Abstract

Geopolymer concrete (GC) is green and environmentally friendly. In order to comprehensively study the mechanical properties and influence mechanism of geopolymer concrete-filled steel tubular (GCFST) columns under various working conditions, this study takes the strength grade of geopolymer concrete, length-diameter ratio and wall thickness of steel tube as design parameters. Eight GCFST columns are designed and the compressive performances are conducted under repeated axial compression. The load–displacement curve, the skeleton curve, the characteristic load and displacement, the ductility, and the energy dissipation were analyzed. Furthermore, the numerical analysis models were established through finite element software and the test results were compared with the simulation results to verify the accuracy of the finite element model. The results indicate that under different length-diameter ratios, the variation trends of the load–displacement curves for the specimens are slightly different, while the stiffness degradation curves present similar variation laws. The design parameters have significant effects on the bearing capacity, average compressive force, and energy dissipating capacity of the specimens. The simulation results are in good agreement with the experimental results. Research results show the excellent bearing capacity of GCFST columns and the precision of finite element calculation results, which can provide a reference for related experimental research.

Similar content being viewed by others

Introduction

As the construction industry develops rapidly, the consumption of cement as the main raw material of concrete is increasing. However, many hazardous substances will be generated during cement production, which will seriously damage the ecological environment and pose a threat to the health of related employees1. Therefore, it is an urgent issue to find an environmentally friendly cement substitute with early strength and fast hardening. The presence of geopolymers provides ideas for resolving this difficulty2. Geopolymers belong to a new type of inorganic polymer with high performance. After polymerization under appropriate conditions, substances with properties similar to those of ordinary Portland cement are generated3. According to studies by relevant scholars, the carbon emission from the preparation of 1 kg of geopolymer cement is only 0.18 kg or even less, which is significantly less than that of the preparation of ordinary Portland cement4,5. Therefore, when geopolymer cement is used instead of ordinary Portland cement to make GC, the emission of hazardous substances can be decreased in its preparation process, thus reducing the damage to the environment. It is called the ‘green eco-friendly material’ in the twenty-first century6. The concrete-filled steel tube is a structure formed by pouring concrete inside the steel tube, which has excellent bearing performance, good ductility and seismic performance, and is widely applied in high-rise buildings7,8,9,10,11,12,13.

Characterized by early strength, fast hardening, good corrosion resistance, green environmental protection, environmental friendliness, etc., GC has been studied by some scholars on its workability, mechanical properties, microstructure, durability, etc. Fan et al.14 conducted a comprehensive analysis of the research status of GC, posed the problems to be solved concerning the large-scale use of GC. Zhang et al.2 analyzed 173 relevant articles, revealing the great mechanical properties of GC and predicting its wide application prospects in the field of engineering. However, the proportion of mixture still needs to be optimized for its better application. Mishra et al.15 analyzed the influence of ferrochrome ash admixture on the workability, compressive strength, microstructure, and mineral composition of fly ash (FA) GC, and evaluated the feasibility of applying ferrochrome ash and FA base polymer concrete in engineering. Zhao et al.16 studied the mechanical properties of recycled aggregate geopolymers concrete reinforced with steel fiber by considering the amount of steel fiber and recycled aggregate, and observed the microstructure of the interface transition zone between the geopolymer matrix and recycled aggregate or steel fiber through a scanning electron microscope. Saranya et al.17 studied that using the mixture of the dolomite and ground granulated blast furnace slag mixture in a certain proportion could effectively improve the impact resistance of GC. Nithya et al.18 studied the flexural performance of lightweight environmentally friendly GC with coconut shells as coarse aggregate, providing a new idea for further application of GC. The adhesive property of geopolymer concrete with glass fiber and carbon fiber was studied by Dong et al.19,20, and the results showed that geopolymer concrete had good adhesive properties.

In view of the excellent mechanical properties, fire resistance, and earthquake resistance capacity of concrete-filled steel tube structures, many experts and scholars have carried out extensive research on them21,22,23. Wang et al.24 evaluated the applicability and reliability of the calculation results by current six international design codes and summarized the measures to prevent the buckling failure of circular concrete filled steel tube columns. Tang et al.25 conducted low-cycle load tests on recycled aggregate concrete (RAC)-filled steel tube columns and analyzed the seismic performance and failure mechanism, providing a reference for the application of steel tubes. Dai et al.26 studied the bond slip relationship between stainless steel tube and concrete, and proposed an ideal bond slip curve. Yu et al.27 studied the load-bearing capacity of self-compacting RAC-filled steel tube columns and derived the load-bearing capacity prediction formula, ultimate strain, stiffness, and stress–strain models according to the test results. Song et al.28 studied the fire resistance of geopolymer RAC filled steel tubes and predicted the maximum load-bearing capacity of the composite structure under specific fire exposure time according to relevant specifications. Fang et al.29 studied GCFST members under bending, compression, or the combined loading, and evaluated the applicability of current standards to geopolymer steel tubular members. The GCFST composite structure can effectively play the advantages of GC and steel tubes.

Although experts and scholars have conducted extensive research on concrete filled steel tube composite structures, the repeated axial compression performance of GCFST columns has not been investigated perfectly. In this article, eight short GCFST columns are made for repeated axial compression tests, and the accuracy of the finite element analysis model is verified by the analysis and test results, providing references for the application of GCFST structures in engineering.

Test Overview

Specimen material

In the article, steel tubes of Q235B grade with wall thickness of 2.75 mm and 4.00 mm were used, respectively. The average measured thickness was 2.70 mm and 3.97 mm, respectively. Standard tensile specimens were prepared and tested according to the standard30,31. Table 1 shows the results obtained.

GC uses metakaolin and Grade II fly ash (FA) to replace cement as cementing materials, and its strength is improved by chemical reactions caused by alkali activation. The raw materials for GC in this test include solid sodium hydroxide, sodium silicate solution with a concentration of 35%, 1250 mesh metakaolin, Grade II FA, natural river sand, continuously 5–20 mm diameter graded gravel, water, superplasticizer, and retarder. Industrial sugar was used as a retarder, and liquid polycarboxylate superplasticizer was also used. The content of the retarder is 5% and superplasticizer is 2%. Standard test blocks were reserved for concrete pouring in steel tubes, and the strength tests were carried out according to the Standard32. The cubic compressive strengths of the geopolymer concrete in a 28 d cube were measured as 29.90 MPa of GC1 and 42.30 MPa of GC2. The mixture of GC is the same as the literature33.

Specimen design and measurement point layout

In order to comprehensively study the mechanical properties and influence mechanism of geopolymer concrete-filled steel tubular (GCFST) columns under various working conditions, this study takes the strength grade of geopolymer concrete, length-diameter ratio and wall thickness of steel tube as design parameters. Eight GCFST columns are designed and the compressive performances are conducted under repeated axial compression. L represents the specimen length. D is the diameter of the steel tube. t is the nominal wall thickness and L/D is the length-diameter ratio of the steel tube. The detailed design parameters are shown in Table 2. Two vertical and two circumferential strain gauges were symmetrically placed in the middle of the specimens to measure the vertical strain and the longitudinal strain. A displacement meter was arranged on the top and bottom cover plates of the specimens, respectively, to test the vertical displacement value.

Loading scheme

The repeated axial compression test of GCFST columns was conducted through one 5000kN SANS universal loading machine. The loading device is shown in Fig. 1.

According to the code34, the peak load-bearing capacity Fmax of the specimen is calculated, as shown in Eq. (1). The calculation results are shown in Table 3. In the preload stage, it was loaded at 10% Fmax and maintained for 1 min, which was mainly aimed to ensure the tight connection between the specimens and the loading device and ensure normal operation of the device. The formal loading includes two stages. In the force control stage, the load of each stage was 5% of Fmax and was maintained for 1 min, with a loading rate of 3000 N/s. After completion of loading of each stage, it was unloaded to 20,000 N and then the next stage load was applied. Displacement control was performed after loading to 80% Fmax. And the loading rate is 0.6 mm/min.

where, N1 is the axial repeated compression load-bearing capacity of concrete filled steel tubular column. α is a parameter related to the compressive strength grade of concrete. When the concrete strength value ≤ C50, take 2.00; \(\zeta\) is the constraint coefficient corresponding to the component.

Test results analysis

Experimental phenomena

The typical failure patterns are shown in Fig. 2.

It can be seen from the Fig. 2 that:

(1) There is no significant change in the force control loading stage. The GC and steel tubes inside resisted vertical pressure jointly and there was almost no residual displacement after unloading. In the link of displacement control, the specimens suffered significant axial deformation, the damage to the internal GC was aggravated, and some concrete was crushed. With increasing vertical displacement, the steel tubes bulging was more obvious, the crushed concrete and steel tubes were reintegrated closely, and the load-bearing capacity of some specimens improved slightly, but the specimens showed significant deformation.

(2) The failure modes of the short columns with different length diameter ratios are slightly different. The bulging deformation of the columns with a large length-diameter ratio was mainly located at the 1/4 distance from the bottom, while the smaller length-diameter ratio shear failure occurs first in the middle of the specimens, such as GC1-F1. Specifically, it was manifested as shear failure occurring at both ends of specimens with one larger length-diameter ratio.

Load–displacement curve

The load–displacement curves are shown in Fig. 3. F denotes the vertical load. U denotes the vertical displacement.

Figure 3 shows that:

(1) The load–displacement curves for the GC1-E1, GC1-E2, GC2-E1 and GC2-E2 specimens follow roughly the same trend and, after reaching the peak load, the load decreases step by step. Although the load increases slightly in some loading steps, the overall trend is downward. In the early stage of force control, the deformation of the members could be recovered after unloading. The specimens were in the elastic stage and the loading and unloading curves approximately coincided. As the loading continued, under the non-linear influence of the material properties of GC, the concrete suffered plastic deformation. When the peak load was reached, with the vertical displacement continuing to increase, the bearing capacity significantly degraded, the plastic deformation of the members became more significant, and the stiffness decreased dramatically. In displacement loading stage, the load-bearing capacity of the columns increased slightly due to the bulge of the steel tubes. In the later stage of the test, the inside of the GC was crushed with serious deformation and a significant decrease in bearing capacity, and the specimen suffered failure. After the load–displacement curve for specimen GC1-E1 reached the peak load, the bearing capacity continuously declined, and a slight increase of bearing capacity was not observed at last stage. This is because the nonuniform deformation of the specimen under load.

(2) The variation laws of the load–displacement curves of the GC1-F1, GC1-F2, GC2-F1, and GC2-F2 specimens were similar, but they had slight differences. As the loading continued to increase, the specimen transformed from the elastic stage to the elastic–plastic stage and suffered unrecoverable plastic deformation. When the vertical displacement continued to increase, the steel tube partially presented obvious buckling phenomena, and the damage to the GC inside was aggravated but not crushed. The two were not closely integrated in the bulging position, and the load-bearing capacity of the member was reduced. With increasing displacement, the steel tube was closely combined with the damaged and crushed internal GC, and its bearing capacity increased again.

Analysis of skeleton curves, characteristic load, and ductility

Figure 4 shows the skeleton curves, and Table 4 shows the characteristic loads and displacements. YL and YD represent the yield load and yield displacement. PL and PD represent peak load and peak displacement. UL and UD represent the ultimate load and ultimate displacement. When one of the following conditions was met, the load was taken for the ultimate load: (1) when the minimum load value was achieved after the peak load was first reduced. (2) when the load was reduced to 85% of the peak load. (3) when a particularly obvious failure phenomenon was presented in the specimen. The characteristic displacement was compared with the characteristic load, and the coefficient of ductility coefficient μ denotes the ratio of the UD to the YD.

It can be seen from Fig. 4 and Table 3 that:

(1) In the elastic stage, the skeleton curves for the GCFST columns presented a linear variation law, and with increasing vertical displacement, the load increased linearly. When the loading was continued, the skeleton curves showed obvious nonlinear characteristics with elastic–plastic stage. The plastic damage of the GC inside accumulated.

(2) The initial stiffness of the members with thicker external steel tubes was greater. As the load increased, the skeleton curves showed non-linear variation laws obviously, and then the load-bearing capacity continuously degraded.

(3) The constraint effect of steel tubes on GC increased with decreasing member length-diameter ratio. For the short columns under repeated compression, the lateral deflection could be ignored in the load application process. Meanwhile, the constraint effect of the steel tubes was uniformly distributed along the circumference. Taking specimens GC2-E2 and GC2-F2 as examples, the peak load increased by 64.85%, from 1220.98 kN to 2012.83 kN. This indicates that specimens with smaller length-diameter ratio are more suitable for axial compression.

(4) The calculated displacement ductility coefficient for each GCFST column was in the range of 4.63 to 10.77, with an average value of 6.98. This indicates that the specimen has better ductility and can bear larger deformations.

Energy dissipation analysis

There were three energy dissipation indicators for the GCFST columns in total. E is total energy absorption. Fm is the average compression force, represents the ratio of the total energy absorption E to the displacement. The compression force efficiency is \(\eta\), as shown in Eq. (2). d is the compression amount of the members. P is the compression force. Under unit displacement, the energy absorbed by the specimens can be expressed by the average compression force, which can directly reflect their energy dissipation characteristics. Table 5 shows the energy absorption indices for each specimen.

It can be seen from Table 4 that:

(1) The strength grade of the GC has little influence on the energy absorption and the average compression force of the specimen, but the length-diameter ratio has more influence. When the length-diameter ratio of the members was smaller, the steel tube had better constraint effects on the inner GC. The constraint effect was more uniform in the circumferential direction, the average compression force on the specimen was greater, and the energy dissipation capacity was greater. Taking GC1-E1 and GC1-F1 as examples, when the diameter of the specimen increases from 165 to 219 mm, the average compression force of the specimen increases by 67.85%.

(2) The compression force efficiency of the GCFST columns is between 0.846 and 0.901, with an average value of 0.873. It indicates the compression force efficiency of the GCFST is excellent and the performance of the materials can be fully utilized.

Finite element simulation

Based on the experimental study, one numerical analysis model is established by ABAQUS, and the coincidence degree between the simulation and test results were compared.

Constitutive relation of materials

The Q235 B steel tube, which is commonly used in engineering, was selected for this test. Steel is a kind of ideal elastic–plastic material. To make the simulation results more consistent, the five-stage constitutive relation shown in Eq. (3) was selected for steel35.

where, the \(f_{y}\) is the yield strength of the steel, \(\varepsilon_{{\text{e}}} = {{0.8f_{{\text{y}}} } \mathord{\left/ {\vphantom {{0.8f_{{\text{y}}} } {E_{{\text{s}}} }}} \right. \kern-0pt} {E_{{\text{s}}} }}\), \(\varepsilon_{{{\text{e1}}}} = 1.5\varepsilon_{{\text{e}}}\), \(\varepsilon_{{{\text{e2}}}} = 15\varepsilon_{{\text{e}}}\),\(\varepsilon_{{{\text{e3}}}} = 150\varepsilon_{{\text{e}}}\), \(A = {{0.2f_{{\text{y}}} } \mathord{\left/ {\vphantom {{0.2f_{{\text{y}}} } {\left( {\varepsilon_{{{\text{e}}1}} - \varepsilon_{{\text{e}}} } \right)}}} \right. \kern-0pt} {\left( {\varepsilon_{{{\text{e}}1}} - \varepsilon_{{\text{e}}} } \right)}}^{2}\), \(B = 2A\varepsilon_{{{\text{e}}1}}\), \(C = 0.8f_{{\text{y}}} + A\varepsilon_{{\text{e}}}^{2} - B\varepsilon_{{\text{e}}}\).

The stress–strain relationship of the GC is shown in Eq. (4)36,37.

where, \(y = \frac{\sigma }{{\sigma_{0} }}\), \(\sigma_{0} = \left[ {1 + \left( { - 0.054\xi^{2} + 0.4\xi } \right)\left( {\frac{24}{{f_{{\text{c}}} }}} \right)^{0.45} } \right]f_{{\text{c}}}\),\(q = \frac{{\xi^{0.745} }}{2 + \xi }\), \(\beta = \left( {2.36 \times 10^{ - 5} } \right)^{{\left[ {0.25 + \left( {\xi - 0.5} \right)^{7} } \right]}} f_{{\text{c}}}^{2} \times 3.51 \times 10^{ - 4}\), \(\varepsilon_{0} = \varepsilon_{{\text{c}}} + \left[ {1400 + 800\left( {\frac{{f_{{\text{c}}} }}{24} - 1} \right)} \right]\xi^{0.2}\), \(\varepsilon_{{\text{c}}} = (1300 + 12.5f{\text{c}})10^{ - 6}\). \(f_{{\text{c}}}\) is the compressive strength of the GC cylinder.

Finite element model

Model construction

Finite element model for GCFST columns was established. The steel tube and cover plate element type was S4R with four nodes, and the GC element was C3D8R. Figure 5 shows the whole model and mesh division results with the 30 mm size.

Setting of boundary conditions

Standard universal contact was employed between the steel tube and GC. The interaction properties included normal behavior and tangential behavior. The ‘hard’ contact can accurately simulate the compressive stress characteristics between the contact surfaces, avoid penetration and conform to the physical law, and has good numerical stability. Therefore, a ‘hard’ contact was used for normal behavior. The tangential behavior of the contact surface was simulated as ‘penalty’ with a friction coefficient 0.6. As the load is applied to the bottom of the actual test, the vertical upward displacement is applied in the U3 direction at the bottom of the steel tube.

Calculation results analysis

Failure modes

The stress nephogram and failure mode of GCFST columns at failure are shown in Fig. 6.

It can be seen from Fig. 6 that:

(1) The failure mode of the specimens coincided well with the results of the finite element simulation. For all specimens, local buckling failure occurred at the end of the steel tubes, and the corresponding internal concrete showed a stress concentration in this area, verifying the precision of the finite element simulation for circular GCFST columns.

(2) With distance from the top of the specimen increasing, the stress of the steel tube gradually decreased, and the stress of the concrete decreased first and then increased, which was within the reasonable stress range.

(3) The strength of the specimens was fully utilized, providing effective restraint effects for concrete columns, and the strength of the GC was significantly improved. Influenced by the restraint effects of the steel tubes, the GC was in the triaxial stress state, the strength increased more than that under uniaxial compression, and the overall stress state was better.

(4) The GCFST columns could greatly improve the strength of internal concrete and make full use of the material properties of steel tube and concrete. Although the GC in the upper part of the specimen was also constrained by the steel tube, it was located at the edge of the specimen and not completely in the triaxial stress state, so the stress concentration was prone to occur. In practical application, appropriate strengthening measures should be taken to prevent influenced stress from being imposed on the structure.

Bearing capacity

The peak load of a specimen can directly reflect its bearing capacity, that is, the greater the peak load carried by a specimen, the better its bearing capacity. The measured values were compared with the simulation results. Table 6 shows the finite element calculation value Nf, measured value Nm and Nf/Nm of each specimen.

According to Table 5:

(1) The ratios of the calculated peak load to the measured value of each specimen ranged from 0.79 to 1.13, with an average of 0.955. The standard deviation is 0.105. The variation coefficient is 0.11. The errors between the calculation and measured values of most specimens were less than 10%, indicating that the numerical analysis model for the GCFST column specimens was accurate and the calculation results coincided better with the test results.

(2) Only the error between the calculation results of specimens GC1-E1 and GC1-F1 and the measured results is greater than 15%. This is because the ‘hard contact’ was used, and when the contact surface between the steel tube and GC was separated under the action of load. In the actual test, the damage of GC accumulated until failure, but it still interacted with the steel tube and its load-bearing capacity was greater than the result of the finite element calculation. The finite element model was relatively ideal, but the actual stress and deformation of the members were different.

Skeleton curves

The comparison between the analysis and measured load–displacement curves are shown in Fig. 6, where TC denotes the test curve and SC denotes the simulation curve.

It can be seen from Fig. 6 that:

(1) The trends of the skeleton curve of different specimens were different. For specimens with a larger length-diameter ratio, the load gradually decreased after reaching the peak value. However, for those with a smaller length-diameter ratio, the load first decreased and then increased after reaching the peak value. This was due to the case that under the action of load, the specimens suffered deformation and the cross-section area increased, leading to the bearing capacity increases.

(2) The GC strength grade and the steel tube wall thickness had less influence on the trend of the skeleton curves, but had an obviously influence on the peak load. When the GC strength grade increased, the peak load increased to some extent, but the increased amplitude was smaller than that when the wall thickness of the steel tube increased.

(3) For specimens GC1-E1 and GC1-F1, the simulation and measured skeleton curves roughly represented the same trend. This was manifested mainly by the differences in peak load, and the simulation peak was lower than the test value. This is because the concrete has a more significant accumulation effect of plastic damage, leading to the simulation results being lower than the actual test values.

Conclusions

(1) Different design parameters had different effects on the bearing capacity of specimens, and the length-diameter ratio had more significant effects on the bearing capacity of specimens. Increasing the strength of GC, increasing the wall thickness of the steel tube, and reducing the length-diameter ratio could effectively improve the bearing characteristics of circular GCFST columns. The higher the GC strength, the larger the wall thickness of the steel tube and the smaller the length-diameter ratio, the greater the average compression force and energy dissipation characteristics of the specimens.

(2) The ductility of the GCFST columns was better, which can effectively alleviate the weakness of the high brittleness of the GC. The variation and development laws of the stiffness degradation curves of all members were basically the same. At the early stage of loading, the members were in the elastic stage and the stiffness degradation speed was higher, presenting a linear development trend. In the later stage of loading, the stiffness slowly degraded and tended to be steady. The length-diameter ratio of the specimens has a more significant influence on the initial stiffness of the members. The smaller the length-diameter ratio, the stronger the restraint effect and the greater the initial stiffness of the members.

(3) The results of the finite element simulation coincided better with the test results, the stress nephogram was basically consistent with the stress concentration position of the specimens, and the load–displacement curves presented the same trend. The peak load values of some specimens were different from the measured values, but were within a reasonable range, which can provide a reference for related research.

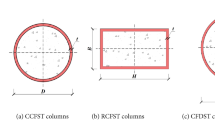

(4) In order to promote the application of geopolymer concrete filled steel tubular columns in construction engineering, more experimental parameters need to be studied, such as the shape of steel tube section (such as square, rectangle, polygon, special-shaped), the strength of steel tube, the type of core concrete (such as self-compacting concrete, coal gangue concrete, etc.)

Data availability

The datasets used and analyzed during the current study available from the corresponding author on reasonable request.

References

Yang, J. et al. Low-carbon wet-ground fly ash geopolymer activated by single calcium carbide slag[J]. Constr. Build. Mater. 353, 129084. https://doi.org/10.1016/j.conbuildmat.2022.129084 (2022).

Zhang, P. et al. Fabrication and engineering properties of concretes based on geopolymers/alkali-activated binders-A review[J]. J. Clean. Prod. 258, 120896. https://doi.org/10.1016/j.jclepro.2020.120896 (2020).

da Luz, P. C. A. Compressive strength, modulus of elasticity and hardness of geopolymeric cement synthetized from non-calcined natural kaolin[J]. J. Clean. Prod. 280, 124293. https://doi.org/10.1016/j.jclepro.2020.124293 (2021).

Sandanayake, M. et al. Greenhouse gas emissions of different fly ash based geopolymer concretes in building construction[J]. J. Clean. Prod. 204, 399–408. https://doi.org/10.1016/j.jclepro.2018.08.311 (2018).

Ge, X., Hu, X. & Shi, C. Impact of micro characteristics on the formation of high-strength class f fly ash-based geopolymers cured at ambient conditions[J]. Constr. Build. Mater. 352, 129074. https://doi.org/10.1016/j.conbuildmat.2022.129074 (2022).

Duxson, P. et al. The role of inorganic polymer technology in the development of ‘green concrete’[J]. Cem. Concr. Res. 37(12), 1590–1597. https://doi.org/10.1016/j.cemconres.2007.08.018 (2007).

Zhou, J. & Wang, L. Repair of fire-damaged reinforced concrete members with axial load: A review[J]. Sustainability 11(4), 963. https://doi.org/10.3390/su11040963 (2019).

Lie, T. T. & Irwin, R. J. Fire Resistance of steel columns filled with bar-reinforced concrete[J]. J. Struct. Eng. 121(5), 30–36. https://doi.org/10.1061/(ASCE)0733-9445(1996)122:1(30) (1995).

Huang, C. S. et al. Axial load behavior of stiffened concrete-filled steel columns[J]. J. Struct. Eng. 128(9), 1222–1230. https://doi.org/10.1061/(ASCE)0733-9445(2002)128:9(1222) (2002).

Sakino, K. et al. Behavior of centrally loaded concrete-filled steel-tube short columns[J]. J. Struct. Eng. 130(2), 180–188. https://doi.org/10.1061/(ASCE)0733-9445(2004)130:2(180) (2014).

Hou, W. Q. et al. Experimental study and application of manufactured sand self-compacting concrete in concrete-filled-steel-tube arch bridge: A case study[J]. Case Stud. Constr. Mater. 15, e00718. https://doi.org/10.1016/j.cscm.2021.e00718 (2021).

Han, X. et al. Seismic stability analysis of the large-span concrete-filled steel tube arch bridge considering the long-term effects[J]. Eng. Struct. 268, 114744. https://doi.org/10.1016/j.engstruct.2022.114744 (2022).

Nguyen, T. T. et al. Behaviour and design of eccentrically loaded CFST columns with high strength materials and slender sections[J]. J. Constr. Steel Res. 188, 107004. https://doi.org/10.1016/j.jcsr.2021.107004 (2022).

Fan, X. A brief introduction on the research status and future prospects on geopolymer concrete[C]//IOP conference series: Earth and environmental science. IOP Publ. 508(1), 012124. https://doi.org/10.1088/1755-1315/508/1/012124 (2020).

Mishra, J. et al. Influence of ferrochrome ash on mechanical and microstructure properties of ambient cured fly ash-based geopolymer concrete[J]. J. Mater. Cyc. Waste Manag. 24(3), 1095–1108. https://doi.org/10.1007/s10163-022-01381-1 (2022).

Zhao, Q. et al. Experimental study on mechanical behavior of steel fiber reinforced geopolymeric recycled aggregate concrete[J]. Constr. Build. Mater. 356, 129267. https://doi.org/10.1016/j.conbuildmat.2022.129267 (2022).

Saranya, P., Nagarajan, P. & Shashikala, A. P. Impact resistance of GGBS-dolomite geopolymer concrete[C]//IOP conference series: Materials science and engineering. IOP Publ. 936(1), 012008. https://doi.org/10.1088/1757-899x/936/1/012008 (2020).

Nithya, S., Gunasekaran, K. & Sankar, G. A study on the flexural behaviour of geopolymer lightweight eco-friendly concrete using coconut shell as coarse aggregate[J]. Adv. Civ. Eng. 2021, 1–20. https://doi.org/10.1155/2021/5534019 (2021).

Dong, M. et al. Material and glass-fibre-reinforced polymer bond properties of geopolymer concrete[J]. Mag. Conc. Res. 72(10), 509–525. https://doi.org/10.1680/jmacr.18.00273 (2020).

Liu, J., Su, X. & Yan, F. Experimental investigation on the effect of geopolymer adhesive on the bond behavior between CFRP and concretes[J]. Polym. Compos. 43(5), 3259–3275. https://doi.org/10.1002/pc.26615 (2022).

Zhou, X. et al. Seismic performance of concrete-encased column connections for concrete filled thin-walled steel tube piers[J]. Eng. Struct. 269, 114803. https://doi.org/10.1016/j.engstruct.2022.114803 (2022).

Li, W., Chen, B. & Wang, T. Seismic performance of concrete-filled double-skin steel tubes after exposure to fire: Analysis[J]. J. Constr. Steel Res. 162, 105753. https://doi.org/10.1016/j.jcsr.2019.105753 (2019).

Liu, F. et al. Experimental and numerical study on behaviour of square steel tube confined reinforced concrete stub columns after fire exposure[J]. Thin-Walled Struct. 139, 105–125. https://doi.org/10.1016/j.tws.2019.02.037 (2019).

Wang, X., Fan, F. & Lai, J. Strength behavior of circular concrete-filled steel tube stub columns under axial compression: A review[J]. Constr. Build. Mater. 322, 126144. https://doi.org/10.1016/j.conbuildmat.2021.126144 (2022).

Tang, Y. C. et al. Seismic performance of recycled aggregate concrete–filled steel tube columns[J]. J. Constr. Steel Res. 133, 112–124. https://doi.org/10.1016/j.jcsr.2017.02.006 (2017).

Dai, P. et al. Bond stress-slip relationship in concrete-filled square stainless steel tubes[J]. Constr. Build. Mater. 326, 127001. https://doi.org/10.1016/j.conbuildmat.2022.127001 (2022).

Yu, F. et al. Experimental and theoretical investigations of recycled self-compacting concrete filled steel tubular columns subjected to axial compression[J]. Constr.Build. Mater. 248, 118689. https://doi.org/10.1016/j.conbuildmat.2020.118689 (2020).

Song, T. Y. et al. Fire resistance tests on concrete-filled steel tubular columns with geopolymeric recycled aggregate[J]. Fire Technol. 58(5), 2727–2754. https://doi.org/10.1007/s10694-022-01271-w (2022).

Fang, H. & Visintin, P. Structural performance of geopolymer-concrete-filled steel tube members subjected to compression and bending[J]. J. Constr. Steel Res. 188, 107026. https://doi.org/10.1016/j.jcsr.2021.107026 (2022).

Standards Press of China, GB/T 2975–2018, Steel and steel products—Location and preparation of samples and test pieces for mechanical testing, 2018.

Standards Press of China, GB/T 228.1–2021, Metallic materials-Tensile testing-Part 1: Method of test at room temperature, 2021.

China Architecture & Building Press, GB/T 50081–2019, Standard for test methods of concrete physical and mechanical properties, 2019.

Hui, C. et al. Test study on axial compression behavior of GCFST columns under unidirectional repeated load[J]. Intl. J. Steel Struct. 23, 1077–1090. https://doi.org/10.1007/s13296-023-00751-1 (2023).

China Architecture & Building Press, GB/T 50936–2014, Technical code for concrete filled steel tubular structures, 2014.

Han, L. H. Concrete-filled steel tube structure-Theory and Practice (third edition) [M] (Science Press, 2016).

Nguyen, H. T. & Kim, S. E. Finite element modeling of push-out tests for large stud shear connectors[J]. J. Constr. Steel Res. 65(10–11), 1909–1920. https://doi.org/10.1016/j.jcsr.2009.06.010 (2009).

Genikomsou, A. S. & Polak, M. A. Finite element analysis of punching shear of concrete slabs using damaged plasticity model in ABAQUS[J]. Eng. Struct. 98, 38–48. https://doi.org/10.1016/j.engstruct.2015.04.016 (2015).

Acknowledgements

This study is funded by the National Natural Science Foundation of China (52208226) and Henan Province Key Research and Development Program (241111322000).

Funding

National Natural Science Foundation of China,52208226,Henan Province Key Research and Development Program,241111322000

Author information

Authors and Affiliations

Contributions

Cun Hui: The proposer and coordinator of the experiment are responsible for the design of the test scheme and the revision of the subsequent papers. Yun Cao and Xiang Chen: Prepare materials, test collaborators. The whole process of the experiment operation, first draft editing, and subsequent paper revision. Jianwei Zhang: Explain the operation process of the test instrument, and test cooperation personnel. Ran Hai: Provide resources, guide, supervise and review thesis writing.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hui, C., Zhang, J., Cao, Y. et al. Repeated axial compressive performance of GCFST columns: Test investigation and numerical analysis. Sci Rep 15, 2460 (2025). https://doi.org/10.1038/s41598-025-86516-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-86516-8