Abstract

To reduce the vibration frequency superimposed on the original vibration frequency of a coal seam containing structural coal, damage to the coal structure should be reduced, and the occurrence of coal and natural gas outburst accidents should be prevented. Therefore, the influence of different loading rates on the vibration frequency of structural coal assemblages is studied. In this paper, an HG-01 equipment vibration frequency test system is used, and the percussion method is used to determine the influence of different structural coal ratios on the inherent vibration frequency of the combined sample. The self-developed integrated experimental bench of high- and low-frequency impact mechanics and frequency comprehensive testing is used to load the sample and test the vibration frequency of the sample containing tectonic coal combinations at various loading rates. The results show that the vibration frequency of the combined samples containing tectonic coal gradually increases, whereas the average value of the amplitude gradually decreases as the loading rate increases. During the vibration of a tectonic coal assembly, the amplitude of vibration is related to its intrinsic vibration frequency. When an external force or pressure is applied to the tectonic coal assembly at a frequency close to the natural frequency, resonance is reached, and then the amplitude of vibration increases. However, if the applied loading rate causes the vibration frequency of the coal body to exceed the resonance frequency, the tectonic coal assembly will not have enough time to respond to the change in the external pressure. At this point, the vibration amplitude decreases. Studying the vibration frequency characteristics of samples containing tectonic coal assemblages at various loading rates can offer basic theoretical support for the gas transportation law of coal seams and guide gas extraction and prevention of mine gas accidents.

Similar content being viewed by others

Introduction

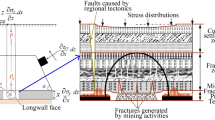

Coal plays an important role in promoting the development of the national economy as an important energy source in China1. Coal seams have been affected by tectonic stresses over a long time, forming tectonic coal with low strength and weak viscosity. Tectonic coals are rich in primary defective structural systems, leading to a significant increase in the permeability of the coal seam when disturbed, and high-intensity gas desorption occurs, which makes it extremely easy for a coal and gas outburst to occur2,3,4,5,6. China has large tectonic coal reserves, and coal seams containing structural coal are widely distributed in all kinds of mines. Mining easily results in stress concentration in front of the work, under a constant change in stress, easily causing the vibration frequency and the original vibration frequency of the coal seam to be superposed at the same frequency, increasing the degree of destruction of the coal body structure and subsequently inducing coal and gas protrusion7,8,9,10,11,12,13.

The study of coal body vibration frequency has important practical significance in coal mining. By reasonably controlling the vibration frequency of coal body, the safety and efficiency of coal mining can be effectively improved. In the process of gas extraction, by adjusting the vibration frequency, the adsorption and desorption characteristics of gas can be optimized, and the efficiency of gas extraction can be improved. In the process of coal mine excavation and mining back, by monitoring the change of vibration frequency of the coal body, potential risks of geologic disasters, such as coal and gas protrusion, roof slab fall, etc., can be discovered in time. Thus, corresponding preventive measures can be taken to ensure the safe conduct of coal mining.The influence law of the loading rate on the vibration frequency of tectonic coal-containing assemblages was investigated, which is crucial for ensuring the safety of mines having prominent coal and gas production.

At present, the influencing factors of media vibration frequency have been studied worldwide. Li Shugang et al.14 investigated this phenomenon under conditions of reduced coal pore pressure, adsorption strength and vibrational stresses. The calculated porosity reflects the variation in uniaxial compressive strength under vibration. Wei Jianping et al.15,16, based on the test principle of the percussion method, reported that the Hanning window is more suitable for FFT analysis of coal vibration signals, can accurately identify the frequency corresponding to the spectrum peak, and can directly obtain the natural frequency of coal. Zhang Su et al.17 analysed the influence of water content on the natural vibration frequency of raw coal through its spectrum characteristics and reported that with increasing water content, the stiffness of coal and rock decreases, the mass increases, the damping ratio increases, and the natural vibration frequency clearly tends to decrease. Li Chengwu et al.18 studied the variation identity of the natural vibration frequency of coal and rock masses in the case of floor disturbance and failure and its relationship with stability and concluded that under the influence of vibration, cracks in coal and rock masses expand, and the degree of damage increases, resulting in a reduction in the stiffness coefficient and an increase in the damping ratio coefficient. Mullakaev M S et al.19 obtained a longitudinal natural vibration frequency of the reservoir formation environment of 19,969 Hz through theoretical analysis and simulation research and developed ultrasonic stimulation equipment for oil reservoir permeability. Yin S et al.20 reported that the natural frequency of high-density hard rock ranges from 20 and studied the relationship between hard rock rupture and vibration energy by using ultrasonic waves with an excitation frequency of 20 kHz. Li W et al.21 reported that the intrinsic frequencies of grey sandstone, siltstone and sandy mudstone were between 1.58 and 2.46 kHz, the intrinsic frequencies of rock samples decreased with sample rupture, and the highest drilling efficiency was achieved at a vibratory excitation frequency of 1.5 kHz. Sun Xiaoyuan et al.22 performed mode separation and signal reconstruction of monitoring signals during forced vibration of coal rock bodies via the Hilbert–Huang transform (HHT), focusing on the mechanism of the resonance amplification effect combined with the knowledge of vibration mechanics. Li et al.23 studied the vibration response of rocks under the action of harmonic shock by considering three main controlling factors: the excitation frequency, shock amplitude and rock density. Li Chengwu et al.24 studied the natural frequency of coal samples and combined samples of coal and rock to understand the evolution law of the resonance frequencies of coal and rock under forced vibration by using a seismic shaking table vibration system. Li Lianggang et al.25 analysed the influence of the vibration frequency of an acoustic drilling rig on the effect of rock block crushing and the reasonable selection of the drilling process. Song Yang et al.26 carried out experiments on the permeability and internal fine structure evolution law of coal rock under low-frequency vibration loading and reported that after low-frequency vibration loading, the permeability of coal rock can improve, the vibration frequency is 10 Hz, the coal rock itself reaches resonance, and at this time, the permeability of the coal rock appears to be the peak value. Li Haopeng et al.27 reported that the vibration frequency was positively correlated with the rate of gas desorption, with the best desorption effect and the largest gas diffusion coefficient for coal samples at 60 Hz. Xu Zhipeng et al.28 obtained the number of wavelet packet decomposition layers of vibration signals based on the denoising method of optimal wavelet bases via spectral analysis and wavelet packet analysis.

During coal mining, the mechanical loading environment is an important part of the stress state of the coal body. It not only affects the stability of the coal seam, but is also directly related to the changes in the vibration characteristics of the coal body. As a reflection of the physical properties of the coal body, the intrinsic frequency is closely related to its internal microstructure and mechanical properties. The loading vibration frequency, on the other hand, is a direct reflection of the vibration response of the coal body under external mechanical loading. The interaction between the two is of great significance for understanding the mechanism of coal and gas herniation, predicting the risk of herniation and formulating effective preventive and control measures. In recent years, with the increase of coal mining depth and mining intensity, the problem of coal and gas prominence has become more and more prominent. It is particularly urgent to study the vibration characteristics of tectonic coal seam and its relationship with the loading vibration frequency. Research on the influence of mechanical loading environment on the vibration frequency of tectonic coal combinations. It can not only reveal the response mechanism of coal body under external perturbation, but also provide new theoretical perspectives and technical means for the prediction, forecasting and prevention of coal and gas herniation. By performing experiments on the vibration frequency of tectonic coal-containing assemblages under different loading rates, their vibration frequency under the impact of the loading rate is investigated. The results of this study can provide basic theoretical support for coal seam gas transportation laws and guide gas extraction and prevent mine gas accidents.

Vibration frequency test method and experimental program

Preparation of coal samples

Coal samples from the main face of a high-gas mine in the Inner Mongolia Autonomous Region were selected for the experiment. As a high-gas mine, the gas content in its coal seams is usually high, and the gas pressure may gradually increase with the increase of mining depth. This increases the safety risk in the mining process and requires effective gas control measures. The coal sample is processed into a cylindrical sample with a diameter of 50 mm and a height of 100 mm, and its nonparallelism and nonperpendicality are ensured to be less than 0.02 mm. To eliminate the differences in physical and chemical properties between individuals as much as possible, coal samples are cut and polished from the same lump of raw coal. After preparation, a coal sample with a regular structure and complete surface was polished smooth. The longitudinal wave velocity of the coal sample is measured by an ultrasonic detector. Coal samples with similar physical properties were selected for numbering, and the tested coal samples were wrapped in plastic wrap for subsequent experiments. The coal sample collected on site is shown in Fig. 1.

The primary coal and tectonic coal samples at the site were collected and tested for industrial composition. The national standard GB/T212-2008 “Industrial Analysis Methods of Coal” was used to analyse and test the composition of the coal samples. The coefficient of robustness of the coal samples was tested via the drop‒hammer method. The specific test results are shown in Table 1.

Vibration frequency testing system

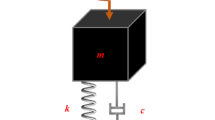

The integrated experimental platform for high- and low-frequency impact mechanics and frequency comprehensive tests is composed of a hydraulic slow pressure loading module, an active high-frequency impact module, a PC + PLC integrated control module, a frequency monitoring system and a data acquisition system. The main functions are as follows: (1) Stamping the coal rock material and slow pressure to construct a model; (2) uniaxial compression mechanical parameters and frequency tests of the rock, coal and coal-like materials; and (3) impact testing and frequency testing of the rock, coal rock, and coal-like rock materials. The equipment vibration frequency test system includes a vibration sensor, a collector, and computer software. The HG-01 vibration frequency test system uses a piezoelectric IEPE vibration acceleration sensor. The connection diagram is shown in Fig. 2. The sensor-related parameters are shown in Table 2. A collector is a device that supplies power to sensors and collects dynamic signals from them. Power ports, power switches, power indicators, signal input ports for channel 1 and channel 2, and USB communication ports are distributed on the panels on both sides of the collector. The computer software used includes a collector driver and data management analysis software.

Principles and methods of vibration frequency testing

The vibration frequency of tectonic coal-containing assemblages is a result of a combination of factors, including the size of the coal sample, water content, initial state of the coal sample, material properties, percentage of tectonic coal, loading rate, etc.

The principle of vibration frequency testing is mainly based on the characteristics of the signals generated when an object vibrates. These signals are collected, processed and analyzed by sensors or instruments to determine the vibration frequency of the object. When an object is subjected to an external force, it will vibrate. This vibration creates strain or displacement within the object, which in turn creates a vibration signal that can be measured. The acceleration sensor used in the experiment is based on Newton’s second law, which determines the intensity and frequency of vibration by measuring the acceleration on the object. The acquired vibration signals usually contain a large number of noise and interference components. Therefore, signal processing techniques such as filtering, amplification and analog-to-digital conversion are required to extract useful vibration information. In the experiments, an impulse hammer is used to gently strike the tested point of the specimen. If the strike is short enough, the specimen is actually subjected to a shock pulse that contains energy at all frequencies from 0 to infinity and whose frequency spectrum is continuous. Only those frequency components of the pulse that have the same frequency as the self-oscillation frequency of the coal rock specimen will act on the specimen. The specimen is made to vibrate freely at its intrinsic lower order self-oscillation frequency, which is the intrinsic frequency of the coal sample. At present, there are few studies on the influence of different loading rates on the vibration frequency of structural coal assemblages. Therefore, this paper studies the effects of different structural coal proportions and loading rates on the vibration frequency of structural coal assemblages.

The experimental system is composed of an HG-01 vibration frequency test system and high- and low-frequency impact mechanics instruments. According to the experimental program, seven standard samples with 0%, 11.1%, 20%, 33.3%, 50%, 62.5%, and 100% tectonic coal were taken from each group for the experiment. The experimental procedure was as follows.

-

(1)

Specimen preparation: the end surfaces of the samples were smoothed, weighed and dimensioned sequentially by group. The samples with greater homogeneity in weight and dimension were selected for subsequent experimental studies to improve the accuracy of the experimental results.The coal samples were dried in a 60 °C drying oven for 12 h before the experiment to avoid the effect of moisture content on the intrinsic frequency.

-

(2)

Parameter setting: the experiments were conducted using high- and low-voltage impact frequencies, displacement-controlled loading was used as the loading method, and different loading rates were set as 0.02 mm/s, 0.03 mm/s, 0.04 mm/s, 0.05 mm/s, and 0.06 mm/s. The vibration frequency measurement sensor was combined to carry out the experiment.

-

(3)

Sensor arrangement: The vibration frequency test transducer is arranged at the rear of the sample to avoid influencing the vibration frequency test transducer during the experiment.

-

(4)

Experimental calibration: The sensor is tested before the experimental test to avoid signal acquisition failure due to movement of the sensor or loosening of the connection. The proper acquisition of vibration sensors during loading experiments should be ensured.

-

(5)

Specimen layout: the samples were placed on the central axis of the pressure plate on the integrated test bench for high- and low-frequency impact mechanics and comprehensive frequency testing. The pressure plate of the test machine was adjusted by the key of the high- and low-frequency impact mechanics instrument to ensure that it closely fit the sample.

-

(6)

Carry out the experiment. The data is collected through the collector and passed to the software at the computer end, the windowing function is added to filter and process the data.

Results and analysis of natural frequency tests for coal assemblages with different structures

Acceleration signal processing

The acceleration signal is the signal obtained from the vibration source through the acceleration sensor, which is mathematically expressed as a function of time as the independent variable. Common vibration signal analysis methods include Fourier transform, waveform analysis, order analysis, and spectrum analysis. These methods can help identify the frequency characteristics of object vibration. Experiments using Fourier transform can convert the vibration signal from the time domain to the frequency domain, thus visualizing the distribution of the signal at different frequencies. The raw signal obtained through the signal acquisition system is often interfered with by external noise. Therefore, the vibration signal needs to be processed for the purpose of removing noise and enhancing the signal. The time-domain description of the vibration signal can reflect only the change in the signal with time. The time-domain description is transformed to a frequency-domain description to identify the periodic component of the signal and its magnitude, thus revealing the frequency information of the signal and determining the vibration frequency of the sample29,30,31. The collected vibration acceleration signals were filtered and then subjected to fast Fourier variation to calculate the intrinsic frequency of the coal sample.

The acquired data signals were subjected to fast Fourier transform (FFT) via Origin software. The Fourier transform formula of the vibration signal is as follows32,33:

where X(f) is the frequency domain of the signal; x(t) is the time domain of the signal; and f is the frequency, Hz.

The window function needs to be added to truncate the time-domain signal, and since each FFT transform can be performed only on a finite length of time-domain data. When using the percussion method to test the intrinsic frequency of the coal body, the size of the intrinsic frequency of the coal sample is the focus of the analysis, and from the point of view of reducing the leakage, the use of the Hanning window is the best. Therefore, in this paper, the Hanning window is chosen for signal truncation.

Natural frequency test results

To study the natural frequency characteristics of tectonic coal-containing assemblages under different tectonic coal ratios, 7 groups of samples with tectonic coal ratios of 0%, 11.1%, 20%, 33.3%, 50%, 62.5%, and 100% were selected for the natural frequency test experiments. FFT analysis was performed for the vibration signals of each sample, resulting in the frequency characteristics shown in Fig. 3.

The anomalous signals of the vibration time-domain map are rejected, and the time-domain signals are statistically analysed via the FFT. The natural frequency of the tectonic coal-containing assemblage can be described, and graphs of acceleration amplitude versus frequency for different tectonic coal-containing assemblages are obtained. The peak amplitude of the natural frequency of the entire primary coal sample is 27.88 mm, and the amplitude remains at 0–10 mm after stabilization. The peak amplitude of the natural frequency of the assemblage sample containing 11.1% tectonic coal thickness is 53.33 mm, and the amplitude remains at 0–20 mm after stabilization. The peak amplitude of the natural frequency of the assemblage sample containing 20.0% tectonic coal thickness is 28.41 mm, and the amplitude after stabilization, the peak value of the natural frequency amplitude is 28.41 mm, and the amplitude is 0–15 mm. The peak amplitude of the natural frequency of the natural frequency of the test sample with 62.5% tectonic coal thickness is 66.61 mm, and the amplitude is 0–35 mm. The peak amplitude of the natural frequency of the test sample with 50% tectonic coal thickness is 57.21 mm, and the amplitude is 0–34 mm. The peak amplitude of the natural frequency of the test sample with 62.5% tectonic coal thickness is 0–34 mm. The peak amplitude of the natural frequency of the sample with 62.5% tectonic coal thickness is 55.85 mm, and the amplitude is 0–35 mm after stabilization; the peak amplitude of the natural frequency of the sample with all tectonic coals is 73.13 mm, and the amplitude is 0–32 mm after stabilization. The amplitude of the acceleration decreases with increasing frequency and reaches stabilization at 15 Hz.

Test results and analysis of the vibration frequency of tectonic coal assemblages under different loading rates

Influence of different percentages of tectonic coal on the vibration frequency of tectonic coal-containing assemblages

The effects of different percentages of tectonic coal on the vibration frequency of the samples were investigated. The vibration signals of all the primary coal samples, tectonic coal samples with percentages of 11.1%, 20.0%, 33.3%, 50.0%, and 62.5% assemblage samples, and all the tectonic coal samples were analysed via the FFT at a loading rate of 0.03 mm/s, and frequency domain plots of frequency-specific vibrations were derived. The effects of different tectonic coal occupancies on the vibration frequency of the samples were analysed. The vibration frequency domain diagrams of the combined samples with different tectonic coal occupancy ratios are shown in Fig. 4.

The amplitudes of all the primary coal samples peak at a frequency of 5.09 Hz, gradually decrease with increasing frequency, and reach a stable value at 60.00 Hz, with an average frequency amplitude of 370.23 mm. The amplitude of all the structural coal samples reaches a peak value when the frequency is 5.00 Hz, and then the amplitude decreases suddenly. With increasing frequency, the amplitude tends to decrease, and the average frequency amplitude is 15.56 mm. The amplitude of the sample containing 11.1% structural coal peaked when the frequency was 4.99 Hz, and then the amplitude decreased. With increasing frequency, the amplitude gradually stabilized, and the average amplitude of the frequency was 15.51 mm. The amplitude of the sample containing 20.0% structural coal peaked when the frequency was 4.99 Hz, and then the amplitude suddenly decreased. With increasing frequency, the amplitude gradually stabilized, and the average amplitude of the frequency was 16.10 mm. The amplitude of the composite sample with a structural coal thickness of 33.3% reached its peak when the frequency was 4.99 Hz, and then the amplitude suddenly decreased. With increasing frequency, the amplitude gradually stabilized, and the average amplitude of the frequency was 14.81 mm. The amplitude of the composite sample containing 50.0% structural coal reached its peak when the frequency was 5.03 Hz, and then, with increasing frequency, the amplitude gradually decreased and stabilized, and the average frequency amplitude was 14.92 mm. The amplitude of the 62.5% composite sample with structural coal thickness peaked when the frequency was 4.99 Hz, and then the amplitude suddenly decreased. With increasing frequency, the amplitude gradually stabilized, and the average amplitude of the frequency was 16.23 mm.

The influence of different proportions of tectonic coal on the vibration frequency of a sample is shown in Fig. 5. With increasing proportion of structural coal, the average frequency and its amplitude basically remain unchanged. The overall density of protoplasmic coal is relatively uniform because it is not affected by tectonic deformation. The distribution of density inside the structural coal assemblage is not average because it contains structural faults. This difference in density leads to inconsistent damping effects during vibration propagation, which causes differences in the amplitude of vibration frequencies, resulting in a relatively large amplitude of vibration frequencies for whole protoplasmic coals. Signal waves propagate in tectonic coal-containing assemblage seams with rapid frequency changes. Due to their complex geological structure, assemblage seams have different elasticities and densities. The rapid change in vibration frequency in a sample containing a tectonic coal assemblage is caused mainly by the complexity and nonhomogeneity of the sample, as well as the response of the vibration signal to different substances in the propagation process.

Influence of different loading rates on the vibration frequency of tectonic coal-containing assemblages

The vibration signals of the assemblage samples with 50.0% tectonic coal were analysed via FFT at loading rates of 0.02 mm/s, 0.03 mm/s, 0.04 mm/s, 0.05 mm/s, and 0.06 mm/s, and frequency domain plots of frequency-specific vibrations were derived. The influence of different loading rates on the vibration frequency of samples containing tectonic coal assemblages was analysed. The vibration frequency domain plots for each loading rate are shown in Fig. 6.

When the loading rate is 0.02 mm/s, the amplitude peaks when the frequency is 5.01 Hz. With the gradual increase in frequency, the amplitude gently oscillates, and the average amplitude of the frequency is 16 mm. When the loading rate is 0.03 mm/s, the amplitude reaches the peak value when the frequency is 5.03 Hz. With increasing frequency, the amplitude shows a decreasing trend and gradually becomes stable, and the average amplitude of the frequency is 14.92 mm. When the loading rate is 0.04 mm/s, the amplitude reaches the peak value when the frequency is 5.03 Hz. With the gradual increase in frequency, the amplitude gently oscillates, and the average amplitude of the frequency is 10.36 mm. When the loading rate is 0.05 mm/s, the amplitude reaches the peak value when the frequency is 5.04 Hz. With the gradual increase in frequency, the amplitude gently oscillates, and the average amplitude of the frequency is 10.12 mm. When the loading rate is 0.06 mm/s, the amplitude reaches the peak value when the frequency is 5.05 Hz. With the gradual increase in frequency, the amplitude gently oscillates, and the average amplitude of the frequency is 9.98 mm.

The influence of the loading rate on the vibration frequency of the tectonic coal assemblage is analysed in Fig. 7. As the loading speed increases, the frequency of structural coal composite samples increases gradually, and the average amplitude decreases gradually. When the loading speed increases, the external pressure on the structural coal assembly changes faster. In the process of vibration of a structural coal assembly, the amplitude of vibration is related to its natural vibration frequency. When the external force or pressure is applied to the structural coal assembly at a frequency close to the natural frequency, the resonance is reached, and the vibration amplitude increases. However, if the applied loading speed causes the vibration frequency of the coal body to exceed the resonance frequency, then the structural coal assembly will not have enough time to respond to the change in external pressure, and the vibration amplitude will be reduced. Studying the variation in the vibration frequency of tectonic coal-containing assemblages is important for geological investigations and monitoring of coal mines.

Conclusions

-

(1)

Primary coals are not affected by tectonic deformation, and their overall density is relatively uniform. Tectonic coal-containing assemblages have uneven density distributions within the coal body due to tectonic faults and other causes. This density difference leads to an inconsistent damping effect during vibration propagation, which causes a difference in the vibration frequency amplitude, resulting in the vibration frequency amplitude of all primary coal being relatively large.

-

(2)

As the loading rate increases, the stress wave propagation speed of the specimen is accelerated, the deformation speed increases, and the elastic potential energy accumulation speed is accelerated. This leads to an increase in the vibration frequency of the specimen, which is maximized to 5.05 Hz at a loading rate of 0.06 mm/s^. In contrast, the mean value of the amplitude decreases due to energy dissipation and is minimized to 9.98 at a loading rate of 0.06 mm/s^.

-

(3)

During the vibration of a tectonic coal assemblage, the amplitude of vibration is related to the intrinsic vibration frequency. Resonance is reached when an external force or pressure is applied to the constructed coal assemblage at a frequency close to the natural frequency, after which the amplitude of vibration increases. However, the vibration amplitude decreases if the applied loading rate causes the vibration frequency of the coal body to exceed the resonance frequency, resulting in a tectonic coal assemblage that does not have enough time to respond to changes in external pressure.

Data availability

Data sets generated during the current study are available from the corresponding author on reasonable request. 1552093401@qq.com.

References

Li, S. G., Zhang, J. F. & Shang, J. X. Conceptualization and connotation of gas co-production technology system under dual-carbon target. Coal J. 47(04), 1416–1429 (2022).

Liu, J. J., Gao, J. L., Zhang, X. B., Jia, G. N. & Wang, D. Experimental study of the seepage characteristics of loaded coal under true triaxial conditions. Rock. Mech. Rock. Eng. 52, 2815–2833 (2019).

Zhang, C. L., Wang, P. Z. & Wang, E. Y. 70 years of development and prospect of the mechanism of coal and gas herniation in China. Coalf. Geol. Explor. 51(02), 59–94 (2023).

Tang, J. P., Zhang, X. & Pan, Y. S. Current status and prospect of physical simulation test research on coal and gas protrusion. J. Rock Mech. Eng. 2023, 1–21 (2023).

Cheng, Y. P. & Lei, Y. Study on the relationship between tectonic coal and coal-gas protrusion. J. Coal Sci. 46(01), 180–198 (2021).

Cheng, Y. P. & Wang, C. H. Tectonic coal deformation energy and its role in coal and gas herniation. J. Coal Sci. 49(02), 645–663 (2024).

Hou, S. H., Wang, X. M. & Li, D. Y. Pore fractal characteristics of tectonic coals with different grain sizes. China Coal Geol. 35(10), 1–7 (2023).

Wang, B., Liu, X. & Tu, Q. Pore structure characteristics of tectonic coal and its effect on gas extraction. Min. Technol. 23(05), 163–170 (2023).

Yang, X. G., Pan, C. S. & Chen, Y. Current status of research on the mechanism and main influencing factors of coal and gas protrusion. Min. Technol. 24(01), 203–213 (2024).

Guo, D. Y., Tuai, X. S. & Zhang, J. G. Control effect of tectonic stress field on coal and gas herniation. J. Coal Sci. 48(08), 3076–3090 (2023).

Liu, J. J., Yang, D., Yang, M., Nie, Z. S. & Wang, D. Research on the main control factors of gas desorption in middle and low rank coals based on orthogonal testing. Fuel 2024, 129862 (2024).

Liu, J. J., Nie, Z. S., Li, Y. L., Yang, M. & Zhang, Y. L. Evolution characteristics of coal microstructure before and after supercritical CO2 treatment based on the L-Weighing-LNMR method. Energy Fuels 37(13), 9347–9358 (2023).

Li, W. T., Xia, F. F. & Zhu, Y. N. Progress of machine learning-based coal and gas protrusion risk assessment and early warning. China Coal 50(07), 52–62 (2024).

Li, S. G., Zhao, Y. & Xu, M. G. Porosity equation of gas-containing coal by low-frequency mechanical vibration and its test. J. Coal 41(10), 2612–2619 (2016).

Wei, J. P., Zhang, J. Z., Wen, Z. H., Ren, Y. J. & Zhang, L. B. Characterization of natural frequency of coal body based on the influence of seam and coal rank. J. Henan Univ. Technol. (Nat. Sci. Ed.) 42(01), 1–8 (2023).

Ren, Y. J., Wei, J. P., Wen, Z. H., Zhang, J. Z. & Yao, S. Experimental study on the influencing factors of coal rock self-oscillation frequency. Chin. J. Saf. Sci. 31(08), 104–111 (2021).

Zhang, S. & Wang, J. G. Research on the change rule of coal rock self-oscillation frequency under the condition of water erosion. Coal Mine Saf. 50(12), 6–9 (2019).

Li, C. W., Sun, X. Y. & Gao, T. B. Research on the characteristics of self-oscillation frequency change in the process of coal rock vibration damage. J. Coal 40(10), 2422–2429 (2015).

Mullakaev, M. S., Abramov, V. O. & Abramova, A. V. Development of ultrasonic equipment and technology for well stimulation and enhanced oil recovery. J. Petrol. Sci. Eng. 125, 201–208 (2015).

Yin, S., Zhao, D. & Zhai, G. Investigation into the characteristics of rock damage caused by ultrasonic vibration. Int. J. Rock Mech. Min. Sci. 84, 159–164 (2016).

Li, W., Yan, T. & Li, S. Rock fragmentation mechanisms and an experimental study of drilling tools during high-frequency harmonic vibration. Pet. Sci. 10, 205–211 (2013).

Li, C. W., Sun, X. Y. & Gao, T. B. Coal rock body vibration damage test and microseismic signal characteristics. J. Coal 40(08), 1834–1844 (2015).

Li, S. Q., Yan, T. & Li, W. Modeling of vibration response of rock by harmonic impact. J. Nat. Gas Sci. Eng. 23, 90–96 (2015).

Li, C. W., Liu, J. K. & Wang, C. X. Spectrum characteristics analysis of microseismic signals transmitting between coal bedding. Saf. Sci. 50(4), 761–767 (2012).

Li, L. G., Zhang, B. & Luo, Q. Study on vibration frequency and rock fragmentation effect of sonic drill rig. Procedia Eng. 73, 3–9 (2014).

Song, Y., Li, Z. & Li, Y. Q. Permeability characteristics and fine-scale rupture test of coal rock under the influence of low-frequency vibration. J. Liaoning Univ. Eng. Technol. (Nat. Sci. Ed.) 38(5), 390–395 (2019).

Lv, L. S., Li, H. P. & Li, B. Experimental study on desorption characteristics of acid-soaked granular coal under mechanical vibration. Coal Technol. 42(11), 108–112 (2023).

Xu, Z. P., Liu, Z. J. & Zhuang, D. Y. Optimal wavelet basis-based feature frequency extraction technique for coal miner rocker vibration signal. Coal Technol. 42(01), 230–233 (2023).

Yan, L. P. Research on vibration characteristics of fractured rock and finite element analysis. J. Changjiang Univ. (Nat. Sci. Ed.) 16(07), 104–108 (2019).

Ji, G., Wang, G. & Liu, L. The micro vibration equation of rock and its analysis in flat indenter basing on the principle of least action. Adv. Pet. Explor. Dev. 16(1), 44–48 (2018).

Liu, C. S., Na, H. L. & Han, D. L. Dynamic characteristics of disc vibration cutting and crushing coal rock mechanism based on ADAMS. J. Heilongjiang Univ. Sci. Technol. 30(3), 284–290 (2020).

Wei, J. P., Zhang, J. Z. & Wen, Z. H. Natural frequency of coal: Mathematical model, test, and analysis on influencing factors. Geofluids 2022, 7891894 (2022).

Wen, Z. H., Zhang, L. B. & Wei, J. P. Study on natural frequency response characteristics of coal vibration excited by simple harmonic wave. Sci. Rep. 12(1), 14892–14901 (2022).

Acknowledgements

This research is supported by the National Natural Science Foundation of China (52174205); Shaanxi Provincial Outstanding Youth Science Fund Project (2023–JC–JQ–40); Xinjiang Uygur Autonomous Region Key Research and Development Task Special Project (2022B01034-3); Key Research Project of Shaanxi Province (2024GX-YBXM-490); Key Laboratory of Green Coal Mining in Xinjiang, Ministry of Education (KLXGY-KA2404).

Author information

Authors and Affiliations

Contributions

Conceptualization, P.Z.; Data curation, C.C. and Y.L.; Formal analysis, Y.L., C.W. and X.Y.; Funding acquisition, S.L.; Investigation, L.W., C.W. and X.Y.; Methodology, S.L. and P.Z.; Project administration, S.L.; Software, P.Z.; Supervision, P.Z. and C.W.; Writing – original draft, C.C.; Writing – review & editing, P.Z.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhao, P., Cao, C., Li, S. et al. Study of the vibration frequency characteristics of tectonic coal containing assemblages at different loading rates. Sci Rep 15, 9559 (2025). https://doi.org/10.1038/s41598-025-86402-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-86402-3