Abstract

In China, more than 90% of transportation tunnels are constructed by drill-and-blast method. As the only path for air exchange between the construction period of drill-and-blast method tunnel and the external environment, the ventilation system is the lifeline for tunnel construction personnel. However, due to the lack of attention to the installation and maintenance of ventilation ducts on site, the actual ventilation performance of the ventilation system hardly reaches the designed level. As a result, the working environment at the tunnel face is difficult to meet the design standards, which affects the safety of construction personnel and the construction efficiency. Based on years of practice and research, it has been confirmed that one of the main factors causing the decay of ventilation performance in tunnel construction ventilation systems is air leakage and increased air resistance in ventilation ducts. Through investigating the existing literature on the installation and maintenance techniques of the tunnel construction ventilation system, this review looks back on the connection techniques between ventilation ducts and fans, the suspension techniques for ventilation ducts in the main tunnel, and the techniques for ventilation ducts to pass through the construction trolley, so as to provide certain reference for the maintenance personnel of the tunnel construction ventilation system.

Similar content being viewed by others

Introduction

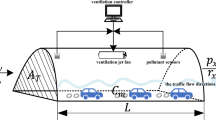

As one of the most widely applied excavation methods in tunnel engineering, the drill-and-blast method is employed in more than 90% of transportation tunnel constructions in China, demonstrating significant technical and economic advantages under hard rock geological conditions. However, dust generated during drill-and-blast construction, harmful blasting gases (such as CO and NOx), and exhaust gases emitted by mechanical equipment easily accumulate in the enclosed tunnel space. This leads to the deterioration of the working environment, poses a serious threat to the health of construction personnel and significantly restricts engineering efficiency1,2,3,4. The tunnel construction ventilation system, as the only channel for air exchange between the drill-and-blast tunnel construction zone and the external environment, delivers fresh air to the vicinity of the tunnel face through natural or mechanical ventilation, diluting harmful gas concentrations to below permissible levels. It serves as the lifeline for tunnel construction personnel, playing a critical role in timely removing blasting dust and toxic gases form the tunnel face, providing fresh air, ensuring the health and safety of workers, and improving construction efficiency5,6,7. With the development of the ventilation technology for drill-and-blast tunnel construction in China, large-diameter ventilation ducts with low air leakage rates are widely used in the ventilation system of long tunnels, which provides greater air volume for the construction ventilation system and reduce air resistance from the product perspective. However, in practical application, the construction ventilation system often fails to achieve the expected designed ventilation performance, making it difficult for the working environment at the tunnel face to meet the design standards. These technical bottlenecks at the application level include frequent exceedance of safety thresholds for air quality in key indicators like dust concentration and harmful gas content in the tunnel face area, insufficient dynamic regulation capability of the ventilation network, and poor system matching8,9,10.

Regarding the problem of inadequate ventilation effect at the tunnel face, most researchers mainly focus on the impact of construction ventilation system design parameters on the ventilation performance. The research priorities are mostly concentrated on the influence of ventilation mode selection, ventilation duct parameters calculation and its arrangement on the airflow filed distribution and energy consumption efficiency11,12,13. And the design parameters of construction ventilation systems are optimized through parametric analysis based on methods such as multi-factor analysis, orthogonal experimental design, response surface methodology, finite difference modeling, and computational fluid dynamics (CFD)14,15,16,17,18. Yang Zhou et al. propose a calculation formula for air supply volume by applying the least squares method to fit experimental data, revealing that the forced ventilation effect deteriorates with the increase of distance, while the energy consumption the ventilation fan increases exponentially with distance19. Wang Jinghua et al. adopt a phased ventilation design strategy based on the existing construction scheme of the Dabashan Tunnel project, which involves matching corresponding ventilation modes to the characteristics of different construction stages, thereby significantly optimizing the overall ventilation effect of the tunnel20. Gou Weidong et al. employ the CFD numerical simulation coupled with the orthogonal experimental design to investigate the influence of key factors such as the distance between the ventilation duct outlet and the tunnel face, the hanging position of the ventilation duct and the diameter of the duct on the CO emission efficiency of the tunnel face, so as to reveal the priority ranking of the importance among the parameters and determine the optimal combination of duct parameters21. Relying on the Yuelongmen tunnel, Pu Qingsong et al. study the spatiotemporal evolution law of CO concentration fields under different duct positions. The result shows that the ventilation effect is the best when the duct is arranged near the wall at the tunnel vault, which can reduce the CO concentration to the permissible limits22.

However, solely enhancing the ventilation performance of the construction ventilation system from the ventilation design perspective greatly increases ventilation energy consumption. Moreover, with the operation of the construction ventilation system, the actual ventilation performance of the enhanced ventilation system remains inferior to its design performance23,24. Therefore, carrying out research on the installation and maintenance technology of ventilation systems for drill-and-blast tunnel construction is not only an urgent technical problem to be solved, but also a critical factor to ensure the construction safety and efficiency of ongoing and upcoming drill-and-blast tunnel projects.

The rest of this paper is organized as follows: section “Scope of literature indexing” overviews the basics of tunnel construction ventilation system to help civil engineers understand the content of this article. Section “Installation and maintenance techniques for ventilation ducts” presents the installation and maintenance techniques of ventilation ducts, including the processes of connecting ventilation ducts to fans, hanging ventilation ducts in the tunnel and passing through the construction trolleys. Section “Comparison and discussion” focuses on the comparative analysis of various connection technologies for fans and ventilation ducts and various technologies of ventilation ducts passing through construction trolleys. Section “Conclusion” summarizes the main conclusions of this study.

Scope of literature indexing

The tunnel construction ventilation system is a core component for ensuring operational safety and construction efficiency. Its design and management primarily focus on air quality control and airflow field distribution, involving key parameters such as air volume supply25wind speed distribution26,27, harmful gas dilution, dust concentration regulation28,29,30 and temperature-humidity control31. During tunnel construction, airflow regulation and harmful gas monitoring are more fundamental and directly impact personnel safety32,33. Therefore, ventilation systems prioritize the effective air supply capacity of ventilation ducts and the real-time feedback from gas sensors. The traditional ventilation equipment mainly includes axial fans, ventilation ducts and auxiliary ventilation systems34, achieving air circulation through mechanical or natural ventilation methods35,36,37. With the development of tunnel engineering towards greater depth, length and complexity, the deficiencies of traditional ventilation systems in dynamic adaptability, energy efficiency optimization and intelligent control gradually become prominent. In particular, these systems struggle to achieve precise responses under conditions of sudden geological risks or high concentration pollutant. At present, most optimization researches on construction ventilation systems are limited to design parameters such as the migration mechanisms of harmful gas and dust, the selection of ventilation ducts, the application of advanced material, and the calculation of air volume. However, merely optimizing the design parameters of the ventilation systems makes it difficult for its actual ventilation performance to meet the expected design standard38,39,40.

Based on the above-mentioned content and requirements of the ventilation system during tunnel construction, this review aims to summarize the installation and maintenance techniques of the ventilation duct system. The literature searching tools are Web of Science, Scopus and Google Scholar, and the search keywords include “tunnel construction ventilation”, “ventilation ducts”, “installation and maintenance techniques for ventilation duct systems”, ect. Literature screening covers publications in the time frame 2011–2025, with database weight allocated as follows: Web of Science at 50%, Scopus at 30% and Google Scholar at 20%. The inclusion criteria requires that studies are peer-reviewed scholarly articles and books focusing on the duct installation and maintenance in drill-and-blast tunnels, excluding conference papers, newspapers, reporting literature, and literature lacking complete author, keyword or journal information. By screening and analysis of 301 initially searched relevant literatures, 53 keywords with a co-occurrence frequency of 6 times or more were extracted, based on which a clustering knowledge map was drawn, as shown in Fig. 1.

Installation and maintenance techniques for ventilation ducts

Connection technology between the ventilation duct and the air outlet of fan

In the construction ventilation system, the air pressure at the outlet end of the ventilation fan is the highest, making the connection between the fan outlet and the duct particularly prone to air leakage. In severe cases, the duct at the fan outlet ruptures due to the excessive air pressure, leading to the air leakage at the source of the ventilation system41. Therefore, the connection between the fan outlet and the duct is crucial. At the construction site, the multiple strands of soft iron wire are generally used to connect the fan outlet and the duct to reduce air leakage, as depicted in Fig. 2. The wire is wrapped 3–5 times around the joint, and then manually tighten the wire fasteners to seal the joint. However, the connection method has significant drawbacks. On the one hand, solely relying on manual tightening of soft iron wire fails to generate uniform, sustained and sufficient sealing pressure, resulting in local gaps at the joint. On the other hand, the duct undergoes slight displacement due to fan vibration, and thus the sharp ends of the iron wire rub repeatedly against the surface of the duct, which easily punctures and wears it42,43.

For flexible ventilation ducts44, the ventilation duct adapter with the pre-tensioned straps can be utilized, as shown in Fig. 3(a). The elastic straps are pre-installed on the inner lining of the duct to fix the fan outlet and the duct. And then the straps are secured with buckles to achieve a tight connection between the fan outlet and the duct. Generally, the length of the outer lining skin at the air inlet of the duct and the inner lining skin at the air outlet of the duct not be less than 20 cm.

For rigid ventilation ducts45, the ventilation duct adapter with pre-drilled bolt holes can be employed, as presented in Fig. 3(b). High-strength bolts are employed to connect the pre-drilled circular holes arranged at the outlet end of the fan with the corresponding holes on the duct adapter. Subsequently, the rigid duct is connected with the fan adapter to form a pressure buffer section at the fan outlet, avoiding the duct rupture or air leakage at the connection caused by excessive air pressure at the fan outlet.

Duct installation technology from the fan frame to the tunnel entrance section

In tunnel construction, the ventilation fan is positioned approximately 10 m away from the tunnel entrance and the duct from the fan outlet to the main tunnel is in a suspended state. The highest air velocity and wind pressure occurs at the fan outlet, causing the suspended section duct to experience shaking violently. And the irregular swinging exerts pulling forces on the connection between the duct and the fan, leading to the joint loosening and the air leakage46,47.

In order to address the issue of joint loosening, air leakage and reduced fan exhaust capacity caused by duct shaking, a stabilization mechanism within the mounting frame is designed by Zhou Xiaoxiong48 as shown in Fig. 4. The system incorporates horizontal guide rods, sleeve plates, support arms and brackets. When docking the fan with the duct, loosen the fixing bolts to move the adjustment sleeve plate, raise the bracket to support the suspended section of the connected duct, and then tighten the bolts to limit the support arms, thereby stabilizing the connection between the duct and the fan.

Two φ12mm stainless steel wire ropes are installed from the ventilation duct rack to the tunnel entrance. A portal frame with reserved reinforced steel hooks is set up at intervals of ten meters from the duct rack to the entrance. The wire ropes are secured to the tunnel roof using wire rope clips, and then tension the steel wire ropes with a wire tightener. Suspend the flexible duct on the steel wire ropes using the hooks. This ensures that the duct section from the fan rack to the tunnel entrance is straight, level, and free of twists or folds.

Suspension technology for ventilation duct in main tunnel

Firstly, determine the installation position of the duct within the tunnel cross-section. Typically, the duct is installed along the centerline of the tunnel vault or adjusted to the left or right side based on the position of the reserved duct passage openings in the formwork trolley. It is recommended to arrange the duct along the centerline of the tunnel vault, as it allows for the installation of larger-diameter ducts or multiple parallel ducts49,50. When pre-ordering formwork trolley in later stages, ensure that the passages for duct are reserved at the vault centerline. Secondly, based on the designed duct installation position, determine the location of expansion bolts/reinforcing bars (typically M12 expansion bolts with a length of 12 cm are used). In order to ensure the ducts is installed straight and level, the observation window of the formwork trolley is the optimal choice as the installation position of expansion bolts/reinforcing bars. The installation spacing of expansion bolts/reinforcing bars as follows:

-

1.

For ducts with diameter < 1.5 m, the expansion bolts are installed at 5-meter intervals.

-

2.

For ducts with diameter ≥ 1.5 m, reduce the spacing to 3-meter intervals.

After installation, weld duct hooks to the tail ends of the bolts/reinforcing bars, as illustrated in Fig. 5.

Then, according to the installed position of the expansion bolts, install steel wire ropes (generally φ8mm steel wire ropes). The wire ropes are divided into two sections: the first section is from the formwork trolley to the tunnel entrance, and the second section is from the formwork trolley to the tunnel face.

The first section of the steel wire rope is a continuous rope that is fixed in place as the formwork trolley advances. The wire rope is secured to the foremost bolt using wire rope sleeves and clamps. At the rear part, a steel wire rope with a diameter of 8 mm is used as the suspension line, which is straightened and anchored to hooks. The clamping buckles on the duct are then fastened to the wire rope laid in advance to ensure that the flexible duct maintains a straight line as a whole. The second section of the steel wire rope is installed every 15 m. It is knotted with wire rope sleeves and fixed on the hooks to prevent the sleeves failure and detachment of the entire duct. Fasten the locking buckles on the duct to the wire rope laid in advance, then straighten and fix it to expansion bolts.

There are two essential points: Firstly, determine the positions of the hanging points required for suspending the ventilation duct and accurately snap a longitudinal line along these points to ensure that the duct is laid straight along the longitudinal direction of the tunnel. Additionally, after leveling the wire ropes, fix them to the hooks with iron wires to ensure that the duct is hung straight in the height direction of the tunnel. The above two points are critical for maintaining the duct hanging flat and straight, and serve as a guarantee for reducing the ventilation resistance and preventing the duct damage. To suspend the ducts on the installed steel wire ropes, first attach the hanging rings on each single section duct sequentially into the buckles laid in advance on the wire ropes. Then connect adjacent duct sections with the zipper and install all ducts in sequence. After the ducts are hung, readjust the entire duct line starting from the fan outlet to ensure the whole duct remains straight and level.

Ventilation duct passing through construction trolley technology

In drill-and-blast tunnel construction, the secondary lining must closely follow the excavation face to satisfy the safety distance requirements. Consequently, the lining formwork trolley needs to advance longitudinally along the tunnel with the construction progress. Meanwhile, the duct must sequentially pass through the curing trolley51, secondary lining trolley52 and waterproofing board trolley53. It is common to route the duct through the side drainage ditches of the inverted tunnel arch, through the gaps in the top framework of the lining trolley or through the spaces between the lining trolley framework and the triangular inclined bracing since the traditional ventilation duct traversing construction trolley process lacks the dedicated channel. When passing through these trolleys, a common scheme is to reserve a section of duct without hanging, including both the section passing through trolleys and the section normally connected to the tunnel lining. This facilitates the movement of secondary lining trolley and waterproofing board trolley, reducing the time occupied by the duct rerouting during the trolley relocation54. However, the scheme has the following significant shortcomings:

-

1.

If the position of the duct reserved on the trolley does not match the suspension position or dimensions of the duct in the main tunnel, axial bending as shown in Fig. 6a or radial compression as shown in Fig. 6b will occur when ducts pass through the construction trolley, resulting in severe scraping and air leakage. Even if holes with the same diameter as the ventilation duct are reserved on the construction trolley, the suspension arrangement of ventilation ducts in front of and behind the construction trolley requires to be adjusted whenever the trolley is moved. And each adjustment requires that the ventilation is suspended to facilitate the operation. (During normal operation, the whole ventilation duct is in a high-pressure expanded state due to high internal air pressure. Therefore, stopping the air supply is necessary to make the duct soft enough for hanging adjustments55). The operation significantly affects the ventilation efficiency at the tunnel face and the ventilation fabric is often scratched and torn due to the movement of the construction trolley, causing air leakage.

-

2.

Excessive bending occurs in slack sections of the duct ahead of and behind the construction trolley, as illustrated in Fig. 6(c) and (d). In some cases, the slack sections of the duct even require to be bent three to four times before passing through the construction trolley, leading to extremely high local wind resistance of the duct. Meanwhile, the duct accumulates near the construction trolley, where it suffers severe damage with a high air leakage rate.

The above defects result in most of the air volume being lost after traversing the trolley, which fails to improve the air quality in the tunnel face and increases the energy consumption of the fan. Therefore, in order to ensure that the ventilation duct maintains a straight, smooth and undamaged state when traversing the construction trolley, the position, shape and dimension of the duct reserved holes are designed in advance during the construction trolley manufacture based on the suspension position and diameter of the main tunnel duct, and protective and guiding devices are installed additionally.

Yang Guanfei et al.56 install 2 ~ 3 protective positioning devices on the construction trolley as depicted in Fig. 7. The ventilation duct passes through the rigid conveying pipe (protective pipe) inside the device, preventing damage to the duct during the trolley movement. Additionally, the trumpet-shaped guide pipes are set at both ends of the conveying pipe to facilitate the stability of the duct to pass in and out. The 2 ~ 3 protective positioning devices are linked through a transmission shaft connected to the middle of gears. One device is equipped with a stepping motor on its outer wall. One of the short shafts is driven to move by activating the stepping motor, causing the spur gears and bevel gears to rotate and driving the rotation of the remaining protective positioning devices to achieve the positioning of the conveying pipe and adapt to ventilation ducts of different sizes. However, this device is difficult to implement on-site, and the duct still experiences sliding friction within the protective device, which is prone to damaging the duct fabric. In addition, the design neglects how the duct transitions between adjacent construction trolleys.

Zhu Rongjun et al.57 install a duct protection device as illustrated in the Fig. 8 on the construction trolley. The inner wall of the device is equipped with multiple sets of rollers, allowing the tunnel duct to convert from the original rigid friction to the sliding friction when the ventilation duct passes through the device. This innovation significantly reduces the friction force experienced on the duct and the probability of air leakage to ensure the air circulation and quality in the tunnel. In order to prevent tunnel dust form depositing in the roller mechanism and causing the rollers to fail to rotate, the fixed bristles are installed on the outside of the rollers and an air supply mechanism is set in the middle of the rollers. The fixed bristles block dust from depositing inside the rollers during the duct passage and the air supply mechanism utilizes high-pressure gas injection to drive the rollers to rotate. Meanwhile, the dust deposited at the roller mechanism can be purged by airflow.

Wang Juntao et al.58 install the guided pipe with the multi-pulley assemblies in the reserved ventilation duct holes of the construction trolley, as shown in Fig. 9. When the lining trolley moves, the multiple sets of pulleys on the guided pipe of the tunnel lining trolley move relative to the flexible ventilation duct, replacing the original sliding friction with rolling friction to eliminate abrasion during duct traversal. Additionally, curved sections and guide sections with pulleys are set at the front and rear of the lining trolley, which avoids the bending and wrinkling of the ventilation duct when entering and exiting the construction trolley. This design drastically reduces resistance between the duct and guided pipe, enabling smooth and stable traversal of the duct through the construction trolley while extending its service life.

However, there are practical challenges in application for the above protective devices. Firstly, The operation that the ventilation duct passes through two consecutive bent and largely enclosed guide sections and curved sections before and after the construction trolley is highly difficult. Additionally, the longitudinal dimensions of the two extended sections are relatively large to result in the large weights and the overhangs are eccentric structures. The guide pipe will be twisted or deformed if no supporting frames or hoisting structures. Secondly, since the axis position of the guidance section and the entry or exit points are fixed, the ventilation duct is damaged by pulling force exerted between the suspension points and the guidance pipe when the position of trolley deviates from the next nearest suspension point.

Yang Xinmin et al.59 improve the scheme shown in Fig. 10 by transforming the curved and guidance sections of the ventilation duct entering and exiting the construction trolley from an integral protective pipe into two split-type transit guidance devices. As illustrated, each device consists of a base and two transit guidance units. The base is connected to the vertical columns of the construction trolley as a structural support and its height is adjustable. And the transit guidance units comprise an adjustable support, an outer deflecting body and an inner deflecting ring. The adjustable support is connected to the base and is laterally adjustable within a certain range. The outer deflector body is rotationally connected to the adjustable support along the first axis, while the inner deflection ring is rotationally connected to the outer deflector along the second axis which is perpendicular to the first axis. Multiple pulleys are arranged on the inner side of the inner deflecting ring and are in contact with the outer surface of the ventilation duct. This configuration greatly preserves the flexible deformation ability of the duct, enabling it to more effectively support and guide the curved section of the duct passing through the construction trolley. Moreover, by dynamically adjusting the angle and position of the transit guidance device, the system adapts to the changes in the height and horizontal positions of the duct suspension points, or accommodates the temporary adjustments to the lateral duct position on the construction trolley.

Guo Yabin et al.60 install auxiliary ventilation duct suspension devices before and after the reserved duct holes at the top of the construction trolley. These devices employ the movable hanging rods to ensure that the duct maintains a smoother linear shape when entering or exiting the construction trolley, without bending and breaking, thereby reducing the local wind resistance, as depicted in Fig. 11. Within the movable hanging rod, the rod unit A is fixed at the top of the reserved hole on the construction trolley, while the rod unit B is anchored to the expansion bolts or the reinforcing bars at the tunnel vault. The rod unit A and B are connected by a connection plate. The rod unit A is joined to the connection plate using vertically arranged flange bolts, which controls the horizontal rotation of the rod unit (A) And the rod unit B is connected to the connection plate by horizontally arranged flange bolts, which allows the vertical rotation of the rod unit (B) The horizontal and vertical angles of the movable hanging rod are adjusted through the rod Units A and B to assure a smoother linear shape of the duct as it enters the secondary lining trolley and exits the waterproofing board trolley.

The above mentioned technologies for ventilation ducts traversing construction trolleys often adopt roller devices to reduce friction on the ducts. However, in the high-dust environment of drill-and-blast tunnels, the roller devices are highly susceptible to wear caused by dust accumulation, leading to degradation in the motion accuracy of the rollers, reduction in strength and even complete loss of ability to work. Consequently, full-time maintenance workers are assigned to inspect roller protection devices of the construction trolley each shift. If issues such as dust blockage or roller wear are detected, they should be handled immediately. For slight blockage of roller devices, high-pressure air nozzles are used for dust removal, followed by adding lubricating oil to provide lubrication for the friction surfaces of components and extend their service life. When phenomena such as wear, scratches or dust appear on the roller surfaces, the damaged parts are repaired or replaced in a timely manner.

Comparison and discussion

Comparison of connection technologies between fans and ducts

The traditional connection technology between fans and ducts generally adopt the multiple strands of soft iron wire binding process. Although this approach provides initial sealing, there are risks that the interface become loose easily resulting in air leakage, and that the iron wire may puncture the duct. In comparison, the new duct adapter technology offers a better solution. The reserved tensioning belt adapter designed for flexible ventilation ducts has the advantages of good sealing at the high-pressure interfaces and significantly reducing the risk of duct rupture. The reserved bolt hole adapter designed for rigid ventilation ducts create a pressure buffer zone to resist high-pressure impacts while providing higher durability for rigid connections.

Comparison of ventilation duct passing through construction trolley technologies

The traditional technology for ventilation ducts to pass through construction trolleys typically involves threading the ducts through side ditches, gaps in the top frame of the trolley or diagonal bracing spaces. This method causes serious bending, damage and air leakage of the duct, and significant construction interference. The comparative advantages and implementation challenges of several ventilation duct passing through construction trolley technologies mentioned in this paper are compared and explained in detail in Table 1.

Conclusion

Through comprehensive investigation of the installation and maintenance techniques for ducts in drill-and-blast tunnel construction, the following are the main highlights of the paper:

-

(1)

The connection between construction fans and ducts can adopt the duct adapters with pre-installed tension straps or pre-drilled bolt holes, which effectively prevents duct damage caused by excessive air pressure at the fan outlet or air leakage at the connection points.

-

(2)

The suspension system for the ventilation duct from the fan frame to the tunnel entrance is achieved by installing two φ12mm steel wire ropes along the portal, tightening them with a wire tightener, and then suspending the flexible duct on the wires using hooks to ensure that the duct in this section is hung flat, straight and free of twisting or wrinkling.

-

(3)

The suspension of ventilation ducts in the main tunnel generally prioritizes the vault centerline position to accommodate larger dimensions and a greater quantity of ducts, and it is necessary to reserve duct passage openings in advance when ordering the construction trolley. During installation, a longitudinal line should be snapped along hoisting points, and after adjusting the steel wire ropes to be horizontal, they should be fixed to the duct hooks. These ensure that ducts are straight in both height and longitudinal direction, so as to reduce air resistance and minimize the risk of duct damage.

-

(4)

Measures such as optimizing the position, shape and dimensions of reserved ventilation duct holes on the construction trolley, installing protective sleeves and guide tubes, and equipping multiple rollers on the sleeve walls to replace the sliding friction with the rolling friction can effectively prevent abrasion and scraping of the ducts when passing through the construction trolley.

Data availability

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

References

X. Chen, D. Zhang, Z. Sun, et al; Extrusion prediction of tunnel face reinforced with fiberglass bolts considering interface debonding. Physics of Fluids 1 March 2025; 37 (3): 036611.

Zhang, X., Wang, Z. & Chen, W. Optimisation of synergistic ventilation between dust and gas in a gas tunnel. Sci. Rep. 14, 27582 (2024).

Fu, S. et al. Study of harmful gas migration law and influencing factors after tunnel blasting in high-altitude tunnels under push ventilation conditions. Sci. Rep. 15, 8785 (2025).

Wang, J. et al. Head-neck local ventilation mode for long-narrow mine working face. Sci. Rep. 14, 19663 (2024).

Huang, R., Shen, X., Wang, B. & Liao, X. Migration characteristics of CO under forced ventilation after excavation roadway blasting: A case study in a plateau mine. J. Clean. Prod. 267, 122094 (2020).

Raaschou-Nielsen, O. et al. Traffic air pollution and mortality from cardiovascular disease and all causes: a Danish cohort study. Environ. Health Glob Access. Sci. Source. 11, 60 (2012).

Li, C., Jiang, Z., Zhang, G., Feng, X. & Zeng, F. Dust pollution during shotcrete process in high-altitude tunnel based on numerical simulation. Particuology 75, 82–95 (2023).

Sun, Z. & Gou, H. Comments on equipment selection for ventilation during Long-distance Dead-end tunneling. Tunn. Constr. 34, 408–412 (2014).

Lie, R. The application of pressure tunnel ventilation technology in long tunnel construction. SX Arch. 43, 164–165 (2017).

Wang, W., Wang, Y. & Shi, G. Waveband selection within 400–4000 cm^-1 of optical identification of airborne dust in coal mine tunneling face. Appl. Opt. 55, 2951 (2016).

Yang, W. et al. A hybrid ventilation scheme applied to bidirectional excavation tunnel construction with a long inclined shaft. J. Cent. South. Univ. 31, 3187–3205 (2024).

Wei, N., Zhongan, J. & Dongmei, T. Numerical simulation of the factors influencing dust in drilling tunnels: its application. Min. Sci. Technol. China. 21, 11–15 (2011).

Xie, Z. et al. Numerical research on airflow-dust migration behavior and optimal forced air duct installation position in a subway tunnel during drilling operation. Powder Technol. 388, 176–191 (2021).

He, D. et al. Energy saving in metro ventilation system based on multi-factor analysis and air characteristics of piston vent. Appl. Energy. 307, 118295 (2022).

Wu, B., Chen, H. & Huang, W. Optimization principle and application of forced ventilation in railway tunnels based on improved TOPSIS theory and CFD simulations. Adv. Mech. Eng. 13, 16878140211017613 (2021).

Ji, Y. et al. Optimization of ventilation efficiency in tunnel-type underground spaces using response surface methodology: a case study of Yunlong mountain civil defense in Xuzhou. Sci. Rep. 14, 22989 (2024).

Wang, J., Xue, Y., Xiao, J. & Shi, D. Diffusion characteristics of airflow and CO in the Dead-End tunnel with different ventilation parameters after tunneling blasting. ACS Omega. 8, 36269–36283 (2023).

Study on the utilization of non-mechanical ventilation power in extra-long highway tunnels with shafts. J. Wind Eng. Ind. Aerodyn. 221, 104909 (2022).

Zhou, Y., Yang, Y., Bu, R., Ma, F. & Shen, Y. Effect of press-in ventilation technology on pollutant transport in a railway tunnel under construction. J. Clean. Prod. 243, 118590 (2020).

Wang, J., Chen, Q. & Tian, W. Research and application of construction ventilation design for long incline shaft and Extra-long tunnel. Highw 69, 416–424 (2024).

Guo, W. et al. Numerical simulation study on ventilation optimization design of Extra-Long Double-Line mountain tunnels with parallel heading: a case study. Appl. Sci. 12, 12416 (2022).

Pu, Q. et al. Simulation study on the effect of forced ventilation in tunnel under single-head drilling and blasting. Shock Vib. 2020, 8857947 (2020).

Mei, M. et al. Large-scale mechanized construction technology of Extra-long highway tunnel with Full-section drilling and blasting. Tunn. Constr. 53, 49–54 (2024).

Konorev, M. M. & Nesterenko, G. F. Present-Day and promising ventilation and Dust-and-Gas suppression systems at open pit mines. J. Min. Sci. 48, 322–328 (2012).

Jena, M. C., Mishra, S. K. & Moharana, H. S. Experimental investigation on power consumption of an industrial fan with different flow control methods. Environ. Prog Sustain. Energy. 39, 13237 (2020).

Numerical study on the mean velocity distribution law of air. Backflow and the effective interaction length of airflow in forced ventilated tunnels. Tunn. Undergr. Space Technol. 46, 104–110 (2015).

Chang, X., Chai, J., Liu, Z., Qin, Y. & Xu, Z. Comparison of ventilation methods used during tunnel construction. Eng. Appl. Comput. Fluid Mech. 14, 107–121 (2020).

Feng, X., Jiang, Z., Zhang, G., Luo, X. & Zeng, F. Study on CO diffusion law and concentration distribution function under ventilation after blasting in high-altitude tunnel. J. Wind Eng. Ind. Aerodyn. 220, 104871 (2022).

Zou, Z., Hu, X., Yuan, Y. & Chen, J. Monitoring study on CO and dust diffusion in high altitude tunnel under blasting operation. IOP Conf. Ser. Mater. Sci. Eng. 741, 012111 (2020).

Chang, X. et al. Tunnel ventilation during construction and diffusion of hazardous gases studied by numerical simulations. Build. Environ. 177, 106902 (2020).

Numerical investigation on temperature–humidity field under mechanical ventilation in the construction period of hot-humid tunnel along the Sichuan–Tibet railway. Undergr. Space. 8, 123–143 (2023).

Cepa, J. J., Pavón, R. M., Caramés, P. & Alberti, M. G. A review of gas measurement practices and sensors for tunnels. Sensors 23, 1090 (2023).

Zosel, J., Oelßner, W., Decker, M., Gerlach, G. & Guth, U. The measurement of dissolved and gaseous carbon dioxide concentration. Meas. Sci. Technol. 22, 072001 (2011).

Menéndez, J. et al. Auxiliary ventilation systems in mining and tunnelling: air leakage prediction and system design to optimize the energy efficiency and operation costs. Tunn. Undergr. Space Technol. 140, 105298 (2023).

Numerical study of modeling methods and evaluation indexes for jet fans. Build. Environ. 206, 108284 (2021).

Zhang, Z., Zhang, H., Tan, Y. & Yang, H. Natural wind utilization in the vertical shaft of a super-long highway tunnel and its energy saving effect. Build. Environ. 145, 140–152 (2018).

Large Eddy Simulation of effectiveness of solid screen. On improving natural ventilation performance in urban tunnels. Tunn. Undergr. Space Technol. 86, 174–185 (2019).

Wei, J., Xu, X. & Jiang, W. Influences of ventilation parameters on flow field and dust migration in an underground coal mine heading. Sci. Rep. 10, 8563 (2020).

Tao, Y. et al. A new ventilation system for extra-long railway tunnel construction by using the air cabin relay: a case study on optimization of air cabin parameters length. J. Build. Eng. 45, 103480 (2022).

Cao, Z. Study on ventilation characteristics and key technologies of long tunnels and complicated underground engineering in the construction stage (Southwest Jiaotong University, 2016).

Wang, Y. et al. Road tunnel axial fan performance in situ test: taking qinling zhongnan mountain highway tunnel as an example. Math. Probl. Eng. 2019, 7036538 (2019).

Liu, J. et al. Theoretical prediction on supply air performance and CO Dilution effect of the pressed-in ventilation system during the construction period. Tunn. Undergr. Space Technol. 157, 106304 (2025).

Szelka, M., Woszczyński, M., Jagoda, J. & Kamiński, P. Wireless leak detection system as a way to reduce electricity consumption in ventilation ducts. Energies 14, 3774 (2021).

Dai, H. K. et al. Investigation of pressure drop in flexible ventilation ducts under different compression ratios and bending angles. Build. Simul. 14, 1251–1261 (2021).

Francoeur, M., Bowling, J. R. R. & McFadden, A. Extensive Duct-Fan systems with In-line booster fans: planning for partial vacuum and an algorithm for In-line booster fan positioning. Min. Metall. Explor. 39, 947–959 (2022).

Nie, W. et al. The effects of ventilation parameters on the migration behaviors of head-on dusts in the heading face. Tunn. Undergr. Space Technol. 70, 400–408 (2017).

Rusinski, E., Czmochowski, J., Moczko, P. & Pietrusiak, D. Monitoring and testing of high power industrial fans vibration. Procedia Eng. 199, 2190–2195 (2017).

Zhou, X. A tunnel construction fan. Case Stud. Therm. Eng. 2021, 7 (2021).

Bai, J. et al. Influence of ventilation duct parameter optimization on pollutant diffusion in spiral tunnels. Sustainability 14, 10540 (2022).

Xiao-zhen, W. Anlysis of dust concentration influence factor in coal roadway driving. J. Saf. Sci. Technol. (2011).

Fan, S. Design and application of intelligent tunnel spray maintenance trolley. Die Mold Manuf. 25, 216–218 (2025).

Chen, Q. Design analysis and application of large cantilever portal Pre-stressing cap beam support. Val. Eng. 44, 95–97 (2025).

Zhou, Z. Application of automatic waterproof board welding trolley technology in tunnel construction. Stn 2023, 37–39 (2023).

Yang, L. A new method for ventilation duct to pass formwork and waterproofing membrane stand. Mod. Tunn. Technol. 2011, 60–62 (2001).

Ai, Z. T. & Mak, C. M. Pressure Losses across Multiple Fittings in Ventilation Ducts. Sci. World J. 2023, 195763 (2013).

Yang, G. et al. A ventilation device for tunnel construction trolleys. Sustainability 2022, 8 (2022).

Zhu, R. et al. A tunnel ventilation duct support structure and a tunnel construction trolley. Sustainability 15, 5263 (2024).

Wang, J. & Liu, G. A tunnel lining trolley with smooth passage for ventilation ducts. Sustainability 2025, 23 (2025).

Yang, X. et al. A tunnel lining trolley that maintains the smooth passage of ventilation ducts (2022).

Guo, Y. et al. A duct auxiliary suspension device for tunnel construction ventilation passing through the construction trolley 7 (2024).

Funding

This work was sponsored by the National Natural Science Foundation of China (No. 51508556, 42172319, 41771083); Science and Technology Program of China Academy of Railway Sciences (No. 2023YJ339); Sichuan Science and Technology Program (No. 2023ZDZX0029);Chengdu Science and Technology Program (No. 2022-XT00-00002-GX).

Author information

Authors and Affiliations

Contributions

Hongbo Zhao: data curation, image processing, writing—review and editing; Xu Wang: writing—original draft, image processing, funding acquisition; Benguo He: study conception and design, supervision, writing—review and editing; Gan Feng: writing—review and editing; Zhenyu Sun: data collection. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhao, H., Wang, X., He, B. et al. Research progress on installation and maintenance techniques of ventilation ducts in drill-and-blast tunnel construction. Sci Rep 15, 34914 (2025). https://doi.org/10.1038/s41598-025-18821-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-18821-1