Abstract

This study investigates the effect of vibration duration on the porosity, permeability, and compressive strength of pervious concrete incorporating 50% recycled concrete aggregate. Mixtures were prepared with Portland cement (CEM I) and blended cement (CEM II), and compacted by tamping or table vibration for durations ranging from 10 to 60 s. A refined falling-head permeability test was developed, using a novel circumferential heat-shrink sealing to eliminate lateral flow and ensure axial water penetration. Pore structure and connectivity were characterized using optical microscopy and X-ray micro-computed tomography. Increasing vibration duration reduced porosity and permeability while enhancing compressive strength. An optimal compaction window of approximately 30 s, corresponding to a normalized vibration dose of 226, provided the best balance between hydraulic and structural performance. Micro-computed tomography confirmed a highly interconnected pore network and strong agreement with effective porosity, demonstrating the value of three-dimensional metrics in mix design. The results show that combining recycled aggregate with low-carbon blended cements can meet functional performance targets while reducing cradle-to-gate carbon dioxide emissions by up to 25%. These findings offer practical guidance on compaction regimes and testing protocols, supporting reproducible and sustainable applications of pervious concrete in pavement infrastructure.

Similar content being viewed by others

Introduction

Pervious concrete (PC) is a cement-based composite distinguished by its intentionally high interconnected porosity, which is achieved by combining a controlled paste—comprising water and cementitious binders—with an open-graded coarse aggregate and little to no fine aggregate. The absence (or minimization) of sand generates a substantial void ratio. When the aggregate particles are uniformly coated and bonded by the paste, a continuous system of open and interconnected pores is formed that allows rapid passage of water and gases through the hardened matrix. Although the reduced binder content and elevated porosity inevitably lower mechanical strength compared to conventional concrete, the strength achieved is sufficient for structural and pavement applications1. These hydraulic and mechanical attributes have positioned PC as a sustainable pavement material for parking areas, low-traffic roads, and pedestrian surfaces2. Beyond load bearing, PC offers further societal and environmental benefits: reduction of tyre-road noise3, mitigation of the urban heat island effect4, water accumulation, improving stormwater quality, and aquifer recharge5,6. In addition, the void network can facilitate both mechanical filtration and bio-mediated degradation of contaminants, thus providing in-situ stormwater polishing7. Within the ‘Sponge City’ paradigm, PC—characterized by porosity levels of 15–25% and permeability coefficients of 0.4–0.8 cm/s—simultaneously fulfils structural and hydrological roles in densely urbanized areas8,9. Consequently, porosity is the key design parameter governing PC’s mechanical, hydraulic, acoustic, and durability performance10. Porosity and density are primarily dictated by aggregate gradation and mixture proportions. Coarse aggregates with nominal sizes of 9.5–19 mm are typically employed. Selecting a finer fraction enhances strength at the expense of permeability, whereas larger sizes favor hydraulic conductivity but may compromise load capacity. The unit weight of PC generally ranges from 1600 to 2000 kg/m3—approaching the upper limit for lightweight concretes—with air-void contents of 15–35% yielding permeability coefficients between 0.14 and 1.22 cm/s and compressive strengths from 2.8 to 28 MPa1. Because load transfer is concentrated within the narrow interfacial transition zone (ITZ) encasing each aggregate, mechanical performance is strongly influenced by ITZ thickness and porosity11. Partial replacement of coarse aggregate by smaller particles or incorporation of a modest quantity (approx. 7% by weight of aggregate) of fine sand can densify the ITZ and significantly raise compressive strength but usually diminishes permeability12. A more advantageous strategy is to refine and strengthen the ITZ by introducing mineral admixtures that do not detrimentally affect the global void structure.

Among production variables, the compaction method exerts a pronounced effect on the void system and pore tortuosity. Rodding typically yields higher porosity and lower strength than vibration. For example, rodding generated 22.8% porosity and 9.6 MPa strength, whereas 10 s of table vibration reduced porosity to 18.5% and increased strength to 13.2 MPa13. A separate investigation reported porosities up to 25%, strengths up to 5.5 MPa, and permeabilities up to 0.53 cm/s for rod-compacted specimens, compared with 15% porosity, 32 MPa strength, and 0.09 cm/s permeability after 5 s vibration at higher amplitude14. Excessive vibration, however, can induce paste settlement and partial clogging at the mold base, undermining both hydraulic and mechanical performance. For pavement applications, an optimal vibration of 8–12 s (10 ± 2 s) has been recommended to balance strength (fc > 10 MPa) and permeability (k ≥ 0.3 cm/s)15,16,17. Extending vibration to 20 s can further raise compressive strength by 15–20%, albeit with an acceptable decline in the permeability coefficient18.

Previous studies on pervious concrete incorporating recycled concrete aggregate (RCA)15,16,17 have shown that increasing RCA content generally leads to higher water absorption and greater paste demand, which may reduce compressive strength unless the mix design is optimized and supplementary cementitious materials are used to densify the ITZ. Nevertheless, moderate RCA replacement levels (≈30–60%) tend to preserve or enhance permeability due to the rougher surface texture and more tortuous pore structure, provided that compaction is properly controlled. Further experimental evidence19,20,21 confirms that RCA significantly affects workability due to its high water absorption and irregular surface morphology. Pre-wetting the aggregate can improve mix consistency. The physical characteristics and surface texture of RCA influence the bond with the cement matrix, thereby affecting the mechanical performance of pervious concrete. Replacing natural aggregate (8/16 mm) with RCA sourced from demolished concrete structures (8/31.5 mm) represents a trade-off between strength and porosity. RCA-based concrete achieved a compressive strength of 26.7 MPa—a reduction of approximately 15% compared to natural aggregate—while porosity increased by over 26%, favoring permeability. Other studies22 have reported only minor reductions in compressive strength (≈10%) and elastic modulus (≈3%) when using RCA. Moreover, RCA activated with additives such as silica fume or fly ash can yield compressive strengths exceeding 40 MPa23. These findings collectively prove that RCA can be effectively used in pervious concrete without necessarily compromising its mechanical properties, provided that mix design, compaction, and binder selection are carefully managed.

Globally, the volume of municipal solid waste is projected to increase from approximately 2.1 billion tons in 2023 to nearly 3.8 billion tons by 205024,25. A substantial part of this waste stream originates from construction and demolition (C&D) activities. For instance, the EU-27 generated around 807 million tons of C&D waste in 202026, the United States produced approximately 544 million tons in 201827,28, and China reported an annual output of about 2.36 billion tons between 2003 and 201329. These figures underscore the critical importance of circular economy strategies in the construction sector, particularly the reuse of recycled concrete aggregate in concrete30. Incorporating RCA not only contributes to waste reduction but also supports sustainable material cycles and resource efficiency in infrastructure development. Recycling of construction and demolition waste is increasingly employed to reduce embodied environmental impacts while maintaining material functionality. Recent innovations in this field include the use of recycled precursors—such as waste powder derived from ground granulated blast furnace slag (GGBS)–based geopolymers—and recycled clay brick powder (RCBP) in low-carbon concrete mixes31,32. Other notable developments involve fully recycled mortars that combine thermoactivated recycled cement with recycled aggregates, as well as nano-silica surface modification techniques applied to RCBP systems33,34. This broader context provides the foundation for our investigation into pervious concrete incorporating recycled concrete aggregate under controlled vibration conditions.

This study advances the field of sustainable pervious concrete design by systematically evaluating the role of compaction regimes in mixtures incorporating recycled concrete aggregate. Recognizing that both mix design and placement method influence the mechanical performance of pervious concrete, a controlled investigation of vibration duration (0–60 s) was conducted on specimens representative of field placement. These mixtures incorporated 50% RCA and several environmentally optimized binders. The overarching aim was to develop a ready-mix pervious concrete that conserves natural resources and aligns with circular economy principles, while meeting structural and durability requirements.

Sustainability was the principal goal of this study. Replacing 50% of natural coarse aggregate with RCA can further reduce cradle-to-gate global warming potential (GWP), particularly when RCA is sourced locally. Transport distance is the dominant factor influencing RCA’s environmental footprint. According to recent Environmental Product Declarations (EPDs)35, in-situ RCA exhibits a GWP of approximately 3.16 kg CO2e/t, compared to 3.28 kg CO2e/t for natural crushed aggregate. However, the GWP of RCA increases to 4.83, 6.50, 11.5 and 19.8 kg CO2e/t when demolition material is transported over distances of 10, 20, 50 and 100 km, respectively.

On the binder side, blended cements such as CEM II—with high proportions of fly ash or ground granulated blast furnace slag—demonstrate substantial reductions in production-stage CO2 emissions compared to pure Portland cement (CEM I). Based on EPDs for Polish production, CEM I 42.5R exhibits a weighted-average GWP of 664 kg CO2e/t (gross) and 508 kg CO2e/t (net)36. In contrast, the blended cements used in this study show lower footprints: CEM II/B-V 32.5R-HSR37 at 535 (gross), 393 (net) kg CO2e/t, and CEM II/B-M (S-V) 42.5R38 at 492 (gross), 381 (net) kg CO2e/t. These values represent approximately 22–26% lower gross GWP (and 21–25% lower net GWP) compared to the CEM I baseline.

The observed reductions are attributed to clinker substitution with supplementary cementitious materials, the high share of alternative fuels in clinker production, and the use of renewable electricity at manufacturing sites. When combined with local RCA sourcing and optimized placement practices, these strategies support the production of pervious concrete aligned with circular economy principles and low-carbon construction goals. In this manuscript, “low-carbon cements” refers to CEM II binders that exhibit a substantially lower cradle-to-gate GWP compared to CEM I—specifically, approximately 22–26% lower gross GWP for the materials used in this study.

Novelty and contribution

This study isolates the effect of vibration duration on the performance of pervious concrete incorporating 50% RCA, using a normalized vibration dose (NVD) as a quantitative compaction metric. An initial mix, designed at a fixed water-to-binder ratio of 0.34, served as the baseline for an expanded experimental program assessing the efficacy of RCA utilization. To ensure accurate permeability measurement, a refined falling-head test protocol was implemented, incorporating circumferential RTDS heat-shrink sealing to eliminate lateral side-flow and enforce one-dimensional flow—an approach not previously reported in the literature. The analysis integrates both effective porosity and three-dimensional pore connectivity, as measured by X-ray micro-computed tomography (micro-CT), to establish their relationship with hydraulic conductivity and compressive strength. A direct comparison between Portland cement (CEM I) and blended low-carbon cements (CEM II) under identical mixture proportions revealed an optimal compaction window of approximately 30 s (NVD ≈ 226), which balances mechanical integrity and permeability. These findings represent a novel contribution to the field, offering actionable guidance for mix design, field calibration, and the integration of sustainable materials in pervious concrete technology.

Materials and methods

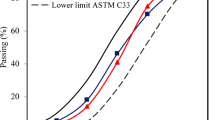

Prior to initiating the main experimental program, recommendations for the mix design of pervious concrete—including component dosing—were reviewed based on ACI 522R1 and FHWA guidance2, given the absence of a dedicated European EN standard for pervious concrete mix design. Preliminary trial mixes were prepared to determine optimal proportions, drawing on prior research involving analogous formulations39. For pervious concrete, a water-to-cement (w/c) ratio in the range of 0.27 to 0.34 is generally recommended1,7. Ratios below 0.27 tend to result in poor workability, while values exceeding the optimal range may lead to paste leakage between aggregate particles, adversely affecting both mechanical properties and permeability. To ensure sufficient workability, a w/c ratio of 0.34—at the upper limit of the recommended range—was selected for the final mixes. Anticipating a potential reduction in compressive strength due to the elevated w/c ratio, a small amount of fine sand was added, following established guidelines12,40. The concrete mixtures were further modified with a high-range water-reducing admixture (superplasticizer) to enhance fluidity while preserving the interconnected pore structure essential for permeability. This approach is consistent with best practices reported in the literature41,42,43,44,45,46.

Materials

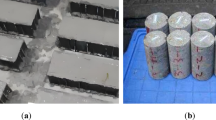

The materials employed in the experimental program (see Fig. 1) comprised fine aggregates (FA, 0/2 mm) fixed at 90 kg/m3, representing 5.6% of the total aggregate mass, natural coarse aggregates (NCA, 8/16 mm), and recycled concrete aggregates (RCA, 2/31.5 mm). The deliberate inclusion of a fine 0/2 mm fraction was intended to enhance workability and densify the ITZ, without compromising the interconnected porosity required to maintain adequate permeability. The adhered mortar content and short-term water absorption of coarse RCA were not assessed in this study. The particle size distribution, determined through sieve analysis, is presented in Fig. 2 and Table 1. Three types of cement were used in this study: Portland cement CEM I 42.5R and two general-purpose blended cements classified as CEM II, in accordance with PN-EN 197–1. The first, CEM II/B-V 32.5R-HSR, is a sulfate-resistant binder, while the second, CEM II/B-M (S-V) 42.5R, was formulated in line with sustainable development principles and contains up to 35% siliceous fly ash and blast furnace slag. The latter incorporates decarbonized raw materials, enabling a reduction in the carbon footprint, expressed as CO2 emissions per ton of cement produced. The chemical and physical properties of the cements are summarized in tables (see Tables 2, 3 and 4).

To improve the overall performance of designed pervious concrete, a MC Bauchemie PowerFlow 2650 superplasticizer of 0.4% (by binder weight) was applied within the recommended dosage range. Due to the action of superplasticizer that causes high dispersion of cement grains, the workability of the mix was significantly improved, enabling efficient process from production to application.

Preparation of test specimens

According to the MIX proportions of pervious concrete presented in Table 5, the constituent materials were introduced into a mechanical mixer. To account for aggregate water absorption—particularly that of recycled concrete aggregate—a two-stage mixing procedure was adopted, following FHWA guidance. Mixing was standardized as follows: (i) Stage 1 (pre-coat): Coarse aggregate (> 2 mm; natural or recycled, without pre-wetting) was charged into the mixer together with a preliminary mortar blend comprising approximately 50% of the total cement and water, 30% of the fine sand, and a plasticizing admixture. Mixing proceeded for ~ 2 min, until visual inspection confirmed a uniform thin mortar coating on the aggregate particles. (ii) Stage 2 (final blend): The remaining fine sand (~ 70%) and the remainder of the cement paste (~ 50% of cement and water) were added. The complete mixture was then blended for an additional 2–3 min to ensure homogeneity. After mixing, the reference mixtures (P1–P4) were cast into molds and compacted manually using 20 tamping blows, without the application of vibration. In the remaining test series, fresh concrete was placed into molds and compacted using vibration for durations of 10 s (w1), 20 s (w2), 30 s (w3), and 60 s (w4) – see Fig. 3. Verification of the saturated surface-dry conditions of aggregates was performed during batching in accordance with PN-EN 1097–6; the corresponding densities are reported in the Materials section. A vibrating table operating at a frequency f = 50 Hz and an average amplitude A = 0.75 mm was used for this purpose (manufacturer: Italvibras G. Silingardi, model: MVSI3/200-S02). To ensure transferability across different equipment setups, vibration kinematics and a non-dimensional vibration dose were reported. The vibrating table generated a peak velocity (vpk) and a peak acceleration (apk) calculated as follows:

A normalized vibration dose was defined as:

where: g is the standard acceleration due to gravity [9.81 m/s2], and tv is the vibration duration in seconds.

For the respective durations of 10, 20, 30, and 60 s, the calculated NVD values were 75.5, 151, 226, and 453, respectively.

An appropriate number of specimens were prepared for permeability testing (cylindrical specimens, ø150 mm × 300 mm, cast in acrylic tubes) and compressive strength testing (cylindrical specimens, ø150 mm × 300 mm, cast in standard molds). All specimens were covered with construction foil to prevent moisture loss. They remained in the molds for 24 h at a temperature of 20 ± 2 °C. After demolding, the specimens were transferred to a curing chamber maintained at a relative humidity of ≥ 95% and a temperature of 20 ± 2 °C.

In addition to volumetric replacement, a 50% equal-mass substitution of natural coarse aggregate with recycled concrete aggregate was applied in mixes P2–P4 (see Table 5). This kept the RCA level constant across P1–P4 and isolates the influence of vibration duration while allowing a direct CEM I versus CEM II comparison. For documentation purposes, the specific densities of the constituent materials, determined during batching process, were as follows: natural aggregate (gravel) – ρNA = 2690 kg/m3, recycled concrete aggregate – ρRCA = 2340 kg/m3, and fine aggregate (sand) – ρFA = 2650 kg/m3. The specific gravities of the binders used were 2.95 g/cm3for CEM II/B-V, 2.94 g/cm3 for CEM II/B-M (S-V), and 3.12 g/cm3 for CEM I.

Test methods and data analysis

In accordance with EN 12390-3, a uniaxial compressive load was applied to cylindrical specimens after 28 days of curing, at a constant loading rate until failure. The mean compressive strength (fcm,28) was calculated by dividing the maximum load by the cross-sectional area of the specimen, based on the results from three tested samples. According to ACI Report1, two standardized methods are recommended for determining the porosity of hardened pervious concrete. One of these is described in ASTM C1754. In this method, the specimen is first immersed in a water bath until air bubbles cease to emerge, indicating full saturation. It is then weighed underwater using a hydrostatic balance. Subsequently, the specimen is oven-dried at 105 °C for 24 h, cooled, and weighed again. The effective porosity (ne) is calculated using the following equation:

where: m1 – mass of the specimen weighed underwater [g], m2 – weight of the specimen after drying [g], V – volume of the specimen [cm3], ρw – density of water [g/cm3].

Statistical analysis

Linear relationships among key variables—effective porosity (ne), permeability (k), compressive strength (fcm,28), bulk density (ρ), and vibration duration (t)—were evaluated using ordinary least-squares (OLS) regression and Pearson’s correlation coefficient (r). For each fitted model, we report the slope (with physical units), the 95% confidence interval of the slope, the correlation coefficient (r), the two-sided p-value, and the sample size (n). Analyses were conducted both on the pooled dataset across all mixes (P1–P4) and at the individual mix level. Only relationships that satisfied the a priori assumption of linearity and reached statistical significance (α = 0.05) are visualized with trend lines in the figures; otherwise, results are presented descriptively without fitted lines. Measurements marked as NF (not feasible) or n/a (not available) were excluded listwise, with no imputation applied. For datasets with limited sample sizes (e.g., micro-CT series, n ≈ 8), effect estimates are interpreted with caution due to reduced statistical power.

To validate the aforementioned porosity determination method, an image analysis technique recommended in both the ACI Report1 and relevant literature47,48 was employed on 70 × 70 × 70 mm cubes. Porosity values represent the mean of measurements taken from at least four plain sections per specimen. The present study utilized a state-of-the-art digital microscope (manufacturer: Keyence; model: VHX-6000), which integrates observation, measurement, and reporting functionalities within a single platform. This system enables non-invasive, operator-independent, rapid, and high-precision analysis of concrete microstructures. The Multi-Scan function captures a series of pixel-shifted micrographs and digitally merges them into a single high-resolution 18 MP image, ensuring accurate representation of even the smallest pores (see Fig. 4). The integrated software facilitates microstructural analysis and allows for the measurement of up to 29,999 individual features with a resolution of 1 µm. Measurement data can be filtered based on user-defined parameters, such as minimum and maximum diameter or circularity. Batch image acquisition, digital stitching, and automated measurement provide a robust dataset for further quantitative evaluation.

Specimen during scanning under a digital microscope (left); merged high-resolution image of the top surface of specimen P2w4 (70 × 70 mm, × 30 magnification) (center); and processed binary image used for digital porosity analysis, with segmented pores highlighted in red (right). All images correspond to mix P2 with 60 s vibration (w4).

It is important to note that higher porosity does not necessarily result in increased permeability, as no definitive correlation exists between these two parameters. This is primarily due to the fact that, in addition to porosity and pore size, a critical factor influencing the permeability of pervious concrete is the tortuosity and connectivity of the pore network1,49. Including three-dimensional pore-structure metrics such as tortuosity, alongside porosity, significantly enhances the accuracy of predictions made by machine learning algorithms for pervious concrete properties. In the present study, these characteristics were assessed using X-ray micro-computed tomography, which is widely recognized as one of the most accurate techniques for three-dimensional analysis of porous concrete structures50,51,52,53,54. Cubic specimens measuring 70 × 70 × 70 mm (series P1–P4), previously examined using an optical digital microscope, were subjected to scanning. The measurements were conducted using a Bruker SkyScan 1173 micro-CT scanner available at the research facility. Micro-CT data were processed using Bruker’s dedicated software suite, including NRecon for reconstruction and CTAn for quantitative analysis of pore structure and tortuosity. The scanning parameters were as follows: 130 kV voltage, 61 µA current, 0.25 mm copper filter, 4000 ms exposure time, and a voxel size of 39.68 µm. Images were acquired at 0.2° rotational increments over a 0–180° range. To enhance image quality and reduce noise, each projection was averaged over four frames, resulting in a total scan time of approximately 4 h per specimen. Thanks to its large chamber and micrometer-level resolution, the scanner enabled simultaneous visualization of both macro- and micro-scale voids without damaging the specimens. The resulting 3D reconstructions allowed for the automated differentiation between open and closed pores (see Fig. 5), as well as the analysis of pore tortuosity. This facilitated the establishment of a relationship between the geometric characteristics of the pore network and the filtration performance of the pervious concrete.

The permeability coefficient was determined using the falling-head method, as described in ACI Report1. In this procedure, water is introduced into the graduated cylinder until both the specimen chamber and the overflow pipe are completely filled. The system is initially stabilized by allowing water to drain through the overflow pipe until the water level in the graduated cylinder aligns with the upper outlet of the pipe. This step minimizes the presence of air pockets and ensures full saturation of the specimen. With the valve closed, the cylinder is refilled to the desired initial water level. The valve is then opened, and the time required for the water column to fall from the initial level to the final level is recorded in seconds. Each test is repeated at least three times per specimen to obtain an average permeability coefficient. The coefficient is calculated using Darcy’s law for one-dimensional, laminar flow through a porous medium, as expressed by the following equation:

where: k— permeability coefficient [cm/s], a—cross-sectional area of the graduated cylinder with internal diameter 144 mm [a = 162.9 cm2], A— cross-sectional area of the cylindrical specimen ∅150 mm [A = 176.7 cm2], L—length of the specimen [L = 30.0 cm], h₁—initial water level [h1 = 33.5 cm], h2—final water level [h2 = 3.5 cm], t—time required for water to fall from level h₁ to h2 [s].

High water permeability values were recorded for the majority of specimens within the P1–P4 mixtures, which may be attributed to water bypassing through the annular space between the specimen and the inner wall of the acrylic tubes. To verify this effect, measures were taken to eliminate the possibility of lateral water flow along the specimen circumference. Following the removal of the tubes, a circumferential seal was applied using an innovative method involving large-diameter heat-shrink sealing to ensure watertightness (see Fig. 6). Once the specimens were properly sealed to prevent any leakage along the sidewalls, permeability tests for the P1–P4 mixtures were repeated. The corrected permeability coefficients were subsequently determined based on the revised measurements (see Fig. 7).

Falling-head permeability test setup after circumferential sealing: graduated cylinder internal diameter 144 mm (a = 162.9 cm2); sample cross-section A = 176.7 cm2 and height L = 30.0 cm; initial and final water levels h1 = 33.5 cm and h2 = 3.5 cm. The arrangement eliminates lateral side-flow along the specimen.

Results and discussion

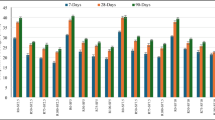

This study investigated the effect of vibration on the mechanical properties of pervious concrete incorporating RCA, which constituted 50% of the total mass of the coarse aggregate fraction. Additionally, various types of cement were used across the different mixtures, allowing for an assessment of their influence on the final material properties. The RCA replacement level was consistently maintained at 50% by mass across mixes P1–P4. This design choice isolates the effect of vibration duration and enables a direct comparison between binder types (CEM I vs. CEM II) under a fixed coarse aggregate fraction. Four concrete mix series, designated as P1–P4, were prepared, and the results of the laboratory tests are summarized in the table (see Table 6). The investigation into the influence of vibration duration on the properties of pervious concrete revealed statistically significant relationships between compaction time and both structural and hydraulic performance parameters. Pearson’s correlation analysis, conducted across four concrete mixtures (P1–P4) and five vibration durations (0, 10, 20, 30, and 60 s), showed consistent trends in effective porosity, filtration coefficient, compressive strength, and bulk density.

The experimental findings of this study prove that vibration duration exerts a decisive influence on the hydro-mechanical performance of recycled aggregate pervious concrete. The observed trends—namely, a progressive reduction in porosity and permeability accompanied by an increase in compressive strength with extended vibration—are consistent with previously reported behaviors for vibrated pervious concrete systems55,56,57. Literature indicates that vibration durations exceeding 5–10 s can yield notable strength enhancements, albeit at the expense of hydraulic conductivity, with reductions in permeability ranging from 20 to 60%57,58. The optimal vibration duration identified herein (≈30 s) aligns with recommended consolidation windows for field applications and with prior observations, particularly in mixtures incorporating CEM I. Quantitative analysis of the pooled linear regressions across all mixtures reveals statistically significant relationships between vibration duration and key material properties. Effective porosity decreases at a rate of − 0.165% per second (95% CI [− 0.238, − 0.093]; r = − 0.748; p = 0.0001; n = 20), while permeability declines by − 0.016 cm/s per second (95% CI [− 0.030, − 0.003]; r = − 0.598; p = 0.0186; n = 15). In contrast, compressive strength increases by + 0.164 MPa per second (95% CI [0.073, 0.256]; r = + 0.666; p = 0.0013; n = 20), and bulk density rises by + 4.499 kg/m3 per second (95% CI [2.305, 6.694]; r = + 0.713; p = 0.0004; n = 20). The identified optimum of approximately 30 s falls within the range previously recommended for laboratory consolidation of pervious concrete. For example, study59 proposed a duration of ≈40 s (at w/c ≈ 0.35) as a practical compromise between mechanical enhancement and permeability retention. This is consistent with the strength–permeability trade-off observed in the present study and reinforces the notion that the optimal vibration duration is contingent upon mixture-specific parameters, including binder type, RCA content, target porosity, and compaction methodology. Furthermore, the finding that excessive vibration promotes densification of the lower concrete layers—leading to hydraulic discontinuity—supports broader evidence that permeability is governed by the formation of a compacted interface under over-vibration. In agreement with prior research55, which emphasizes the sensitivity of pervious concrete properties to vibration duration and advocates for mix-specific calibration, the present results underscore the importance of employing short-to-moderate vibration windows validated through project-specific trial panels to achieve a balanced structural and hydraulic performance.

In general terms, the bulk density of the pervious concrete mixtures ranged from 1696 to 2194 kg/m3. The effective porosity varied between 6.12 and 22.45%, while the permeability coefficient ranged from 0.09 to 1.49 cm/s for specimens compacted by vibration, and from 1.26 to 1.79 cm/s for those compacted solely by tamping (without vibration). The variation in mixture parameters was primarily attributed to differences in aggregate composition, including the use of RCA, as well as the type of cement employed. Significant differences in specimen porosity were observed, which directly influenced the variability of the permeability coefficient. These parameters are closely related to a number of structural factors, such as total pore volume, pore size and distribution, and the continuity of the open pore network that facilitates water flow. For all tested mix designs (P1–P4), the obtained permeability values can be classified as high relative to typical engineering requirements and applications for pervious concrete.

The average compressive strengths for the reference samples P1 and P3, compacted by 20 tamper blows without the use of vibration, were 14.1 MPa and 16.2 MPa, respectively (cylindrical specimens). For the corresponding mixtures J1 and J3, prepared as cubic specimens during the initial trial batches39, the compressive strengths were 17.6 MPa and 18.4 MPa, respectively. The resulting ratio of compressive strength obtained from cylindrical to cubic specimens (fc,cyl/fc,cube) ranged from 0.80 to 0.88, which aligns with values reported in the literature for pervious concrete, where the typical range is 0.75–0.9060,61,62. The relationship between the porosity of pervious concrete and its mechanical and hydraulic properties has been confirmed both in the present study and in the literature63,64,65. For pervious concrete mixtures produced using various types of aggregates (both natural and recycled) and different types of cement, the 28-day average compressive strength and the filtration coefficient (permeability) are presented in the Fig. 8. A clear trend is observed: as porosity increases, compressive strength decreases from approximately 25–10 MPa, while the filtration coefficient increases from approximately 0.4–1.8 cm/s. The analysis revealed a statistically significant positive correlation between permeability and effective porosity, and a statistically significant negative correlation between compressive strength and effective porosity. These findings prove that, within the examined range, an increase in effective porosity results in a statistically significant improvement in permeability, accompanied by a corresponding reduction in compressive strength.

Compressive strength after 28 days and permeability of pervious concrete as functions of effective porosity. X-axis: effective porosity, ne (%); left Y-axis: permeability, k (cm/s); right Y-axis: compressive strength, fcm,28 (MPa). Trend lines are shown only for statistically significant relationships, shaded bands show 95% confidence intervals (CI). Linear fits (all mixes): fcm,28 versus ne — slope = − 0.730 MPa per 1% ne (95% CI [− 1.149, − 0.309]), r = − 0.652, p = 0.0018, n = 20; k versus ne — slope = + 0.072 cm/s per 1% ne (95% CI [0.024, 0.120]), r = + 0.672, p = 0.0061, n = 15.

The results of the present study unequivocally confirm the significant influence of compaction method and duration on the porosity, permeability, bulk density and compressive strength of pervious concrete (see Figs. 9 and 10), which aligns with the results reported by66. Samples compacted solely by mechanical means (without vibration) using 20 tamper blows (mixes P1–P4) showed effective porosity in the range of 13.80–22.45%, permeability between 1.26 and 1.79 cm/s, and 28-day compressive strength ranging from 8.4 to 16.2 MPa. The application of vibration for 10 s (P1w1–P4w1) reduced porosity to 10.20–11.92%, decreased permeability to 0.09–1.49 cm/s, and increased compressive strength to 9.6–21.4 MPa. A comparable trend was observed in the study55, which demonstrated that increasing the vibration duration from 5 to 15 s reduced permeability by 22–56% while boosting 28-day compressive strength from 19.9–31.0 MPa to 23.5–38.4 MPa, illustrating the typical trade-off between hydraulic and mechanical performance in pervious concrete. Extending the vibration duration to 30 s (P1w3–P4w3) further reduced porosity to 6.73–7.48% and permeability to 0.47–1.04 cm/s, while increasing compressive strength to 14.5–22.6 MPa. The best mechanical properties were achieved with 60 s of vibration (P1w4–P4w4), where compressive strength reached 19.7–28.4 MPa, and porosity and permeability decreased to 6.12–8.98% and 0.19–0.49 cm/s, respectively.

Effective porosity and permeability of pervious concrete as functions of vibration duration. X-axis: vibration duration, t (s); left Y-axis: effective porosity, ne (%); right Y-axis: permeability, k (cm/s). Trend lines are shown only for statistically significant relationships. Linear fits (all mixes): ne versus t — slope = − 0.165% per 1 s (95% CI [− 0.238, − 0.093]), r = − 0.748, p = 0.0001, n = 20; k versus t — slope = − 0.016 cm/s per 1 s (95% CI [− 0.030, − 0.003]), r = − 0.598, p = 0.0186, n = 15.

Compressive strength after 28 days and bulk density of pervious concrete as functions of vibration duration. X-axis: vibration duration, t (s); left Y-axis: bulk density, ρ (kg/m3); right Y-axis: compressive strength, fcm,28 (MPa). Trend lines are shown only for statistically significant relationships. Linear fits (all mixes): fcm,28 versus t — slope = + 0.164 MPa per 1 s (95% CI [0.073, 0.256]), r = + 0.666, p = 0.0013, n = 20; ρ versus t — slope = + 4.499 kg/m3 per 1 s (95% CI [2.305, 6.694]), r = + 0.713, p = 0.0004, n = 20.

A vibration duration of 30 s, corresponding to a reported normalized vibration dose of approximately 226, provided an optimal balance between compressive strength (≈15–23 MPa) and permeability (≥ 0.30 cm/s). This regime may have practical relevance for field placement of pervious concrete in pavement applications. Laboratory results—particularly for mixes P2 and P4—identified this duration as most favorable, offering a compromise between structural integrity and hydraulic functionality that meets stormwater management requirements, including the FHWA-recommended minimum infiltration rate of 0.14 cm/s2.This vibration duration aligns with the external consolidation phase typically occurring during and immediately after strike-off under site conditions. Current construction standards, such as those outlined in the ACI Report1, recommend vibratory or roller screeds for strike-off, followed by rolling consolidation to achieve target density and surface finish. To translate laboratory findings into field practice, preconstruction calibration trials are recommended for the specific concrete mix. Equipment settings (frequency, amplitude) should be adjusted to achieve the target NVD, with a practical quality assurance tolerance of ± 10%. These trials should define site-specific vibration parameters—including equipment type, number and speed of screed and roller passes—to ensure compliance with key performance criteria: mechanical strength and in-place infiltration ability.

These trends are consistent with findings reported in the literature. In study13, the rodding method resulted in a porosity of 22.8% and a compressive strength of 9.6 MPa, whereas the vibration method (10 s) yielded a porosity of 18.5% and a compressive strength of 13.2 MPa. Similarly, in study14, compaction by rodding (25 strokes in 3 layers) led to porosity values up to 25%, compressive strength starting from 5.5 MPa, and permeability up to 0.53 cm/s. Vibration for 5 s at various amplitudes reduced porosity to 15%, increased compressive strength to 32 MPa, and decreased permeability to 0.09 cm/s. In the scientific research18, it was demonstrated that the duration of compaction (vibration) significantly affects the homogeneity of the pervious concrete structure, which directly influences its functional and mechanical properties. Specimens compacted for 10 s exhibited a uniform material distribution, whereas compaction times of 30 and 60 s resulted in aggregate segregation in the lower part of the specimen, leading to reduced permeability. This study identified a similar sedimentation-driven sealing effect at the base of concrete specimens during vibration-based compaction (10–60 s), resulting in partial closure of the bottom surface pores (see Fig. 3). The phenomenon was most pronounced in mixes containing pure Portland cement (CEM I), where paste settlement reached 2–3 cm and significantly reduced permeability. In contrast, mixes incorporating blended cements with fly ash (CEM II) exhibited limited sedimentation (< 1 cm), preserving partial filtration capacity.

The sealing mechanism is attributed to thixotropic breakdown and shear-thinning of the fresh paste under table vibration (50 Hz, ~ 0.75 mm amplitude), which facilitates gravity-driven squeeze-flow through the aggregate skeleton. The downward flux accumulates at the mold base, locally narrowing pore entrances and progressively reducing permeability with increasing vibration duration. Binder composition played a critical role. At a constant water-to-cement ratio (w/c = 0.34) and identical superplasticizer dosage (0.4% by binder weight), CEM II mixes exhibited higher Blaine fineness and water demand (CEM II/B-V 32.5R-HSR: 4282 cm2/g; 28.5%; CEM II/B-M(S-V) 42.5R: 4934 cm2/g; 33.0%) compared to CEM I 42.5R (3504 cm2/g; 27.5%) – see Tables 2, 3 and 4. These characteristics indicate a higher solids content and yield stress in CEM II pastes, which limited paste mobility and mitigated sealing under vibration. Consequently, base sealing was prominent only in CEM I mixes subjected to extended vibration, while CEM II mixes remained more permeable. Although the present study focused on mixtures containing 50% recycled concrete aggregate, previous research15,16,17 indicates that RCA contents exceeding 60% often necessitate increased paste volume and/or the incorporation of supplementary cementitious materials (SCMs) to maintain compressive strength at a given porosity. Conversely, RCA replacement levels in the range of 30–60% tend to preserve or even enhance permeability, primarily due to the rough surface texture of RCA and the increased tortuosity of the pore network—provided that compaction is appropriately calibrated.

The influence of vibration duration on the effective porosity and filtration properties of pervious concrete was evaluated using a combined dataset for mixes P1–P4 (see Fig. 9). The results indicate that effective porosity decreases significantly with increasing vibration duration from 0 to 60 s (r = − 0.748, p = 0.0001). However, the variability of effective porosity within individual mixtures was more pronounced. In most cases, a downward trend was observed with increasing vibration duration. For instance, mix P2 exhibited a strong negative correlation (r = − 0.790), although this relationship was not statistically significant (p = 0.1116), suggesting a potential reduction in the proportion of open pores as compaction intensity increases. Filtration parameters, particularly the filtration coefficient, showed strong to very strong negative correlations with vibration duration for mixes P2 (r = − 0.779), P3 (r = − 0.916), and P4 (r = − 0.996). For mix P4, the correlation was statistically significant (p = 0.0043). In contrast, no reliable results were obtained for filtration parameters in mix P1, likely due to incomplete data.

The findings once again demonstrate that vibration duration is a key factor influencing the overall performance of pervious concrete (see Fig. 10). While mechanical properties such as compressive strength and bulk density also improved with longer vibration durations, their variability appeared to be more dependent on the specific composition of each mix. Compressive strength exhibited a very strong positive correlation with vibration duration for mixes P2 (r = + 0.990; p = 0.0012), P3 (r = + 0.931; p = 0.0214), and P4 (r = + 0.996; p = 0.0003), confirming the beneficial impact of extended compaction on mechanical performance. These findings suggest that optimizing vibration duration can enhance both the structural integrity and hydraulic functionality of pervious concrete. However, the extent of improvement is mix-dependent, highlighting the importance of tailored compaction strategies in achieving desired performance outcomes.

Based on the conducted analysis, it was found that a combined dataset for all tested concrete mixtures (P1–P4) exhibited a clear decreasing trend in porosity with increasing vibration duration, regardless of the measurement method used. Statistical analysis showed that in all examined cases, there was a negative Pearson correlation between vibration duration and concrete porosity. This indicates that as the compaction time increases, the pore volume within the material structure systematically decreases. The correlation coefficient for effective porosity was r = − 0.748 with p = 0.0001, showing a strong and statistically significant relationship. For porosity determined using the microscopic method (see Fig. 11), the correlation with the target parameter was moderate but statistically insignificant (r = − 0.517, p = 0.1896). This outcome reflects inherent limitations of the microscope-based image analysis technique, which interrogates only two-dimensional sections. As a result, the method is susceptible to orientation bias, field-of-view limitations, size of the sample, and the randomness of the analyzed plane resulting from sample preparation. Moreover, it cannot detect closed pores or quantify three-dimensional features such as connectivity and tortuosity, which are critical for accurately characterizing the pore structure of pervious concrete. In contrast, for measurements obtained via micro-computed tomography, the coefficient was r = − 0.828 with p = 0.0111, confirming a strong and significant inverse relationship. The consistency of results obtained using different measurement techniques—particularly between effective porosity and micro-CT—confirms the coherence and repeatability of the observed phenomenon, regardless of the applied testing method. Based on the analysis of selected samples (P1w1, P2w1, P2w3, P2w4, P3w1, P4w1, P4w3, P4w4), it was determined that effective porosity and micro-CT measurements are very strongly correlated (Pearson correlation coefficient r = 0.978, p < 0.001), indicating that the effective porosity assessment method accurately reflects the total porosity measured by tomography. Microscopically determined porosity showed a moderate correlation with the other methods but did not reach statistical significance (p > 0.05), which may be due to a smaller dataset or greater variability in the measurement cross-sections.

Comparison of measured effective porosity, porosity by microscope, and total porosity measured by micro-CT as functions of vibration duration. X-axis: vibration duration, t (s); Y-axis: porosity ne / nmic / nm-CT (%). Trend lines are shown only for statistically significant relationships. Linear fits (all mixes): ne versus t — slope = − 0.165% per 1 s (95% CI [− 0.238, − 0.093], r = − 0.748, p = 0.0001, n = 20; nm-CT versus t — slope = − 0.104% per 1 s (95% CI [− 0.175, − 0.034]), r = − 0.828, p = 0.011, n = 8; for nmic versus t no significant linear trend was found (p = 0.190) and the trend line is omitted.

Further analysis of the micro-CT data showed that in the P2 series, the proportion of open pores in the total pore volume ranged from 83 to 87%, while in the P4 series it ranged from 92 to 94% (see Fig. 12). A high proportion of open pores indicates good continuity of the pore network, which directly translates into the effective permeability of the material. This supports the thesis that it is not the total porosity value itself, but rather the shape, size, and interconnectivity of the pores that determine the concrete’s ability to transport fluids52,67. A comparison of micro-CT results with the method described in ASTM C1754 showed that porosity values obtained from CT imaging were on average 15% higher68. This difference arises from the fact that the underwater weighing method does not account for closed pores, which do not participate in fluid flow but are detected by micro-CT. It is also worth emphasizing that porosity levels exceeding 25–30% are undesirable from the perspective of the material’s mechanical properties. Importantly, achieving high permeability does not require increasing total porosity—what matters most is the optimization of pore structure, not the quantity of pores69.

In the laboratory tests conducted using the falling-head method, high water permeability was observed for most samples from series P1–P4. This may have resulted in water filtration along the walls of the acrylic molds. To verify this effect, the possibility of water flow along the lateral surfaces of the specimens was eliminated. Subsequent measurements of the filtration coefficient for mixtures P1–P4 were performed, accounting for the correction resulting from the elimination of lateral water flow (see Fig. 6). The obtained results confirmed a reduction in water permeability ranging from 4% to as much as 49% (see Table 6 and Fig. 13). Particularly promising and repeatable results were obtained for samples from series P2 and P4, where reductions in the permeability coefficient were recorded in the ranges of 20–45% and 15–36%, respectively. The measured permeability values ranged from 0.11–0.35 cm/s for series P2 and 0.31–1.24 cm/s for series P4, with vibration durations from 10 to 60 s. Even at the maximum vibration duration (60 s), samples P2w4 and P4w4 exhibited permeability exceeding the reference value defined for the purpose of this study (0.1 cm/s), indicating sustained high water permeability of these mixtures despite the applied circumferential sealing method.

Analysis of the filtration coefficient before and after circumferential sealing of specimens using RTDS heat-shrink sealing as functions of vibration duration. X-axis: vibration duration, t (s); Y-axis: filtration coefficient k / kRTDS (cm/s). Trend lines are shown only for statistically significant relationships. Linear fits (all mixes): k versus t — slope = − 0.016 cm/s per 1 s (95% CI [− 0.030, − 0.003]), r = − 0.598, p = 0.0186, n = 15; kRTDS versus t — slope = − 0.016 cm/s per 1 s (95% CI [− 0.027, − 0.004]), r = − 0.642, p = 0.010, n = 15.

Limitations

This study was conducted using a single RCA replacement level (50%) and employed laboratory-scale table vibration rather than full-scale field compaction methods such as screed or roller systems. While permeability was assessed on cylindrical specimens with corrected axial flow using RTDS circumferential sealing, residual anisotropy due to potential base sealing effects may persist. Additionally, microstructural imaging via microscope and micro-CT was performed on 70 mm cubes, which do not capture the full height of the cylindrical specimens, potentially limiting representativeness in pore connectivity analysis. Prior to batching, the aggregates were verified to be in a saturated surface-dry conditions, ensuring reliable input parameters for mix design and water balance. However, the adhered mortar content (RMC) and short-term absorption were not determined, which may affect absolute values; thus, they are interpreted with caution while relative trends remain valid. Durability aspects, including freeze–thaw resistance and clogging under sediment-laden flow, were also not evaluated. These limitations may introduce bias in the absolute values of the filtration coefficient, particularly at extended vibration durations. However, the relative trends observed across vibration durations and binder types remain consistent and robust, supporting the validity of comparative conclusions drawn from the experimental data.

Conclusions

This study investigated the influence of vibration duration on the hydro-mechanical performance of recycled aggregate pervious concrete, integrating micro-CT pore structure analysis with mechanical and hydraulic testing. Laboratory results confirmed that mixtures incorporating 50% recycled concrete aggregate and blended cements (CEM II) can meet structural and hydraulic performance criteria under optimized compaction regimes. If applied in real-world construction, this material configuration can reduce cradle-to-gate CO2e by ≈22–26% (CEM II vs. CEM I) compared to conventional mixtures with natural aggregate and CEM I, contributing to circular economy objectives and low-carbon infrastructure development. The principal findings are as follows:

-

Influence of vibration duration. Vibration duration was identified as a key factor governing the hydraulic–mechanical balance in RCA-based pervious concrete. Increasing vibration duration from tamping-only (0 s) to 60 s decreased effective porosity (≈13.8–22.5% → 6.1–9.0%) and permeability (≈1.26–1.79 cm/s → 0.19–0.49 cm/s), while increasing 28-day compressive strength (≈8.4–16.2 MPa → 19.7–28.4 MPa). Linear fits on the pooled dataset confirmed significant trends for all four responses (see Figs. 9, 10 and 13): porosity (r = − 0.748; p = 0.0001), permeability (r = − 0.598; p = 0.0186), strength (r = + 0.666; p = 0.0013), and bulk density (r = + 0.713; p = 0.0004).

-

Normalized vibration dose (NVD) and optimal compaction. By reporting vibration kinematics and introducing a non-dimensional vibration dose, the study identified an optimal compaction regime around NVD ≈ 226 (corresponding to ~ 30 s at 50 Hz and 0.75 mm amplitude). This regime provided the most favorable balance between structural integrity and hydraulic functionality, with compressive strengths of 14.5–22.6 MPa and corrected permeability values (via RTDS sealing) of 0.32–0.81 cm/s. Extending vibration to 60 s further improved strength in some mixes but induced paste sedimentation and partial base sealing—particularly in highly fluidized CEM I mixtures—leading to permeability reductions of up to 80% relative to the tamped control. Therefore, vibration durations beyond 30 s are not recommended unless structural demands clearly outweigh hydraulic requirements or calibration trials justify such adjustments.

-

Refined permeability testing protocol. To ensure accurate permeability measurement, a refined falling-head test protocol was introduced, eliminating lateral side-flow via circumferential RTDS heat-shrink sealing and enabling one-dimensional flow. This approach, not previously reported in the literature, reduced measured permeability by 4–49%, resolving a common source of overestimation and enhancing the reproducibility of hydraulic assessments.

-

Material sustainability and performance. The study demonstrated that a 50% substitution of natural aggregate with RCA, combined with the use of low-carbon CEM II cements, can sustain target performance levels. Blended cement mixtures (P2, P4) matched or exceeded the CEM I benchmark in compressive strength (up to + 45%) while maintaining adequate permeability (> 0.30 cm/s), confirming the feasibility of circular-economy aggregates and low-carbon binders in structural pervious concrete applications.

-

Role of micro-CT in mix design. Micro-computed tomography proved essential for performance-oriented mix design. Tomographic analysis revealed that 83–94% of pores remained interconnected, and micro-CT porosity showed a strong correlation with effective porosity (r = 0.978). Additionally, tortuosity metrics derived from 3D scans provided critical insights into permeability variability that were not captured by conventional porosity measurements. Notably, three-dimensional pore connectivity—rather than total porosity alone—emerged as the key structural correlate of permeability.

These findings represent a novel contribution to the literature, offering practical guidance for mix design, performance optimization, and sustainable material integration in pervious concrete technology. The proposed methods and metrics are equipment-agnostic and support reproducible practice with recycled aggregates in low-carbon infrastructure development.

Further directions

In the light of the conducted analyses and literature review, it can be unequivocally stated that the currently applied testing methods developed for conventional concretes are not fully adequate for evaluating the properties of pervious concrete. Due to its specific structure and function—particularly its ability to allow water infiltration—it is necessary to develop new or adapt existing testing methods that account for the unique characteristics of this material. Porosity is the most frequently analyzed parameter in studies on pervious concrete. However, as demonstrated, the porosity value alone is insufficient for predicting the material’s performance. Permeability, a key functional property of pervious concrete, depends not only on the quantity of pores but also on their size, surface characteristics, and the tortuosity of the flow channels.

In this context, modern testing techniques such as X-ray micro-computed tomography are of particular importance. This method enables three-dimensional analysis of the material’s microstructure, including the identification of open and closed pores and the assessment of their interconnectivity. On the other hand, the method described in ASTM C1754, while simpler and more cost-effective, allows for rapid and sufficiently accurate determination of effective porosity—which is critical from the perspective of water permeability. Therefore, the choice of testing method should be closely aligned with the design objective and the intended application of the material. Properly designed macroporosity can not only ensure high permeability but also contribute to improved material durability. Thus, a comprehensive understanding of pore structure and its influence on the functional and mechanical properties of pervious concrete is essential for the development of modern, performance-based mix design methodologies.

Data availability

All data supporting the findings of this study are available within the article and its Supplementary Information files.

References

ACI Committee 522. & American Concrete Institute. Report on Pervious Concrete. (American Concrete Institute, Farmington Hills, MI, 2010).

Federal Highway Administration (FHWA). Pervious Concrete, TechBriefFHWA-HIF-13–006. https://www.fhwa.dot.gov/pavement/concrete/pubs/hif13006/hif13006.pdf (2013).

Olek, J. et al. Development of Quiet and Durable Porous Portland Cement Concrete Paving Materials. in Final Report SQDH 2003–5 / HL 2003–18 1–172 (Institute for Safe, Quiet & Durable Highways, Purdue University, 2003).

Haselbach, L., Boyer, M., Kevern, J. T. & Schaefer, V. R. Cyclic heat island impacts on traditional versus pervious concrete pavement systems. Transp. Res. Record: J. Transp. Res. Board 2240, 107–115 (2011).

Meininger, R. C. No-fines pervious concrete for paving. Concr. Int. 10, 20–27 (1988).

Ho, H.-L., Huang, R., Hwang, L.-C., Lin, W.-T. & Hsu, H.-M. Waste-based pervious concrete for climate-resilient pavements. Materials 11(6), 900 (2018).

Schaefer, V., Wang, K., Suleiman, M. & Kevern, J. Mix design development for pervious concrete in cold weather climates. Center for Transportation Research and Education 8–72 (Iowa State University, 2006).

Huang, Y., Sun, H., Liu, Y. & others. Application of pervious concrete pavement in the “breathe in–breathe out” design for sponge cities in China. Environ. Sci. Pollut. Res. (2024).

Luan, J., Ma, Q., Liu, C., Ma, Y. & Li, C. Application status and development suggestions of sponge city pervious concrete. in Proceedings of 4th International Social Sciences and Education Conference (ISSEC 2019) 822–827 (Francis Academic Press, UK, 2019). https://doi.org/10.25236/issec.2019.161.

Alemu, A. S. et al. Practical considerations of porosity, strength, and acoustic absorption of structural pervious concrete. Case Stud. Constr. Mater. 15, e00764 (2021).

Yang, J. & Jiang, G. Experimental study on properties of pervious concrete pavement materials. Cem. Concr. Res. 33, 381–386 (2003).

Wang, K., Schaefer, V. R. & Kevern, J. T. Development of mix proportion for functional and durable pervious concrete. In Proceedings of the 2006 NRMCA Concrete Technology Forum—Focus on Pervious Concrete 1–12 (2006).

Sahdeo, S. K., Chandrappa, A. & Biligiri, K. P. Effect of compaction type and compaction efforts on structural and functional properties of pervious concrete. Transp. Dev. Econ. 7, 19 (2021).

Suleiman, M., Kevern, J. & Schaefer, V. Effect of compaction energy on pervious concrete properties. (2006).

Zaetang, Y., Sata, V., Wongsa, A. & Chindaprasirt, P. Properties of pervious concrete containing recycled concrete block aggregate and recycled concrete aggregate. Constr. Build. Mater. 111, 15–21 (2016).

Vieira, G. L., Schiavon, J. Z., Borges, P. M., da Silva, S. R. & de Oliveira Andrade, J. J. influence of recycled aggregate replacement and fly ash content in performance of pervious concrete mixtures. J. Clean. Prod. 271, 122665 (2020).

El-Hassan, H., Kianmehr, P. & Zouaoui, S. Properties of pervious concrete incorporating recycled concrete aggregates and slag. Constr. Build. Mater. 212, 164–175 (2019).

Ni, L. Pervious Concrete Piles: Development and Investigation of an Innovative Ground Improvement System. Theses and Dissertations. Lehigh University. Paper 1572. http://preserve.lehigh.edu/etd (2014).

Güneyisi, E., Gesoğlu, M., Kareem, Q. & İpek, S. Effect of different substitution of natural aggregate by recycled aggregate on performance characteristics of pervious concrete. Mater. Struct. 49, 521–536 (2016).

Amin, A. A., Younis, K. H., Jirjees, F. F. & Ibrahim, T. K. Experimental study on mechanical properties of pervious concrete containing recycled aggregate. Civil Eng. Archit. 9, 1735–1743 (2021).

Kurpińska, M. & Wcisło, A. Wpływ parametrów kruszywa na właściwości betonu przepuszczającego. Dni betonu 547–558 (2018).

Rahal, K. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 42, 407–415 (2007).

Ajdukiewicz, A. & Kliszczewicz, A. Influence of recycled aggregates on mechanical properties of HS/HPC. Cem. Concr. Compos. 24, 269–279 (2002).

United Nations Environment Programme. Global Waste Management Outlook 2024: Beyond an Age of Waste — Turning Rubbish Into a Resource. Preprint at https://doi.org/10.59117/20.500.11822/44939 (2024).

Kaza, S., Yao, L. C., Bhada-Tata, P. & Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050 (World Bank, 2018). https://doi.org/10.1596/978-1-4648-1329-0.

Eurostat. Generation of waste by waste category, hazardousness and NACE Rev. 2 activity (env_wasgen). Preprint at https://doi.org/10.2908/env_wasgen (2024).

United States Environmental Protection Agency. Advancing Sustainable Materials Management: 2018 Fact Sheet. https://www.epa.gov/sites/default/files/2020-11/documents/2018_ff_fact_sheet.pdf (2020).

United States Environmental Protection Agency. Construction and Demolition (C&D) Debris: Material-Specific Data. Preprint at (2024).

Zheng, L. et al. Characterizing the generation and flows of construction and demolition waste in China. Constr. Build. Mater. 136, 405–413 (2017).

Qasim, O. A., Hilal, N., Al Biajawi, M. I., Sor, N. H. & Tawfik, T. A. Studying the usability of recycled aggregate to produce new concrete. J. Eng. Appl. Sci. 71, 129 (2024).

Wu, H., Gao, J., Liu, C. & Chen, X. Cementitious properties of sustainable alkali-activated materials with ground GGBS-based geopolymer waste powder as recycled precursor. J. Build. Eng. 88, 109210 (2024).

Wu, H., Gao, J., He, Z. & Shen, X. Reusing waste clay brick powder for low-carbon cement concrete and alkali-activated concrete: A critical review. J. Clean Prod. 449, 141755 (2024).

Wu, H., Gao, J., Liu, C. & Zhao, Y. Development of nano-silica modification to enhance the micro–macro properties of cement-based materials with recycled clay brick powder. J. Build. Eng. 86, 108854 (2024).

Wu, H., Luo, X., Li, S. & Xu, Z. Combine use of 100% thermoactivated recycled cement and recycled aggregate for fully recycled mortar: Properties evaluation and modification. J. Clean Prod. 450, 141841 (2024).

CEMEX Polska Sp. z o.o. Environmental Product Declaration Type III (EPD) - ITB No. 674/2024 — Natural Crushed and Gravel Aggregates and Recycled Crushed Aggregates, CEMEX Polska. https://www.itb.pl/wp-content/uploads/2024/10/ITB-EPD_674_CEMEX-Polska-Sp.-z-o.o.-Natural-crushed-and-gravel-aggregates-and-recycled-crushed-aggregates-offered-by-Cemex-Polska.pdf (2024).

CEMEX Polska Sp. z o.o. Environmental Product Declaration (EPD) — Group of Cements CEM I 42.5 Produced in Poland. (2023).

CEMEX Polska Sp. z o.o. Environmental Product Declaration (EPD) — CEM II/B Cements Including CEM II/B-V 32.5 R HSR, Plant Gdynia. (2023).

CEMEX Polska Sp. z o.o. Environmental Product Declaration (EPD) — CEM II/B-M (S-V) 42.5 R, Plant Chełm. (2023).

Mitrosz, O., Kurpińska, M., Miśkiewicz, M., Brzozowski, T. & Abdelgader, H. S. Influence of the addition of recycled aggregates and polymer fibers on the properties of pervious concrete. Materials 16, 5222 https://doi.org/10.3390/ma16155222 (2023).

Ćosić, K., Korat, L., Ducman, V. & Netinger, I. Influence of aggregate type and size on properties of pervious concrete. Constr. Build. Mater. 78, 69–76 (2015).

Kevern, J. T. Pervious Concrete. in 261–273 (2014). https://doi.org/10.1007/978-3-662-44719-2_8.

Kevern, J. T., Wang, K. & Schaefer, V. R. Pervious Concrete Mix Design for SCPC. in Third North American Conference on the Design and Use of Self-Consolidating Concrete (SCC2008) (Northwestern University, 2008).

Lund, M. S. M., Hansen, K. K., Jensen, A. H., Mølgaard, E. & Madsen, P. K. Self-compacting pervious concrete mix design for permeable concrete soakaway rings. Adv. Civ. Eng. Mater. 7, 340–352 (2018).

E. Koehler, M. O. J. M. A. A. J. Chemical admixture system for pervious concrete. In SP-262: Ninth ACI International Conference on Superplasticizers and Other Chemical Admixtures 273–286 (American Concrete Institute, 2009). https://doi.org/10.14359/51663238.

Ghosh, S. & Singh, P. Effect of Superplasticizer on Characteristics of Pervious Concrete. in 27–37 (2023). https://doi.org/10.1007/978-981-99-3142-2_3.

Sonebi, M., Bassuoni, M. & Yahia, A. Pervious concrete: Mix design, properties and applications. RILEM Tech. Lett. 1, 109–115 (2016).

Neithalath, N. Development and Characterization of Acoustically Efficient Cementitious Materials (Purdue University, 2004).

Neithalath, N. Influence of aggregate size and gradation on acoustic absorption of enhanced porosity concrete. ACI Mater. J. 101, 82–91 (2004).

Yu, F., Chu, W., Zhang, R., Gao, Z. & Yang, Y. Predicting the permeability and compressive strength of pervious concrete using a stacking ensemble machine learning approach. Sci. Rep. 15(22506), 1–14 (2025).

Skarżyński, Ł & Tejchman, J. Investigations on fracture in reinforced concrete beams in 3-point bending using continuous micro-CT scanning. Constr. Build. Mater. 284, 122796 (2021).

Zhang, J. et al. Numerical study on seepage flow in pervious concrete based on 3D CT imaging. Constr. Build. Mater. 161, 468–478 (2018).

Chandrappa, A. K. & Biligiri, K. P. Pore structure characterization of pervious concrete using X-ray microcomputed tomography. J. Mater. Civil Eng. 30, (2018).

Shan, J. et al. Pore characteristics of pervious concrete and their influence on permeability attributes. Constr. Build. Mater. 327, 126874 (2022).

Yu, F. et al. Pore structure identification method for pervious concrete based on improved UNet and fusion algorithm. KSCE J. Civ. Eng. 27, 4834–4848 (2023).

Chilmon, K., Jaworska, B., Kalinowski, M., Jackiewicz-Rek, W. & Podkoń, A. Significance of vibration time in developing properties of precast pervious concrete. Materials 16, 6239 (2023).

Mikami, R. J., Pieralisi, R. & Pereira, E. Influence of compaction energy on pervious concrete properties and vertical porosity distribution. Revista IBRACON de Estruturas e Materiais 17, (2024).

Martin, W. D., Kaye, N. B. & Putman, B. J. Impact of vertical porosity distribution on the permeability of pervious concrete. Constr. Build. Mater. 59, 78–84 (2014).

Haselbach, L. M. & Freeman, R. Vertical porosity distributions in pervious concrete pavement. ACI Mater. J. 103, 452–458 (2006).

Ximenes, J., Jesus, C., Aguiar, J. & Pais, J. Mix design and physical and mechanical properties of pervious concretes. Mater. Constr. 72, e297 (2022).

Chopda, S. M. & Chhattani, B. M. Mechanical properties of pervious concrete. Int. J. Technol. 5, 113–117 (2015).

Kevern, J. T. Evaluating permeability and infiltration requirements for pervious concrete. J. Test. Eval. 43, 544–553 (2015).

Chockalingam, T., Vijayaprabha, C. & Leon Raj, J. Experimental study on size of aggregates, size and shape of specimens on strength characteristics of pervious concrete. Constr. Build. Mater. 385, 131320 (2023).

Hou, F. et al. Properties and relationships of porous concrete based on Griffith’s theory: Compressive strength, permeability coefficient, and porosity. Mater. Struct. 57, 52 (2024).

Vu, V.-H., Tran, B.-V., Hoang, V.-H. & Nguyen, T.-H.-G. The effect of porosity on the elastic modulus and strength of pervious concrete. In Modern Mechanics and Applications. Lecture Notes in Mechanical Engineering. (Springer, Singapore, 2022). https://doi.org/10.1007/978-981-16-3239-6_63.

Wijekoon, S. H. B., Sathiparan, N. & Subramaniam, D. N. Optimisation of pervious concrete performance by varying aggregate shape, size, aggregate-to-cement ratio, and compaction effort by using the Taguchi method. Int. J. Pavement Eng. 25, (2024).

Kumar, V. S., Ferić, K., Romić, A. & Gotovac, H. Comparative study on the hydraulic conductivity of pervious concrete slabs by constant and falling head permeability tests. Mech. Time Depend. Mater. 28, 2643–2660 (2024).

Neithalath, N., Sumanasooriya, M. S. & Deo, O. Characterizing pore volume, sizes, and connectivity in pervious concretes for permeability prediction. Mater. Charact. 61, 802–813 (2010).

Hung, V. V., Seo, S.-Y., Kim, H.-W. & Lee, G.-C. Permeability and strength of pervious concrete according to aggregate size and blocking material. Sustainability 13(1), 426 (2021).

Neithalath, N., Weiss, W. & Olek, J. Predicting the permeability of pervious concrete (Enhanced Porosity Concrete) from non-destructive electrical measurements. Paper 08-1234. in Proceedings, 87th Transportation Research Board Annual Meeting 1–14 (Washington DC, 2008).

Acknowledgements

The authors express their gratitude and sincere appreciation to the Faculty of Civil and Environmental Engineering, Gdańsk University of Technology for sharing the expertise and laboratories, and geotechnical contractor Keller Polska sp. z o.o. for technical support of the research.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

Conceptualization, O.M. and T.B.; Methodology, O.M., M.K. and M.M.; Software, O.M.; Validation, O.M. and M.K.; Formal Analysis, O.M and M.K.; Investigation, O.M.; Resources, O.M.; Data Curation, O.M. and T.B.; Writing—Original Draft Preparation, O.M.; Writing—Review and Editing, M.K. and M.M.; Visualization, O.M. and T.B.; Supervision, M.M.; Project Administration, O.M. and M.K.; All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Mitrosz, O., Kurpińska, M., Miśkiewicz, M. et al. Effect of vibration duration on strength and permeability of pervious concrete with recycled aggregate and low-carbon cements. Sci Rep 15, 35905 (2025). https://doi.org/10.1038/s41598-025-19842-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-19842-6