Abstract

In order to solve the problems of rutting and early fatigue cracks in emulsified asphalt cold recycled pavement, and the shortage of natural stone resources and new environmental hazards caused by the use of traditional limestone powder filler. In this study, coal gangue powder was added to prepare Emulsified Asphalt Mastic (EAM) to improve the rheological properties and fatigue performance. A series of tests, including frequency scanning, temperature scanning, Multiple Stress Creep Recovery (MSCR), Linear Amplitude Scanning (LAS), and Fourier Transform Infrared spectroscopy (FTIR) were conducted. Through rheology theory, viscoelastic damage theory, the impact of three fillers: Coal Gangue Powder (CGP), Limestone Powder (LP) and Portland Cement (PC), as well as four kinds of Powder-Binder ratios (P/B) (0.6, 0.9, 1.2, 1.5) on the high temperature rheology and medium temperature fatigue performance of EAM was analyzed. The findings reveal that the filler content has a great influence on the proportion of viscoelastic components of EAM in the low frequency domain. The complex shear modulus (G*) and phase angle (δ) of EAM were suitable for Christensen-Anderson-Marasteanu model (CAM) model in the wide frequency domain. Increasing the filler content and Rotating Thin Film Oven Test (RTFOT) aging can improve the high-temperature stability and stress sensitivity of EAM, but it reduced its fatigue resistance. The high temperature performance of EAM containing PC and CGP exhibit superior high-temperature performance compared to LP fillers. Conversely, LP mastic demonstrate superior anti-fatigue performance under actual strain levels in both thin and thick asphalt pavement layers, surpassing the performance of PC mastic and CGP mastic. Therefore, coal gangue powder can be used as a new type of green filler to replace limestone powder. An appropriate amount of incorporation can improve the high temperature stability of the mortar and does not have a huge impact on the fatigue performance. The most suitable range of P/B is identified as 0.6–1.0 when utilizing LP as the filler, 1.2–1.5 when utilizing PC or CGP as the filler.

Similar content being viewed by others

Introduction

Asphalt pavement is the main structure type of highway pavement, which has the advantages of flat, wear resistance and good driving comfort1. In the past 30 years, 60% of the expressway asphalt pavements have reached or approached the design service life. In the face of huge highways that are close to or exceed the design life, China is facing important problems in highway reconstruction, expansion and maintenance management2. The maintenance and repair of expressway will produce a large amount of accumulation of old asphalt solid waste. If it is not reasonably utilized, it is easy to cause waste of resources and environmental pollution. The emulsified asphalt cold recycling technology is a typical sustainable pavement technology because of its energy saving and environmental protection, good technical and economic benefits, and high utilization rate of old asphalt solid waste3,4,5,6.

Asphalt mixture is a decentralized system with multi-level spatial network structure. The mastics play the role of bonding aggregate and filling voids, and is also the fundamental factor affecting the viscoelasticity of asphalt mixture. Therefore, it is of great significance to study the rheological properties of emulsified asphalt cold recycled mastics based on the perspective of mastics to improve the performance of cold recycled asphalt pavement. It is also a trend in the development of materials science. Many scholars have found that the type and content of fillers have an important influence on the properties of asphalt mastics by studying the rheological properties of asphalt mastics7,8,9,10,11. Researchers have explored various fillers, including steel slag12, fly ash13, lime kiln dust14, and granulated blast furnace slag15, to modify asphalt mastic properties. Among these, fillers like steel slag and fly ash have shown promising improvements in high-temperature rheological properties, while fillers like slaked lime enhance the elasticity and low-temperature performance of asphalt mastics. However, the most commonly used filler in asphalt mixtures is limestone powder (LP), which poses environmental concerns due to the depletion of natural resources and the environmental impact of mining16. In addition to the materials mentioned above, which can be used as substitutes for traditional limestone powder fillers, Jin et al.17,18 found that rubber powder instead of LP can improve the high temperature rutting resistance and crack resistance of asphalt mortar and mixture. Cui et al.19 studied the adhesion characteristics of asphalt and iron tailings filler, and then analyzed the fatigue performance of mortar, and found that iron tailings can replace LP. Therefore, it is of great theoretical significance and research value to study the type and content of filler to guide the composition design of asphalt mixture and improve its performance. However, at present, most asphalt roads use limestone powder as filler, which not only requires mountain excavation, consumes a large amount of natural sand and gravel materials, but also causes certain damage to the environment. Therefore, it is necessary to look for alternatives to replace these modifiers.

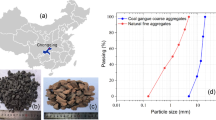

In recent years, coal gangue, a byproduct of coal mining, has attracted attention as an alternative filler for asphalt mastics20. With the rapid development of the coal industry, large quantities of coal gangue are produced, yet its utilization rate remains low, under 20%21. Coal gangue has been successfully used in various applications, including power generation, brick making, and cement production22,23. More recently, researchers have turned to coal gangue powder (CGP) as a potential green filler for asphalt mastic, providing a dual benefit of solving the disposal problem of coal gangue and reducing the need for limestone mining24. Most researchers study the rheological properties of mastics based on the perspective of mastics, and use Coal Gangue Powder (CGP) as filler in hot asphalt mastics. Xiong et al.25 demonstrated that the high-temperature performance of asphalt mastics could be significantly enhanced by using activated coal gangue powder (CGP) as a filler, with the powder-binder ratio (P/B) being the key factor influencing this improvement. Yang et al.26 found that activated CGP asphalt mastics exhibited better shear strength and high-temperature performance than those with limestone powder (LP), though the low-temperature performance remained largely unchanged. Amir et al.27 showed that CGP enhanced the mechanical properties, water stability, fatigue resistance, and tensile toughness of asphalt mixtures, while also stabilizing heavy metals in CGP, thus reducing environmental pollution. Jin et al.28 reported that a 2.28% addition of CGP significantly improved the high-temperature rheological properties, shear resistance, medium-temperature fatigue damage resistance, and low-temperature flexibility of asphalt mastics. Wang et al.29 investigated the interaction between CGP, traditional mineral powder fillers, and asphalt, revealing that CGP exhibited the strongest adsorption effect on asphalt. Finally, Zhang et al.30 prepared asphalt mastics with CGP and CGP-LP blends and found that CGP-based mastics offered the best high- and low-temperature performance, along with superior temperature sensitivity. In summary, there have been a lot of studies on CGP modified hot mix asphalt mastics and hot-mixed asphalt mixture. The literature research mainly focuses on the influence of the type of filler and the P/B on the three basic indexes, rheological properties and pavement performance of modified asphalt. However, the research on the anti fatigue damage performance of asphalt mastics, the residue formed after demulsification of emulsified asphalt used in cold regeneration technology, and the mastics system formed with CGP is not involved. EAM is more complicated due to the influence of emulsifier, stabilizer and modifier.

In the current design of emulsified asphalt cold recycled mixtures, LP is mostly used as a filler. This not only exacerbates the depletion of natural stone resources but also generates new environmental hazards associated with rock excavation. Moreover, investigations have shown that emulsified asphalt cold-recycled pavements often suffer from early damage such as rutting and fatigue cracking due to insufficient high and medium temperature performance. Therefore, improving the performance of emulsified asphalt cold-recycled pavements and finding alternative green resources to replace traditional limestone fillers have become urgent engineering challenges. Therefore, it is necessary to study the application of CGP in emulsified asphalt cold recycling technology. The need for this research can be summarized in two main points: First, CGP, as a solid waste-based material, increases the added value of coal gangue utilization in road engineering, aligning with the research direction of green and sustainable recycling of solid waste. Second, due to the complexity of emulsified asphalt, which is influenced by water, asphalt, emulsifiers, and various additives, it significantly differs from hot-mix asphalt. Research on the high and medium temperature rheological properties of coal gangue EAM lays the technical foundation for replacing traditional limestone powder with CGP. Additionally, due to its composition and physical–chemical properties (such as porous adsorption and activity), CGP can improve the characteristics of the Reclaimed Asphalt Pavement (RAP) interface, enhancing the performance of emulsified asphalt cold-recycled mixtures. This also provides a new approach and direction for the high-value utilization of coal gangue as a solid waste. Therefore, in this study, coal gangue solid waste was processed and ground into coal gangue fine powder as green filler, which was applied to EAM. The investigation employs Dynamic Shear Rheological (DSR) and Multiple Stress Creep Recovery (MSCR) tests for high-temperature performance analysis, along with Linear Amplitude Scanning (LAS) tests and the Viscoelastic Continuous Damage (VECD) model for evaluating fatigue performance. The mechanism of rheological properties of CGP modified EAM was studied by Atomic Force Microscope (AFM) and Fourier Transform Infrared spectroscopy (FTIR). Comparisons are made with EAM prepared using conventional LP and Portland cement (PC) as fillers, thus examining the feasibility of CGP’s high-value utilization in asphalt pavement engineering and offering guidance on suitable Powder-Binder ratios (P/B).

Materials

Raw materials

Asphalt

The 70# matrix asphalt used in this study was supplied by the Shandong Guangrao Petrochemical Company. All of the relevant technical indicators were tested in accordance with Standard Test Method of Bitumen and Bituminous Mixture for Highway Engineering in China (JTG E20-2011). Key performance indicators for the matrix asphalt are summarized in Table 1.

Emulsifier

For the emulsification process, a cationic slow crack cold regeneration emulsifier was chosen. The main parameters of the emulsifier were tested following JTG E20-2011. The results are shown in Table 2.

Filler

The fillers employed in the study consisted of LP, PC, and CGP. The basic properties were tested in accordance with the methods in the Testing Procedures of Aggregate for Highway Engineering in China (JTG E42-2005). The results are shown in Table 3.

Emulsified asphalt mastics preparation

Emulsified asphalt preparation

The emulsified asphalt was prepared using a German RINKMD-1 asphalt colloid mill. The preparation materials involved an emulsifier content of 3%, an asphalt content of 62%, and a configuration soap liquid pH 2.0–2.5. The preparation procedure is illustrated in Fig. 1. According to the relevant requirements in the Technical Specifications for Highway Asphalt Pavement Recycling in China (JTG/T 5521-2019), the performance indexes of emulsified asphalt were tested, and the test results are shown in Table 4.

Using JTG E20-2011, preparation of emulsified asphalt residue was prepared by direct heating method. Approximately 300 g of emulsified asphalt was placed in a heated dish and slowly heated by an electric furnace and continuously stirred until the water is completely evaporated. The emulsified asphalt residue was then prepared by maintaining the temperature of 160–166 °C for 1 min.

Preparation of emulsified asphalt residue mastics

Using JTG E20-2011, emulsified asphalt residue was heated to a constant temperature of 150 °C for 1 h. Subsequently, LP, PC, and CGP were dried to a constant weight, heated to 105 °C, and held for 30 min. The fillers were then added to the emulsified asphalt residue at different P/B (0.6, 0.9, 1.2, 1.5) while maintaining a constant temperature of 150 °C. The mixture was stirred for approximately 20 min until no bubbles were visible.

Test methods

In this section, we clarify the experimental procedures employed for evaluating the properties of EAM. The test contents include the Rotating Thin Film Oven Test (RTFOT), Temperature Scanning Test, Frequency Sweep Test, the application of the Time–Temperature Superposition Principle, Linear Amplitude Scanning Test, and Viscoelastic Continuous Damage Theory.

Test schedule

The full text of EAM is mainly divided into four parts, (1) Preparation of EAM sample; (2) Study on high temperature rheological properties; (3) Research on medium temperature fatigue damage; (4) AFM and FTIR tests were carried out for microscopic analysis. Figure 2 presents a technical flowchart of these processes.

RTFOT test

The first experimental procedure was the RTFOT. The RTFOT test was referred to as the standard specification in JTG E20-2011. The procedure was carried out by adjusting the rotating film oven to a level position. The oven was then preheated at 163 °C ± 0.5 °C for at least 16 h. Following this, the temperature controller was adjusted and the sample bottles were placed within the annular metal frame. Afterwards, adjust the temperature of the oven to 163 °C ± 0.5 °C within 10 min. The samples were maintained at this temperature for 75 min. Stopping the rotation and heating of the oven when the time was reached. Removed all sample bottles and poured each sample into a clean container for subsequent tests.

Temperature scanning test

The viscoelastic properties of EAM at different temperatures were investigated by using the temperature scanning function of DSR. The Temperature Scanning test was referred to as the standard specification in ASTM D7175—201531. Strain control mode was selected for temperature scanning test. The temperature scanning test was conducted in the strain control mode with a maximum strain set at 12%, a frequency of 12 rad/s, and a temperature range spanning from 58 °C to 84 °C. A parallel plate fixture with a spacing of 1 mm and a diameter of 25 mm32. Five parallel samples were applied for each sample type.

Frequency sweep test

The application of the Time–Temperature Superposition Principle was based on the Williams-Landel-Ferry (WLF) equation33,34, which is derived from the free volume theory. The temperature shift factor can be calculated using Eq. (1).

where \(\text{lg} \alpha_{T}\) represents the temperature shift factor; represents the testing temperature; represents the reference temperature; and represent the fitting parameters of WLF equation.

The viscoelastic properties of EAM were studied by using the complex modulus and phase angle master curve, which can be expressed by Christensen-Anderson-Marasteanu model (CAM) model. The master curve expressions of complex shear modulus (G*) and phase angle (\(\delta\)) in the CAM model35 are shown in Eqs. (2–4).

where G* (Pa) represents the corresponding complex modulus at frequency \(f^{\prime}\); \(f^{\prime}\) (Hz) represents conversion frequency; \(G_{g}^{*}\) (Pa) represents the glass complex modulus when the load frequency tends to infinity; \(G_{g}^{*}\) represents platform modulus when load frequency tends to 0, for asphalt binders \(G_{e}^{*} = 0\); \(f_{c}\) (Hz) represents the crossover frequency; \(k,\, m_{e},\, R_{d},\, m_{d}\) represent the model parameter; \(\delta\) (°) represents the corresponding phase angle at frequency \(f^{\prime}\); \(\delta_{m}\) represents the maximum phase angle of asphalt and asphalt mixture; \(f_{d}\) represents the corresponding frequency when the phase angle reaches the maximum value; I represents the indicator factor for asphalt binder type material(when \(f^{\prime}\) > \(f_{d}\) , \(I = 0\); when \(f^{\prime}\) < \(f_{d}\), \(I = 1\)).

The Frequency Sweep Test was carried out to assess the response of the EAM under varying frequencies. The Frequency Sweep Test was referred to as the standard specification in ASTM D7175—201531. At a fixed strain of 0.1%, the test was conducted within a temperature range of 20 °C to 60 °C with a gradient of 10 °C. At 20 °C and 30 °C, an 8 mm parallel plate fixture was utilized with a gap of 2 mm. At 40 °C, 50 °C and 60 °C, a 25 mm parallel plate fixture was chosen, with a gap of 1 mm. The loading frequency range was 0.1–10 Hz36. Five parallel samples were applied for each sample type.

Multiple stress creep recovery test

The high temperature performance of EAM was evaluated by the employment of MSCR test. The effects of filler types and P/B on the high temperature performance of EAM were investigated by the indexes of irrecoverable creep compliance Jnr and load sensitivity Jnr-diff37. The calculation formulas are shown in Eqs. (5–6).

where \(y_{c}\) represents the residual strain; \(\tau\) represents the creep stress.

The MSCR test was referred to as the standard specification in AASHTO MP19-1038. Continuous creep tests of EAM under two creep stress levels: 0.1 kPa and 3.2 kPa, were carried out. The test temperature was 64 °C, and the total test time was 200 s39. Five parallel samples were applied for each sample type.

Linear amplitude scanning test

Results from the LAS were processed by the viscoelastic continuous damage (VECD) model; this has been increasingly applied in the prediction of asphalt fatigue performance. Based on the theory of VECD40, the data obtained from the linear amplitude scanning test are processed. Fatigue performance indexes of EAM can be calculated according to Eqs. (7–14).

(1) Calculate the parameter \(\alpha\):

(2) Calculate the cumulative damage of EAM \(D\left( t \right)\):

where \(t\) represents the testing time; \(t_{i}\) represents the time of current test step; \(t_{{i{ - }1}}\) represents the time of the previous test step; \(N\) represents the total test step; \(\left| {G^{*} } \right|\) represents the complex shear modulus; \(\delta\) represents the phase angle; \(I_{D}\) represents the initial value of \(\left| {G^{*} } \right|\) at 1% strain; represents the strain amplitude.

(3) The model parameters \(C_{1}\) and \(C_{2}\):

To obtain the relationship between fatigue life and load amplitude of asphalt and asphalt mixture, developing a fitting model to establish the relationship between material properties and damage is essential. For EAM, the parameter G* was selected as the representative material property. The fitting model is shown in Eq. (11).

where \(C_{0}\) represents the average value of G* at 0.1% strain level; \(C_{1}\) and \(C_{2}\) represents the model coefficients.

(4) Calculate the fatigue life \(N_{f}\) of EAM:

The research found that when the fatigue life is reduced by 35%, the life value predicted by LAS test has the best correlation with the fatigue life. Consequently, the 35% reduction of \(\left| {G^{*} } \right|\sin \delta\) is selected as the criterion for judging the fatigue failure in EAM. The relationship between the number of failure cycles \(N_{f}\) and the estimated peak strain \({\upgamma }_{\max }\) of the mastics material is shown in Eqs. (12–14).

where \(k = 1 + \left( {1 - C_{2} } \right)\alpha\), \(B = 2\alpha\).

The LAS test was referred to as the standard specification in AASHTO TP101-1241. Prior to conducting the experiment, it was essential to ensure that the linear viscoelastic range was established. The frequency scanning tests were carried out across a range of 0.2–30 Hz, with a material strain level of 0.1%, to obtain the characteristic of the material without damage. The amplitude scanning test was then carried out in the linear amplitude range of 0.1%–30%, employing a consistent frequency of 10 Hz under the strain control mode. The test temperature maintaining during this study was 25 °C42,43. Five parallel samples were applied for each sample type.

Fourier transform infrared spectroscopy (FTIR) test

The effects of short-term aging process and different fillers on the chemical structure of EAM were analyzed by FTIR test. The scanning speed is 40 times/s, the resolution is 0.09 cm−1, and the scanning range is 4000–600 cm−1. Emulsified asphalt residue and residue mastics samples were prepared by liquid film method. When preparing the sample, 1 mg residue or glue sample is weighed with a precision balance. Drop 10 mL of CCl4 into the test tube. The sample is placed in CCl4 solvent until it is fully dissolved. The sample solution was evenly dropped on the dry KBr material window several times and evaporated under an infrared lamp until the CCl4 solvent evaporated completely.

Results and discussion

High temperature performance analysis

Frequency sweep test

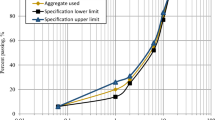

40 °C was selected as the reference temperature of frequency sweep test. The displacement factor was derived using the WLF Eq. (1), and the CAM model was employed for data fitting. The primary curves of complex shear modulus (G*) and phase angle (\(\delta\)) of EAM were generated, which is as shown in Fig. 3.

From Fig. 3, the fitting of the primary curve demonstrates good alignment with the scatter points of G* and \(\delta\). It shows that the G* and \(\delta\) of EAM are well-suited for CAM model across a broad frequency range. From the low frequency region to the high frequency region, the G* gradually increases and \(\delta\) gradually decreases, this phenomenon suggests that EAM exhibits greater elastic behavior at higher frequencies, whereas more viscous behavior is observed at lower frequencies, this is consistent with the results of Jin et al.44. With the increase of the P/B, the G* master curve of EAM gradually moves upward. The addition of fillers and the increase of content can improve the high temperature performance of EAM, which may be attributed to the fact that the addition of filler will adsorb emulsified asphalt molecules, reduce the number of free asphalt, increase the flow resistance of EAM, so that the high temperature flow deformation resistance of EAM is significantly improved. The \(\delta\) decreases significantly in the low frequency domain and does not change significantly in the high frequency domain. The filler content has a great influence on the proportion of viscoelastic components of EAM in the low frequency domain. This result occurs due to the fact that the asphalt in the mastic has a large viscoelastic energy at high and low frequencies, making it impossible for the filler in the asphalt mastic to achieve an increase in elasticity, which results in a smaller difference between the main curves of the phase angle of the asphalt mastics45.

Multiple stress creep recovery test

The MSCR test curve of EAM with different filler types at 64 °C is drawn as shown in Figs. 4, 5, 6.

Figures 4, 5, 6 reflect the change of cumulative strain of EAM over time. The interval of 0–100 s corresponds to mastics loading and creep recovery under the stress level of 0.1 kPa. while 100 s–200 s corresponds to mastics loading and creep recovery under the stress level of 3.2 kPa. It can be seen that the cumulative strain of EAM increases over time. This shows that the vehicle load affects the deformation of the road surface, and the heavier the vehicle, the deeper the deformation. RTFOT aging substantially reduces the cumulative strain of EAM. Incorporating fillers and elevating P/B values lead to decreased cumulative strain. It shows that RTFOT aging and the increase of filler content will significantly improve the anti-deformation ability of EAM.

The results of irrecoverable creep compliance (Jnr) of EAM before and after RTFOT aging are shown in Figs. 7 and 8.

From Figs. 7 and 8, RTFOT aging will lead to a significant decrease in Jnr of EAM. The increase of temperature and load will increase Jnr. It shows that short-term aging will improve the high temperature performance of EAM, while high temperature and heavy load will reduce the permanent deformation resistance of EAM. This result occurs due to the temperature increases, the light components in the asphalt are partially volatilized, the small molecular chains are cracked, the macromolecular groups are destroyed to varying degrees, the mobile phase is reduced, the viscous components are increased, and the elasticity is deteriorated46. The increase of filler content will lead to the decrease of Jnr and the increase of elastic response of EAM. The strengthening effect of the filler in the EAM system leads to the improvement of its high temperature rheological properties47.

Before and after RTFOT aging, under the same P/B, the order of EAM is: PC mastic < CGP mastic < LP mastic. It shows that the high temperature performance of PC mastic and CGP mastic is significantly better than that of LP mastic. The cement mastics has the best high temperature stability, which may be because the cement hydration rate is faster, and more hydration products are produced, so that the elastic components of the mastics are increased, so it has better high temperature performance at the macro level. After RTFOT aging, under the low P/B, the difference of Jnr between CGP mastic and PC mastic is not obvious. Appropriate amount of CGP mastic as filler can effectively improve the anti-deformation ability of EAM after RTFOT aging. This shows that after RTFOT aging heat treatment, CGP as a filler instead of LP can make a great contribution to improving the high temperature rutting resistance of EAM, this is similar to the results of Li et al.48.

The change rate of irrecoverable creep compliance difference (Jnr-diff) can be used to characterize the stress sensitivity of EAM materials31. The Jnr-diff of EAM before and after RTFOT aging are shown in Fig. 9.

From Fig. 9, the Jnr-diff of emulsified asphalt residue increases to varying degrees after adding filler. Under the same filler, the larger the P/B, the larger the Jnr-diff. After RTFOT aging, the Jnr-diff of each group of EAM increased to varying degrees, especially in the case of high P/B. It shows that short-term aging and the increase of filler content will significantly enhance the stress sensitivity of EAM. Before RTFOT aging, the order of Jnr-diff of EAM with different fillers is CGP mastic > PC mastic > LP mastic. After aging, Jnr-diff is ranked as PC mastic > CGP mastic > LP mastic. Before and after aging, the stress sensitivity of CGP mastic and PC mastic is greater than that of LP mastic, which may be attributed to the fact that the LP mastic system is closer to the elastomer. The increase of the LP particles makes the mastics bear more load, has low sensitivity to stress changes, and also makes the service life of the asphalt pavement longer. PC mastic shows high stress sensitivity at high P/B, while coal gangue shows the opposite. The stress sensitivity of PC mastic is more affected by the short-term aging process than that of CGP mastic.

A Bruker atomic force microscope (AFM) has been widely applied to study the surface morphology of asphalt microscopic characteristics. To determine the influence of the filler types on the high temperature creep behavior, the surface morphology of three types of mastics with the F-B of 0.9 (LF-0.9, PC-0.9, CG-0.9) was examined using AFM (Fig. 10).

The atomic force microscopy surface topography of the three EAM at a P/B of 0.9 is shown in Fig. 10, where the black and white area is called the typical bee-type structure. The formation of bee-type structure on the surface of EAM is mainly due to the mutual adsorption of the wax crystal and polar fractions in asphalt. The more the number of bee-type structures and the larger the proportion area, the stronger the interaction between filler and asphalt29. Under the same P/B, the number and area ratio of bee-type structures are ranked as follows: CGP mastic > PC mastic > LP mastic. Among them, the number and area of CGP account for the largest proportion, indicating that CGP has a stronger interaction with emulsified asphalt.

High-temperature performance classification was carried out by MSCR test. The requirements of AASHTO MP19-10 high-temperature performance classification for MSCR test indexes are shown in Table 5.

According to the requirements of the classification index in Table 5, the MSCR of EAM before and after RTFOT aging at 64 °C and 70 °C was classified at high temperature. The results are shown in Tables 6, 7.

From Tables 6 and 7, short-term aging and the increase of filler content will improve the applicable traffic grade of EAM. However, the increase of temperature will lead to the decrease of traffic level. This is because the increase of temperature will lead to the increase of stress sensitivity of EAM, which is easy to cause one-time heavy load damage to the road surface. Under the same conditions, the traffic suitability grade of PC mastic and CGP mastic is greater than that of LP mastic.

Medium temperature fatigue resistance performance analysis

Linear amplitude scanning test

Based on the VECD theory, the LAS test results of EAM are analyzed, and the fitting parameters are shown in Tables 8 and 9.

The damage curve of EAM under LAS test is shown in Fig. 11.

Fatigue damage curves are an important part of fatigue performance. From Fig. 11, under the same P/B, the aging curves of the three EAM are higher than the unaged curves. With the increase of cumulative damage, shows a trend of first fast and then slow, and finally tends to be gentle. The slope of the curve represents the damage rate of the material. The greater the slope of the curve, the faster the material damage rate. It shows that with the increase of filler content, the slope of the curve increases, the damage speed of the mastics increases, and the corresponding fatigue life decreases. RTFOT aging can significantly accelerate the damage rate of EAM and reduce its fatigue resistance.

Fatigue parameter analysis

Figures 12 and 13 show the fatigue parameters A and B of VECD of EAM with different fillers, respectively. Parameter A represents the materials ability to keep its integrity during loading cycles and due to accumulated damage. This parameter is directly related to the storage modulus. The sensitivity of the asphalt binder to strain level change is described by parameter B. In general, more fatigue resistant binders tend to have higher A values and lower absolute B values49,50.

From Figs. 12 and 13, the increase of the P/B will significantly reduce the fatigue parameters A and B of EAM. With the increase of filler content, the ability of mastics to maintain integrity gradually decreases, and the attenuation ratio gradually decreases. It shows that the increase of filler content may reduce the anti-fatigue damage ability of EAM. This result occurs due to the increase of filler particles, the filler has a hardening effect on the asphalt phase in the mastics, resulting in a higher stress sensitivity of the mastics, which leads to the decay of the fatigue performance of the mastics. RTFOT aging will significantly reduce the fatigue parameter A of the mastics, but will increase the fatigue parameter B, indicating that, after RTFOT ageing, these mastics were more susceptible to fatigue resistance and exhibited worse fatigue performance, this is similar to the results of Xing et al.51. This observation can be explained by the fact that ageing effects can cause bitumen-filler interactions to deteriorate, which further increases the stiffness modulus.

Under the same P/B, the fatigue parameter A of LP mastic is significantly higher than that of PC mastic and CGP mastic, indicating that the fatigue resistance of LP mastic is higher than that of PC mastic and CGP mastic. And with the increase of P/B, the ability of EAM to resist deformation decreases significantly, but the rate of reduction of three mastics with is different. The fatigue parameters A of LP mastic show a trend of slow first and then fast, and decrease significantly when the P/B is 0.9 to 1.2. However, PC mastic and CGP mastic decreased significantly when the P/B is 0.6 to 0.9. However, in practice, asphalt mastics are required to have a low fatigue life decay rate. This phenomenon is due to the fact that the filler increases the stiffness of the mastics, resulting in partial attenuation of fatigue resistance. Therefore, when LP is selected as the filler, the range of P/B should be avoided to 0.9–1.2. When PC and CGP are selected as fillers, the range of P/B should be avoided to 0.6–0.9.

Fatigue life analysis

The fatigue life of EAM before and after RTFOT aging at 2.5% and 5% strain levels is shown in Figs. 14 and 15.

From Figs. 14 and 15, the increase of filler will lead to a significant decrease in the fatigue life of EAM. Some filler particles are not completely wrapped by asphalt, and cannot form a continuous asphalt structure layer; this makes the mastics more brittle, accelerates the damage rate and reduces the fatigue life, this is similar to the results of Xu et al. and Akbari et al.52,53. It may also be due to the increase of filler content, more contact between filler particles occurs, resulting in higher stiffness of the mastics54. By analyzing the change trend of fatigue life of EAM, it can be found that the decline trend of fatigue life of EAM with three kinds of fillers is different. For example, under the condition of 2.5% strain level and before RTFOT aging, compared to 0.6 P/B, the reduction rates of fatigue life of LP mastic under 0.9, 1.2 and 1.5 P/B are 12.7%, 56.7% and 6.0%, respectively. The fatigue life reduction rates of PC mastic are 66.1%, 16.3%, 37.0%, and the fatigue life reduction rates of CGP mastic are 50.8%, 21.1%, 8.2%. The downward trend of fatigue life is consistent with the results of fatigue parameters above. The PC mastic shows a trend of slow first and then fast, and the fatigue life decreases significantly when the P/B is 0.9–1.2. However, the fatigue life of PC mastic and CGP mastic shows a trend of fast first and then slow, and the fatigue life decreases greatly when the P/B is 0.6–0.9. It shows that LP mastic is suitable for low P/B, while PC mastic and CGP mastic are more suitable for high P/B.

After RTFOT aging, the fatigue life of EAM decreased significantly. When the stress level is 5%, before and after aging, LP-0.6 and LP-1.5 decreased by 28.22% and 55.65% respectively; PC-0.6 and PC-1.5 decreased by 22.89% and 44.18% respectively; CGP-0.6 and CGP-1.5 decreased by 47.74% and 40.43% respectively. It shows that short-term aging has a more obvious effect on LP and PC mastic with high P/B, while the effect on coal gangue mastics with different P/B is similar. Under the actual strain level of thin and thick layers of asphalt pavement, the fatigue resistance of LP mastic is obviously better than that of PC mastic and CGP mastic. When using low P/B, the construction quality should be strictly controlled to avoid short-term aging. Therefore, combined with the fatigue life change trend and size comparison of three different filler EAM, when only the anti-fatigue performance of EAM is considered. When LP is selected as the filler, the range of P/B should be 0.6–0.9. When PC is selected as the filler, the range of P/B should be 0.9–1.2. When the CGP is selected as the filler, the range of P/B should be 1.2–1.5.

Medium temperature fatigue resistance performance analysis

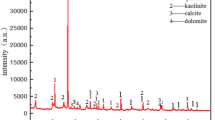

To investigate the effect of RTFOT aging and filler type on the chemical composition of EAM, FTIR tests were conducted on emulsified asphalt evaporation residue mastics both before and after RTFOT aging, as well as on LP mastic, PC mastic, and CGP mastic at 0.9P/B. Figure 16 shows the test results of the emulsified asphalt evaporation residue mastics before and after RTFOT aging.

From Fig. 16, comparing with the emulsified asphalt evaporation residue, the EAM after RTOFT aging does not produce new characteristic peaks, indicating that RTFOT aging does not produce new products. There are two strong absorption peaks at 2910 cm−1 and 2850 cm−1 in the first peak region, which are caused by the symmetric and antisymmetric stretching vibration of bond (C–H). The 1600 cm−1 peak in the second peak region is caused by the stretching vibration of the aromatic conjugated double bond (C=C). The peaks at 1455 cm−1 and 1375 cm−1 in the third peak region correspond to the in-plane bending vibrations of (–CH2–) and (–CH3) bonds on alkanes, respectively. In addition, the peak at 1030 cm−1 indicates that there is a stretching vibration of sulfoxide group (S=O) in the molecular component of emulsified asphalt evaporation residue55.

Figure 17 shows the FTIR spectra of three different fillers and EAM under 0.9 P/B.

From Fig. 17, Comparing these spectra with those of EAM, there were no notable new absorption peaks observed in LP mastic and PC mastic. This suggests that no chemical reaction occurs between LP fillers and emulsified asphalt upon contact. However, CGP mastic exhibited an enhanced absorption peak at 1030 cm−1 due to the high SiO2 content in CGP mastic, resulting in a stretching vibration absorption peak of the (Si–O) bond. Additionally, a weak absorption peak at 3600 cm−1 was observed in CGP mastic, indicating the presence of (O–H) bonds due to the interaction between CGP mastic and emulsified asphalt55. The order of absorption peak intensity was as follows: residue mastics > LP mastic > CGP mastic > PC mastic. This suggests that CGP and PC absorb more light components upon contact with emulsified asphalt than LP. Consequently, the content of resin and asphaltene in emulsified asphalt increases, leading to improved viscosity and enhanced high-temperature performance and temperature sensitivity.

Conclusions

This study explored the effects of three fillers (LP, PC, CGP) and four P/B ratios (0.6, 0.9, 1.2, 1.5) on the rheological properties of EAM at medium and high temperatures, along with their high-temperature stability and fatigue resistance under short-term aging. Key findings include:

-

(1)

CGP and PC mastics demonstrated superior high-temperature rheological properties compared to LP mastics. Higher filler content enhanced high-temperature stability but increased stress sensitivity, significantly affecting the viscoelastic composition in the low-frequency domain.

-

(2)

LP mastics exhibited better fatigue resistance than CGP and PC mastics. Short-term aging and higher filler content reduced deformation resistance, exacerbated stress sensitivity, and shortened fatigue life, with a pronounced impact on LP and PC mastics with high P/B ratios.

-

(3)

AFM and FTIR results indicated that CGP mastics had the highest number and area ratio of bee-type structures and absorbed more light components, enhancing viscosity, high-temperature performance, and temperature sensitivity.

-

(4)

For LP fillers, the optimal P/B range was 0.6–1.0, while for PC and CGP fillers, 1.2–1.5 was ideal CGP, being a low-carbon, environmentally friendly material, is a promising alternative to LP for sustainable and high-value asphalt pavement engineering.

In summary, this research deepens our understanding of EAM, emphasizing the sustainable application of coal gangue. Future studies should explore low-temperature performance, practical implementation in highway projects, composite filler improvements, and interaction mechanisms.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Ma, T. et al. Development of emulsified asphalt and foamed asphalt cold recycling technology. J. Traffic Transport. Eng. 23(02), 1–23 (2023).

Lyu, S. T. et al. Review on long-life-oriented life extension design of existing expressway asphalt pavement. J. Traffic Transport. Eng. 24(02), 20–49 (2024).

Xiao, F. et al. A literature review on cold recycling technology of asphalt pavement. Constr. Build. Mater. 180, 579–604 (2018).

Gu, F. et al. Structural performance and sustainability assessment of cold central-plant and in-place recycled asphalt pavements: A case study. J. Clean. Prod. 208, 1513–1523 (2019).

Li, D. et al. Literature overview of Chinese research in the field of better coal utilization. J. Clean. Prod. 185, 959–980 (2018).

Rodriguez-Fernandez, I., Lastra-Gonzalez, P., Indacoechea-Vega, I. & Castro-Fresno, D. Recyclability potential of asphalt mixes containing reclaimed asphalt pavement and industrial by-products. Constr. Build. Mater. 195, 148–155 (2019).

Zhu, H. Z., Fang, S. P. & Lu, T. Z. Fatigue evolution law of asphalt under constant strain based on DSR time-sweep. J. Chongqing Jiaotong Univ. (Nat. Sci.) 37(02), 29–34 (2018).

Dong, S. et al. Quantitative assessment and mechanism analysis of modification approaches for cold recycled mixtures with asphalt emulsion. J. Clean. Prod. 323, 129163 (2021).

Gong, Y. F., Wu, S. Z., Zhang, Y. W., Pang, Y. Z. & Ma, Y. L. Investigation of the high-temperature and rheological properties for asphalt sealant modified by SBS and rubber crumb. Polymers 14(13), 2558 (2022).

Ma, F. et al. Evaluation of high temperature rheological performance of poly phosphoric acid-SBS and polyphosphoric acid-crumb rubber modified asphalt. Constr. Build. Mater. 306, 124926 (2021).

Huang, L., Geng, J. G., Chen, M. Y. & Niu, Y. H. Investigation into the rheological properties and microstructure of silt/crumb rubber compound-modified asphalt. Polymers 15(11), 2747 (2023).

Li, C. et al. Effects of steel slag fillers on the rheological properties of asphalt mastic. Constr. Build. Mater. 145, 383–391 (2017).

Li, Z. et al. Effect of replacement of limestone mineral powder with fly ash and direct coal liquefaction residue on the rheological properties of asphalt mastic. Constr. Build. Mater. 412, 134803 (2024).

Kumlai, S., Jitsangiam, P. & Nikraz, H. Assessments of moisture damage resistance of asphalt concrete mixtures and asphalt mastic with various mineral fillers. Transport. Eng. 7, 100106 (2022).

Feng, X. J., Peng, Q. & Zhang, Q. Road performance and microscopic mechanism of granulated blast furnace slag powder asphalt mastics. J. Chang’an Univ. (Nat. Sci. Ed.) 42(04), 20–29 (2022).

Ma, X. Y. et al. Prediction of fatigue life of asphalt mastics based on improved S-VECD model. J. Chang’an Univ. (Nat. Sci. Ed.) 39(04), 35–43 (2019).

Jin, D. et al. Performance of rubber modified asphalt mixture with tire-derived aggregate subgrade. Constr. Build. Mater. 449, 138261 (2024).

Jin, D. et al. Resurface of rubber modified asphalt mixture with stress absorbing membrane interlayer: From laboratory to field application. Constr. Build. Mater. 441, 137452 (2024).

Cui, Y. et al. Iron tailings as mineral fillers and their effect on the fatigue performance of asphalt mastic. Materials 17(12), 2927 (2024).

Liu, S. et al. Performance enhancement of modified asphalt via coal gangue with microstructure control. Constr. Build. Mater. 367, 130287 (2023).

Yaofei, L., Xingchen, Z. & Ke, Z. Coal gangue in asphalt pavement: a review of applications and performance influence. Case Stud. Constr. Mater. 20, e03282 (2024).

Li, Z. X., Guo, T. T., Chen, Y. Z. et al. Road performance analysis of cement stabilized coal gangue mixture. Mater. Res. Express 8(12) (2021).

Zou, G. L., Yuan, Y. & Zhang, X. N. Effect of fillers on the pavement performance of asphalt binder. J. South China Univ. Technol. (Nat. Sci. Ed.) 33(1), 52–56 (2015).

Amir, M. & Morteza, R. Application of coal waste powder as filler in hot mix asphalt. Constr. Build. Mater. 66, 476–483 (2014).

Xiong, R. et al. Influence factors of high temperature performance of activated coal gangue modified asphalt binder. J. Chongqing Jiaotong Univ. (Nat. Sci.) 34(5), 44–48 (2015).

Yang, X. K. et al. Laboratory investigation upon the rheological property of activated coal gangue-modified asphalt binder. Mater. Rev. 29(6), 135–139 (2015).

Amir, M., Morteza, R. & Pooyan, A. Effect of coal waste powder in hot mix asphalt compared to conventional fillers: mix mechanical properties and environmental impacts. J. Clean. Prod. 11(78), 1–7 (2014).

Jin, J. et al. Interaction characteristics of activated coal gangue synergistic crumb rubber powder modified asphalt. China J. Highw. Transport 36(12), 155–170 (2023).

Wang, Z. C. et al. Study on interaction evaluation between TPU modified asphalt and coal gangue based on palierne model. Mater. Rep. 36(S2), 245–251 (2022).

Zhang, Y. J. et al. Experimental on road performance of coal gangue powder asphalt concrete. J. Chang’an Univ. (Nat. Sci. Ed.) 42(05), 33–42 (2022).

ASTIM D4402M-2015. Standard test method for determining the rheological properties of asphalt binder using a dynamic shear rheometer (ASTM, 2015).

Gao, Y. et al. Interaction, rheological and physicochemical properties of emulsified asphalt binders with direct coal liquefaction residue based geopolymers. Constr. Build. Mater. 384, 131444 (2023).

Chen, J., Yan, K. & You, L. Rheological and spectroscopic properties of ethylene vinyl acetate–modified rubberized asphalt. J. Mater. Civ. Eng. 32(6), 04020142 (2020).

Bao, D. X. et al. Effect of graphene on anti-aging properties of rubber modified asphalt. J. Build. Mater. 23(05), 1113–1120 (2020).

Tang, C. et al. Two-stage method for developing mechanical behavior master curve of asphalt base materials. J. Build. Mater. 25(09), 938–944 (2022).

Wang, Q. et al. Research on high-temperature rheological properties of emulsified asphalt mastics and their influencing factors. Coatings 12(5), 635 (2022).

Sun, Y. et al. Approach for accurately characterizing nonlinear viscoelastic and nonrecoverable properties of asphalt binders based on MSCR test. Constr. Build. Mater. 403, 133098 (2023).

American Association of State Highway and Transportation Officials (AASHTO). Standard specification for performance-graded asphalt binder using multiple stress creep recovery (MSCR) test. AASHTO MP19-10 (AASHTO, 2010).

Jafari, M., Babazadeh, A. & Shahri, M. The role of stress sensitivity of modified binders with the same linear viscoelastic properties in evaluating rutting resistance of asphalt mixtures. Int. J. Pavement Eng. 24(2), 2027417 (2023).

Motamedi, M., Shafabakhsh, G. & Azadi, M. Evaluating fatigue-damage of asphalt binder and mastic modified with nano-silica and synthesized polyurethane using VECD method. J. Mater. Civ. Eng. 32(8), 04020218 (2020).

American Association of State Highway and Transportation Officials (AASHTO). Standard method of test for estimating fatigue resistance of asphalt binders using the linear amplitude sweep. AASHTO TP101-12 (AASHTO, 2018).

Sabouri, M., Mirzaiyan, D. & Moniri, A. Effectiveness of Linear Amplitude Sweep (LAS) asphalt binder test in predicting asphalt mixtures fatigue performance. Constr. Build. Mater. 171, 281–290 (2018).

Ishaq, M. A. & Giustozzi, F. Correlation between rheological fatigue tests on bitumen and various cracking tests on asphalt mixtures. Materials 14(24), 7839 (2021).

Jin, D. et al. Laboratory performance and field demonstration of asphalt overlay with recycled rubber and tire fabric fiber. Constr. Build. Mater. 438, 136941 (2024).

Ma, X. J. Effect of Aging and Recycling on the Performance of Asphalt and Asphalt Mixtures (Chang’an University, 2023).

Jin, D. et al. Waste cathode-ray-tube glass powder modified asphalt materials: Preparation and characterization. J. Clean. Prod. 314, 127949 (2021).

Li, S., Shi, X. X., Si, C. D. et al. Evaluation of high-temperature rheological properties of asphalt mastic and its filler stiffening effect. J. Jilin Univ. (Eng. Technol. Ed.), 1–11 (2023).

Li, F., Zhao, X. & Zhang, X. Utilizing original and activated coal gangue wastes as alternative mineral fillers in asphalt binder: Perspectives of rheological properties and asphalt-filler interaction ability. Constr. Build. Mater. 365, 130069 (2023).

Ameri, M. et al. A study on fatigue modeling of hot mix asphalt mixtures based on the viscoelastic continuum damage properties of asphalt binder. Constr. Build. Mater. 106, 243–252 (2016).

Wang, R. R. et al. Investigating the differences between steel slag and natural limestone in asphalt mixes in terms of microscopic mechanism, fatigue behavior and microwave-induced healing performance. Constr. Build. Mater. 328, 127107 (2022).

Xing, B. et al. Effects of filler particle size and ageing on the fatigue behaviour of bituminous mastics. Constr. Build. Mater. 230, 117052 (2020).

Xu, J. et al. Experimental characterization of the compatibility between bitumen and fillers from a perspective of bitumen components and filler characteristics. Mater. Struct. 56(7), 116 (2023).

Akbari, A. et al. Investigating the influence of aging and filler type on the fatigue behavior of bitumen mastics. Constr. Build. Mater. 269, 121254 (2021).

Micaelo, R. et al. Study of the effect of filler on the fatigue behaviour of bitumen-filler mastics under DSR testing. Constr. Build. Mater. 155, 228–238 (2017).

Feng, X. J., Zhao, M. L., Chen, W. & Xie, M. W. Research of road performances and microcosmic mechanisms of coal waste powder asphalt mastics. J. Build. Mater. 22(1), 113–119 (2019).

Acknowledgements

This study was supported by the Key Research and Development Project of Henan Province: [Grant Number 222102320407], Key Scientific Research Projects of Higher Education Institutions in Henan Province under Grant 25A580003 and 25A580005, Zhengzhou Science and Technology Collaborative Innovation Project: [Grant Number 2021-212-15 and 2023XTCX024], the Research and Development Project of China Construction Seventh Engineering Division. Co. Ltd.: [Grant Number CSCEC7b-2021-Z-20]. The authors would like to express their sincere appreciation to the aforementioned organizations.

Author information

Authors and Affiliations

Contributions

Wang D C. and Wei J W. wrote the main manuscript text. Wei J W. developed the theory and performed the computations. Cheng K. and Yang L. prepared Figs. 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16. Hu L. analyzed the results. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, D., Wei, J., Wu, Z. et al. The high value utilization characteristics of coal gangue powder with emulsified asphalt mastic through rheological and viscoelastic damage theory. Sci Rep 15, 973 (2025). https://doi.org/10.1038/s41598-025-85377-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-85377-5