Abstract

Due to the fact that a large number of farms are equipped with surface irrigation systems, the proper design and use of these systems increases their efficiency, which is of particular importance due to the current water crisis. In this context, it is possible to use models and tools that increase efficiency and reduce water wastage in these irrigation systems and achieve even higher efficiency than pressurized irrigation. Among the tools used in this field, we can mention floater valves. The performance of furrow irrigation is highly dependent on the inflow. One of the irrigation methods in this system is irrigation with constant inflow. To stabilize and create this state in the furrows, a flow stabilizing set is used at the head of the fields. One of these sets includes a stabilization tank with an overflow and a pump. Disadvantages of this method include excess water overflow from the tank and its wastage, as well as the need for excess energy for the pump. In this study, for solving these problems, the use of floating valves has been investigated to provide a constant inflow in furrow irrigation. For this purpose, a concrete platform was constructed on which the water storage sources were placed. A hydraulic slope was provided with a height difference of about 30 cm to transfer water from them to the flow stabilization tank. Inside the stabilization tank, two two-inch brass floating valves were used to stabilize the water level. Numerous field experiments and evaluations have shown that a height difference of 30 cm, before completely draining water from water storage sources, stabilizes the maximum inflow of 2.2 and the minimum of 1.3 L per second into the tank. Floating valves keep the water level inside the stabilization tank constant at a height of 50 cm from the outlet center of the stabilization tank with inflow of 0.8 L per second. Measurement of the inflow to the furrows by flow measuring instruments (flume) also confirmed that the intensity of the inflow to the furrows was always constant throughout the test. The main purpose of this study was to create a constant input flow in irrigation systems, especially furrow irrigation, using simple mechanical tools that can be used by all farmers. Also, reducing water loss in farms and water management in the field with the approach of reducing energy consumption is important. These goals were investigated during 60 furrow irrigation operations, and measurements showed that they could be achieved by gravity-free energy provided the minimum water head was observed and mechanical tools such as valves were used. Therefore, considering the importance of inflow in furrow irrigation, according to the results of this research, it is possible to use mechanical and piping tools, including valves, etc., in the facilities at the head of the farm to control the water entering the furrow, and one of these tools is a floater valve. In the furrow irrigation method with constant input flow rate, in order to reduce water wastage and also reduce energy costs in secondary pumping, a mechanical set that stabilizes the flow with the help of gravity energy can be used. This issue is very important due to the reduction of energy consumption and production of greenhouse gases, as well as the reduction of water wastage in the current water crisis. Therefore, the innovation presented in this current manuscript has economic, environmental, social and etc. importance.

Similar content being viewed by others

Introduction

Irrigation is an infrastructure asset that needs to be used optimally. This is because water; water resources and irrigation infrastructure can provide greater benefits to farms1. The sustainability of irrigation agriculture in semi-arid climates hinges upon the effective utilization of irrigation water2. Despite the prevalent use of pressurized irrigation systems, a majority of farming systems rely on surface irrigation methodologies3. Therefore, ensuring the proper design of surface irrigation systems is vital to enhance irrigation performance and mitigate water losses. Notably, recent research has revealed that alterations in the inlet flow rate within furrow irrigation systems can significantly impact infiltration parameters and the Manning roughness coefficient4. Utilizing new models and optimizing design parameters within furrow irrigation systems can substantially elevate their efficiency, thereby enabling these systems to serve as proficient mechanisms for conserving water and reducing energy consumption while boosting overall agricultural production5. In developed nations like the United States, surface irrigation systems, notably furrow and flood irrigation, surpass the utilization of rainfed and drip irrigation methods. However, the efficiency of these systems has been hindered by water losses in the form of deep percolation and runoff. Various innovative approaches such as surge irrigation, cutback irrigation, and end-blocking methods have been introduced to enhance the efficiency of surface irrigation systems6. In furrow irrigation, crucial parameters such as infiltration opportunity time, cutback ratio, advance ratio, tail-water reuse ratio, and surface runoff ratio serve as key indicators of water use efficiency, directly influencing high application efficiency and uniformity coefficient. Research has demonstrated that distribution uniformity and the uniformity coefficient remain independent of furrow length and flow rate. Notably, an inverse relationship between flow rate and application efficiency has been observed for cutback flow and tail-water reuse methods across various crops. It has been observed that a lower flow rate tends to result in a higher deep percolation ratio for all crops. Among the studied methods, application efficiency was observed to be highest in the cutback flow, tail-water reuse, and fixed flow methods, respectively, although these differences were not statistically significant. Conversely, the deep percolation ratio was found to be lowest for the fixed flow, tail-water reuse, and cutback flow methods, respectively7. The effective utilization of lower inflow rates and precise irrigation timing significantly contributes to enhanced management outcomes within furrow irrigation systems8. Thoughtful design, effective management, and understanding the interplay of various parameters influencing the performance of surface irrigation systems are critical factors in augmenting their efficiency. Accurate estimation of parameters such as advance distance at specific flow rates can enable the estimation of infiltrating water volume, subsequently minimizing water loss and substantially enhancing irrigation efficiency9. Simulations conducted using the SIRMOD model illustrated that by employing appropriate irrigation cut-off timings and inlet flow rates, water savings ranging from 29 to 49% could be achieved, contingent on the furrow’s length. Additionally, the SIRMOD model showcased the potential for conserving water in furrow irrigation systems, presenting critical insights for irrigation development programs, subsidies, and informing policy and decision-making for the country’s farmers10. Studies have underscored the high sensitivity of all aspects of furrow irrigation performance to the inlet flow11. For instance, improper inflow and infiltration management may lead to water overuse, subsequently reducing irrigation water use efficiency12. Consequently, optimizing furrow irrigation performance necessitates proper management techniques, including inflow correction, implementing inflow hydrograph strategies, and employing appropriate cut-off timings13. On the other hand, constant inflow hydrograph in surface irrigation is one of the different methods of water entering the field14. Notably, this method exhibits the lowest sensitivity to changes in input characteristics when assessing furrow irrigation efficiency with the zero-inertia model. In contrast, the cutback and modified cutback methods display the highest sensitivity15. To maintain a constant inflow in furrow irrigation, the inflow stabilization tank method has traditionally been employed. However, in this study, an automatic control valve was used to introduce variable inflow into the furrow over time. The study’s results demonstrated that the control valve can create various inflow hydrographs with relatively high accuracy. In the realm of irrigation and drainage systems, various controllers are used to regulate water levels. Simple and precise regulators have been designed and developed for this purpose16. In irrigation canals, achieving complete control over the canal’s water level and rectifying water controller faults can be realized by treating the main canal as a storage tank, employing regulators, controls, and a suitable combination of upstream and downstream water regulation17. In the method of furrow irrigation with constant inlet flow, a mechanical set of flow stabilizers can be used with the aid of gravity energy to reduce water loss and cut secondary pumping energy costs. This is a significant advancement in the context of decreasing energy consumption and greenhouse gas emissions, as well as addressing water loss during the ongoing water crisis. Consequently, the innovation proposed in this manuscript holds economic, environmental, and societal importance. The study aims to assess water level control and create a consistent flow inlet in surface irrigation, particularly furrow irrigation, through the application of floater valves. Floater valves are instrumental for enhancing farm irrigation systems through automation. They enable the distribution, control, and measurement of irrigation water on the farm while maintaining a specified water level for pumping stations in irrigation operations18,19,,19. In recent years, floating valves have been utilized to regulate soil water content and soil moisture profiles20. Achieving the highest efficiency in hydraulic parameter control, flow regulation, and water management in irrigation can be facilitated through the application of floater valves21,22,23. Floating valves have also been implemented for stabilizing water levels in reservoirs in drip irrigation systems24. Furthermore, they have been used in level stabilization and water management to reduce the accumulation of heavy metals in agricultural products25,26,27,28,29,30,31,32. Considering the extensive use of surface irrigation systems worldwide, an in-depth examination of the hydraulic properties of water flow in these systems and the application of tools and techniques to enhance these properties in order to reduce water and energy consumption and increase food production remains a pertinent and logical endeavor. In many countries, including Iran, pressure irrigation systems are often prioritized to achieve the highest irrigation efficiency, even though the majority of farms in these regions are equipped with traditional surface irrigation systems. The conversion to pressurized irrigation systems often results in increased energy consumption, time, and costs, with expected outcomes not always fully realized. Consequently, a thorough exploration of the capabilities of surface irrigation systems and the intelligent and optimal utilization of computer tools and systems is warranted.

The results of this research can be used on a larger scale, such as using regulating valves to ensure the continuity of water supply in a watershed33.

The outcomes of this research hold significant potential for planning and enhancing water management systems. Implementing the method detailed in this article at a macro level and in large-scale industries could offer a practical and effective solution for furrow irrigation in farming, particularly with the application of hydro-flumes and the integration of floater valves. The adoption of electronic floater valves presents an opportunity to optimize furrow irrigation methods, such as surge irrigation, aimed at augmenting overall efficiency.

Materials and methods

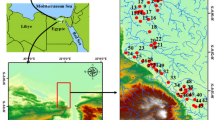

The research conducted at Isfahan University of Technology (IUT) in Isfahan Province, Isfahan City, Iran, and the specific location is delineated in Fig. 1. The project area is situated at 32° 42′ north latitude and 51° 32′ east longitude, with an elevation of 1645 m above sea level and an average air pressure of 1011 millibars. The local climate is categorized as hot and arid. The experimental setup within the farm encompasses various components such as water storage sources, a water level stabilization tank, a platform, storage sources, farm discharge line, and associated fittings, depicted in Fig. 2. Notably, the key features of the stabilization tank are detailed in Fig. 3. An experimental field was meticulously chosen at the University of Technology, with the soil characteristics summarized in Table 1. A gated pipe was employed for consistent water flow transfer from storage tanks and the water level stabilization tank to the furrows, as indicated in Fig. 4. To store water upstream of the farm, two storage units with a combined volume of 16 m3 were utilized. The creation of a hydraulic slope for water transfer from the storage source to the water leveling tank involved constructing a 60 cm high concrete platform, where the storage sources were positioned. This platform facilitated stabilizing the 30 cm height difference between the output of the storage sources and the inflow of the reservoir, as illustrated in Fig. 2a. Within the stabilization tank, two floater valves, each approximately 75 cm in length, were implemented to maintain a consistent water level. The selection of floating valves was based on the largest size available on the market to pass the desired discharge. The selection of these specific floating valves was determined through a series of hydraulic calculations and prior experience. Each valve, devoid of a flange, comprised three principal body components: a double-headed lever and a brass ball, depicted in Fig. 2b. The float body encompassed an adjustable inlet cross-section, a threaded section for connection to the tank body, a location for installing the floater valve lever, and sealing washers. The floater valve lever was affixed to the body on one end and connected to the ball on the other end. By adjusting the ball’s movement up and down, it regulated the flow and cross-sectional area of water entering the tank, thereby controlling the volume of incoming water. The floating valves were vertically installed on the tank body to direct water outflow towards the tank bottom in a perpendicular manner. The lever and ball were positioned to ensure the proper floating alignment of the ball, as demonstrated in Fig. 2.

Experimental area map. Produced by ArcGIS10.8 and Google Earth Pro 7.3 (URL link: https://www.google.com/earth/about/versions/download-thank-you/?usagestats=1) software.

To initiate the tillage and leveling procedures, the farm was surveyed using both surveying techniques and Surfer software to develop an overview. The subsequent operations included plowing, soil overturning, breaking up soil clumps, and surface troweling. Following the troweling for leveling purposes, the field surface profile was mapped. A regular grid was then established on the ground, identifying both low and high points. Traditional tools, specifically ‘Zanbeh’, were utilized for smoothing. After the smoothing and leveling processes, a furrower machine was employed to create 12 main furrows. These furrows were 42 m in length, 60 cm wide, and approximately 25 cm deep, as illustrated in Fig. 5. To ensure parallel furrow alignment, a straight line was drawn using a surveying camera along the lateral boundary of the plastering farm, guiding the furrowing operation. Following the furrow creation, the slope of each furrow was independently determined. The mean longitudinal and transverse slopes of the furrows were calculated to be 0.1%. In simulating real farming conditions, two lateral furrows were assigned for each main furrow, as indicated in Fig. 6. Notably, the experimental field had no existing crops and had not been previously irrigated. The initial average volumetric humidity of the farm was measured at approximately four percent before the project’s commencement. The furrows were spaced at three-meter intervals from the primary nave installation site to the downstream side, with 15 stations in each furrow. The experimental phase began with the water transfer to the furrows, where parameters such as advance time, regression time, inlet, and outlet flow rates were recorded for each experiment. Water entry into the furrows continued until the output flow was stabilized and maintained a constant rate for a specific duration. Regression time measurements were recorded at various stations along the furrows immediately after halting water flow to the furrows. By utilizing the field’s slope, erosion-free conditions were established. Measurements of various outflows indicated the maintenance of a constant water level inside the stabilization tank. The flow rate from the stabilization tank (depicted in Fig. 2a) maintained a consistent inflow of 0.8 L per second into all furrows. This ensured the water level remained at approximately 50 cm from the reservoir’s outlet center due to the balanced inflow and outflow rates from the stabilization tank. Throughout the testing phase, the storage sources were consistently maintained at full capacity to ensure stabilized water levels. To precisely deliver the required flow to each furrow, a calibrated container and timer were used to mark the discharge pipe valves’ opening rates for specific flow rates. During each test, the valves were adjusted to meet the required flow rates. The stabilization tank and its outflow were meticulously installed at a level position. The inlet and outflow of the furrows were measured using WSC (Washington State College) type 2 equipment (Figs. 7, 8, Table. 2). To mitigate soil erosion, infiltration, and experimental error, several meters of the flume at the entrance and exit were covered with plastic. These flumes were positioned to prevent water seepage and ensure free-flowing, non-submerged conditions. They were installed entirely level using a leveling device (Fig. 7) to maintain the accuracy of the experiments. Through the transfer of water to the furrows, a series of experiments and measurements were conducted. In this study, recognizing the absence of a specific method for water supply in furrow irrigation within most farms, where water is primarily directed from main streams and canals to the furrow heads, an innovative management tool was explored. This tool was employed to optimize the management of water entering the furrows, aiming to attain consistent or varying water inflow. The research sought to establish a more efficient process, resulting in enhanced irrigation outcomes.

Results and discussion

The results showed that if the water tanks were full, the inflow to the tank was stabilized at 2.2 L per second and when they were almost completely empty, the inflow to the tank was 1.3 L per second. Therefore, considering the choice of inflow of 0.8 L per second, until the sources were almost completely empty, there was a guarantee of a constant flow of inflow to the furrows. Numerous field experiments have also proven these results. Also, due to the inflow and outflow of the stabilization tank, the water level was always maintained at a height of about 50 cm from the outflow center of this tank as measured by a barometer installed on the water stabilization tank (Fig. 3). Storage sources were also kept full to ensure that the water level stabilized during the test period. With the start of irrigation and water entering in the furrow, reading of the inlet tanks and flume installed (tool for flow measurement) at the inlet of the furrow showed that the desired inlet flow reached its constant value after a short time (about one minute). As well, targeted inlet water supply head always remains constant during the irrigation condition. An example of an inlet flow curve (inlet hydrograph) to a furrow drawn by inlet flow measurements in one of the irrigation operations were recorded in Fig. 9. According to the observations, water never overflowed from inside the stabilization tank. After stabilizing the inflow, the investigator proceeded to other stages of testing and measurements because there were no problems such as fluctuations of inflow and overflow from the stabilization tank. Figure 10 shows the field being furrowed.

As it was said, the water transfer system to furrow included water storage and sewage sources, water level stabilization tank and gated pipe (Fig. 4). The results showed that by storing water upstream of the farm in two sources of 6 and 10 cubic meters, a hydraulic gradient can be created to transfer water from the storage source to the stabilization tank. Also, to ensure this hydraulic object, a concrete platform with a height of 60 cm should be built to place storage sources on it. This platform creates a height difference of about 30 cm between the outlet of the storage source and the inlet of the stabilization tank. The results showed that if the sources are full, the intensity of the flow entering the stabilization tank will be 2.2 L per second, and when they are close to being completely empty, the flow entering the stabilization tank will be 1.3 L per second, which is less than the design flow rate. It is in Faros. The use of two two-inch brass floating valves of the stabilization tank was suitable for keeping the water level stable, which shows the suitability of the inlet and outlet flow rates from the tank with the size of these valves. By using the slope of the field and the condition of no erosion and paying attention to the intensity of the flow that can be provided from the stabilization tank (measurement of different output discharges under the condition that the water level inside the stabilization tank remains constant), the amount of water entering the furrows has been selected as 0.8 L per second, which shows It shows that the stable output current from stabilization tank is about half of the current provided by the floaters. The results showed that due to the intensity of the inlet and outlet flow of the stabilization tank and the use of floaters, the water level is always maintained at a height of about 50 cm from the outlet center of this tank. To ensure the stability of the water level during the experiment, the storage sources can always be kept full. The results showed that in order to accurately provide the required flow of each groove, it is necessary to mark the degree of opening of the valves of the hydroflum tube for the intensity of different flows by using a graduated container and a timer, and in each test, the valve should be opened to the required amount. After measuring the intensity of the output flow from the hydro-flume valve with a graduated container and a timer, the results of these 60 irrigation operations showed that the measurement of the input flow (and comparing it with the intensity of the output flow from the hydro-flume valve) and the output in each groove using a short-throat type flume A trapezoid is made with high precision. Also, in order to increase the accuracy in reading the water height upstream of the primary flumes and also to reduce the flow turbulence, a short section should be considered between the valves and the location of the flume.

Conclusion and recommendations

By removing water wastage from common flow stabilization tanks, and water management in the farm with the approach of reducing energy consumption by substituting gravity for water flow, and increasing the efficiency and effectiveness of water consumption using floating valves instead of overflow or pumps to provide constant inflow in Surface irrigation was achieved. By modifying the hydraulic flow design and calculations in the pipes and fittings, the desired pressure and flow can be created at the head of the furrow irrigation farm, and by modeling, mathematical relations can be extracted so that the intensity of the different head flows can be provided. The use of new and even simple techniques and tools in surface irrigation can help to improve the quality and quantity of this irrigation system, and an exclusive look at irrigation systems under pressure and…to determine it for each farm according to the results of This research is worth considering. In many countries, including Iran, most consider the use of pressure irrigation systems as a priority to achieve the maximum efficiency of irrigation systems. This is despite the fact that most farms in these countries are equipped with traditional and surface irrigation systems, and converting them to pressurized irrigation systems increases energy consumption in addition to time and cost. This is despite the fact that in many cases the expected results are not obtained from these new irrigation systems. Therefore, designing, implementing and mechanizing surface irrigation systems, in addition to reducing time and energy consumption and cost, sometimes also increases efficiency compared to pressurized systems. Therefore, it is necessary to study the capacities of surface irrigation systems more and try to make intelligent and optimal use of computer tools and systems as much as possible. Many studies have been presented on the use of float valves. In this research, this tool has been used to create a constant input flow to the furrow irrigation (without the use of a pump and with the help of gravity). The results of this research in obtaining the minimum water height above the floater’s head and also the design of the water relaxation box in which the floater works can be used in agriculture with furrow irrigation in order to increase the efficiency of this irrigation system. As no similar research has been done in this case. About energy required in this methods, in the usual method, a pump with a flow rate of about 2.4 L per second and a pressure of at least 10 m should be used to irrigate the three furrows. This pump has a consumption power of at least 1.5 kilowatts, which should work at least 8 h a day, considering the cost. Electricity consumption in Iran will be about 3$ in weekly energy savings. Of course, the depreciation and side costs of the pump should also be considered. It should be noted that for a larger number of holes, a stronger pump should be used, and as a result, more will be consumed. A search in the sources shows that little research has been done in this field, and the importance of this issue is doubled in developing countries such as Iran, which only consider pressurized irrigation as a solution to the water crisis. Therefore, such topics should be raised to give ideas and motivation to researchers and other researches in order to improve surface irrigation systems. The purpose of this research is to achieve higher efficiency in furrow irrigation, land preparation and tillage is an integral part of this issue and is one of the first things that must be observed. In the method of furrow irrigation with constant inlet flow, to reduce water loss and also reduce energy costs in secondary pumping, a mechanical set of flow stabilizers can be used with the help of gravity energy. This is important because of the reduction in energy consumption and greenhouse gas emissions, as well as the reduction of water loss in the current water crisis. Therefore, the innovation proposed in this manuscript has economic, environmental, social and … importance. The main purpose of this paper is to create a constant input flow in irrigation systems, especially furrow irrigation, using simple mechanical tools that can be used by all farmers. Also, reducing water loss in farms and water management in the field with the approach of reducing energy consumption. These goals were investigated during 60 furrow irrigation operations, and measurements showed that they could be achieved by gravity-free energy provided the minimum water head was observed and mechanical tools such as valves were used. In this paper, to solve the problems of supplies that are commonly used to stabilize the flow in surface irrigation systems, a float valve and a stabilization tank have been used, which eliminates the use of a pump to create a constant pressure and flow and thus energy consumption. Also, water loss at the beginning of the farm was eliminated.

Data availability

Some or all data, models, or code generated or used during the study are available from the corresponding author by request.

Abbreviations

- WSC:

-

Washington State College

- IUT:

-

Isfahan University of Technology

- ECe :

-

Electrical conductivity of saturated soil extract

- pHe :

-

Acid-base degree of saturated soil extract

References

Asmelita, L. L., Bisri, M., Soetopo, W. & Farni, I. Rice self-sufficiency and optimization of irrigation by using system dynamic. Civil Eng. J. 10(2), 489–501 (2024).

Fadul, E., Masih, I., De Fraiture, C. & Suryadi, F. X. Irrigation performance under alternative field designs in a spate irrigation system with large field dimensions. Agricult. Water Manag. https://doi.org/10.1016/j.agwat.2019.105989 (2020).

Kazemi, H., Sadraddini, A. A., Nazemi, A. H. & Sanchez, C. A. Moment analysis for modeling soil water distribution in furrow irrigation: Variable vs. constant ponding depths. Water 13(10), 1415. https://doi.org/10.3390/w13101415 (2021).

Mazarei, R., Soltani Mohammadi, A., Ebrahimian, H. & Naseri, A. A. Temporal variability of infiltration and roughness coefficients and furrow irrigation performance under different inflow rates. Agricult. Water Manag. https://doi.org/10.1016/j.agwat.2020.106465 (2021).

Raeisi Vanani, H. et al. Development of a new method for determination of infiltration coefficients in furrow irrigation with natural non-uniformity of slope. Sustain. Water Resour. Manag. 3, 163–169. https://doi.org/10.1007/s40899-017-0091-x (2017).

Kandpal, V. & Henry, C. A review of improving efficiencies in furrow irrigation. In 2016 ASABE Annual International Meeting (p. 1). American Society of Agricultural and Biological Engineers (2016). https://doi.org/10.13031/aim.20162462974.

Shaw, S. K., Sharma, A., Khatua, K. K. & Oliveto, G. An integrated approach to evaluating crop water requirements and irrigation schedule for optimizing furrow irrigation design parameters in Kurnool District, India. Water 15(10), 1801. https://doi.org/10.3390/w15101801 (2023).

Sayari, S., Rahimpour, M. & Zounemat-Kermani, M. Assessment of straight and meandering furrow irrigation strategies under different inflow rates. Afr. J. Online (AJOL) https://doi.org/10.17159/wsa/2019.v45.i4.7550 (2019).

Golestani Kermani, S., Sayari, S., Kisi, O. & Zounemat-Kermani, M. Comparing data driven models versus numerical models in simulation of waterfront advance in furrow irrigation. Irrig. Sci. 37, 547–560. https://doi.org/10.1007/s00271-019-00635-5 (2019).

Alejo, L. A. & Espino, A. N. Jr. Evaluation of the SIRMOD model for optimum furrow irrigation performance. CIGR J. 22(1), 30–39 (2020).

Zerihun, D., Feyen, J. & Reddy, J. M. Sensitivity analysis of furrow-irrigation performance parameters. J. Irrig. Drain Eng. ASCE 122(1), 49–57 (1996).

Trout, T. J. Furrow inflow and infiltration variability impacts on irrigation management. Trans. ASAE 33(4), 1171–1178 (1990).

Moravejalahkami, B., Mostafazadeh-Fard, B., Heidarpour, M. & Abbasi, F. Furrow infiltration and roughness prediction for different furrow inflow hydrographs using a zero-inertia model with a multilevel calibration approach. Biosyst. Eng. 103, 374–381 (2009).

Walker, W. R. & Skogerboe, G. V. Surface Irrigation: Theory and Practice (Prentice-Hall, 1987).

Alazba, A. A. Simulating furrow irrigation with different inflow patterns. J. Irrig. Drain Eng. ASCE. 125(1), 12–18 (1999).

Schuurmans, J., Hof, A., Dijkstra, S., Bosgra, O. H. & Brouwer, R. Simple water level controller for irrigation and drainage canals. J. Irrig. Drain Eng. ASCE 125(4), 189–195 (1999).

Clemmens, A. J. Water-level difference controller for main canals. J. Irrig. Drain Eng. ASCE. 138(1), 1–8 (2012).

Robinson, A. R. Distribution, Control, and Measurement of Irrigation Water on the Farm (No. 926). US Department of Agriculture (1963).

Yenphayab, C. Study the engineering aspect of an advance siphon pump (Pha Ya Rangh Hai Nam) for a small farm irrigation. In IOP Conference Series: Earth and Environmental Science (Vol. 301, No. 1, p. 012001). IOP Publishing (2019). https://doi.org/10.1088/1755-1315/301/1/012001.

Cichello, A., Bruch, A. & Earl, H. J. A novel method for irrigating plants, tracking water use and imposing water deficits in controlled environments. Front. Plant Sci. 14, 1201102 (2023).

Ramesh, A. & Ostad-Ali-Askari, K. Effects of magnetized municipal effluent on some physical properties of soil in furrow irrigation. Appl. Water Sci. 13, 26. https://doi.org/10.1007/s13201-022-01811-3 (2023).

Ramesh, A. & Ostad-Ali-Askari, K. Effect of effluent and magnetized effluent on Manning roughness coefficient in furrow irrigation. Appl. Water Sci. 13, 21. https://doi.org/10.1007/s13201-022-01818-w (2023).

Shayannejad, M., Ghobadi, M. & Ostad-Ali-Askari, K. Modeling of surface flow and infiltration during surface irrigation advance based on numerical solution of saint-venant equations using Preissmann’s Scheme. Pure. appl. Geophys. 179(3), 1103–1113. https://doi.org/10.1007/s00024-022-02962-9 (2022).

Liu, X., Han, M. & Zhang, L. 2023 A new subsurface ceramic emitter for smallholders without pumps: Design, hydraulic performance, and field application. Irrig Sci https://doi.org/10.1007/s00271-023-00877-4 (2023).

Rahmany-Samani, A., Ghobadinia, M., Tabatabaei, S. H., Nourmahnad, N. & Danesh-Shahraki, A. The effect of irrigation and zeolite management on the reduction of cadmium accumulation in rice. Agricult. Water Manag. 287, 108448. https://doi.org/10.1016/j.agwat.2023.108448 (2023).

Ostad-Ali-Askari, K. Developing an optimal design model of furrow irrigation based on the minimum cost and maximum irrigation efficiency. Abstr. Appl. Water Sci. 12(7) https://doi.org/10.1007/s13201-022-01646-y (2022).

Najafabadi, M. A., Nafchi, R. F., Salami, H., Vanani, H. R., Ostad-Ali-Askari, K. Effect of different managements with drip irrigation (tape). Abstr. Appl. Water Sci. 13(2) https://doi.org/10.1007/s13201-022-01847-5 (2023).

Nafchi, R. F. Valiyari-Eskandari, M., Vanani, H. R., Ostad-Ali-Askari, K., Bahrami, A. Evaluation of wetting front detector to estimate the dimensions of wetting front in the drip irrigation. Abstr. J. Eng. Appl. Sci. 70(1) https://doi.org/10.1186/s44147-023-00295-5 (2023).

Javadi, A. & Ostad-Ali-Askari, K. Effect of different irrigation managements on infiltration equations and their coefficients. Civil. Eng. 4(3), 949–965. https://doi.org/10.3390/civileng4030051 (2023).

Ostad-Ali-Askari, K., Sadeghi, F., Raeisi Vanani, H., Monem, M. J., & Kianmehr, P. Evaluation of variable frequency drive system in pumping stations of irrigation networks using INACSEM model ABSTRACT. Irrig. and Drainage 74(3), 933–943. https://doi.org/10.1002/ird.3071 (2025).

Ostad-Ali-Askari, K. et al. Impermanent changes investigation of shape factors of the volumetric balance model for water development in surface irrigation. Model. Earth Syst. Environ. Springer Nat. Switz. AG. 6(3), 1573–1580. https://doi.org/10.1007/s40808-020-00771-4 (2020).

Ostad-Ali-Askari Mohammad, K., & Shayannejad, M. Impermanent changes investigation of shape factors of the volumetric balance model for water development in surface irrigation. Model. Earth Syst. Environ. 6(3), 1573–1580. https://doi.org/10.1007/s40808-020-00771-4 (2020).

Amitaba, I. W., Juwono, P. T., Limantara, L. M. & Asmaranto, R. Real time operation simulation model with early release reservoir storage. J. Human Earth Future 5(4), 574–590 (2024).

Funding

Funding information is not applicable. No funding was received. No grants were received.

Author information

Authors and Affiliations

Contributions

K.O-A-A., H.R.V. and P.K. wrote the main manuscript text and prepared figures. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval and consent to participate

The present Study and ethical aspect was approved by Water Engineering Department. All authors designed the study, collected data, wrote the manuscript and revised it.

Consent for publication

All authors agree to publish this manuscript. There is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ostad-Ali-Askari, K., Raeisi-Vanani, H. & Kianmehr, P. Use of floater valves to provide a constant inlet flow in furrow irrigation. Sci Rep 15, 36183 (2025). https://doi.org/10.1038/s41598-025-19960-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-19960-1