the contact angle reduces with rising NaCl and CaCl2 concentrations, and after reaching the optimal salinity, the contact angle increases as the concentration rises. The optimum salinity of the system for NaCl and CaCl2 solutions was around 10,000 and 25,000 ppm, respectively.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Hama, S., Muheedin, A. K., Manshad & Jagar, A. A. Experimental investigation of new derived anionic natural surfactant from peanut oil: Application for enhanced oil recovery. Journal of Molecular Liquids 395. Elsevier: 123876. (2024). https://doi.org/10.1016/j.molliq.2023.123876

Manshad, A. et al. Performance Evaluation of the Green Surfactant-Treated Nanofluid in Enhanced Oil Recovery: Dill-Hop Extracts and SiO2/Bentonite Nanocomposites. Energy & Fuels 38. ACS Publications: 1799–1812. (2024). https://doi.org/10.1021/acs.energyfuels.3c04335

Yekeen, N. et al. Impact of nanoparticles–surfactant solutions on carbon dioxide and methane wettabilities of organic-rich shale and CO2/brine interfacial tension: Implication for carbon geosequestration. Energy Reports 8. Elsevier: 15669–15685. (2022). https://doi.org/10.1016/j.egyr.2022.10.377

Abdulelah, H. et al. Synergetic Effect of Surfactant Concentration, Salinity, and Pressure on Adsorbed Methane in Shale at Low Pressure: An Experimental and Modeling Study. ACS Omega 5. ACS Publications: 20107–20121. (2020). https://doi.org/10.1021/acsomega.0c01738

Afekare, D., Garno, J. & Rao, D. Enhancing oil recovery using silica nanoparticles: Nanoscale wettability alteration effects and implications for shale oil recovery. Journal of Petroleum Science and Engineering 203. Elsevier: 108897. (2021). https://doi.org/10.1016/j.petrol.2021.108897

Mirzavandi, M. et al. Performance evaluation of Silica–Graphene quantum Dots for enhanced oil recovery from carbonate reservoirs. Energy & Fuels 37 ACS Publications. 955–964. https://doi.org/10.1021/acs.energyfuels.2c03150 (2023).

Pogaku, R., Fuat, N. H. M., Sakar, S., Cha, Z. W. & Musa, N. Dayang Nurul Afiqah Awang Tajudin, and Leonard Owen Morris. Polymer flooding and its combinations with other chemical injection methods in enhanced oil recovery. Polymer Bulletin 75. Springer: 1753–1774. (2018). https://doi.org/10.1007/s00289-017-2106-z

Motraghi, F., Manshad, A. K., Akbari, M. & Jagar, A. A. Impact of mutual solvents on wettability alteration for EOR application by hybrid smart water and green SiO2/KCl/Xanthan nanocomposites in carbonate reservoirs. Energy & Fuels 37 ACS Publications. 18560–18575. https://doi.org/10.1021/acs.energyfuels.3c02979 (2023).

Afolabi, R. O. Enhanced oil recovery for emergent energy demand: challenges and prospects for a nanotechnology paradigm shift. International Nano Letters 9. Springer: 1–15. (2019). https://doi.org/10.1007/s40089-018-0248-0

Devakumar, N. P., Seetharaman, G. R., Kumar, G. & Jitendra, S. S. Synergistic effect of low salinity surfactant nanofluid on the interfacial tension of Oil–Water systems, wettability alteration, and surfactant adsorption on the quartz surface. Energy & Fuels 37 ACS Publications. 7094–7110. https://doi.org/10.1021/acs.energyfuels.3c00393 (2023).

Ahmadi, A. et al. Insight into Nano-chemical enhanced oil recovery from carbonate reservoirs using environmentally friendly nanomaterials. ACS Omega 7 ACS Publications. 36165–36174. https://doi.org/10.1021/acsomega.2c03076 (2022).

Yekeen, N. et al. and. Synthesis and pore-scale visualization studies of enhanced oil recovery mechanisms of rice straw silica nanoparticles. Geoenergy Science and Engineering 221. Article: 111292. (2023). https://doi.org/10.1016/j.petrol.2022.111292

Divandari, H., Hemmati-Sarapardeh, A., Schaffie, M. & Ranjbar, M. Integrating synthesized citric acid-coated magnetite nanoparticles with magnetic fields for enhanced oil recovery: Experimental study and mechanistic understanding. Journal of Petroleum Science and Engineering 174. Elsevier: 425–436. (2019). https://doi.org/10.1016/j.petrol.2018.11.037

Hou, B. et al. and Wuhua Chen. Surfactant-Induced Wettability Alteration of Oil‐Wet Sandstone Surface: Mechanisms and Its Effect on Oil Recovery. Journal of Surfactants and Detergents 19. Springer: 315–324. (2016). https://doi.org/10.1007/s11743-015-1770-y

Khaksar Manshad, Abbas, A. et al. Application of a novel green nano polymer for chemical EOR purposes in sandstone reservoirs: synergetic effects of different fluid/fluid and rock/fluid interacting mechanisms. ACS Omega 8 ACS Publications. 43930–43954. https://doi.org/10.1021/acsomega.3c05921 (2023).

Shalbafan, M., Esmaeilzadeh, F. & Reza Vakili-Nezhaad, G. Enhanced oil recovery by wettability alteration using iron oxide nanoparticles covered with PVP or SDS. Colloids and Surfaces A: Physicochemical and Engineering Aspects 607. Elsevier: 125509. (2020). https://doi.org/10.1016/j.colsurfa.2020.125509

Downs, H. H. & Hoover, P. D. Enhanced Oil Recovery by Wettability Alteration. In, 577–595. ACS Publications. (1989). https://doi.org/10.1021/bk-1989-0396.ch032

Ehrlich, R. & Hasiba, H. H. and P Raimondi. Alkaline Waterflooding for Wettability Alteration-Evaluating a Potential Field Application. Journal of Petroleum Technology 26. SPE: 1335–1343. (1974). https://doi.org/10.2118/4905-PA

Vledder, P., Fonseca, J. C., Wells, T. & Gonzalez, I. and Dick Ligthelm. Low Salinity Water Flooding: Proof Of Wettability Alteration On A Field Wide Scale. In All Days, SPE-129564. SPE. (2010). https://doi.org/10.2118/129564-MS

Salehi, M., Johnson, S. J. & Jenn-Tai, L. Mechanistic Study of Wettability Alteration Using Surfactants with Applications in Naturally Fractured Reservoirs. Langmuir 24. ACS Publications: 14099–14107. (2008). https://doi.org/10.1021/la802464u

Mohammadi, N. and Behnam Mousazadeh. Carbon Capture and Utilization as an Alternative for Renewable Energy Storage. In Synergy Development in Renewables Assisted Multi-carrier Systems, 229–254. Springer. (2022). https://doi.org/10.1007/978-3-030-90720-4_9

Noruzi, Y. et al. The State-of-the-Art of wettability alteration in sandstones and Carbonates: A mechanistic review. Fuel 356. Elsevier: 129570. (2024). https://doi.org/10.1016/j.fuel.2023.129570

ABDUL RAHIM, Z. A. H. I. D. A. H. The Impact of Temperature on the Effectiveness of Surfactant To Change the Wettability (Universiti Teknologi PETRONAS, 2011).

Menezes, J. L., Yan, J. & Sharma, M. M. The Mechanism of Wettability Alteration Due to Surfactants in Oil-Based Muds. In All Days, SPE-18460. SPE. (1989). https://doi.org/10.2118/18460-MS

Mandal, A., Kar, S. & Kumar, S. The Synergistic Effect of a Mixed Surfactant (Tween 80 and SDBS) on Wettability Alteration of the Oil Wet Quartz Surface. Journal of Dispersion Science and Technology 37. Taylor & Francis: 1268–1276. (2016). https://doi.org/10.1080/01932691.2015.1089780

Kumar, N. and Ajay Mandal. Wettability alteration of sandstone rock by surfactant stabilized nanoemulsion for enhanced oil recovery—A mechanistic study. Colloids and Surfaces A: Physicochemical and Engineering Aspects 601. Elsevier: 125043. (2020). https://doi.org/10.1016/j.colsurfa.2020.125043

Qi, Z., Yuan, Y. F., Wang, H. Y. Y. & Xiao Li, X. Study on Wettability Alteration of Quartz Surface by Surfactants. Advanced Materials Research 962–965. Trans Tech Publ: 539–543. (2014). https://doi.org/10.4028/www.scientific.net/AMR.962-965.539

Hu, J., Fu, M., Zhou, Y., Wu, F. & Li, M. Experimental Study on SiO2 Nanoparticles-Assisted Alpha-Olefin Sulfonate Sodium (AOS) and Hydrolyzed Polyacrylamide (HPAM) Synergistically Enhanced Oil Recovery. Energies 16. MDPI: 7523. (2023). https://doi.org/10.3390/en16227523

Gbadamosi, A. O., Radzuan Junin, M. A., Manan, A., Agi & Adeyinka, S. Y. An overview of chemical enhanced oil recovery: recent advances and prospects. International Nano Letters 9. Springer: 171–202. (2019). https://doi.org/10.1007/s40089-019-0272-8

Manshad, A. et al. and Alireza Keshavarz. Green synthesise of CuO@Fe3O4 @Xantan nanocomposites and its application in enhanced oil recovery by considering IFT and wettability behaviours. Micro & Nano Letters 15. Wiley Online Library: 550–555. (2020). https://doi.org/10.1049/mnl.2019.0431

Mohanty, U. et al. and Stefan Iglauer. Physicochemical Characterization of Zirconia Nanoparticle-Based Sodium Alginate Polymer Suspension for Enhanced Oil Recovery. Energy & Fuels 35. ACS Publications: 19389–19398. (2021). https://doi.org/10.1021/acs.energyfuels.1c02724

Verma, A., Pal, N., Kumar, N., Al-Yaseri, A. & Ali, M. and Keka Ojha. Nanoparticles stabilized foam fluid for hydraulic fracturing application of unconventional gas reservoirs: A review of the properties, progress and future prospects. Petroleum Research 10. Elsevier: 149–165. (2025). https://doi.org/10.1016/j.ptlrs.2024.08.004

Motraghi, F. et al. Interfacial tension reduction of hybrid crude-oil/mutual-solvent systems under the influence of water salinity, temperature and green SiO2/KCl/Xanthan nanocomposites. Fuel 340. Elsevier: 127464. (2023). https://doi.org/10.1016/j.fuel.2023.127464

Karimi, A. et al. and. Wettability Alteration in Carbonates using Zirconium Oxide Nanofluids: EOR Implications. Energy & Fuels 26. ACS Publications: 1028–1036. (2012). https://doi.org/10.1021/ef201475u

Al-Anssari, S. et al. and Stefan Iglauer. Wettability Alteration of Carbonate Rocks via Nanoparticle-Anionic Surfactant Flooding at Reservoirs Conditions. In Day 1 Tue, November 07, 2017, D011S001R001. SPE. (2017). https://doi.org/10.2118/189203-MS

Nazari Moghaddam, Rasoul, A., Bahramian, Z., Fakhroueian, A. K. & Sharareh Arya. and. Comparative Study of Using Nanoparticles for Enhanced Oil Recovery: Wettability Alteration of Carbonate Rocks. Energy & Fuels 29. ACS Publications: 2111–2119. (2015). https://doi.org/10.1021/ef5024719

Ehtesabi, Hamide, M. M., Ahadian, V., Taghikhani & Hossein Ghazanfari, M. Enhanced Heavy Oil Recovery in Sandstone Cores Using TiO2 Nanofluids. Energy & Fuels 28. ACS Publications: 423–430. (2014). https://doi.org/10.1021/ef401338c

Sun, Conroy, Jerry, S. H., Lee & Zhang, M. Magnetic nanoparticles in MR imaging and drug delivery. Advanced Drug Delivery Reviews 60. Elsevier: 1252–1265. (2008). https://doi.org/10.1016/j.addr.2008.03.018

Daghlian Sofla, S., Jafari, M., Sharifi & Abdolhossein Hemmati Sarapardeh Toward mechanistic understanding of natural surfactant flooding in enhanced oil recovery processes: The role of salinity, surfactant concentration and rock type. Journal of Molecular Liquids 222. Elsevier: 632–639. (2016). https://doi.org/10.1016/j.molliq.2016.07.086

Leslie Zhang, D., Liu, S., Puerto, M., Miller, C. A. & George, J. H. Wettability alteration and spontaneous imbibition in oil-wet carbonate formations. Journal of Petroleum Science and Engineering 52. Elsevier: 213–226. (2006). https://doi.org/10.1016/j.petrol.2006.03.009

Hendraningrat, L., Ole & Torsæter Metal oxide-based nanoparticles: revealing their potential to enhance oil recovery in different wettability systems. Applied Nanoscience 5. Springer: 181–199. (2015). https://doi.org/10.1007/s13204-014-0305-6

Shahrabadi, A., Bagherzadeh, H., Roustaei, A. & Golghanddashti, H. Experimental Investigation of HLP Nanofluid Potential to Enhance Oil Recovery: A Mechanistic Approach. In All Days. SPE. (2012). https://doi.org/10.2118/156642-MS

Jadhunandan, P. P. & Norman, R. M. Effect of Wettability on Waterflood Recovery for Crude-Oil/Brine/Rock Systems. SPE Reservoir Engineering 10. OnePetro: 40–46. (1995). https://doi.org/10.2118/22597-PA

Morrow, N. R. Wettability and its effect on oil recovery. J. Petrol. Technol. 42, 1476–1484. https://doi.org/10.2118/21621-PA (1990).

Ziaraty, A., Saboori, R., Sabbaghi, S. & Rasouli, K. Investigation of the effect of Fe3O4/SiO2 nanofluid on asphaltene adsorption and wettability alteration in hydrocarbon reservoirs: Optimization of nanocomposite composition and nanofluid concentration. Chemical Engineering Research and Design 194. Elsevier: 810–828. (2023). https://doi.org/10.1016/j.cherd.2023.05.028

Ebrahimi, M., Ghalenavi, H., Schaffie, M., Ranjbar, M. & Abdolhossein Hemmati-Sarapardeh Toward mechanistic understanding of wettability alteration in carbonate rocks in the presence of nanoparticles, gelatin biopolymer, and core-shell nanocomposite of Fe3O4@gelatin. Scientific Reports 14. Nature Publishing Group UK London: 31679. (2024). https://doi.org/10.1038/s41598-024-80893-2

Yılmaz, H. & Senay Hamarat, S. Preparation of magnetic gelatin nanoparticles and investigating the possible use as chemotherapeutic agent. Artificial cells, nanomedicine, and biotechnology 41. Taylor & Francis: 69–77. (2013).

Ghalenavi, H., Hemmati-Sarapardeh, A., Schaffie, M. & Saeid Norouzi-Apourvari Application of synthesized Fe3O4@Gelatin nanoparticles on interfacial properties and enhanced oil recovery. Scientific Reports 15. Nature Publishing Group UK London: 2558. (2025). https://doi.org/10.1038/s41598-024-84953-5

Hosseini, H., Apourvari, S. N. & Schaffie, M. Wettability alteration of carbonate rocks via magnetic fields application. Journal of Petroleum Science and Engineering 172. Elsevier: 280–287. (2019). https://doi.org/10.1016/j.petrol.2018.08.022

Rosen, M. J. & Joy, T. K. Surfactants and Interfacial Phenomena (Wiley, 2012).

Mousavi, S. P. et al. and. Toward mechanistic understanding of wettability alteration in calcite and dolomite rocks: The effects of resin, asphaltene, anionic surfactant, and hydrophilic nano particles. Journal of Molecular Liquids 321. Elsevier: 114672. (2021). https://doi.org/10.1016/j.molliq.2020.114672

Ali, M., Shar, A. M., Yekeen, N., Abid, H., Kamal, M. S. & Hussein Hoteit Impact of methylene blue on enhancing the hydrocarbon potential of early cambrian Khewra sandstone formation from the Potwar basin, Pakistan. ACS Omega 8 ACS Publications. 47057–47066. https://doi.org/10.1021/acsomega.3c06923 (2023).

Sirivat, A. and Nophawan Paradee. Facile synthesis of gelatin-coated Fe3O4 nanoparticle: Effect of pH in single-step co-precipitation for cancer drug loading. Materials & Design 181. Elsevier: 107942. (2019). https://doi.org/10.1016/j.matdes.2019.107942

Stuart, B. H. Infrared Spectroscopy: Fundamentals and Applications. Analytical Techniques in the Sciences (Wiley, 2004). https://doi.org/10.1002/0470011149

Stuart, B. Infrared spectroscopy. In Kirk-Othmer Encyclopedia of Chemical Technology. Wiley. https://doi.org/10.1002/0471238961.0914061810151405.a01.pub2. (2005).

Jarrahian, K., Seiedi, O., Sheykhan, M., Vafaie Sefti, M. & Ayatollahi, S. Wettability alteration of carbonate rocks by surfactants: A mechanistic study. Colloids and Surfaces A: Physicochemical and Engineering Aspects 410. Elsevier: 1–10. (2012). https://doi.org/10.1016/j.colsurfa.2012.06.007

Kumar, G., Behera, U. S., Mani, E. & Jitendra, S. S. Engineering the wettability alteration of sandstone using Surfactant-Assisted functional silica nanofluids in Low-Salinity seawater for enhanced oil recovery. ACS Eng. Au 2 ACS Publications. 421–435. https://doi.org/10.1021/acsengineeringau.2c00007 (2022).

Li, W. et al. Microscopic pore structure in shale reservoir in the argillaceous dolomite from the Jianghan Basin. Fuel 181. Elsevier: 1041–1049. (2016). https://doi.org/10.1016/j.fuel.2016.04.140

Moradi, B., Pourafshary, P., Jalali, F., Mohammadi, M. & Emadi, M. A. Experimental study of water-based nanofluid alternating gas injection as a novel enhanced oil-recovery method in oil-wet carbonate reservoirs. Journal of Natural Gas Science and Engineering 27. Elsevier: 64–73. (2015). https://doi.org/10.1016/j.jngse.2015.07.009

Mousavi, M. A., Hassanajili, S. & Rahimpour, M. R. Synthesis of fluorinated nano-silica and its application in wettability alteration near-wellbore region in gas condensate reservoirs. Applied Surface Science 273. Elsevier: 205–214. (2013). https://doi.org/10.1016/j.apsusc.2013.02.014

Ahmadi, R., Ranjbarnodeh, E. & Gu, N. Synthesizing cysteine-coated magnetite nanoparticles as MRI contrast agent: Effect of pH and cysteine addition on particles size distribution. Materials Science-Poland 30. Springer: 382–389. (2012). https://doi.org/10.2478/s13536-012-0048-6

GAIHRE, B. & M KHIL, D. L. E. E. and H KIM. Gelatin-coated magnetic iron oxide nanoparticles as carrier system: Drug loading and in vitro drug release study. International Journal of Pharmaceutics 365. Elsevier: 180–189. (2009). https://doi.org/10.1016/j.ijpharm.2008.08.020

Belikov, V. G., Kuregyan, A. G. & Ismailova, G. K. Standardization of magnetite. Pharmaceutical Chemistry Journal 36. Springer: 333–336. (2002). https://doi.org/10.1023/A:1020845110683

Dorniani, D. et al. Preparation of Fe3O4 magnetic nanoparticles coated with Gallic acid for drug delivery. International J. Nanomedicine Taylor Francis. 5745. https://doi.org/10.2147/IJN.S35746 (2012).

Rahimi, A., Honarvar, B. & Safari, M. The role of salinity and aging time on carbonate reservoir in low salinity seawater and smart seawater flooding. Journal of Petroleum Science and Engineering 187. Elsevier: 106739. (2020). https://doi.org/10.1016/j.petrol.2019.106739

Tiab, D. & Erle, C. D. Petrophysics: Theory and Practice of Measuring Reservoir Rock and Fluid Transport Properties (Gulf professional publishing, 2015).

Lagerge, S., Rousset, P., Zoungrana, T., Douillard, J. M. & Partyka, S. Adsorption of benzoic acid from organic solvents on calcite and dolomite: Influence of water. Colloids and Surfaces A: Physicochemical and Engineering Aspects 80. Elsevier: 261–272. (1993). https://doi.org/10.1016/0927-7757(93)80207-U

Thomas, M., Moisio, J. A., Clouse & John, M. L. Adsorption of organic compounds on carbonate minerals. Chemical Geology 109. Elsevier: 201–213. (1993). https://doi.org/10.1016/0009-2541(93)90070-Y

Hou, B., Jia, R., Fu, M., Wang, Y. & Bai, Y. and Youqing Huang. Wettability Alteration of an Oil-Wet Sandstone Surface by Synergistic Adsorption/Desorption of Cationic/Nonionic Surfactant Mixtures. Energy & Fuels 32. ACS Publications: 12462–12468. (2018). https://doi.org/10.1021/acs.energyfuels.8b03450

Goldstein, J. I. et al. Scanning Electron Microscopy and X-ray Microanalysis (springer, 2017).

Babu, K., Pal, N., Bera, A., Saxena, V. K. & Mandal, A. Studies on interfacial tension and contact angle of synthesized surfactant and polymeric from castor oil for enhanced oil recovery. Applied Surface Science 353. Elsevier: 1126–1136. (2015). https://doi.org/10.1016/j.apsusc.2015.06.196

Hou, B. & Huang, Y. Ye-fei Wang, and Mechanistic study of wettability alteration of oil-wet sandstone surface using different surfactants. Applied Surface Science 330. Elsevier: 56–64. (2015). https://doi.org/10.1016/j.apsusc.2014.12.185

Ghalamizade Elyaderani, S., Masoud, A. H. S. & Dehaghani and Javad Razavinezhad. Tuned Low-Salinity Waterflooding in Carbonate Reservoirs: Impact of Cr2O72–, C6H5COO–, and SO42–. SPE Journal 28. OnePetro: 1250–1263. (2023). https://doi.org/10.2118/214299-PA

Zhang, P. & Tweheyo, M. T. and Tor Austad. Wettability alteration and improved oil recovery by spontaneous imbibition of seawater into chalk: Impact of the potential determining ions Ca2+, Mg2+, and SO42–. Colloids and Surfaces A: Physicochemical and Engineering Aspects 301. Elsevier: 199–208. (2007). https://doi.org/10.1016/j.colsurfa.2006.12.058

Noorizadeh Bajgirani, S., Soheil & Dehaghani, A. H. S. Experimental investigation of wettability alteration, IFT reduction, and injection schemes during surfactant/smart water flooding for EOR application. Scientific Reports 13. Nature Publishing Group UK London: 11362. (2023). https://doi.org/10.1038/s41598-023-37657-1

Lashkarbolooki, M., Ayatollahi, S. & Riazi, M. Mechanistical study of effect of ions in smart water injection into carbonate oil reservoir. Process Safety and Environmental Protection 105. Elsevier: 361–372. (2017). https://doi.org/10.1016/j.psep.2016.11.022

Safari, M., Rahimi, A., Gholami, R., Permana, A. & Wee Siaw, K. Underlying mechanisms of shale wettability alteration by low salinity water injection (LSWI). Journal of Dispersion Science and Technology 43. Taylor & Francis: 33–41. (2022). https://doi.org/10.1080/01932691.2020.1813156

Abdel-Wali, A. A. Effect of Simple Polar Compounds and Salinity on Interfacial Tension and Wettability of Rock/Oil/Brine System. Journal of King Saud University - Engineering Sciences 8. Elsevier: 153–162. (1996). https://doi.org/10.1016/S1018-3639(18)30655-X

Chandrasekhar, S. & Mohanty, K. K. Wettability Alteration with Brine Composition in High Temperature Carbonate Reservoirs. In Day 2 Tue, October 01, 2013, D021S030R002. SPE. (2013). https://doi.org/10.2118/166280-MS

Serrano-Saldaña, E. Armando Domı́nguez-Ortiz, Hermilo Pérez-Aguilar, Isaac Kornhauser-Strauss, and Fernando Rojas-González. 2004. Wettability of solid/brine/n-dodecane systems: experimental study of the effects of ionic strength and surfactant concentration. Colloids and Surfaces A: Physicochemical and Engineering Aspects 241. Elsevier: 343–349. https://doi.org/10.1016/j.colsurfa.2004.04.025

Rajabi, M., Sadegh, R., Moradi & Pirouz Kavehpour, H. Interfacial tension of acidic heavy crude oil type and dolomite surface wettability: salinity and nanoparticles impact. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 44. Taylor & Francis: 5340–5357. (2022). https://doi.org/10.1080/15567036.2022.2086325

Bahaloo Horeh, Mohsen, M. J. S., Afra, B., Rostami & Ghorbanizadeh, S. Role of Brine Composition and Water-Soluble Components of Crude Oil on the Wettability Alteration of a Carbonate Surface. Energy & Fuels 33. ACS Publications: 3979–3988. (2019). https://doi.org/10.1021/acs.energyfuels.9b00007

Rego, F., Bordeaux, E., Eltahan & Sepehrnoori, K. Wettability alteration and improved oil recovery in unconventional resources. Journal of Petroleum Science and Engineering 212. Elsevier: 110292. (2022). https://doi.org/10.1016/j.petrol.2022.110292

Wasan, D., Nikolov, A. & Kondiparty, K. The wetting and spreading of nanofluids on solids: Role of the structural disjoining pressure. Current Opinion in Colloid & Interface Science 16. Elsevier: 344–349. (2011). https://doi.org/10.1016/j.cocis.2011.02.001

Wasan, D. T. & Alex, D. N. Spreading of nanofluids on solids. Nature 423. Nature Publishing Group UK London: 156–159. (2003). https://doi.org/10.1038/nature01591

Rong, M. Z., Zhang, M. Q. & Ruan, W. H. Surface modification of nanoscale fillers for improving properties of polymer nanocomposites: A review. Materials Science and Technology 22. Taylor & Francis: 787–796. (2006). https://doi.org/10.1179/174328406X101247

Kango, S. et al. Surface modification of inorganic nanoparticles for development of organic–inorganic nanocomposites—A review. Progress in Polymer Science 38. Elsevier: 1232–1261. (2013). https://doi.org/10.1016/j.progpolymsci.2013.02.003

Sperling, R. A. & Wolfgang, J. P. Surface modification, functionalization and bioconjugation of colloidal inorganic nanoparticles. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences 368. The Royal Society Publishing: 1333–1383. (2010). https://doi.org/10.1098/rsta.2009.0273

Zhou, Y. et al. and Guangya Zhang. Peptide-Inspired One-Step Synthesis of Surface-Functionalized Fe3O4 Magnetic Nanoparticles for Oriented Enzyme Immobilization and Biocatalytic Applications. ACS Applied Nano Materials 5. ACS Publications: 8260–8270. (2022). https://doi.org/10.1021/acsanm.2c01346

Brown, M. A. et al. Electronic structure of sub-10 Nm colloidal silica nanoparticles measured by in situ photoelectron spectroscopy at the aqueous-solid interface. Phys. Chem. Chem. Phys. 13, 12720. https://doi.org/10.1039/c1cp21131e (2011). Royal Society of Chemistry.

Keykhosravi, A., Bedrikovetsky, P. & Simjoo, M. Experimental insight into the silica nanoparticle transport in dolomite rocks: Spotlight on DLVO theory and permeability impairment. Journal of Petroleum Science and Engineering 209. Elsevier: 109830. (2022). https://doi.org/10.1016/j.petrol.2021.109830

Lim, S., Horiuchi, H., Nikolov, A. D. & Wasan, D. Nanofluids Alter the Surface Wettability of Solids. Langmuir 31. ACS Publications: 5827–5835. (2015). https://doi.org/10.1021/acs.langmuir.5b00799

Mousazadeh, B., Mohammadi, N. & Hamoule, T. Removal of phosphate from the aqueous environment using iron oxide/activated carbon composites: activated carbon derived from Ziziphus nuts as a new precursor. Iranian J. Chem. Eng. (IJChE) 18 Iran. Association Chem. Eng. (IAChE. 52–62. https://doi.org/10.22034/ijche.2022.315429.1415 (2021).

Mohammadi, N., Mousazadeh, B. & Hamoule, T. Synthesis and characterization of NH2-SiO2@Cu-MOF as a high-performance adsorbent for Pb ion removal from water environment. Environment, Development and Sustainability 23. Springer: 1688–1705. (2021). https://doi.org/10.1007/s10668-020-00646-9

Kazemzadeh, Y. et al. Behavior of Asphaltene Adsorption onto the Metal Oxide Nanoparticle Surface and Its Effect on Heavy Oil Recovery. Industrial & Engineering Chemistry Research 54. ACS Publications: 233–239. (2015). https://doi.org/10.1021/ie503797g

Sadegh Mazloom, Mohammad, A., Hemmati-Sarapardeh, M. M., Husein, H. S., Behbahani & Zendehboudi, S. Application of nanoparticles for asphaltenes adsorption and oxidation: A critical review of challenges and recent progress. Fuel 279. Elsevier: 117763. (2020). https://doi.org/10.1016/j.fuel.2020.117763

Shirin, S., Bila, A. & Torsæter, O. Experimental Investigation of the Effect of Silica Nanoparticles on Interfacial Tension and Wettability during Low Salinity Water Flooding: A Micromodel Study. Journal of Modern Nanotechnology 2. Innovation Forever Publishing Corporation. (2022). https://doi.org/10.53964/jmn.2022002

Hsieh, C. T., Chen, J. M., Kuo, R. R., Lin, T. S. & Chu-Fu, W. Influence of surface roughness on water- and oil-repellent surfaces coated with nanoparticles. Applied Surface Science 240. Elsevier: 318–326. (2005). https://doi.org/10.1016/j.apsusc.2004.07.016

He, L., Lin, F., Li, X., Sui, H. & Xu, Z. Interfacial sciences in unconventional petroleum production: from fundamentals to applications. Chem. Soc. Rev. 44, 5446–5494. https://doi.org/10.1039/C5CS00102A (2015). Royal Society of Chemistry.

Nourinia, A. et al. and Muhammad Ali. Synergistic Efficiency of Zinc Oxide/Montmorillonite Nanocomposites and a New Derived Saponin in Liquid/Liquid/Solid Interface-Included Systems: Application in Nanotechnology-Assisted Enhanced Oil Recovery. ACS Omega 7. ACS Publications: 24951–24972. (2022). https://doi.org/10.1021/acsomega.1c07182

Yekeen, N., Elakkari, A. M. A., Khan, J. A., Ali, M., Al-Yaseri, A. & Hussein Hoteit Experimental and computational fluid dynamics investigation of mechanisms of enhanced oil recovery via Nanoparticle-Surfactant solutions. Energy & Fuels 37 ACS Publications. 5114–5129. https://doi.org/10.1021/acs.energyfuels.3c00136 (2023).