Abstract

Methane accumulation in the upper corners of coal mine working faces poses significant safety risks. Y-type ventilation combined with gob-side entry retaining has been applied to improve gas dispersion; however, airflow convergence can still result in high methane concentrations near the return airway. To address this, a computational fluid dynamics (CFD) model was developed to simulate methane migration in the goaf under different drainage strategies. Results indicate that methane concentration increases with elevation and distance from the working face, and is consistently higher along the gob-side entry than on the intake side. Buried pipelines effectively reduced methane levels near the floor and along the gob-side, while high-level boreholes were more effective in the caved zone but less so in the overlying fractured zone. A combined drainage approach was found to yield the most comprehensive reduction across all regions of the goaf. These findings provide valuable insights for optimizing methane control in Y-type ventilated mining operations.

Similar content being viewed by others

Introduction

Coal remains a cornerstone of China’s energy system and accounts for a major share of the country’s primary energy consumption1. As shallow coal resources are gradually depleted, mining activities have extended to deeper seams, exposing operations to complex geological conditions such as elevated in-situ stress, high methane pressure, and intense mining-induced disturbances. These challenges have rendered traditional mining technologies increasingly inadequate2. Although advanced technologies such as intelligent mining and precision geological exploration have greatly improved safety and efficiency3 methane-related hazards remain a major concern in deep coal mining4,5. Methane explosions are consistently the leading cause of coal mine accidents in China, highlighting the urgent need for effective gas control6. Compared to traditional U-type ventilation systems, Y-type ventilation with gob-side entry not only reduces coal loss but also mitigates methane accumulation in the upper corner7,8,9. However, due to the convergence of airflow, this configuration can result in methane over-concentration in the return airway, thereby threatening mine safety.

In response to these challenges, numerous scholars have conducted relevant research. Zhang et al. used numerical simulations to investigate key factors influencing methane emission from residual coal in the goaf and concluded that a modified Y-type ventilation system can not only control methane accumulation in the upper corner but also effectively prevent spontaneous combustion of residual coal10. Ding, Deng, and others employed Fluent-based numerical simulations to examine the distribution patterns of methane flow fields in the goaf under different directions and under gob-side entry Y-type ventilation conditions11,12. Juganda et al. applied a CFD model to study the spatial distribution of methane in the goaf under various ventilation schemes13. Tian et al. integrated tracer methane detection with numerical simulation to investigate the air leakage behavior in goafs under Y-type ventilation14. Zhao et al. used User Defined Functions (UDFs) in simulations to analyze the characteristics of methane flow fields in the goaf and derived predictive equations for methane concentration in the upper corner and the ventilation linkage roadway15. Geng et al. investigated air leakage flow fields and multi-component methane concentration distributions in the goaf based on the “O-ring” theory and found that methane and oxygen concentrations under Y-type ventilation exhibited an approximate “L-shaped” spatial pattern16. Kang et al. examined the methane flow field in goafs under the combined application of high-level drainage roadways and pre-buried vertical extraction pipes and identified the optimal spatial configuration of the drainage roadway and the best spacing for embedded vertical pipes17. Recent international studies have increasingly used advanced CFD modeling techniques to investigate methane distribution and control strategies in goaf environments. For instance, Wang et al. developed a longwall goaf CFD model calibrated with field borehole data, improving the accuracy of methane migration simulations18. Liu et al. explored complex methane emissions in composite goaf areas using CFD approaches to optimize extraction layouts19. Pan et al. integrated multiphysics simulations with field measurements to investigate gas flow behavior under Y-type ventilation20. Saki et al. conducted parametric CFD studies on ventilation rates and methane hazard evolution, highlighting the critical role of airflow configuration. These studies demonstrate the importance of data-informed CFD modeling in enhancing gas control strategies for underground mining operations21.

At present, most studies have focused on the spatial distribution of methane in the goaf under Y-type ventilation conditions, yet few have systematically explored the influence of specific extraction technologies on the dynamic behavior of methane migration. In particular, limited attention has been paid to comparing the performance of different drainage strategies—such as buried pipes, high-level directional boreholes, and their combination—under such ventilation systems. To address this gap, this study selects the 2206 working face of the Lutaishan Coal Mine as a representative case and employs computational fluid dynamics (CFD) modeling via Fluent to simulate methane migration under various drainage configurations. The objective is to quantitatively assess the extraction performance of each method, clarify the spatial migration characteristics of methane, and propose targeted optimization strategies for methane control in goafs with Y-type ventilation and gob-side entry retaining.

General description of the working face

The surface of the 2206 working face is located in the Beiling and Maoyaogou area, with ground elevations ranging from + 1103.13 m to + 982.94 m. This working face is situated in the northwestern part of the mining area, with its northern end adjacent to the mine boundary, and its southern end connected to the Main return airway, track roadway, and belt roadway of the mining district. The 2205 working face Lies to the east, and the 2207 working face Lies to the west. The elevation of the 2206 working face ranges from + 702.82 m to + 805.53 m. It extends 1,378 m along the strike direction and 172 m in face length, forming a rectangular layout. The recoverable length along the strike is 1,270 m. The coal seam has an average thickness of 2.2 m and an apparent density of 1.45 t/m³.

Model construction and parameter configuration

Geometric modeling and meshing

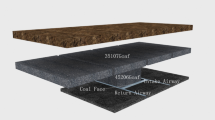

According to commonly accepted strata classification in longwall mining, the overburden above the mined-out area can be divided into a caved zone and a fractured zone. The caved zone refers to the immediate area above the goaf, where roof collapse has occurred, and the rock mass is completely broken and compacted. The fractured zone, located above the caved zone, is characterized by partially broken rock with developed fractures but without full collapse. This classification is widely adopted in coal mine strata studies22,23.

Based on the actual parameters of the 2206 working face and the heights of the three zones, the goaf was modeled with a strike length of 240 m, a dip length of 172 m, and a total height of 40 m. The caved zone was set to 15 m in height, and the fractured zone to 25 m. The intake and return airways were each 4 m wide and 3 m high; the working face was 5 m wide; and the backfill wall was 3 m wide and 3 m high. Detailed parameters for each goaf region are listed in Table 1.

In this study, the vertical height of the caved zone (15 m) and fractured zone (25 m) were determined based on empirical formulas commonly adopted in Chinese coal mining engineering practice, considering the mining height and overburden lithology24. These values were further calibrated using field monitoring data and engineering experience from mines with similar geological conditions. The chosen values are also consistent with previous numerical studies in the region.

Based on these parameters, a geometric model of the goaf without methane extraction was established using the DesignModeler module, as shown in Fig. 1.

Tetrahedral meshing was employed, with grid sizes set at 4 m for the goaf and 1.5 m for the roadways, working face, and filling wall. The final mesh consisted of 652,693 elements and 123,105 nodes. The meshed model is illustrated in Fig. 2.

Mathematical model

The composition of methane within the goaf is complex, but it can be approximated as a mixture primarily consisting of methane and air. Given that the methane mixture contains various components whose concentrations cannot change arbitrarily, the flow behavior of the mixture in the goaf can be described using the continuity equation, momentum conservation equation, and species transport equation.

(1) Continuity equation

By introducing a scalar function ϕ, Eq. (1) can be reformulated as:

Assuming that ϕ is a non-zero constant, Eq. (2) can be further simplified to:

Where, ρ denotes the fluid density (kg/m³); u, v, and w represent the velocity components in the x, y, and z directions, respectively; and is the velocity vector.

(2) Momentum conservation equation

Where, µ is the dynamic viscosity coefficient, p is the pressure acting on the fluid element, and Su, Sv, and Sw are the generalized source terms in the momentum conservation equations.

(3) Species transport equation

Where, cs is the mass fraction of the species, ρcs is the mass concentration, Ds is the diffusion coefficient, Ss represents the additional generation rate, Rs is the net generation rate, div(ρUcs) denotes the convective term, and div(Dsgrad(ρcs)) represents the diffusive term.

Boundary conditions

The Main and auxiliary intake airways of the 2206 working face were defined as velocity-inlet boundaries, while the return airway outlet was set as an outflow boundary. The total required ventilation rate was 1800 m³/min, which was obtained from the mine’s design documents and represents the standard ventilation capacity under normal production conditions. This design value was applied as the inlet boundary condition in the simulation. The goaf was modeled as a porous medium. The interfaces between the goaf and both the working face and the supports were designated as interior boundaries. The interfaces between the backfill wall and both the roadway and goaf were treated as wall boundaries, while the top of the gob-side entry retaining roadway was treated as a porous jump boundary. All internal regions were assumed to be fluid domains by default. The goaf and the working face were defined as methane emission sources. The goaf was divided into caved and fractured zones, each with distinct parameter settings. The methane emission rate was defined as a function of the distance from the working face, and the methane density was set to 0.717 m³/kg. During simulation, the methane source term, oxygen consumption rate, viscous and inertial resistances, and porosity functions were all implemented using UDFs.

Results and analysis of methane migration

No drainage

The three-dimensional distribution of methane in the goaf without drainage is shown in Fig. 3.

As shown in Fig. 3(a), the region adjacent to the main intake airway exhibits relatively low methane concentrations due to significant air leakage. In contrast, the return airway side maintains higher methane concentration because of limited air leakage. Notably, in the upper corner of the return side under Y-type ventilation, the unique airflow structure tends to generate vortices, resulting in localized methane accumulation25. Additionally, as the distance from the working face increases, methane concentration gradually rises until stabilizes at a relatively constant level. This trend reflects the migration and accumulation behavior of methane within the goaf.

A comparative analysis of Figs. 3(a), (b), and (c) provides a clearer visualization of methane migration patterns in the goaf. As leakage airflow from the main intake side continuously enters the goaf, methane progressively migrates toward the return airway side. This migration not only alters the methane distribution within the goaf but may also cause methane over-concentration in the gob-side entry retaining roadway, posing a significant safety risk to mine safety.

(1) Vertical direction.

To further investigate into the vertical distribution of methane concentration within the goaf, four horizontal slices located at 5 m, 10 m, 20 m, and 30 m above the floor were selected for analysis. These elevations correspond to the vertical positions of the caved zone and the fractured zone, respectively. By analyzing the methane concentrations on these slices, the vertical distribution of methane within the goaf can be obtained, as illustrated in Fig. 4.

As shown in Fig. 4, methane concentration in the goaf increases progressively with elevation. This is mainly due to two reasons: (1) buoyant methane rises and diffuses upward into the fractured zone; (2) the low porosity of this zone restricts airflow, which limits dilution and causes methane to accumulate. Although air leakage from the working face affects the overall distribution, it has minimal impact on ventilation within the fractured zone. As a result, methane concentrations remain high in this region26.

(2) Horizontal direction.

To assess the horizontal distribution of methane concentration within the goaf, representative cross-sections were selected at distances of 1 m, 80 m, 160 m, and 239 m from the working face, as well as at lateral distances of 1 m, 60 m, 120 m, and 170 m from the main intake airway. The corresponding results are shown in Fig. 5.

As illustrated in Fig. 5(a), methane concentration increases significantly with distance from the working face. In the deeper regions of the goaf, concentrations reach 80–95%. This trend is primarily caused by rock compaction, which reduces porosity and limits both methane diffusion and airflow velocity.

Figure 5(b) shows the relationship between methane concentration and air leakage paths. Near the main intake airway, ventilation is strong, and methane concentrations remain low. In contrast, areas farther from ventilation roadways—particularly the upper corner—suffer from poor airflow. As a result, methane accumulates, leading to elevated concentrations that may exceed safety thresholds and pose a high explosion risk27.

Buried pipe drainage

To facilitate mesh generation, square boreholes with dimensions of 0.5 m × 0.5 m were used to replace circular ones in the numerical model. The extraction pipes were positioned in the upper-central section of the backfill wall, with a negative extraction pressure of 5 kPa. The spacing between adjacent pipes was set to 30 m.

(1) Vertical direction.

To enable direct comparison with the results in Fig. 4, horizontal slices at 5 m, 10 m, 20 m, and 30 m above the floor were selected. The methane concentration variations in these slices are shown in the vertical distribution characteristics of methane under borehole extraction conditions. The results are presented in Fig. 6.

A comparison between Figs. 4 and 6 reveals notable changes in the spatial distribution of methane. In the caved zone, methane concentration shows an overall decline, particularly near the gob-side entry. This suggests that methane in this region is effectively controlled through extraction or natural leakage.

In the fractured zone, especially near the main intake airway, methane concentration also decreases significantly. This reduction is likely due to localized pressure drops induced by negative pressure extraction. The pressure drop enhances airflow and intensifies air leakage, which facilitates methane dilution and discharge. Despite these improvements, the overall methane concentration in the goaf remains relatively high.

(2) Horizontal direction.

Given that the boreholes were Mainly arranged along the gob-side entry, additional horizontal analysis was conducted to assess methane distribution along that direction. For comparative analysis with pre-extraction conditions, horizontal slices were taken at 1 m, 60 m, 120 m, and 170 m from the main intake airway. The results are shown in Fig. 7.

As shown in Fig. 7, at the cross-Sect. 170 m from the intake airway, an “arched” low-concentration zone appears beneath the borehole, indicating strong localized extraction. However, due to the shallow penetration of the embedded pipe (only about 3 m into the goaf), the upper regions still show relatively high methane concentrations.

Overall, the concentration remains elevated, with only minor dilution caused by partial leakage near the working face. Compared to previous slices, this section exhibits a slightly expanded leakage zone near the face, leading to somewhat lower concentrations. Nevertheless, the overall distribution pattern remains largely unchanged.

At y = 1 m, close to the intake airway, ventilation-induced leakage has a strong effect. Here, methane concentrations below 1% cover nearly half of the cross-section, forming a trapezoidal pattern that reflects effective methane dilution.

Directional high-level borehole drainage

To facilitate numerical modeling and mesh generation, four uniformly sized square boreholes (0.5 m × 0.5 m) were configured in the model, each extending 100 m in length. These boreholes were arranged along the strike direction with 10 m spacing, with the first borehole located 3 m from the gob-side entry. This layout aimed to ensure uniform gas extraction coverage. To target gas accumulation at different vertical heights, the boreholes were installed at 35 m, 30 m, 25 m, and 20 m above the floor. A constant negative pressure of 10 kPa was applied during extraction to ensure continuous gas removal.

(1) Vertical direction.

To enable direct comparison with the results presented in Fig. 4, horizontal slices taken at 5 m, 10 m, 20 m, and 30 m above the floor. The corresponding methane concentration distributions are shown in Fig. 8.

As illustrated in Fig. 8, methane concentration in the caved zone decreases significantly under high-level directional borehole drainage, indicating effective extraction in this area. However, severe accumulation persists in deeper regions near the gob-side entry.

In the fractured zone (z = 20 m and z = 30 m), methane concentration is reduced near the boreholes but remains high farther away. This suggests that extraction efficiency declines with increasing height and distance from the source.

Overall, methane control in the fractured zone is less effective than in the caved zone. This is mainly due to the lower porosity and denser rock structure, which increase resistance to gas flow and reduce storage capacity. Additionally, irregular and discontinuous fractures further hinder methane migration and drainage. These differences are fundamentally governed by geological factors such as porosity, rock structure, and fracture connectivity. To improve extraction efficiency, it is necessary to adopt region-specific strategies based on local geology and to optimize borehole layout and negative pressure control.

(2) Horizontal direction.

As the directional boreholes were arranged along the dip direction within the goaf, the spatial distribution characteristics of methane concentration were further analyzed in the horizontal plane along the dip direction. Using slices taken the pre-drainage state, horizontal slices were taken at positions 1 m, 80 m, 160 m, and 239 m from the working face, as shown in Fig. 9.

As illustrated in Fig. 9, the slice at x = 1 m exhibits low methane concentrations across most of the area, except for a small region at the top of the fractured zone near the gob-side entry. This indicates effective drainage near the working face. At x = 80 m, the methane concentration further decreases, with nearly the entire area exhibiting concentrations below 30%, suggesting optimal extraction performance at this location. In contrast, slices at x = 160 m and x = 239 m still show methane concentration remains above 50% in most areas, although lower than those observed before drainage. These results indicate that methane extraction efficiency gradually decreases with increasing distance from the working face, and methane concentration tends to rise in deeper regions far from the borehole layout, highlighting a persistent risk of methane accumulation in those areas.

Combined drainage

(1) Vertical direction.

To evaluate the effectiveness of the combined extraction technology with that of single extraction methods in controlling methane concentration within the goaf, four horizontal slices at 5 m, 10 m, 20 m, and 30 m above the floor were selected for detailed analysis of the vertical distribution characteristics of methane concentration under the combined conditions of embedded pipes and high-level directional boreholes. These slices cover the main vertical distributions of the caved zone and fractured zone, providing critical insight into the methane concentration distributions at different heights. The corresponding results are presented in Fig. 10.

As shown in Fig. 10, within 50 m from the working face, methane concentration is significantly reduced to below 5%, indicating excellent extraction effectiveness near the face. In the deeper regions of the goaf, methane concentration stabilizes around 20%, with slight increases concentrations near the monitoring points. While concentration slightly rises from z = 1.5 m to z = 10 m, the overall distribution remains relatively unchanged, suggesting a diminishing extraction effect within the caved zone. In contrast, methane concentration shows a substantial reduction within the fractured zone between z = 20 m and z = 30 m, demonstrating that the combined extraction technology achieves better control in this region compared with single high-level borehole extraction. This phenomenon may be attributed to the local pressure reduction caused by the buried pipe system, which narrows the pressure differential between the caved and fractured zones. This pressure equilibration enhances methane mobility within the fractured zone, resulting in a more balanced extraction effect and improving the overall methane control efficiency.

(2) Horizontal direction.

Under the combined drainage system of embedded pipes and high-level directional boreholes within the goaf, horizontal slices at distances of 1 m, 80 m, 160 m, and 239 m from the working face were selected to analyze methane concentration variations along the strike direction. Simultaneously, slices at 1 m, 60 m, 120 m, and 170 m from the gob-side entry along the dip direction. The results are presented in Fig. 11.

As shown in Fig. 11, the combined extraction technology effectively reduces methane concentrations in the goaf across multiple regions while preserving the general spatial distribution trend of methane. In the dip direction, methane concentration gradually decreases from the gob-side entry toward the main intake airway, reflecting the airflow dilution effect, resulting in relatively lower methane concentrations near the intake airway. Conversely, In the strike direction, methane concentration increases progressively with distance from the working face, indicating a reduction in drainage effectiveness deeper into the goaf.

In summary, the combined extraction method of embedded pipes and directional boreholes demonstrates promising efficacy in controlling methane concentrations within the goaf. However, final methane distribution pattern is still influenced by airflow pathways, ventilation structure, and geological conditions. Therefore, site-specific extraction strategies tailored to local mining conditions are essential that integrate specific ventilation and geological contexts to achieve efficient and coordinated methane management in the goaf.

Limitations of the CFD model

While the CFD simulations provide valuable insights into methane migration patterns under different drainage conditions, several limitations should be acknowledged. First, the model assumes steady-state conditions and does not consider time-dependent changes in gas emission or ventilation parameters. Second, the goaf is simplified as a homogeneous porous medium, which may not fully reflect the complex spatial variability of porosity and permeability in real field settings. Third, the boundary conditions and gas emission parameters are based on design documents and engineering estimates rather than continuous field monitoring data, which may introduce discrepancies between simulated and actual conditions. Finally, interactions between methane flow and dynamic coal deformation or roof collapse were not included. These simplifications, while necessary for model tractability, may lead to deviations in predicting gas distribution. Future work should aim to incorporate more detailed geological and temporal data to improve model fidelity.

Conclusions

(1) The spatial distribution of methane concentration in the goaf is distinct and exhibits a clear pattern. Vertically, concentrations increase with elevation—being lower in the caved zone and higher in the fractured zone. Horizontally, higher concentrations are observed along the gob-side entry compared to areas near the Main intake airway. Near the intake side, methane levels remain low, with a volume fraction below 1%. In contrast, deep regions of the goaf located far from the working face exhibit significant methane accumulation, with concentrations reaching up to 95%, indicating a serious risk of gas buildup.

(2) Buried pipe drainage exhibits a localized control effect. While the overall concentration in the goaf shows only a slight and stable decrease, methane concentration along the gob-side entry decreases significantly. This indicates that buried pipe extraction is highly effective in controlling methane accumulation in targeted regions, making it suitable for areas requiring focused drainage.

(3) The effectiveness of directional high-level borehole drainage is limited by poor permeability in the fractured zone. Although it reduces methane concentration in the caved zone, its performance is suboptimal in the fractured zone due to low porosity and poor fracture connectivity. For high-methane coal seams, increasing borehole density in the fractured zone is recommended to enhance extraction efficiency.

(4) The combined use of buried pipes and high-level boreholes offers more effective and balanced methane control. This method reduces concentrations in both the caved and fractured zones and enhances spatial coverage of extraction. The results suggest its potential for broader engineering application, particularly in complex goaf environments.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Liu, F., Guo, L. F. & Zhao, L. Z. Research on coal safety range and green low⁃carbon technology path under the dual⁃carbon background. J. China Coal Soc. 47 (1), 1–15 (2022).

Wang, J. H. et al. Coal development and utilization theory and technical system of near-zero ecological environment impact. J. China Coal Soc. 43 (5), 1198–1209 (2018).

Wang, Y. M. et al. Guidance and review: advancing mining technology for enhanced production and supply of strategic minerals in China. Green. Smart Min. Eng. 1 (1), 2–11 (2024).

Zhai, C. et al. Reflection and prospect on the prevention of gas outburst disasters in china’s coal mines. J. China Univ. Min. Technol. 52 (6), 1146–1161 (2023).

Yuan, L. et al. Scientific problems and key technologies for safe and efficient mining of deep coal resources. J. China Coal Soc. 50 (1), 1–12 (2025).

Zhang, J. Y. et al. Study on permeability enhancement by deep⁃hole shaped⁃charge controlled blasting of deep soft and high gas coal seam floor. J. Min. Saf. Eng. 41 (6), 1311–1322 (2024).

Chen, L. et al. Deformation and air leakage mechanism of gob-side entry retaining and multiple collaborative prevention and control technology in Thick coal seam. Coal Sci. Technol. 52 (10), 114–126 (2024).

Liu, J. J. et al. Simulation study on propagation characteristics of gas explosion in Y-shaped ventilated coal face. Explos Shock Waves. 43 (8), 182–194 (2023).

Hua, X. Z. et al. Current situation of gob-side entry retaining and suggestions for its improvement in China. Coal Sci. Technol. 51 (1), 128–145 (2023).

Zhang, D. & Nie, H. Y. Study on roadway layout and air volume distribution in fully-mechanized caving face based on FLAC3D. Coal Sci. Technol. 50 (S1), 132–141 (2022).

Ding, H. C. et al. Study on gas seepage and distribution in Goaf of fully mechanized mining face under Y-type ventilation collaborative drainage. Saf. Environ. Eng. 30 (6), 146–153 (2023).

Deng, B. Z. et al. Research on gas transportation law and air volume regulation of Y-type ventilation along gob-side entry retaining. Min. Saf. Environ. Prot. 51 (3), 16–27 (2024).

Juganda, A. et al. Discrete modeling of a Longwall coal mine gob for CFD simulation. Int. J. Min. Sci. Technol. 30 (4), 463–469 (2020).

Tian, Y. et al. Study on the law of air leakage in working face of Y-type ventilation in Goaf based on tracer detection method and numerical simulation. Min. Saf. Environ. Prot. 47 (5), 40–45 (2020).

Zhao, C., Zhang, L. & Liu, Y. Q. Study on gob gas emission laws and control of gas exceeding limit under inclined type Y-Ventilation. Coal Sci. Technol. 47 (4), 127–133 (2019).

Geng, X. W. et al. Laws of gas distribution in Goaf with Y-type ventilation based on o།type caving. J. Saf. Sci. Technol. 13 (1), 71–76 (2017).

Kang, J. H. et al. Gas distribution in Goaf with high drainage roadway and buried pipe drainage. J. Min. Saf. Eng. 38 (1), 191–198 (2021).

Wang, Y. H. et al. CFD modelling of Longwall Goaf atmosphere under vertical boreholes gas drainage. Int. J. Coal Geol. 280, 104400 (2023).

Liu, C. G. Optimizing methane control in composite Goaf areas: insights from multisource emission analysis and numerical modeling in the Tongxin coal mine. ACS Omega. 9 (40), 41171–41178 (2024).

Pan, H. T. et al. Construction of multiphysics coupling equations and study on flow field migration patterns in shallow buried Goaf under air leakage conditions. Sci. Rep. 15, 29437 (2025).

Saki, S. A. et al. CFD study of the effect of face ventilation on CH4 in returns and explosive gas zones in progressively sealed Longwall gobs. J. South. Afr. Inst. Min. Metall. 117 (3), 257–262 (2017).

Li, L. et al. Formation mechanism and height calculation of the caved zone and water-conducting fracture zone in solid backfill mining. Int. J. Coal Sci. Technol. 7, 208–215 (2020).

Ma, K. et al. The influence of backfilling of a caved zone and magma intrusion-type faults on surface deformation in a metal mine caused by sublevel caving mining. Int. J. Rock. Mech. Min. Sci. 175, 105677 (2024).

Han, Y. et al. Research progress and prospects of methods for estimating methane reserves in closed coal mines in China. Processes 13 (8), 2586 (2025).

Zhao, P. X. et al. Coupling mechanism of pseudo-slope length change and gas concentration in upper corner of fully mechanized caving surface of inclined Thick coal seam in Xinjiang. Coal Sci. Technol. 51 (S1), 73–85 (2023).

Zhang, X. B., Wang, P. & Wang, H. Study on gas migration law in Goaf under the influence of small faults. Coal Sci. Technol. 52 (4), 214–230 (2024).

Peng, B. et al. Characteristics and control technology of breathing phenomenon of sealed Goaf in low-gas mine. J. China Coal Soc. 44 (2), 490–501 (2019).

Acknowledgements

We thank LetPub (www.letpub.com.cn) for its linguistic assistance during the preparation of this manuscript.

Funding

This research was supported by the National Natural Science Foundation of China (Nos. 51974108 and 51404093), the Natural Science Foundation of Henan Province (No. 232300420077), the Scientific and Technological Project of Henan Province (242102320213), the Fundamental Research Funds for the Universities of Henan Province (No. NSFRF240638), and the Post-doctoral Research Project in Henan Province (No. 001701014).

Author information

Authors and Affiliations

Contributions

Formal analysis, investigation, writing—original draft preparation, F.Z. and Y.H.; resources, data curation, super vision, project administration, funding acquisition, F.Z., Z.Y., and C.W.; writing—review and editing, F.Z. and Y.H. All of the authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Han, Y., Wang, C., Zhang, F. et al. Methane migration patterns in the goaf of a Y-type ventilated working face with gob-side entry. Sci Rep 15, 33151 (2025). https://doi.org/10.1038/s41598-025-18816-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-18816-y