Abstract

Ti-40 wt% TiC and Ti-6Al-4 V- 40 wt% TiC metal matrix composites were obtained by the hydrogenated powder metallurgy approach, followed by post-sintering densification by hot pressing. The composites obtained were characterized by high hardness values, which were 700–1300 HV due to nearly-dense microstructure, high content of reinforcing titanium carbide particles and non-uniform redistribution of reinforcing phase in the matrixes. The high hardness of the composites in the as-densified state resulted in a significant improvement of ballistic performance of two-layer Ti-based metal matrix composites. It is shown that the proposed approach for the manufacturing of layered Ti-based metal matrix composites is promising for practical application.

Similar content being viewed by others

Introduction

Titanium-based structural and functional materials play crucial role in engineering due to their unique combination of high specific strength and corrosion resistance1,2,3. Commercial titanium alloys have demonstrated good ballistic performance against high kinetic energy projectiles, showing strength and hardness comparable to conventional protective materials4,5. However, because their hardness does not exceed 350–380 HV even in the thermally hardened condition, titanium alloys cannot be as efficient as rolled homogeneous armor (RHA) steels when exposed to armor-piercing bullets. Chen et al.6 showed that the addition of the refractory compound to the metals significantly enhances their mechanical properties, not only in conventionally processed but also in additively manufactured materials.

Therefore, to mitigate the aforementioned limitation, it is essential to increase the hardness of titanium-based materials by at least a factor of two. Moreover, enhanced hardness improves other properties, such as wear resistance. Hardness characteristics can be enhanced by the addition of the hard particles of high-temperature boride or carbide7. These refractory compounds are characterized by high hardness, thermal properties, and oxidation resistance7,8. The development of the metal matrix composites (MMC) reinforced with high-modulus TiC or TiB in the form of highly dispersed inclusion particles, has been shown to significantly improve hardness9,10 strength11 and even electrical properties12.

Previously13,14,15 microstructurally uniform MMCs based on a Ti-6Al-4 V (wt%) alloy matrix reinforced with 5–10% (vol.) TiC or TiB particles were produced with press-and-sinter blended elemental powder metallurgy. However, residual pores, whose volume content and size in sintered MMC increase with a higher amount of carbide and boride particles in the initial powder blend, noticeably reduce strength, ductility and hardness characteristics of sintered materials. As shown in16, post-sintering hot isostatic pressing (HIP) of MMC allows the reduction of residual porosity to almost zero level even at 20–40% TiB and TiC phases. Moreover, long-term high-temperature exposure under the external forces applied on HIP activates diffusion redistribution of carbon and boron in the alloy matrix, promoting desirable uniformity and useful changes of phase composition and microstructures of corresponding MMCs. Depending on the amount of the reinforced phases (up to 40%), MMCs treated by HIP demonstrated hardness values within a wide range up to 600–1000 HV and even more.

Achieving materials with densities close to 100% of the theoretical value through hot pressing requires heating to 0.7–0.9 of the melting temperature and applying sufficient pressure to induce plastic deformation. In our previous work, we showed that Ti-based MMC with the addition of TiC or TiB can be densified by hot-pressing in the temperature range of 1300–1500 °C17,18. When the amount of refractory compound exceeded 15 vol%, residual porosity was observed in the composite even after sintering at 1300 °C. However, increasing the hot-pressing temperature to 1400–1500 °C, enabled the production of pore-free materials. Furthermore, when the densification temperature was 1500 °C, the composites exhibited strengths 15–30% higher than those obtained at 1400 °C, due to the element redistribution of chemical elements in the material and structural-phase transformations17. Increasing the content of a high-melting-point reinforcing phase requires higher hot-pressing temperature to achieve full densification and to improve the adhesion between inclusions and the matrix. Despite noted advantages, HIP is technologically complex, time-consuming and relatively expensive process. Therefore, this work was initiated to evaluate the potential of hot pressing (stamping) as a faster, cheaper, and more productive alternative for densification, useful microstructure modification and, hence, performance improvement of sintered titanium-based MMCs.

Materials and experimental procedure

Two MMC compositions reinforced with 40 wt% titanium carbide (TiC) particles were prepared and studied. The first was based on commercially pure titanium (CP-Ti) matrix and was strengthened with 40 weight% of dispersed TiC particles (hereafter designated as Ti-40wt%TiC). The second one was prepared using as the base matrix Ti-6Al-4 V (wt%) alloy (thereafter – Ti64-40 wt% TiC). The selected amount of reinforcing phase was chosen based on previous findings10. This composition demonstrated the highest hardness values achieved without negatively impacting other critical properties of the sintered metal matrix composite (MMC).

These MMCs were produced using a blended elemental powder metallurgy approach based on titanium hydride powder15,19 taking advantage of titanium hydride’s ability to accelerate diffusion and sintering processes. For the manufacturing of both MMCs, the following raw powders were used: titanium hydride (ТіН2, d = < 100 μm, O = 0.14 wt%, C = 0.04 wt%), titanium carbide (d = < 15 μm, O = 0.5 wt%). For manufacturing of the second MMC 60Al-40 V (wt%) master alloy (d = < 63 μm, O = 0.19 wt%, C = 0.06 wt%) was also employed.

The raw materials and Ti64 grinding media were placed in a box filled with argon to prevent oxidation during mixing. Mixing was performed for 6 h at 50 rpm. The homogeneous mixture was sieved through a 120-mesh sieve in a glove box.

Then the powder mixture was sieved and die-compacted by cold pressing at a pressure of 150 MPa, forming green compacts with dimensions of 100 × 100 × 10 mm.

The green compacts were sintered in a vacuum of 10−3 Pa at 1250 °C with isothermal exposure for 4 h. The heating rate to the sintering temperature was 10°C/min after isothermal holding, the samples were cooled in the vacuum furnace. The noted sintering conditions ensure complete dehydrogenation of the titanium hydride, hydrogen evacuation and formation of either sintered CP-Ti or sintered homogeneous Ti-64 alloy matrices with a given content of the reinforcing TiC phase particles and residual porosities up to 14–15%. More details of the sintering procedure are described in10.

The shrinkage, densification, and MMC sintering processes occurring during vacuum heating of compacted powder blends were studied with a high-temperature dilatometer20.

To obtain fully dense MMCs, the hot pressing of sintered porous materials was used. This process was carried out on the SPD-120 unit without a protective environment21. MMCs were placed in a graphite mold coated with boron nitride. Induction-heating at 100 °C/min was set to achieve the sintering temperature of 1300 °C, 1400 °C, and 1500 °C, defined according to the piston movement during shrinkage. The initial load was 8 MPa and, once the peak temperature was achieved, the load was increased to 32 MPa. After dwelling at the maximum temperature for 30 min, the furnace was slowly cooled to 600 °C to avoid crack formation. The temperature inside the graphite die was calculated based on the die wall temperature measured with a pyrometer.

The samples for microstructural investigations were cut using an electrical discharge machine, Tousun DK 7725 EDM. After cutting, the sample surfaces were ground with a final polishing (Al2O3 suspension) using Struers LaboPol-21 and LECO Spectrum System 1000 equipment. The microstructure of the composites was studied using scanning electron microscopy (TESCAN MIRA and TESCAN VEGA 3). The local phase composition was determined by micro-X-ray spectral analysis using an Oxford X-Max 80 energy-dispersive detector with an active crystal area of 80 mm2 (INCA X-Max, Oxford Instruments, Abingdon on Thames, UK). Phase composition and crystallographic texture were examined by X-ray Diffraction analysis using RIGAKU ULTIMA IV (Japan) diffractometer.

The Vickers hardness was investigated using Wolpert Wilson Instruments 452 SVD equipment. Ballistic tests were conducted at the certified ballistic testing laboratory of the Military University of Technology in Warsaw. For ballistic testing, special two-layer samples were prepared. Firstly, cylindrical disks with a diameter of 55 mm were cut from finally hot-pressed Ti-40wt%TiC and Ti64-40wt%TiC MMCs. Then these discs were attached to a plate made of industrial titanium alloy T110 (Ti-5.5Al–0.5Zr–4Nb–1.5 V–1.5Mo–0.5Fe, wt%) with dimensions 100 × 100 × 3 mm using a polyethene adhesive resin. The assembled targets were wrapped on top with Kevlar fiber for defragmentation.

Ballistic performance was evaluated using NATO 7.62 × 51 mm armor-piercing ammunition with a steel flat-nose core weighing 9.45 g. The same type of ammunition had been used in previous tests of titanium-based and armor steel materials16,22 allowing a direct comparison of ballistic performance of the produced material. A cross-section of the bullet is shown in Fig. 1, and its main characteristics are summarized in Table 1. The cartridges were manufactured by MESKO S.A., Poland. To capture projectile impact, deformation and fracture, a high-speed Phantom v1612 camera was employed, operating at about 130,000 fps (frames per second) with reduced resolution of 256 × 256 dpi. Further details of the ballistic test setup are provided in previous work23.

The general view (a) and cross-section (b) of the AP bullets23.

At this stage of ballistic performance assessment, only one test for each MMC type was conducted to enable a detailed evaluation of impact behavior and structural changes. The test was designed to assess the feasibility of producing high-quality, impact-resistant MMCs suitable for ballistic protection systems. In standard ballistic testing, at least three shots per configuration are typically required, however, considering the extensive characterization of the investigated material, including microstructural analysis and 3-point flexure testing, it was decided to perform only one impact test for each material type.

Results

Shrinkage of the Ti-based composites

In our previous work10,19 the processes of MMC sintering and formation of their final microstructure and properties were studied in detail.

The shrinkage of the titanium hydride powder compact achieved the level of 10% on heating up to 1200 °C (Fig. 2a), while the TiH2-based powder blend compact, whose composition corresponds to Ti64 alloy under the same conditions, was characterized by almost the same shrinkage of 9.5%. Such values of shrinkage correspond to dehydrogenation of TiH2 particles and activated powder sintering, resulting in the formation of nearly-dense titanium-based materials obtained by the hydride approach24.

Adding 40 wt% TiC reinforcing particles to titanium hydride or Ti64 powder blend reduces shrinkage values down to 4-4.5%, Fig. 2a. Titanium carbide particles retard sintering and act as barriers to shrinkage due to their high melting point (3160 °C), stability and low interaction with the dehydrogenated titanium particles.

Figure 2b, c shows the shrinkage curve during hot-pressing of the as-sintered composites (Ti-40 wt% TiC (Fig. 2b) and Ti64-40 wt% TiC (Fig. 2c)) at different temperatures. The low shrinkage value (5%) at 1300 °C was due to the high amount of the reinforcing phase, which does not allow complete densification of the MMC compacts. At the same time, hot pressing at 1500 °C results in a shrinkage of 7.5%, which leads to the formation of nearly dense material with low residual porosity (~ 1%), Fig. 2b, c.

In the temperature range of 600–800 °C, titanium’s yield strength demonstrates a nearly linear temperature dependence, with a value of about 50 MPa25. At the same time, the Ti-6Al-4 V alloy is generally characterized by higher strength, which decreased to 12 MPa at 1050 °C26. The presence of reinforcing phases gives MMCs higher strength, necessitating higher hot-pressing temperatures. At 1500 °C, the material exhibits high plasticity; therefore, the applied pressure (up to 32 MPa) is sufficient for the porosity healing.

Shrinkage curve for powder compacts of various compositions: Ti64 (black line), TiH2 (red line), Ti64-40wt%TiC (blue line) and TiH2-40wt%TiC (purple line) during vacuum heating in a high-temperature dilatometer (a), Shrinkage curve of sintered MMC Ti-40 wt% TiC during post- sintering hot pressing (b), and shrinkage curve of sintered MMC Ti64-40 wt% TiC during post- sintering hot pressing (c).

Microstructure and strength characteristics of the hot-pressed Ti-based composites

The microstructure of the as-sintered Ti-40 wt.%TiC MMC (Fig. 3a) and Ti64- 40wt.% TiC MMC (Fig. 3b) is shown in Fig. 3. The microstructure of Ti-40 wt.%TiC MMC is porous and consists of large-scale pores and partially sintered powder particles. In contrast, Ti64- 40wt.% TiC shows significantly lower porosity and a high content of the TiC phase. This difference in microstructure arises due to the different shrinkage behavior of the material.

The microstructure of the Ti-40 wt.%TiC MMC after sintering and subsequent hot pressing is presented in Fig. 4. The composite with a matrix of the titanium alloy Ti64, with the same amount of the reinforcing phase (40 wt% TiC), is shown in Fig. 5.

As reported in recent work10 after sintering, the porosity in both MMCs based on titanium and Ti64 alloy matrices hardened with 40% TiC particles is at the level of 14–16%. During hot deformation, it is possible to completely heal the porosity around the rigid framework of reinforcing components due to plastic deformation of a highly ductile metallic matrix under such thermal and force conditions.

Figure 4a shows the fine microstructure of the Ti-40%TiC composite formed after sintering and hot pressing. The fully dense MMC consists of a titanium matrix with grains 40–100 μm in size and TiC particles of various sizes, some of which achieved up to 100 μm. In some coarse TiC particles or conglomerate is inclusions of titanium chips were found (Fig. 4b, c). This can be explained by the adhesion of small particles of titanium and carbides, even at the stage of mixing the initial mixture. During sintering and hot pressing, conglomerates of fine initial TiC particles united into large carbide regions up to 100 μm in size; thus, titanium inclusions became trapped inside them. Also, the tiny tungsten-enriched particles were found in the titanium matrix (Fig. 4c, d). It happened because the commercial titanium carbide became contaminated by a small amount of WC, which was used as the material for grinding balls used for the preparation of titanium carbide powder. The content of tungsten-enriched inclusions is less than 1%, and they were distributed in the titanium matrix mainly near large clusters of titanium carbide particles.

Three characteristic zones were found in the Ti64- 40%TiC microstructure after hot pressing (Figs. 5 and 6). It should be noted that texture appears in the material under the influence of pressure (Fig. 7). The first zone consists of clusters of round carbide particles with a size of ~ 15 μm, which corresponds to the size of the initial TiC powder (Fig. 5b). Between TiC particles, the matrix phase with a thickness of 1–5 μm was observed. The second zone is characterized by the matrix phase of the Ti64 alloy with a typical uniform lamellar α + β structure and relatively small (~ 10 μm) TiC particles (Fig. 5c). The third zone (Fig. 5d) is primarily composed of large titanium carbide areas. These areas have a residual porosity of 3–4% because a hot-pressing temperature of 1500 °C is not high enough to fully densify such large agglomerates, given that the melting point of TiC is 3150 °C. Such a region enriched by TiC was obviously formed at the stage of powder mixing because the addition of 60Al-40 V master alloy powder to the TiH2 + TiC blend promotes the coagulation of carbide particles during blending of the powders before sintering and hot pressing.

For the Ti-40%TiC composite, segregation of titanium carbide particles was not observed, unlike in Ti64-40%TiC, as shown in Fig. 5d. The analysis of the local chemical composition of the material (Fig. 6) reveals a gradual transition in carbon concentration between the Ti and TiC constituents of the MMC10.

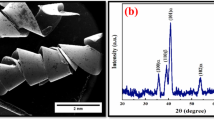

The effect of hot pressing on diffusion redistribution of elements was also studied in more detail for the Ti64-TiC MMC (Fig. 7), as three specific microstructural zones were observed in this material, Fig. 5. As a result of interaction between the mixture component at high temperature and pressure applied during hot pressing, titanium carbide is partially transformed into Ti2C (Fig. 7b) which is equilibrium phase at elevated temperatures19. Using BSE SEM mode, it is possible to observe a slight difference in the tone of the color of large carbide zones from their center to the periphery, which indicates some chemical heterogeneity (Figs. 5 and 8). In particular, the local concentrations of carbon and titanium are non-uniform (Fig. 8c, f). The central, porous part of the large carbide zone consists of a stoichiometric TiC composition, whereas the lower carbon content and higher titanium content were observed at the periphery. During hot pressing, carbon diffuses from carbide particle clusters into the surrounding titanium-based matrix, increasing the volume fraction of carbide inclusions in the composite material. However, the newly formed portions of the titanium carbide phase are characterized by lower carbon content.

General view of the SEM BSE micrographs of the Ti64- 40%TiC MMC (a, b) and EDS maps of elements distribution for local microstructure (b): Ti (c), V (d), Al (e), C (f), (g) region with porous TiC, dense TiC and TiC with Ti64, (h, i) microstructure at the high magnification of the dense TiC and Ti64, (h) BSE mode, (i) SE mode.

The hot pressing had a positive effect on the microstructure of the Ti-based material. The residual porosity was healed, and accelerated diffusion redistribution of carbon led to an increased amount of high-strength reinforcing phase, even despite the change in composition from equiatomic to more carbon-depleted.

One of the most important mechanical characteristics for the ballistic resistance of materials against armor-piercing bullets is their hardness, which determines the material’s ability to resist fracture by the hard projectile core. It is important to note that the hardness of the AP bullets’ core used in this study is 870 HV27, and to effectively withstand such an impact, the target material should have a comparable or higher hardness.

Titanium alloys typically exhibit hardness values within 200–400 HV. The most effective way to increase hardness is by producing composite materials.

As reported in10, sintered MMCs with varying amounts of the reinforcing phase achieved hardness values up to 480 HV at 40 wt% TiC. Heat treatment of the Ti64-40 wt.%TiC MMC due to additions of alloying elements, can further increase hardness to 570 HV. Nevertheless, this value is still below the hardness value of the bullet core. A similar microhardness value of 575 HV for Ti64-40 wt.%TiC MMC was reported in work27 based on 5 measurements.

Figures 5, 6, 9 demonstrate that the microstructure of the composite material is not homogeneous; resulting in variations in hardness across different regions. For the Ti-40 wt% TiC composite (Fig. 10a) the hardness value ranges from 715 HV in zones dominated by the matrix phase with thin inclusions of separate TiC phase, to 774 HV in zones where increased volume part of carbide particles coexists with some matrix Ti phase, and up to 895 HV in zones composed entirely of carbide phases. For the Ti64-40 wt% TiC composite (Fig. 10b), the hardness of the matrix phase with a lower amount of carbide particle inclusions (712 HV) is similar to the corresponding areas of MMC with a titanium matrix. The zones with increased volume fraction of carbide particles have a hardness of ~ 860 HV (Fig. 10b). The central part of large carbide clusters, which have a residual porosity of 5 vol%, demonstrates a hardness of 1170 HV, while the zone around such clusters formed due to carbon diffusion (and completely free of pores) has the highest hardness value of 1335 HV, Fig. 10b. This effect can be explained by the in-situ formation of dense carbide phases by solid state reaction between TiC clusters and Ti64, Fig. 8g-i.

The additional process of hot pressing of the Ti-based MMC makes it possible to obtain non-porous materials. The amount of refractory TiC particles in the MMC was higher than in the raw materials. According to SEM + EDS and XRD (Figs. 5, 6, 7 and 8), the secondary particle of TiC and Ti2C was formed as a result of diffusion from the primary TiC particle into Ti. This is possible because TiC has a homogeneity region and can release carbon atoms from the lattice when the temperature increases. At the temperatures above 920 °C (α-Ti↔β-Ti transformation), the processes of diffusion and interaction of Ti with boron and carbon are accelerated28,29. In this condition, a gradient zone of carbon is formed at the boundary, Figs. 6 and 8. The residual Ti that has not reacted with carbon is subject to viscous flow since the temperature is 0.9 Tm. Soft and viscous Ti flows into all pores and makes the MMC dense. Since hot pressing is not a comprehensive simultaneous deformation, the material has a texture in the direction of the hot deformation, Fig. 7. Therefore, during hot pressing of the Ti-40 wt.%TiC and Ti64-40 wt.%TiC, the main densification mechanisms are diffusion and plastic flow.

Comparison of representative stress-stain curves obtained during quasi-static tests of TiC-based MMC material with data available in literature for ballistic ceramics30 showed high quality and high strength parameters of newly-produced specimens. The maximum flexural strength (which is fundamental for ballistic applications) obtained during quasi-static tests reached the value of ~ 1000 MPa. The obtained result is comparable (for modified Zirconia Ceramics) or higher (in some cases at least twice) than the value for ballistic ceramics, as examples summarized in Table 231,32. Comparative studies of material characteristics were limited to the TiC-based material, since this type of specimen was widely tested in the framework focused on BEPM technology. Coupling of obtained relatively high hardness of the tested material, which is higher than in the case of previously-tested BEPM material providing high ballistic performance, with its high strength, seems to be a promising option as the disruptive layer of the ballistic protection. It should also be noted, that the obtained material is characterized by lower hardness in comparison with typical ballistic ceramics. This feature provides a higher level of material deformation.

Ballistic tests and post-impact analysis

The samples prepared for ballistic tests are shown in Fig. 10a-с. Since the composite material consists of over 40% ceramic phases, it was assumed that severe fragmentation and scattering of fragments would occur on ballistic impact; therefore, composites were wrapped in Kevlar, Fig. 10b, c. The MMC of the Ti-40 wt% TiC and Ti64-40 wt% TiC after test are shown in Fig. 10d, e respectively.

Figure 11 shows consecutive frames of a bullet impacting an armor element, taken at the same interval using a high-speed camera (frame rate 130,000 frames per second). This behavior is typical for both Ti-40 wt% TiC and Ti64-40 wt% TiC materials. High-speed recordings reveal no significant difference in stability between the composite materials. As illustrated in Fig. 11, the bullet fractures upon impact with the composite, and its fragments are expelled rearward. A noticeable part of the bullet’s energy is converted into an intense flash, partial burning of the titanium-containing material, and a sound wave. The high-strength steel core of the bullet is also destroyed. Upon impact, the top layers of both MMC samples are damaged, exhibiting 8–9 radial cracks along which the composites fractured. These cracks originate at the point of impact, propagate toward the edges, and traverse the entire thickness of the MMC samples.

The fracture surfaces of the broken in ballistic test elements of Ti-40 wt% TiC composite are characterized by two zones (carbide and matrix phases) with a brittle fracture pattern (Fig. 12). Even in the zones of titanium matrix, no usual for ductile titanium pitting fracture pattern was observed, which can be explained by the high deformation rates and the low plasticity of the composite as whole. The traces of molten lead from the destroyed bullet can be observed in all zones near the point of contact of the projectile with the composite (Fig. 12b, c). The destruction of the carbide phase occurs along the boundaries between individual carbide grains (Fig. 12f, h). Clear straight edges of carbide grains and cracks propagated along the grain boundaries can be observed, Fig. 12h. No destroyed carbide particles were observed, which may indicate that, under the intense impact, the fractured particles were expelled from the composite. Figure 12g, i, shows the zones where the titanium matrix phase was damaged. The titanium surface appears fractured without obvious traces of plastic deformation and with clear friction traces (Fig. 12i) resulting from the friction of two destroyed parts of the material was observed.

The fractured surface of Ti-40 wt.%TiC composite fragment after the ballistic test: (a) general view; (b, c) region on the center of the fracture part; (d, e) region near the penetration, (f, h) region with intergranular fracture of TiC; (i, g) region with the fracture of Ti matrix. SEM, SE (b,d,f-i), BSE (a,c,e).

The fractured surface of the Ti64-40 wt%TiC composite fragments is characterized by two zones with a brittle fracture mode, Fig. 13. The traces of molten lead from the destroyed projectile can be observed in the zones that were oriented towards the point of contact of the bullet and composite, Fig. 13a-e. Figure 13b, c demonstrate the grooves that were formed by the movement of hard carbide particles that were carried away by the moving projectile. Near this area, similar traces were also made by moving carbides, but their direction was shifted because in this area movement of the projectile made shear action, Fig. 13d, e. In the far part of the fractured surface of the material, a destruction area of large conglomerates of the TiC (Fig. 10) was observed, Fig. 13g, i.

The destruction of the carbide phase is observed over a large area, rather than along the boundary between the matrix and the reinforcing phase (Figs. 14a). Clear friction lines are also evident (Fig. 14b-d), formed as a result of the mutual movement and friction of two destroyed fragments of the material. This indicates significant local stress at the point of contact. Larger differences in the destruction process can be examined on cross-sections of the destroyed material, Figs. 15 and 16.

The cross-section of the Ti-40 wt.%TiC composite fragment after ballistic test showed that secondary cracks propagate in the material over a distance of 0.1–0.2 cm from the fracture surface (Fig. 13a). These cracks propagated mainly along the matrix/reinforcing phase interfaces (Fig. 13b, d). No traces of plastic deformation were detected in the matrix phase, which can be attributed to the high deformation rate. The high initial projectile velocity (impact velocity of 850 m/s) and the significant energetic loads upon impact (above 3000 J) caused the destruction of the target material along the interface and brittle TiC phase (Fig. 14c). Under such conditions, the very strong localization of applied stresses leaves insufficient time for stress redistribution and relaxation, preventing any plastic deformation from occurring.

A somewhat different result is observed for the Ti64-40 wt.%TiC MMC, which differs by another matrix composition (i.e. the Ti64 alloy) as well as by the distribution and shape of reinforcing inclusions (Fig. 5). Secondary cracks propagate over slightly longer distances (2–4 mm) in the MMC (Fig. 15). Unlike the Ti-40 wt.%TiC composite, these cracks do not follow the interfaces between the matrix and reinforcing phases. Instead, they propagate along chains of carbide phases (Fig. 15a, f), passing through and destroying the carbides (Fig. 15g). Cracks eventually stop at theTi64/TiC interface (Fig. 15h, i). In the zone of direct action of the bullet core on the composite material Fig. 15b, c,d, crushed carbide inclusions are observed (Fig. 15b, c, d, e). In some regions, cracks pass between carbide inclusions (Fig. 15c), while in others it is not observed. It can be assumed that this process occurs similarly, and the cracks are located in different regions of the materials. Due to the high speed of interaction between the projectile and the target and the stresses strongly localized in the latter, plastic deformation processes does not occur. Therefore, in non-porous composites, energy absorption on dynamic loading occurs preferably by means of fracture of the reinforcing phase22. In this case, the bullet’s energy is dissipated through the destruction of the carbide components of the composite.

Cross section of Ti64-40% TiC MMC fragment after ballistic test: (a) general view; (b-c) region near bullet penetration channel; (e) fragmentation of the large carbide particle into the small parts; (f-i) examples of the cracks that illustrate the tendency of their propagation preferably through carbide phase. SEM, BSE.

After the ballistic tests, only slight deformation of the T110 alloy base substrate with a thickness of 3 mm used for the composite material was observed (Fig. 16). In the central zone where interaction with the ejected plug or bullet core occurred (Fig. 16c, d) the typical microstructure for the T110 alloy is retained, showing no evident signs of plastic deformation. There is a minor crack, up to 20 μm in length, passing through the structure. This crack may have been caused by the sharp edges of fragmented material interacting with this place.

Discussion

It should be noted that the bullet with a blunt hard core used in this study is designed specifically to penetrate high-strength armor elements during ballistic testing22. The mechanism of action of such a core involves shearing a plug from the armor material. Due to high hardness of the target, it has the tendency for the generation of adiabatic shear bands, which facilitate the plugging process. For two MMCs, we observed the formation of a plug from which 9 main cracks spread in radial directions, resulting in fracture of the composite material. The titanium alloy substrate remains intact with minor deformation, since all the energy of the bullet is spent on the destruction of the composite and the bullet due to the high hardness of the armor MMC element.

As can be seen in the frames from a high-speed video recording of the testing process (Fig. 11), part of the core after destruction flies away in the opposite direction. Using high-speed video recording, the speed of the core fragment flying away was calculated. At this flight’s initial stage, the main core remnant had a speed of 3.6–4.7 m/s, compared to the initial bullet speed of 850 m/s. Naturally, numerous fragments from both the MMC and the bullet were generated, each with varying masses and dispersal speeds. For a more insightful analysis, it is better to consider the bullet’s energy. The bullet used in the test had an initial kinetic energy of 3410 J. After interacting with the composite material, nearly all of this energy is dissipated on bullet impact and fracturing the MMC target, while the part of the core that was expelled backward retained only about 0.7–1 J of energy. In this scenario, only the 7.5 mm-thick front composite undergoes destruction, whereas the underlying T100 titanium alloy substrate remains largely undamaged.

To understand how such two-layer materials stand in comparison with other titanium-based armor materials, it is necessary to compare their ballistic characteristics with already known data5,33,34. This comparison has previously been performed on 3D-printed titanium materials34 and on sintered and Hot Isostatically Pressed (HIP) materials16. In all cases, similar 7.62 × 51 mm armor-piercing cartridges were used, the only difference was in the shape of the hard steel core’s nose. Firstly, it is necessary to note the works of J. Fanning, who conducted a detailed analysis of the influence of the thickness of rolled and some heat-strengthened plates of different commercial titanium alloys on the value of such a parameter as V505,35. His results are in good agreement with work carried out by the US Army laboratory33. For a wide range of rolled titanium alloys, this dependence is a straight line (Fig. 16). As shown in Fig. 14, for a bullet speed of 850 m/s, the thickness of the titanium alloy plate (including Ti-6Al-4 V) must exceed 19 mm when tested with 7.62 × 51 mm AP bullets with steel ogive-shaped core. As shown in work23 the use of high-quality Ti64 alloy material in the test with similar bullets with the same kinetic energy but having a hard steel core with a blunt nose, V50 equal to 850 m/s was achieved for a 14 mm thick plate from Ti64 alloy. For the previously studied titanium-based composite materials containing hard TiC or TiB particles manufactured by the powder approach14,16 V50 could not be determined because the plates were either not pierced or not completely fractured, partly due to their limited size. For the two-layer materials studied in the present work, there was a destruction of the front composite layer only, but the base layer remained intact. Therefore, this cannot be considered a fully determined V50 parameter, however, it demonstrates that the ballistic resistance is significantly higher than the straight-line dependence (red point in Fig. 17). For a total thickness of 11 mm, the composite did not completely collapse at a speed of 850 m/s. This point lies almost twice above the reference curve, which indicates the prospects of this approach for obtaining dense composite materials to be applied in ballistic protection systems.

Moreover, based on observation of post-impact effects (no serious damage to the bottom (basic), ductile layer), we can assume that the impact velocity is relatively far above the ballistic limit for the considered target. More extensive tests, with a more comprehensive statistical analysis, are planned as part of the ongoing layer thickness optimization process.

Comparison of ballistic test results for titanium composites investigated in this work and other titanium materials, V50 dependence is adopted from35.

Conclusions

-

1.

The successful densification of titanium-based metal matrix composites with a high content of reinforcing TiC phase (40 wt%) using post-sintering hot pressing without a protective atmosphere is demonstrated.

-

2.

Densified microstructures with a non-uniform redistribution of the reinforcing carbide phase in titanium and Ti-64 alloy matrixes were achieved after hot pressing, ensuring high hardness values ranging within 710–1300 HV, depending on the local morphology and carbide phase content.

-

3.

Ballistic tests indicate that these composites can withstand the impact of a 7.62 × 51 mm armor-piercing bullet with a blunt core, having a hardness of 870 HV and kinetic energy of 3410 J. This performance is primarily attributed to low porosity (< 1%), high hardness, and the combination of the MMCs with a supporting base layer made of rolled titanium alloy.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.

References

Lütjering, G. & Williams, J. C. Titanium. vol. 2end (Springer Berlin) https://doi.org/10.1007/978-3-540-73036-1 (2007).

Zwicker, U. Titan Und Titanlegierungen (Springer Berlin, 1974).

Jawed, S. F. et al. Strengthening mechanism and corrosion resistance of beta-type Ti-Nb-Zr-Mn alloys. Mater. Sci. Engineering: C. 110, 110728 (2020).

Cooch, W. Potential Applications of Titanium Alloys in Armor Systems. In Titanium-2011; International Titanium Association: San Diego, CA, USA, 2011 (2011).

Fanningl, J. Ballistic Evaluation of Titanium Alloys Against Handgun Ammunition. Science and Technology, Proceedings of the 11th World Conference on Titanium, Kyoto, Japan, 3–7 June ; The Japan Institute of Metals Publish.: Tokyo, Japan, 2007; (2007).

Chen, L. Y., Qin, P., Zhang, L. & Zhang, L. C. An overview of additively manufactured metal matrix composites: preparation, performance, and challenge. Int. J. Extrem Manuf. 6, 052006 (2024).

Fahrenholtz, W. G., Wuchina, E. J., Lee, W. E. & Zhou, Y. Ultra-High Temperature Ceramics Materials for Extreme Environment Applications (John Wiley & Son, 2014).

Fahrenholtz, W. G., Binner, J. & Zou, J. Synthesis of ultra-refractory transition metal diboride compounds. J. Mater. Res. 31, 2757–2772 (2016).

Vedel, D. et al. Formation of the gradient metal matrix Ti-TiB-TiC composite by 3D-printing with coaxial electron-beam technology and cored wire. J. Alloys Compd. 1027, 180617 (2025).

Markovsky, P. E. et al. Significant hardening effect of high-temperature aging of alloy Ti-6Al-4V composite reinforced with tic. Mater. Design. 234, 112208 (2023).

Wu, Y. Y. et al. In-situ SEM characterization of fracture mechanism of TiB/Ti2Al-6Sn titanium matrix composites after electroshocking treatment. Rare Met. 43, 2805–2818 (2024).

Xie, L., Sun, H., Wen, Y., Hua, L. & Zhang, L. C. Electromagnetic treatment enhancing performance of metal materials: A review. Prog. Mater. Sci. 153, 101488 (2025).

Markovsky, P. E. et al. Mechanical behavior of titanium based metal matrix composites reinforced with tic or TiB particles under Quasi-Static and high Strain-Rate compression. Materials 14, 6837 (2021).

Іvasishin, O. M. et al. Microstructure and properties of Titanium-Based materials promising for antiballistic protection. Usp Fiz. Met. 20, 285–309 (2019).

Baglyuk, G. A., Ivasyshyn, O. M., Stasyuk, O. O. & Savvakin, D. G. The effect of charge component composition on the structure and properties of titanium matrix sintered composites with High-Modulus compounds. Powder Metall. Met. Ceram. 56, 45–52 (2017).

Markovsky, P. et al. Ballistic performance of titanium-based layered composites made using blended elemental powder metallurgy and hot isostatic pressing. Def. Technol. 39, 1–14 (2024).

Oryshych, D., Stasiuk, O. & Vedel, D. Microstructure and properties of Ti-TiС composite obtained by hot pressing.

Stasiuk, O., Vedel, D. & Oryshych, D. A new approach to densification of titanium-based hard composites reinforced by TiВ. International Scientific Journal "Machines. Technologies. Materials",18 6, (2024)

Song, Y. et al. Microstructural characteristics of Ti-Based composites with various ceramic reinforcements manufactured via Hydrogen-Assisted blended elemental powder metallurgy. Adv. Eng. Mater. 25, 2101689 (2023).

Ivasishin, O. M., Cherepin, V. T. & Kolesnik, V. N. Gumenyak, N. M. An automated dilatometric system. Instruments Experimental Techniques. 53, 457–460 (2010).

Vedel, D., Osipov, A., Melakh, L., Brodnikovskyi, M. & Grigoriev, O. Contact interaction and hot pressing of ZrB2-MoSi2 in CO/CO2 atmosphere. J. Eur. Ceram. Soc. 43, 3025–3033 (2023).

Kovalchuk, D. V. et al. Terminal ballistic effects for 3D-printed multi-layered material consisting of Ti-6Al-4V alloy, metal matrix composite and porous titanium. Sci. Rep. 15, 12767 (2025).

Markovsky, P. et al. New approach for manufacturing Ti–6Al–4V + 40%TiC Metal-Matrix composites by 3D printing using Conic electron beam and cored wire. Pt. 2: layered mmc/alloy materials, their main characteristics, and possible application as ballistic resistant materials. Prog Phys. Met 24, 4, 741–763, (2023).

Ivasishin, O. & Moxson, V. 8 - Low-cost titanium hydride powder metallurgy. In Titanium Powder Metallurgy (eds Qian, M. & Sam) Froes, F. H.) 117–148 (Butterworth-Heinemann, 2015). https://doi.org/10.1016/B978-0-12-800054-0.00008-3.

Yang, Y. F. & Qian, M. 13 - Spark plasma sintering and hot pressing of titanium and titanium alloys. In Titanium Powder Metallurgy (eds Qian, M. & Sam) Froes, F. H.) 219–235 (Butterworth-Heinemann, 2015). https://doi.org/10.1016/B978-0-12-800054-0.00013-7.

Kim, K. T. & Yang, H. C. Densification behavior of titanium alloy powder during hot pressing. Mater. Sci. Engineering: A. 313, 46–52 (2001).

Sienkiewicz, J., Stasiuk, O., Vedel, D. & Markovsky, P. Strain Rate Influence on Mechanical Behavior of Ti-6Al-4V + TiC or TiB Composites Produced by Sintering and Hot Isostatic Pressure on Compression (in press.). Materials Characterization.

Duan, Y., Wu, Y., Peng, M. & Qi, H. The interstitial diffusion behaviors and mechanisms of Boron in α-Ti and β-Ti: A first-principles calculation. Comput. Mater. Sci. 184, 109866 (2020).

Arvieu, C., Manaud, J. P. & Quenisset, J. M. Interaction between titanium and carbon at moderate temperatures. J. Alloys Compd. 368, 116–122 (2004).

Markovsky, P. E. et al. Mechanical behavior of bilayer structures of Ti64 alloy and its composites with tic or TiB under quasi-static and dynamic compression. Mater. Design. 223, 111205 (2022).

ggsceramic. Top 6 Bulletproof Ceramic Materials in (2025). https://ggsceramic.com/news-item/the-6-best-bulletproof-ceramic-materials-performance-comparison-and-selection-analysis-in-2025

Fortini, J. I. N., Silveira, P. H. P. M. D., Monteiro, S. N., Pereira, A. S. & Lima, E. S. Mechanical, microstructural properties and ballistic performance of SiC/Si ceramics against 5.56 x 45 mm projectile. J. Mater. Res. Technol. 35, 208–219 (2025).

Burkins, M. S., Hansen, J. S., Paige, J. I. & Turner, P. C. The effect of Thermo-mechanical processing on the ballistic limit velocity of extra low interstitial titanium alloy Ti-6AL- 4V, Army Research Laboratory (2000).

Markovsky, P. E. et al. Titanium-Based layered armour elements manufactured with 3D-Printing approach. Metallofiz Noveishie Tekhnol. 44, 1361–1375 (2022).

Fanning, J. C. Military applications for β titanium alloys. J. Mater. Eng. Perform. 14, 686–690 (2005).

Acknowledgements

This study was performed within the frames of the Agreement on collaboration between G.V. Kurdyumov Institute for Metal Physics and Jarosław Dąbrowski Military University of Technology. This work was partially funded by the National Academy of Science of Ukraine (Grant for Young Scientists N 0124U002070) and co-financed by Military University of Technology under research project UGB 22-047/2025/WAT.

Funding

This work was partially funded by the National Academy of Science of Ukraine (Grant for Young Scientists N 0124U002070) and co-financed by the Military University of Technology under research project UGB 22–047/2025/WAT.

Author information

Authors and Affiliations

Contributions

D.G. S.: Writing - Original Draft, Formal analysis; O.O. S.: Writing - Original Draft, Methodology, Formal analysis; D.V. V.: Writing - Original Draft, Visualization; B. F.: Methodology, Investigation, Formal analysis, Writing - Review & Editing, Supervision; K. P.: Investigation; J. S.: Investigation; J. J.: Investigation, Formal analysis; D.V. O.: Investigation; A.E.O.: Investigation; S. T.: Investigation;,P.E. M.: Conceptualization, Formal analysis, Writing - Original Draft, Writing - Review & Editing, Supervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Savvakin, D., Stasiuk, O., Vedel, D. et al. Formation of the structural-phase state of titanium-matrix composites reinforced with tic during synthesis and hot pressing, and their testing as ballistic-resistant (bulletproof) protective materials. Sci Rep 15, 36206 (2025). https://doi.org/10.1038/s41598-025-20136-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-20136-0