Abstract

To clarify the influence of blast-induced seismic wave characteristics due to borehole coupling medium changes is an important guiding significance for blast vibration control. The energy calculation method of blasting seismic wave was derived and the influence of blasting source factors on seismic wave spectral characteristics was investigated. Then, the energy, composition and attenuation difference of seismic wave induced by explosive blasting with different coupling medium were compared and analyzed. Finally, experiments were carried out to verify analysis. The results show that the energy of blasting seismic wave is related to coupling medium, and the energy of water-coupled blasting induced seismic wave is higher than that of air-coupled blasting. The difference of seismic wave energy between water-coupled blasting and air-coupled blasting is not constant and influenced by rock, explosive categories and decoupling charge coefficient. The existence of water makes seismic wave have richer low-frequency components, and the main frequency is also lower than that of air-coupled blasting. In the process of propagation, air-coupled blasting attenuates faster, and the energy difference of seismic wave between water-coupled blasting and air-coupled blasting increases exponentially with propagation distance increase. The research results can provide reference for the safety control of water-rich rock blasting.

Similar content being viewed by others

Introduction

Blasting vibration, as the most harmful negative blasting effect, has received widespread attention1,2. Radial decoupling charge is the most used charge structure in engineering, it refers to the charge method that charge diameter is smaller than borehole diameter, and there is a gap between explosive and borehole wall. which can effectively control blast-induced vibration3,4. The decoupled coefficient Dc is the ratio of borehole diameter to charge diameter. However, due to rainfall, water seepage or active water injection into the borehole, the air interval of decoupling charge is often filled with water, forming water-coupled blasting. Due to the different physical properties and dynamic characteristics of air and water, there are differences in blast-induced seismic wave characteristics when used as a coupling medium.

Many studies have been conducted on the seismic wave characteristics excited by blasting with different coupling media. Cai and Liu5 studied the influence of water on detonation wave formation and stress wave energy, and pointed out that when charge decoupling coefficient is 1.5, the strongest sub-energy of blasting stress wave in water within 10 Hz ~ 50 Hz and the highest signal-to-noise ratio. Ma et al.6 explored the energy distribution and attenuation law of underwater borehole blasting vibration signals. The results show that the blasting vibration induced by underwater blasting has the characteristics of low main frequency, short duration and fast attenuation, and the vibration energy decreases rapidly with the increase of blasting free surface. On this basis, more researchers pointed out that the existence of water in borehole can improve blasting coupling relationship, enhance transmission of explosion energy, and thus improve the characteristics of blasting seismic wave7. Bastante et al.8, Sher and Aleksandrova9 studied the influence of charge decoupling coefficient on blasting seismic wave, and indicated that for any coupling medium, the increase of decoupling coefficient will reduce the energy of blasting seismic wave.

In the study of seismic wave characteristics caused by change of borehole coupling medium, Yin et al.10 simulated and analyzed the blasting dynamic response of silt-rock strata under different coupling medium conditions, and concluded that the rock dynamic response is not affected by hole depth when air-coupled charge is used. Zhong et al.11 analyzed the effect of blast load duration, charge and other microscopic source factors on the characteristics of blast vibration spectrum, giving the change characteristics in vibration spectrum with source factors change. Based on theoretical analysis and field test, Gu et al.12 pointed out that water-coupled blasting makes more energy to be used for blast fragmentation of rock masses and effectively reduces blast vibration energy compared to air-coupled blasting, but the findings differ from the field monitoring results by Gou et al.13, who concluded that water-coupled blasting induces a greater blast seismic wave energy. From the perspective of blasting vibration control, Xie et al.2 compared the blasting effect of decoupled charge with different axial media. Based on the field test, Wang et al.15 compared the influence of coupling medium change on the peak blasting vibration of concrete supporting structure with the same charge, and results show that the water can effectively reduce the damage of tunnel supporting structure.

To date, research has primarily focused on the seismic wave characteristics induced by blasting with a specific coupling medium, and the analysis of difference in blasting seismic wave characteristics caused by changes in the coupling medium is still relatively rare, and some of the existing results have inconsistent conclusions. This paper explores the differences of seismic wave characteristics induced by blasting with different coupling medium through theoretical analysis and indoor tests, and makes an accurate scientific evaluation of the differences, which is of great significance for the charge design of water-coupled blasting and the objective quantitative control of water-coupled blasting disturbance.

Generation mechanism of blast-induced seismic wave

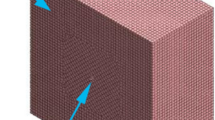

The detonation product generated by explosive blasting begin to propagate from the center of charge to surroundings. A violent compression disturbance is exerted on surrounding rock to produce a compression wave transmitted outward16. The propagation velocity is much larger than rock acoustic velocity. This wave propagating at high speed in high temperature and high-pressure environment is the blast shock wave. The pressure amplitude of shock wave is extremely high in near blasting source area, which is far greater than the dynamic tensile compressive strength of rock, resulting in rock mass being crushed into a crushing zone within a range of 1.2 to 5 times the charge radius from explosion center.

The rock mass in crushing zone is presented in a molten plastic state. Although the propagation speed of shock wave is very large, the propagation distance is very short due to its extremely fast attenuation speed, and the range of crushing zone is limited to a small area near borehole. The damage degree in crushing zone is great, significantly consuming blast shock wave energy, so the shock wave attenuates into stress wave at the outer boundary of crushing zone, and continues to propagate around with increase of the distance between the explosion center. The stress wave amplitude is smaller than the shock wave amplitude, the wave velocity is also significantly reduced, but still greater than the dynamic tensile strength of rock. when it acts on surrounding rock, it will generate compressive stress in radial direction and tensile stress in circumferential direction and cause complex rock mass failure problems. The circumferential tensile stress can easily exceed the dynamic tensile strength of rock and cause radial cracks. Subsequently, the detonation gas penetrates into rock to further expand and extend radial cracks, resulting in the damage or residual deformation of rock. The new cracks and original cracks in crushing zone expand rapidly under the action of compressive stress wave and finally connect with each other to form a fracture zone within the range of about 150 times the charge radius. The energy of stress wave is not only inducing the vibration of rock mass, but also dissipated in initial crack formation and expansion.

Outside the fracture zone, as the distance from blasting center continues to increase, the stress intensity continues to decay, action time increases significantly, and wave velocity also decreases to rock acoustic velocity. The stress wave field no longer causes plastic damage to rock, but it will cause elastic deformation. At this time, the stress wave attenuates into elastic seismic wave (blasting seismic wave) and continues to spread around. Therefore, the propagation of blasting seismic wave is the elastic dynamic response of rock. The propagation and evolution process of three waves in space is shown in Fig. 1.

The propagation of blasting seismic wave is the elastic dynamic response of rock. For any particle in medium space domain, the particle vibrates under the disturbance of blasting. Since propagation medium is continuous, the vibration of a particle drives the vibration of its adjacent particles. At this time, blasting seismic wave can be considered as transmission process of medium particle vibration17. The disturbance of blasting seismic wave causes particle to do elastic reciprocating motion. Therefore, the blasting vibration signal monitored in medium can be considered as the carrier and physical manifestation of blasting seismic wave information. Blasting seismic wave is reflected in the movement process of medium particle in time domain. This explains the generation of blasting seismic waves from the perspective of particle vibration, as shown in Fig. 2.

Wave theory emphasizes the state of particles with different blasting center distance and the speed of wave propagation at a certain time, including wave velocity, wavelength and frequency of seismic wave. Vibration theory focuses on the continuous motion state of particles at different distances from blasting center over time, including vibration intensity and frequency of particle2. In engineering, particle vibration parameters are easier to measure, so the vibration characteristics of particles, namely blasting vibration, are used to study blasting seismic waves characteristics in application.

Theoretical analysis on characteristic difference of blasting seismic wave

The change of coupling medium in borehole will affect the form and size of blasting disturbance to surrounding rock, and the induced blasting seismic wave will also have some differences in strength and frequency. In theoretical analysis, it is assumed that the rock is isotropic, in which there is no joint crack.

Blasting seismic wave energy difference

The explosive energy is mostly dissipated in the formation of rock crushing zone and fracture zone. Outside the fracture zone, blast load no longer causes rock mass damage, but only causes elastic vibration, the explosion energy to elastic seismic wave situation in rock propagation. The energy required for elastic deformation of unit volume rock mass in cylindrical coordinate system is19:

where σ and ε represent stress and strain, respectively, and the subscripts r and θ represent radial and tangential directions. Em represents the elastic modulus of rock, Pa; λ represents the lateral pressure coefficient.

The seismic wave energy causing elastic deformation of rock mass per unit length is:

where E represents the seismic wave energy, J; rb represents the borehole radius, m; R represents the range of elastic deformation of rock, m.

The radial stress at any point r within rock mass is:

where Pt represents the borehole pressure; αs represents the stress wave attenuation index.

Combining Eqs. (1)–(3), the elastic seismic wave energy can be obtained:

For blasting in semi-infinite rock mass, the propagation range of elastic seismic wave is close to + ∞ considering that the rock mass in elastic deformation zone will not be damaged. The energy of elastic seismic wave from elastic deformation region R to + ∞ is:

From Eq. (5), the blasting seismic wave energy is related to the peak pressure of borehole wall, borehole radius, rock elastic modulus and stress attenuation coefficient. when blasting object and charge parameters are determined, it means that the parameters Em, λ, αs and rb are determined. At this time, the difference in peak pressure of borehole wall is the only factor causing the energy difference of seismic waves induced by blasting.

In order to further explore the difference of seismic wave energy induced by blasting with different coupling medium, and the influence of blasting medium, decoupling coefficient and explosive type on the difference. Based on the distribution of rock mass types in actual excavation, commonly used blasting parameters and industrial explosive types, three kinds of rock masses with obvious differences in properties, such as siltstone, limestone and granite, are selected to represent soft, medium hard and hard rock, respectively. At the same time, six commonly used decoupling coefficients are selected. Two typical industrial explosives, emulsion explosive and porous granular ammonium oil explosive are calculated and analysed. This setting of multiple calculation conditions based on engineering field can supplement the richness of research results and strengthen the applicability of research results.

The peak pressure calculation results of air-coupled blasting and water-coupled blasting under different working conditions are directly based on the calculation results in references20,21. The peak pressure calculation results are shown in Table 1.

The ratio of calculated blasting seismic wave energy of blasting with different coupling medium to explosive energy is shown in Fig. 3.

Comparing the elastic seismic wave energy induced by blasting with different coupling medium, it can be found that water-coupled blasting has higher elastic seismic wave energy than air-coupled blasting. When the coupling medium in borehole changes from air to water, the disturbance intensity of blasting seismic wave increases.

In addition, the difference of elastic seismic wave energy is not a fixed value, which is affected by blasting medium, explosive properties and decoupling coefficient. The difference in elastic seismic wave energy becomes larger with the increase of rock strength and decoupling coefficient under the same charge amount. The energy difference is smaller than that by blasting with ammonium oil explosive when emulsion explosive is used.

Composition difference of blasting seismic wave

Blasting seismic wave consist of many waves with different characteristics, and the blasting vibration signal, as the carrier and physical manifestation of blasting seismic wave information, is a direct indicator of the negative effects control of blasting seismic wave. The amplitude intensity, vibration frequency and vibration duration of blasting vibration are commonly used in engineering to describe blasting vibration. The difference in vibration intensity has been analyzed above. This section focuses on the difference in vibration frequency induced by blasting with different coupling medium.

In order to obtain the frequency domain solution of blast-induced vibration, it is necessary to derive the frequency domain expression of blast load. At present, scholars often use triangular load as the blast load time curve to simplify the blasting process. The general form of triangular load function is22:

where Pt represents the borehole pressure; tr represents the rise time of blast load; td represents the dropping time of blast load.

Taking the Fourier change of P(t) as \({P_F}\left( f \right)\), then \({P_F}\left( f \right)\) is:

where f represents the frequency (Hz); i represents the imaginary unit.

The corresponding amplitude spectrum is:

From Eq. (8), the parameters affecting the blast load spectrum are mainly the load rise time tr and the load duration ts. Next, these two influencing factors are analyzed separately. The normalized load amplitude spectrum after taking ts as 10 ms and tr as 0.5, 1, 2 and 5 ms respectively is shown in Fig. 4.

From Fig. 4, the spectral amplitude of the triangular load first decreases with increasing frequency until it is 0, and then begins to gradually decay in fluctuation. Comparing the curves of different load rise time, it can be found that the load rise time mainly affects the spectrum composition of the whole load. The longer the rise time, the faster the spectrum amplitude approaches zero and the smaller the spectrum range as the frequency increases.

The triangular load rise time tr is taken to be 2 ms and the load fall time td is 6, 8, 10, 12 and 14 ms to explore the effect of load duration on the load spectrum composition. The normalized results are shown in Fig. 5.

According to the calculation results, as the load duration increases, the load spectrum amplitude gradually decreases, and the proportion of low-frequency components gradually increases. It can be inferred that the change of load duration will affect load spectrum distribution. The longer the load duration, the higher the proportion of low frequency components.

Engineering blasting mostly adopts columnar charge structure, and the results of the stress wave field excited can be equivalently calculated by the spherical charge superposition model or the short column charge superposition model, which has achieved remarkable results in recent years and has a good match with actual situation23. Considering that the columnar charge can be regarded as the superposition of spherical charge, the basic characteristics of its induced vibration are the same as those of spherical charge. The analysis of the frequency domain solution of blast-induced vibration is carried out next with the spherical charge as an example.

Blasting vibration propagates in the elastic deformation zone of rock, which does not involve complex problems such as blasting fracture. Therefore, the part within the elastic deformation zone can be regarded as an equivalent blasting source. After the spherical charge is detonated, the spherical symmetric elastic wave excited on the elastic boundary is24:

where \(\tau =t - \frac{{r - {r_e}}}{{{C_p}}}\); re represents the elastic boundary radius; Cp represents the elastic longitudinal wave velocity of rock; λ and µ represent the Lamé constant, calculated from the Young’s modulus E and Poisson’s ratio v.

Taking the Fourier change of u(t) as \({u_F}\left( f \right)\)and the Fourier change of σ(t) as \({\sigma _F}\left( f \right)\), From the transformation of Eqs. (9)~(10), it can be obtained:

According to the relationship between vibration velocity and displacement in frequency domain, the expression of vibration velocity in frequency domain is:

The amplitude spectrum is:

The amplitude spectrum of vibration wave generated by spherical charge blasting can be obtained by combining Eqs. (8) and (13). It can be seen from Eq. (13) that the amplitude spectrum function \({A_v}\left( f \right)\) is directly affected by the load spectrum \({A_p}\left( f \right)\), so the influence law of the blast source parameters tr and td on the load spectrum is also applicable to the blasting vibration amplitude spectrum. That is, the longer the load rise time, the smaller the spectrum range, the longer the load duration, and the higher the proportion of low-frequency components in blasting seismic wave components.

In addition, the equivalent elastic boundary radius re also has some influence on the amplitude spectral function. The influence relationship is analysed by an example. The calculation parameters used are tr = 2 ms, td = 10 ms, ρ = 2700 kg/m3, v = 0.24, Cp = 5000 m/s, E = 68 Gpa, and the calculation results are shown in Fig. 6.

From Fig. 6, with the increase of the elastic boundary radius, the proportion of high frequency components of vibration wave gradually decreases, and the main frequency also gradually shifts to the low frequency. The elastic boundary radius has a certain influence on the composition of the vibration spectrum.

For blasting with different coupling medium, in the case of the same blasting design parameters and blasting medium, the change of coupling medium in borehole will significantly affect the duration of blast load and the boundary of elastic zone25. When the detonation mode is hole-bottom detonation, it is usually considered that the blast load rise time that the blast wave from the bottom of charge to the top of the time, the borehole coupling medium impact is small. For the duration of blast load, due to the large flow viscosity and low compressibility of water, it is generally believed that the existence of water greatly delays the duration of blast load, that is, the duration of blast load of water-coupled blasting is longer than that of air-coupled blasting26. Meanwhile, water in the borehole substantially increases the strength of blast load, and the crush zone and fracture zone of water-coupled blasting are larger than those of air-coupled blasting under the same rock damage criterion, i.e., the equivalent elastic boundary radius of water-coupled blasting is larger than that of air-coupled blasting.

Combined with the analysis of the influence of blast load parameters on the composition of blast-induced seismic wave, it can be inferred that blast seismic wave induced by water-coupled blasting should be richer in low-frequency components than those induced by air-coupled blasting. The overall spectral distribution is predominantly low-frequency compared to air-coupled blasting, and the main frequency of blast vibration is lower than that of air-coupled blasting.

Differences in propagation attenuation of blasting seismic wave

Mastering the attenuation characteristics of blasting seismic wave propagation is conducive to the prediction and control of blasting vibration. There are differences in blasting seismic wave components induced by blasting with different coupling medium, which will inevitably affect the propagation attenuation of seismic wave. After the explosive blasting, the wave radiates from explosion sources to surrounding rock. For the mass unit with mass Δm in space, at a certain moment, the energy of blasting vibration can be expressed as:

where \({E_{\Delta m}}\) represents the energy of blasting seismic wave at a certain moment; \(v\left( t \right)\) represents the blast vibration velocity at moment t.

From Eq. (14), it can be seen that the blast vibration energy is proportional to the square of vibration velocity, both.

where Ep represents 2 times the unit mass blasting vibration energy at a certain moment, which can indirectly measure the size of blasting vibration energy.

The relative total energy of blasting vibration at a certain position can be obtained by integrating the whole blasting process, which is expressed as:

In the process of wave radiation to surrounding area, with the increase of the distance from blasting center, the blasting seismic wave can be approximated as a plane wave. The wave attenuation in medium can be approximately assumed as follows: The relative decrease of wave energy is proportional to the traveled distance of wave. If dE is the change of energy on the distance dx, there is27:

By integrating and omitting the mass of element, the relative total energy of blasting vibration at the x position is:

where E0 represents the energy when x = 0, that is, the total energy of blasting into seismic wave; 2α represents the energy absorption coefficient of medium, because the energy is proportional to the square of vibration amplitude, that is, α represents attenuation coefficient of the wave amplitude with distance.

From Eq. (18), the ratio of blasting seismic wave energy at any point x in rock mass during blasting with different coupling media is:

where η represents the ratio of blasting seismic wave energy; E0 − w and E0 − a represents the total energy of blasting into seismic wave in water-coupled blasting and air-coupled blasting, respectively; αa and αw represents attenuation coefficient of the wave amplitude with distance in air-coupled blasting and water-coupled blasting, respectively; Pt−w and Pt−a represents the borehole pressure in water-coupled blasting and air-coupled blasting, respectively.

From Eq. (20), when the blasting site and conditions are determined, there are differences in attenuation of blasting seismic wave induced by blasting with different coupling media during propagation. The energy difference of blasting seismic wave induced by water-coupled blasting and air-coupled blasting is not fixed, but changes exponentially, which is related to the peak pressure of borehole wall and attenuation coefficient of vibration velocity. Based on the analysis of blasting seismic wave composition, combined with the difference in attenuation rate of high and low frequency waves, it can be inferred that the attenuation of blasting vibration velocity induced by water-coupled blasting is slower than that of air-coupled blasting, that is, αw < αa. It can be further determined that the energy difference of blasting seismic wave induced by water-coupled blasting and air-coupled blasting increases exponentially with the increase of propagation distance.

Experimental study on blast-induced vibration characteristics

Test site and working condition setting

Indoor blasting test mainly explores blasting seismic wave characteristics by testing and analyzing blasting vibration. The indoor blasting test was conducted on a C30 concrete bench 5 m in length, 4 m in width, and 1.8 m in height. The bench was poured below the ground surface and closely combined with the surrounding soil to reduce the influence of boundary reflection waves. The explosive source hole is drilled on the bench to carry out blasting tests with different coupling media, and numbered 1#. The diameter of explosive source hole is 78 mm, the hole depth is 1 m, and the distance from the edge of concrete bench is 0.6 m. During blasting, a blasting vibration testing line is arranged in blasting area. Multiple velocity sensors are arranged on testing line according to the distance from blasting source to obtain the propagation and attenuation laws of blasting vibration under different working conditions. The vibration test points are 0.35 m, 0.85 m, 1.5 m, 2.0 m and 2.5 m away from the explosion source respectively, and are numbered 2#~6# in sequence. The layout of test bench is shown in Fig. 7. The test sensors are arranged on the concrete bench surface, and layout position is strictly arranged according to the pre-selected vibration test point.

In order to compare the difference of seismic wave energy under the conditions of water and air in explosion source hole and different dosage, multiple sets of blasting comparison tests were designed according to the explosive dosage and coupling conditions. The blasting test conditions are shown in Table 2. During test, in order to prevent the concrete table from being damaged by blasting, the charge diameter of explosive shall be kept at 15 mm, and ensure that each test is detonated at same position in hole. The explosive used in test is 2# rock emulsion explosive, which is one of the most commonly used explosive types in engineering blasting. The explosive density ρe = 1244 kg/m3, the detonation velocity D = 5000 m/s, and the explosive energy is 3.182 mJ/kg. In air-coupled blasting test, the coupling medium is atmospheric air, and in water-coupled blasting, the coupling medium is tapwater. The source of coupling medium is consistent with the engineering site.

It should be noted that the thin tubes and small surface pits on the concrete bench in Fig. 6 are other tests planned. These tests were carried out separately from the blasting vibration test, and have no effect on vibration test.

Test result

The blasting vibration curve under typical working conditions monitored at the measuring point 0.85 m away from explosive source is shown in Fig. 8. The results show that the vibration waveform and peak velocity induced by blasting with different coupling media are significantly different. The change of coupling medium in borehole causes the change of explosive energy release process, which has an impact on the characteristics of blasting-induced seismic wave field.

To further compare the composition differences of blast-induced seismic wave which blasting with different coupling media, the fast Fourier transform function built-in Matlab is used to transform the test blasting vibration signal. The fast Fourier transform amplitude is converted into actual vibration signal amplitude according to the conversion relationship.

where x(k) represents the amplitude of the Fourier transform corresponding to the frequency index k; A represents the amplitude of harmonic signal corresponding to the frequency index k of test signal; n represents the test sampling point, N represents the maximum sampling point.

The difference of vibration spectrum was analyzed. Considering that the wave will attenuate during propagation, resulting in vibration spectrum changes28, the measuring points closer to explosive source should be selected for analysis. However, during the test, due to the close distance between 2# measuring point and explosion source, the strong blasting vibration loosens the sensor and makes detection result distorted. Therefore, the 3# measuring point is selected for spectrum comparison and analysis. The frequency spectrum distribution of blasting-induced vibration waves under different working conditions is shown in Figs. 9 and 10.

The results show that the composition of blasting seismic wave induced by blasting with different coupling medium is different. When the charge is same, the blasting seismic wave induced by air-coupled blasting has more high-frequency components, and the overall spectrum distribution is biased towards high frequency compared with water-coupled blasting. The apparent dominant frequency of blasting vibration is also higher than that of water-coupled blasting. The test results are consistent with the theoretical analysis results, which verifies the correctness of theoretical analysis.

Wavelet analysis was used to compare the frequency band energy distribution characteristics of blasting vibration signals when blasting with different coupling media of 10 g charge. After wavelet reconstruction, it is decomposed into the following 13 bands: the first band is 0 ~ 78.1 Hz, the second band is 78.1 ~ 195.3 Hz, the third band is 195.3 ~ 312.5 Hz, the fourth band is 312.5 ~ 429.7 Hz, the fifth band is 429.7 ~ 546.875 Hz, the sixth band is 546.875 ~ 664.1 Hz, the seventh band is 664.1 ~ 781.3 Hz, the eighth band is 781.3 ~ 898.4 Hz, the ninth band is 898.4 ~ 1015.6 Hz, the tenth band is 1015.6 ~ 1132.8 Hz, the eleventh band is 1132.8 ~ 1250.0 Hz, the twelfth band is 1250.0 ~ 1367.2 Hz, and the thirteenth band is above 1367.2 Hz. The relative energy distribution of vibration signals in different frequency bands is shown in Fig. 11.

It can be seen from the figure that the proportion of low-frequency components of blasting seismic wave excited by water-coupled blasting is significantly higher than that of air-coupled blasting. With the increase of seismic wave propagation distance, the high-frequency component of seismic wave induced by air-coupled blasting decreases rapidly, and the attenuation rate of seismic wave energy is significantly higher than that of water-coupled blasting.

In spectrum analysis of blasting vibration, although the power spectral density does not represent the power or energy in true physical sense, the power spectrum characterizes the relative size of a certain frequency harmonic component energy, so it can be used to analyze and study blast vibration energy distribution in a certain frequency band29. For spectrum analysis of blasting vibration discrete signal, the power spectrum value at the discrete frequency point is obtained. Assuming that the spectrum analysis of a blasting vibration signal v(t) is carried out to obtain the discrete frequency value series fi and the corresponding power spectral density value PSDi, the ratio of energy to the total vibration energy in a specific frequency band range (fm< f < fn) can be expressed as:

where PEf represents the energy proportion in the frequency range (fm < f < fn).

Therefore, for a specific blasting vibration signal, after spectrum analysis, if the whole frequency domain is divided into several sections, according to Eq. (22), the energy ratio in each frequency section can be obtained. Based on this, the relative energy of vibration wave is obtained by integral superposition of each frequency range of blasting vibration wave, as shown in Table 3.

The relative energy comparison results show that the seismic wave energy induced by water-coupled blasting is significantly higher than that of air-coupled blasting, which is consistent with the theoretical analysis results. Through regression analysis, the law of energy ratio of seismic wave induced by blasting with different coupling medium in the process of propagation attenuation is:

5 g explosive charge:

10 g explosive charge:

The regression results show that the energy difference of blasting seismic wave induced by water-coupled blasting and air-coupled blasting increases exponentially with propagation distance increase, and the attenuation of air-coupled blasting seismic wave is faster, which is consistent with previous theoretical analysis. Substituting x = 0 into the regression formula, it can be obtained that the seismic wave energy of water-coupled blasting is about 23 times that of air-coupled blasting when the decoupling coefficient is about 5.2. The density of C30 concrete is about 2360 kg m− 3, the elastic modulus is about 30 Gpa. The material parameters are basically the same as those of limestone. The calculated difference of seismic wave energy conversion efficiency is basically consistent with the theoretical calculation law, which verifies the correctness of theoretical analysis results.

Conclusions

The main conclusions of this study were the following:

-

(1)

There is a significant difference in the energy of blasting seismic wave induced by blasting with different coupling medium. Under the same charge, the energy of blasting seismic wave induced by water-coupled blasting is high, and with the increase of rock mass strength and decoupling coefficient, the difference of elastic seismic wave energy becomes larger.

-

(2)

The composition of blasting seismic wave induced by blasting with different coupling media is different. The existence of water in borehole prolongs the duration of blasting load and increases the damage range of rock mass, so that the induced blasting seismic wave has more abundant low-frequency components, and the main frequency of blasting vibration is also lower than that of air-coupled blasting.

-

(3)

The attenuation of blasting seismic wave induced by blasting with different coupling media is different in the process of propagation. The attenuation of air-coupled blasting is faster. The energy difference of blasting seismic wave between water-coupled blasting and air-coupled blasting increases exponentially with the increase of propagation distance.

-

(4)

The existence of water in borehole changes the characteristics of blasting disturbance induced by explosive blasting, which makes the intensity of blasting disturbance greater, the attenuation slower, and the more harmful low-frequency wave components. When blasting in a water-rich environment, targeted safety precautions should be formulated according to these characteristics to ensure construction safety.

Data availability

The datasets generated and analyzed during the current study are available from the corresponding author on reasonable request.

References

Gómez, S., Sanchidrián, J. A. & Segarra, P. Near-field vibration from blasting and rock damage prediction with a full-field solution. Int. J. Rock Mech. Min. Sci. 134, 104357 (2020).

Fissha, Y. et al. Predicting ground vibration during rock blasting using relevance vector machine improved with dual kernels and metaheuristic algorithms. Sci. Rep. 14, 20026 (2024).

Taji, M. et al. ODM: A new approach for open pit mine blasting evaluation. J. Vib. Control 19(11), 1738–1752 (2013).

Yi, L. et al. Vibration velocity and frequency characteristics of surrounding rock of adjacent tunnel under blasting excavation. Sci. Rep. 12, 8453 (2024).

Cai, F. & Liu, Z. G. Impact of water decoupling charging on the energy of stress waves generated by blast in the process of deep-hole presplit blast in coal-bed. J. Saf. Sci. Technol. 10(08), 16–21 (2014).

Ma, C. Y. et al. Influence of free face numbers on energy distribution characteristics of blast vibration signal in underwater drilling blasting. IOP Conf. Ser. Earth Environ. Sci. 560(1), 012076 (2020).

Jang, H. et al. Effects of water deck on rock blasting performance. Int. J. Rock Mech. Min. Sci. 112, 77–83 (2018).

Bastante, F. G., Alejano, L. & Gonzalez-Cao, J. Predicting the extent of blast-induced damage in rock masses. Int. J. Rock Mech. Min. Sci. 56(1), 44–53 (2012).

Sher, E. N. & Aleksandrova, N. I. Effect of borehole charge structure on the parameters of a failure zone in rocks under blasting. J. Min. Sci. 43(4), 409–417 (2007).

Yin, T. et al. Dynamic response characteristics of blasting strata in silt-rock stratum under different working conditions. J. Vib. Shock 40(11), 269–276 (2021).

Zhong, M. S. et al. Effect analysis of different borehole coupling media on explosion seismic signal of carbonate rocks. Chin. J. Rock Mech. Eng. 30(04), 702–708 (2011).

Gu, W. B. et al. Experimental and theoretical study on influence of different charging structures on blasting vibration energy. Shock. Vib. 2015, 1–11 (2015).

Gou, Q. Q. et al. Effect of charge structure on energy transfer of blasting vibration. Blasting 37(01), 61–67 (2020).

Xie, L. X. et al. Excavation method of reducing blasting vibration in complicated geological conditions. Shock. Vib. 2018, 1–12 (2018).

Wang, L. C. et al. 3D numerical simulation of tunnel blasting vibration laws under axial uncoupled charge with water medium. Mod. Tunn. Technol. 55(02), 96–102 (2018).

Shin, J.-H., Moon, H.-G. & Chae, S.-E. Effect of blast-induced vibration on existing tunnels in soft rocks. Tunn. Undergr. Space Technol. 26(1), 51–61 (2011).

Bollinger, G. A. Explosion vibration analysis. Liu, X. & Xiong, J. Translation (Science Press, 1975)

Zhou, J. R. et al. Frequency-dependent attenuation of blasting vibration waves. Rock Mech. Rock Eng. 49(10), 4061–4072 (2016).

Li, T. et al. Study on the energy transfer efficiency of explosive blasting with different coupling medium. Explos. Shock Waves 41(06), 4–14 (2021).

Chen, M., Ye, Z. W., Lu, W. B., Wei, D. & Yan, P. An improved method for calculating the peak explosion pressure on the borehole wall in decoupling charge blasting. Int. J. Impact Eng 146, 103695 (2020).

Ye, Z. W. & Chen, M. Characteristics of peak load on a borehole wall in water-coupling blasting. J. Eng. Mech. 149(1), 04022087 (2023).

Yilmaz, O. & Unlu, T. Three dimensional numerical rock damage analysis under blasting load. Tunn. Undergr. Space Technol. 38(9), 266–278 (2013).

Starfield, A. M. & Pugliese, J. M. Compression waves generated in rock by cylindrical explosive charges: A comparison between a computer model and field measurements. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 5(1), 65–77 (1968).

Achenbach, J. Wave Propagation in Elastic Solids (Elsevier, 1984).

Esen, S., Onederra, I. & Bilgin, H. A. Modelling the size of the crushed zone around a blasthole. Int. J. Rock Mech. Min. Sci. 40(4), 485–495 (2003).

Zong, Q. & Luo, Q. Experimental study on distribution character of blasting stress when boreholes with water-couple charge. J. Exp. Mech. (03), 393–395+397–398 (2006).

Savarenski, F. P. Seismic wave (Science Press, 1981).

O’Brien, P. Seismic energy from explosions. Geophys. J. Int. 1, 29–44 (2010).

Li, H. T. et al. Study on energy distribution characteristics of seismic waves induced by different forms of blasting resource. J. Sichuan Univ. Eng. Sci. 42(01), 30–34 (2010).

Acknowledgements

This work is supported by Chinese National Natural Science Foundation (No. 52309156), the Science and technology development fund project of the Yellow River Water Conservancy Research Institute (202306), and the Special Items of Basic Business Expenses of Central Public Welfare Scientific Research Institutes (HKY-JBYW-2023-04). The authors wish to express they’re thanks to the supporter.

Author information

Authors and Affiliations

Contributions

Tong LI.LI Song.Ming Chen and Bo-wen Guo.Bing Fan wrote the main manuscript text and Tong LI.Shan-Shan Cui. prepared figures. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, T., Song, L., Chen, M. et al. Analysis of the characteristics of blasting seismic wave induced by explosive blasting with different coupling medium. Sci Rep 15, 6721 (2025). https://doi.org/10.1038/s41598-025-86682-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-86682-9

Keywords

This article is cited by

-

Experimental study on dynamic response of existing tunnel lining structure by adjacent tunnel blasting load

Scientific Reports (2025)

-

Study on Blast-Induced Crack Propagation in a Nine-Hole Model with Sequential Detonation Control

Rock Mechanics and Rock Engineering (2025)