Abstract

In the context of the global promotion of net zero emissions, the mining industry is confronted with a substantial transformation. This paper focuses on the value system that has undergone changes following the low-carbon transformation of mines as the core research object, and conducts an in-depth analysis of the various impacts of low-carbon development on the industrial structure of mines, encompassing the enhancement of resource utilization efficiency and the transformation of product structure. The new value system relinquishes the production mode that solely focuses on economic interests as the sole guide and places great emphasis on the synergy between environmental benefits and social benefits. Based on this transformation of the value system, a green value chain model is constructed to assess the value of mines. Simultaneously, taking a specific gold mine in Shandong as an example, the carbon reduction measures for the utilization of solid waste resources, along with their practical application effects and economic benefits, are analyzed in depth to provide a reference for the optimization of the marginal grade of mines. By integrating the green elements in the value chain, the efficient utilization of resources and the minimization of environmental impact can be genuinely achieved, paving a new way for the sustainable development of mines and providing solid theoretical support and practical guidance for promoting the transformation and upgrading of the mining industry in the low-carbon era.

Similar content being viewed by others

Introduction

The significant increase in metal mining volume and its inevitable trend of sustained development indicate that the environmental pressure and related impacts of metal mines have become a global issue. Especially in the mining process of non-ferrous metal mines, environmental issues such as carbon dioxide emissions and land occupation are particularly prominent1. These issues not only affect the ecological environment, but also have profound impacts on society and the economy. For mines, environmental, social, and governance issues are not limited to a specific link in the mining lifecycle, but run through various stages of the entire lifecycle2.

In the context of global net zero emissions, the structure of the mining industry has undergone a transformation, shifting from relying on high-carbon energy to embracing green development. This change has led to an increase in the green and low-carbon value related to the environment in the mine value, rendering the mine value system based primarily on output and economic income no longer applicable. Therefore, the mine value needs to be reorganized and recalculated. Currently, how to accurately calculate the mine value in the context of low carbon has become an urgent issue to be addressed.

Value accounting has a significant impact on mining enterprises, mainly reflected in the assessment of resource value and decision-making in production and operation. At present, domestic and foreign scholars mainly adopt methods such as cost calculation, value increment, and comprehensive evaluation3,4. By calculating the cost of production activities, the value increment in each stage of production, and considering the influence of multiple factors on the value of mining enterprises, the mining value accounting was studied. Many scholars have used the calculation of economic value and the cost of the value chain as the basis for measurement to solve problems, and can further increase the value of products by improving the degree of greenness and establishing the value chain5,6. Julian M. Ortiz et al. proposed that all links from mineral deposit mining to final product consumption and waste stream treatment should be taken into account to maximize the value of mine operations and reduce its impact on the environment and society7. Among them, tailings, as an important by-product of mines, have obvious raw material potential in the transformation of the mining industry to low-carbon and green development, but the obstacle of establishing a complete value chain needs to be overcome to bring new value to mines8. The use of mine waste as building materials also has the potential to enhance the value of the circular economy and enable green mining activities9. Zhaoyang Ma et al. constructed the ore value chain model through Petri net and conducted cost analysis on gold mining enterprises to realize the fine evaluation of the formation, flow, transfer, and realization of ore value10.

Analyzing the impact of different production activities on the environment under the background of low-carbon policies and studying the impact of the generated environmental value on the overall value of enterprises is of great significance. A. Paat et al. used the fuzzy analytic hierarchy process to assess the environmental, social, and governance risks involved in mining operations, and the results showed that ecological environmental risks were considered key factors by all stakeholder groups11. Kari - Anne Lyng et al. constructed the BioValueChain model to quantify and analyze the environmental impact of different links to calculate the total environmental impact of the value chain4. Yoshito Izumi et al. established a carbon cycle system in the value chain of product production to reduce carbon dioxide emissions during the product production process12. Reiner Wassmann et al. studied the carbon emissions of the product value chain and found that the carbon footprint can be significantly reduced by improving the product recovery rate and reducing resource loss13.

In summary, most of the current studies on enterprise value accounting only focus on one aspect, and there are few studies on the overall enterprise value accounting that integrates production costs and environmental factors, as well as the impact of different factors on enterprise value. Moreover, mining enterprises have not yet formed a unified quantitative method for environmental benefits, ignoring the cost of mine carbon emissions and the economic and environmental benefits brought by carbon emission reduction measures. Therefore, this paper comprehensively and systematically sorts out the mine value by constructing the mine green value chain model, studies the quantification method of the production cost, carbon emission cost, and environmental benefit of mining enterprises under the background of net zero emissions, and takes a gold mine in Shandong as the actual engineering background to systematically and comprehensively calculate the value of mining enterprises to obtain its value distribution, so as to provide a reference for optimizing resource allocation and improving the utilization efficiency of resources, and provides a value accounting model and method for the production planning of other similar enterprises.

Green extension and expansion of the mining value chain

The traditional mining mode in mines mainly relies on extensive production, overly pursuing the maximization of economic benefits, often neglecting the impact of carbon emissions on the environment, which can lead to land and air pollution as well as resource waste14,15. With the government advocating for green and low-carbon production modes, requiring mines to achieve carbon emission control on the basis of economic benefits, the mining value chain has undergone significant changes. The main production chain of the mine mainly includes the links of ore drilling, mining, transportation, hoisting, ore processing, etc., and incorporating the impact of mine carbon emissions and carbon reduction measures into it means extending and expanding the value chain, reducing environmental pollution, and increasing economic benefits.

-

(1)

The extension of the main production chain. In traditional mining production, waste rock and tailings are often regarded as “waste” and discarded indiscriminately. However, with the rise of the green concept, these wastes are now redefined as potential resources. After processing and utilization, these wastes can be transformed into building materials, industrial raw materials, etc., realizing the rational utilization of resources and extending the value chain to the stage of resource recycling and utilization.

-

(2)

The expansion of the value chain. Traditional mining operations often neglect the environmental impact of mining production. However, in the context of green and low-carbon development, mining companies are beginning to prioritize carbon emissions and the rational utilization of resources. Building a green value chain for mines requires not only considering how to reduce carbon emissions but also pondering the environmental impact brought by the optimized allocation of resources, comprehensively promoting the low-carbon development of mines.

-

(3)

Reducing environmental pollution. Traditional mining operations often exhibit irresponsible behavior towards the environment, leading to significant environmental pollution. With the resource utilization of waste, mining companies have reduced land occupation, increased carbon sinks, and decreased pollution to the surrounding soil and atmosphere, thereby improving environmental quality and achieving green sustainable development.

-

(4)

Increasing additional economic benefits for mines. The resource utilization of solid waste from mines not only benefits the environment but also brings additional economic benefits to mining companies. For example, selling the processed waste rock and tailings can provide raw materials to other enterprises, creating additional profits, promoting the coordinated development of the industrial chain, and enhancing the economic benefits of the mine.

Based on the above analysis, this study proposes a research framework for an underground mine green value chain that covers the entire process, including gold mining, mineral processing, waste rock utilization, and tailings utilization. The activity-based costing method is applied to perform cost accounting for the main chain of the green value chain, with the inclusion of carbon emission costs, thereby developing a mine cost accounting model to achieve quantitative evaluation of the green value chain in gold mining. The effectiveness of the model is validated through a case study, and the resource utilization pathways for waste rock, tailings, and other solid wastes are comprehensively analyzed. From the perspective of economic feasibility, the comprehensive utilization benefits are evaluated to enhance resource utilization efficiency and promote the green and sustainable development of mining operations. The specific research framework is shown in Fig. 1.

Construction of the green value chain model

The main production chain of the mine only includes the production process and value realization process of the ore, and with the improvement of environmental quality demand, the mine is optimized on the basis of the main production chain. The green value chain considers environmental factors in every operation link of the value chain, and builds a new green value chain with ore, waste rock, tailings, and carbon quotas as products, centered on the environment and resources, to achieve the extension and expansion of the value chain, reduce environmental pollution, and increase economic benefits. From the perspective of the value chain, the consumption of materials, equipment, power, and manpower in mines is grouped into the value input stage, the production of mineral products belongs to the value creation stage, the sale of mineral products belongs to the value transfer stage, and the consumption of mineral products marks the final stage of value realization16. The mine green value chain thus constructed is shown in Fig. 2.

(1) Traditional ore chain

The main production chain of the mine, including the processes of excavation, mining, transportation, hoisting, ore processing operations, and the sale of concentrate, has a relatively simple product, which is a value chain with ore as the product. Mining enterprises mainly focus on the costs of mining, mineral processing, and other production links, using activity - based costing for cost accounting, and regarding the sale of concentrate as the main source of income. Products such as waste rock and tailings are treated as insignificant waste, and the resulting pollution of the surrounding land and air is often ignored.

(2) Green additional chain

By analyzing the traditional ore chain of mining enterprises and taking the waste and carbon emissions of mine production as the entry point, this paper reasonably introduces some additional chains. Taking the tailings and waste rock and carbon emissions produced in the traditional ore chain as the raw materials of the additional chains, and by analyzing the source of solid waste, the process of processing and utilization, the generation and absorption of carbon emissions, and the process of realizing the value of each product, it is possible to construct a green additional chain, thus forming a complete green value chain.

(1) Waste rock additional chain

During mine production, waste rock is generated in the processes of drilling and mining and is transported to the surface through transportation and hoisting operations. By comprehensively analyzing the direction of waste rock, it is possible to reuse mine waste and form an additional chain of waste rock. This additional chain mainly includes the links of drilling, mining, transportation, hoisting, waste rock processing and utilization, and waste rock product sales, etc. The processed waste rock resources are sold to customers in the construction, road construction, and other industries, reducing the mining land occupation and bringing economic value to the mining enterprise at the same time.

(2) Tailings addition chain

Mines generate tailings in the ore processing operation. The tailings are processed to be filled in the goaf or transformed into useful building materials and industrial raw materials17,18 to achieve waste reduction and resource reuse. According to the resource utilization of tailings, a tailings additional chain is constructed, which includes the links of ore processing operations, tailings processing and utilization, and tailings product sales, reducing the mining land occupation and bringing economic value at the same time.

(3) Carbon emission chain

In the mining process, mechanical equipment usually requires the use of fossil fuels such as diesel, gasoline, and explosives, and a large amount of electricity is needed for the lighting and electrical equipment in the mine. The burning and consumption of these energy sources is the main source of carbon emissions in the mine. If the carbon emissions of the mine exceed the specified carbon quota, the mine needs to purchase carbon quotas to avoid potential fines or legal liabilities due to non - compliant emissions, thereby protecting its value. When the carbon emissions of a mine are below the specified carbon quota, the mine can earn additional revenue by selling carbon quotas to convert the accumulated carbon reductions into economic value. The resource utilization of waste rock and tailings reduces land occupation, protects and increases the vegetation on the land, and thus increases the carbon sink. The carbon sink can be converted into economic value through the carbon trading market price, bringing additional income to the enterprise.

Accounting for green and Low-carbon value

In order to calculate the mine value systematically and comprehensively, it is necessary to first determine the scope of the green and low-carbon mine value accounting, then classify the production activities that generate value, and finally calculate the mine value by parts according to the classification. Starting from the economic value, the cost of mine production input and carbon emission is calculated first to determine the distribution of mine value, and then the economic and environmental value brought by carbon reduction measures to improve resource utilization and surface vegetation restoration, such as the increase of vegetation carbon sink and land resources, is calculated to lay the foundation for the green and sustainable development of mines. Through these steps, the value of mine green value chain model is fully quantified, and the win-win situation of the economy and the environment in mines is promoted.

Scope of green and Low-carbon value accounting

Under the current dual promotion of global economic and environmental policies, the green and low - carbon transformation of the mining industry has become a key path to achieving sustainable development. During this transition, the traditional accounting of mine production costs remains a central theme, but the environmentally relevant costs of carbon emissions also need to be taken into account. This involves not only the investment required to reduce greenhouse gas emissions but also the potential cost savings from adopting environmentally friendly processing methods. In addition, mining companies need to assess the impacts of their activities on land resources, so the scope of mine value accounting is gradually expanding, as shown in Fig. 3.

-

(1)

Mine production cost: Mine production cost mainly calculates the cost of labor, power, equipment, materials, and other inputs consumed by mine production operations, including drilling, mining, transportation, hoisting, ore processing operations, and the processing and utilization of waste rock and tailings.

-

(2)

Carbon emission cost: It mainly calculates the carbon emissions generated by the consumption of diesel, gasoline, explosives, and electricity in the mine, multiplies the carbon emissions by the carbon trading price, internalizes the external cost of carbon emissions, and obtains the economic cost incurred by the mining enterprise due to carbon emissions19,20.

-

(3)

Environmental benefits: The environmental benefits of the mine mainly include the carbon sink generated by the reduction of land occupation and the green economic value brought by the reduction of land expropriation.

Carbon sinks: After the resource processing of solid wastes, it is no longer necessary to build tailing ponds and discharge sites, which reduces the damage to agricultural land or other natural landscapes. The amount of carbon dioxide absorbed and stored by vegetation from the atmosphere is calculated and multiplied by the price of carbon trading, which gives the green economic value of the carbon sinks of vegetation.

Land resource benefits: The utilization of tailings and waste rock resources avoids the need for new land development, while saving the costs associated with land acquisition.

Accounting model

Production costing model

In order to more accurately account for the cost of each link in the green value chain of mines, this paper adopts the activities-based cost method for cost accounting, where direct cost expenses are directly included in the total cost, and indirect cost expenses are apportioned to the operation center by the standard of resource motive, and then apportioned to the products by the standard of job motive21. The specific apportionment steps are shown in Fig. 4.

Let a firm produces m (\(i=1,2, \ldots ,m\)) products and there are n (\(j=1,2, \ldots ,n\)) operation centers. Then the costing relationship equation for overhead costing of mineral products is as follows.

Related symbols are explained as follows. \({c_i}\) represents the cost of i product; \({d_{ij}}\) represents the amount of cost driver consumed by product i in operation center j; \({r_j}\) represents the cost driver rate of operation center j. Through the calculation of formula (1), the value-added value of mine production value-added operation can be finally obtained.

Carbon emission cost accounting

In accordance with the 2006 IPCC Guidelines for National Greenhouse Gas Inventories22, this study uses quantitative methods to calculate CO2 emissions from mining activities. According to the standard procedures presented in this document, the energy consumption of carbon emission sources is determined, and the carbon emission factor values provided by the IPCC corresponding to these activities are multiplied. The carbon emission data thus obtained are quantified in monetary terms through the carbon trading price in the market mechanism or the carbon tax price in policy tools, and then converted into specific economic cost indicators, which are used as a way to measure the environmental impact in the production process of mines. The calculation method is shown in formula (2)22.

Related symbols are explained as follows. c represents carbon emission cost, unit: RMB; i represents i carbon emission source, (\(i=1,2, \ldots ,n\)); \({F_i}\) represents the consumption of i carbon emission source, unit: t or kWh; \(E{F_i}\) represents the carbon emission factor of i carbon emission source, unit: t/t; P stands for carbon trading unit price or carbon tax price, unit: RMB/t.

Environmental benefit accounting

The carbon sinks generated by the mine production can be obtained by multiplying the carbon content of vegetation per unit area and the land area of solid waste deposited in the mine. Then, the carbon trading unit price in the market mechanism or the carbon tax price in the policy tool can be quantitatively processed in money, and then converted into specific economic cost indicators. The calculation methods are shown in formulas (3) and (4).

Related symbols are explained as follows. \({S_1}\) represents the monthly storage area of solid waste resources, unit: m2; s represents the area of the tailings pond or waste dump, unit: m2; v stands for the storage capacity of the tailings pond or the capacity of the dump, unit: t; \({V_1}\) represents the monthly production of solid waste resources, unit: t; \({C_1}\) represents the environmental benefits generated by vegetation carbon sink, unit: RMB; B represents carbon storage generated by vegetation per unit area, unit: \(tC\).

By collecting the monthly production of solid waste resources in the mine, calculating the monthly occupied area of solid waste resources, and calculating the land acquisition cost of land resources saved according to the local land area price of the mine, the calculation method is shown in formula (5).

Related symbols are explained as follows. \({C_2}\) stands for saving land resources expropriation costs, unit: RMB; \({P_1}\) represents the area price of land in the area where the mine is located, unit: RMB/m2.

The total environmental benefits of mine solid waste resource utilization can be obtained by adding the environmental benefits of carbon sinks and land resources saved.

Model validation

Case background

This paper takes an underground gold mining enterprise in Shandong Province as an example for analysis. The production process of this mine includes the links of drilling, mining, transportation, hoisting, ore processing, processing and utilization of waste rock and tailings, as shown in Fig. 5. For the production of waste rock, in the process of drilling and mining operations, the mine not only produces ore but also produces waste rock. Part of the waste rock is left underground for dry filling, while the rest of the ore is also transported to the surface through transportation and hoisting operations. A small part is transported to the tailings reservoir for building tailings dams, and a part is transported to the waste rock plant for making building materials. The stone and sand produced by the stone factory are first used for construction in the mine, such as slope road construction, etc., and the remaining products are for sale. Therefore, the mine does not have a dump site for waste rock, reducing part of the land occupation. The ore processing operation of the mine not only produces gold concentrate but also produces a large number of tailings. After the classification processing of the mine tailings, the coarse tailings are filled into the gob area or made into building materials for construction or sale in the mine, and the fine tailings are dry-drained after pressing and filtering, mainly sent to various village enterprises, quarry pits, etc., and a small part of the tailings are discharged to the tailing ponds. The processing and utilization of waste rock and tailings in the mine reduces the accumulation of waste, reduces the land area, reduces the pollution to the environment, and brings certain green value to the mine.

Cost accounting

Traditional ore chain cost accounting

Based on the actual cost data of the mine, the calculation results are summarized and shown in Table 1.

Activity-based costing was used for calculation, and the calculation results are shown in Table 2.

Through the allocation of various operational costs, it can be concluded that the value-added of mining drilling operations is 14.7681 RMB/t, that of mining operations is 257.0722 RMB/t, that of transportation operations is 83.9178 RMB/t, and that of hoisting operations is 27.5552 RMB/t. The value added in the ore processing operation is 71.5699 RMB/t, and the total value added in ore production is 454.8834 RMB/t.

Green additional chain cost accounting

In the mine, 45% of the coarse grade tailings are used for underground filling, and a small part of 55% of the fine grade tailings is stacked in the tailings pond, and the remaining part is dry drainage. The cost accounting of comprehensive utilization of tailings is shown in Table 3 below.

According to the calculation results in Table 3, it can be concluded that the total cost of comprehensive utilization of tailings is 53.1672 RMB/t, and for a unified standard, it is converted into the ore cost of 40.4093 RMB/t.

After processing, the mine waste rock can be sold as building materials. After processing, the waste rock can be divided into four products of different specifications: 1–3, 2–4, 0.5 stone, and stone sand. The cost accounting of comprehensive utilization of waste rock is shown in Table 4 below.

According to the calculation results in Table 4, it can be concluded that the total cost of comprehensive utilization of waste rock is 18.5781 RMB/t The sales price is 29.5399 RMB/t. For a unified standard, the cost is converted into the ore cost of 20.9471 RMB/t, and the sales price is 33.3066 RMB/t.

Carbon emission cost accounting

According to the analysis of each mine production operation, the carbon emission sources of each operation link are determined, as shown in Table 5.

The consumption of diesel, gasoline, explosives, and electricity is counted, and according to the calculation method in the 2006 IPCC Guidelines for National Greenhouse Gas Inventories20, the carbon emissions of each operation link of mine production can be calculated, as shown in Table 6.

Based on the calculation of carbon trading price of 45.61 RMB/t, the total carbon emission cost of mine production operation is 2.3447 RMB/t. According to the consumption of carbon emission sources in each link of the ore production value-added operation, the carbon emission cost is apportioned, and the carbon emission cost of each operation link of the ore production is shown in Table 7.

Combining Table 2 with Table 7, the total cost value of the ore production operation link can be obtained, as shown in Table 8.

Environmental benefits of solid waste resource utilization

Through literature search, the capacity and land area of different dumps are obtained. Since the accumulation density of waste rock is 2.7 t/m3, the land area per unit of waste rock volume and the average land area per unit of waste rock volume in the dump site can be calculated, as shown in Table 9 below.

According to the calculation in Table 9, it can be obtained that the land area of one ton of waste rock is approximately 0.00516 m2. The amount of waste rock in a gold mine in Shandong is about 710,045.70 t per month, and the block price of the area where a certain mining enterprise in Shandong is located is 74,000 RMB/mu. Based on the carbon trading price of 45.61 RMB/t, it is calculated through formulas (3)–(5) that the monthly cost of land acquisition for waste rock storage is 407,000 RMB, and the unit cost is 0.6463 RMB/t. The increased vegetation carbon sink cost due to the resource utilization of mine waste rock is 309.69 RMB, and the unit cost is 0.000492 RMB/t. Therefore, the total environmental benefit generated by the resource utilization of waste rock is 0.6468 RMB/t.

The storage capacity of the mine tailings reservoir is 30.52 million tons, the area is 271,120 m2, and the density of the tailings is 1.09 t/m3. Through formula (3)–(5), it is calculated that the monthly cost of land expropriation for the construction of tailings pond in the mine is 472,120 RMB, and the unit cost is 0.7497 RMB/t. The increased vegetation carbon sink due to the resource utilization of mine tailings is 359.41 RMB, and the unit cost is 0.000751 RMB/t. Therefore, the total environmental benefit generated by the resource utilization of tailings is 0.7505 RMB/t.

Analysis of results

Comparison of results

The data calculated in Sections “Traditional ore chain cost accounting”–“Environmental benefits of solid waste resource utilization” are statistically analyzed to obtain the comparison results of the monthly unit cost, profit, and carbon emission cost of the mining enterprise before and after the implementation of green and low-carbon measures, as shown in Table 10.

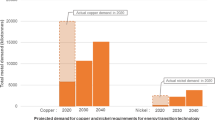

The traditional production chain only considers the links of ore drilling, mining, transportation, hoisting, ore processing and ore sales, and finally gets the total cost of ore mining is 458.6240 RMB/t, of which the ore mining cost is 454.8834 RMB/t, and the carbon emission cost is 2.3446 RMB/t. The cost of waste rock and tailings storage is 1.3960 RMB/t, and the total profit of ore sales is 250.3852 RMB/t. After considering the green and low-carbon production mode, the tailings and waste rock processing process is added, and the total cost is reduced to 455.4325 RMB/t, of which the carbon emission cost is reduced to 2.3433 RMB/t. It also saves the land cost of waste rock and tailings storage, which increases the sales profit of ore to 253.5767 RMB/t, and increases the sales profit of waste rock to 12.3595 RMB/t, and the total profit increases to 265.9362 RMB/t. The data comparison results are shown in Fig. 6.

By comparing the data of main production chain and green value chain in the table, it can be seen that the application of green value chain in this mine can reduce the cost by 3.1915 RMB/t and increase the profit by 15.5510 RMB/t. Regarding the reduction of mining land acquisition fees and the increase of carbon sinks generated by vegetation photosynthesis after the resource processing of waste rock and tailings as environmental benefits, the mine has increased the environmental benefit by 1.3973 RMB/t, achieving a win-win situation between the economic and environmental benefits of the mine.

Break-even analysis

The investment brought by the extension of the green value chain is mainly used for the infrastructure construction of stone processing plants, with a total investment of 86,440,000 RMB, monthly fixed costs of 5,860,000 RMB, waste rock processing costs of 20.9471 RMB/t, sales price of 33.3066 RMB/t, and waste rock utilization profit of 12.3595 RMB/t. In addition, the environmental benefits brought by utilizing waste rock resources include reducing land occupation costs and increasing vegetation carbon sinks, with a total environmental benefit of 0.6468 RMB/t. In summary, the total benefit of waste rock treatment is 13.0063 RMB/t. Based on the average monthly waste rock volume of 710045.70 tons at a gold mine in Shandong, the estimated monthly profit is 9235061.708 RMB, reaching the break even point in approximately 25.63 months.

Sensitivity analysis

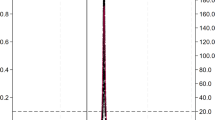

To evaluate the robustness of the proposed green value chain model under different geological and regulatory conditions, important parameters in the model were discussed. Due to the fixed carbon emission factor values provided by the IPCC, which do not change due to external conditions, this sensitivity analysis mainly focuses on two parameters: carbon trading price (P) and land acquisition cost (P1). Due to changes in geological background, policy framework, and market environment, these parameters may vary by region, thereby affecting profitability and environmental benefits.

(1) Carbon trading price (P)

This study used a carbon trading price of 45.61 RMB/t as the baseline data. To reflect possible market fluctuations, we examined the scenario where carbon trading prices (P) fluctuate by 50%. The results show that for carbon sinks, an increase in P can enhance their economic benefits. When P rises to 68.4 RMB/t, the environmental benefits increase by about 0.04%. On the contrary, when P drops to 22.8 RMB/t, the environmental benefits decrease by about 0.04%, which reduces the enthusiasm of carbon reduction measures. Meanwhile, for carbon emissions, the increase in P significantly increases the carbon emission cost in the production process.

(2) Land acquisition cost (\({P_1}\)).

The baseline calculation of this study assumes that the local industrial land price is 74,000 RMB/mu. By conducting sensitivity tests with a ± 50% variation, it can be seen that \({P_1}\) has a significant impact on the estimated environmental benefits of reducing waste rock and tailings storage areas. When \({P_1}\) increased to 111,000 RMB/mu, the environmental benefits increased by about 49.96%. On the contrary, when \({P_1}\) dropped to 37,000 RMB/mu, the environmental benefits decreased by about 49.96%, reducing the enthusiasm for carbon reduction measures. Therefore, in areas with high \({P_1}\), waste recycling strategies can bring greater economic returns, especially in areas with scarce land resources or strict environmental protection regulations.

The sensitivity analysis results are shown in Fig. 7, indicating that the green value chain model consistently provides economic and environmental benefits within a wide range of reasonable parameter values. However, the scale of these parameters is sensitive to regional conditions, especially land acquisition prices. Therefore, when applying this model to mines in different jurisdictions or geological backgrounds, key parameters must be calibrated according to local conditions to ensure accurate assessment of the profitability and sustainability of mining operations, enabling decision-makers to develop tailored low-carbon strategies and maximize economic and environmental outcomes.

Discussion

Through the above data analysis, it can be found that there are differences between the green value chain of mines and the main production chain. After increasing the processing and utilization of waste resources, the costs, profits, and carbon emissions of mines have changed significantly.

-

(1)

Reduction of mine production cost: The reuse of solid waste resources can reduce the demand for raw materials in the mine, especially for some common solid waste resources, such as waste rock and tailings. Through reuse, they can be used for underground filling or for construction in the mine to reduce the purchase of materials, thereby reducing the mine production cost.

-

(2)

Increase of product profit: By processing and treating solid waste resources, the mine can produce raw materials with commercial value and sell them to other industries, thereby achieving profit growth.

-

(3)

Increase of environmental benefits: The utilization of solid waste resources is conducive to reducing solid waste emissions and reducing pollution to the environment, thereby reducing the cost of environmental protection management, including waste processing, emission management, storage, and land acquisition costs. At the same time, compared with the original landfill method, the carbon sink generated by vegetation is increased.

-

(4)

Optimization of marginal grade: With the improvement of the sales income of mining products and the increase of environmental benefits, the marginal grade of mining enterprises can be reduced, which makes the low-grade resources that were originally difficult to utilize feasible, thereby improving the overall utilization rate of resources. In addition, this change also promotes a more comprehensive and sustainable development of resources by mining enterprises, reducing the waste of resources caused by grade restrictions.

By comparing the economic data before and after the utilization of solid waste resources, including mine production cost, profit from selling mineral products, carbon emission cost, and environmental benefit, we can evaluate the effect of the utilization of solid waste resources on the increase of income and the reduction of environmental pollution. In general, the utilization of solid waste resources can improve the total output of the mine, thus improving the overall profit of the mine and producing certain environmental benefits. This will make the originally economically unfeasible low-grade resources become economically feasible, thereby reducing the marginal grade.

Although the current research has achieved phased results, there are still the following aspects that need to be improved:

-

(1)

Cost analysis method: Activity based costing (ABC) has significant applicability in mining cost analysis, especially in resource intensive industries. This method can refine cost allocation, effectively reflect the actual cost of each activity, and provide accurate economic analysis for mine management. In addition, the data collection method used in the production and operation process of the case mine in this study is also based on the ABC method, which enables this analysis to be closely integrated with actual operational data. Although the ABC method performs well in direct cost and emission allocation, mixed cost models and other methods are more capable of comprehensively capturing indirect emissions. Therefore, future research can be further optimized based on mixed cost models.

-

(2)

Model applicability: This model is developed and optimized based on actual data from a gold mine with a well-established waste treatment infrastructure. The parameters involved in the model, such as carbon trading price, land value, and emission factors, are specific to the mining area. For mines without tailings utilization facilities and mines under different geographical conditions, it is necessary to adaptively adjust the model parameters according to their specific situations to ensure the effectiveness of the model.

-

(3)

Benchmark comparison: Benchmarking against comparable studies or established industry standards can further confirm the model and improve the credibility of the model results. However, current research is still in the exploratory stage, and mature industry standards have not yet been established, especially in the mining industry, which makes direct comparison challenging. Therefore, by closely monitoring the development and release of relevant standards and incorporating them into future research, more robust comparative analysis can be conducted.

Conclusion

This study successfully constructed a mine green value chain model that comprehensively considers key elements such as ore, waste rock, tailings, and carbon emissions. This green value chain model not only provides a new quantitative method to analyze the carbon emissions of mines and the environmental and economic benefits of carbon reduction measures but also intuitively reveals the potential of solid waste recycling in reducing environmental pollution. Through in-depth analysis of the comprehensive utilization strategy of solid waste resources, we find that it has a significant effect on reducing the environmental burden and can effectively reduce the marginal grade requirements of mines. This is of great significance because it shows that even in the face of lower-grade mineral resources, the economic viability and profitability of enterprises can be maintained through the implementation of solid waste recycling strategies.

In the process of the low-carbon transformation of mining enterprises, the green value chain model provides a clear path to achieve environmental protection goals and emphasizes the importance of optimizing resource allocation throughout the production process. This proves that taking environmental protection measures does not necessarily require sacrificing economic benefits. In the face of mining enterprises under different mining conditions, this model can adapt to the diversification of mining conditions through appropriate adjustments and integrate more innovative solutions to enhance its effectiveness.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Tost, M. et al. Metal mining’s environmental pressures: A review and updated estimates on CO2 emissions, water use, and land requirements. Sustainability 10, 2881 (2018).

Maybee, B., Lilford, E., Hitch, M. & Environmental Social and governance (ESG) risk, uncertainty, and the mining life cycle. Extr. Ind. Soc. 14, 101244 (2023).

Ungureanu, A. The smart products value chain. Acad. J. Econ. Stud. 4(2), 146–151 (2018).

Lyng, K. A. et al. The BioValueChain model: A Norwegian model for calculating environmental impacts of biogas value chains. Int. J. Life Cycle Assess. 20, 490–502 (2015).

Linder, M., Sarasini, S. & van Loon, P. A metric for quantifying product-level circularity. J. Ind. Ecol. 21, 545–558 (2017).

Gengyuan, L., Ping, H. & Yongyang, W. Agro-ecological product and its value realization pathway. Chin. J. Appl. Ecol. 32, 737–749 (2021).

Ortiz, J. M. et al. Uncertainty and value: Optimising geometallurgical performance along the mining value chain. Elements 19, 377–383 (2023).

Kinnunen, P. H. M. & Kaksonen, A. H. Towards circular economy in mining: Opportunities and bottlenecks for tailings valorization. J. Clean. Prod. 228, 153–160 (2019).

El Machi, A. et al. Use of flint from phosphate mine waste rocks as an alternative aggregates for concrete. Constr. Build. Mater. 271, 121886 (2021).

Zhaoyang, M. & Shuwei, H. Mine value chain modeling and ore cost analysis based on petri net. Min. Res. Dev. 41, 179–184 (2021).

Paat, A., Majak, J., Karu, V. & Hitch, M. Fuzzy analytical hierarchy process based environmental, social and governance risks assessment for the future phosphorite mining in Estonia. Extr. Ind. Soc. 17, 101438 (2024).

Izumi, Y., Iizuka, A. & Ho, H. J. Calculation of greenhouse gas emissions for a carbon recycling system using mineral carbon capture and utilization technology in the cement industry. J. Clean. Prod. 312, 127618 (2021).

Wassmann, R. et al. Carbon footprint calculator customized for rice products: Concept and characterization of rice value chains in Southeast Asia. Sustainability 14, 315 (2021).

Junhao, B. et al. Investigation and comprehensive utilization analysis of metal resources in tailings of gold mines in Henan province, China. Acta Mineral. Sinica 42, 683–691 (2022).

Huahui, Y. et al. Current status and development of comprehensive utilization of waste rock in metal mines in China. Chin. J. Nonferrous Met. 31, 1649–1660 (2021).

Wenping, C. & Chunxiao, X. Research on the process and mode of tourism business form agglomeration based on tourism value chain model: A case from OCT group. Tourism Tribune. 39, 109–123 (2024).

Qizhan, H. The application of sustainable development concept in mining enterprises—Review of comprehensive utilization technology series of waste resources—Tailings and waste rock comprehensive utilization technology. Min. Res. Dev. 40, 165 (2020).

Wenwen, M. & Peng, L. Tailings disposal policy and comprehensive utilization practice in gold industry. Gold Sci. Technol. 31, 1023–1034 (2023).

Weixing, L., Yuantao, Z., Liu, Q. & Renze, O. Thoughts on the layout of mineral resources development under carbon Peakand carbon neutrality goals. Min. Res. Dev. 42, 153–159 (2022).

Zhenfang, Z. Study on Carbon Emissions Accounting and Carbon Emission Reduction Approach of Surface Coal Mine. (PhD Thesis, China University of Mining and Technology, 2013).

Guoqing, L. et al. Mining cost prediction model for underground metal mine. Metal Mine. 5, 62–69 (2022).

Intergovernmental Panel on Climate Change (IPCC). IPCC Guidelines for National Greenhouse Gas Inventories (2006).

Funding

This research financially supported by the State Key Research Development Program of China “Green mining mode and engineering demonstration of open-pit mines in cold and ecologically fragile areas” (No. 2022YFC2903905); the State Key Laboratory of Intelligent Optimized Manufacturing in Mining & Metallurgy Process (No. BGRIMM-KZSKL-2023-3) and Beijing Key Laboratory of Process Automation in Mining & Metallurgy (No. BGRIMM-KZSKL-2023-3).

Author information

Authors and Affiliations

Contributions

C.F. developed the methodology, conducted the investigation, and wrote the original draft. G.L. conceptualized the study and supervised the project. M.C. conducted the investigation and handled Data Analysis. J.H. conceptualized the study, contributed to methodology development, and reviewed and edited the manuscript. Q.W. conducted the investigation and polished the article. P.W. provided validation and resources. G.G. handled data curation. All authors reviewed and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Fan, C., Li, G., Chen, M. et al. The green value chain model of mining company based on zero carbon emissions. Sci Rep 15, 35175 (2025). https://doi.org/10.1038/s41598-025-19094-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-19094-4