Abstract

In the previous study, discarded oyster farming bamboo scaffolding (BS) demonstrated the potential for application in pulping and papermaking through the soda pulping process. However, soda pulping involves high temperatures and chemical dosages. Therefore, this study develops an alternative pulping process to lower temperature and chemical demands by utilizing a high-consistency kneader (HCK), simultaneously promoting the utilization of BS in pulping and papermaking. This study applies a factorial experimental design to assess the impact of thermo-alkali pretreating conditions (temperature and NaOH dosage) by analyzing pulping yield, freeness, fiber appearance, and handsheet properties. The factorial analysis shows that the temperature and NaOH dosage of thermo-alkali pretreatment significantly affect the pulp properties. The optimal condition of 125℃ and 7.5% NaOH dosage has the highest accepts ratio, the best refining capacity, and the highest handsheet strength. Further compared with previous soda pulping research, utilizing HCK can produce similar pulp properties while increasing the pulping yield and reducing the temperature (-26.5%) and chemical demands (-46.4%). In summary, HCK demonstrates feasibility and potential for application in the pulping process, offering a new perspective on mechanical pulping as presented in this study, while also creating an opportunity to promote BS utilization.

Similar content being viewed by others

Introduction

Due to an increasing awareness of environmentally friendly and sustainable development, establishing a circular economy is becoming important. Especially the circular utilization of agricultural surplus materials, which has gradually been focused on1,2. Because of the increasing demand for fiber feedstock in papermaking industries3, more and more agricultural surplus materials are used as non-wood fiber feedstocks for pulping to supply the fiber demands of the global papermaking industry4,5,thus, agricultural surplus materials in Taiwan also have the chance to be applied in pulping and papermaking.

According to the previous study6, the discarded bamboo scaffolding (BS) obtained from the oyster farming industry in Taiwan has the potential to be applied in pulping and papermaking, in which the BS can be pulped by soda methods and produced the high strength handsheets. With consideration that the recovered amount of BS is 4,000 to 5,000 tons per year and that the relevant controlling department is facing the challenge of applying it effectively and in a value-added manner, there is an opportunity to promote the use of BS in pulping and papermaking.

Pulping methods can be divided into three different types, mechanical, chemi-mechanical, and chemical pulping. Most agricultural surplus materials can be considered non-wood fibers, so the conventional pulping process for these materials is soda pulping7,8. The soda pulping process needs a higher temperature and chemical dosage. To reduce environmental damage, soda pulping needs to build a chemical recovery system to support the production, so the capital cost is relatively higher. However, the pulping production for agricultural surplus materials needs a smaller scale and the increasing awareness of environmentally friendly,the economic benefit and cost demands for soda pulping have limited the utilization of these materials9,10,11

In recent years, there have been gradually applied the mechanical methods on non-wood fiber pulping, in which chemi-mechanical pulping (CMP) has a higher pulping yield and a lower chemical dosage compared to chemical pulping. CMP is operated by softening the material by chemicals and refining by mechanical force12. Mboowa (2004)13 has indicated that non-wood fiber pulped by chemi-thermo mechanical pulping (CTMP) can be operated under lower chemicals and mechanical force demands to soften lignin and disintegrate the fibers. It can be assumed that CMP or CTMP has a better potential for greener pulping development.

Besides the pros of CMP and CTMP, compared to chemical pulping, Westenbroek14 has indicated that the mechanical process operated by extrusion for non-wood fiber pulping has a better feasibility of technique and economy, which can produce the pulp with lower consumption of energy and chemicals. The extruding process is mainly operated through the high-consistency extruder with a pulp consistency of 20 ~ 70%15. Liang et al.16 applied a twin-screw extruder (TSE) and a model screw device (MSD) to investigate the impacts on CTMP production of bamboo. The process began with bamboo softening, extruding, and finally chemical treatment, which the pulping yields after refining are 62.52% (TSE) and 79.78% (MSD). Hu et al.17 extruded the bamboo, treated the materials with ZnCl2, and then refined the materials, which had a pulping yield of 75.5% under the 10% ZnCl2 treatment. The above research applied the extruder to pulp the bamboo, which indicates that the high-consistency mechanical treatment has the potential to be applied in bamboo CMP or CTMP. Thus, this study is going to develop a CMP process for the BS by a high-consistency kneader with a similar operating mechanism to an extruder.

Kneader is a type of high-consistency treatment facility, which has conditions with lower rotating speed (100 ~ 200 rpm) and high consistency (25 ~ 40%) to lead the materials that generate the rubbing action between each other to furtherly disintegrate or disperse18. It has a similar screwing structure and operating conditions to TSE and MSD. Besides, according to the number of cylinders or kneading chests deployed, the functions of the kneader include dewatering, steam heating, washing, and chemical adding that each cylinder can be controlled separately16,19,20. The functions show benefits in the development of CMP pulping applications. Our previous research21 applied HCK as the pretreatment process in bio-mechanical rice straw pulp, showing the potential for applying HCK in mechanical pulping. However, no research has applied HCK as the refiner in the defibration stage of the mechanical pulping process. Based on the features of HCK and the literature review of TSE and MSD, this study assumes that HCK is feasible for defibration. Therefore, this study plans to apply HCK for the defibration process of CMP, aiming to develop a pulping process with lower temperature and chemical demands compared to soda pulping, further enhancing the feasibility of the BS applied in the pulping and papermaking industries.

The purpose of this study is to develop a CMP process as an alternative to soda pulping for the application of BS in pulping and papermaking, by incorporating HCK into the defibration process, which will be named the CMP-K process for the following description. The CMP-K process begins with a thermo-alkali pretreatment to soften the BS and then disintegrate the BS with a high-consistency kneader. This study applies a factorial experimental design to assess the impact of conditions (temperature and NaOH dosage) during the thermo-alkali pretreatment by analyzing the pulping yield, freeness before/ after refining, fiber appearances, and handsheet properties. After the assessment, this study will select an optimized condition to compare the pulping results with the optimized soda pulp in the previous study6, hoping that the CMP-K can promote the application of the BS in pulping and papermaking.

Experimental

Materials

The dried and chopped discarded oyster farming bamboo scaffolding (BS) chips are provided by Tainan City Fishing Harbor and Coastal Fisheries Management Office (Tainan City, Taiwan), with a moisture content of 9.21%, and size with a length of 0.5–1.0 cm, a width of 0.5–1.0 cm and a thickness of 0.3–0.5 cm. NaOH (extra pure grade) is provided by KATAYAMA PURE CHEMICAL Co., Ltd., Changhua, Taiwan.

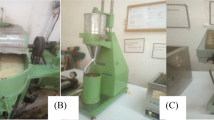

High-consistency kneader

The high-consistency kneader (HCK, ALL NEW BONAFIDE Co., Ltd., New Taipei City, Taiwan) applied in this study is shown in Fig. 1 (A). This HCK is equipped with three kneading cylinders in a series (three kneading sections), and each cylinder is paired with a cover with 9 fixed kneading blocks on it as shown in Fig. 1 (B). The cover is locked to the cylinder during the kneading operation, and the motion of the fixed kneading blocks and the moving blocks Fig. 1 (C) is staggered to produce the shear force on the materials. This study only operates the third cylinder of HCK with the constant condition, 500 g materials, 30% material consistency and 20 min retention time, to simulate the whole kneading process at the experimental scale.

CMP-K process

The pulping process is shown in Fig. 2. First, 500 g BS chips were replaced in the digestor and soaked in measured tape water for 5 min, then added the measured NaOH and started digesting. The constant conditions of thermo-alkali pretreatment include a heating rate of 1.5℃/min, solid-to-liquid ratio of 1: 5, and retention time at a target temperature of 90 min. After the pretreatment, the pretreated BS chips were washed with tap water and a 200-mesh filter till the filtered water turned clear, and then the materials were conditioned to the consistency of 30% for kneading. At the beginning of the kneading step, the materials with a consistency of 30% were replaced in the third cylinder of HCK (Fig. 1) and preheated by injecting a 1.2 kg/m2 steam till the temperature approaching 85℃, then started to knead for 20 min. After kneading, the pulp was collected by a 200-mesh filter and cooled down with tape water washing, then shortage by a plastic bag for the following screening and analysis.

Experimental design

In addition to the constant conditions mentioned above, this study applied a 22-factorial experimental design to determine the impact of two variables of thermo-alkali pretreatment, temperature, and NaOH dosage, on pulping properties. The variables are designed to further decrease the demands of temperature and chemical dosage from the previous study6. The experimental design of this study is shown in Fig. 3. Factor X1 is the temperature of the pretreatment, which is designed at a high level of 170℃ and a low level of 80℃; Factor X2 is the NaOH dosage, which is designed at a high level of 10.0% and a low level of 5.0%. This study also designed a middle point of two variables (125℃; 7.5%) with a duplicate experiment to assess the significance of the impact.

Pulp properties

Pulping yield

After the kneaded pulping, the unscreened pulp is screened through a flat screen with a slot width of 0.25 mm (Model 302, LESSON INDUSTRIAL Co., Ltd., Taiwan) according to TAPPI UM204. The shives are defined as the materials that cannot pass the slot; the accepted fibers (accepts) are defined as the pulp that can pass the slot and be retained by a 200-mesh filter; the fines are defined as the subjects that are washed out by the 200-mesh filter during the pulping and screening process. The shives and accepts are collected separately after the screening process. The shives and accepts are collected separately after the screening process. As the oven-dried weight of shives and accepts are measured, each containing ratio is calculated according to the following Eqs. (1), (2), (3).

Pulp freeness

A Canadian standard freeness (CSF) tester (Model 305, LESSON INDUSTRIAL Co., Ltd., Taiwan) measures the before and after refining pulps of accepted fibers according to TAPPI T227 om-17. Each sample does a duplicated measurement and is calibrated according to the temperature and the oven-dried weight of the testing pulp.

Accepted fiber appearance

The appearances of accepted fibers in the pulps, both before and after refining, were observed under an optical microscope (ECLIPSE E100, Nikon, Japan) equipped with a microscope camera (HDC588, MicroTech, Canada), and the images were captured using the MicroCam V5 software (M&T Optics Co., Ltd., Taipei).

Handsheet properties

After the screening, the accepts are refined by a Hollander beater (Model 304, LESSON INDUSTRIAL Co., Ltd., Taiwan) according to TAPPI T200 sp-96 for 120 min. The refined pulps are made the handsheets of 100 g/m2 according to TAPPI T205 sp-12 to analyze the grammage (TAPPI T410 om-08) and the thickness (TAPPI T411 om-21) first, and then select 6 handsheet samples with similar weight and thickness to record the bulk value and analyze the strength properties, including tensile index (TAPPI T494 om-01), burst index (TAPPI T403 om-15), and ring crush index (TAPPI T818 cm-18). In addition, the sample with the highest accepts ratio in the factorial experiment is refined by the Hollander beater for 60 min, compared with soda pulping properties from Sun et al.6. All the handsheets and analyses are conditioned and operated under 50.0 ± 2.0%RH and 23.0 ± 1.0℃ according to TAPPI T402 sp-13.

Statistical analysis

This study applies factorial experimental design on thermo-alkali pretreatment to investigate the impact of temperature and NaOH dosage on pulp properties. The analysis is calculated by Excel (Microsoft, USA) and follows the guidelines outlined in ‘Design and Analysis of Experiments 7/e’ written by Montgomery22.

Results and discussion

Pulping yield

Based on the factorial analysis chart of the pulping yield (Fig. 4), it can be observed that the pulping accepts ratios are around 34.96–47.39%, close to the bamboo chemical pulping yield results (35.7–51.7%) from laboratory research23,24, but lower than the bamboo mechanical pulping through refiner (50.7–79.78%)16,25. Although the accepts ratios are lower than the other mechanical pulping research, the total yields (accepts plus shives ratio: 47.58–74.62%) in this research are still in the yield range from other research, which can be indicated that the accepts yield still have an opportunity to be increased by further enhancing the defibration process.

increasing either the temperature or the NaOH dosage during pretreatment reduces the shives ratio while increasing the generation of fines. When both factors are at their highest levels in the factorial experiment, significant disintegration of shives occurs; however, this also leads to a higher production of fines, preventing the accepts ratio from reaching its highest value (Fig. 4(A)).

The results of the factorial impact analysis are shown in Table 1. All three factors significantly influence the accepts ratio, with the impact values ranked from highest to lowest as follows: X1X2 |-6.625|> X2 |4.215|> X1 |3.125|. This indicates that the interaction between temperature and NaOH dosage (X1X2) has the greatest effect on the accepts ratio. The shives and fines ratios are affected by both X1 (temperature) and X2 (NaOH dosage), with X1 showing a greater absolute impact value. This suggests that the temperature of the thermos-alkali pretreatment has a more significant impact on BS disintegration and fiber degradation than the NaOH dosage. From the above, both temperature and NaOH dosage significantly impact the shives and fines ratios, and their interaction results in the highest accepts ratio (47.39%) at the middle point conditions (125℃; 7.5% NaOH dosage).

Freeness

The factorials impact analysis and the charts of the accepted fiber and the refined pulp are presented in Table 2 and Fig. 5. It can be observed that the accepted pulp at each factorial point all have a freeness exceeding 700 mL (Fig. 5(A)) which is higher than the mechanical pulp produced by a refiner (Guerra et al.,27; Ref.28). From these results, it can be assumed that the kneading process does less fibrillation on pulp fibers. According to the impact analysis, the freeness of accepted fiber is not affected by the pretreatment factors. However, after a 120-min refining using a Hollander beater, the freeness at each point exhibits different changes and outcomes. In Fig. 5 (B), pulp subjected to higher temperatures and lower NaOH dosages during pretreatment demonstrates a lower freeness after refining. In Table 2, both factors X1 and X2 significantly affect the refined freeness, in which the absolute value shows X2 |85|> X1 |-45|. This trend aligns with the observations in Fig. 5 (B). From the above, it can be inferred that the pretreatment condition affects the refined capacity refining capability of the accepted fiber. Changes in the chemical properties of fiber, such as chemical compositions and the lignin distribution resulting from the thermos-alkali pretreatment, impact the refining characteristic of the fibers29,30. In this study, the middle point of the factorial experiment achieves the lowest freeness (172.5 mL), indicating that the fiber is easier to refine under these conditions.

Fiber appearance

Accepted fiber

The accepted fiber appearances at each factorial point are shown in Fig. 6, with images captured at 40X magnification. In Fig. 6, it can be observed that all accepted fibers exhibit an unbroken surface and a long, slender shape. The pulp fiber that is produced through the refiner shows fibrillation and extended fines on the surface25,26. This suggests that the kneading process effectively separates the softened BS chips into single-strand fibers without causing fibrillation. The fiber appearance of CMP-K is similar to the previous soda pulping study6, both demonstrating a slender shape and unbroken surface. With the freeness of accepted fiber exceeding 700 mL and no fibrillation observed on the fiber surface, it can be concluded that HKC does not exert a refining impact on fibers during the kneading process.

After refining

The accepted pulps are refined by a Hollander beater for 120 min to prepare them for handsheet making. The appearances of refined fiber are shown in Fig. 7. Compared to the fibers before refining (Fig. 6), the refined fibers exhibit extended fibrils on their surface, indicating the occurrence of external fibrillation. Additionally, slender fibers still can be observed in the images, as indicated by the red arrow in Fig. 7. The tethered fibril on the surface can increase the contact area, while the slender fibers contribute to forming a strong fiber network structure during papermaking (Smook,31; Ref.32). The refined fiber appearance shows an excellent fiber processing capability, as the fibers maintain their long and thin shape after refining. This indicates that the CMP-K process can produce an applicable fiber from the BS.

Handsheet properties

Physical properties

The BS CMP-K pulps were refined by a Hollander beater for 120 min, and handsheets of 100 gsm were prepared for testing. The factorial impact analysis and corresponding chart are shown in Table 3 and Fig. 8. As shown in Fig. 8, under the same refining conditions, the higher temperature and NaOH dosage of pretreatment results in a handsheet with higher strength, while higher temperature results in a lower bulk. The trends are confirmed by the factorial analysis in Table 3. X1 significantly affects all the handsheet properties, and X2 affects only the tensile and burst index. A comparison of the impact values for X1 and X2 reveals that temperature (X1) causes more impact on the handsheet properties.

When the handsheet properties are discussed alongside freeness, it can be found that the change in handsheet properties does not directly correlate with the freeness. Although the highest level of the two factors produces a pulp with higher refined freeness, the pulp still exhibits a better strength and lower bulk compared to points 1–3. This suggests that higher levels of factors can produce the pulp with better strength and drainage ability. However, the highest strength and the lowest bulk of the handsheet exhibits in the middle in this study, probably due to the lowest freeness (172.5 mL).

Surface structure

The SEM images of the handsheet surface at 50X magnification are presented in Fig. 9. It can be observed that higher temperature produces the handsheet with a denser fiber formation, where the external fibrils contact and entangle more tightly with each other (highlighted by the red circles at points 2 and 4). The phenomenon aligns with the bulk result in Fig. 8 (D), and the denser handsheet has higher strength properties. At the middle point, which has the lowest freeness, a denser fiber formation is observed from the surface, with the tethered fibril forming a net between the main strand of fiber (the red circle at point 5). Based on these observations, better handsheet strength is associated with lower bulk, which is attributed to denser fiber formation.

Comparing with soda pulp

From the above, the middle point (125℃; 7.5%) of the factorial experiment demonstrates the highest accepts ratio, the best refining capacity, and the best handsheet performance, which is asserted as the optimal condition in this study. The condition is compared with the optimal condition of the previous soda pulping research6, as shown in Table 4. Soda pulping achieves an accepts ratio of 40.28%, whereas the CMP-K exhibits a higher ratio of 47.39%. Besides the higher accepts ratio, in Fig. 10, it can be observed that CMP-K and soda pulp have similar fiber appearances. However, CMP-K shows fewer freeness changes, in which the freeness of soda pulp decreases by 415 mL and CMP-K only decreases by 272.5 mL under a 60-min refining process by the same Hollander beater. This study infers that the difference in refining properties between CMP-K and soda pulp is related to lignin content. The delignification level is lower in CMP-K, causing stiffer fiber that is more challenging to refine33,34. At lower freeness, the soda pulp also shows a higher handsheet strength and a lower bulk. However, based on the handsheet results of CMP-K, extending the refining time can further improve its handsheet strength. Although CMP-K requires more refining time to reach a similar quality to soda pulp, the CMP-K process has significantly lower demands for temperature (a 26.5% reduction) and NaOH dosage (a 46.4% reduction) during the pulping process compared to soda pulping. It also has a higher accepts ratio and similar accepted fiber appearances to soda pulp, which exhibits the feasibility of substituting soda pulp.

Conclusion

Based on the results, the CMP-K process demonstrates the potential to be applied in high-consistency mechanical pulping. The temperature and NaOH dosage conditions of the thermos-alkali pretreatment significantly influence the pulping properties of the CMP-K process. The optimal condition of 125℃ and 7.5% NaOH dosage results in the highest accepts ratio (47.39%), the best refining capacity, and the highest handsheet strength. Compared to the previous soda pulping research, the CMP-K process achieved a higher yield and similar pulp characteristics while requiring lower temperature and reduced chemical dosage. These advantages exhibit the potential and feasibility of the CMP-K process as a substitute for soda pulping in utilizing agricultural surplus materials for pulping and papermaking. Furthermore, the application of HCK in this study pulping process provides new insight into high-consistency mechanical pulping.

Data availability

The datasets presented in this current study are available from the corresponding author on reasonable request.

Abbreviations

- BS:

-

Discarded oyster farming bamboo scaffolding

- HCK:

-

High-consistency kneader

- CMP:

-

Chemi-mechanical pulp

References

Freitas, L. C. et al. From waste to sustainable industry: How can agro-industrial wastes help in the development of new products? Resour. Conserv. Recycl. 169, 105466. https://doi.org/10.1016/j.resconrec.2021.105466 (2021).

Ng, H. S. et al. Recent advances on the sustainable approaches for conversion and reutilization of food wastes to valuable bioproducts. Biores. Technol. 302, 122889. https://doi.org/10.1016/j.biortech.2020.122889 (2020).

Berg, P. & Lingqvist, O. Pulp, Paper, and Packaging in the Next Decade: Transformational Change (McKinsey & Company, 2019).

Pydimalla, M., Chirravuri, H. V. & Uttaravalli, A. N. An overview on non-wood fiber characteristics for paper production: Sustainable management approach. Mater. Today: Proc. https://doi.org/10.1016/j.matpr.2023.08.278 (2023).

Hawanis, H. S. N. et al. Insights into lignocellulosic fiber feedstock and its impact on pulp and paper manufacturing: A comprehensive review. Sustain. Mater. Technol. https://doi.org/10.1016/j.susmat.2024.e00922 (2024).

Sun, H. C. et al. Circular utilization of discarded oyster farming bamboo scaffolding in pulp and papermaking. Sci. Rep. 13, 21230. https://doi.org/10.1038/s41598-023-48191-5 (2023).

Sridach, W. The environmentally benign pulping process of non-wood fibers. Suranaree J. Sci. Technol. 17(2), https://www.thaiscience.info/journals/Article/SJST/10890500.pdf (2010).

Liu, Z., Wang, H. & Hui, L. Pulping and papermaking of non-wood fibers. Pulp and paper process. 1, 4–31. https://doi.org/10.5772/intechopen.79017 (2018).

Leponiemi, A. Non-wood pulping possibilities-a challenge for the chemical pulping industry. Appita: Technol., Innov., Manuf., Environ. 61(3), 234–243. https://doi.org/10.3316/informit.113971606209440 (2008).

Abd El-Sayed, E., El-Sakhawy, M. & El-Sakhawy, M. A. M. Non-wood fibers as raw material for pulp and paper industry. Nordic Pulp & Paper Res. J. 35(2), 215–230. https://doi.org/10.1515/npprj-2019-0064 (2020).

Worku, L. A., Bachheti, A., Bachheti, R. K., Rodrigues Reis, C. E. & Chandel, A. K. Agricultural residues as raw materials for pulp and paper production: Overview and applications on membrane fabrication. Membranes 13(2), 228. https://doi.org/10.3390/membranes13020228 (2023).

Liu, R. et al. The effect of hemicellulose pre-extraction on the wood viscoelasticity and its implications on the fiber separation mechanism in Chemi-mechanical pulping. Biomass and Bioenerg. 177, 106949. https://doi.org/10.1016/j.biombioe.2023.106949 (2023).

Mboowa, D. A review of the traditional pulping methods and the recent improvements in the pulping processes. Biomass Conv. Bioref. 14(1), 1–12. https://doi.org/10.1007/s13399-020-01243-6 (2024).

Westenbroek A. P. H. Extrusion pulping of natural fibers, determination, implementation and verification of constitutive equations required for modelling. Ph.D. Thesis. Wageningen University and Research Centre, Wageningen, 150 p. (2000).

Li, J., Thompson, M. & Lawton, D. J. Improved chemical reactivity of lignocellulose from high solids content micro-fibrillation by twin-screw extrusion. J. Polym. Environ. 27, 643–651. https://doi.org/10.1007/s10924-019-01377-3 (2019).

Liang, F. et al. The use of twin screw extruder instead of model screw device during bamboo chemi-mechanical pulping. BioResources 13(2), 2487–2498. https://doi.org/10.15376/biores.13.2.2487-2498 (2018).

Hu, Z., Musikavanhu, B., Li, J., Li, J. & He, Z. ZnCl2 pretreatment of bamboo chips to produce chemi-thermomechanical pulp: Saving refining energy and improving pulp properties. BioResources 13(3), 5164–5178 (2018).

Kumar, S. et al. Past, present and future of dispersion and kneading. Prog. Paper Recycl. 16(4), 6 (2007).

Matsukura, H. An effective method for waste paper treatment using a new kneading action taizen washer has a concentration system to extract fiber within the white water and awarded the sasaki prize in 1999 for this innovative technology. Jpn. TAPPI J. 54(1), 31–38. https://doi.org/10.2524/jtappij.54.31 (2000).

Yue, J. Q., Huang, X. L., Wang, H. Y. & Lu, W. A new method for the pulping of aspen branch wood. Adv. Mater. Res. 2010(113–116), 847–853. https://doi.org/10.4028/www.scientific.net/AMR.113-116.847 (2010).

Lai, Y. H. et al. Development of bio-mechanical rice straw pulp by high consistency kneader with thermal and Alkaline. Heliyon https://doi.org/10.1016/j.heliyon.2023.e19317 (2023).

Montgomery, D. C. Design and analysis of experiments. John Wiley & Sons. (2017).

Chibudike, H. O., Ndukwe, N. A., Nkemdilim Ifeanyi, O. B. I., Adeyoju, O. A., & Chibudike, E. C. Soda pulping experiments and yield optimization on bamboo fiber for pulp and paper production. GSJ, 8(11). (2020).

Suhaimi, N. M., Hassan, N. H. M., Ibrahim, R. & Jasmani, L. Pulping yield and mechanical properties of unbeaten bamboo paper. Pertanika J. Sci. Technol. https://doi.org/10.47836/pjst.30.2.30 (2022).

Ashaari, Z., Salim, S., Halis, R., Yusof, M. N. M. & Sahri, M. H. Characteristics of pulp produced from refiner mechanical pulping of tropical bamboo (Gigantochloa scortechinii). Pertanika J. Tropical Agric. Sci. 33(2), 251–258 (2010).

Do, V. T., Tanifuji, K., Jin, G. & Ohi, H. Neutral sulfite semi chemical pulping of moso bamboo. Jpn. TAPPI J. 74(4), 379–387. https://doi.org/10.2524/jtappij.74.379 (2020).

Guerra, A., Mendonça, R. & Ferraz, A. Bio-chemimechanical pulps from eucalyptus grandis: Strength properties, bleaching, and brightness stability. J. wood Chem. Technol. 25(4), 203–216. https://doi.org/10.1080/02773810500366573 (2005).

Sha, J., Nikbakht, A., Wang, C., Zhang, H. & Olson, J. The effect of consistency and freeness on the yield stress of chemical pulp fibre suspensions. BioResources 10(3), 4287–4299. https://doi.org/10.15376/biores.10.3.4287-4299 (2015).

Anjos, O., Santos, A., & Simões, R. Influence of hemicelluloses content on the paper quality produced with Eucalyptus globulus fibres. In Progress in Paper Physics Seminar 2004 (pp. 50–52). http://hdl.handle.net/10400.11/2185.

Gharehkhani, S. et al. Basic effects of pulp refining on fiber properties—A review. Carbohydr. Polym. 115, 785–803. https://doi.org/10.1016/j.carbpol.2014.08.047 (2015).

Smook, G. Handbook for Pulp & Paper Technologists 5th edn. (TAPPI Press, 2016).

Kerekes, R. J., McDonald, J. D. & Meltzer, F. P. External fibrillation of wood pulp. Tappi. J. 22(6), 363–371. https://doi.org/10.32964/TJ22.6.363 (2023).

Henriksson, Å. & Gatenhalm, P. Surface properties of CTMP fibers modified with xylans. Cellulose 9, 55–64. https://doi.org/10.1023/A:1015826713109 (2002).

Małachowska, E., Dubowik, M., Lipkiewicz, A., Przybysz, K. & Przybysz, P. Analysis of cellulose pulp characteristics and processing parameters for efficient paper production. Sustainability 12(17), 7219. https://doi.org/10.3390/su12177219 (2020).

Acknowledgements

Special thanks to Rong-Zai. Wu, chief of coastal fisheries at the Tainan City Fishing Harbor and Coastal Fisheries Management, for providing the BS materials and valuable information on oyster farming surplus materials management.

Author information

Authors and Affiliations

Contributions

Y.S. conceived the study. H.C., Y.H. and Y.J developed and performed the experiment of pulping. K.Y. and J.G. analyzed data. All the authors discussed and analyzed the results. H.C. and Y.S. wrote the paper. Y.H., K.Y., S.Y. and J.G. discussed and amended the paper. All the authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sun, HC., Lai, YH., Lo, YJ. et al. Feasibility of substituting soda pulping with high consistency kneaded chemi mechanical pulping for discarded oyster farming bamboo scaffolding. Sci Rep 15, 1457 (2025). https://doi.org/10.1038/s41598-025-85656-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-85656-1