Abstract

Removal of accumulated dyes from the environment water bodies is essential to prevent further harm to humans. The development and design of new alternative nanoadsorbents that can conveniently, quickly, and efficiently improve the adsorption and removal efficiency of dyes from wastewater remains a huge challenge. An amorphous TiO2 with a magnetic core-shell-shell structure (Fe3O4@PDA@a-TiO2, denoted as FPaT) was constructed through a series of steps. The studies on the formation mechanism of FPaT indicated that the reaction temperature was the most important parameter affecting crystal structure. To analyze the magnetic properties of the core, the amorphous structure of the shell, and the surface properties (size and morphology, elemental composition, functional groups, crystal structure, magnetic properties, etc.) of FPaT, various analytical techniques including scanning electronic microscopy (SEM), transmission electron microscopy (TEM), Fourier transform infrared spectroscopy (FT-IR), X-ray diffraction (XRD) and vibrating sample magnetometer (VSM) were utilized to characterize it. Based on the unique physicochemical properties of its surface, the FPaT was applied to highly adsorb methylene blue (MB) from simulated wastewater. Furthermore, batch adsorption experiments towards MB were performed to assess the high adsorption ability and reusability of the prepared FPaT. Using 4.5 mg of FPaT to adsorb MB solution with an initial concentration of 10 mg/L (pH = 8.2), 97% adsorption rate was achieved within 30 min. Compared with the previously reported values of other absorbent materials, the maximum adsorption capacity (313.7 mg/g) is much higher. The equilibrium adsorptions and the adsorption kinetic data were better depicted by the Langmuir isothermal adsorption model (R2 = 0.943) and by a second-order kinetic model (R2 = 0.999), respectively. In conclusion, this work indicates that FPaT, as a novel adsorbent, has good application prospects for removing MB from actual dye wastewater.

Similar content being viewed by others

Introduction

With the rapid development of industrialization and global urbanization, the use of dyes has become essential in diverse industries such as papermaking, printing and dyeing, and electroplating. In particular, as one of the most conventional pollutants in wastewater, organic dyes are regarded as toxic and highly dangerous components, which even in little quantities compromise the quality of water bodies1,2. Among of them, methylene blue (MB) is a typical water-soluble cationic contaminant and exhibits carcinogenic aromatic amines that is difficult to decompose. If it enters aquatic environments, which will pose a threat to the health of humans or other organisms through the food chain3. Moreover, MB not only affects the appearance of the water body, but also impedes sunlight penetration and weakens the photosynthesis of aquatic organisms, ultimately hindering the growth animals and plants4. Therefore, the low-cost removal of MB dyestuff has garnered significant attention in wastewater treatment5.

Some wastewater treatment processes have been used to deal with the organic dyes in wastewater thus far, such as membrane separation6, adsorption7, biodegradation8 and advanced oxidation9,10. Adsorption is regarded as a alternative method among these processes for removing organic dyes from wastewater with ease of operation, low cost, greenness and efficiency11,12. Magnetic nanomaterials have attracted much attention in the field of pollutants adsorption because they can be easily separated and recycled from solution13,14,15,16,17. Numerous magnetic adsorbents have been shown to have good adsorption and removal properties for dyes in water, such as magnetic metal-organic frameworks (MIL-100(Fe), Fe3O4@UiO-66 and MIL-101(Fe))18,19,20, magnetic metal oxides Fe3O4/CeO2 and Fe3O4@TiO221,22 and magnetic biochar (MBC)23. However, there are still many drawbacks that need to be overcome. For instance, some adsorbents are suffering from low efficiency. Additionally, expensive and hazardous reagents may be necessary, and toxic by-products can result in secondary pollution. Hence, developing a good adsorption performance, environmentally friendly magnetic nanoadsorbent alternative materials with a straightforward synthesis process is imperative.

Under alkaline conditions, polydopamine (PDA) can be easily formed by self-polymerization of dopamine hydrochloride (DA), containing abundant noncovalent functional groups such as amino groups and catechol, as well as π-π bonds. It is widely known that PDA establish multiple interaction with organic contaminants and their surfaces are readily modified24. Accordingly, the PDA coating compound have arouse great interest among researchers in the field of environmental remediation25,26,27.

Titanium dioxide (TiO2), a typical metal oxide with stability, low toxicity, and high catalytic activity28,29,30,31,32, has been widely used for removing organic dyes from water through photocatalytic degradation. Under normal conditions, TiO2 contains in three main crystal structures: stable rutile, metastable anatase, and brookite phases. And the majority of the literature reports on the use of crystalline TiO2 as adsorbents and catalysts. In the last several years, compared with crystalline TiO2, amorphous TiO2 has a larger specific surface area and higher adsorption capacity, making it a promising adsorbent and photocatalyst33. TiO2 is used as a catalyst, and the previous adsorption process is crucial. It is accustomedly considered that amorphous TiO2 is a provider of hole channels and adsorption sites, but is not involved in the photocatalytic reaction34. As far as we know, the utilization of a pristine amorphous TiO2 for removal of MB is unordinary reported35, and improving the potential adsorption capacity of amorphous TiO2 is very challenging.

In this present study, magnetic amorphous TiO2 with a core-shell-shell structure (Fe3O4@PDA@a-TiO2, FPaT) was synthesized, for an adsorbent, which was employed in removing Methylene blue (MB) from simulated wastewater. The physicochemical properties of the prepared FPaT material was characterized by Fourier transform infrared spectroscopy (FT-IR), X-ray diffraction (XRD), transmission electron microscopy (TEM), X-ray photoelectron spectroscopy (XPS) and vibrating sample magnetometer (VSM), etc. Based on their merits of multiple adsorption active sites, higher adsorption capacity, excellent dispersibility and rapid separation properties, the performances of FPaT was assessed by removing MB from simulated wastewater. In addition, batch adsorption experiments were carried out, including exploring the effects of different initial concentrations of MB solution, different initial pH of MB solution, contact times and different amounts of FPaT on the adsorption process, and the adsorption kinetics and isotherm of FPaT, as well as the possible mechanism of MB adsorption removal, were investigated in detail. These pieces of information will contribute to practical application and further research of novel adsorbent in the treatment of printing and dyeing wastewater.

Experimental section

Materials

Sodium acetate (CH3COONa·3H2O), ferric chloride hexahydrate (FeCl3·6H2O) and Methylene blue (MB) were bought from Tianjin Damao Reagent Factory. Ethylene glycol (EG) was provided by Chongqing Wan Sheng Chuan Dong Chemical Co., Ltd. Dopamine hydrochloride (DA) was supplied from Shanghai Lin’en Science and Technology Development Co., Ltd. Tris-HCl buffer was obtained from Beijing Solarbio Science & Technology Co., Ltd. Tetrabutyl titanate (TBOT) was originated from Tianjin Kemiou Chemical Reagent Co., Ltd. Absolute ethanol, acetonitrile, HCl, NH3·H2O (25–28%) and NaOH were analytical grade and were used without any further purification. Deionized (DI) water was gained using an Antesheng (ATS) gene 1820 C ultrapure water system (Chongqing Antesheng Environmental Protection Equipment Ltd, Chongqing, China).

Synthesis of materials

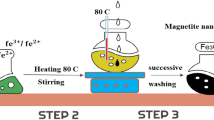

Preparation of Fe3O4 nanoparticles

The Fe3O4 nanoparticles were prepared via a simple solvothermal method at 200 °C for 8 h according to previously reported procedure36,37,38. In detail, FeCl3·6H2O (2.7 g) was first dissolved in ethylene glycol (80 mL) and ultrasonicated to obtain an orange-yellow solution. After when sodium acetate (7.2 g) was added to the solution, the mixture was stirred continuously for 10 min. The resulting solution was transferred into a Teflon-lined stainless-steel autoclave (100 mL capacity) and heated for 8 h at 200 °C. The Fe3O4 nanoparticles were gained with the help of a magnet and washed with DI water and anhydrous ethanol for several times. The final products were dried at 60 °C for later use.

Preparation of Fe3O4@PDA nanocomposites

As-prepared Fe3O4 nanoparticles were introduced into 100 mL tris-HCl buffer (10 mM, pH 8.5), followed by incorporating 100 mg dopamine hydrochloride into the aforementioned solution and mechanical stirring for 12 h at room temperature. The obtained Fe3O4@PDA nanocomposites were washed alternately with DI water and anhydrous ethanol, finally dried in a vacuum at 60 °C for overnight39.

Preparation of Fe3O4@PDA@a-TiO2 (FPaT) nanocomposites

FPaT was synthesized by coating Fe3O4@PDA with ordered TiO2 shells according to the reported reference with certain small modifications40. Simply, 150 mg of synthesized Fe3O4@PDA nanocomposites were uniformly dispersed in the mixture of acetonitrile and ethanol (V:V = 80:120). Subsequently by the addition of 0.5 mL NH3·H2O solution (25–28 wt%), after which a certain volume of TBOT was slowly added, and magnetically stirring for 90 min. The resultant mixture accomplished through a magnetic separation process, then which dispersed in the mixture of ethanol and DI water (V:V = 40:20) again, and sealed in a reaction kettle and subjected to a reaction in an oven at 120 °C with lasting for 24 h. The ensuing FPaT composites were collected by the aid of a magnet. Ultimately, the products were rinsed with DI water and ethanol several times and dried overnight at 60 °C. To optimize the synthesis conditions of TiO2 shell on the surface of the FPaT material, the effect of different volume of TBOT at 3.0 mL, 7.0 mL, and 10.0 mL were studied on the property of the products, which were denoted as FPaT-x (x = 3, 7, 10), respectively. The preparation of FPaT were exhibited in Fig. 1.

Characterization

The morphology and composition of Fe3O4, Fe3O4@PDA and Fe3O4@PDA@a-TiO2 that of them were measured by scanning electronic microscopy (SEM), transmission electron microscopy (TEM) and energy dispersive X-ray spectroscopy (EDS), respectively. Fourier-transform infrared (FT-IR) spectra of the three kinds of materials were collected on a Fourier transform-infrared spectrometer (FT-IR, Nexus 470, Germany) using KBr pellets. Crystallographic phases of Fe3O4, Fe3O4@PDA and Fe3O4@PDA@a-TiO2 were investigated respectively by the X-ray power diffraction method (XRD) (XRD, Bruker D8 Advance, Germany) at a scanning rate of 10o min−1 and a detection range from 10o to 80o. The magnetic properties were mensurated by employing a vibrating sample magnetometer (VSM, Lake Shore 735). X-ray photoelectron spectroscopy (XPS) analyses for the nanoparticles were measured on a X-ray photoelectron spectroscopy (XPS, Axis Ultra DLD600W).

Adsorption experiment

MB was selected as a model contaminant in the research (Its structure is shown in supplementary data (Supplementary Fig. S1)). Batch experiments were carried out systematically explore the adsorption efficiency of the three composites (Fe3O4, Fe3O4@PDA, and Fe3O4@PDA@a-TiO2 (FPaT) for MB. Control various operational parameters to determine the optimal adsorption conditions, including different pH parameters (2–12), contact time (1–120 min), initial concentrations of MB (3–300 mg/L), adsorbent mass (1–10 mg) as well as temperatures (25.0–45.0 °C). All batch experiments were carried out in a 15 mL centrifuge tube, with the volume of MB solution was kept constant at 15 mL. In the typical adsorption process, 5 mg adsorbent and 15 mL 10 mg/L MB solution were added into a 15 mL centrifugal tube, then placed in a thermo-static shaker for 0.5 h (200 rpm, 25 °C). After when the MB-loaded FPaTs were magnetically isolated from the solution, being detected the absorbance of supernatants concentrations in MB solution by ultraviolet-visible (UV-Vis) adsorption spectrophotometry (UV-1100, Shanghai Instrumental and Electrical Analysis Instrument Co., Ltd., Shanghai, China) at 664 nm. And the adsorption capacity (Qt, mg/g), together with removal rate (R, %), was calculated from the followed equations (Eqs.) (1) and (2), respectively:

where C0 and Ct denotes the initial and time concentrations (mg/L) of MB solutions, V and m signifies the volume (L) of the pollutant solution and the mass (g) of adsorbents, respectively.

Regeneration of FPaT

To investigate the recoverability of the FPaT, cycling experiments were performed on MB adsorption. At the end of each batch of MB adsorption, the nanoparticles were isolated from the MB solution with the help of a magnet, the following rinsed several times with anhydrous ethanol to release MB. The used-FPaT was dried overnight at 60 °C to remove any remaining anhydrous ethanol before the next round.

Adsorption isotherms

The specific adsorption pathways of FPaT were investigated using two standard isotherm models, Langmuir and Freundlich. The relative formulas in their nonlinear forms were respectively presented as follows Eqs. (3) and (4):

where Qe (mg/g) is the equilibrium adsorption capacity; Ce (mg/L) represents stand for the equilibrium MB concentration; KL, qmax (mg/L), KF and n are the Langmuir constants, the maximum adsorption capacity, Freundlich constants and the intensity of the adsorption process, respectively.

Adsorption kinetics

Three models (Pseudo-first-order, Pseudo-second-order and Intra-particle diffusion) were designed to estimate potential mechanism of the adsorption process. The corresponding equations were expressed as Eqs. (5), (6) and (7):

where K1: adsorption rate constant (1/min); K2: the rate constant (g/mg·min); C: intercept relating to the boundary layer thickness; Kp: rate constant (mg/g·min0.5).

Thermodynamic variables

The thermodynamic variables ΔG (Eq. (9)), ΔH (Eq. (10)), and ΔS (Eq. (10)) were calculated to explore the feasibility of FPaT nanocomposite on MB41.

where R: the universal gas constant (8.314 J/(mol·K)); T: the absolute temperature; Kc: the equilibrium constant, which is equal to Qe/Ce.

Results and analyses

Morphology and characterization of FPaT

The structure and morphology of Fe3O4, Fe3O4@PDA and FPaT were respectively detected using SEM and TEM as shown in Fig. 2a–c. SEM image of Fe3O4 revealed a spherical structure with rough surface and good dispersibility, and its average diameter was estimated to be approximately 240 nm based on statistical analysis for size measurement of 60 microspheres (as shown in the inset of Fig. 2a). Comparing with pure Fe3O4, the surface of Fe3O4@PDA became smooth, and the average diameter increases significantly to about 300 nm. Moreover, the Fe3O4@PDA@a-TiO2 showed obvious agglomeration and the average diameter further increase to about 370 nm. Similarly, the TEM image in Fig. 2d clearly shows the magnetic core structure of Fe3O4, with an average size of approximately 237 nm. As expected, the average thickness of PDA shell was about 60 nm as shown in Fig. 2e, underscoring the successful coating of PDA on the surface of Fe3O4. The average thickness of outermost layer was approximately 70 nm after Fe3O4@PDA nanomaterials were covered with TiO2 as shown in Fig. 2f, evidencing the formation of core-shell-shell structural nanomaterials42. These results of TEM (d-f) were in good conformity with those of SEM (a-c). Furthermore, the HR-TEM image in Fig. 2g corresponding to Fe3O4 nanomaterials revealed that two interplanar distances of 0.31 nm and 0.26 nm, consistent with the (220) and (311) interplanar spacings of Fe3O4 (JCPDS card No. 19-0269). The things must to be noted is that the PDA layer and the TiO2 shell in Fig. 2h and i show layer a lack of crystalline surfaces, which confirms the amorphous TiO2 layer in FPaT has been successfully synthesized43.

The uniform distribution of Fe, Ti, C, N and O element of FPaT was confirmed by TEM elemental mapping images showing in supplementary data (Supplementary Fig. S2). Obviously, Fe element is only distributed in the core region, while Ti element is only distributed in the shell layer. This further indicated that the FPaT material possesses a core-shell-shell structure. The EDS spectra of Fe3O4, Fe3O4@PDA, and FPaT were measured as shown in supplementary data (Supplementary Fig. S3a–c). The EDS energy peaks of elemental Fe, O, C, N, Ti, Cl illustrated the exact distribution of fundamental compositions and contents. It should be noted that the presence of a very small amount of Cl element may be result from incomplete polymerization of tris-HCl and DA-hydrochloride or washing residues.

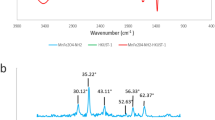

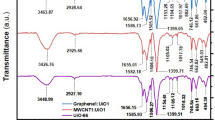

The FT-IR spectra of Fe3O4, Fe3O4@PDA and FPaT in the range 4000–450 cm−1 is shown in Fig. 3a. From the figure, we can see that the absorption peak at 560 cm−1 was related to the Fe-O bond in Fe3O4, while the O-H stretching vibration peak at 3450 cm−1 was generated due to the hydroxyl group from bond water44. Compared to the spectrum of Fe3O4, additional peaks at 1295 cm−1, 1380 cm−1, 1450 cm−1 and 1608 cm−1 respectively corresponded to the C-O bending vibrations, C-N stretching vibrations, N-H deformation and aromatic shear vibrations as well as the C=C resonance vibrations and the N-H bending vibrations in the spectrum of Fe3O4@PDA. And the wide band in the wavenumber range from 3000 to 3600 cm−1 were originated from characteristic peaks of -NH2 and -OH in PDA45,46. Importantly, the peak occurred at 560 cm−1 shifted slightly to 580 cm−1 was correspond to chelation of Fe3O4 and PDA. Stronger absorbance peak at 500–800 cm−1 and 1033 cm−1 compared with that of Fe3O4@PDA was represent the vibration of Ti-O and the bridging stretching of Ti-O-Ti respectively, indicating that TiO2 successfully coated on PDA surface47. Base on above analyses, the functional group structure of Fe3O4@PDA@a-TiO2 nanoparticles was initially determined.

To further verify the amorphous structure of TiO2 layer in FPaT, XRD (X-ray diffraction) was conducted to analyze the purity and crystal structure of Fe3O4, Fe3O4@PDA, and Fe3O4@PDA@a-TiO2 as shown in Fig. 3b. The identified signals were at angles 18.3o, 30.1o, 35.4o 43.1o, 53.4o, 57o, and 62.5o, these peaks (marked with *) matched well with (111), (220), (311), (400), (422), (511), and (440) lattice planes respectively for Fe3O4 (JCPDS card No. 19–0629). Similar patterns were detected for Fe3O4@PDA and the FPaT, which indicated that coating with PDA and TiO2 in sequence will not cause significant changes in the crystalline phase of Fe3O4, nor will new phase structures be formed. To prospect the influence of synthesis reaction temperature on the formation of TiO2 shell crystal structure, we further investigated the FPaT obtained from the reaction at different synthesis temperatures (120 oC, 150 oC and 180 oC), as shown in Fig. 3c. In addition, we found a sharp peak (30o) (marked with Δ) in the as-synthesized products at 150 oC and 180 oC, which can be attributed to Fe2TiO4 (JCPDS card No. 75-1378). This may be due to the formation of Fe2TiO4 between free Fe2+/Fe3+ and Ti4+/Ti3+ at high temperatures, or the entry of Ti4+/Ti3+ into the Fe3O4 lattice, forming a titanium iron spinel structure. Similarly, as the reaction temperature increases, the two peaks appearing at 25o and 47o (marked with □) are respectively put down to the (101) and (200) lattice planes of anatase-type TiO2 (JCPDS card No. 71-1166). These results indicate that the structure of TiO2 slowly transforms from an amorphous into a crystalline structure as the reaction temperature increases. Consequently, the results firmly established that the outer layer is the amorphous TiO2 shell. All these data demonstrated the successful fabrication of Fe3O4@PDA@a-TiO2 nanoparticles.

The VSM curves were given in Fig. 3d to facilitate comparison of the magnetization strengths of Fe3O4, Fe3O4@PDA, and FPaT. Their maximum value of saturation magnetizations (Ms) were respectively determined as 74.6 emu/g, 47.8 emu/g, and 41.4 emu/g. The downward trend in saturation magnetization strengths of Fe3O4@PDA and FPaT compared to Fe3O4 was attributed to the introduction of PDA and TiO2, which leads to a decrease in magnetic content. Despite FPaT composite exhibiting the lowest magnetic performance among the three composites, it can still easily separated from the aqueous solution with the aid of a magnet. As despicted in the illustration of Fig. 3d, after contact with an external magnetic field, all the FPaT nanoparticles can be fleetly separated from the solution within 10 s. Consequently, it can be inferred that FPaT nanoparticles achieve convenient and fast magnetic separation by applying an external magnetic field, and they are also easily redispersed by shaking the sample solution without an external magnetic field.

The total XPS spectrum of FPaT in Fig. 4a distinctly reveals the composite is consisted of C, N, Ti, O and Fe elements at binding energies of 285.78 eV, 399.7 eV, 452.37 eV, 530.88 eV and 720 eV, respectively. In light of the XPS broad scanning spectrum of Fig. 4b, transparently, the C 1s area was fitted with three components. The XPS peak at 284.8 eV ascribed the C=C and C-C bonds of the benzene ring, and at 286.07 eV was consistent with the C-O and C-N bonds, while at 288.87 eV was consistent with the C=O48. The N 1s spectrum of FPaT in Fig. 4c can be deconvoluted into three peaks located at about 398.81 eV, 400.15 eV, and 402.01 eV, which were associated with C-N, N-H, and NH2, respectively. The XPS characteristic peaks for C and N endorsed the self-polymerization of DA into PDA49.

Upon close examination of the O 1s spectrum, as depicted in Fig. 4d, the peaks of the C-O, C=O and Ti-O bond respectively are were identified at 532.36 eV, 531.18 eV and 530.12 eV. These results indicate that TiO2 was successfully encapsulated on the PDA surface, which is completely in line with the FT-IR spectrum of FPaT. Figure 4e offers insight into the Fe 2p spectrum, the peaks at bonding energy of Fe 2p3/2 and Fe 2p1/2 respectively appeared at 711.7 eV and 723.8 eV. The extremely weak peak intensity of Fe 2p maybe difficult to detect due to the depth distribution of Fe element in the core of FPaT. As well, the peaks respectively appeared at bonding energy of 458.71 eV for Ti 2p3/2 and 464.4 eV for Ti 2p1/2, as shown in Fig. 4f, demonstrating that the Ti element in the FTaT nanomaterial was primarily in its highest oxidation state (IV)50,51.

Adsorption properties of FPaT composites

To probe the adsorption capabilities of the FPaT composites on MB, Fe3O4, Fe3O4@PDA, and three different FPaT-x (FPaT-3, FPaT-7, FPaT-10) materials were selected as the contrast as shown in supplementary data (Supplementary Fig. S4(a)). Under identical conditions, the removal efficiencies of MB dyes by Fe3O4 and Fe3O4@PDA amount to 10.25% and 60.2%, respectively. Notably, FPaT-3, FPaT-7 and FPaT-10 composites adsorbent exhibit a remarkable removal exceeded 90%. Evidencing the a-TiO2 layer modification can improve the adsorption performance significantly for MB. Considering saving reagents and economic costs, in light of the three FPaTs performed similar removal efficiency, FPaT-3 was chosen as the subsequent adsorbents. For convenience, it is simply abbreviated as FPaT.

In adsorption process, various factors including initial MB concentration (C0), MB solution pH, adsorbent mass (m) and contact time (t) as well as coexisting ions were could be better elucidate adsorption mechanism. Supplementary Fig. S4(b) shows the adsorption process over a period of 0 to 60 min while keeping the Fe3O4 and Fe3O4@PDA as comparisons. It was clear that the removal efficiency increased rapidly during early contact, then gradually went down and eventually became balance. The removal rate of Fe3O4, Fe3O4@PDA and FPaT reached equilibrium up to 15%, 60% and 91% respectively at 30 min. Notably, the larger adsorption rate of FPaT on MB before 30 min was attributed to the presence of sufficient active adsorption centers as well as a high concentration gradient in MB solution. However, after 30 min, the active adsorption sites became gradually occupied, meanwhile the concentration difference reduced, resulting in the adsorption rate slowed down until equilibrium reaching. Therefore, 30 min was adopted as the subsequent adsorption condition for MB molecules.

Supplementary Fig. S4(c) displays the removal efficiency of Fe3O4, Fe3O4@PDA and FPaT through adsorption experiment with different initial concentrations of MB solutions. 5 to 60 mg/L of MB solutions were prepared and then 5 mg FPaT were added to explore the variation of adsorption rate with the initial concentration (C0). Similarly, 5 mg of Fe3O4, Fe3O4@PDA were added to prepared concentrations of MB solution as a control. The adsorption rate of FPaT toward MB remained above 90% when increasing from 5 mg/L to 15 mg/L, whereas the adsorption rate decreased from 92 to 40% with increasing the pollutant concentration from 20 to 60 mg/L. These results display that the number of adsorption sites provided by a certain mass of FPaT microspheres remains constant. At low concentrations of MB solution, the FPaT can provide sufficient adsorption sites, resulting in a high adsorption rate. However, at high concentrations of MB solution, the active adsorption sites provided by the microspheres were relatively insufficient. As a result, even after MB molecules have occupied almost all of the sites, a large number of MB molecules remain in the aqueous phase, leading to a low removal rate. In view of this, 10 mg/L of MB solution was chosen as follow-up test condition from an economical point of view.

Further investigation into the efficiency of composites mass for MB adsorption using 1.0 to 8.1 mg (see supplementary Fig S4(d)). While keeping aforementioned parameters constant (30 min, 10 mg/L and 25 oC). With the increase the number of three sorbents from 1 to 4.6 mg, the removal rate increased from 39.5 to 77.2%. With the further adsorbent mass increased to 8.1 mg, the adsorption efficiency keep almost constant at 91%, which was attributed to the increase in the active center with the mass of adsorbent material, resulting in a higher rate of adsorption. When the adsorbent was overdosed, the diffusion of the MB onto its surface was hindered and the active center could not be fully utilized. This led to the rate of adsorption just slightly increased within a certain concentration range52. Thus, the subsequent adsorption experiments were performed using 4.6 mg of adsorbents to minimize material costs.

The pH value of the adsorbate solution was an essential factor affecting the adsorption process, which influences both the morphology of the adsorbent molecules and the charge distribution on the adsorbent surface42. The adsorption of MB by FPaT was regulated in the entire pH interval 2–12 while keeping all other parameters unchanged (30 min, 10 mg/L, 4.6 mg and 25 oC), according to supplementary Fig. S4(e). Due to the pH of zero point charge(pHPZC) of FPaT is 3.75 (Seeing in Fig. S4(f)), it will bring about the same external surface charge state of adsorbent and adsorbate under in high acidic condition (pH < 3.75), resulting in electrostatic repulsion between FPaT and MB limiting the adsorption efficiency. On the contrary, under low acidic, neutral and alkaline conditions (pH > 3.75), the FPaT surface will be negatively charged and easily combine with positively charged MB+, augmenting the adsorption efficiency in the range of pH. Accordingly, FPaT exhibited with lower removal rate for MB adsorption under strong acidic conditions (pH 2.0–4.0). The overall removal raised from 65% at pH = 2.0 to 93% at pH = 4.0. With the further increase of pH from 4.0 to 8.2, the removal rate enhanced to 97%. The adsorption rate of FPaT toward MB showed negligible improvement after the pH value of MB solution was added from 8.2 to 12.0, illustrated that the FPaT maintain the higher adsorption efficiency in this pH range. Therefore, the optimal value pH = 8.2 will be utilized for the next experiment.

Supplementary Fig. S4(g) presents the influence of four typical inorganic ions (including Na+, Mg2+, HCO3−, SO42−) on the adsorption of MB by FPaT. According to the results, the coexisting of Na+ and HCO3− have almost negligible effect on MB adsorption, whereas Mg2+ and SO42− have a negative effect on adsorption. For the effect of cations, which might be explained because the monovalent cation Na+ would bind to the surface of FPaT, and only one adsorption site was occupied. While, divalent cations Mg2+ would occupy more adsorption sites of the FPaT particles, which hindered the effective adsorption of MB. For the effect of anionics, as HCO3− is more hydrolyzed than ionized in aqueous solution makes the solution weak alkaline, resulting to facilitate to electrostatic pull and increase MB adsorption by FPaT. So it has less effect than SO42−53.

Regeneration of FpaT

The regeneration capability is an important index to evaluate the properties of obtained-adsorbents due to this consideration of economic value of the method. Hence, regeneration study were conducted. Supplementary Fig. S5 displays the reusability of FPaT toward MB after 1–4 adsorption-desorption cycles. The removal of MB dye by FPaT after two consecutive cycles was found to be negligible, with an adsorption rate of 85.03% at the end of the third and fourth cycles. During the four consecutive extraction processes using the same batch of materials, the analytical performance did not attenuate, indicating that FPaT has a significant recyclability effect in removing MB. In addition, the desorption rate of FPaT-MB during 4 cycles was range of 75-82% as shown in Figure S5(Seeing red column). FPaT, as a magnetic adsorbent, can adsorb Methylene blue from water bodies and reduce its footprint in the environment through magnetic recovery.

Adsorption model of FPaT composites

By utilizing adsorption kinetics models, including the pseudo primary kinetic model, pseudo secondary kinetic model, and intraparticle diffusion model, the pathway and potential mechanism of the adsorption process were analyzed to further determine the control mechanisms of adsorption types and rates. The non-linear fitting curves and corresponding paraments of the three models are presented in Fig. 5a and Supplementary Table S1. The experimental data of Fe3O4, Fe3O4@PDA and FPaT show more in accordance with the fitted parameters originated from the pseudo-second-order model, as circumstantiated by the correlation coefficient (R2) of pseudo-second-order kinetic model for Fe3O4, Fe3O4@PDA and FPaT (R2 = 0.764, R2 = 0.974, R2 = 0.999, respectively) was higher than that of the proposed primary kinetic model (R2 = 0.759, R2 = 0.928, R2 = 0.998, respectively). It was further indicated that the adsorption process of three materials toward MB was primarily determined by chemisorption. The fitted kinetic adsorption constant K2 is in the order of FPaT > Fe3O4@PDA > Fe3O4, this suggests that FPaT has the fastest adsorption rate among the three composites during the MB adsorption process.

Adsorption isotherm can not only provides important information on the interaction between adsorbate and adsorbent, but also could be served for quantitatively analyzing the removal efficiency of adsorbed compounds. The aim of this study was to determine the adsorption isotherms of FPaT for different initial concentrations of MB (5–300 mg/L) at different temperature ranges (293–308 K). The MB adsorption isotherms data were fitted nonlinearly using Langmuir and Freundlich isotherm models, respectively. The corresponding curves at different temperature are shown in Fig. 5(b-d). The values of correlation coefficients (R2) together with the parameters for FPaT, Fe3O4 and Fe3O4@PDA are respectively tabulated in Table 1, Supplementary Table S2 and Table S3. It could be found that the adsorption behavior is basically consistent with the two models at different temperatures. Therefore, the Langmuir isotherm is propitious to interpret the adsorption progress, with a higher correlation coefficients (R2) value than that of Freundlich.

It can be determined that the maximum adsorption capacity (qmax) of FPaT was 313.7 mg/g according to the Langmuir model. The comparison of the adsorption capacity of FPaT with various adsorbents reported in different literature is listed in Supplementary Table S4, indicating that the synthesized FPaT was superior adsorption performance for MB to other adsorbents, as well as avoiding secondary pollution of the environment due to its excellent recyclability. Furthermore, from Fig. 5(b-d), it can be seen that as the temperature increased, the adsorption capacity of the three adsorbents for MB increased. While the temperature was raised from 293 K to 308 K, the adsorption capacity of Fe3O4, Fe3O4@PDA and FPaT for MB decreased from 28.84 to 22.57 mg/g, increased 77.77 to 88.7 mg/g, 297 to 313.7 mg/g, respectively. The above results strongly indicate that the adsorption process of FPaT for MB is endothermic in nature54, and further demonstrated the importance of a-TiO2 shell structure of FPaT in adsorption.

According to the derivation process of the Langmuir isothermal adsorption model Eqs55,56, it can be seen that the surface coverage (θ) can be expressed by the following equation:

θ = (Qe/qm) %.

Where Qe and qm represent the equilibrium and maximum saturated adsorption capacity, respectively. According to Fig. 4(b) and Table 1, it can be seen that the Qe value and qm value at 293 K are 238.25 mg/g and 295.6 mg/g, respectively, the calculated θ value is 80.59%.Similarly, the θ values at 298 K and 308 K is 79.14% and 79.23%, respectively.

Based on the cited references57, when there is a linear relationship between qt and t1/2 as well as the intercept is zero, the intraparticle diffusion completely controls the entire adsorption process. Conversely, if there are multiple linear regions in the intraparticle diffusion plot, the multiple diffusion steps directly controls the adsorption process. We obtained fitted curves for different adsorption rates, as shown in supplementary Fig. S6. Obviously, the first segment does not cross the origin, demonstrating that internal diffusion is determined by more than one mechanisms, and it is believed that the entire adsorption process may be followed by three sequential steps. Accordingly, the first stage (3–10 min) was considered to be the external transfer adsorption phase. During this phase, MB reaches the outer surface of FPaT through an external diffusion process. MB molecules diffuses to the external surface of the FPaT through an internal diffusion process. In the second stage (15–30 min), when the adsorption saturation was reached on the outer surface of FPaT, MB molecules were transferred from the external surface into their internal (intraparticle diffusion). Then as the amount of adsorption sites diminished, the adsorption eventually attained equilibrium corresponds to the third stage (40–120 min). In supplementary Table S5, the rate constant for intra-particle diffusion, Kp (mg/g·min0.5), and the intercept C followed a specific order: Kp3<Kp2<Kp1 and C1 < C2 < C3, respectively. These results showed that the outer surface adsorption dominated the initial stage of the adsorption process, while diffusion resistance was higher in the latter stage than in the former stage. In summary, the adsorption of MB by FPaT is not only influenced by intra-particle diffusion, but also by external diffusion and surface adsorption.

Adsorption thermodynamics can be employed to elucidate the direction and nature of adsorption reactions. The results of adsorption isotherm plots at various temperatures are shown in supplementary Fig. S7(a). It can be seen that as the temperature increased from 293 K to 323 K, the adsorption efficiency of FPaT on MB increased, indicating an endothermic process. Supplementary Fig. S7(b) illustrates the plot of lnKc versus 1/T (C0 = 10 mg/L). The values of ΔS and ΔH were calculated from the intercept and the slope of the fitted equation respectively, while the ΔG values were estimated from Eq. (8). All the thermodynamic parameters are presented in supplementary Table S6. The ΔG values are all negative suggested the adsorption of MB on FPaT is spontaneous and feasible58. As the adsorption temperature increased, the ΔG values decreased, indicating a greater adsorption driving force at higher temperatures. In addition, the positive value of ΔH further reveals that the adsorption of MB on FPaT was an endothermic process. Besides, ΔS is defined as a measure of the randomness or disorder present in a system. Positive ΔS values indicate that the interface between FPaT particles and MB solution exhibits higher randomness and disorder during adsorption process.

Adsorption mechanism

The adsorption mechanism of FPaT toward MB was investigated by analyzing the FT-IR spectra before and after adsorption, as shown in supplementary Fig. S8. Noteworthily, in FPaT-MB (after MB adsorption), a significant increase in the stretching vibration intensity of aromatic C =C (1646–1631 cm−1) can be observed, which mainly was contributed to involvement π-π interaction between partly bare aromatic ring of FPaT and conjugated benzene ring of MB in the adsorption process59,60. After MB adsorption, an additional peak at 1606 cm−1, which was attributed to the cyclic C=N, demonstrated the MB molecules had been bonded onto the adsorbent surface61. Additionally, the FPaT-MB induced the slight increase in peak intensity at 500–800 cm−1 and the decrease of peak intensity around 1038 cm−1, suggesting that Ti-O bond was possibly involved in the adsorption process.

To further investigate other possible adsorption mechanism, the XPS analysis of FPaT before and after MB adsorption (FPaT-MB) has also been studied. The results of the high-resolution XPS spectra of C 1s for FPaT and FPaT-MB are shown in supplementary Fig. S9(a). It is obvious that three peaks of the FPaT at 284.8 eV, 286.07 eV and 288.48 eV respective match along with C-C or, C=C, C-N or C-O and C=O respectively shifted to 284.81 eV, 286.23 eV and 288.87 eV after MB absorption, resulted from the π-π interaction between MB and the aromatic rings in the small amount of exposed PDA on FPaT. This observation aligns with the findings from FT-IR spectroscopy before and after adsorption61. Supplementary Fig. S9(b) shows the XPS spectra of O 1s for FPaT before and after MB adsorption. Comparing with pure FPaT whose the binding energy of O 1s was located at 530.12 eV (Ti-O), FPaT-MB was exhibited slightly shift to higher binding energy positions which was at 530.25 eV. And the disparity in binding energies between the two fractions of Ti 2p in FPaT and FPaT-MB shifted slightly to the higher binding energy in supplementary Fig. S9(c), which can be attributable to changes in the chemical microenvironment62. Furthermore, the N 1s binding energies of FPaT were located at 400.76 eV and 402.01 eV from -NH- and -NH2 of PDA as shown in supplementary Fig. S9(d), while the N1s binding energies of FPaT-MB respectively moved to 400.25 eV and 402.05 eV. It was noteworthy that the intensity of -NH2 peak reduced obviously, resulted from the N+(CH3)2 of MB. The FPaT-MB could be depicted as promoting electron transfer process through electrostatic attraction associated with N63, which can be demonstrated by the generally high adsorption capacity of FPaT in MB solution in the pH range of 4–12.

According to the results presented above, the following conclusions is that the main adsorption mechanism in the process was electrostatic interactions (Ti-O−…+N(CH3)2-MB). Meanwhile, π-π stacking promoted the adsorption of MB by FPaT as shown in Fig. 6.

Conclusion

In this paper, amorphous titania-coated magnetic polydopamine with a core-shell-shell structure (Fe3O4@PDA@a-TiO2, FPaT) materials were synthesized through a series of self-assembly steps and successfully characterized using various techniques. In addition, the formation mechanism of amorphous TiO2 in FPaT indicated that its crystal structure was closely related to low-temperature dependence. The excellent adsorption performance of FPaT was evaluated using methylene blue (MB) as a pollutant model. The effects of contact time, adsorbent mass, and initial concentration and pH value of MB solution on the adsorption process were investigated, with emphasis on the adsorption kinetics together with adsorption isotherms to explore the adsorption pathways and mechanisms. Under the optimal conditions (t = 30 min, C0 = 10 mg/L, m = 4.6 mg, pH = 8.2), these experimental results showed that the maximum adsorption amount of MB on the FPaT was 313.7 mg/g. The adsorption process respectively obeyed the secondary kinetic model and Langmuir isothermal adsorption model well, denoting chemisorption and monolayer adsorption. The adsorption mechanism of FPaT on MB was initially explored. It was concluded that the adsorption mechanism was mainly due to electrostatic effect, while the π-π stacking effect also promoted the adsorption of FPaT on MB. From the cyclic regeneration experiments, the adsorption rate decreased from 97 to 87% after four cycles of experiments, showing that the FPaT still maintains good adsorption performance on MB after multiple uses. In conclusion, FPaT, as a novel adsorbent, has good application prospects for the adsorption and removal of methylene blue in wastewater. However, in practical water bodies applications, we also need to comprehensively consider the complexity of the water bodies (such as inorganic salts, organic matter, microorganisms, etc.), the characteristics of actual wastewater (acidic, neutral, alkaline), the limitations of scaling up experiments, and the optimal adsorption conditions (such as the need to add additional reagents to adjust the pH value of the solution). Therefore, there is still a long way to go from small laboratory experiments to large-scale application experiments.

Data availability

Data is provided within the manuscript or supplementary information files. Data is available on request from Xingyu Long (zrblxy@gznu.edu.cn).

References

Cai, H. et al. Ultra-efficient and selective adsorption of cationic dyes by Ti-doped SiO2 functionalized hydrophilic Fe3O4 nanoparticles with superior structural stability. J. Water Process. Eng. 57, 104729 (2024).

Tang, Q. et al. Floating-separation adsorbent for methylene blue and Pb(II) removal: Structure construction and adsorption mechanism. Chemosphere 295, 121332 (2022).

Subhan, F. et al. Catalytic reduction of nitrophenol and MB waste water using homogeneous Pt NPs confined in hierarchically porous silica. J. Environ. Chem. Eng. 9, 105567 (2021).

He, T., Hua, J. Q., Chen, R. P. & Yu, L. Adsorption characteristics of methylene blue by a dye-degrading and extracellular polymeric substance -producing strain. J. Environ. Manage. 288, 112446 (2021).

Qin, P. et al. Highly efficient, rapid, and simultaneous removal of cationic dyes from aqueous solution using monodispersed mesoporous silica nanoparticles as the adsorbent. Nanomater 8, 4–18 (2017).

Georgouvelas, D., Abdelhamid, H. N., Li, J., Edlund, U. & Mathew, A. P. All-cellulose functional membranes for water treatment: Adsorption of metal ions and catalytic decolorization of dyes. Carbohydr. Polym. 264, 118044 (2021).

Zagklis, D. P., Vavouraki, A. I., Kornaros, M. E. & Paraskeva, C. A. Purification of olive mill wastewater phenols through membrane filtration and resin adsorption/desorption. J. Hazard. Mater. 285, 69–76 (2015).

Pereira, R. A., Pereira, M. F. R., Alves, M. M. & Pereira, L. Carbon based materials as novel redox mediators for dye wastewater biodegradation. Appl. Catal. B. 144, 713–720 (2014).

Cao, Y., Zhang, H., Liu, K., Zhang, Q. & Chen, K. J. Biowaste-derived bimetallic Ru–MoOx catalyst for the direct hydrogenation of furfural to tetrahydrofurfuryl alcohol. ACS Sustainable Chem. Eng. 7, 12858–12866 (2019).

Moro Daniel, D. et al. Cerium oxide nanoparticles: Biosynthesis, characterization, antimicrobial, ecotoxicity and photocatalytic activity. J. Photoch Photobio A. 442, 114773 (2023).

Chen, B., Long, F., Chen, S., Cao, Y. & Pan, X. Magnetic chitosan biopolymer as a versatile adsorbent for simultaneous and synergistic removal of different sorts of dyestuffs from simulated wastewater. Chem. Eng. J. 385, 123926 (2020).

Pompeu, L. D., Viana, A. R., Fernandes, L. D. S. & Silva, W. L. D. Evaluation of cytotoxicity, reactive oxygen species and nitrous oxide of nanochitosan from shrimp shell. Int. J. Biol. Macromol. 235, 123730 (2023).

Zhang, S. et al. Mussel-inspired polydopamine biopolymer decorated with magnetic nanoparticles for multiple pollutants removal. J. Hazard. Mater. 270, 27–34 (2014).

Yao, Y. et al. Synthesis, characterization, and adsorption properties of magnetic Fe3O4@graphene nanocomposite. Chem. Eng. J. 184, 326–332 (2012).

Bouzidia, M. et al. Efficient removal of organophosphate insecticide employing magnetic chitosan-derivatives. Int. J. Biol. Macromol. 279, 134992 (2024).

Salles, T. R. et al. Magnetic graphene derivates for efficient herbicide removal from aqueous solution through adsorption. Environ. Sci. Pollut R. 31, 25437–25453 (2024).

Nunesa, F. B. et al. Removal of selective serotonin reuptake inhibitor using magnetic graphene oxide derivatives: Adsorption study in low drug concentration using HPLC quantification, in vitro safety, and phytotoxicity. J. Environ. Chem. Eng. 12, 112336 (2024).

Lee, H., Kim, D. I., Kim, Y. & Jang, A. Efficient one-pot synthesis of magnetic MIL-100(Fe) using nitric acid without additional Fe ion addition and adsorption behavior of charged organic compounds. Chemosphere 314, 137696 (2023).

Ahmadipouya, S. et al. Magnetic Fe3O4@UiO-66 nanocomposite for rapid adsorption of organic dyes from aqueous solution. J. Mol. Liq. 322, 114910 (2021).

Huang, Z. et al. Electrospun graphene oxide/MIL-101(Fe)/poly(acrylonitrile-co-maleic acid) nanofiber: A high-efficient and reusable integrated photocatalytic adsorbents for removal of dye pollutant from water samples. J. Colloid Interf Sci. 597, 196–205 (2021).

Gao, S., Zhang, W., Zhou, H. & Chen, D. Magnetic composite Fe3O4/CeO2 for adsorption of azo dye. J. Rare Earth. 36, 986–993 (2018).

Chen, Y., Yuan, T., Wang, F., Hu, J. & Tu, W. Magnetically separable Fe3O4@TiO2 nanospheres: Preparation and photocatalytic activity. J. Mater. Sci. -Mater El. 27, 9983–9988 (2016).

Luo, Z. et al. Novel insights into the adsorption of organic contaminants by biochar: A review. Chemosphere 287, 132113 (2022).

Chen, B. et al. A novel Fe3+-stabilized magnetic polydopamine composite for enhanced selective adsorption and separation of Methylene blue from complex wastewater. J. Hazard. Mater. 392, 122263 (2020).

Zhang, Y. et al. Recyclable polydopamine-functionalized sponge for high-efficiency clean water generation with dual-purpose solar evaporation and contaminant adsorption. ACS Appl. Mater. Interfaces. 11, 32559–32568 (2019).

Zhang, L. P. et al. Novel composite membranes for simultaneous catalytic degradation of organic contaminants and adsorption of heavy metal ions. Chemosphere 237, 116364 (2020).

Zhang, Y. et al. A dual-functional lignin containing pulp foam for solar evaporation and contaminant adsorption. Desalination 573, 117153 (2024).

Zamani, W., Rastgar, S., Hedayati, A., Tajari, M. & Ghiasvand, Z. Solvent-thermal approach of MIL-100(Fe)/Cygnea/Fe3O4/TiO2 nanocomposite for the treatment of lead from oil refinery wastewater (ORW) under UVA light. Sci. Rep. 14, 4476 (2024).

Bibi, S. et al. Cu-doped mesoporous TiO2 photocatalyst for efficient degradation of organic dye via visible light photocatalysis. Chemosphere 339, 139583 (2023).

Subagyo, R. et al. Converting red mud wastes into mesoporous ZSM-5 decorated with TiO2 as an eco-friendly and efficient adsorbent-photocatalyst for dyes removal. Arab. J. Chem. 15, 103754 (2022).

Hu, J. et al. Catalytic oxidation of lignite by Pt/TiO2 can enhance cadmium adsorption capacity. J. Hazard. Mater. 465, 133207 (2024).

Zhang, Y. et al. TiO2/BiOI p-n junction-decorated carbon fibers as weavable photocatalyst with UV–vis photoresponsive for efficiently degrading various pollutants. Chem. Eng. J. 415, 129019 (2021).

Bella, F. et al. Unveiling the controversial mechanism of reversible na storage in TiO2 nanotube arrays: Amorphous versus anatase TiO2. J. Nano Res. 10, 2891–2903 (2017).

Kumar, D. P. et al. Nanocavity-assisted single-crystalline Ti3+ self-doped blue TiO2(B) as efficient cocatalyst for high selective CO2 photoreduction of g-C3N4, mater. Today Chem. 24, 100827 (2022).

Mathew, R. M., Jose, J., Zachariah, E. S. & Thomas, V. Defect induced ultrafast organic dye adsorption by amorphous titanium dioxide/phosphorus-doped carbon nanodot hybrid. J. Cluster Sci. 35, 1045–1062 (2024).

Kusyak, A. et al. Study of the adsorption activity of Fe3O4 synthesized by the solvothermal method in relation to doxorubicin. Appl. Nano Sci. 10, 4923–4930 (2020).

Pan, X. et al. Fenton-like catalyst Fe3O4@polydopamine-MnO2 for enhancing removal of methylene blue in wastewater. Colloids Surf. B. 181, 226–233 (2019).

Sheng, W. et al. Amine-functionalized magnetic mesoporous silica nanoparticles for DNA separation. Appl. Surf. Sci. 387, 1116–1124 (2016).

Li, Y., Lin, X., Zhang, C., Zhuang, Q. & Dong, W. Polydopamine magnetic microspheres grafted with sulfonic acid groups for efficient adsorption of tetracycline. Colloids Surf. A. 628, 127263 (2021).

Chen, G., Zhang, G. & Yang, F. The elaboration of multifunctional hollow core–shell Fe3O4@PDA@TiO2 architecture with dual magnetic- and photo-responsive performance. New. J. Chem. 44, 3487–3492 (2020).

Wang, Q. et al. One-step synthesis of magnetic asphalt-based activated carbon with high specific surface area and adsorption performance for methylene blue. Chemosphere 321, 124205 (2023).

Zhang, H., Dai, Z., Sui, Y., Xue, J. & Ding, D. Adsorption of U(VI) from aqueous solution by magnetic core–dual shell Fe3O4@PDA@TiO2. J. Radioanal Nucl. Ch. 317, 613–624 (2018).

Jin, S., Liu, L. & Zhou, P. Amorphous titania modified with boric acid for selective capture of glycoproteins. Microchim Acta. 185, 308 (2018).

Si, J. & Yang, H. Preparation and characterization of bio-compatible Fe3O4@polydopamine spheres with core/shell nanostructure. Mater. Chem. Phys. 128, 519–524 (2011).

Feng, J. et al. Designed core–shell Fe3O4@polydopamine for effectively removing uranium(VI) from aqueous solution. B. Environ. Contam. Tox. 106, 165–174 (2021).

Davodi, B., Jahangiri, M. & Ghorbani, M. Magnetic Fe3O4@polydopamine biopolymer: synthesis, characterization and fabrication of promising nanocomposite. J. Vinyl Add Tech. 25, 41–47 (2019).

Li, W. et al. Fabrication of Fe3O4@Ti-PDA nanoparticles with enhanced photocatalytic activities for degradation of organic dye. J. Phys. Chem. Solids. 172, 111047 (2023).

Yang, F. et al. Bamboo-based magnetic activated carbon for efficient removal of sulfadiazine: Application and adsorption mechanism. Chemosphere 323, 138245 (2023).

Wang, C. et al. Fabrication of core–shell Fe3O4@polypyrrole@sodium dodecyl benzene sulfonate composite for high-performance adsorption of methylene blue and malachite green in water. Chemosphere 329, 125140 (2024).

Krishnan, P. et al. Characterization of photocatalytic TiO2 powder under varied environments using near ambient pressure X-ray photoelectron spectroscopy. Sci. Rep. 7, 43298 (2017).

Nguyen-Le, M. T. & Lee, B. K. High temperature synthesis of interfacial functionalized carboxylate mesoporous TiO2 for effective adsorption of cationic dyes. Chem. Eng. J. 281, 20–33 (2015).

Li, D., Hua, T., Yuan, J. & Xu, F. Methylene blue adsorption from an aqueous solution by a magnetic graphene oxide/humic acid composite. J. Colloids Surf. A. 627, 127171 (2021).

Tan, Y. et al. Insight into the adsorption of magnetic microspheres with large mesopores: tailoring mesoporous structure and ethylenediamine functionalization for ultrahigh Congo red removal. Chemosphere 311, 123265 (2023).

Xi, J., Zhang, R., Ye, L., Du, X. & Lu, X. Multi-step preparation of Fe and Si modified biochar derived from waterworks sludge towards methylene blue adsorption. J. Environ. Manage. 304, 114297 (2022).

Greydanus, B. et al. Probing surface-adsorbate interactions through active particle dynamics. J. Colloid Interf Sci. 614, 425–435 (2022).

Bird, P. G. A derivation of Langmuir’s adsorption isotherm. J. Chem. Educ. 10, 237 (1933).

Liu, Y. et al. Preparing a magnetic activated carbon with expired beverage as carbon source and KOH as activator. J. Taiwan. Inst. Chem. Eng. 96, 575–587 (2019).

Hassan, H. M. A. et al. Alsohaimi, sulfanilic acid-functionalized magnetic GO as a robust adsorbent for the efficient adsorption of methylene blue from aqueous solution. J. Mol. Liq. 361, 119603 (2022).

Zhang, F. et al. Effective removal of tetracycline antibiotics from water by magnetic functionalized biochar derived from rice waste. Water Environ. Pollut. 330, 121681 (2023).

Hossain, M. A., Mondol, M. M. H. & Jhung, S. H. Functionalized metal-organic framework-derived carbon: Effective adsorbent to eliminate methylene blue, a small cationic dye from water. Chemosphere 303, 134890 (2022).

Yuan, X., Wang, X., Hu, S., Sun, S. & Li, C. PDA@UiO-66-NH2-derived nitrogen and oxygen-doped hierarchical porous carbon for efficient adsorption of BPA and dyes. J. Sep. Purif. Technol. 343, 127169 (2024).

Balajka, J. et al. High-affinity adsorption leads to molecularly ordered interfaces on TiO2 in air and solution. Science 361, 786–789 (2018).

Li, W. et al. Studies on the adsorption of dyes, Methylene blue, Safranin T, and Malachite green onto polystyrene foam. Sep. Purif. Technol. 276, 119435 (2021).

Funding

This work was supported by Guizhou Basic Research Program (Natural Science) (QKH-ZK[2024]440); Guizhou Basic Research Program (Science and Technology Foundation) (QKH-ZK[2021]073).

Author information

Authors and Affiliations

Contributions

Z.J.Q. Writing – original draft, Visualization, Methodology, Investigation, Formal analysis, Data curation, Conceptualization. L. X.Y. Writing – review & editing, Writing – original draft, Validation, Supervision, Resources, Project administration, Methodology, Funding acquisition, Conceptualization. H. M. Writing – original draft, Validation, Investigation. W. W.L. Validation, Resources, Methodology. G. J.N. Validation, Methodology, Funding acquisition. Y. C. Validation, Methodology, Funding acquisition. X. P.H. Supervision, Funding acquisition, Conceptualization. W. A.P. Supervision, Methodology, Conceptualization. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, J., Long, X., Hu, M. et al. New insights in the low-temperature-dependent formation of amorphous titania-coated magnetic polydopamine nanocomposites for the adsorption of methylene blue. Sci Rep 15, 1388 (2025). https://doi.org/10.1038/s41598-025-85414-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-85414-3