Abstract

During the underbalanced pressure drilling, the conical rubber core of the rotary blowout preventer((RBOP) is susceptible to alternating cyclic stress due to the alternating passage of the drill pipe body and its joint, which can easily lead to fatigue cracking and sealing failure. To improve the performance of the rubber core, the constitutive parameters of the rubber were obtained by fitting the uniaxial tension and compression test results with the Yeoh constitutive model. Subsequently, the finite element model of the dynamic sealing was established to simulate the sealing and stress law of the contact surface between the rubber core and the drill pipe. It can be concluded that the inner cylindrical surface of the rubber core is the main force bearing surface compared to other parts. The stress value is highest during the transition period when the drill pipe joint alternates with the drill pipe body. The stress amplitude of the sealing surface under the initial structure is 5.14 MPa, and the peak stress is 22.98 MPa. Then, Plackett-Burman (PB) design was used to screen out three structural parameters, which had significant effects on the sealing surface. Sensitivity analysis was conducted on significant factors to determine their effects on sealing stress. Combined with response surface design, the optimal combination of structural parameters was cone angle 27.7°, contraction angle 68.2°and inner diameter 82.1 mm. After optimization, the peak value of Mises stress was reduced by 3.64 MPa, the amplitude of Mises stress was reduced by 39%, and the prediction error was only 0.42 MPa, which verified the validity and accuracy of the response surface prediction model. This research can help effectively prolong the service life of the rubber core and reduce the risk of wellhead blowout.

Similar content being viewed by others

Introduction

With the continuous deepening of oil and gas drilling and development, the proportion of deep and ultra deep exploration and development is increasing, making it increasingly difficult to carry unbalanced drilling1. Deep and ultra-deep formations are usually accompanied by higher formation of pressure2 and more complex geological structures such as faults, cracks, and caves. These geological anomalies may cause irregular ejection, increasing the difficulty and risk of well control3,4. Therefore, the deep drilling operation system have raised higher requirements for the sealing performance and pressure bearing capacity of the rotary blowout preventer. The performance of the equipment was urgently needed to be further improved5. Once well control fails, it will lead to serious blowout accidents, causing incalculable economic and safety losses, and accompanied by significant environmental pollution6,7. The self-sealing conical rubber core is the core sealing component of RBOP, which relies on interference fit with the drill rod to form a self-sealing effect. When the radial contact stress between the two is greater than the wellhead fluid pressure, it can effectively prevent wellhead fluid overflow and blowout. However, due to frequent tripping and lowering operations in unbalanced drilling and production operations, the drill rod body and drill rod joint constantly alternate and reciprocate through the sealing surface of the rubber core, causing the rubber core to constantly bear cyclic loads of tension and compression, which is prone to fatigue cracking8,9,10, as shown in Fig. 1, and thus unable to form an effective seal. Therefore, effectively improving the fatigue life and sealing performance of the rubber core can greatly prevent well control failure.

To improve the performance of rubber cores, optimize drilling parameters, and reduce the possibility of well blowout accidents, many scholars have conducted research. In terms of sealing mechanism, Kaisong Wu et al.11 and Gang Hu et al.12 explored the sealing principle, main failure modes, and influencing factors of the 7100 type rotary blowout preventer rubber core produced by Williams Tool Company during the drilling process. To explore the influence of material properties on the stress of the rubber core, Zheng Xu et al.13 used the Mooney Rivlin constitutive model to study the influence of temperature and stress relaxation on the packer rubber seal system. Hu Gang14 studied the selection of rubber materials and their additives. Wang Yue et al.15 proposed an experimental based method for fitting the constitutive parameters of rubber core materials. When performing an unbalanced drilling, the operating conditions undergo transient changes. Ting Chen16 analyzed the effects of different drilling speeds, stress states, etc. on the fatigue failure of the packer’s rubber matrix. Zhang Jie et al.17 revealed the surface morphology changes of the rubber core under forced tripping and drilling conditions. Zhang et al.18 studied the sealing performance of conical rubber cores under high temperature conditions. Lianglin Guo et al.19 analyzed the distribution and changes of contact pressure on the sealing surface and verified the accuracy of the finite element analysis results by comparing them with existing experimental results. Li B20 explored the stress concentration effect and time-domain variation law. Structural parameters are important influencing factors of fatigue failure. He Y et al.21 analyzed the influence of the main structural parameters of the rubber core on its mechanical properties. Jiwei W et al.22 improved the service life of rubber cores by optimizing the thickness, shape, and fillet size of the iron core. Liu Yang et al.23,24 reduced the peak stress by improving the chamfer cutting amount of the spherical rubber core. Guidance for improving the performance of the blowout preventer was provided by these structural modifications. The service life of the partially optimized core had been successfully extended in laboratory and field tests.

Based on the above analysis, the finite element numerical simulation, lab experiments and field tests were used to study the sealing conditions and failure mechanisms of the rubber core. In current research, the stress changes on the sealing surface of the rubber core during the dynamic sealing process were studied. The effects of material types and additives, working conditions of unbalanced drilling, types and shapes of rubber cores, and structural dimensions of rubber cores and iron cores on the stress state to the sealing surface were studied. However, there are few attempts to optimize performance by improving the structure. In existing research, only single factor analysis was used to optimize structural parameters, without considering the interactions between factors. There was no efficient and convenient optimization method formed, and multi-objective optimization was not involved.

The test data was fitted with constitutive model to determine the constitutive parameters of the material. The influence of the interaction of various structural parameters on the stress of the sealing surface was comprehensively considered. Combined with 3D finite element analysis, PB design, and BBD response surface method, multi objective optimization of Mises stress extreme values and stress amplitudes on the sealing surface of the rubber core was carried out. By optimizing multiple structural parameters of the rubber core, the Mises stress extremum and Mises stress amplitude can be reduced, thereby achieving an increase in the fatigue life of the rubber core and providing new methods and ideas for optimizing the performance of the RBOP rubber core.

Determination of constitutive parameters of rubber

Uniaxial tensile and compression tests

The material parameters required for three-dimensional finite element numerical simulation of the rubber core were determined by conducting uniaxial tensile and compression tests on nitrile rubber samples. Figure 2a shows the tensile testing equipment (universal testing machine) and the tensile specimen (dumbbell shaped specimen). In the tensile test, the operations were based on the Chinese standard GB/T 528-200925. The upper and lower ends of the sample were respectively installed on the clamping head of the equipment. And the extensometer was installed on the middle of sample to improve the measurement accuracy. The universal tensile testing machine performed constant tensile loading on the sample at a speed of 500 ± 50 mm/min until the sample broke. And 8 sets of tests were tautologically conducted to reduce error. The average value was taken as the result.

Figure 2b shows the compression test equipment (uniaxial compression tester) and the compression specimen (the cylindrical specimen). The maximum load of the equipment is 100kN, the sampling frequency is 400 Hz, the adjustment range of the speed is 1–300 mm/min, and the effective test width is 500 mm. In the compression test, the operations were based on the Chinese standard GB/T 7757-200926. The specimen was placed between two indenters. And the extensometer was installed to improve the measurement accuracy. A downward continuous compression was performed with a speed of 10 ± 2 mm/min, and was stopped when the strain of the specimen reached 25%. And 8 sets of tests were tautologically conducted to reduce error. The average value was taken as the result.

Material parameters fitting

There is significant deformation behavior during the sealing process of the rubber core, which is described based on phenomenological theory. It involves constitutive models such as Mooney Rivlin, Ogden, and Yeoh27,28,29, which can effectively express the strain energy density function of rubber in different applicable situations. In the data fitting module of finite element software, the uniaxial test data of materials were fitted with Mooney-Rivlin, Ogden and Yeoh models respectively, and the results were recorded in Fig. 3. Subfigure (a) in Fig. 3 shows the fitting of tensile test data, while subgraph (b) shows the fitting of compression test data.

The fitting degree between the uniaxial compression test data and the Yeoh model in Fig. 3 was well. Therefore, the Yeoh model was selected to effectively express the stress-strain constitutive relationship of the rubber core. The Yeoh model is a variation of the reduced Polynomial model. And the expression of the Polynomial model under the assumption that the material is constant temperature and incompressible is as follows:

In the formula: W - strain energy density function; \(\:{C}_{ij}\)- Rubber characteristic parameters; \(\:{I}_{1}\), \(\:{I}_{2}\:\)- first and second Green’s strain invariants. When \(\:j=0\) and \(\:N=3\) in Eq. (1), the Yeoh model is obtained, which is expressed as follows:

Its expression can be simplified as follows:

The model coefficient obtained by fitting the uniaxial compression test data with the Yeoh constitutive model was C10 = 1.118 MPa, C20 = 0.058 MPa, C30 = 0.413 MPa. It was used as the material parameters for the rubber core in numerical simulation.

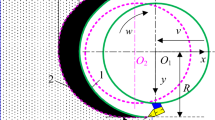

Transient sealing and deformation simulation

As shown in Fig. 4, to accurately simulate the stress state and nonlinear large deformation of various parts of the sealing surface when the drill pipe joint and body passed through the rubber core, a dynamic sealing simulation model for drilling in and tripping out was established. The size of the conical rubber core model of Williams’ 7100 self-sealing rotating blowout preventer was taken as the original size. The model consists of 3 1/2"drill pipe, rubber core, and iron core, with the drill pipe consisting of the drill pipe body, pin joint, and box joint.

In Figs. 1 and 4-drill pipe, 2-iron core, 3-rubber core, I-drill pipe body, II- drill pipe pin joint, III-drill pipe box joint, ρ-contraction angle, θ-base angle, φ-cone angle, R1–round 1(fillet radius 1), R2-round 2(fillet radius 2), d–inner diameter.

In this model, the drill pipe was set as a rigid body, while the rubber core and iron core as deformable during pre-processing stage. The upper surface of the iron core was fixed, the contact surfaces between the rubber core and the iron core were bound and the contact type between the rubber core and the drill pipe was set to surface-to-surface contact. A wellhead pressure of 7.2 MPa was loaded on the outer surface of the rubber core based on the on-site working conditions. A drilling speed of 0.72 m/s was loaded on the coupling reference point of the drill pipe. The friction coefficient was 0.2. The structural parameters that affect the force on the sealing surface mainly include the cone angle φ, contraction angle ρ, base angle θ, round 1-R1, inner diameter d, and round 2-R2. The dimensions of each parameter in the initial structure of the rubber core were φ = 26°, ρ = 63°, θ = 56°, R1 = 15 mm, R2 = 15 mm, d = 76 mm.

The stress nephogram for each part was recorded in Fig. 5 when the drill pipe passed through the sealing surface during the drilling process The Mises stress values on the inner cylindrical surface and the bottom of the sealing surface of the rubber core were greater than those on other parts. The maximum stress during tripping out was 15.13 MPa, and the maximum stress during drilling in was 13.85 MPa.

Five points O1 ~ O5 were taken from top to bottom on the inner cylindrical surface of the rubber core to observe the changes in Mises stress during the entire drilling process. In Fig. 6, at the initial moment of 0, the drill pipe has not yet contacted the rubber core. 0 ~ t1 is the time span which the drill pipe body gradually inserts into the rubber core during drilling in. t1 ~ t2 is the time span which the first section of the drill pipe body smoothly passes through the rubber core during drilling in. The period from t3 to t4 is when the drill pipe joint smoothly passes through the rubber core during drilling in. t5 ~ t6 is the time span which the second section of the drill pipe body smoothly passes through the rubber core during drilling in. t6 ~ t7 is the period when the first section of the drill pipe body smoothly passes through the rubber core during tripping out. t8 ~ t9 is the period when the drill pipe joint passes through the rubber core during tripping out. t10 ~ t11 is the period when the second section of the drill pipe body smoothly passes through the rubber core during tripping out.

Among them, t2 ~ t3, t4 ~ t5, t7 ~ t8, and t9 ~ t10 are the transition periods during which the drill pipe joint and the drill pipe body alternate through the rubber core sealing surface. During the drilling process, the stress when the drill pipe body smoothly passes through the rubber core is lower than that of the drill pipe joint. The contact pressure between the first section of drill pipe body and the second section of drill pipe body is equal when they smoothly pass through the rubber core. For ease of expression, the stress amplitude when the drill pipe body and joint alternate through the rubber core sealing surface is denoted as σa, the stress peak when the drill pipe body passes smoothly is denoted as σF, and the stress peak when the drill pipe joint passes smoothly is denoted as σf. Then σa=(σF-σf)/2. The field output of the Mises stress on the sealing surface during the whole simulation process was established. By calculation, it was found that under the initial scheme, σa = (15.66–5.38)/2 = 5.14 MPa. Figure 6 also reflects that during the transition period when the drill pipe body and drill pipe joint alternate through the rubber core, the Mises stress changes significantly, and the stress peak is the highest.

The stress nephogram was recorded in Fig. 7 when the drill pipe joint and the drill pipe body alternately pass through the sealing surface during the drilling process. It can be seen from Fig. 3 that during the transition period when the drill pipe joint and the body alternately pass through, the stress concentration is prone to occur. And at this period, the sealing surface experiences the highest stress value, with a peak Mises stress of 22.22 MPa during drilling in and 22.98 MPa during tripping out. If the peak Mises stress during the entire drilling process is recorded as σm(max), then σm(max) under the initial structure is 22.98 MPa.

Based on the analysis of the above results, it can be concluded that the peak Mises stress σm(max) and Mises stress amplitude σa on the sealing surface under the initial structure of the rubber core are relatively large. Among them, σm(max) = 22.98 MPa, σa = 5.14 MPa, the risk of fatigue failure of the rubber core is high, so that its structure needs to be improved.

Optimization design of rubber core structure

Significant impact factors in PB design

There are many structural parameters that can affect the performance of the rubber core in the rotary blowout preventer. Before optimizing the structure, significant impact factors need to be screened first. This facilitates subsequent analysis and optimization design. Screening of influencing factors was done in Minitab 19 software for PB design30,31. The cone angle φ (A), contraction angle ρ (B), Base angle θ (C), round 1-R1 (D), inner diameter d (E), round 2-R2 (F) were the experimental factors.

The experimental factors and their levels were designed in Table 1. Combined with the geometry of the rubber core, the smaller the cone angle, the shorter the length of the sealing surface. To ensure the sealing length, the range value of the cone angle was selected as 25 ~ 35°. The contraction angle and the base angle have a certain effect on the bottom thickness of the rubber core. To ensure the bottom thickness was in a reasonable range, the range value of the contraction angle was selected as 58 ~ 72°, and the base angle 44 ~ 64°. To ensure the appropriate amount of interference between the drill pipe and rubber core, the minimum value of the diameter was selected as 74 mm, and the maximum value was selected as 86 mm. Combined with the relevant standard GB/T 25,430–201932, a common design and processing range of R1 and R2 was 6 ~ 20 mm.

Then, numerical experiments were carried out using the ABAQUS testing platform. To consider the influence of various structural parameters on the fatigue life of the rubber core, 12 sets of experiments were conducted using σm(max) (Y1) and σa (Y2) as indicators, and the results were recorded in Table 2. The analysis in the software showed that the model had extremely high significance (P < 0.01).

As shown in Fig. 8, the significance of each factor was expressed in percentage form. The experimental factors that have a significant impact on indicator Y1 are E, A, and B (P < 0.01), while the factors that have a significant impact on indicator Y2 are A, E, and B (P < 0.01). In summary, three structural parameters, namely cone angle (A), contraction angle (B), and inner diameter (E) respectively, could be selected as the investigation factors for structure optimization.

Sensitivity analysis

To carry out structural optimization design more effectively, sensitivity analysis was applied. Keeping other parameters constant, the stress situations of the sealing surface under different cone angles, contraction angles, and inner diameters were analyzed with a single factor experiment. Through sensitivity analysis, the influence of changes in individual structural parameters on the stress of the sealing surface was determined, which provided mechanical foundation and data support for optimization and indirectly verified the accuracy of the results in PB design.

The influence of cone angle

The sealing surface of the rubber core can be divided into an inner conical surface and an inner cylindrical surface. According to the analysis in the second section, the inner cylindrical surface is the main sealing surface, and the inner conical surface is the auxiliary sealing surface. As shown in Fig. 4, the cone angle of the rubber core is the angle between the inner cylindrical surface and the inner cone surface. The cone angle of the initial structure is 26°. To ensure the sealing length, the range value of the cone angle was selected as 24 ~ 39°. Keeping other parameters constant, the dynamic sealing state of the sealing surface under cone angles of 24 °, 29 °, 34 °, and 39 ° was simulated. And the Mises stress values at the parts with large force fluctuations during the whole process were output and plotted in Fig. 9. As shown in Fig. 9, during drilling in, as the cone angle increases, the Mises stress value also increases. During tripping out, as the cone angle increases, the Mises stress value decreases and then increases. The reason is because the larger cone angle during drilling in increases the interference fit between the auxiliary surface and the drill pipe. During tripping out, the rubber core is subjected to axial compression due to friction, and the larger cone angle makes it easier for the inner cone surface to radially peel off from the drill pipe, thereby reducing the stress value. But after exceeding 35 °, an increase in cone angle will result in excessive magnitude of interference, causing stress to increase during the drilling process.

The influence of contraction angle

As shown in Fig. 4, the contraction angle reflects the inward tightening degree of the outer conical surface of the rubber core, which affects the plastic flow volume and flow resistance of the rubber core. The contraction angle of the initial structure is 63°. To ensure that the bottom thickness of the rubber core was in a reasonable range, the value was made to vary within 63 ± 7°. To quantitatively analyze the influence of the contraction angle on the sealing state and provide data reference for structural optimization, the simulation was performed at contraction angles of 56 °, 59 °, 62 °, 65 °, and 68 ° respectively. It can be seen from Fig. 10 that the change of the overall stress state of the sealing surface during the whole process. As the contraction angle increases, the Mises stress value first decreases and then increases. Meanwhile, Fig. 10 shows that there is also a degree of variation in stress amplitude. The reason is that when the contraction angle changes, the plastic resistance volume of rubber core to prevent drill pipe intrusion changes, causing stress fluctuations.

The influence of inner diameter

The inner diameter of the rubber core affects the interference fit when the drill pipe is inserted, affects the degree of tightness during wrapping, and thus affects the large deformation of the sealing surface. The schematic diagram of the inner diameter of the rubber core is shown in Fig. 4. The inner diameter of the initial structure is 76 mm. To ensure the appropriate amount of interference between the drill pipe and rubber core, the value was made to vary within 76 ± 11 mm. To quantitatively analyze the influence of the inner diameter on the sealing state and provide data reference for structural optimization, the finite element simulation was done at inner diameters of 65 mm, 70 mm, 75 mm, 80 mm, and 85 mm respectively. Mises stress values of the parts with significant force fluctuations in sealing surface were output and plotted in Fig. 11. As shown in Fig. 11, during the drilling process, as the inner diameter increases, both the stress value and stress amplitude of the rubber core decrease significantly. The larger the inner diameter, the lower the degree of expansion and fitting between the inner cylinder and the drill pipe, so that the stress and its variation range are reduced.

Parameters optimization

To optimize the structural parameters of the rubber core, based on the PB test analysis and the sensitivity analysis, the cone angle, contraction angle, and inner diameter were selected as independent variables, while σm(max) and σa were used as dependent variables. The goal was to establish a coupled response relationship between the independent and dependent variables. Therefore, a BBD response surface test was designed in Design Expert software33,34. Table 3 provided the levels and values of each factor in the response surface experiment, with the base angle θ = 56 °, round R1 = 15 mm, and round R2 = 15 mm maintained during the experiment.

The scheme and results of the response surface test were recorded in Table 4. According to the experimental data in Table 4, regression fitting was performed in Design Export software, and the expression of the regression equation was obtained as: Y1 = 2.64A2 + 4.17B2 + 1.27C2 + 5.19AB−0.99AC + 0.8BC + 1.71 A−1.52B−3.94 C + 21, Y2 = 1.09A2 + 1.29B2 + 1.68C2 + 0.93AB + 0.99AC + 0.65BC + 1.02 A−0.37B−0.85 C + 3.17.

Subsequently, the variance analysis was conducted, and the results of the variance analysis with Y1 as the response indicator were recorded in Table 5 while that of Y2 recorded in Table 6. According to Tables 5 and 6, the P-value of the model was less than 0.01, and the model correction coefficient R2 was greater than 0.98, indicating a high degree of model fitting. The P-value of the lack of fit was greater than 0.05, indicating that the lack of fit was not significant, and the prediction error was negligible. Therefore, the response surface model can be applied to effectively predict the response indicators Y1 and Y2.

Based on the analysis results of the above response surface test, the three-dimensional response surface plots of the three factors on the main response indicator Y2 were plotted in Fig. 12.

It is revealed from Fig. 12 that there is a strong interaction between the cone angle and the contraction angle, between the cone angle and the inner diameter, and between the contraction angle and the inner diameter. So that the influence of parameter interactions was fully considered when the response indicators was predicted, thus enhancing the comprehensiveness of system optimization and avoiding mutual interference effect between factors to affect the reliability of optimization. At the same time, the optimization model was established in the Design Export software and its expression was shown in Eq. (4). In the optimization model, the constraint ranges of the optimization parameters were set, while the remaining structural parameters were kept at fixed values (θ = 56 °, R1 = 15 mm, R2 = 15 mm). In this model, the goal was to minimize Y1 and Y2 within the range of independent variable values, and the weight ratio of Y1 and Y2 was set to 2:3.

Subsequently, optimization analysis was conducted in the software to obtain six frontier solutions as shown in Table 7, and the first one was selected as the optimal solution. The optimal combination of three structural parameters was cone angle φ 27.7 °, contraction angle ρ 68.2 °, and inner diameter d 82.1 mm. The theoretical predicted values of the response index were Y1 = 18.92 MPa, Y2 = 2.83 MPa; that was, Mises stress peak σm(max) = 18.92 MPa, and stress amplitude σa = 2.83 MPa.

Verification of optimization results

Firstly, based on the optimal combination of structural parameters predicted by the response surface model, the finite element simulation model was reconstructed in ABAQUS software with a cone angle of 27.7 °, a contraction angle of 68.2 °, and an inner diameter of 82.1 mm. The predicted values obtained from the finite element simulation were compared with those predicted by the response surface model. According to Table 8, the error between the predicted values of the response surface model and the simulation software was relatively small, only 0.42 MPa, which verified the prediction accuracy of the response surface model.

Secondly, the stress peak and stress amplitude of the initial structure and the optimal structure were compared, and the results were recorded in Table 9. And the relative cloud diagrams were compared and recorded in Fig. 13.

Based on Table 9; Fig. 13, σm(max) of the optimal structure was reduced by 3.64 MPa compared to the initial structure. The Mises stress peak of the optimized structure was significantly reduced, while the stress amplitude was reduced by 39%. That will help prevent fatigue cracking of the rubber core and extends its service life, thus verifying the prediction effectiveness of the response surface model.

Conclusion

-

(1)

When the drill pipe body and joint alternate through the sealing surface of the rubber core, it is subjected to alternating cyclic stress, and there is a large stress amplitude and peak value. The initial structure of the rubber core needs to be optimized.

-

(2)

Based on the PB design, the factors that have a significant impact on the stress of the sealing surface are the cone angle, contraction angle, and inner diameter. From the sensitivity analysis, the mechanical action of each factor on the sealing surface was revealed.

-

(3)

Based on the response surface method, the optimal combination of structural parameters is determined as cone angle 27.7 °, contraction angle 68.2 °, and inner diameter 82.1 mm. After optimization, the Mies stress peak was reduced by 3.64 MPa and the Mises stress amplitude was reduced by 39%. Thus, the possibility of fatigue cracking of the rubber core was reduced.

-

(4)

The comparison error between the results of finite element numerical simulation and the prediction results of the BBD response surface model is only 0.42 MPa, indicating a small prediction error, which verifies the accuracy of the response surface model.

Data availability

Data will be made available on request. And you can contact the corresponding author Zhiqiang Huang though the email: huangzq1356@163.com for the concrete data from this study.

References

Zhao, M. et al. Investigation on Cracking Cause of Drill Pipe Joint Used in an Ultra Deep Well[C]//Journal of Physics: Conference Series. IOP Publishing, 2679(1): 012035. (2024).

Gowida, A. et al. Impact of pressure and temperature on foam behavior for enhanced underbalanced drilling operations. ACS Omega 9(1), 1042–1055 (2023).

Wen, Y. et al. Study on well control and killing in deep well drilling[C]//IOP Conference Series: Earth and Environmental Science. IOP Publishing, 859(1): 012059. (2021).

Liu, J., Li, Q. & Wang, Y. Risk analysis in ultra deep scientific drilling project—A fuzzy synthetic evaluation approach. Int. J. Project Manage. 31(3), 449–458 (2013).

Ashena, R., Ghorbani, F. & Mubashir, M. The root cause analysis of an oilwell blowout and explosion in the Middle East. J. Petrol. Sci. Eng. 207, 109134– (2021).

Cai, B. et al. Using Bayesian Networks in Reliability Evaluation for Subsea Blowout Preventer Control system10832–41 (Reliability Engineering & System Safety, 2012).

Xu, L., Wu, J. & Li, H. Analysis on environment impact of Chongqing Kaixian blowout. China Saf. Sci. J. 15(5), 4 (2005).

Kang, X. Developing trend of rotary control head and its application. Drill. Prod. Technol., (04):61–64. (2000).

Liu, W. Analysis and optimization of rubber core structure of rotary BOP. China Petroleum Mach. 49(02), 7–14 (2021).

Schieppati, J. et al. Effect of mechanical loading history on fatigue crack growth of non-crystallizing rubber. Eng. Fract. Mech. 257, 108010 (2021).

Wu, K. et al. Analysis of mechanical behavior and failure for stripper rubber in rotating control head. Lubr. Eng. 38(10), 83–86 (2013).

Hu, G. et al. Sealing performance and failure mechanism analysis of packing unit used in rotary blowout preventer for under-balanced drilling. Eng. Fail. Anal. 129, 105654 (2021).

Zheng, X. & Li, B. Study on sealing performance of packer rubber based on stress relaxation experiment. Eng. Fail. Anal. 129, 105692 (2021).

Hu, G. et al. The influence of rubber material on sealing performance of packing element in compression packer. J. Nat. Gas Sci. Eng. 38, 120–138 (2017).

Wang, Y. et al. Research on constitutive model of sealant core for annular BOP. Mach. Tool. Hydraulics. 50(14), 46–49 (2022).

Chen, T. et al. Analysis on mechanical influencing factors of fatigue behavior for the packer on pipe ram in snubbing unit. Eng. Fail. Anal. 103, 20–31 (2019).

Zhang, J. et al. Mechanical behavior of rubber core of spherical blowout preventer during lifting and releasing drill pipe after well sealing. Lubr. Eng. 47(11), 172–180 (2022).

Zhang, J. et al. High-temperature sealing performance and structure optimization of rubber core for conical blowout preventer. Geoenergy Sci. Eng. 234, 212606 (2024).

Guo, L. et al. Fatigue optimization of rotary control head rubber core based on steady sealing. Eng. Fail. Anal. 132, 105935 (2022).

Li, B. & Zhang, S. Contact pressure research of drill pipe and packer of rotating blowout preventer. Appl. Mech. Mater. 121, 3200–3204 (2012).

He, Y. et al. Fatigue life optimization towards rubber core sealing surface of under-balanced drilling rotating blowout preventer. Eng. Fail. Anal. 117, 104965 (2020).

Wu, J. et al. The performance optimization of the stripper rubber for the rotating blowout preventer based on experiments and simulation. J. Petrol. Sci. Eng. 204, 108623 (2021).

Liu, Y. et al. Failure analysis and structural optimization of rubber core and support rib of full-size spherical blowout preventer. Eng. Fail. Anal. 143, 106865 (2023).

Liu, Y. et al. Safety performance and structural optimization of rubber core of spherical blowout preventer. J. Xi’an Shiyou University(Natural Sci. Edition). 39(01), 97–105 (2024).

National Technical Committee for Standardization of Rubber and Rubber Products. Rubber, Vulcanized or thermoplastic-Determination of Tensile stress-strain Properties: GB/T 528–2009 [S] (China Quality Standards Publishing Media Co., Ltd, 2009).

National Technical Committee for Standardization of Rubber and Rubber Products. Rubber, Vulcanized or thermoplastic-Determination of Compression stress-strain Properties: GB/T 7757 – 2009 [S] (China Quality Standards Publishing Media Co., Ltd, 2009).

Gopesh, T. & Friend, J. Facile analytical extraction of the hyperelastic constants for the two-parameter mooney–rivlin model from experiments on soft polymers. Soft Rob. 8(4), 365–370 (2021).

Wang, Z. et al. Study of the effect of carbon black filling on the mechanical behavior of rubber hyper-elasticity. Materials 16(19), 6561 (2023).

Renaud, C. et al. The Yeoh model applied to the modeling of large deformation contact/impact problems. Int. J. Impact Eng. 36(5), 659–666 (2009).

Nazha, H. M. et al. Response surface analysis of Zn–Ni coating parameters for corrosion resistance applications: A plackett–Burman and box–behnken design of experiments approach. J. Mater. Sci. 58(30), 12465–12480 (2023).

Lee, S. J. et al. The construction of a mock-up test building and a statistical analysis of the data acquired to evaluate the power generation performance of photovoltaic modules. Energies 13(7), 1546 (2020).

Petroleum drilling and production equipment-Rotating control devices. GB/T 25430 – 2019 [S] (China Quality Standards Publishing Media Co., Ltd, 2019).

Han, J. et al. Experimental and numerical study on flow characteristics of dual cavity die based on multi-objective optimization. Polym. Eng. Sci. 64(5), 2096–2106 (2024).

Van, T. N. et al. Applying response surface methodology to optimize partial nitrification in sequence batch reactor treating salinity wastewater. Sci. Total Environ. 862, 160802 (2023).

Funding

This work was supported by Key Research and development program of Hubei Province: “Research on Intelligent High Temperature Resistant Rotary Steerable Bit and Supporting Well Control Technology” (2021BAA053) and National Natural Science Foundation of China: “Research on Spatial Stress Field Reconstruction and Fracture Expansion Law of CO2 Enhanced Fracturing in Shale Oil Stereoscopic Well Network” (52374027).

Author information

Authors and Affiliations

Contributions

Lianglin Guo (First Author): Conceptualization, Methodology, Software, Investigation, Formal Analysis, Writing - Final Draft.Zhiqiang Huang & Hao Huang (Corresponding Author): Conceptualization, Funding Acquisition, Resources, Supervision, Writing - Review & Editing.Hao Zhang: Conceptualization, Data Curation, Formal Analysis, Investigation, Writing - Original Draft.Fubin Xin: Visualization, Investigation.Junjie Ji: Resources, Visualization.Chengyu Xia:. Funding Acquisition.Hengda Che: Software, Validation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Guo, L., Huang, Z., Huang, H. et al. Dynamic sealing simulation and performance optimization of conical rubber core in rotary blowout preventer. Sci Rep 15, 9442 (2025). https://doi.org/10.1038/s41598-025-86462-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-86462-5