Abstract

It is significant to study the stability of surrounding rock in soft rock tunnels to ensure construction safety and improve efficiency. Through triaxial shear tests on soft rock at various confining pressures, we observed the failure characteristics transitioning from strain softening to strain hardening as confining pressure increases. An improved Hoek-Brown strength criterion has been proposed to characterize the critical confining pressure effect of soft rock, with tensile strength in the tensile zone aligning with experimental results, showing an error of less than 5%. By assuming that the micro-unit strength of soft rock follows a two-parameter Weibull distribution, we constructed a statistical damage constitutive model for soft rock in mountain tunnels. This model provides a more realistic depiction of damage change, failure processes, and stress-strain evolution in soft rock, thereby validating its scientific and rational foundation. The research findings can serve as a valuable reference for mountain tunnel construction.

Similar content being viewed by others

Introduction

A large number of experts and scholars, both domestically and internationally, have conducted research on the triaxial shear and creep characteristics of soft rock, resulting in significant academic achievements. Wan Liaorong1performed a series of triaxial shear tests on soft rock dam materials with a stone skeleton structure, investigating the effects of gradation and density on the strength and deformation characteristics of these materials. Deng Huafeng2conducted a comprehensive study involving a series of triaxial loading and unloading tests on sandy mudstone, addressing the critical issue of determining the compressive strength parameters in these tests for soft rock. Li Hangzhou3validated the triaxial shear and creep characteristic mechanisms through conventional triaxial test results of soft rock, comparing the theoretical predictions of deviatoric stress-strain with experimental data. The findings indicated that the constitutive model accurately reflects the deviatoric stress-strain relationship of soft rock, particularly its strain softening characteristics. Building on endochronic theory, Chen Yuanjiang4incorporated Newton’s time into intrinsic time and introduced a damage variable into Helmholtz free energy, reconstructing both concepts. The endochronic rheological constitutive equation for soft rock was derived using the fundamental principles of irreversible thermodynamics for continuous media. Subsequently, the equation was solved, analyzed, and validated through experiments conducted under uniaxial stress conditions. Shao Lei5adopted the unit cell propagation method to generate a simulated aggregate of rockfill particles, using a regular tetrahedron as the core. A large triaxial test was simulated under drained shear conditions. By analyzing the variation of mesoscopic parameters during the numerical test, the mesoscopic mechanism of rockfill deformation under triaxial shear conditions was discussed. The analysis showed that the numerical particles generated by the unit cell propagation method better simulate rockfill compared to circular particles, as the interlocking forces formed by particle clusters create a more realistic force-deformation relationship. The stress-strain and volume change curves obtained from the numerical test were largely consistent with the results of laboratory triaxial tests. Bao Mengdie6used a continuous gradation equation to quantitatively describe the experimental gradation of graded continuous coarse-grained soil. This study explored the relationship between gradation and permeability coefficient, established an empirical formula for the permeability coefficient considering the area under the gradation curve, and verified the applicability of the formula with permeability test results from other existing studies. Yoshinaka R7, Liu H8, Cui K9, Wang Y10, Tatsuoka F11and Abel J F12have conducted extensive experimental and theoretical analysis on the mechanical properties of soft rock, such as strength, deformation, and failure. Among them, the determination and analysis of strength characteristics of soft rock (such as compressive strength, shear strength and tensile strength) was one of the main achievements. Xia Jiaguo13used a large triaxial shear tester to conduct consolidated undrained shear tests on unconventional soil-rock mixture samples with stone volume contents of 25% and 35% under three different confining pressures. The test results indicated that the soil-rock mixture containing super-diameter particles still experienced volume changes under undrained shear conditions. At high confining pressures, the volume strain of the soil-rock mixture with 35% stone content exhibited initial shear contraction, followed by subsequent shear expansion, secondary shear contraction, and secondary shear expansion. In contrast, the stress-strain curve for the soil-rock mixture with 25% stone content was relatively smooth. However, the stress-strain curve for the mixture with 35% stone content displayed a serrated pattern and was accompanied by an indirect stress jump phenomenon. Corresponding volume strain and pore water pressure also exhibited jump phenomena, demonstrating a strong relationship with the stress changes in the sample. The research of Li C14, Zang C W15, Lyu X16and Zhang Y17also covered the theoretical study of rock mechanics of soft rock mass, including failure criterion, rock mechanics model and constitutive relation of soft rock. Schwartz A E18, Hamidi A19and Holtz W G20simulated the deformation and failure behavior of materials under multiaxial stress to evaluate the strength, strain characteristics and fracture mode of materials. Liuliu L21and Cao P22focused on the mechanical behavior of soft rock materials under compression loading, such as the deformation characteristics, fracture modes, and load-deformation curve characteristics of soft rock. The research results of Haberfield C M23, Yadong Z24, Vlastelica G25, Yu W26and Miščević P27involved experimental research, empirical formula, numerical simulation and strength criterion model, etc., aiming to deeply understand the mechanical behavior of soft rock and provide scientific basis for practical engineering. Based on a large number of experimental data and analysis, the researchers put forward some empirical formulas to estimate the strength parameters of soft rock. These formulas were usually based on the physical properties, structural characteristics and stress state of soft rock to simplify the calculation and design process. -Li H28,29,30 proposed a new criterion to capture the strength response of intact rock and verified it by experiments.

Although scholars both domestically and internationally have conducted numerous experiments and theoretical studies on the strength criterion of soft rock, a comprehensive examination of the strength criterion that describes the entire process of tension and compression failure, along with a damage constitutive model based on probabilistic micro-unit failure, has not been systematically undertaken. Therefore, through triaxial shear tests of soft rock under various confining pressures and triaxial tests involving constant axial compression with unloading confining pressure, we propose an improved Hoek-Brown strength criterion and establish a statistical damage constitutive model. This model assumes that the strength of soft rock micro-units follows a two-parameter Weibull distribution, providing guidance for tunnels in the design and construction of mountain soft rock.

2 Triaxial shear test scheme

2.1 Test instrument

The triaxial shear tests and triaxial graded loading creep tests of soft rock are carried out in the Rock Mechanics Research Center of the State Key Laboratory of Nuclear Resources and Environmental Engineering. The soft rock used in the test is taken from K0 + 470 ~ K0 + 510 section of a mountain tunnel in Hunan Province. Soft rock is a complex rock mechanics medium with significant plastic deformation in a specific environment. There are a large number of joints and fissures in the rock. These structural planes are easy to become failure surfaces during tunnel excavation and affect the stability of the tunnel. Hunan Province is located in the South China plate, with complex geological structure and complete stratigraphic development. Under the influence of multi-stage tectonic movement, in mountainous areas, the formation of common strata includes mudstone, shale, siltstone, etc. The rocks in these strata often have lower strength and higher plastic deformation ability, and are easy to form soft rock. The type of soft rock used in this study is shale. The geological evaluation of the surrounding rock section indicates a length of approximately 40 m, with the tunnel buried at depths varying from 21.05 to 40.02 m. This section is classified as Grade IV surrounding rock. The predominant material is moderately weathered carbonaceous slate, characterized by well-developed joints and fissures. While the rock is relatively hard, the overall rock mass exhibits considerable fragmentation. The self-stability of the surrounding rock is somewhat poor; without support, small collapses or falling blocks may occur at the arch, although the side walls remain generally stable, with only localized falling blocks possible. During on-site sampling, cylindrical samples with a diameter of 50 mm and a height of 100 mm were collected for laboratory analysis. The longitudinal wave velocity of these samples was then tested. After removing samples with significant wave velocity deviations, the longitudinal wave velocities of the soft rock samples ranged from 3000 to 3500 m/s.

The test instrument used is the MTS-837.15 electro-hydraulic servo rock testing machine, which has a maximum axial load capacity of 250kN and a maximum confining pressure of 50 MPa. The axial loading rate can be controlled within 10 − 5 ~ 1 mm/s, and the temperature control range is from − 40 °C to 80 ℃. This equipment is capable of conducting uniaxial, triaxial, creep tests, and temperature-seepage-creep-damage coupling tests based on the specific test requirements.

2.2 Triaxial shear test scheme

The main steps of triaxial shear tests are as follows:

-

(1)

According to the actual buried depth of the tunnel, the confining pressures of the test are 0, 5, 10, 15, 20, 25, 30 MPa, a total of seven levels. To ensure the reliability of the test results, three parallel tests are conducted at each level. The test arrangement is shown in Table 1.

-

(2)

Set test parameters, including sample size, test termination conditions, and load settings.

-

(3)

Conduct triaxial shear tests under both loading and unloading stress paths.

-

(4)

Establish the criteria for the test’s conclusion and obtain the axial and radial deformation law.

-

(5)

Repeat the above steps to perform bot loading and unloading triaxial shear tests.

The confining pressure is applied at a rate of 0.02 MPa/s until it reaches the set value, at which point it is maintained constant. A displacement control method is used to apply axial pressure, with the confining pressure loaded at a rate of 0.05 mm/min to obtain the stress-strain curve.

Unloading test method: After the confining pressure is loaded to the test set values (20 MPa, 25 MPa, 30 MPa), the axial load is applied to 80% of the strength at each confining pressure level, and then the axial pressure is maintained unchanged. The confining pressure is unloaded at a rate of 0.02 MPa/s to obtain the stress-strain curve.

Result analysis of soft rock

3.1 Stress-strain relationship of soft rock

The deviatoric stress-strain curves of soft rock under different confining pressures of 0, 5, 10, 15, 20, 25, and 30 MPa are obtained through tests, as shown in Fig. 1.

It can be observed from Fig. 1that confining pressure significantly affects the deviatoric stress-strain curve of soft rock. When the confining pressure during the test is low (0, 5, 10, 15 MPa), a strain softening phenomenonis observed. Conversely, at higher confining pressures (20, 25, and 30 MPa), the material gradually begins to exhibit strain hardening behavior. The improved Duncan-Zhang model31 presented in Formula (1), effectively describes the deviatoric stress-strain curves of soft rock under varying confining pressures, with the relevant parameters detailed in Table 2.

Where \(\:{a}_{1}\), \(\:{a}_{2}\), and \(\:{a}_{3}\) change with the variation of confining pressure, all in units of MPa−1.

3.2 Deformation characteristics of soft rock

The relationship between peak strain, volume strain and confining pressure corresponding to deviatoric stress-strain curve of soft rock under different confining pressures is shown in Fig. 2.

As can be seen from Fig. 2, with the increase of confining pressure, the peak strain \(\:{{\upepsilon\:}}_{\text{f}}\:\)corresponding to the deviatoric stress-strain curve of soft rock increases linearly, while the volume strain decreases nonlinearly, and the correlation formulas are shown in Formulas 2 (a) and (b).

3.3 Characteristics of initial tangent modulus

In the conventional triaxial shear process of soft rock \(\:{\text{d}\sigma\:}_{1}={\text{d}\sigma\:}_{2}=0\), the initial tangent modulus \(\:{E}_{0}\)can be obtained according to the expression of improved Duncan-Chang model.

According to the stress-strain curve of soft rock in Fig. 4, the relationship between initial tangent modulus \(\:{E}_{0}\) of soft rock and confining pressure is obtained, as shown in Fig. 3.

It can be seen from Fig. 3 that with the increase of confining pressure, the initial tangent modulus \(\:{E}_{0}\) of soft rock increases nonlinearly. The relationship between initial tangent modulus \(\:{E}_{0}\) of soft rock and confining pressure can be expressed by Slogisticl function, and the fitting formula is shown in Fig. 3.

3.4 Strength characteristics

The variation law of soft rock strength \(\:{\left({\sigma\:}_{1}-{\sigma\:}_{3}\right)}_{\text{f}}\) with confining pressure is obtained through test, as shown in Fig. 4.

It can be seen from Fig. 4 that when the confining pressure in the test is lower than 20 MPa, the strength \(\:{\left({\sigma\:}_{1}-{\sigma\:}_{3}\right)}_{\text{f}}\)of soft rock increases as the confining pressure rises. This increase is particularly notable when the confining pressure is below 15 MPa, where the strength of soft rock rises rapidly. However, when the confining pressure exceeds 20 MPa, the strength \(\:{\left({\sigma\:}_{1}-{\sigma\:}_{3}\right)}_{\text{f}}\) of soft rock decreases slightly with further increases of confining pressure.

3.5 Failure characteristics of specimens

In the triaxial compression test of soft rock under different confining pressures, the failure form of soft rock is shown in Fig. 5.

As can be seen from Fig. 5, when the confining pressure is 0 MPa, the failure mode of soft rock is brittle shear failure, and the failure surface runs through the sample, which is about 60º with the load direction. When the confining pressure is greater than 0 MPa, the failure mode of soft rock is conjugate shear failure.

3.6 Unloading confining pressure triaxial test results and analysis

The characteristics of deviatoric stress-strain curve are obtained by unloading confining pressure test of soft rock, as shown in Fig. 6.

The peak strength obtained by conventional triaxial tests and unloading confining pressure tests at confining pressures of 20 MPa, 25 MPa and 30 MPa is shown in Table 3.

It can be observed from the table that the peak strength of unloading confining pressure tests is lower than that of conventional triaxial tests at confining pressures of 20 MPa, 25 MPa, and 30 MPa. The difference is 11.7 MPa at a confining pressure of 20 MPa. However, at a confining pressure of 30 MPa, the two values are similar, with a difference of only 1.5 MPa. In excavation and support design, the influence of stress path on design parameters should be fully considered when the confining pressures. Conversely, this influence can be disregarded when the confining pressure is high.

Construction of improved Hoek-Brown strength criterion of soft rock

By analyzing the existing Mohr-Coulomb strength criterion, Hoek-Brown strength criterion, exponential strength criterion and other geotechnical material strength criteria, combined with triaxial test data, an improved Hoek-Brown strength criterion of soft rock is constructed.

4.1 Mohr-Coulomb strength criterion

The linear Mohr-Coulomb strength criterion is one of the most common geotechnical strength criteria, as shown in Formula (4):

The parameters of Mohr-Coulomb strength criterion shown in Formula (4) are \(\:a=2 C\text{c}\text{o}\text{s}\phi\:/\left(1-\text{s}\text{i}\text{n}\phi\:\right)\) and \(\:b=\left(1+\text{s}\text{i}\text{n}\phi\:\right)/\left(1-\text{s}\text{i}\text{n}\phi\:\right)={\text{t}\text{a}\text{n}}^{2}\left({45}^{^\circ\:}+\phi\:/2\right)\) respectively.

In the conventional triaxial tests under different confining pressures, the obtained \(\:{\sigma\:}_{1\text{m}\text{a}\text{x}}\) and \(\:{\sigma\:}_{3}\) are fitted based on the linear Mohr-Coulomb strength criterion, as shown in Fig. 7. The fitting parameters a and b are 22.7255 and 1.3238, respectively.

It can be seen from Fig. 7 that the linear Mohr-Coulomb strength criterion describes the relationship between \(\:{{\upsigma\:}}_{1\text{m}\text{a}\text{x}}\) and \(\:{{\upsigma\:}}_{3}\) obtained from the conventional triaxial tests of soft rock samples under different confining pressures. However, the tensile strength \(\:{\varvec{\upsigma\:}}_{\mathbf{t}}\) of soft rock samples obtained by Formula ( 4 ) is quite different from the experimental values, and the error is more than 6 times.

4.2 Hoek-Brown strength criterion

The nonlinear Hoek-Brown strength criterion is also one of the common strength criteria, and its expression is as follows.

Where \(\:{\sigma\:}_{\text{c}}\) is the uniaxial compressive strength of soft rock, and B is the material fitting parameter.

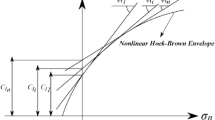

In conventional triaxial tests under different confining pressures, the obtained \(\:{\sigma\:}_{1\text{m}\text{a}\text{x}}\) and \(\:{\sigma\:}_{3}\) are fitted based on the nonlinear Hoek-Brown strength criterion, as shown in Fig. 8.

As can be seen from Fig. 8, the nonlinear Hoek-Brown strength criterion can describe the relationship between \(\:{{\upsigma\:}}_{1\text{m}\text{a}\text{x}}\) and \(\:{{\upsigma\:}}_{3}\) obtained from conventional triaxial tests of soft rock samples under different confining pressures, but the tensile strength \(\:{\varvec{\upsigma\:}}_{\mathbf{t}}\) of soft rock samples obtained by Formula (5) is quite different from the experimental values.

4.3 Exponential strength criterion

The expression of exponential strength criterion is shown in Formula (6).

Where \(\:{Q}_{{\infty\:}}\) is the ultimate principal stress difference, MPa; \(\:{\sigma\:}_{\text{c}}\) is the uniaxial compressive strength of soft rock, MPa; \(\:{K}_{0}\) is the influence coefficient on the strength of soft rock when the confining pressure is 0 MPa.

In the conventional triaxial tests of soft rock under different confining pressures, the obtained \(\:{\sigma\:}_{1\text{m}\text{a}\text{x}}\) and \(\:{\sigma\:}_{3}\) are fitted based on the exponential strength criterion, as shown in Fig. 9.

It can be seen from Fig. 9 that the exponential strength criterion can describe the relationship between \(\:{\sigma\:}_{1\text{m}\text{a}\text{x}}\) and \(\:{\sigma\:}_{3}\) obtained from conventional triaxial tests of soft rock samples under different confining pressures. However, it has the same problem as the above criteria, and the tensile strength \(\:{\sigma\:}_{\text{t}}\) of soft rock samples obtained by Formula (6) is quite different from the experimental values.

In summary, although the linear Mohr-Coulomb strength criterion, nonlinear Hoek-Brown strength criterion, generalized Hoek-Brown strength criterion, and exponential strength criterion can all fit the relationship between the maximum axial stress \(\:{\sigma\:}_{1\text{m}\text{a}\text{x}}\) and confining pressure \(\:{\sigma\:}_{3}\) of soft rock samples under different confining pressures, the obtained tensile strength \(\:{\sigma\:}_{\text{t}}\) of soft rock samples is quite different from the experimental values.

In addition, the figure clearly shows a significant deviation between the strength evaluated using the previously mentioned criteria and the experimental strength at high confining pressures, particularly at 30 MPa. This indicates that under high-stress conditions, the strength criterion overestimates the strength of soft rock, potentially skewing tunnel support design results towards excessive safety. This presents a major hidden risk. Therefore, it is crucial to develop a more accurate description of the relationship between the principal stresses in the ultimate stress state of soft rock.

4.4 Proposal of improved Hoek-brown strength criterion of soft rock

The proposed improved nonlinear Hoek-Brown strength criterion expression is as follows.

Where \(\:{\sigma\:}_{\text{c}}\) is the uniaxial compressive strength of soft rock, and A and B are fitting parameters. Compared with Formula (5), it can be seen that the improved Hoek-Brown strength criterion does not introduce new parameters, the number of parameters to be determined remains unchanged, and the square term of \(\:{\sigma\:}_{3}\) does not appear. Only the coefficient A is added at \(\:{\sigma\:}_{3}\), so the calculation after processing is simpler. Compared with Formula (5), it greatly simplifies the difficulty of subsequent research.

In conventional triaxial tests under different confining pressures, the obtained \(\:{\sigma\:}_{1\text{m}\text{a}\text{x}}\) and \(\:{\sigma\:}_{3}\) are fitted based on the proposed improved Hoek-Brown strength criterion, as shown in Fig. 10.

It can be seen from Fig. 10 that the improved Hoek-Brown strength criterion can well describe the relationship between \(\:{\sigma\:}_{1\text{m}\text{a}\text{x}}\) and \(\:{\sigma\:}_{3}\) obtained from conventional triaxial tests of soft rock samples under different confining pressures, and the correlation coefficient obtained by fitting is close to 1. Moreover, the results consistent with the test can be obtained under both low confining pressure and high confining pressure. The most important thing is that the tensile strength \(\:{\sigma\:}_{\text{t}}\) of the soft rock sample obtained by the Formula ( 7 ) is consistent with the experimental value of the test, and the error is within 3.0%.

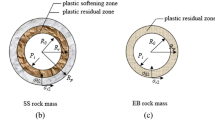

Soft rock damage constitutive model based on improved Hoek-Brown criterion

Assuming that the soft rock micro-unit strength follows a two-parameter Weibull distribution, the soft rock micro-unit strength F is determined using the improved Hoek-Brown strength criterion. The shape and scale parameters are then adjusted based on confining pressure. Ultimately, a statistical damage constitutive model suitable for soft rock, which reflects the critical state confining pressure, is established.

5.1 Model establishment

According to the strain equivalence hypothesis and its extension, the stress-strain relationship of soft rock damage under load is shown in Formula (8).

Where \(\:\sigma\:\) is the apparent stress of soft rock; \(\:E\) is the benchmark elastic modulus of soft rock; \(\:D\) is the damage variable of soft rock under load; \(\:\epsilon\:\) is the strain.

The damage variable \(\:D\) can be obtained according to Formula ( 9 ).

Where \(\:{N}_{\text{f}}\) refers to the number of damaged units in soft rock under load, and \(\:{N}_{\text{t}}\) refers to the total number of units in soft rock.

Considering the randomness and heterogeneity of initial defects in soft rock samples, it can be considered that the soft rock micro-unit strength \(\:F\) obeys the two-parameter Weibull distribution, and the damage variable \(\:D\) caused by load can also be considered to obey the two-parameter Weibull distribution, as shown in Formula (10).

Where m is the shape parameter and \(\:{F}_{0}\) is the scale parameter.

The proposed improved Hoek-Brown strength criterion is used to describe the soft rock micro-unit strength. The expression is shown in Formula ( 14 ).

Where \(\:{\sigma\:}^{\ast\:}\) is the effective stress corresponding to the apparent stress \(\:\sigma\:\) of soft rock. The relationship between effective stress \(\:{\sigma\:}^{\ast\:}\) and apparent stress \(\:\sigma\:\) is shown in Formula (12).

\(\:{\sigma\:}_{i}^{\ast\:}={\sigma\:}_{i}/(1-D)\), i = 1, 2, 3 (12).

Apparent stress \(\:{{\upsigma\:}}_{1}\), \(\:{{\upsigma\:}}_{2}={{\upsigma\:}}_{3}\) and axial strain \(\:{\epsilon\:}_{1}\) can be obtained by conventional triaxial tests of soft rock samples, and then according to Hooke’s law, Formula (13) is as follows.

Further, the soft rock micro-unit strength \(\:F\) expressed by apparent stress \(\:{\sigma\:}_{1}\), \(\:{{\upsigma\:}}_{2}={{\upsigma\:}}_{3}\) is shown in Formula (15).

According to Formula (15), Formula (16) is obtained.

Take the logarithm on both sides of Formula (16), and then take the logarithm after shifting the term to obtain Formula (17):

Let \(\:Y=\text{l}\text{n}\left[-\text{l}\text{n}\left(\frac{{\sigma\:}_{1}-{2\mu\:\sigma\:}_{3}}{{E\epsilon\:}_{1}}\right)\right]\), \(\:X=\text{l}\text{n}F\), \(\:W=m\text{l}\text{n}{F}_{0}\) in Formula (17), then Formula (18) is obtained.

By observing Formula ( 18 ), m and W can be determined by linear fitting of conventional triaxial test data of soft rock samples under different confining pressures. Further, the expression \(\:{F}_{0}\) can be obtained as shown in Formula ( 19 ).

5.2 Determination of model parameters

Based on the conventional triaxial shear tests of soft rock, the shape parameter \(\:{F}_{0}\) and scale parameter m of Weibull distribution are determined, as shown in Table 4.

It can be seen from Table 4 that under different confining pressures, the shape parameter \(\:{F}_{0}\) and scale parameter m of the Weibull distribution obeyed by the micro-unit strength \(\:F\) of soft rock are also different. The shape parameter \(\:{F}_{0}\) and scale parameter m of the Weibull distribution obeyed by the micro-unit strength \(\:F\) are modified by confining pressure. The relational expressions are shown in Formulas 20 ( a ) and 20 ( b ). The results are shown in Fig. 11 ( a ) and 11 ( b ).

It can be seen from Fig. 11that with the increase of confining pressure \(\:{\sigma\:}_{3}\), the shape parameter \(\:{F}_{0\:}\)of Weibull distribution obeyed by the micro-unit strength \(\:F\) of soft rock shows a parabolic trend, and the coefficient in front of the square term of confining pressure \(\:{\sigma\:}_{3}\) is less than zero, indicating that there is a maximum value, that is, the critical state confining pressure.

Finally, a statistical damage constitutive model suitable for soft rock which can reflect the critical state confining pressure is established as shown in Formula ( 21 ).

\(\:{F}_{0\:}\)and \(\:m\) in Formula (21) are obtained by Formula (20), and \(\:F\) is obtained by Formula (15).

5.3 Correctness verification of the established model

According to Formula (15), the theoretical deviatoric stress-strain curves for soft rock samples under varying confining pressures \(\:{{\upsigma\:}}_{3}\) can be derived. These results are compared with conventional triaxial tests conducted on soft rock samples, as illustrated in Fig. 12(a). To verify the correctness of the model, conventional triaxial tests of soft rock samples with confining pressures of 8 MPa, 18 MPa, 28 MPa and 38 MPa are carried out. The comparison between the theoretical derivation and the laboratory test results is presented in Fig. 12(b).

It can be seen from the figure that the damage constitutive model suitable for soft rock, which reflects the critical state confining pressure, aligns well with the experimental results when the confining pressure exceeds 0 MPa.

5.4 Evolution characteristics of damage variables

The change curves of the damage variable D of the soft rock sample under different confining pressures with the axial strain under load are obtained, as shown in Fig. 13.

Figure 13 shows that the shapes of the relationship curves between the damage variable D of soft rock under different confining pressures and axial strain are similar in shape. The deviatoric stress-strain curves, it can be seen that when the confining pressure is small, the strengthening effect of confining pressure on soft rock is predominant. Conversely, at high confining pressures, the weakening effect becomes dominant, resulting in a significant increase in the damage variable D when the axial strain is small.

6. Discussion

Although domestic and foreign scholars have conducted extensive experimental and theoretical research on the strength criterion of soft rock, the failure constitutive model that describes the entire process of tension-compression failure has not been systematically studied. This research presents an improved Hoek-Brown strength criterion based on triaxial shear tests of soft rock under different confining pressures, as well as triaxial tests involving constant axial compression with unloading confining pressure. Additionally, a statistical damage constitutive model of soft rock micro-unit strength, following a two-parameter Weibull distribution, is established, providing valuable insights for the field. However, this study has some limitations. Specifically, it only considers the confining pressure of soft rock, while other influencing factors, such as initial water content, temperature, and mineral composition, remain unaddressed. Furthermore, although a statistical damage constitutive model based on the two-parameter Weibull distribution is proposed, it may not fully capture all damage behaviors of soft rock under complex stress states. For instance, the model does not account for the processes of microcrack propagation, intersection, and coalescence. These factors will be thoroughly examined in future research to facilitate a more comprehensive understanding.

7.Conclusion

Based on the engineering background of a highway soft rock tunnel in Hunan, laboratory research was conducted on soft rock. Initially, conventional triaxial shear tests were performed on soft rock under various confining pressures, along with triaxial tests involving constant axial compression and unloading of confining pressure. An improved Hoek-Brown strength criterion was established to reflect the critical state confining pressure. It was assumed that the micro-unit strength of soft rock follows a two-parameter Weibull distribution. Using the proposed improved strength criterion, the micro-unit strength F of soft rock was determined, the shape and scale parameters were adjusted based on confining pressure. Ultimately, a statistical damage constitutive model suitable for soft rock, which can account for the critical state confining pressure, was developed. The following conclusions were drawn.

-

(1)

The results of conventional triaxial shear tests on soft rocks under varying confining pressures indicate that the shape of the deviatoric stress-strain curve is significantly influenced by the confining pressure. As the confining pressure increases, the curve transitions from strain softening to strain hardening.

-

(2)

The deviatoric stress-strain curves of soft rock under different confining pressures can be described by the improved Duncan-Chang model, which is suitable for the mechanical response of soft rock under static tunnel loading. The initial tangent modulus of soft rock increases nonlinearly with increasing of confining pressure.

-

(3)

The strength obtained using the existing strength criterion is generally consistent with the measured strength form soft rock triaxial shear tests at low confining pressures. However, as the confining pressure increases, the strength predicted by the existing criterion exceeds the measured strength, with the disparity between the two growing larger. While the strengths derived from the modified Mohr-Coulomb and modified Hoek-Brown strength criteria closely align with the measured strengths in both low and high confining pressure scenarios, the tensile strength obtained through extrapolation differs significantly from the measured values.

-

(4)

The improved Hoek-Brown strength criterion proposed in this study can characterize the critical confining pressure effect on soft rock and also confirms that the tensile strength of the tensile zone aligns with the experimental results. Compared with the existing strength criterion, the improved Hoek-Brown strength criterion can characterize the confining pressure strengthening effect and weakening effect of soft rock, and the tensile strength of the tensile zone is in good agreement with the experimental results. It can better show the difference between soft rock and hard rock, and provide guidance for tunnel excavation and support in soft rock strata.

-

(5)

The damage constitutive model based on the improved Hoek-Brown strength criterion proposed in this study more accurately describes the stress-strain curve of soft rock and reflects the critical state confining pressure.

Data availability

The datasets generated or analysed during the current study are not publicly available due project research is confidential, but are available from the corresponding author on reasonable request.

References

WAN Liao-rong wu Ping Ll Jian-hua WANG et al. Triaxial shear tests on Underfilled Soft Rockfills Dam materials [J]. Water Resour. Power. 40 (06), 79–82 (2022).

Hua-feng, D. E. N. G. et al. Research on failure characteristics and determination method for compressive strength of soft rock in triaxial loading and unloading tests [J]. Rock. Soil. Mech. 35 (04), 959–964 (2014).

Hangzhou, L. I., Hongjian, L. I. A. O. & Qian, S. H. E. N. G. Study on statistical damage constitutive model of soft rock based on unified strength theory [J]. Chin. J. Rock Mechan. Eng. 25 (7), 1331–1336 (2006).

Yuan-jiang, C. E. H. N. et al. Endochronic rheological constitutive model of soft rock [J]. Chin. J. Nonferrous Met. 13 (3), 735–742 (2003).

Lei, S. H. A. O. et al. Study of triaxial shear tests for rockfill based on particle flow code [J]. Rock. Soil. Mech. 34 (3), 711–720 (2013).

Meng-die, B. A. O. et al. Empirical formula for permeability coefficient of coarse grained soil based on gradation equation and its verification [J]. Chin. J. Geotech. Eng. 42 (08), 1571–1576 (2020).

Yoshinaka, R., Tran, T. V. & Osada, M. Mechanical behavior of soft rocks under triaxial cyclic loading conditions[J]. Int. J. Rock Mech. Min. Sci. 34 (3–4), 354. https://doi.org/10.1016/S1365-1609(97)00243-8 (1997).

Liu, H., Qiu, T. & Xu, Q. Dynamic acceleration response of a rock slope with a horizontal weak interlayer in shaking table tests[J]. PloS One. 16 (4), e0250418. https://doi.org/10.1371/journal.pone.0250418 (2021).

Cui, K. et al. An extended super/subloading surface model for soft rock considering structure degradation[J]. PLoS One. 16 (10), e0258813. https://doi.org/10.1371/journal.pone.0258813 (2021).

Wang, Y. et al. Analysis on hydraulic characteristics of improved sandy soil with soft rock[J]. Plos One. 15 (1), e0227957. https://doi.org/10.1371/journal.pone.0227957 (2020).

Tatsuoka, F., Lo Presti, D. & Kohata, Y. Deformation characteristics of soils and soft rocks under monotonic and cyclic loads and their relationships[J]. (1995).

Abel, J. F. Soft rock pillars[J]. International Journal of Mining and Geological Engineering, 6: 215–248. Eberhardt E. The hoek–brown failure criterion[J]. Rock mechanics and rock engineering, 45: 981–988. (2012) (1988).

Jiaguo, X. I. A. et al. Large-scale triaxial shear testing of soil rock mixtures containing oversized particles [J]. Chin. J. Rock Mechan. Eng. 36 (8), 2031–2039 (2017).

Li, C. et al. Roof failure mechanism and control technology of large section open-off cut in soft rock strata with thin thickness[J]. Shock Vib., 1–16. (2021).

Zang, C. W. et al. Research on deformation characteristics and control technology of soft rock roadway under dynamic disturbance[J]. Shock and 1–14. (2021).

Lyu, X. et al. 2D semimodel of full-section anchorage in thick soft rock roadway[J]. Shock Vib., 1–12. (2018).

Zhang, Y., Yang, Y. & Ma, D. Mechanical characteristics of coal samples under triaxial unloading pressure with different test paths[J]. Shock Vib., 1–10. (2020).

Schwartz, A. E. Failure of rock in the triaxial shear test[C]//ARMA US Rock Mechanics/Geomechanics Symposium. ARMA-64-109. (1964).

Hamidi, A. & Hooresfand, M. Effect of fiber reinforcement on triaxial shear behavior of cement treated sand[J]. Geotext. Geomembr. 36, 1–9 (2013).

Holtz, W. G. & Gibbs, H. J. Triaxial shear tests on pervious gravelly soils[J]. J. Soil. Mech. Found. Div. 82 (1), 1–22 (1956).

Liuliu, L., Fengqiang, G. & Vibration Experimental Investigation on the Energy Storage Characteristics of Red Sandstone in Triaxial Compression Tests with Constant Confining Pressure[J]. Shock and 1–12. (2020).

Cao, P. et al. Study on nonlinear damage creep constitutive model for high-stress soft rock[J]. Environ. Earth Sci. 75, 1–8 (2016).

Haberfield, C. M. & Johnston, I. W. Determination of the fracture toughness of a saturated soft rock[J]. Can. Geotech. J. 27 (3), 276–284. https://doi.org/10.1016/0148-9062(91)92684-q (1990).

Yadong, Z. et al. Stability analysis of soft rock surrounding tunnel based on Hoek-Brown strength criterion[J]. J. Eng. Geol. 27 (5), 980–988 (2019).

Vlastelica, G., Miščević, P. & Pavić, N. Testing the shear strength of soft rock at different stages of laboratory simulated weathering[J]. Građevinar 68 (12.), 955–965. https://doi.org/10.14256/JCE.1878.2016 (2016).

Yu, W. et al. Field investigations of high stress soft surrounding rocks and deformation control[J]. J. Rock Mech. Geotech. Eng. 7 (4), 421–433 (2015).

Miščević, P. & Vlastelica, G. Impact of weathering on slope stability in soft rock mass[J]. J. Rock Mech. Geotech. Eng. 6 (3), 240–250 (2014).

Li, H. et al. Enhanced Hoek-Brown (HB) criterion for rocks exposed to chemical corrosion[J]. Int. J. Min. Sci. Technol. 34 (5), 609–630. https://doi.org/10.1016/j.ijmst.2024.05.002 (2024).

Li, H. et al. A new volumetric strain-based method for determining the crack initiation threshold of rocks under compression[J]. Rock Mech. Rock Eng. 57 (2), 1329–1351. https://doi.org/10.1007/s00603-023-03619-2 (2024).

Li, H. et al. Stress-dependent Mohr–Coulomb shear strength parameters for intact rock[J]. Scientific Reports, 14(1): 17454. (2024). https://doi.org/10.1038/s41598-024-68114-2 (2024).

Nu, N. T., Van Loi, B. & Huong, N. T. T. An analytical model for residual stress prediction in rebound deformation of the foundation pit[J]. J. Appl. Sci. Eng. 23 (4), 661–668. https://doi.org/10.6180/jase.202012_23(4 (2020).

Acknowledgements

the study was supported by National Natural Science Foundation of China ( No. 42061011,No. 41977236 ), the Key Research and Development Program Project of Jiangxi Natural Science Foundation (No.20223BBG71W01), the Key Research and Development Program of Jiangxi Science and Technology Special Fund Project (No. 20232BBE50025), Doctoral Scientific Research Foundation Project of East China University of Technology (No. DHBK2023014 ).

Author information

Authors and Affiliations

Contributions

Zhenhua Wang: Formal analysis, Investigation, Visualization, Funding acquisition. Zecheng Wang: Writing-original draft, Supervision. Xin Chen: Conceptualization, Methodology.Gang Wang: Writing- review & editing. Dongwei Li: Writing - review & editing, Funding acquisition.All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, Z., Wang, Z., Chen, X. et al. Statistical damage constitutive model of soft rock based on Improved Hoek-Brown strength criterion. Sci Rep 15, 891 (2025). https://doi.org/10.1038/s41598-025-85333-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-85333-3

Keywords

This article is cited by

-

Influence of Fault Geometry on the Development Height of Overlying Rock Fissures in Phosphate Ore Bodies

Geotechnical and Geological Engineering (2026)

-

A nonlinear strength criterion for rock based on the peak value of deviatoric stress under conventional triaxial compression

Scientific Reports (2025)