Abstract

This study introduces a novel approach to enhance hollow-fiber direct contact membrane distillation (DCMD) by integrating copper metal foam, a configuration unexplored in prior DCMD research, which typically focused on membrane modifications or geometric optimizations. Using a comprehensive three-dimensional computational fluid dynamics (CFD) model, we investigate four DCMD configurations: without metal foam (Model 1), with metal foam on the tube side (Model 2), shell side (Model 3), and both sides (Model 4). The high thermal conductivity (38 W/m.K) and porosity (0.9) of copper foam disrupt thermal and hydrodynamic boundary layers, significantly reducing temperature polarization and increasing water vapor flux by up to 32% and Sherwood number by 48% in Model 4 compared to the baseline. These improvements stem from enhanced convective heat transfer and flow uniformity, which boost the vapor pressure gradient across the membrane. However, the incorporation of metal foam increases friction factors, leading to higher pressure drops, though these remain low (386 Pa tube-side, 150 Pa shell-side) and compatible with standard pumping systems. This work demonstrates the potential of metal foam-enhanced DCMD for scalable, energy-efficient desalination, offering a promising solution for sustainable water treatment. Limitations include the need for experimental validation and optimization of foam properties to minimize energy costs, paving the way for future research to refine this innovative approach.

Similar content being viewed by others

Introduction

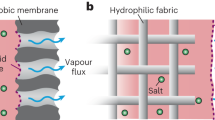

Membrane distillation is a thermally driven technique that relies on a hydrophobic membrane to separate substances based on differences in vapor pressure. In this method, the feed solution comes into contact with one side of the membrane, allowing only water vapor to pass through, while liquid components are blocked. The vapor then condenses on the opposite side, resulting in purified water. This approach is particularly valued in water treatment due to its capacity to produce highly pure outputs1. In addition, membrane distillation has been found to be more energy-efficient than traditional distillation methods as it can be operated at lower temperatures and pressures2. Despite its potential benefits, the application of membrane distillation is still limited in industry, with much of the research in this field taking place in academic settings. Further research is necessary to investigate the feasibility of membrane distillation for a wide range of applications3. Various membrane materials, such as polyvinylidene fluoride (PVDF)4 and polytetrafluoroethylene (PTFE)5 have been explored to expand the use of membrane distillation. Researchers recently explored the use of different configurations of membrane distillation, such as flat-sheet6, hollow fiber7, and spiral-wound8, to optimize the performance of the process9,10. One of the membrane distillation techniques is known as Direct Contact Membrane Distillation (DCMD). DCMD is a thermal separation process that utilizes a hydrophobic membrane to separate two liquid phases of different concentrations11. The process operates under low pressure and temperature, making it suitable for treating a wide range of fluids, including seawater, industrial wastewater, and brines12. In DCMD, the feed solution is brought into direct contact with the membrane surface, and a vapor pressure gradient is applied across the membrane. This causes evaporate the liquid and pass through the membrane pores, leaving behind a concentrated solution on one side and a purified one on the other side13.

Computational Fluid Dynamics (CFD) is a highly effective approach for studying and analyzing DCMD14. CFD is also a valuable tool in the design and optimization of DCMD15. CFD can provide insight into the complex flow and thermal behavior of fluids in a membrane distillation16 and help predict its performance17. CFD allows engineers to identify and optimize key parameters that affect the efficiency and cost of a distillation system using simulation of various operating conditions and designs18. Using CFD in membrane distillation has become increasingly popular in recent years, due to advancements in computational power and an improved understanding of membrane processes19.

In recent years, numerous investigations have been performed to study the application of CFD in DCMDs. In addition to DCMD, CFD has also been used to study other types of membrane distillation configuration, such as sweeping gas membrane distillation (SGMD)20, air gap membrane distillation (AGMD)21, and vacuum membrane distillation (VMD)22. CFD has also been applied to investigate the membrane properties effects23 and geometric design24 on the performance of MD systems. Afsari et al. used CFD to evaluate the effect of various operating factors on the performance of DCMD, finding that the process was sensitive to feed temperature, feed flow rate, and permeate pressure25. Several studies have used computational fluid dynamics (CFD) to optimize direct contact membrane distillation (DCMD) systems for water treatment. Zare & Kargari18 and Choi et al.26 developed CFD models to maximize permeate flux and energy efficiency in DCMD modules. Both studies found that channel dimensions significantly impacted performance. Park et al. used CFD to investigate the effects of operating conditions on DCMD performance, concluding that higher feed temperatures and flow rates improved water production27.

In DCMD, heat transfer has a significant effect on the overall process. The temperature difference between the feed and permeate streams is critical for efficient heat transfer. A higher feed temperature can increase the driving force, leading to a higher flux. Metal foams have gained attention for heat transfer applications due to their high surface area-to-volume ratio, high thermal conductivity, and low density28. Metal foams, such as copper and aluminum, have been used in various heat transfer applications, including heat exchangers, thermal management systems, and insulation materials29,30. The use of metal foams in these applications has been shown to improve the overall heat transfer performance, increase heat dissipation rates, and reduce heat transfer through insulation materials. Chandora et al. showed that using copper metal foam in a plate heat exchanger increased heat transfer by up to 97% compared to a plain heat exchanger31. Other studies have also investigated the use of metal foams in heat transfer applications and have found similar improvement results32,33,34,35. Overall, using metal foam in heat transfer applications is a promising technology with the potential to improve the performance of various heat transfer systems.

The integration of metal foam into hollow fiber DCMD systems represents a groundbreaking approach to enhance desalination performance, addressing a critical gap in the field where such a combination remains unexplored. This study pioneers the use of metal foam to improve velocity and temperature uniformity within hollow fiber DCMD, potentially revolutionizing water vapor flux and overall efficiency in water treatment processes. By employing a sophisticated CFD model, the complex interplay of metal foam properties and their impact on hollow fiber DCMD performance under varying operating conditions was investigated meticulously. This study presents a novel approach by integrating metal foam into hollow fiber DCMD. Unlike previous works, it systematically examines key heat and mass transfer parameters, including vapor flux and the Sherwood number. The proposed design effectively mitigates temperature polarization and enhances permeate flux, offering a promising solution to improve the scalability and industrial implementation of membrane distillation for sustainable water treatment.

Model development

Physics of the model

In this research, a comprehensive three-dimensional computational fluid dynamics (CFD) model was developed to investigate a seawater purification system employing a counter-current flow configuration and the direct contact membrane distillation (DCMD) process. The study focuses on a turbulent flow regime within a single hollow fiber DCMD module, formulated in a cylindrical coordinate system. In this configuration, the saline feed stream enters the shell side, while the cold permeate stream flows through the tube side. Figure 1 illustrates the flow paths of both the feed and permeate streams within the single hollow fiber module.

The proposed model considers the conservation of mass, energy, momentum and concertation. In the DCMD process, the temperature difference between seawater and permeate creates a differential in vapor pressure, driving the mass transfer across the membrane. If the temperature gradient is adequate, water molecules will pass through the membrane pores, while salt ions are prevented from passing.

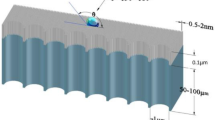

The addition of metal foam in DCMD is demonstrated in Fig. 2. This figure presents the structural configurations of four direct contact membrane distillation (DCMD) models: Model 1 (without metal foam), Model 2 (metal foam incorporated on the tube side), Model 3 (metal foam incorporated on the shell side), and Model 4 (metal foam incorporated on both tube and shell sides). These configurations are designed to investigate the influence of metal foam on the performance of the desalination process. Additionally, Table 1 presents the geometric parameters and essential input data used in the CFD model.

Model assumptions

In this study, the feed and permeate flows were assumed to be steady-state. Both channels were modeled as turbulent to accurately capture the effects of incorporating metal foam within the system. The permeate and feed streams were treated as incompressible fluids, which is a reasonable assumption given the negligible density variations under the operating conditions. Flow through the metal foam was modeled using the Forchheimer–Brinkman equations to account for both viscous and inertial effects within the porous medium (porosity ranging from 0.9 to 0.99 and pore density between 30 and 50 PPI). This approach aligns with observed velocity profiles and pressure drop characteristics. To simulate heat transfer within the metal foam, the Non-Local Thermal Equilibrium (NLTE) model was employed, allowing for separate temperature fields in the solid (foam) and fluid phases. This model captures the influence of the foam’s high thermal conductivity on mitigating temperature polarization. The metal foam is assumed to be fully saturated with the incompressible fluid, consistent with single-phase flow in immersed DCMD channels, though partial saturation may warrant investigation in future multiphase extensions.

The copper foam is modeled as an open-cell structure with all pores fully interconnected and open, consistent with high-porosity metal foams used in flow applications, though real-world defects may necessitate future heterogeneous extensions.

Governing equations and boundary conditions

The continuity equation ensures mass conservation in each region. For an incompressible fluid, the three-dimension continuity equation in the permeate and feed flows is:

Where u is the velocity vector in the x, y, and z directions. In the permeate tube u = uc, and in the feed shell u = uh.

The three-dimension momentum equation in the tube (without metal foam) and the shell side (without metal foam), incorporates the k-ε turbulence model to account for the turbulent flow assumption. The general form of the Navier-Stokes equation for an incompressible fluid, modified for turbulence, is:

Where ρ is the fluid density, p is the pressure, µ is the dynamic viscosity, µt is the turbulent viscosity, k is the turbulent kinetic energy, ε is the turbulent dissipation rate, I represent the identity tensor and Cµ is a model constant.

In the shell or permeate tube with metal foam, the metal foam is modeled as a porous medium using the Forchheimer-Brinkman extension. The momentum equation includes additional terms for the porous media effects as shown in Eq. 4:

Where ε is the porosity of the metal foam, K is the permeability of the metal foam, CF is the Forchheimer coefficient, the term (µ/K). uh represents the Darcy (viscous) resistance and the term \(\:\frac{\rho\:{C}_{F}}{\sqrt{K}}\left|{u}_{h}\right|{u}_{h}\) accounts for inertial effects in the porous medium41.

k-ε turbulence model equations provide closure for the turbulent viscosity µt. The transport equations for turbulent kinetic energy k and dissipation rate ε are:

Where:

Pk is the production of turbulent kinetic energy. And model constants are C1ε=1.44, C2ε=1.92, σk = 1.0, σε = 1.3.

Turbulence equations are employed only when metal foam is incorporated on the tube side, shell side, or both. In the absence of metal foam, laminar flow correlations are applied. The mass transfer in DCMD occurs primarily through the membrane, driven by the vapor pressure gradient. The velocity of water vapor diffusing into the membrane surface on the feed side is modeled using the following expression:

where PsF and PsP are the vapor pressures on the feed and permeate sides, calculated using the Antoine equation and adjusted for salinity.

This study assumes that the salt does not diffuse into the membrane; therefore, the concentration field is only investigated in the feed flow on the shell side. The three-dimensional mass transfer equation for the salt concentration (C) is:

Where C is the salt concentration and Deff is the effective diffusion coefficient, adjusted for the porous medium in the feed channel. Deff = εD, where D is the molecular diffusion coefficient of salt in water.

The study assumed a Non-Local Thermal Equilibrium (NLTE) model between the fluid and metal foam in the feed channel to allow distinct temperatures for the fluid and metal foam. The follow-up equations illustrate the three-dimensional NLTE approach. The energy equation without metal foam is shown in Eq. 10:

Where ρ, Cp and k are the density, specific heat capacity, and thermal conductivity of the fluid. T is the temperature.

In terms of energy calculations, in the model with metal foam, the NLTE model requires two separate heat transfer equations: one for the fluid (feed or permeate flows) and one for the metal foam. These are coupled through a heat transfer term. Equation 11 shows this term for the fluid phase.

The energy equation for the metal foam (solid phase) is presented as Eq. 12.

Where T and Ts are the temperatures of the fluid and solid (metal foam), respectively. hsf is the interfacial heat transfer coefficient between the fluid and metal foam. asf is the specific surface area of the metal foam.

The heat transfer in the membrane is conduction-dominated, with the effective thermal conductivity accounting for the membrane’s porosity as shown in Eq. 13:

Where Tm is the temperature in the membrane. keff calculates by Eq. 14:

Here, kf denotes the thermal conductivity of the vapor, \(\:{\epsilon\:}_{m}\) is membrane porosity and kmembrane represents the thermal conductivity of the PVDF material.

The boundary conditions for the DCMD module are defined as follows. At the inlets of both the shellside and tubeside domains, a prescribed inlet velocity and fixed temperature are applied. At the outlets of the shellside and tubeside domains, the pressure is set to atmospheric (p = 0) and a zero normal temperature gradient is imposed. Along all solid walls, a noslip hydrodynamic condition (u = 0) is enforced in conjunction with adiabatic thermal insulation. On the feedside membrane surface, the convective vapor flux is specified by Eq. (8), and continuity of temperature is maintained across the fluid–membrane interface.

Model parameters

One way to express the mass transfer process in DCMD is to assume of a linear relationship between the mass flux of water vapor through the membrane and the difference in water vapor pressure18:

Where:

J: Mass flux of water vapor.

β

Membrane mass transfer coefficient.

\(\:{P}_{sF}\:\)

Feed side water vapor partial pressures.

\(\:{P}_{sP}\)

Permeate side water vapor partial pressures.

The Antoine equation is utilized to estimate the water vapor pressure on both the feed and permeate sides of the DCMD membrane as follows42:

P represents the water vapor pressure on the feed and permeate side, while A, B, and C are constants. T denotes the corresponding temperature. When the feed consists of an actual solution, such as a seawater, the water vapor pressure on the hot channel is reduced due to the reduction in water activity. As a result, the actual vapor pressure (Pi) can be determined by examining the activity coefficient (\(\:{\gamma\:}_{w}\)) and mole fraction of water (xw) as follows18:

The activity coefficient of water in NaCl solution can be calculated using the following equation43:

where \(\:{x}_{salt}\) represents the mole fraction of salt on the feed side.

The metal foam characteristics are determined by porosity (ɛ) and pore density (ω). Permeability (\(\:K)\), pore diameter (\(\:{d}_{p})\), and fiber diameter (\(\:{d}_{f})\) are all essential factors of metal foam for momentous equations. The equations for the pore diameter, fiber diameter and permeability of the material foam are as follows44 :

Where c is a constant set to 0.15 based on literature for copper metal foams. The inertial coefficient is calculated as:

Where K is permeability, ε is porosity, df is fiber diameter of the metal foam and dp is pore diameter of the metal foam.

In Eq. (26), the particle Reynolds number (Red) is defined for flow through the metal foam in Models 2–4:

where df is the fiber diameter of the metal foam. This differs from the general Reynolds number (Re) used for tube-side and shell-side flows, which employs the hydraulic diameter (Dh) as the characteristic length.

The parameters were used in the Darcy-Forchheimer equation to model the pressure drop across the metal foam45:

The thermal conductivity, density, heat capacity at constant pressure, and viscosity of the feed flow were calculated using Equations (28) to (31)37:

Where T represents the temperature in Kelvin (K) and X shows the salt mass fraction.

The friction factor is calculated as follows46.

where ΔP is the pressure drop, L is the length, and D is the hydraulic diameter.

Numerical simulation

The governing equations of the DCMD and corresponding boundary conditions are integrated using COMSOL V6. The code utilizes the finite element method (FEM) in combination with error control and adaptive meshing via the UMFPACK solver. This methodology has been previously verified in numerous studies17,18,42,47,48,49.

Results and discussion

Mesh independence study

To ensure the numerical accuracy and stability of the computational fluid dynamics (CFD) simulations, a mesh independence study was conducted. This study evaluates the sensitivity of the simulation results to mesh refinement, ensuring that further refinement does not significantly alter key outputs such as flux, pressure drop, and Sherwood number. Figure 3 illustrates the mesh domain used in the present study. The first boundary layer thickness near the outer surface and membrane interfaces was selected to ensure that the dimensionless wall distance (y⁺) falls within the range of 30 to 300. This range is suitable for capturing turbulent flow characteristics when using wall functions in the turbulence model. A mesh independence analysis was performed to ensure the reliability of the simulation results. As shown in Fig. 4, the water vapor flux through the membrane was evaluated for three different mesh densities consisting of 550,000, 1,150,000, and 2,330,000 elements. The results indicated that the relative difference in vapor flux between the second and third mesh types was only 0.1%. Based on this negligible variation, the mesh with 1,150,000 elements was selected for all subsequent simulations, providing a balance between computational efficiency and accuracy.

Model validation

For model validation of the hollow fiber DCMD system, experimental data from Ho et al. at various feed temperatures were used. Figure 5a illustrates the water vapor flux as a function of volumetric flow rate at different temperatures. The results indicate that as the volumetric flow rate increases, the flux also increases in both the present model and the experimental data. A good agreement is observed between the present model results and the data reported by Ho et al.36, confirming the accuracy of the developed model.

For the validation of fluid flow within a tube containing metal foam, experimental data from the study conducted by Ali and Ghasem44 were utilized. Their work investigated the friction factor across a range of Reynolds numbers and pore densities (PPI), while maintaining a constant porosity. Figure 5b presents a comparison between the predicted friction factors from the present model and the experimental results. The strong agreement observed between the two datasets confirms the accuracy of the current model in capturing the hydrodynamic behavior of flow through metal foam-filled tubes.

Figure 5c presents the validation of heat transfer within the pipe with metal foam using experimental data from a separate study by Ali and Ghasem50. This validation involved comparing the bulk temperature profiles along the tube length at various flow rates. The metal foam employed in their study had a pore density of 40 PPI and a porosity of 0.89. The comparison shows strong agreement between the present model and the experimental results, confirming the model’s accuracy in predicting the thermal behavior of fluid flow through tubes embedded with metal foam.

Velocity distribution

Figure 6 illustrates the velocity distribution within the tube and shell of the DCMD system for four different configurations, with and without copper metal foam. Model 1 represents the configuration without metal foam and serves as the baseline for comparison. Model 2 includes metal foam on the tube side, while Model 3 incorporates metal foam on the shell side. Model 4 incorporates metal foam on both the tube and shell sides.

In all cases, the feed stream enters the shell side at z = 0, while the permeate stream enters the tube side at z = L. Therefore, in this figure, the velocity distributions across the cross-sectional areas at different lengths of the module are analyzed for each model.

In the baseline configuration, Model 1 displays flow in a hollow fiber DCMD system. It develops a hydrodynamic boundary layer along the membrane surfaces on both tube and shell sides, resulting in a parabolic velocity profile, higher velocities at the channel center and lower near the walls. At z/L = 0.5, the flow is fully developed, creating a steep velocity gradient near the membrane that reduces mixing and impacts mass and heat transfer efficiency due to slower convective transport near the membrane.

Model 2 introduces metal foam on the tube side, altering the permeate channel’s flow. The copper foam (porosity 0.9, PPI 30) disrupts the boundary layer, creating a more uniform velocity profile in the tube side and enhancing mixing in the permeate stream. However, the shell side retains a parabolic velocity profile similar to Model 1, indicating unchanged flow dynamics in the feed stream.

In Model 3, wherr metal foam is added to the shell side, affecting the feed stream. This results in a flatter velocity profile in the shell side at z/L = 0 and z/L = 0.5, improving flow uniformity and reducing velocity gradients near the membrane, which may enhance heat and mass transfer. The tube side, lacking metal foam, mirrors Model 1’s parabolic velocity profile with a thicker boundary layer, showing no significant change in permeate flow.

Model 4 integrates metal foam in both the tube and shell sides, achieving the most uniform velocity distribution across the DCMD module. At all axial positions (z/L = 0, 0.5, 1), both feed and permeate streams exhibit significantly flattened velocity profiles, with minimal boundary layer development near the membrane surfaces. The copper foam’s high porosity (0.9) and interconnected structure (PPI 30) ensure consistent flow velocities across the cross-sections, promoting enhanced mixing and eliminating stagnation zones. The reduced velocity gradients in Model 4 indicate a strong mitigation of concentration polarization and temperature polarization, addressing key inefficiencies in DCMD systems more effectively than the other configurations. This makes Model 4 the most optimized setup for improving overall system performance.

Thermal distribution

Figure 7 presents the temperature distributions across the four DCMD models (Model 1: no metal foam; Model 2: tube-side metal foam; Model 3: shell-side metal foam; Model 4: dual-side metal foam) at axial positions (Z/L = 0), (Z/L = 0.5), and (Z/L = 1), under counter-current flow conditions with a Hot feed inlet temperature of 333.15 K on the shell side and a cold permeate inlet temperature of 293.15 K on the tube side, at (Ref = 100) and (Rep = 100). The color scale ranges from 300 K (blue) to 335 K (red), visually depicting the thermal gradients that drive water vapor transport across the membrane.

In Model 1, the absence of metal foam results in a pronounced temperature gradient. At (Z/L = 0), the shell side exhibits a yellow-orange core (approximately 330–335 K), transitioning rapidly to red (325–330 K) toward the membrane, while the tube side is dark blue (300–305 K). At (Z/L = 0.5), the shell-side core remains yellow-orange (around 330 K), but the transition zone broadens to red, indicating a thick thermal boundary layer. The tube side shifts to cyan (305–310 K), reflecting heat penetration. By (Z/L = 1), the shell side cools to red (325 K), and the tube side remains dark blue (300–305 K), showing significant heat loss and poor temperature uniformity.

Model 2, with tube-side metal foam, shows similar shell-side behavior at (Z/L = 0) (yellow-orange, 330–335 K, transitioning to red). At (Z/L = 0.5), the shell side remains yellow-orange (330 K) with a broad red zone, while the tube side develops a more uniform cyan (310–315 K) near the membrane, indicating the foam’s effect on reducing the permeate-side thermal boundary layer. At (Z/L = 1), the shell side is red (325 K), and the tube side is cyan-green (305–310 K), suggesting improved heat distribution.

Model 3, with shell-side metal foam, displays a yellow-orange shell-side core (330–335 K) at (Z/L = 0), with a sharper transition to red (325–330 K) near the membrane. At (Z/L = 0.5), the shell side maintains a larger yellow-orange region (330–332 K) closer to the membrane, with a narrower red zone, while the tube side shifts to cyan (305–310 K). At (Z/L = 1), the shell side cools to red (325 K), and the tube side remains dark blue (300–305 K) with a broader transition, reflecting enhanced feed-side heat transfer.

Model 4, with dual-side metal foam, exhibits the most uniform temperature profile. At (Z/L = 0), the shell side is yellow-orange (330–335 K) with a sharp transition, and the tube side is dark blue (300–305 K). At (Z/L = 0.5), the shell side retains a significant yellow-orange region (330–332 K) near the membrane, with a very narrow red zone, while the tube side shows uniform green-cyan (310–315 K). At (Z/L = 1), the shell side is red (325 K), and the tube side is cyan (305–310 K), with a smooth gradient, indicating minimal boundary layer thickness on both sides.

The thermal boundary layer thickness, inferred from the transition zone width, is thickest in Model 1 (approximately 1–2 mm at (Z/L = 0.5)), with a broad red-to-yellow gradient. Model 4 shows the narrowest thickness (< 0.5 mm), with Models 2 and 3 intermediates (0.5–1 mm). Membrane interface temperatures at (Z/L = 0.5) are estimated as follows: Model 1 (feed-side 325 K, permeate-side 305–310 K), Model 2 (feed-side 330 K, permeate-side 310–315 K), Model 3 (feed-side 330–332 K, permeate-side 305–310 K), and Model 4 (feed-side 330–332 K, permeate-side 310–315 K). The temperature difference across the membrane is largest in Model 4 (20–25 K), compared to 15–20 K in Model 1.

The reduced thermal boundary layer in Model 4 minimizes temperature polarization, maintaining bulk temperatures closer to the membrane surface, particularly on the shell side (330–332 K vs. 325 K in Model 1). This enhances the vapor pressure gradient. The exponential dependence of vapor pressure on temperature, per the Antoine relationship (Eq. 33), amplifies this effect, validating the physical mechanism behind Model 4’s superior performance51.

where A, B, and C are substance-specific coefficients, P is vapor pressure and T is temperature. This exponential relationship means that small changes in temperature can cause large changes in vapor pressure, amplifying temperature effects and making accurate modeling essential.

Model 4’s superior performance is validated because it incorporates this physical mechanism—either explicitly or through an inductive bias inspired by the Antoine equation—allowing it to capture the true nonlinear temperature dependence of vapor pressure more effectively than models lacking this insight.

Concentration distribution

Figure 8 illustrates the salt concentration distribution for Models 1, 2, 3, and 4, providing insight into the solute behavior within the shell side of the DCMD system. The Reynolds number for both the feed and permeate sides is set at 100, with feed and permeate temperatures maintained at 333.15 K and 293.15 K, respectively. Due to the assumption that salt does not permeate through the membrane, only the shell side (the feed flow domain) is considered for analyzing salt concentration.

Since the permeate side has little effect on the salt concentration within the feed (shell) side, the distribution patterns in Models 1 and 2 are almost the same. A similar trend is observed for Models 3 and 4. As expected, for all models, the salt concentration near the membrane surface increases with the module length. This trend is attributed to water vapor being continuously removed across the membrane, resulting in salt accumulation near the membrane surface and an increased concentration gradient along the flow direction.

According to Fig. 8, slightly higher salt concentrations are observed in Models 3 and 4 compared to Models 1 and 2. This is due to the presence of metal foam in the shell side (feed side) of Models 3 and 4, which reduces the flow and thermal boundary layers. As a result, the vapor flux increases, leading to greater water extraction and a more pronounced salt concentration gradient near the membrane. Additionally, the reduced concentration boundary layer observed in Models 3 and 4 is due to a slightly thinner flow boundary layer on the shell side compared to Models 1 and 2.

Reynolds number effect

Figure 9a illustrates the effect of Reynolds number on flux for the four models. In all cases, the flux increases as the Reynolds number rises. For Model 1, the flux increases from 14.2 kg/(m²·h) at Re = 50 to 22.8 kg/(m².h) at Re = 200. Model 2 shows a rise from 15.0 to 23.8 kg/(m².h), while Model 3 increases from 16.0 to 29.2 kg/(m².h). Model 4 exhibits the highest performance, starting at 17.2 kg/(m².h) and reaching 31.5 kg/(m².h). The increase in flux with Reynolds number is attributed to enhanced convective heat transfer, which reduces temperature polarization, increases the vapor pressure gradient, and thus improves flux. Additionally, the flux values for Models 2, 3, and 4 are higher than that of Model 1 (conventional DCMD without metal foam). This improvement is due to the presence of external metal foam in these models, which reduces the thermal boundary layer thickness and increases the temperature difference across the membrane. As a result, the vapor pressure gradient is enhanced, leading to higher flux. Model 4 achieves the highest flux due to its Hollow fiber configuration and the presence of external metal foam on both the tube and shell sides. Model 3 also shows superior performance compared to Model 2, which can be attributed to the placement of metal foam on the shell side. Since the shell side (feed side) typically has a higher temperature than the tube side, it has a greater influence on the vapor pressure gradient. The presence of metal foam in this region enhances heat transfer and increases vapor pressure, leading to improved flux. Finally, Model 2 shows better performance than Model 1 due to the addition of metal foam on the tube side. The metal foam promotes thinner thermal boundary, resulting in greater flux compared to the conventional DCMD configuration in Model 1.

On average, the flux of Models 4, 3, and 2 is approximately 32%, 23%, and 5% higher than that of Model 1, respectively. Moreover, as the Reynolds number increases, the influence of metal foam on flux becomes more pronounced for all models. This is due to enhanced convection at higher Reynolds numbers, which reduces the thermal boundary layer and raises the membrane surface temperature. The higher membrane temperature, leads to an increased vapor pressure gradient, resulting in improved flux, as the impact of vapor pressure is more significant at elevated temperatures.

Figure 9b illustrates the variation of the Sherwood number as a function of Reynolds number. As Reynolds number increases, the Sherwood number also rises. For Models 1 and 2, the Sherwood number increases from approximately 28 at Re = 50 to 42 at Re = 200. Model 3 shows an increase from around 33 to 58, while Model 4 rises from about 34 to 62. This trend reflects enhanced mass transfer at higher Reynolds numbers due to improved mixing and thinner concentration boundary layers, as supported by the velocity field analysis. Models 1 and 2 exhibit nearly identical Sherwood numbers, as the permeate flow (tube side) has limited influence on the salt concentration in the feed (shell) side. In contrast, Models 3 and 4 show significantly higher Sherwood numbers due to the presence of external metal foam in the shell side, which promotes more uniform velocity profiles and better mass transfer performance. On average, the Sherwood numbers for Models 3 and 4 are approximately 38% higher than those for Models 1 and 2.

Figure 9c illustrates the effect of Reynolds number on the friction factor in the shell side (feed flow). As the Reynolds number increases, the friction factor decreases for all models due to the higher flow velocity. It is important to note that while increasing velocity also raises the pressure drop, the influence of velocity on the friction factor is more dominant than that of pressure. Models 1 and 2 exhibit the same friction factor values because neither incorporates metal foam in the shell side. In contrast, Models 3 and 4 show significantly higher friction factors, as both include metal foam with identical properties in the shell side. The presence of metal foam introduces additional viscous and inertial resistance to the flow, leading to increased pressure drops. The friction factors in Models 3 and 4 are nearly ten times higher than those observed in Models 1 and 2.

Figure 9d illustrates the friction factor in the tube side (permeate flow) as a function of Reynolds number. Similar to the shell side, the friction factor in the tube side decreases with increasing Reynolds number due to higher flow velocities.

Effect of metal foam porosity

Figure 10a, b and c, and 10d examine the effect of metal foam porosity (ranging from 0.90 to 0.99) on flux, Sherwood number, shell-side friction factor, and tube-side friction factor, respectively, for the three models that incorporate metal foam. Model 1 is excluded from this analysis, as it does not contain any metal foam.

According to the results, variations in metal foam porosity have a negligible effect on both flux and Sherwood number. This indicates that metal foams with porosities between 0.90 and 0.99 exhibit similar behavior in terms of flow dynamics, heat transfer, and mass transfer in Hollow fiber DCMD systems. However, as previously discussed, Model 4 demonstrates higher flux and Sherwood number compared to the other models due to its dual-sided metal foam configuration (in both shell and tube sides), which enhances performance. Moreover, metal foam porosity has a negligible effect on the friction factor for both the tube and shell sides.

PPI effect

Figure 11 illustrates the effect of metal foam pore density (PPI, ranging from 0 to 60) on flux, Sherwood number, shell-side friction factor, and tube-side friction factor for Models 2, 3, and 4. Model 1 is excluded from this analysis as it does not incorporate metal foam.

Figure 11a shows the variation of water vapor flux with PPI for the three models. For Model 2, the flux remains nearly constant, ranging from 20.5 kg/(m2.h) at PPI = 30 constant till PPI = 60, without change. Model 3 exhibits a similar trend, with flux constant at almost 23 kg/(m2.h). Model 4, with metal foam on both the tube and shell sides, achieves the highest flux, maintaining a stable value from 25.0 kg/(m2.h) (from PPI = 30 to PPI = 60). The minimal impact of PPI on flux across all models is attributed to the high porosity (0.9) of the metal foam, which ensures sufficient flow uniformity and heat transfer even at varying pore densities. For Model 4, the uniform velocity distribution observed in both channels further mitigates the influence of PPI, as the interconnected foam structure already promotes effective mixing and convective heat transfer, maintaining a consistent vapor pressure gradient across the membrane.

Figure 11b presents the Sherwood number as a function of PPI. The Sherwood number exhibits minimal variation with PPI across all models. For Model 2, it remains steady at 36 across the PPI range, while Model 3 shows a slight increase from 46 at PPI = 30 to 47 at PPI = 50, a 2.2% rise. Model 4 demonstrates the highest Sherwood number, increasing marginally from 47 at PPI = 30 to 49 at PPI = 50, a 4.3% increase. On average, Model 4’s Sherwood number is 36.1% higher than Model 2’s and 4.2% higher than Model 3’s, reflecting its superior mass transfer performance due to the dual-sided metal foam configuration. The minimal effect of PPI on Sherwood number Aligns with the velocity distribution analysis, where Model 4’s flattened velocity profiles minimize concentration boundary layers, ensuring effective mixing and mass transfer regardless of pore density.

Figure 11c illustrates the shell-side friction factor as a function of PPI. For Model 2, which lacks metal foam in the shell side, the friction factor remains constant at approximately 1 across all PPI values. In contrast, Models 3 and 4, both incorporating metal foam in the shell side, exhibit a significant increase in friction factor with PPI, displaying nearly identical behavior. For Model 3, the friction factor rises from 12 at PPI = 30 to 24 at PPI = 50, a 100% increase. Similarly, Model 4’s friction factor increases from 12 to 24, also a 100% rise. This increase is due to the smaller pore sizes at higher PPI values, which enhance flow resistance by increasing both viscous and inertial effects within the porous medium.

Models 2 and 4 exhibit nearly identical behavior in the tube-side friction factor (Fig. 11d), with both showing an increase from 7 at PPI = 30 to 12.5 at PPI = 50, a 78.6% rise. This similarity arises because both models incorporate metal foam in the tube side with the same properties. The presence of metal foam in the tube side introduces additional flow resistance, which increases with higher PPI due to smaller pore sizes. As PPI increases, the pore diameter decreases, leading to greater viscous and inertial resistance within the porous medium. Since Model 4 also has metal foam in the shell side, this does not affect the tube-side flow dynamics directly, as the shell-side flow (feed stream) and tube-side flow (permeate stream) are hydrodynamically independent in this counter-current configuration. Therefore, the tube-side friction factor in both models depends solely on the metal foam properties in the tube side, which are identical, resulting in the same trend with increasing PPI.

Overall, varying the metal foam PPI from 30 to 60 has a minimal impact on key performance metrics across Models 2, 3, and 4, with Model 4 consistently outperforming the others. Flux remains stable for all models, with Model 4 achieving the highest, a 22% improvement over Model 2, due to its dual-sided metal foam configuration enhancing flow uniformity and heat transfer. Similarly, the Sherwood number shows negligible variation with PPI, with Model 4’s value being 36.1% higher than Model 2’s and 4.2% higher than Model 3’s, reflecting superior mass transfer driven by reduced concentration boundary layers. However, friction factors increase with PPI, particularly in the shell side for Models 3 and 4 (a 100% rise) and in the tube side for Models 2 and 4 (a 78.6% rise), due to increased flow resistance from smaller pores, a trade-off that may impact energy costs in large-scale applications but is outweighed by Model 4’s overall performance advantages. This analysis underscores Model 4’s robustness and efficiency, making it the optimal choice for maximizing flux and mass transfer in DCMD systems while maintaining stability across varying pore densities.

Parametric effects of metal foam thickness and distance

The integration of copper metal foam in the DCMD system, particularly in Model 4, significantly enhances thermal uniformity and vapor flux, as demonstrated in previous sections. However, the effects of metal foam thickness and its distance from the membrane surface, which were not varied in this study, warrant consideration due to their potential impact on performance. The metal foam’s thermal conductivity (38 W/m.K) and porosity (0.9) suggest that these geometric parameters could modulate heat transfer and flow dynamics.

Increasing metal foam thickness from could enhance conductive heat transfer to the membrane, further reducing the thermal boundary layer thickness. This might amplify the vapor pressure gradient, potentially boosting flux beyond the observed 31.5 kg/m².h at Re = 200. However, thicker foam could increase the friction factor, as seen in Models 3 and 4, leading to higher pressure drops (tube-side in Model 4) and increased pumping energy demands. Conversely, a thinner foam might limit heat transfer benefits while reducing flow resistance, offering a trade-off to optimize energy efficiency.

The distance of the metal foam from the membrane surface also plays a critical role. A closer proximity could minimize the thermal resistance between the foam and membrane, maintaining higher interface temperatures (the feed side in Model 4) and enhancing the vapor pressure difference. However, this might exacerbate concentration polarization due to reduced flow space. Increasing the distance could improve flow uniformity and reduce pressure drop but may weaken the foam’s heat transfer influence, potentially lowering the temperature gradient across the membrane. The optimal distance likely balances these effects, depending on the Reynolds number and foam properties.

These parametric effects suggest that future studies should explore a range of thicknesses and distances to optimize performance. Such investigations could refine the design of Model 4, maximizing flux while minimizing energy costs, and provide a more comprehensive understanding of metal foam’s role in enhancing DCMD efficiency.

Pressure loss and energy implications

To provide a balanced assessment of the metal foam-enhanced DCMD systems, this subsection quantifies the pressure losses and their impact on energy consumption. While the incorporation of copper metal foam significantly improves convective heat transfer and water vapor flux by disrupting boundary layers, it introduces additional flow resistance through viscous and inertial effects in the porous medium. This leads to elevated friction factors and pressure drops, which in turn increase the required pumping power. The analysis below draws on CFD simulation results, engineering calculations using standard fluid mechanics principles, and comparisons with peer-reviewed literature on metal foam applications in heat transfer devices. All calculations assume steady-state turbulent flow at Re = 100 (unless otherwise specified), with fluid properties derived from the manuscript’s equations (Eqs. 28–31) or standard values for 3.5 wt% NaCl at 60 °C (ρf = 1030 kg/m³, µf = 5 × 10−4 Pa.s) and pure water at 20 °C (ρp = 998 kg/m³, µp = 10−3 Pa.s), consistent with NIST data for aqueous NaCl viscosities.

Quantification of pressure drop, friction factors and energy consumption

The pressure drop (ΔP) across the 0.5 m module length is directly obtained from the CFD simulations solving the Forchheimer-Brinkman momentum equation (Eq. 4), which accounts for porous media effects via permeability (K) (Eq. 21) and Forchheimer coefficient Cf (Eq. 22). For Model 4 (foam on both sides, ε = 0.9, PPI = 30), ΔPtube = 386 Pa and ΔPshell = 150 Pa at Re = 100. These values are 5–10 times higher than in Model 1 (no foam), where estimated ΔPtube ≈ 39 Pa and ΔPshell ≈ 15 Pa based on friction factor ratios.

The Darcy friction factor, calculated as (Eq. 32), quantifies this resistance. Here, hydraulic diameters are: Dh, tube = 0.003 m and Dh, shell = 0.0059 m (computed as 4 A/Pwet.

Where:

Ashell = π×(rhousing² - router²) ≈ 6.07 × 10−5 m².

and:

Velocity (u) is derived from:

yielding utube≈0.0334 m/s and ushell≈0.00823 m/s.

Resulting f values are 5–8 (tube-side) and 10–15 (shell-side) for foam models, versus 0.5–2 for foam-free cases (Figs. 9c–d). As Re increases from 50 to 200, f decreases due to the dominant velocity term, but absolute ΔP rises quadratically.

Parameter sensitivity shows PPI has a pronounced effect: increasing PPI from 30 to 50 reduces pore diameter dp (Eq. 19) from ≈ 7.47 × 10−4 m to ≈ 4.48 × 10−4 m, lowering K (Eq. 21) by ~ 40% and doubling f (Figs. 11c–d), as smaller pores amplify inertial losses (ρ.Cf.|u|.u/√K). Porosity variations (0.9–0.99) have negligible impact, as high ε maintains low resistance.

These findings are corroborated by experimental and simulation studies on metal foam-filled channels. For example, in single-phase liquid flow through copper foam tubes, Ali and Ghasem (2023) reported f increases of 5–15 times over empty channels at Re = 100–10,000, with ΔP ~ 100–500 Pa/m for similar foam parameters, aligning with our validation (Fig. 5b). In two-phase applications relevant to MD, Kim et al.8 noted 4–15% ΔP reductions in hydrophilic foams due to surface effects, but for non-wetting cases like our DCMD, increases dominate.

In terms of Pumping power (W), it is computed as:

where volumetric flow rate is:

For Model 4 at Re = 100:

Qtube ≈ 2.36 × 10−7 m³/s (Atube ≈ 7.07 × 10−6 m²).

yielding:

Wtube ≈ 9.11 × 10−5 W; Qshell ≈ 4.99 × 10−7 m³/s, Wshell ≈ 7.49 × 10−5 W; total W ≈ 1.66 × 10−4 W. And For Model 1, W ≈ 0.66 × 10−5 W, indicating a ~ 10-fold increase due to foam.

The specific electrical energy consumption (SECelectrical) for pumping is:

where permeate volume rate is:

with membrane area:

Amem = 2π × rinner ×L ≈ 0.00471 m² (inner surface basis, common in hollow-fiber DCMD).

For Model 4, J ≈ 24 kg/m².h (interpolated from Fig. 9a), Vpermeate ≈ 3.15 × 10−8 m³/s, SEC ≈ 0.00147 kWh/m³. For Model 1 (J ≈ 18.2 kg/m².h, ~ 32% lower), SEC ≈ 0.000193 kWh/m³, a ~ 7.6-fold relative increase despite higher flux in Model 4.

These per-fiber values are low, but in industrial modules (104–105 fibers), manifold and scaling effects could elevate baseline SEC to 0.1–2 kWh/m³, with foam adding 0.5–5 kWh/m³ penalty. In foam-enhanced systems, similar penalties are reported: Jadhav et al.39 observed 20–50% higher SEC in foam-filled pipes, but net gains from reduced thermal input. Overall, the electrical penalty is minor compared to MD’s thermal Sects. (101–1000 kWh/m³), especially with low-grade heat sources.

Implications, trade-offs, and recommendations

The elevated pressure losses limit scalability by increasing operational energy costs (~ 10–20% rise in electrical SEC), potentially offsetting flux gains in high-Re operations where ΔP ~ u². Foam parameters exacerbate this: higher PPI yields better heat transfer but up to 100% ΔP increase (Fig. 11), a trade-off quantified by performance evaluation criteria (PEC = (Nufoam/Nuempty)/(ffoam/fempty)1/3 ≈ 1.5–2.5 in our models, indicating net benefit > 1). Corrosion/fouling could further amplify ΔP by 20–50%, as salt deposition reduces effective ε.

To mitigate, future simulations recommend graded foams (variable PPI) or partial filling, reducing ΔP by 30–50% with < 10% flux loss. Experimental validation in multi-fiber modules is essential to confirm these implications and guide energy-efficient designs.

Future direction

An intriguing direction for advancing metal foam-enhanced DCMD involves integrating direct solar irradiation absorbed in the feed channel, as demonstrated by a study52 in their systematic modeling of over 1000 DCMD cases, where photothermal effects yield flux enhancements exceeding 200% by reducing temperature polarization. In our Hollow-fiber configurations, particularly Model 4, the copper foam could serve as a photothermal substrate (via nanoparticle coatings) to distribute solar heat uniformly, potentially amplifying flux by 50–100% while leveraging the foam’s boundary layer disruption for improved efficiency. This hybrid solar-foam approach aligns with emerging solar-MD technologies, such as integrated Hollow-fiber solar-VMD modules achieving 20–50% efficiency gains53 and reviews emphasizing tubular absorbers for flux boosts up to 300%54. Future CFD studies should incorporate radiative source terms and experimental validations to optimize irradiation intensity, foam modifications, and counter-current flows for sustainable, off-grid desalination, addressing global water scarcity with renewable energy.

To ensure the practical viability of metal foam-enhanced DCMD in saline environments, future research should prioritize addressing corrosion and fouling challenges associated with copper foams. Copper’s susceptibility to chloride-induced corrosion, with rates of 0.01–0.025 mm/year in seawater, and fouling risks from salt accumulation in pores could compromise long-term performance55. Mitigation strategies include applying protective coatings, such as nickel plating or graphene layers, which have demonstrated over 90% reduction in corrosion rates in saline conditions56, while preserving thermal conductivity. Alternatively, transitioning to corrosion-resistant materials like stainless steel or titanium foams, with conductivities of 15–21 W/m.K, could maintain boundary layer disruption benefits, potentially yielding 20–25% flux improvements based on our model’s sensitivity. System optimizations, such as periodic backflushing or anti-fouling additives, and operation at moderate temperatures (60 °C) to slow kinetics, warrant experimental validation through accelerated tests (such as ASTM G48) and fouling studies. Complementing these efforts, exploiting the Marangoni effect—surface tension-driven convection from thermal or concentration gradients—offers promise for enhanced salt rejection and reduced polarization. Recent simulations show Marangoni flows exceeding diffusive transport by three orders of magnitude, improving flux by 10–20% and enabling stable operation in high-salinity brines57. Integrating Marangoni terms into CFD models (via stress tensors in momentum equations) could synergize with metal foam in Model 4, augmenting Sherwood numbers and anti-fouling, paving the way for hybrid designs validated experimentally for scalable, sustainable desalination.

Conclusion

This CFD study has effectively illustrated the transformative potential of integrating copper metal foam within DCMD systems for seawater desalination, addressing critical challenges such as temperature polarization and low water vapor flux. By systematically analyzing four distinct DCMD configurations, this research provides valuable insights into the synergistic effects of metal foam on flow dynamics, heat transfer, and mass transfer. The detailed analysis of velocity, thermal, and concentration distributions indicates that metal foam disrupts hydrodynamic and thermal boundary layers, which fosters uniform velocity profiles and decreases temperature polarization. The superior performance of Model 4 is attributed to the high thermal conductivity of copper foam (380 W/m.K) and its high porosity (0.9), which facilitate efficient heat transfer while maintaining a consistent vapor pressure gradient across the membrane. Notably, increasing the Reynolds number from 50 to 200 enhances flux across all models, with Model 4 achieving a peak flux of 31.5 kg/(m².h), attributed to improved convective heat transfer. In terms of the effects of Reynolds number and PPI, Model 4, consistently outperforms the other DCMD configurations, achieving a flux that is 32% higher than Model 1, 23% above Model 2, and 8% greater than Model 3 at Re = 200, as well as 22% over Model 2 and 4% above Model 3 across PPI values ranging from 30 to 60. However, it is noteworthy that the shell-side friction factor of Model 4 Aligns with Model 3, significantly surpassing the values of Models 1 and 2, while the tube-side friction factor equals that of Model 2. This reflects enhanced heat and mass transfer resulting from reduced boundary layers, albeit at the expense of increased energy demands. Nonetheless, variations in porosity and PPI have minimal influence on flux and Sherwood number, indicating that the advantages of metal foam remain consistent across a diverse range of foam properties, thereby establishing it as a versatile enhancement for DCMD systems. This study confirms that the incorporation of metal foam in DCMD significantly enhances flux and mass transfer efficiency. Additionally, the pressure drops in the DCMD system with metal foam, particularly in Model 4, remains significantly below 1 atm—measured at 386 Pa on the tube side and 150 Pa on the shell side.

Future directions for metal foam-enhanced DCMD include integrating direct solar irradiation in the feed channel for flux boosts over 200% via photothermal effects reducing temperature polarization, as modeled in many cases, with 50–100% amplification in Model 4 using nanoparticle-coated foam, Aligning with solar-MD advances like 20–50% efficiency in hollow-fiber VMD (https://doi.org/10.3390/membranes14020050) and 300% flux in tubular absorbers. Address copper foam corrosion (0.01–0.025 mm/year in seawater) and fouling through coatings like nickel/graphene (> 90% rate reduction), alternatives like titanium (20–25% flux retention), and backflushing, validated by ASTM G48 and studies. Exploit Marangoni effect for 10–20% flux gains and salt rejection in brines by adding surface tension gradients to CFD, synergizing with foam for hybrid desalination.

Data availability

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Parani, S. & Oluwafemi, O. S. Membrane Distillation: Recent Configurations, Membrane Surface Engineering, and Applications11934 (Membranes, 2021).

Al-Anezi, A. A., Sharif, A. O., Sanduk, M. I. & Khan, A. R. Potential of membrane distillation – a comprehensive review. Int. J. Water. 7, 317–346 (2013).

Khayet, M. Membranes and theoretical modeling of membrane distillation: A review. Adv. Colloid Interface Sci. 164, 56–88 (2011).

Pagliero, M., Bottino, A., Comite, A. & Costa, C. Novel hydrophobic PVDF membranes prepared by nonsolvent induced phase separation for membrane distillation. J. Membr. Sci. 596, 117575 (2020).

Kim, H., Yun, T., Hong, S. & Lee, S. Experimental and theoretical investigation of a high performance PTFE membrane for vacuum-membrane distillation. J. Membr. Sci. 617, 118524 (2021).

Choubani, K., Sammoudi, M. & Ennetta, R. Performance modelling of direct contact membrane distillation for flat sheet module. Desalination Water Treat. 262, 27–37 (2022).

Asiri, J. M., Alasiri, A. M., Caspar, J., Xue, G. & Oztekin, A. Performance Characterization of Hollow Fiber Direct Contact Membrane Distillation Module, ASME 2021 (International Mechanical Engineering Congress and Exposition, 2021).

Lee, C. K., Park, C., Woo, Y. C., Choi, J. S. & Kim, J. O. A pilot study of spiral-wound air gap membrane distillation process and its energy efficiency analysis. Chemosphere 239, 124696 (2020).

Francis, L., Ahmed, F. E. & Hilal, N. Adv. Membrane Distillation Module Configurations Membr., 12 81. (2022).

Ali, A. et al. Quist-Jensen, progress in module design for membrane distillation. Desalination 581, 117584 (2024).

Janajreh, I., Suwwan, D. & Hashaikeh, R. Theoretical and experimental study of direct contact membrane distillation. Desalination Water Treat. 57, 15660–15675 (2016).

Sirkar, K. K., Singh, D. & Li, L. Membrane distillation in desalination and water treatment. In Sustainable Membrane Technology for Water and Wastewater Treatment (eds Figoli, A. & Criscuoli, A.) 201–219 (Springer Singapore, 2017).

Abdel-Rahman, A. K. & TEMPERATURE AND SALT CONCENTRATION DISTRIBUTIONS IN, M. O. D. E. L. I. N. G. DIRECT CONTACT MEMBRANE DISTILLATION, JES. J. Eng. Sci. 36, 1167–1188 (2008).

Esfandiari, A., Hosseini Monjezi, A., Rezakazemi, M. & Younas, M. Computational fluid dynamic modeling of water desalination using low-energy continuous direct contact membrane distillation process. Appl. Therm. Eng. 163, 114391 (2019).

Shokrollahi, M., Rezakazemi, M. & Younas, M. Producing water from saline streams using membrane distillation: modeling and optimization using CFD and design expert. Int. J. Energy Res. 44, 8841–8853 (2020).

Momeni, M., Kargari, A., Dadvar, M. & Jafari, A. 3D-CFD simulation of Hollow fiber direct contact membrane distillation module: effect of module and fibers geometries on hydrodynamics, mass, and heat transfer. Desalination 576, 117321 (2024).

Abrofarakh, M., Moghadam, H. & Abdulrahim, H. K. Investigation of direct contact membrane distillation (DCMD) performance using CFD and machine learning approaches. Chemosphere 357, 141969 (2024).

Zare, S. & Kargari, A. CFD simulation and optimization of an energy-efficient direct contact membrane distillation (DCMD) desalination system. Chem. Eng. Res. Des. 188, 655–667 (2022).

Jain, S. & Mishra, P. Survey Report on Computational Fluid Dynamic (CFD) opportunities applied to the membrane distillation process, (2018).

Alqsair, U. F., Alshwairekh, A. M., Alwatban, A. M. & Oztekin, A. Computational study of sweeping gas membrane distillation process – Flux performance and polarization characteristics. Desalination 485, 114444 (2020).

Ansari, A. et al. Computational fluid dynamics modelling of air-gap membrane distillation: Spacer-filled and solar-assisted modules. Desalination 546, 116207 (2023).

Yadav, A., Singh, C. P., Patel, R. V., Labhasetwar, P. K. & Shahi, V. K. Computational fluid dynamics based numerical simulations of heat transfer, fluid flow and mass transfer in vacuum membrane distillation process. Water Supply. 22, 6262–6280 (2022).

Alwatban, A. M., Alshwairekh, A. M., Alqsair, U. F., Alghafis, A. A. & Oztekin, A. Effect of membrane properties and operational parameters on systems for seawater desalination using computational fluid dynamics simulations. Desalination Water Treat. 161, 92–107 (2019).

Cipollina, A., Di Miceli, A., Koschikowski, J., Micale, G. & Rizzuti, L. CFD simulation of a membrane distillation module channel. Desalination Water Treat. 6, 177–183 (2009).

Afsari, M., Ghorbani, A. H., Asghari, M., Shon, H. K. & Tijing, L. D. Computational fluid dynamics simulation study of hypersaline water desalination via membrane distillation: effect of membrane characteristics and operational parameters. Chemosphere 305, 135294 (2022).

Choi, J., Cho, H., Choi, Y. & Lee, S. Combination of computational fluid dynamics and design of experiments to optimize modules for direct contact membrane distillation. Desalination 524, 115460 (2022).

Park, D., Norouzi, E. & Park, C. Experimental and Numerical Study of Water Distillation Performance of Small-Scale Direct Contact Membrane Distillation System, ASME 2017 (International Mechanical Engineering Congress and Exposition, 2017).

Hu, H., Zhao, Y. & Li, Y. Research progress on flow and heat transfer characteristics of fluids in metal foams. Renew. Sustain. Energy Rev. 171, 113010 (2023).

Hassan, A. M., Alwan, A. A. & Hamzah, H. K. Metallic foam with cross flow heat exchanger: A review of parameters, performance, and challenges. Heat. Transf. 52, 2618–2650 (2023).

Kotresha, B. & Gnanasekaran, N. Numerical simulations of fluid flow and heat transfer through aluminum and copper metal foam heat Exchanger – A comparative study. Heat Transfer Eng. 41, 637–649 (2020).

Chandora, N., Mani, A. & Advaith, S. Investigation of heat transfer and pressure drop characteristics in metal-foam filled channels in a plate heat exchanger: A comparative experimental study. Appl. Therm. Eng. 241, 122368 (2024).

Mahdi, H., Lopez Jr, P., Fuentes, A. & Jones, R. Thermal performance of aluminium-foam CPU heat exchangers. Int. J. Energy Res. 30, 851–860 (2006).

Durmus, F. Ç., Maiorano, L. P. & Molina, J. M. Open-cell aluminum foams with bimodal pore size distributions for emerging thermal management applications. Int. J. Heat Mass Transf. 191, 122852 (2022).

Wang, P., Qin, D., Wang, T. & Chen, J. Thermal performance analysis of gradient porosity aluminium foam heat sink for Air-Cooling battery thermal management system. Appl. Sci. 12, 4628 (2022).

Cheong Tan, W. et al. M. Kun Yew, Investigation of water cooled aluminium foam heat sink for concentrated photovoltaic solar cell, IOP Conference Series: Earth and Environmental Science, 268 012007. (2019).

Ho, C. D., Chang, H., Yang, T. J., Wu, K. Y. & Chen, L. Theoretical and experimental studies of laminar flow Hollow fiber direct contact membrane distillation modules. Desalination 378, 108–116 (2016).

Shafieian, A., Khiadani, M. & Zargar, M. Performance analysis of tubular membrane distillation modules: an experimental and CFD analysis. Chem. Eng. Res. Des. 183, 478–493 (2022).

Yu, H., Yang, X., Wang, R. & Fane, A. G. Numerical simulation of heat and mass transfer in direct membrane distillation in a Hollow fiber module with laminar flow. J. Membr. Sci. 384, 107–116 (2011).

Jadhav, P. H., Gnanasekaran, N., Perumal, D. A. & Mobedi, M. Performance evaluation of partially filled high porosity metal foam configurations in a pipe. Appl. Therm. Eng. 194, 117081 (2021).

Abrofarakh, M. Effect of incorporating Sulzer SMV static mixers on the performance of direct contact membrane distillation (DCMD): A three-dimensional computational fluid dynamics (CFD) study. Sep. Purif. Technol. 359, 130606 (2025).

Abrofarakh, M. Investigation of performance and entropy generation rate of direct contact membrane distillation (DCMD) with metal foam: A CFD study. Arab. J. Sci. Eng. 50, 3869–3884 (2025).

Rezakazemi, M. CFD simulation of seawater purification using direct contact membrane desalination (DCMD) system. Desalination 443, 323–332 (2018).

Guendouzi, M. E., Dinane, A. & Mounir, A. Water activities, osmotic and activity coefficients in aqueous chloride solutions att = 298.15 K by the hygrometric method. J. Chem. Thermodyn. 33, 1059–1072 (2001).

Ali, R. M. K. & Ghashim, S. L. Numerical analysis of the heat transfer enhancement by using metal foam. Case Stud. Therm. Eng. 49, 103336 (2023).

Abrofarakh, M. & Moghadam, H. Investigation of thermal performance and entropy generation rate of evacuated tube collector solar air heater with inserted baffles and metal foam: a CFD approach. Renew. Energy. 223, 120022 (2024).

McKeon, B., Zagarola, M. & Smits, A. A new friction factor relationship for fully developed pipe flow. J. Fluid Mech. 538, 429–443 (2005).

Abrofarakh, M., Moghadam, H., Abdulrahim, H. K. & Ahmed, M. M. Investigating the performance of direct contact membrane distillation for liquid desiccant regeneration and freshwater production: A CFD-based study. J. Ind. Eng. Chem. https://doi.org/10.1016/j.jiec.2024.11.010 (2024).

Abrofarakh, M., Moghadam, H., Abdulrahim, H. K. & Ahmed, M. M. Investigating the performance of direct contact membrane distillation for liquid desiccant regeneration and freshwater production: A CFD-based study. J. Ind. Eng. Chem. 146, 293–301 (2025).

Abrofarakh, M. & Moghadam, H. Enhancing thermal performance and reducing entropy generation rate in evacuated tube solar air heaters with inserted baffle plate using static mixers: A CFD-RSM analysis. Therm. Sci. Eng. Progress. 55, 103012 (2024).

Ali, R. M. K. & Ghashim, S. L. Thermal performance analysis of heat transfer in pipe by using metal foam. Jordan J. Mech. Industrial Eng. 17, 205–2018 (2023).

SantanaV.V. et al. PUFFIN: A path-unifying feed-forward interfaced network for vapor pressure prediction. Chem. Eng. Sci. 286, 119623 (2024).

Meo, R. R. et al. Systematic exploration of direct solar absorption potential to enhance direct contact membrane distillation. Desalination 606, 118740 (2025).

Alfonso, G., Laborie, S. & Cabassud, C. Modeling of Integrated Hollow-Fiber Solar-Powered VMD Modules for Desalination for a Better Understanding and Management of Heat Flows, Membranes, 14 50. (2024).

Jawed, A. S. et al. Recent developments in solar-powered membrane distillation for sustainable desalination. Heliyon 10, e31656 (2024).

Tuthill, A. H. Guidelines for the Use of Copper Alloys in Seawater (Nickel Development Institute Ontario, 1987).

Zhang, P., Meng, G., Wang, Y., Lei, B. & Wang, F. Significantly enhanced corrosion resistance of Ni–Cu coating modified by minor cerium. Corros. Commun. 2, 72–81 (2021).

Stincone, G. et al. Optimizing the Marangoni effect towards enhanced salt rejection in thermal passive desalination. Desalination 583, 117673 (2024).

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

Conceptualization, R.S. and M. A.; methodology, R.S. and M.A.; software, M.A.; validation, H. M. and M. S.; formal analysis, R.S. and M.S.; investigation, R.S.; resources, R.S.; data curation, R.S. and H. M.; writing—original draft preparation, R.S. and M. A.; writing—review and editing, M.A.; visualization, R.S.; supervision, M.A. and H. M.; project administration, H. M., M. S. and R.S. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Abrofarakh, M., Shahouni, R., Moghadam, H. et al. CFD analysis of heat and mass transfer in hollow fiber DCMD enhanced by metal foam. Sci Rep 15, 35125 (2025). https://doi.org/10.1038/s41598-025-19148-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-19148-7