Abstract

The heat treatment and machining can be considered as necessary post process operations to create functional components manufactured by means of laser powder bed fusion. Therefore, complex investigation of influence of microstructure on the machinability of maraging steel (MS) M300 parts produced by laser powder bed fusion (LPBF) and rolling was performed. The main evaluation was carried out in regard to hardness, milling forces, surface morphology, surface roughness, chip formation, and subsurface hardness and microstructure. The findings revealed that LPBF MS M300 after direct aging heat treatment, containing martensite with dispersed precipitates and reversed austenite, generated highest milling forces. Surface roughness of this material showed a lower surface roughness in comparison to as-built sample Due to the higher hardness, which caused a lower lateral plastic flow and most severe tool wear. The subsurface hardness under the milled area of direct aged samples increased by 24% (900 HV) in comparison to the bulk value, while in case of conventionally manufactured rolled sample the increase was only by 9%. More pronounced increase in subsurface hardness was measured on samples milled utilizing highest cutting speed (60 m.min-1). Furthermore, milling induced strain hardening affecting the subsurface area up to approximately 40 μm in depth.

Similar content being viewed by others

Introduction

In recent times, additive manufacturing (AM) has transitioned from an experimental, prototype-oriented method to a validated manufacturing technology for a production of increasingly sophisticated components1. Powder bed fusion technology stands out as the widely adopted method for crafting these components, offering the capability to design intricate parts with exceptional resolution and favorable mechanical properties2. A distinction between AM and machining lies in the process of material production. While machining involves the removal of material, AM builds the final component by gradually adding material layer by layer3. AM utilizes fine powder to fabricate desired components. The use of the initial powder offers researchers and producers a flexibility to mix unique properties of individual elements, leading to a creation of a broad spectrum of alloys such as maraging steel4,5, Inconel 7186,7, 316 L stainless steel8,9, copper and Titanium alloys10 or plastic materials11. This technology enables the production of intricate shapes that are challenging to achieve through traditional casting, forming, or chip machining methods12,13. Applications of AMed components are virtually limitless, spanning across industries such as automotive, aviation, and healthcare14,15.

Maraging steel (MS) finds extensive application in aerospace components, including aircraft, missile casings, bearings, forgings, transmission shafts and tooling and dies. A suitability of MS powder for processing through laser powder bed fusion (LPBF) is notable Due to its low carbon content, at 0.03%, contributes to its excellent weldability and toughness16. PBF manufacturing process involves various process parameters influencing the final mechanical properties of the part. Key parameters include scanning speed17, flow rate18, infill pattern and density19, layer thickness20, 3D printing strategy21 and so on. Vishwakarma et al.22 studied an effect of build orientation on microstructure and tensile mechanical properties of M300 MS fabricated by LPBF with heat treatment. They found out that most of LPBF samples showed an increase in strength without significant loss of ductility after heat treatment. Omidi et al.23 observed effects of process parameters on MS M300 surface roughness and mechanical properties. They revealed that laser power is the most influential parameter on the roughness value. Souza et al.24 investigated the effect of process parameters (layer thickness) on the microstructure and manufacturing time of M300 MS 3D printed by LPBF. The study revealed that the layer thickness featured a higher influence on the manufacturing time than scanning speed. Rivalta et al.25 examined effects of the scanning strategies on dimensions, average surface roughness, density, and material hardness. It revealed that a hexagonal strategy led to lower density, higher and average surface roughness (Ra).

Although the LPBF has been widely applied for fabrication, the surface quality of parts is not sufficient. The as-built surface quality (Ra) reached about 10 μm, which cannot be used as a functional surface. Hence the machining is a necessary part included as a post process operation. Ni et al.26 focused on the recent research progress on microstructure, mechanical properties and post-machining performance of LPBF Ti–6Al–4 V alloys. They performed the comprehensive study in regards of machinability of SLMed Ti–6Al–4 V samples and discussed it in terms of cutting force, surface morphology and roughness and subsurface microstructure evolution. A similar study was carried out by Kolomy et al.27. They investigated the effect of microstructure on machinability and extruded H13 tool steel. Duval-Chaneac et al.28 utilized abrasive flow machining to improve a surface roughness in cooling channels of a LPBF heat treated part. They used four different media with dissimilar abrasive concentration and viscosity. They found out that the higher abrasive concentration and media viscosity bring about the lower surface roughness. Croccolo et al.29 studied effects of build orientation and of allowance for machining on a fatigue response of aged M300 MS. They discovered that specimens after machining featured a higher fatigue life. Tascioglu et al.30 investigated effects of both aging and finishing via machining on surface roughness and microstructure of LPBF and wrought samples. The finish machining resulted in the reduction of the surface roughness of the LPBF samples similar to the wrought surface and also plastically deformed the surface layer resulting in a slightly higher hardness. Fortunato et al.31 observed differences in machinability of LPBF M300 MS with heat treatment when milling. They discovered that a higher cutting speed resulted in the lower surface roughness. Tamura et al.32 studied cutting forces During milling of the MS processed by LPBF without a heat treatment and compared with a wrought material. They used a 5 mm end mill for slot milling and found out that the LPBF material induced vibrations during cutting due to an inhomogeneity in the material. Bai et al.33 tested a machinability and effects of microstructure of heat-treated MS. A difference in tool wear in milling the LPBF MS corresponded to different sample microstructures on machinability. In addition, precipitates, severely scratched cutting tools.

Although a few papers have described the machinability of AMed parts, comparative studies regarding the machinability of LPBF and wrought M300 MS alloy are limited. Hence, the purpose of the current study is to investigate the effect of cutting conditions (especially the cutting speed) when milling M300 MS. The novelty of this study lies in comparing machinability of LPBF material with the wrought counterpart accompanied by the thorough microstructure analysis of as-built, direct aged and wrought material. The manuscript is unique in the material study and giving this information in relation to the machinability. The machinability of M300 MS material acquired by different manufacturing processes (LPBF, LPBF + heat treatment and rolling) is then evaluated and critically discussed in terms of tool wear, cutting force, surface roughness, chip morphology, microhardness and sub-surface microstructure using series of tools such as optical microscopy, scanning microscopy, EBSD and TEM. This study provides a better understanding of the forming process-structure-machinability relationship of M300 MS alloy and integrates the AM and subtractive process in the production of complex structural components such as injection molds made from M300 MS in order to improve efficiency and reduce costs.

Experimental procedure

Samples preparation

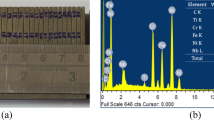

Samples were manufactured using a metal powder feedstock with the chemical composition detailed in Table 1. The production process involved utilization of the Renishaw RenAM 500E 3D printer equipped by the Yb- fiber laser with the 75 μm diameter of the laser beam to create block samples (see Fig. 1a). The meander hatching pattern strategy, incorporating a 67° rotation after each layer, was employed for the parts fabrication, as illustrated in Fig. 1b. This strategic approach (see Fig. 1c) facilitates effective powder melting and the formation of a structure with low porosity31. The building direction (BD) aligns with the Z-axis, and the specific process parameters applied are outlined in Table 2.

Printed samples typically exhibit residual stress after 3D printing. However, this stress can be alleviated through a heat treatment34. The heat treatment not only reduces residual stress but also causes precipitation of Ni3Ti and Ni3Mo, precipitates leading to the formation of a uniform material microstructure35. In this study, three types of samples i.e., as-built (AB), directly aged (DA) at 490 °C/6 h, and as-received wrought (ARW) were compared.

Experimental settings and methodology

Machinability testing was performed by sintered carbide end mills protected with a TiN coating, specifically designed for machining materials with a maximum hardness of 700 HV. Several factors can impact machinability, encompassing workpiece material, cutting conditions, clamping, and cooling. The parameters which were held constant throughout the entire experiment are outlined in Table 3. To evaluate tool wear at the end of the test, scanning electron microscope Tescan Vega (Tescan Orsay Holding, Czechia) was used.

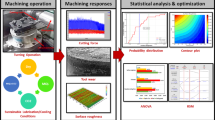

The main objective was to evaluate the impact of cutting speed, when dry machining (DM) of different types of samples, on the machinability and structure of M300 MS. The set cutting parameters encompassing four different cutting speeds i.e. 30 m.min−1, 40 m.min−1, 50 m.min−1 and 60 m.min−1 corresponding to tests in the range I to IV for each sample (AB, DA and ARW). The cutting speed was chosen based on the tool manufacturer’s recommendation. Each test was performed with the new endmill to avoid any adverse effect by the tool wear. This phenomenon was carried out to obtain reliable and functional data. Parameters feed per tooth fz = 0.02 mm, and DM was constant during each test. Each type of the sample (AB, DA, ARW) was used for four individual machinability tests and each individual measurement was repeated three times. The testing methodology is illustrated in Fig. 2a, and the evaluating methodology is detailed in Fig. 2b. The dimensions of the samples tested were 20 × 30 × 60 mm.

Evaluation of microstructure and properties

The microstructure (M) of each sample was studied in XY direction in etched state (5% Nital), in area specified in Fig. 2b, using the light microscope Axio Observer Z1m with motorized X/Y axis (Carl Zeiss AG, Germany). Porosity of individual samples was evaluated on metallographic samples prepared from XY cross sections using Olympus StreamMotion software (Olympus Corp., Japan). The evaluated area was in the range from 250 to 300 mm2 per sample.

The field emission gun scanning electron microscope (FEG-SEM, Ultra Plus, Carl Zeiss AG, Germany) equipped with an electron backscatter diffraction (EBSD) detector (Nordlys Nano, Oxford Instruments, UK) was used for advanced analyses. EBSD measurements were conducted on metallographic samples tilted at 70°, which were prepared using standard methods, including finishing with 0.7 μm diamond paste and vibro-polishing (QPol Vibro, QaTM GmbH, Germany) for 4 h in 0.05 μm colloidal silica. The analyses were performed with an accelerating voltage of 20 kV, a scanning spot size of 0.2 μm, and a 120 μm aperture in high current mode. The minimum grain area was set to 10 pixels. The Kernel Average Misorientation (KAM) for each pixel was calculated as the average misorientation between the measured point and its 8 nearest neighbors, with a sub-grain misorientation threshold of 5°. The preferred orientation of the structure was evaluated based on the pole figures. Upper hemisphere projection with combinations of crystallographic poles {100}, {110} and {111} were used in pole figures. EDS mapping of tool after milling was performed using FEG-SEM Tescan LYRA 3 equipped with an EDS detector (Ultim Max Infinity 100, Oxford Instruments, UK).

To study the nanometric precipitates formed during the manufacturing process, transmission electron microscopy (TEM) analyses on XZ plane of AB and DA samples were carried out by the microscope Jeol 2100 (Jeol Ltd., China) with an accelerating voltage of 200 kV.

Instrumented hardness (IH) was measured to prove the presence and to evaluate the depth of subsurface hardening caused by milling using a load of 2 g with the dwell time of 10 s in a standard hardness mode (CSM Instruments NHT2, Anton Paar Group AG, Austria) in the XY direction. Instrumented hardness was measured in several lines from the bottom and from the side (as depicted in Fig. 2b) of milling areas of all samples (AB, DA and ARW) milled under conditions I and IV. To define sample hardness (HV 0.5) a LECO 247 AT (LECO Corporation, USA) hardness tester with the load of 50 g with the dwell time 10 s was used.

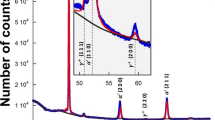

The phase composition of samples ARW, AB, and DA was analyzed using X-ray diffraction (X’Pert Pro, Phillips, Netherlands). The diffractometer operated in Bragg-Brentano geometry with Cu Kα radiation (λ = 1.54 Å) and was equipped with a 1D X’Celerator detector. The Cu lamp was set to a current of 30 mA and a voltage of 40 kV. Diffraction patterns were collected over a 2θ range from 35° to 110° with a step size of 0.016°. Phase identification was conducted based on the known chemical composition, utilizing the PDF2 and ICSD databases. Quantitative phase analysis through Rietveld refinement using X’Pert Highscore software (Malvern Panalytical Ltd., Netherlands) was conducted to study the presence and amount of retained and/or reverse austenite in microstructure of individual samples, especially after direct aging heat treatment.

Evaluation of material machinability

Each test outlined in Sect. 2.2 underwent measurement of cutting forces (F), instrumented hardness (IH), and an examination of microstructure (M) and surface quality (Q). The regions, where particular analysis for each sample was performed, are depicted in Fig. 2b. Cutting forces (F) were measured in phases P1-P4 (marked with an orange color) using a Kistler dynamometer enable the performance of monitoring forces in three perpendicular axes. A total cutting length was divided into four phases (P1st measurement corresponds to the cutting length of 60 mm, P2nd to 260 mm, P3rd to 460 mm and P4th to 610 mm), after each phase the milling forces were measured. Data was recorded at a frequency of 4 kHz and processed using software Dynoware. Forces (Fx, Fy, and Fz) were measured in each test, with different time depending on the cutting speed. Although the time was different in each test, the cutting length remained constant at 610 mm for each tool.

Surface quality (Q) analysis was conducted in areas marked A-D (with the red color), which correlate with the same cutting length as in case of cutting forces measurement. An average surface roughness Ra and parameter Rz were measured using a contour graph Taylor Hopson Form Talysurf 50 (Ametek Ltd, GB). Closer surface observation was carried out with the Alicona Infinite Focus G5 (Bruker Corp., USA). The chips were captured by light microscopy and studied in detail via electron microscope Tescan VEGA (Tescan Orsay Holding, Czechia) equipped with SE detector and using accelerating voltage of 30 kV.

Results and discussions

LPBF manufactured samples hardness and structure characterization

Measured porosity of samples ARW, AB and DA reached values of 0.01, 0.13 ± 0.01 and 0.09 ± 0.01%, respectively. The decrease in porosity of DA sample is related to enhanced diffusion during direct aging heat treatment.

The ARW sample featured a hardness of 390 ± 15 and 400 HV0.5 ± 15 in XY and XZ directions, respectively (Fig. 3). The hardness of the as-built material reached 360 ± 15 and 350 ± 15 HV0.5 in horizontal XY and vertical XZ directions (Fig. 3). The heat treatment (direct aging) yielded an increase of DA sample to 570 ± 12 and 565 ± 20 HV0.5 in XY and XZ directions, respectively.

The difference between hardness of ARW and AB samples is attributed to the individual microstructural characteristics (Fig. 4a-d): the AB sample contains fine cellular structure with strip features along melt track (pool) boundaries (Fig. 4d), whereas the ARW sample predominantly contains very fine lath martensite related to the manufacturing process (rolling, Fig. 4a, b). The rolling caused an increase in dislocation density resulting in slightly higher hardness.

The AB samples exhibited a microstructure characterized by a melt pool structure with two distinct regions, which are attributed to different etching contrasts (Fig. 4c). The edges of tracks solidify first due to the higher heat dissipation into the already cooled tracks beneath leading to element segregation during the cooling and visualization of the melt pool boundaries. Darker regions represent a tempered martensite region, alternating with brighter areas corresponding to less extensively tempered regions (can be marked as quenched region)36. These regions may feature the different microhardness, which can influence cutting forces. The fine cellular microstructure of AB (Fig. 4d) influenced the response of material during milling by more effectively impeding dislocation movement, owing to the increased number of boundaries they introduce (described in Sect. 3.3cutting forces and 3.4 surface quality). This observation aligns with findings reported by Song et al37,38,39..

The superior combination of properties of M300, i.e. high strength, hardness and toughness is caused by peak hardening (aging at 490 °C/6h40,. In the case of DA sample, direct aging heat treatment resulted in a significant increase in hardness in comparison with ARW and AB samples. This enhancement was primarily due to the precipitation of nano-scale precipitates, including Ni3Mo, Ni3Ti and Ni3Al. These small precipitates act as significant barriers to dislocation motion, thereby strengthening the material. Additionally, the hardness plays a significant role considering the cutting forces (described in Sect. 3.3). The elevated hardness of DA sample provided higher resistance against fracture, necessitating increased cutting force for material removal. Consequently, this led to an escalation in cutting forces during machining.

The microstructure of DA samples after heat treatment changed significantly. Melt track boundaries originally present in AB samples dissolved and became non-continuous along with the complete disappearance of cellular microstructure and partial disappearance of strip microstructure in melt pools33,41. The inherent change is visible when comparing etched microstructure of AB and DA samples in Fig. 4c, d, e and f.

The phase composition of AB, DA and ARW samples was examined by XRD. As expected, all samples exhibited phase composition of BCC structured martensite and FCC structured austenite phases. Additionally, samples ARW and DA consisted also of precipitates, identified as type M7C3 carbide with the amount of 1,9 and 6,3%, respectively (see Fig. 5). Other precipitates were not detected via XRD due to their low amount and size42. ARW sample contained also 1,9% o austenite.

During direct aging heat treatment without previous solution treatment, the melt pool boundaries did not completely disappear Due to insufficient time and temperature. Aging treatment mainly caused the precipitate formation, and increased the amount of austenite and carbides present in the microstructure. The size of precipitates restricts their visibility in images acquired by light and scanning electron microscopy. Direct aging was accompanied by an increase in the amount of retained and reversed austenite phase from 1,2% in AB state to 5,6% in DA state. Retained austenite is naturally present in the AB state due to local oversaturation with austenite stabilizing Ni caused by LPBF process and reversed austenite in DA state caused by inevitable martensite-to-austenite transformation during heat treatment reported in several studies33,38,43. The release of Ni into the Fe matrix which accompanies the transformation of Ni3(Mo, Ti) to the more stable Fe2Mo precipitates promotes the austenite reversion40.

EBSD analysis brought useful evidence regarding microstructure, misorientation and texture of ARW, AB and DA samples. Based on the IPF map, ARW samples consisted of a relatively fine grains with the maximum size of 30 μm (Fig. 6a). In many grains fine martensite laths showed similar crystallographic orientation. Pole figures (Fig. 6a) showed relatively weak preferred orientation with the maximum intensity of 4 at < 110 > pole parallel to Z direction of sample section. KAM maps of all samples acquired in the area unaffected by machining showed very similar misorientation (Fig. 6b, d,f).

AB samples consisted of slightly coarser grain with the max grain size was 54 μm (Fig. 6c). More importantly the pole figure (Fig. 6c) showed an increase in preferred orientation intensity to 14,3 at < 111 > pole parallel to Z direction of sample section. The increase in preferred orientation was caused mainly by the LPBF manufacturing process.

Aging heat treatment in case of DA samples led to an increase in the amount of austenite and change in the martensite structure from cells to laths. Static recovery led also to grain coarsening and secondary precipitation. DA sample reached the highest maximum grain size of 114 μm, which is ~ 3 times more than in case of wrought ARW sample. The pole figure (Fig. 6e) shows also a decrease in preferred orientation intensity in comparison with sample AB to 7,6 in pole < 111 > parallel to Z direction of sample Sect41,42,44,45..

The DA sample featured a higher hardness in comparison to the AB and ARW samples. The increase was influenced by the precipitation of needle-like precipitates during the aging. The areas of interest intended for TEM analysis within AB and DA samples were in XZ direction and are depicted in Fig. 7. The detailed cellular structure (pointed with light blue arrows, see Fig. 7a) within the AB sample caused by LPBF process is visible. The structure of the AB sample consisted of a small number of precipitates, which formed during the manufacturing process. The layer-by-layer manufacturing process of the sample can cause heat transformation between the successive layers, and the structure starts to be tempered followed by precipitation of small precipitates46. The aging process of the DA sample resulted in areas full of small precipitates, as illustrated in Fig. 7b. A closer look at Fig. 7c revealed numerous precipitates spread throughout the XZ plane of the samples. The aging temperature (490°) produced a vast number of nanosized precipitates that were evenly distributed and took on needle-like and spheroidal forms, marked by dark blue arrows in the Fig. 7c. These precipitates, particularly the needle-like ones, were similarly noted in study47. Their presence within the martensite structure played a significant role in enhancing the mechanical properties of the material. Specifically, Fig. 7c highlights an extensive presence of needle-like precipitates, with size between ~ 15 and 25 nm in length.

Tool wear evaluation

In this study, all variables such as tool, tool geometry, clamping fixture, machine, tool holder and coolant/lubricant were held constant except for the workpiece material and machining parameters (particularly the cutting speed). This setup highlights how variations in the microstructure and mechanical properties of different workpiece materials with combination of different cutting speeds affect the tool wear. Specifically, the study focuses on the impact of workpiece material produced by rolling and LPBF on tool wear. Measurements of tool wear after milling various maraging steel samples are presented in Fig. 8a. The new endmill was used for each cutting test to avoid any negative influence by the tool wear. The results show noticeable differences in tool wear among the samples. An increase of the tool wear correlates to the cutting speed increase. To clearly demonstrate the differences in tool wear among the samples subjected to varying cutting speed and heat treatment conditions, the morphologies of the cutting tool’s flank face were captured after milling using electron microscopy. Flank wear at the end of the cutting is manifested by equal attrition along the cutting edge (see Fig. 8b). The scaring of the cutting edge is affected by material phases especially by the nickel-based precipitates formed in M300 maraging steel during LPBF process or the subsequent aging treatment. Precipitates such as Ni3Ti, Ni3Mo, and Ni3Al form and disperse within the martensite matrix48,49. These precipitates play a significant role in scratching the cutting tools. Overall, the predominant observed type of tool wear was abrasion. Notably, flank wear, primarily due to abrasion, results from intense friction at the interface between the tool’s flank face and the workpiece material. This is vividly illustrated in Figs. 8c, where it can be seen that after cutting length of 610 mm of DA sample, the coating on the flank face (along the cutting edge) is completely worn out. The DA sample exhibited substantially higher tool wear, primarily attributed to the significantly increased microhardness resulting from the presence of precipitates (presented in Fig. 7c). Tool wear, evidenced by wear at the cutting tip, reached a maximum of 0.22 mm for the DA material, 0.16 mm for AB material, and 0.16 mm for ARW material. An increasing tool wear tendency with the increasing cutting speed is evident. The differences obtained between the AB and ARW samples can be primary attributed to the AB material anisotropy caused by LPBF process as described by Liverani et al.50.

Similarly, to Ni et al.51 to further assess the tool wear, EDS mapping was employed to qualitatively analyze changes in the chemical composition on the tool surface after milling the DA sample. A detailed view of the flank face and cutting edge is provided in Fig. 8d, revealing clear signs of damage (chipping), including delamination of the TiN coating at the cutting edge, flank wear, built-up edge formation, and traces of adhered workpiece material. The TiN coating delamination is evident when comparing Fig. 8e and f, which show the same region of the cutting edge. In Fig. 8f, the yellow area corresponds to the substrate material of the end mill, visible only due to coating damage. This is further confirmed by the absence of the green signal (Ti) in Fig. 8e in the same region. During milling, surface of the end mill was partially covered with adhered material, as shown in Fig. 8g. Here, pink regions indicate the presence of iron, the dominant element in the milled maraging steel. Notably, in the same areas where adhered material is observed in Fig. 8e, no titanium originating from the TiN coating was detected.

Cutting forces evaluation

To effectively evaluate the material machinability the cutting forces measurement are crucial indicators. The cutting forces, namely Fx, Fy, and Fz, were measured along three perpendicular axes, following the testing methodology illustrated in Fig. 2a. The individual forces correspond to the feed force (Fx), cutting force (Fy) and passive force (Fz). The angle of engagement is 30° during the milling, which caused that the only one cutting tip is cutting the material in that time. Hence the cutting forces reached not as high values as in case of using higher angle of engagement. The larger angle of engagement the larger the heat generation causes increase of tool wear, cutting forces and tool deflection. In the milling experiments, cutting forces were measured for the ARW, AB as well as for the DA samples.

Milling force curves for different samples were plotted to observe the difference within one tool rotation. The variations in milling force show a fluctuation pattern resembling sine and cosine waves, which is primarily due to the characteristics of the interrupted cutting that results in a void cutting effect as described by Liu et al.52. In can be stated that for the cutting speed of 60 m.min−1, the AB sample (see Fig. 9a) presented the lower forces during the cutting compared to the DA and ARW samples. The DA sample (see Fig. 9b) is the most challenging material to machine, requiring the highest forces compared to the AB and ARW materials and exhibiting highly dynamic, high-frequency force fluctuations. This phenomenon is mainly influenced by the material hardness, which featured the highest value in the case of DA sample. The ARW sample (see Fig. 9c) featured an intermediate course of cutting force. These observations are critical for understanding tool wear, surface finish, and overall machining efficiency for each material.

The average values of the feed, cutting and passive force for all samples are presented in Fig. 9d-f. When comparing all samples, the machining direction was considered as negligible because the milling direction was parallel to the rolling direction as well as to the BD in case of the wrought sample and all LPBF samples, respectively. Otherwise, the machining direction (transverse or parallel to the BD) can influence the cutting forces due to the higher yield strength along the BD as reported by Suryawanshi et al.53. From Figs. 4 and 7, it is evident that the microstructures of the ARW, AB and DA samples differ significantly. The AB sample possesses cellular microstructure, whereas the DA sample is characterized by lath martensite with a large number needle like precipitates equally dispersed within. These microstructural differences can significantly influence the cutting forces during machining. Furthermore, the samples exhibited the different hardness, which is very likely the main factor affecting the cutting forces. The cutting force Fy yielded a relatively similar value when milling the AB sample as in case of ARW sample. It can be concluded that despite the higher hardness of the ARW sample the AB sample caused similar Fy forces due to the cellular microstructure and a small number of precipitates formed during the manufacturing process. When the material underwent the heat treatment in the case of the DA sample the cutting forces increased rapidly compared to the AB and ARW samples (see Fig. 9e). This increase primarily came from the heightened strength achieved after aging treatment. The cutting forces featured an increase with increasing cutting length (see phases P1-P4) in case of all cutting tests, which is related to the tool wear propagation. In regards of the cutting speed, which differed in each cutting test it can be stated that the highest cutting speed (60 m.min−1) resulted in the lowest observed cutting forces. It is important to note that the machined material starts to soft when heat builds up in a cutting area due to the higher cutting speed54. Considering a cutting force standard deviation, it can be postulated that the AB sample possessed higher value in comparison to the DA sample. It may be caused by the microstructure consisting of grains with less and more extensive tempering (as described in Sect. 3.1). Moreover, when machining this type of microstructure, the cutting tip needed to overcome these regions, which resulted in the higher standard deviation. During the heat treatment the microstructure of the DA sample underwent a transformation, creating the structure without these regions. Hence, the standard deviation did not reach as high value as in case of the AB sample.

The analysis of force data in the frequency domain was performed for each sample. Samples AB (see Fig. 9g) and DA (see Fig. 9h) generally showed very low dominant frequencies (around 0.04 Hz) across majority of cutting tests, suggesting that the primary force variation is slow-changing or related to the overall cutting process rather than high-frequency vibrations. However, the DA sample exhibited a dominant frequency of 53.04 Hz in z axis at the cutting speed 30 m.min−1, which shifted to 0.04 Hz at higher cutting speeds. The ARW sample (see Fig. 9i), in contrast, featured a distinct and significant shift to high dominant frequencies (around 259 Hz) for all force components at intermediate cutting speeds (40 and 50 m.min−1), implying a prominent resonance or strong vibratory behavior specific to these conditions.

The cutting speed generally affected both the dominant frequencies and the amplitudes of the cutting forces. While specific trends can vary between materials and force components, common observations can be stated as follows. The frequency shift is most prominently observed in the ARW sample, where increasing cutting speed from 30 to 40 m.min−1 led to the increase in dominant frequencies (from approximately 0.04 Hz to around 259 Hz) for all axes, before returning to low frequencies at 60 m.min−1. This suggested that specific cutting speeds can trigger distinct vibrational modes for ARW. In regards of DA, the Fz component also exhibited the shift in dominant frequency from 53.04 Hz at 30 m.min−1 to 0.04 Hz at 40 m.min−1 and above.

Milling force curves for different samples (a) sample AB, (b) sample DA, (c) sample ARW, Average Fx, Fy, and Fz forces corresponding to cutting tests and tested materials, (d) force Fx, (e) force Fy and (f) Force Fz, force data in the frequency domain (g) sample AB, (h) sample DA and (i) sample ARW.

Evaluation of the machined surface quality

To assess the impact of microstructure and tool wear on machined surface quality, the surface roughness Ra and Rz measurements were conducted, after milling on flat areas A-C and on the site D listed in Fig. 2b. The as-built surface (parameter Ra reached about 12 μm and Rz 35 μm, respectively) did not comply with roughness requirements due to a larger quantity of powders adheres to the side surface as a result of heat generation during the building process and its transfer to the surrounding powders (similar conclusion was found out by Bai et al.33. After milling in the area A, the surface roughness values of all samples exhibited a notable reduction to an Ra average value below 0.6 μm (see Fig. 10a) and Rz 3.5 μm (see Fig. 10b), respectively. This is twenty times, and ten times lower in comparison to the as-built state. This highlights that milling serves as an effective mechanical process for improving the surface quality of LPBF and wrought MS. Additionally, the surface roughness of the AB sample remained higher than the ARW sample after milling of 260 mm in case of vc = 30 m.min−1 and 40 m.min−1. After milling 460 mm, there was a slight increase in surface roughness for the AB sample Due to the initial rapid tool wear, while the ARW sample featured a slight decrease with the increasing cutting length. However, the decrease in roughness on the ARW sample, was likely Due to the higher hardness of the ARW sample compared to the AB sample. The surface roughness tended to increase with the increasing cutting speed in the case of the ARW sample. Cutting speed is the main factor influencing the tool wear. Hence the higher roughness is attributed to the tool wear propagation. Surface roughness of the DA sample subjected to direct aging conditions suggested that heat treatment significantly influences milled surface quality. The DA sample featured lower surface roughness than the AB sample after 260 mm, 460 mm and 610 mm of the cutting length. In can be observed that the surface roughness possessed a decreasing tendency with the increasing cutting length. This phenomenon is primarily attributed to cutting tool damage, leading to a diminished tool sharpness and lower flank angle, which manifested in reduced surface feed mark heights. Similar findings were observed by Lizzul et al.55 during the milling of Ti6Al4V alloy produced by AM. Under the cutting speed of 60 m.min−1 the roughness of the DA featured a lower value after milled 460 mm, but when the cutting length increased to 610 mm, the quality of the machined surface decreased. It can be caused by the more severe tool wear propagation, when machining the higher strength DA sample. Comparing AB and DA samples, both of them tended to relatively similar roughness values after milling of 610 mm under the vc = 60 m.min−1. It is due to the above-described factors. Not only the surface roughness on the machined face (areas A-C), but also the roughness Ra (see Fig. 10c) and Rz (see Fig. 10d) on site D was evaluated. Based on the obtained results it can be noted that the roughness on site D reached worse quality compared to the flat areas. The reason can be elucidated as the dissimilar material structure in different direction caused by the meander scanning strategy. The strategy created melt tracks (see Fig. 10e) typical for LPBF production. When the tool is milling it must break the material in melt tracks with the feed rate perpendicular to them (see Fig. 10f), which may influence the surface roughness on site D. Additionally, the ARW material exhibited the lower surface roughness under all cutting speed in comparison to the AB and DA samples. The AB featured worse roughness under the vc = 30 m.min−1 and vc = 40 m.min−1 than the DA sample. This occurs because the softer material is more prone to deformation during the milling process, resulting in higher feed mark heights and lateral plastic flow of the material. After the aging treatment the material gained higher strength and hardness and decreased material plasticity, which led to the surface roughness reduction. This phenomenon was described by Chen in56. Under the higher cutting speed (50 m.min−1 and 60 m.min−1) the roughness yielded a slight increase (higher than the AB sample) due to the more severe tool wear. The standard deviation of the AB sample seemed to have the similar trend as in case of cutting forces. It can be postulated that microstructure of the AB sample, particularly the melt pool structure with alternating regions and their anisotropy, resulted in the higher standard deviation in comparison to the DA sample. The microstructure underwent a full recrystallization after the aging treatment, which corresponds to smother milling process with lower standard deviation.

Surface roughness parameter Ra and Rz depicted for different cutting tests and machined materials visualized in areas A-C: (a) surface roughness Ra, (b) surface roughness Rz, (c) surface roughness Ra in the area D and (d) surface roughness Rz in the area D. Triaxial melt tracks and microstructure during milling (e) and (f) the relationship between feed direction when milling the material with melt tracks.

The surface topography of different samples was examined in areas A-D corresponding to the zones mentioned in Fig. 2b. The machined surface morphologies of various samples, with noticeable traces caused by 0.2 mm radial depth of cut (marked with white dashed lines) are illustrated, in Fig. 11. Additionally, some residual chip segments (depicted as plastic material flow, see Fig. 11a and c) formed on the machined surface as machining defects due to the elevated heat generation and plasticity of the material. Because of the strong adhesion between chips and the cutting tool due to the lower cutting speed, the chips adhered to the face surface and created a buildup edge, which caused visible scratches on the machined surface of the samples AB and ARW. A similar small build up edge was observed by Dang et al. when machining wrought Ti6Al4V57. To remove this effect, adversely affecting the quality of the machined surface, is very difficult under the low cutting speed and low hardness of the material. As can be seen in Fig. 11b, none of the visible plastic flow material effect occurred on the surface of the DA sample due to the higher material strength of the sample influencing lateral plastic flow. Moreover, not only the material strength, but also the higher cutting speed yielded a reduction of plastic material flow as illustrated in Figs. 11d-f. The higher cutting speed resulted in clear machined surfaces, but with visible chatter marks (pointed by the red arrows) in a cutting tool leading out phase as the angle of engagement increased. Vibrations can negatively influence tool life causing a chipping of the cutting edge, which may bring about a worse surface quality58. Samples AB and ARW featured clear, uniform and deeper feed marks in comparison to the DA sample. This is because these two samples exhibited lower hardness and higher plasticity than the DA sample, making it easier for the material to deform and flow aside under the cutting forces. The opposite reason appeared on the surface morphology in case of the DA sample. The differences in regard to surface morphology between the samples and cutting speeds diminished on area D. Hence, only results obtained under the cutting speed of 60 m.min−1 are presented. It can be noted that the AB and ARW samples possessed the worse surface roughness due to the more extensive overcut areas (see Figs. 11g-i), caused by the higher tool wear. Under the higher cutting speed and small gaps between each cutting tip, chips are unable to evacuate out of the cutting area and are overcut, which causes adverse effects on the surface quality.

Chip morphology

Different chip morphologies (see Fig. 12) under the discerned cutting conditions and for different materials were observed. Chips display a similar segmented shape for AB, DA and ARW, but distinct geometrical characteristics for different samples. None of the chips exhibited a curling degree or tubular shape as in case of orthogonal cutting of C45E steel investigated by Devotta et al.59. Albeit the AB sample exhibited a chip morphology similar to that of the ARW sample under the cutting speed of 30 m.min−1, the samples possessed a great difference under the cutting speed of 60 m.min−1. Particularly the ARW sample seemed to have a more excessive saw-tooth structures (see Fig. 12f) in comparison to the AB sample. The chips formed during machining of the DA sample featured the lowest level of saw-tooth structures, due to the highest hardness of this material. This variation was primarily due to differences in material microstructure and mechanical properties such as toughness and hardness. The diverse geometrical characteristics of the chips indicated that the microstructure and mechanical properties significantly impact the milling process in regards of chip formation. The chips display a segmented morphology as described by Tönshoff and Denkena60, which can be distinguished by the height of chips serration. The higher toughness of AB and ARW samples compared to the DA sample provided a better possibility for the material to be formed and create the saw-tooth structures (see green arrows in Figs. 12b.2 and 12 f.2) rather than severe cracks propagation at the end of chip free surface (marked with green arrows in Fig. 12c.2). It is important to note that the higher brittleness of the DA sample resulted in chip saw-tooth structure fractures as depicted by the green dashed circle in Fig. 12c.2. Even though the chips appeared segmented shape for all the samples from a macroscopic perspective, as shown in Fig. 12a–f, significant differences are observed under SEM. The chip exhibited a saw tooth appearance due to alternating large zones of high shear strain (called as primary shear bands) followed by small zones of low shear strain (called as secondary shear bands) depicted at chip free surface. This cyclic chip formation results in semi-continuous structures. It can be observed that free surface of all chips featured noticeable primary and secondary shear bands, while the back surface of chips was formed without any visible shear bands. Figures 12a.3-f.3 shows the detailed chip morphologies of the AB, DA and ARW samples free surfaces at high magnification. Coarse lamellar structures (shear bands), marked by green lines L1-L6, are visible, indicating significant deformation in these areas. Distances, which were evaluated as a distance between the coarse lamellar structures, were measured as follows: L1 = 18.98 μm, L2 = 40.86 μm, L3 = 28.28 μm, L4 = 50.28 μm, L5 = 22.95 μm and L6 = 41.56 μm. A decrease in distance correlates with the hardness of the samples (the higher lamellar distance the higher hardness of the sample as depicted in Fig. 3), revealing the relationship between machinability and mechanical properties associated with material microstructures. Moreover, the cutting speed influenced the lamellar chip distance. Additionally, the higher cutting speed the higher chip compression against tool rake face causing a more intensive chip formation, which resulted in the higher distance of primary shear bands, but in higher density of secondary shear bands occurred between the coarse serrations (pointed by yellow square frames in Figs. 12a.3-f.3). These shear bands were observed by Dhale et al. when machining of bulk metallic glass61. The different microstructure of the ARW sample resulted in the most distinctive and the sharpest serration (see Fig. 12e.2) under the cutting speed 30 m.min−1. This phenomenon was not observed for any other sample, which can be attributed to different microstructure and cutting conditions. Research conducted by DeJian et al.62 indicated that workpiece materials with high hardness values and low thermophysical properties (low thermal conductivity, etc.) are more likely to produce serrated chips, which corresponded to obtained results.

Chips of the AB, DA, and ARW samples exhibited bright white colors with the metallic luster, indicating the lower heat transformation during the milling process. There was not any significant difference in chip color in regards of microstructure of individual samples and cutting speeds. Hence it can be stated that under tested feed rate and dept of cut, which created relatively high and thin chips, a decisive role in terms of chips color is a chip cross section and angle of engagement (both were set to relatively low values). The higher chip cross section requires more energy for milling, leading to increased chip temperatures and darker color of the chips as observed by33.

Chip morphology depicted for different materials and cutting speeds. (a) AB sample, cutting speed 30 m.min−1, (b) AB sample, cutting speed 60 m.min−1, (c) DA sample, cutting speed 30 m.min−1, (d) DA sample, cutting speed 60 m.min−1, (e) ARW sample, cutting speed 30 m.min−1, (f) ARW sample, cutting speed 60 m.min−1.

Evaluation of instrumented hardness after machining

As boundary examples, milling conditions I and IV, representing milling speed of 30 and 60 m.min−1, respectively, were selected for ARW, AB and DA samples to be thoroughly studied. Figure 13 shows evolution of subsurface hardness in area designated as “A” under the machined face (areas A-C) and area “D” corresponding to the side of machined face (site D) (Fig. 2b). The increase in cutting speed resulted in an increase also in the tool wear which was even more severe during milling of hard DA samples. Softer ARW and AB samples showed similar results of hardness, milled surface characteristics and tool wear. On the contrary, cutting forces during milling measured when machining using highest cutting speeds (conditions IV) were the lowest due to the increased heating up of the milled area and softening of the material54. In all studied cases high cutting speed caused an increase in the stress and strain imposed on the material during cutting. This resulted in subsurface hardening in areas A and D when compared to the bulk material. Evolution of the hardening into the depth of ~ 40 μm was studied by the means of instrumented hardness testing and is visualized in Fig. 13.

All measured samples showed an increase in hardness in close vicinity of the milled face (area A). The highest increase of about 24% was measured on sample DA milled with the highest cutting speed (Fig. 13c). Sample DA milled under conditions I reached similar hardness when the increase was 21%. Samples AB milled under conditions I and IV showed an increase in hardness in the close vicinity of milled face of 13 and 19%, respectively. The severity of this increase was more pronounced in LPBF samples, while the increase measured on ARW samples was only 5 and 9%, respectively.

In the measured range of ~ 40 μm, the increased hardness of all samples gradually decreased to the values of bulk material. The bulk hardness values of samples ARW, AB and DA were 483 ± 33, 427 ± 21 and 732 ± 28 HV, respectively. Based on the evolution of hardness into the subsurface regions it can be stated that LPBF samples went through more significant hardening than conventionally manufactured ARW samples.

Subsurface area D on the side of machined face also went through a deformation hardening, although the increase was only mild reaching up to 8% case of sample DA milled under conditions I (Fig. 13c). Hardness in the close vicinity to the surface of area D showed in all other cases only negligible increase between 2 and 5%.

Machined structure observation

EBSD analysis performed on area A of samples ARW milled under conditions IV showed as expected, no significant change in preferred orientation in comparison to non-milled area (Fig. 4a). Samples AB under conditions I and DA under conditions IV did not show any substantial changes in the grain size, misorientation nor preferred orientation with weaker preferred orientation in poles < 111 > parallel to Z direction of sample section (Fig. 14). Only sample DA showed a decrease in maximum grain size from 114 to 89 μm. Kernel average misorientation levels remained similar and did not justify the increase in subsurface increase in hardness.

Detailed observation of milled surface with high magnification (in area A) led to the discovery of less than 2 μm thick layer of severely deformed microstructure (depth of affected zone, DoAZ) of all samples. The microstructure below milled surface of all samples including ARW, AB and DA were deformed during the contact with end mill teeth during milling (Fig. 15). This result is lower compared to the DoAZ observed when machining H13 tool steel63. This phenomenon can be explained by the dissimilar milling strategy. In this study the higher axial (2 mm) and lower radial (0.2 mm) depth of cut were applied During machining causing only a 2 μm DoAZ. On the other hand, in the study63 the higher radial (2.4 mm) and lower axial (0.2) depth of cut were used. The usage of lower radial depth of cut manifested in not severe material deformation towards axial direction, which resulted in lower DoAZ. The differences between the DoAZ corresponds to material hardness as described in Fig. 3. The lower hardness of AB sample possessed the higher DoAZ Due to the more severe material deformation. The DoAZ was too thin to perform EBSD analysis but can be marked as cause of increased hardness in the near vicinity of the surface of area A. First measurements were performed in range from 2 to 5 μm from the surface to try and capture its influence. Additionally, the TEM analysis was performed to examine the subsurface texture as can be seen in Fig. 15d. Many dislocations were created as a result of milling and subsequent hardening effects. Not only the individual dislocations but also clusters of them described as the dislocation cells formed within the machined surface as also observed in64.

Summary

The as-built material did not exhibit sufficient surface quality to be considered a functional surface. However, based on the obtained data, the machinability of additively manufactured M300 produced notably interesting results. In terms of tool wear it was observed that the higher the cutting speed the higher the tool flank wear when milling without using a cooling liquid. As far as the cutting forces are concerned an increase with increasing cutting length was observed in case of all cutting tests Due to the flank wear propagation. On the other hand, a cutting force decreasing tendency was observed with the increasing cutting speed, which may have caused the softening effect During the higher cutting speed. Under a cutting speed of 60 m/min, the surface roughness of the DA sample showed a lower value after milling 460 mm. However, when the cutting length increased to 610 mm, the quality of the machined surface deteriorated. This decline in quality can be attributed to more severe tool wear, which occurs when machining the higher strength DA samples. The chip morphology revealed that the increasing material hardness the longer lamellar distance measured on the chip free surface. The printing strategy can influence material anisotropy and mechanical properties in different directions. Hence further research will be focused on printing strategy and its effect on material machinability.

The phase composition analysis of AB, DA, and ARW samples revealed the presence of BCC-structured martensite and FCC-structured austenite. Additionally, DA and ARW samples contained type M7C3 carbides in amounts of 1.9% and 6.3%, respectively. Direct aging without prior solution treatment led to incomplete dissolution of the melt pool boundaries, influencing the martensite morphology, austenite content, and carbide precipitation. The size of Ni3(Mo, Ti, Al) precipitates restricted their visibility even when SEM imaging was utilized. The amount of retained and reversed austenite increased from 1.2% in the AB state to 5.6% in the DA state due to the inevitable transformation of Ni₃(Mo, Ti) into more stable Fe₂Mo precipitates, which facilitated austenite reversion.

Subsurface hardness analysis under milling conditions I and IV showed a direct correlation between cutting speed and deformation hardening. The highest increase in hardness (21 and 24%) was observed in DA samples milled at the highest cutting speed, whereas AB samples exhibited increases of 13% and 19% under conditions I and IV, respectively. ARW samples showed the least subsurface hardening (5 and 9%), indicating a stronger effect of LPBF processing on deformation hardening of subsurface area under milled face (area A).

Conclusion

The machinability of as-built and directly aged maraging steel M300 manufactured via laser powder bed fusion was in this study investigated and compared to the wrought M300. The effect of different cutting conditions on tool wear, cutting forces and surface roughness, chip morphology, microhardness and machined microstructure was evaluated. The main goal was to evaluate these parameters as a function of increasing cutting length. The main conclusions can be described as follows:

-

The microstructure of different M300 samples was distinguished by light microscopy, SEM and TEM analyses. The as-built sample possessed a cellular microstructure, while the directly aged sample underwent a significant dissolution of cellular and strip microstructure and featured vast number of nanosized precipitates that were evenly distributed within the martensite microstructure. LPBF manufacturing process was utilized using an optimized set of processing parameters resulting in almost negligible porosity of as-built (AB) and directly aged (DA) samples. Microstructure scarcely consisted of any micropore or defect referring to manufacturing almost fully dense samples.

-

The flank tool wear featured an increasing tendency with the increasing cutting speed and cutting length. The tool wear was characterized by the attrition on the cutting edge caused by the hard precipitates, formed during the aging treatment in case of the DA sample.

-

The higher cutting speed resulted in lower cutting forces, due to the material softening effect. On the other hand, the higher cutting length the higher cutting forces due to the tool wear propagation in case of all samples. The highest observed cutting forces were noted in the case of the DA sample due to the highest hardness of this material.

-

Surface roughness of the DA sample exhibited a lower surface roughness in comparison to AB sample Due to the higher hardness, which caused a lower lateral plastic flow. The ARW and AB samples featured more notable milled feed marks Due to the lower hardness. The cutting speed of 30 m.min−1 resulted in lower plastic material flow, while an increase in cutting speed resulted in visible chatters the angle of engagement increased during the leading out of the tool.

-

The hardness profile of the samples was affected by milling conditions, but mainly by the manufacturing process. The LPBF-processed DA samples exhibited the most pronounced subsurface hardening. In general, the increase in hardness was most evident near the machined surface, extending to a depth of approximately 40 μm before reaching the bulk hardness values. The presence of a severely deformed surface layer (~ 2 μm) contributed to increase near-surface hardness, emphasizing the role of machining-induced strain in modifying material properties.

Based on the data obtained it can be concluded that this study contributed to more effective manufacturing of M300 maraging steel produced by LPBF technique. Findings gained by this research can be used in industry especially considering production of mold, dies or 3D printed cores with conformal cooling systems.

Data availability

Data is provided within the manuscript or supplementary information files.

References

Pitrmuc, Z. et al. Mechanical and microstructural anisotropy of laser powder bed fusion 316L stainless steel. Materials 15, 551. https://doi.org/10.3390/ma15020551 (2022).

Andronov, V., Šimota, J., Beránek, L., Blažek, J. & Rušar, F. Optimization of process parameters for additively produced tool steel 1.2709 with a layer thickness of 100 µm. Materials 14, 2852. https://doi.org/10.3390/ma14112852 (2021).

LaaksoP. et al. Optimization and simulation of SLM process for high density H13 tool steel parts. Phys. Procedia. 83, 26–35. https://doi.org/10.1016/j.phpro.2016.08.004 (2016).

Kolomy, S. et al. Influence of aging temperature on mechanical properties and structure of M300 Maraging steel produced by selective laser melting. Materials 16, 977. https://doi.org/10.3390/ma16030977 (2023).

Kolomy, S., Jopek, M., Sedlak, J., Benc, M. & Zouhar, J. Study of dynamic behaviour via Taylor anvil test and structure observation of M300 Maraging steel fabricated by the selective laser melting method. J. Manuf. Process. 125, 283–294. https://doi.org/10.1016/j.jmapro.2024.07.057 (2024).

Majerik, J. et al. Analysis of the technological process of welding a membrane wall with inconel 625 nickel alloy. Int. J. Adv. Manuf. Technol. 127, 3031–3048. https://doi.org/10.1007/s00170-023-11499-7 (2023).

Sedlak, J. et al. Effect of heat treatment and hot isostatic pressing on the structure and mechanical properties of inconel 939 manufactured via casting and LPBF. J. Manuf. Process. 145, 556–570. https://doi.org/10.1016/j.jmapro.2025.04.082 (2025).

Greco, S., Kieren-ehses, S., Kirsch, B. & Aurich, J. C. Micro milling of additively manufactured AISI 316L: impact of the Layerwise microstructure on the process results. Int. J. Adv. Manuf. Technol. 112, 361–373. https://doi.org/10.1007/s00170-020-06387-3 (2020).

Opěla, P., Benč, M., Kolomy, S., Jakůbek, Z. & Beranová, D. High cycle fatigue behaviour of 316L stainless steel produced via selective laser melting method and post processed by hot rotary swaging. Materials 16, 3400. https://doi.org/10.3390/ma16093400 (2023).

Shunmugavel, M., Polishetty, A., Nomani, J., Goldberg, M. & Littlefair, G. Metallurgical and machinability characteristics of wrought and selective laser melted Ti-6Al-4V. J. Metall. 2016, 1–10. https://doi.org/10.1155/2016/7407918 (2016).

Sedlak, J. et al. Analysis of the mechanical properties of 3D-Printed plastic samples subjected to selected degradation effects. Materials 16, 3268. https://doi.org/10.3390/ma16083268 (2023).

Liu, Y. J. et al. Compressive and fatigue behavior of beta-type titanium porous structures fabricated by electron beam melting. Acta Mater. 126, 58–66. https://doi.org/10.1016/j.actamat.2016.12.052 (2017).

Kranz, J., Herzog, D. & Emmelmann, C. Design guidelines for laser additive manufacturing of lightweight structures in TiAl6V4. J. Laser Appl. 27, S14001. https://doi.org/10.2351/1.4885235 (2015).

Kučerová, L., Burdová, K., Jeníček, Š. & Chena, I. Effect of solution annealing and precipitation hardening at 250 °C–550 °C on microstructure and mechanical properties of additively manufactured 1.2709 Maraging steel. Mater. Sci. Eng. Struct. Materials: Prop. Microstruct. Process. 814, 1. https://doi.org/10.1016/j.msea.2021.141195 (2021).

Du, W., Bai, Q. & Zhang, B. Machining characteristics of 18Ni-300 steel in additive/subtractive hybrid manufacturing. Int. J. Adv. Manuf. Technol. 95, 2509–2519. https://doi.org/10.1007/s00170-017-1364-0 (2017).

Jägle, E. A., Choi, P., Van Humbeeck, J. & Raabe, D. Precipitation and austenite reversion behavior of a Maraging steel produced by selective laser melting. J. Mater. Res. 29, 2072–2079. https://doi.org/10.1557/jmr.2014.204 (2014).

Lan, L., Wang, W., Cui, Z. & Hao, X. Effect of scanning speed on microstructure and mechanical properties of selective laser melting AlCoCrFeNi2.1 eutectic high-entropy alloy. Mater. Lett. 330, 133321. https://doi.org/10.1016/j.matlet.2022.133321 (2023).

Sun, J. et al. Effect of shielding gas flow rate on cladding quality of direct laser fabrication AISI 316L stainless steel. J. Manuf. Process. 48, 51–65. https://doi.org/10.1016/j.jmapro.2019.10.011 (2019).

Qamar Tanveer, M., Mishra, G., Mishra, S. & Sharma, R. Effect of infill pattern and infill density on mechanical behaviour of FDM 3D printed Parts- a current review. Mater. Today: Proc. 62, 100–108. https://doi.org/10.1016/j.matpr.2022.02.310 (2022).

Nath, S. D., Gupta, G., Kearns, M., Gulsoy, O. & Atre, S. V. Effects of layer thickness in laser-powder bed fusion of 420 stainless steel. Rapid Prototyp. J. 26, 1197–1208. https://doi.org/10.1108/RPJ-10-2019-0279 (2020).

Nong, X. D. & Zhou, X. L. Effect of scanning strategy on the microstructure, texture, and mechanical properties of 15-5PH stainless steel processed by selective laser melting. Mater. Charact. 174, 111012. https://doi.org/10.1016/j.matchar.2021.111012 (2021).

Vishwakarma, J., Chattopadhyay, K. & Santhi Srinivas, N. C. Effect of build orientation on microstructure and tensile behaviour of selectively laser melted M300 Maraging steel. Mater. Sci. Eng. Struct. Materials: Prop. Microstruct. Process. 798, 140130. https://doi.org/10.1016/j.msea.2020.140130 (2020).

Omidi, N., Farhadipour, P. & Barka, N. Investigation into the effect of the SLM processing parameters on the microstructure and mechanical behavior of M300; experimental and statistical analysis. Int. J. Adv. Manuf. Technol. 129, 4419–4434. https://doi.org/10.1007/s00170-023-12495-7 (2023).

de Souza, A. F., Al-rubaie, K. S., Marques, S., Zluhan, B. & Santos, E. C. Effect of laser speed, layer thickness, and part position on the mechanical properties of Maraging 300 parts manufactured by selective laser melting. Mater. Sci. Eng. Struct. Materials: Prop. Microstruct. Process. 767, 138425. https://doi.org/10.1016/j.msea.2019.138425 (2019).

Rivalta, F., Ceschini, L., Jarfors, A. E. W. & Stolt, R. Effect of scanning strategy in the l-pbf process of 18ni300 Maraging steel. Met. (Basel). 11, 826. https://doi.org/10.3390/met11050826 (2021).

Ni, C. et al. Recent advance in laser powder bed fusion of Ti–6Al–4V alloys: microstructure, mechanical properties and machinability. Virtual Phys. Prototyp. 20. https://doi.org/10.1080/17452759.2024.2446952 (2025).

Kolomy, S. et al. Effect of microstructure on machinability of extruded and conventional H13 tool steel. 254 (2025). https://doi.org/10.1016/j.matdes.2025.114132

Duval-chaneac, M. S. et al. Characterization of Maraging steel 300 internal surface created by selective laser melting (SLM) after abrasive flow machining (AFM). Procedia Cirp. 77, 359–362. https://doi.org/10.1016/j.procir.2018.09.035 (2018).

Croccolo, D. et al. Sensitivity of direct metal laser sintering Maraging steel fatigue strength to build orientation and allowance for machining. Fatigue Fract. Eng. Mater. Struct. 42, 374–386. https://doi.org/10.1111/ffe.12917 (2019).

Tascioglu, E. et al. Effect of aging and finish machining on the surface integrity of selective laser melted Maraging steel. Rapid Prototyp. J. 27, 1900–1909. https://doi.org/10.1108/RPJ-11-2020-0269 (2021).

Fortunato, A. et al. Milling of Maraging steel components produced by selective laser melting. Int. J. Adv. Manuf. Technol. 94, 1895–1902. https://doi.org/10.1007/s00170-017-0922-9 (2018).

Tamura, S., Matsumura, T., Ezura, A. & Mori, K. Anisotropic cutting force characteristics in milling of Maraging steel processed through selective laser melting. J. Manuf. Sci. Eng. 144. https://doi.org/10.1115/1.4051920 (2022).

Bai, Y. et al. Microstructure and machinability of selective laser melted high-strength Maraging steel with heat treatment. J. Mater. Process. Technol. 288, 116906. https://doi.org/10.1016/j.jmatprotec.2020.116906 (2021).

Yadroitsev, I. & Yadroitsava, I. Evaluation of residual stress in stainless steel 316L and Ti6Al4V samples produced by selective laser melting. Virtual Phys. Prototyp. 10, 67–76. https://doi.org/10.1080/17452759.2015.1026045 (2015).

Lavender, C. Mechanical and microstructural properties of maraging steel samples produced by additive manufacturing (3D Printing) (Naval Postgraduate School, Monterey, CA, 2020).

Deirmina, F., Peghini, N., Almangour, B., Grzesiak, D. & Pellizzari, M. Heat treatment and properties of a hot work tool steel fabricated by additive manufacturing. Mater. Sci. Eng. Struct. Materials: Prop. Microstruct. Process. 753, 109–121. https://doi.org/10.1016/j.msea.2019.03.027 (2019).

Song, B., Dong, S., Coddet, P., Liao, H. & Coddet, C. Fabrication of NiCr alloy parts by selective laser melting: columnar microstructure and anisotropic mechanical behavior. Mater. Design. 1–7. https://doi.org/10.1016/j.matdes.2013.07.010 (2014).

Kempen, K., Yasa, E., Thijs, L., Kruth, J. P. & Van Humbeeck, J. Microstructure and mechanical properties of selective laser melted 18Ni-300 steel. Phys. Procedia. 12, 255–263. https://doi.org/10.1016/j.phpro.2011.03.033 (2011).

Stanford, M., Kibble, K., Lindop, M., Mynors, D. & Dumall, C. An investigation into fully melting a Maraging steel using direct metal laser sintering (DMLS). Steel Res. Int. 79, 847–852 (2008).

Tan, C. et al. Microstructural evolution, nanoprecipitation behavior and mechanical properties of selective laser melted high-performance grade 300 Maraging steel. Mater. Design. 134, 23–34. https://doi.org/10.1016/j.matdes.2017.08.026 (2017).

Conde, F. F. et al. Effect of thermal cycling and aging stages on the microstructure and bending strength of a selective laser melted 300-grade maraging steel. Mater. Sci. Eng. 758, 192–201. https://doi.org/10.1016/j.msea.2019.03.129 (2019).

Casati, R., Lemke, J. N., Tuissi, A. & Vedani, M. Aging behaviour and mechanical performance of 18-Ni 300 steel processed by selective laser melting. Met. (Basel). 6, 218–218. https://doi.org/10.3390/met6090218 (2016).

Yan, X. et al. Selective laser melting of WC reinforced Maraging steel 300: microstructure characterization and tribological performance. Surf. Coat. Technol. 371, 355–365. https://doi.org/10.1016/j.surfcoat.2018.11.033 (2019).

Shamsdini, S., Shakerin, S., Hadadzadeh, A., AmirkhizB.S. & Mohammadi, M. A trade-off between powder layer thickness and mechanical properties in additively manufactured Maraging steels. Mater. Sci. Eng. Struct. Materials: Prop. Microstruct. Process. 776, 139041. https://doi.org/10.1016/j.msea.2020.139041 (2020).

Shamsdini, S. et al. A relationship between the build and texture orientation in tensile loading of the additively manufactured Maraging steels. Additive Manuf. 41, 101954. https://doi.org/10.1016/j.addma.2021.101954 (2021).

Mazumder, J., Choi, J., Nagarathnam, K., Koch, J. & Hetzner, D. The direct metal deposition of H13 tool steel for 3-D components. Jom 49 (1997), 55–60. https://doi.org/10.1007/BF02914687 (1989).

Bodziak, S. et al. Precipitation in 300 grade maraging steel built by selective laser melting: Aging at 510 degrees C for 2 h. Mater. Charact. 151, 73–83. https://doi.org/10.1016/j.matchar.2019.02.033 (2019).

Tewari, R., Mazumder, S., Batra, I. S., Dey, G. K. & Banerjee, S. Precipitation in 18 wt% Ni Maraging steel of grade 350. Acta Mater. 48, 1187–1200. https://doi.org/10.1016/S1359-6454(99)00370-5 (2000).

Sha, W., Cerezo, A. & Smith, G. D. W. Phase chemistry and precipitation reactions in Maraging steels: part I. Introduction and study of Co-containing C-300 steel. Metall. Mater. Trans. Phys. Metall. Mater. Sci. 24, 1221–1232. https://doi.org/10.1007/BF02668190 (1993).

Liverani, E., Toschi, S., Ceschini, L. & Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 249, 255–263. https://doi.org/10.1016/j.jmatprotec.2017.05.042 (2017).

Ni, C. et al. Machining performance and wear mechanism of PVD tialn/alcrn coated carbide tool in precision machining of selective laser melted Ti6Al4V alloys under dry and MQL conditions. J. Manuf. Process. 79, 975–989. https://doi.org/10.1016/j.jmapro.2022.05.036 (2022).

Liu, D. et al. Effect of anisotropic property on machining response of selective laser melted Ti6Al4V alloys in high-speed milling. J. Manuf. Process. 145, 158–171. https://doi.org/10.1016/j.jmapro.2025.04.066 (2025).

Suryawanshi, J., Prashanth, K. G. & Ramamurty, U. Tensile, fracture, and fatigue crack growth properties of a 3D printed Maraging steel through selective laser melting. J. Alloys Compd. 725, 355–364. https://doi.org/10.1016/j.jallcom.2017.07.177 (2017).

Duan, C. Z., Wang, M. J., Cai, Y. J. & Dou, T. Microcosmic mechanism of material softening and fracture in primary shear zone during high speed machining of hardened steel. Mater. Sci. Technol. 27, 625–630. https://doi.org/10.1179/026708309X12526555493152 (2011).

Lizzul, L., Sorgato, M., Bertolini, R., Ghiotti, A. & Bruschi, S. Influence of additive manufacturing-induced anisotropy on tool wear in end milling of Ti6Al4V. Tribol. Int. 146, 106200. https://doi.org/10.1016/j.triboint.2020.106200 (2020).

Chen, W. Cutting forces and surface finish when machining medium hardness steel using CBN tools. Int. J. Mach. Tools Manuf. 40, 455–466. https://doi.org/10.1016/S0890-6955(99)00011-5 (2000).

Dang, J. et al. Effect of material microstructure on tool wear behavior during machining additively manufactured Ti6Al4V. Archives Civil Mech. Eng. 20. https://doi.org/10.1007/s43452-019-0007-7 (2020).

Fecak, S. I. & Idrisova, Y. V. Effect of vibrations of instrument tools and a treated workpiece a on wear rate and quality of a machined surface. J. Eng. Sci. Technol. Rev. 8, 18–21. https://doi.org/10.25103/jestr.086.05 (2015).

Devotta, A. M., Sivaprasad, P. V., Beno, T. & Eynian, M. Predicting continuous chip to segmented chip transition in orthogonal cutting of C45E steel through damage modeling. Met. (Basel). 10, 519. https://doi.org/10.3390/met10040519 (2020).

Tönshoff, H. K. & Denkena, B. Basics of Cutting and Abrasive Processes (Springer, 2013). https://doi.org/10.1007/978-3-642-33257-9_14.

Dhale, K., Banerjee, N., Singh, R. K. & Outeiro, J. C. Investigation on chip formation and surface morphology in orthogonal machining of Zr-based bulk metallic glass. Manuf. Lett. 19, 25–28. https://doi.org/10.1016/j.mfglet.2019.01.002 (2019).

Liu, D. J., Wang, Y. Q., Ni, C. B., Zhu, L. D. & Zheng, Z. P. Serrated chip characteristics and formation mechanism in high-speed machining of selective laser melted Ti6Al4V alloys. Sci. China Technological Sci. 66, 1435–1450. https://doi.org/10.1007/s11431-022-2304-1 (2023).

Kolomy, S. et al. Machinability of extruded H13 tool steel: effect of cutting parameters on cutting forces, surface roughness, microstructure, and residual stresses. Alexandria Eng. J. 99, 394–407. https://doi.org/10.1016/j.aej.2024.05.018 (2024).

Kolomy, S., Benc, M., Harant, M., Sedlak, J. & Jopek, M. Effect of different strain rates on mechanical behavior and structure of inconel 718 produced by powder bed fusion. Int. J. Mech. Mater. Des. https://doi.org/10.1007/s10999-024-09724-6 (2024).

Acknowledgements

This research study was supported by the grant “Comprehensive technology for interdisciplinary work with advanced materials, emphasizing their multidisciplinary applications.”, FSI-S-25-8787. This research was also supported by Brno University of Technology Specific research project No. FSI-S-23-8305.

Author information

Authors and Affiliations

Contributions

Stepan Kolomy: Conceptualization, Methodology, Validation, Formal analysis, Investigation, Writing – Original Draft, Writing – Review & Editing, Visualization. Martin Slany: Conceptualization, Methodology, Validation, Formal analysis, Investigation, Writing – Original Draft, Writing – Review & Editing. Marek Doubrava: Conceptualization, Methodology, Formal analysis, Resources, Writing - Original Draft, Writing - Review & Editing, Visualization, Supervision, Funding acquisition. Josef Sedlak: Conceptualization, Methodology, Validation, Formal analysis, Investigation, Writing – Original Draft, Writing – Review & Editing, Supervision, Funding acquisition. Jan Zouhar: Conceptualization, Methodology, Validation, Formal analysis, Investigation, Writing – Original Draft, Writing – Review & Editing. Lukas Rehorek: Conceptualization, Methodology, Validation, Writing – Original Draft, Writing – Review & Editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kolomy, S., Slany, M., Doubrava, M. et al. Comparative analysis of machinability and microstructure in LPBF and conventionally processed M300 maraging steel. Sci Rep 15, 35980 (2025). https://doi.org/10.1038/s41598-025-19719-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-19719-8