Abstract

Monitoring and predicting ground vibration levels during blasting operations is essential to safeguard mining sites and surrounding communities. This study introduces an IoT-based ground vibration monitoring device specifically designed for limestone mining operations, combined with machine learning algorithms to predict ground vibration intensity. The primary aim is to provide an efficient predictive tool for anticipating hazardous vibration levels, enabling proactive safety measures. A comparative analysis with the industry-standard Minimate Blaster indicates high accuracy of the IoT device, with percentage errors as low as 0.803% across multiple blasts. The study also employed Support Vector Regression (SVR), Gradient Boosting Regression (GBR), and Random Forest (RF) algorithms to predict Peak Particle Velocity (PPV) values. Among these, the Random Forest model outperformed the others, achieving an R2 score of 0.92, Mean Absolute Error (MAE) of 0.21, and Root Mean Squared Error (RMSE) of 0.31. These findings underscore the reliability and predictive accuracy of the IoT-integrated Random Forest model, suggesting that it can significantly contribute to enhancing safety and operational efficiency in mining. The research highlights the potential of IoT and machine learning technologies to transform ground vibration monitoring, promoting safer and more sustainable mining practices.

Similar content being viewed by others

Introduction

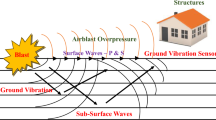

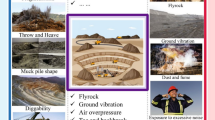

Mining operations, particularly those involving surface excavation, face a significant challenge in the form of blast-induced ground vibrations1,2. These vibrations have been responsible for numerous incidents of structural damage to nearby buildings, degradation of ecosystems, and equipment failures, alongside creating severe safety risks for mine workers. Traditional monitoring systems, while useful for post-blast analysis, often lack real-time responsiveness and predictive capabilities, limiting their effectiveness in mitigating immediate risks. Moreover, these systems fail to provide actionable insights during operations, often resulting in reactive rather than proactive safety management. The urgency of developing more advanced solutions is driven by increasing regulatory pressure on mining operations to minimize their environmental footprint and from the growing importance of proactive safety measures in high-risk industrial settings3. For example, regulatory bodies in India like Directorate General of Mines Safety (DGMS) have introduced stringent vibration limits, requiring innovative solutions to ensure compliance. This creates a pressing need for a more sophisticated, real-time monitoring and prediction system that can effectively address these critical challenges4.

The motivation for this research lies in bridging the existing technological gap by developing an integrated system that combines the Internet of Things (IoT) and machine learning to offer enhanced real-time monitoring and predictive analysis of blast-induced ground vibrations. While previous studies have explored either IoT or machine learning individually for industrial monitoring, few have addressed their combined potential for real-time prediction and decision-making. The novelty of this approach lies in the integration of IoT-enabled sensors with advanced machine learning algorithms, allowing for continuous data collection, analysis, and instant prediction capabilities. Unlike conventional systems that primarily rely on empirical data and reactive measures, our system leverages the latest advancements in sensor technology and artificial intelligence to provide dynamic, data-driven insights that enable proactive decision-making in high-stakes environments5.

In particular, this research addresses two critical challenges: first, the lack of reliable systems capable of providing accurate real-time predictions, and second, the absence of frameworks for integrating safety and operational efficiency in vibration monitoring systems. The primary purpose of this research is to develop and implement an integrated smart system that utilizes IoT and machine learning techniques for the real-time monitoring and predictive analysis of blast-induced ground vibrations in surface mining. Through this innovative integration of state-of-the-art technologies, the research aims to achieve twofold objectives. The first objective is to enhance the safety of mining operations by providing timely and precise information on ground vibrations, enabling mine operators to take proactive steps to mitigate potential risks before they escalate. The second objective focuses on improving operational efficiency and environmental responsibility, addressing the growing demand for sustainable mining practices by minimizing ground disturbance and reducing resource wastage6,7.

This research stands out for its unique combination of IoT and machine learning, which collectively transform ground vibration monitoring from a reactive to a predictive and adaptive process. The real-time insights generated by our system enable mine operators to foresee potential hazards, reduce the likelihood of costly operational delays, and implement immediate safety measures as needed. By advancing monitoring and prediction capabilities, we contribute to a safer working environment for mining personnel, foster more controlled blasting practices, and reduce the adverse impact of vibrations on nearby ecosystems and infrastructure.

Moreover, the system’s predictive capabilities represent a paradigm shift in mine safety management, empowering operators with actionable foresight. This proactive approach not only enhances safety but also aligns with the industry’s shift toward more sustainable and responsible resource extraction practices. As mining plays a pivotal role in global resource extraction, the broader significance of this research lies in its potential to set a new standard for safety, operational efficiency, and environmental stewardship within the industry.

Literature review

Blast-induced ground vibrations pose significant challenges in surface mining operations, impacting structural integrity, worker safety, and environmental sustainability. Previous studies have highlighted the complexities of these vibrations and their far-reaching consequences8,9. The need for a detailed understanding of the dynamics of blast-induced ground vibrations is crucial for the development of effective monitoring and prediction systems10,11. This section reviews the literature in three key research categories: (1) Conventional Monitoring Systems, (2) IoT Applications in Mining, and (3) Advanced Predictive Techniques.

Conventional monitoring systems

Conventional monitoring systems, such as the Minimate Pro and Micromate, have played a critical role in recording ground vibrations. These systems are instrumental in collecting post-blast data for analysis. However, their inherent limitations, including a lack of real-time adaptability and an inability to address the dynamic nature of mining activities, restrict their usefulness in modern mining operations. The evolving needs of the mining sector—driven by stringent safety regulations, operational demands, and environmental considerations—underscore the urgency of developing advanced, integrated monitoring and prediction systems that can effectively address these limitations12,13.

IoT applications in mining

The application of IoT in mining has made remarkable progress, especially in data collection and equipment monitoring14. However, its specific implementation in blast-induced ground vibration monitoring remains an underexplored domain. To bridge this gap, the integration of IoT technology presents a promising avenue for real-time data collection and communication, effectively addressing the limitations of traditional monitoring systems.

IoT technology involves the deployment of sensors strategically placed in mining environments to capture real-time data on ground vibrations. These sensors not only capture but also process the data locally, using signal processing techniques. The processed information is then transmitted in real-time to remote locations, utilising the connectivity provided by IoT technology. This comprehensive approach ensures that timely and accurate data on ground vibrations during blasting activities is available for analysis15,16.

Furthermore, when these sensors are integrated with signal processing techniques, they can provide valuable frequency content information, aiding in the identification of dominant frequencies in induced vibrations during blasting activities. This integration enhances the understanding of the dynamic nature of ground vibrations, allowing for optimized safety measures and improved operational efficiency in mining environments. By utilizing IoT’s capabilities for data processing and communication, coupled with advanced signal processing techniques, this integrated approach marks a significant step toward a comprehensive and effective solution for blast-induced ground vibration monitoring in mining environments17,18.

Advanced predictive techniques

In addition to real-time monitoring, predictive models play a pivotal role in managing blast-induced ground vibrations. By leveraging data collected through IoT-enabled sensors, machine learning (ML) algorithms can anticipate vibration levels with remarkable accuracy. These predictive models are informed by a combination of historical and real-time data, enabling proactive measures to mitigate potential risks. Advanced signal processing techniques further complement these models by isolating dominant frequency components, revealing critical patterns in vibration dynamics. Such integration of IoT-based monitoring systems with ML-driven predictive capabilities represents a transformative approach to vibration management in surface mining. However, existing studies reveal a lack of comprehensive frameworks that fully integrate these technologies, highlighting a significant research gap19,20.

The existing literature reveals a scarcity of studies concerning the utilization of IoT technology for blast vibration monitoring and prediction in surface mining operations. The lack of research in this specific domain highlights the need for further exploration to harness the potential benefits of IoT in overcoming the limitations of conventional blast monitoring systems. The synthesis of available literature underscores the pressing need for a paradigm shift in surface mining operations, particularly in the realm of blast-induced ground vibration monitoring.

Research gaps and motivation

The synthesis of available research underscores the need for a paradigm shift in surface mining operations. The limitations of traditional systems and the evolving demands of modern mining highlight the critical absence of a real-time, comprehensive monitoring and prediction framework tailored to the unique challenges of blast-induced ground vibrations. Recognizing the transformative potential of IoT and ML, this study aims to fill the identified gaps by developing an IoT-based vibration monitoring system.

In the subsequent sections of this research paper, the investigation will delve into the design, development, and validation of a wireless IoT-based system that incorporates tri-axis micro-electro-mechanical capacitive sensors (MEMS) for ground vibration monitoring. Through a strategic incorporation of IoT technology and machine learning approaches, the proposed system aims to bridge the existing gap by furnishing a real-time, comprehensive monitoring, and prediction framework. In doing so, this research not only addresses the limitations of current systems but also contributes to broader goals, ensuring the safety, efficiency, and environmental responsibility of surface mining operations in the aspect of blast-induced ground vibrations.

Design and development of the Wireless IoT-Based System

This section presents a detailed discussion on the architecture and components of the Wireless IoT-Based System, methodically crafted for real-time monitoring of blast-induced ground vibrations, particularly tailored for the mining industry.

Architecture and components of the system

The architecture of the Wireless IoT-Based System, depicted in Fig. 1, is intricately designed to enable accurate and real-time monitoring of blast-induced ground vibrations. The system integrates four fundamental modules: the data sensing module, data visualization & collection module, data processing module, and user interface module.The Data Sensing Module, the cornerstone of the system, incorporates Sensor Module 1 strategically positioned at key locations within the mining site. The sensed data is collected and visualised by the Data Visualization & Collection Module 2 which plays a crucial role in presenting ground vibration data effectively. This module allows the graphical representation and tabular display of collected vibration data, enhancing the understanding of ground vibration patterns. The module 2 wirelessly receives and transmits ground vibration data, in terms acceleration, to the Data Processing Module 3. Advanced signal processing techniques, such as Fast Fourier Transform (FFT) analysis, are employed by the Data Processing Module to transform time-domain vibration signals into the frequency domain. This analysis facilitates the extraction of essential parameters like peak particle velocity (PPV) and frequency content, aiding in the identification of specific frequency ranges associated with the vibrations.

The User Interface Module 4 serves as a user-friendly platform for data visualization and interpretation. Mining operators can view collected vibration data graphically and in tabular formats, fostering a comprehensive understanding of ground vibration patterns. Additionally, the User Interface Module generates automated reports and alerts based on predefined thresholds, providing real-time information on ground vibration levels for proactive decision-making.

Strategic integration of tri-axis MEMS capacitive sensor (ADXL model) for ground vibration monitoring

This section explores a crucial component of the system—the ADXL Model tri-axis MEMS-based capacitive sensor—chosen for its effective ground vibration monitoring in limestone surface mines. The static and dynamic characteristics of the ADXL 345 passive-digital-vector accelerometer used in this research are detailed in Table 1. The sensor was strategically placed in key locations within limestone surface mines, including mining areas, near villages, state highways, and public roads, to efficiently capture blast-induced ground vibrations along three axes: longitudinal (X), transverse (Y), and vertical (Z). Careful positioning ensures a comprehensive dataset, enabling a detailed assessment of ground vibration characteristics, covering amplitude, frequency, and duration. For a clearer understanding, Fig. 2 provides a visual representation of the proposed IoT-based ground vibration monitoring device’s deployment, offering insights into the monitoring of blast-induced waves under real field conditions.

Utilising wireless communication and IoT technology

Wireless communication and IoT technology are pivotal components in enhancing the capabilities of the developed Wireless IoT-Based blast-induced ground vibration monitoring device System. The visual representation in Fig. 3 illustrates the strategic placement of wireless ground vibration monitoring devices at key locations within the mining site. This meticulous placement significantly enhances the system’s analytical capabilities for risk assessment and operational improvement. Importantly, the developed system has undergone testing in a strategically selected mine location to validate its effectiveness.

The system harnesses wireless communication protocols, including Wi-Fi and Bluetooth, to establish a seamless connection between the Sensor Module and the Data Processing Module. This wireless connectivity eliminates the need for physical wiring, providing flexibility in sensor placement and enabling monitoring in challenging terrains and remote areas of the mining site.

Moreover, the integration of IoT technology not only contributes to the system’s functionality but also enhances accessibility. IoT capabilities facilitate seamless data transmission, remote accessibility, and real-time monitoring of vibration data. The Data Processing Module employs IoT protocols to receive and process transmitted data, enabling efficient analysis, visualization, and interpretation. This integrated approach ensures that the system performs reliably in real-world mining scenarios, meeting the demands of diverse terrains and environmental conditions.

Real-time measurement and validation of IoT-Based blast-induced ground vibration monitoring system

Accurate measurement and validation of ground vibrations induced by blasting activities in mining operations are imperative for ensuring the safety of personnel, equipment, and structures. This section explores the methodology employed for real-time measurement and validation of the developed IoT-based blast-induced ground vibration monitoring system, emphasizing its precision, reliability, and conducting a comparative analysis with conventional monitoring instruments.

Field experiments

In operationalizing the previously discussed theoretical concepts, field experiments were conducted at limestone mines in Andhra Pradesh, India, to validate the practical efficacy of the Wireless IoT-Based System in monitoring blast-induced ground vibrations. Seven carefully selected blast events served as pivotal data points for a comparative analysis between the IoT-based blast monitoring system and a conventional ground vibration-monitoring device. Figure 4 provides a specific depiction of the strategic deployment of monitoring points, highlighting one of the several locations encompassing various distances and directions relative to the blast sources.

This visual representation ensures a comprehensive understanding of ground vibration dynamics for both the IoT-based system and the Minimate Blaster. The real-world deployment under identical conditions facilitated a direct comparison, providing insights into the performance and reliability of the IoT-based system in an operational mining setting.

The goal of these experiments was to showcase the Wireless IoT-Based System’s ability to deliver accurate, real-time data essential for effective monitoring of blast-induced ground vibrations. This validation process not only underscored the system’s reliability but also set the stage for the subsequent sections where specific methodologies and detailed results would be discussed, enriching the understanding of the system’s performance in a real-world mining environment.

Monitoring using Instantel Minimate Blaster

The monitoring process utilized the Instantel Minimate Blaster for critical vibration data collection within the mining environment. The study employed strategic deployment and setup, as illustrated in Fig. 5, positioning the Instantel Minimate Blaster precisely at the mining site to capture ground vibrations induced by blasting activities. Over seven monitored events, this conventional vibration monitoring device provided insightful measurements, as summarized in Table 2. The monitoring procedure involved setting up the Instantel Minimate Pro blast vibration monitoring device with geophones configured to capture ground vibrations during blasting. Configured with specific parameters, the instrument recorded data during blasting events. Subsequently, the recorded data was retrieved and analyzed using dedicated software, generating compliance reports based on peak particle velocity and frequency content.

During the seven-day field experiments, the Instantel Minimate Blaster, strategically deployed within the mining environment, recorded notable data on blast-induced ground vibrations. On July 1, 2023, at a distance of 189 m, the highest peak velocities were recorded, reaching 18.680 mm/sec longitudinally, 17.655 mm/sec transversely, and 6.668 mm/sec vertically. The Peak Vector Sum (PVS) of the vibration data on this day stood at 26.553 mm/sec, a critical metric for identifying spikes in vibration.

Conversely, on July 6, 2023, at a distance of 352 m, the recorded velocities were longitudinally: 2.794 mm/sec, transversely: 3.556 mm/sec, and vertically: 2.032 mm/sec, with a corresponding Peak Particle Velocity (PPV) value of 3.556 mm/sec. This data reflects the variability in ground vibration characteristics, showcasing the Instantel Minimate Blaster’s capability to capture a range of velocities during different blasting events.

The comprehensive dataset obtained from the Instantel Minimate Blaster over the course of these seven monitored events, as summarized in Table 1, not only provides insights into the peak velocities but also contributes to a holistic understanding of ground vibrations. The data presented in Table 1 indicates that the recorded ground vibrations, as captured by the Instantel Minimate Blaster, lie within the safer zone. Notably, 81.5% of the dominant frequencies, concerning Peak Particle Velocity (PPV), were recorded above 25 Hz, while 18.5% fell within the dominant frequency range of 8–25 Hz. These results highlight the effectiveness of the Instantel Minimate Blaster in monitoring ground vibrations during various blasting events, indicating a safe blasting practice within the mines.

Monitoring using developed IoT-Based system

Monitoring using the developed IoT-Based System focuses on the system’s capability to measure blast-induced ground acceleration as a function of time. This novel system captures real-time acceleration data during blasting events, providing a foundation for subsequent analyses. The process involves the conversion of recorded acceleration data into the frequency domain, accomplished through Fast Fourier Transform (FFT) analysis. This frequency domain data is then utilized for the calculation of Peak Particle Velocity (PPV) associated with each recorded blast. The subsequent subsections delve into specific aspects of this monitoring process, including the presentation of real-time recorded acceleration data, the FFT analysis methodology for PPV calculation, and the conversion of FFT data from acceleration to velocity. These discussions aim to elucidate the effectiveness and accuracy of the developed IoT-Based System in monitoring blast-induced ground vibrations.

Real-time recorded acceleration data

To capture the dynamics of blast-induced ground vibrations, the IoT-based measurement system employs a carefully designed data acquisition process. Initially, ground vibration acceleration is measured in three directional components—longitudinal, transverse, and vertical—using an ADXL accelerometer sensor, covering a variable recording period for each blast event. The Data Collection Module is configured to operate at a sampling rate of 50 Hz, a frequency selected to capture the vibration spectrum relevant to mining blast-induced ground vibrations.

This sampling rate, though lower than certain industrial standards, is specifically calibrated to record essential vibration data within the low to mid-frequency ranges that are most representative of mining activities. The recorded data in this time-domain format serves as the foundation for both time-domain analysis and frequency-domain calculations, including Fast Fourier Transform (FFT) analysis, ensuring a comprehensive evaluation of vibration characteristics while optimizing data management and processing resources.

The second step involves transitioning from the time-domain signals to the frequency domain. This is accomplished through Fast Fourier Transform (FFT) analysis applied to the peak acceleration values recorded in each direction during every blast event. The FFT analysis facilitates the derivation of peak particle velocities associated with ground vibrations. This transition into the frequency domain enhances the understanding of vibrational characteristics, providing valuable insights into the frequencies dominating the induced ground vibrations.

Figure 6 provides a detailed visualization of the recorded acceleration data at various distances from the blast source over time. Sub-figures (a) through (g) depict recorded acceleration at distances of 356 m, 189 m, 286 m, 294 m, 316 m, 352 m, and 295 m, respectively, with respect to time in seconds. This visual representation enhances our understanding of how blast-induced ground vibrations evolve over time and space. The meticulous two-step approach ensures a comprehensive analysis of the captured data, from the time-domain signals’ raw dataset to the frequency-domain signals enriched with information on vibrational characteristics.

Fast Fourier Transform (FFT) analysis for PPV calculation

In the exploration of frequency components within the recorded acceleration data, the research incorporated Fast Fourier Transform (FFT) analysis—a crucial step in the applied methodology. This mathematical technique plays a pivotal role in converting time-domain acceleration data into the frequency domain, thereby revealing the underlying frequency components associated with ground vibrations.

Before delving into the detailed FFT analysis, it is essential to understand its significance in the broader context of the research. Fast Fourier Transform (FFT) analysis, employed in this study, is a mathematical technique used to convert time-domain signals, such as acceleration data, into the frequency domain. This transformation allows researchers to discern specific frequencies contributing to ground vibrations induced by blasting activities. Figure 7 visually represents the peak acceleration data recorded over seven blast events at varying distances: 356 m, 189 m, 286 m, 294 m, 316 m, 352 m, and 295 m.

The FFT analysis serves a dual purpose. Firstly, it isolates dominant frequencies, facilitating the precise derivation of Peak Particle Velocity (PPV). PPV is a pivotal metric for assessing the potential impact of ground vibrations on structures and personnel. Secondly, the analysis acts as a sophisticated filter, removing unwanted noise and interference from the recorded data. This refined representation of ground vibrations, obtained through spectral analysis, enhances researchers’ ability to identify specific frequency peaks associated with blasting activities.

Figure 7 further illustrates the recorded acceleration at different distances concerning frequency (Hz). This graphical representation contributes to a comprehensive understanding of how ground vibrations vary in frequency and intensity across various distances. By providing insights into the spectral characteristics of blast-induced ground vibrations, FFT analysis, in conjunction with real-time recorded acceleration data, empowers researchers in making informed decisions regarding safety measures and blast management.

Converting FFT data of acceleration to velocity

In the progression of analysis, the FFT-acquired acceleration data from the IoT-based system underwent a subsequent processing step to derive velocity values—an indispensable parameter in evaluating the potential impact of ground vibrations. This conversion from acceleration to velocity is a crucial component of the comprehensive analysis of blast-induced ground vibrations.

During this phase, a straightforward mathematical formula was applied to the FFT data to transform acceleration into velocity, providing values in millimeters per second (mm/s). The conversion equation is represented by Eq. (1):

Here, Vn denotes the velocity for a specific frequency bin, a(n) is the corresponding acceleration from the FFT analysis, Δf is the FFT resolution, and n signifies the index of the sample. This transformation equips us with velocity data corresponding to the dominant frequencies identified during FFT analysis, offering a quantitative foundation for assessing the potential impact of ground vibrations.

Figure 8 illustrates our analysis of ground vibration in terms of particle velocity at varying distances from the blast source. Sub-figures (a) through (g) correspond to recorded peak particle velocities (PPV) at distances of 356 m, 189 m, 286 m, 294 m, 316 m, 352 m, and 295 m, respectively, with respect to time in seconds. This visual representation allows for a detailed examination of ground vibration characteristics, providing crucial insights into the dynamics of the vibration events. The extracted PPV values play a fundamental role in evaluating the potential impact of ground vibrations on structures and the surrounding environment.

In addition to the time-domain analysis presented in Figs. 7 and 8 provides a detailed frequency-domain representation of recorded acceleration at various distances from the blast source, enabling a comprehensive understanding of the dominant frequency components induced by blasting operations. Sub-figures (a) through (g) depict the frequency spectra at distances of 356 m, 189 m, 286 m, 294 m, 316 m, 352 m, and 295 m, respectively, illustrating the variations in ground vibration frequencies at these points.

From Fig. 7, it is evident that the dominant frequency range consistently lies between 25 and 40 Hz across all measured blast events. This frequency range is significant, as it provides essential insights into the primary vibration frequencies that could potentially impact structures and equipment in the vicinity. Identifying and focusing on these dominant frequencies aids in optimizing vibration control measures and refining predictive models to prevent adverse effects on nearby infrastructure.

The complementary use of both frequency-domain (Fig. 7) and time-domain (Fig. 8) analyses thus provides a multi-dimensional view of blast-induced ground vibrations. While the frequency-domain representation highlights the prevalent frequencies crucial for designing vibration mitigation strategies, the time-domain PPV values in Fig. 8 offer practical insights for assessing peak ground velocity impacts over time. Together, these visualizations underscore the necessity of both perspectives, facilitating a more robust approach to managing and predicting ground vibration levels in mining operations.

Validation with conventional monitoring system

Table 3 provides a comprehensive overview of the ground vibration measurements recorded by both the IoT-based system and the Minimate Blaster across seven distinct blast events. The data includes Peak Particle Velocity (PPV) readings from both systems, revealing the magnitude of ground vibrations experienced during each blasting event and the percentage error in measurements between the two systems.

The experiments were conducted on different dates and under varying environmental conditions, which allows for a robust comparison of the two monitoring systems. For instance, on July 1, 2023, the maximum PPV readings from both systems were remarkably close, with a percentage error of only 0.803%. This indicates a high level of agreement between the IoT-based system and the Minimate Blaster in capturing ground vibration intensity during blasting events. Similarly, on July 6, 2023, despite a slight difference in the PPV values, the percentage error remained low at 2.924%. Notably, the maximum percentage error observed during the validation process was 2.924%, demonstrating the reliability of the IoT-based system for accurate monitoring.

Table 2 outlines the detailed comparisons across different blast events, underscoring the system’s consistent performance. The observations indicate that the IoT-based monitoring system aligns well with traditional methods, reinforcing its potential for real-time monitoring applications.

While acknowledging the limitations of the IoT-based monitoring system—such as its lower data sampling rate compared to conventional approaches—it is crucial to highlight that this stems from current sensor technology constraints rather than inherent flaws in the IoT system. Additionally, other limitations, including susceptibility to environmental interference and challenges in data transmission over long distances, should be considered.

Despite these limitations, the integration of the IoT system marks a significant advancement in ground vibration monitoring. By leveraging IoT technology, the system provides a smart and efficient approach to monitoring ground vibrations during blasting operations. The ability to monitor and control remotely enhances both safety and operational efficiency in mining environments. Briefly, the successful implementation of the IoT-based system not only validates its effectiveness in ground vibration monitoring but also paves the way for future research and development. Ongoing advancements in sensor technology are expected to improve data sampling rates and overall system performance, further enhancing the capabilities of IoT-based monitoring systems in mining operations.

Advantages and considerations of IoT-Based monitoring in mining operations

In the context of mining operations, the adoption of IoT technology offers numerous advantages. Firstly, it enhances safety by providing real-time monitoring and early warning systems, thereby reducing risks to both personnel and structures. Secondly, the automation capabilities of IoT systems lead to cost savings and increased operational efficiency by minimizing manual monitoring efforts. Additionally, IoT systems capture extensive datasets on ground vibration patterns, enabling comprehensive hazard analysis and regulatory compliance through continuous and accurate data collection. From an environmental perspective, IoT systems can promote responsible mining practices by precisely tracking ground vibrations, minimizing environmental impact, and contributing to sustainability efforts.

Despite the remarkable accuracy demonstrated by the developed IoT-based blast vibration monitoring device during field experiments, it’s important to note a nuanced aspect related to data sampling frequency. Equipped with the ADXL accelerometer sensor, the device exhibits a lower data sampling rate compared to traditional vibration monitoring instruments, impacting the granularity of recorded data, especially for rapid or transient events. However, this limitation is inherent to the current state of sensor technology rather than a flaw of the IoT-based system itself.

The ongoing technological evolution within the IoT domain offers promise for addressing these limitations. As newer, high-speed IoT sensors become available, constraints associated with data sampling frequency are expected to diminish, enhancing the precision and temporal resolution of ground vibration monitoring systems. Despite these considerations, the demonstrated accuracy and reliability of the developed IoT-based blast vibration monitoring device lay a robust foundation for its application in real-world mining scenarios. Continuous technological advancements are expected to further refine and augment its capabilities over time.

Prediction of Blast-induced ground vibration levels using various machine learning approaches

This section explores the application of machine learning techniques to predict blast-induced ground vibration levels. It provides an in-depth examination of the selected models, their implementation, and an analysis of the obtained outcomes. Machine learning models offer a predictive solution to forecast ground vibrations, which aids in proactive management of environmental and structural impacts in mining operations.

Machine learning methodologies

In predicting blast-induced ground vibrations, selecting the appropriate machine learning models is critical due to the complex, nonlinear nature of ground vibrations influenced by multiple, often interrelated, parameters. This study applies Support Vector Regression (SVR), Gradient Boosting Regression (GBR), and Random Forest (RF) based on a systematic selection process aimed at evaluating model performance across diverse methodologies, ultimately identifying the most accurate and reliable model for this application.

Selection steps and rationale

The algorithm selection process was guided by the following steps to ensure that only the most suitable models were chosen:

-

1.

Data Complexity Assessment: Initial examination of the dataset highlighted significant variance and nonlinearity in the input parameters, such as Max Charge per Delay and Distance, and their complex interactions affecting the target variable (Peak Particle Velocity, PPV). This necessitated models capable of capturing high-dimensional relationships with both linear and non-linear dependencies.

-

2.

Model Pre-Screening for Nonlinearity Handling: Algorithms were screened based on their ability to handle nonlinear patterns. SVR, GBR, and RF were selected for their strengths in handling nonlinearity, with SVR and RF being well-suited for high-dimensional data and GBR offering robust performance through boosting, particularly useful for datasets with moderate sample sizes and high variance.

-

3.

Emphasis on Interpretability and Robustness: Each model’s interpretability and robustness against overfitting were considered crucial. Random Forest’s ensemble approach offers significant interpretability via feature importance analysis, while GBR’s iterative improvement approach builds resilience against overfitting. SVR, with its regularization parameter, provides control over fitting margins, allowing for clear parameter-based adjustments.

Rationale for selecting each algorithm

-

Support Vector Regression (SVR): SVR was chosen for its ability to capture non-linear relationships through kernel functions, a critical feature for managing the complex, non-linear data generated by blast vibrations. SVR’s capacity to create a maximum-margin hyperplane suited it for this dataset, where balancing bias and variance is essential. Additionally, SVR is known to handle smaller datasets effectively, aligning with our data volume and the need for precision in edge cases.

-

Gradient Boosting Regression (GBR): GBR’s sequential learning approach made it a strong candidate for modeling blast-induced vibrations, as it incrementally reduces error by optimizing each new model on the residuals of the previous one. This gradient-based optimization allows GBR to handle the high variance in PPV more flexibly than simpler models. Its learning rate and number of estimators are fine-tuned to avoid overfitting, providing a balance between training accuracy and generalization.

-

Random Forest (RF): RF was selected for its exceptional ability to generalize across complex datasets with high variance. Given the ensemble structure, RF combines multiple decision trees, each trained on bootstrapped samples with random feature subsets, which enhances its predictive accuracy and resistance to overfitting. RF is particularly effective for our dataset, where nonlinear interactions among parameters like Distance, Max Charge per Delay, and Depth contribute to PPV outcomes. Its ensemble structure allows it to capture these relationships more robustly than single learners.

Support Vector Regression (SVR)

Support Vector Regression (SVR) extends the concept of Support Vector Machines (SVM) to the regression domain. SVR aims to find a hyperplane that best fits the data while maximizing the margin between data points and the hyperplane. It handles both linear and non-linear regression tasks by using kernel functions21.

For simple linear SVR, given a dataset with input features ‘x’ and target values ‘y’, the goal of SVR is to find a hyperplane represented as wTx+b = 0 that minimizes the error between predicted values ‘f(x)’ and actual values ‘y’. The optimization problem is formulated as given by Eq. (2).

Where:

-

w and b are the model parameters.

-

C is the regularization parameter.

-

\(\:{\xi\:}_{i}\:\)and \(\:{{\xi\:}_{i}}^{*}\) are slack variables.

-

ε is the margin of tolerance.

-

n is the number of data points.

Gradient boosting regression (GBR)

Gradient Boosting Regression (GBR) is an ensemble learning technique that builds a strong predictive model by combining the predictions of multiple weak learners (typically decision trees). GBR uses a gradient descent-like approach to optimize the model by minimizing the residual errors in each iteration22. Given a dataset with input features ‘x’ and target values ‘\(\:{y}_{i}\)’, GBR aims to learn an additive model \(\:F\left(x\right)\:\)that minimizes the mean squared error as defined by Eq. (3).

In each iteration, GBR fits a weak learner (e.g., a decision tree) to the negative gradient of the loss function with respect to the current model’s predictions.

Random Forest (RF)

Random Forest is another ensemble learning technique that combines the predictions of multiple decision trees to create a robust and accurate regression model. It introduces randomness in both the data and the features to reduce overfitting23,24.

Random Forest aggregates the predictions of multiple decision trees. For regression, the final prediction \(\:F\left(x\right)\) is often the average (mean) of the predictions from individual trees as given by Eq. (4).

where:

-

\(\:F\left(x\right)\)is the final prediction.

-

N is the number of decision trees.

-

\(\:{T}_{i}\left(x\right)\)is the prediction of the i-th decision tree.

Random Forest also introduces randomness during tree construction by considering a random subset of features and bootstrapped samples from the data, which helps reduce overfitting25.

Data processing and preparation

To ensure the accuracy and reliability of the machine learning models employed in this study, a series of data processing steps were undertaken. This systematic approach encompassed data cleaning, normalization, feature selection, and the division of the dataset into training and testing subsets.

-

1.

Data Source and Collection: The primary data source for this study consisted of real-time measurements collected via IoT-based sensors deployed at a surface mining site. The sensors recorded ground vibration levels during blasting activities over a period of 54 field iterations. These sensors were equipped with tri-axis micro-electro-mechanical capacitive (MEMS) accelerometers to capture vibration intensity at various points surrounding the blast site. The raw data from these sensors were transmitted wirelessly to a central repository for further processing and analysis. It is important to note that sensor data may include interference from environmental noise (e.g., wind, nearby machinery) and electrical noise from the sensors themselves. Steps were taken to clean and preprocess the data, ensuring that these interference factors were mitigated.

-

2.

Data Cleaning: The dataset, collected from the IoT sensors, was examined for missing values and outliers that could adversely affect model performance. Missing data points were addressed using mean imputation for continuous variables, while categorical variables were either filled with the mode or excluded based on their relevance. Noise interference in the data, arising from environmental conditions or sensor malfunctions, was reduced using signal filtering techniques, such as low-pass filtering, to eliminate high-frequency noise and ensure the accuracy of the vibration measurements.

-

3.

Normalization: To facilitate effective training of the machine learning algorithms, continuous variables were normalized using Min-Max scaling, transforming the values into a range of [0, 1]. This step was critical to prevent variables with larger scales from disproportionately influencing model training. Furthermore, noise reduction was incorporated in the normalization process to ensure that variations in vibration readings due to random noise were minimized.

-

4.

Feature Selection: Given the potential for multicollinearity among input variables (e.g., Depth, Burden, and Distance), feature selection was conducted using recursive feature elimination (RFE) combined with cross-validation. This approach helped identify and retain the most relevant features for predicting Peak Particle Velocity (PPV), thereby enhancing model performance. Data interference, such as noise, was considered when selecting features, ensuring only the most pertinent data was used.

-

5.

Dataset Partitioning: The complete dataset was divided into training and testing sets using an 80/20 split, ensuring that 45 iterations were allocated for training and 9 for testing. This division was crucial for validating the models’ predictive capabilities on unseen data, while also ensuring that data used in both sets was consistent and free from noise interference.

-

6.

Outlier Handling: Outliers were identified using the IQR method and visualized using box plots. Extreme values that could skew results were either capped at a threshold or further analyzed for their impact on model performance. In addition, any residual interference data, which might have contributed to outliers, was carefully analyzed and treated to maintain the integrity of the predictive models.

Results and performance evaluation

The machine learning models were trained and validated using a dataset comprehensively documented by the IoT-based ground vibration monitoring system. The primary predictive focus of the models was on estimating Peak Particle Velocity (PPV), which served as the target variable for model training. The dataset, collected across 54 field instances of blasting, included multiple input variables that influence vibration characteristics. These input variables are essential blast and site parameters such as Number of Holes, Depth, Burden, Spacing, Charge Length, Stemming Length, Maximum Charge per Delay, Distance from Blast Source, and Scaled Distance.

Table 4 provides a statistical summary of these data attributes, highlighting the range and distribution of values recorded. The selection of these input variables was made to capture the key parameters that affect ground vibration levels, allowing for a robust predictive model. This structured data formed the basis of the machine learning models to accurately predict PPV values, thus contributing valuable insights into safety management in blasting operations.

All models underwent training using 45 out of the total 54 iterations, while the remaining 9 iterations were allocated for testing and evaluating the models. The performance metrics of the models are consolidated in Table 5.

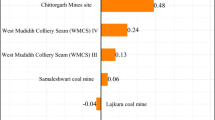

The insights gleaned from Table 5 underscore noteworthy performance distinctions among the three employed machine learning models – Support Vector Regression (SVR), Gradient Boosting Regression (GBR), and Random Forest (RF). Examining the performance metrics, it’s evident that the SVR model, despite meticulous parameter tuning, exhibits suboptimal performance in comparison to its counterparts. The R1 value, indicating the proportion of variance explained by the model, is 0.82 for SVR, slightly trailing behind GBR (0.83) and significantly behind RF (0.92). This suggests that SVR, despite efforts to optimize its parameters, struggles to capture the variance in the data as effectively as GBR and RF.

Additionally, considering the Root Mean Squared Error (RMSE), a measure of the model’s prediction accuracy, SVR shows a higher value of 0.69 compared to GBR (0.44) and RF (0.31). The elevated RMSE for SVR indicates that its predictions deviate more from the actual values, signifying a diminished level of accuracy compared to the other models. Similarly, examining the Mean Absolute Error (MAE), which provides insights into the absolute magnitude of errors, SVR again presents a higher value of 0.34 in contrast to GBR (0.28) and RF (0.21). This implies that SVR, despite parameter adjustments, tends to have larger absolute prediction errors compared to GBR and RF. These performance metrics collectively emphasize the challenges faced by the SVR model in effectively capturing the underlying patterns within the dataset. The nonlinear nature of the data and the presence of outliers, evident from the deviation of minimum and maximum values in Table 3, likely contribute to SVR’s suboptimal performance. Even with a robust regularization parameter of 0.1 and a low tolerance for error (epsilon value of 0.1), SVR’s performance proves to be less satisfactory, as visually depicted in Fig. 9.

Figure 9 provides a visual representation of the comparison between the actual Peak Particle Velocities (PPV) values and the values predicted by the Support Vector Regression (SVR) model. The disparities between the actual and predicted values highlight the challenges faced by SVR in accurately modeling the complex relationships within the data.

Moving to the Gradient Boosting Regression (GBR) model, it was anticipated to perform well due to its ability to handle outliers and nonlinear data. However, as indicated by the performance metrics, GBR did not achieve the expected performance. The limited number of observations in the dataset hindered the model’s ability to optimize its learning rate effectively. Figure 10 visually illustrates the comparison between the actual PPV values and those predicted by the Gradient Boosting Regression (GBR) model. The observed deviations between actual and predicted values underscore the model’s challenges in capturing the nuanced patterns present in the dataset.

In contrast, the Random Forest (RF) model emerges as a standout performer, outclassing the other two models significantly. Hyper-parameter tuned for optimal performance, RF’s success can be attributed to its ensemble nature and its ability to effectively handle complex data, including outliers. Figure 11 visually depicts the comparison between actual PPV values and those predicted by the Random Forest (RF) model. The alignment between actual and predicted values signifies the robust predictive capabilities of the RF model, further reinforcing its superior performance compared to SVR and GBR. These comprehensive evaluations, supported by visual representations in Figs. 9 and 10, and 11, provide a nuanced understanding of the strengths and weaknesses of each model in predicting blast-induced ground vibration levels.

Discussion

The evaluation of machine learning models for predicting blast-induced ground vibration levels provides valuable insights into their effectiveness and applicability in the mining industry. Despite meticulous parameter tuning, Support Vector Regression (SVR) exhibited suboptimal performance compared to its counterparts. The relatively lower R² value, along with higher Root Mean Squared Error (RMSE) and Mean Absolute Error (MAE), suggests that SVR struggled to capture the variance and accurately predict ground vibration levels. This limitation may be attributed to the nonlinear nature of the data and the presence of outliers, which pose challenges for SVR’s optimization process.

Although Gradient Boosting Regression (GBR) was anticipated to perform well due to its ability to handle outliers and nonlinear data, it did not achieve the expected level of performance. The limited number of observations in the dataset hindered the model’s ability to optimize its learning rate effectively, resulting in suboptimal predictions. In contrast, Random Forest (RF) emerged as a standout performer among the three models, significantly outperforming both SVR and GBR. Hyper-parameter tuning enabled RF to achieve optimal performance; its ensemble nature and robustness in handling complex data, including outliers, contributed to its superior predictive capabilities.

The successful application of machine learning algorithms in predicting ground vibration levels plays a crucial role in enhancing safety and promoting sustainability in mining operations. Understanding the mechanisms behind these models allows mining professionals to make informed decisions based on predictive insights. For instance, the ability of RF to manage and interpret complex datasets can help identify specific conditions that exacerbate ground vibrations, enabling the implementation of tailored safety measures.

The implications of this research extend beyond merely predicting vibration levels; it fundamentally enhances mining safety protocols. By providing proactive insights into potential ground vibration impacts, these models facilitate the timely implementation of necessary safety measures during blasting operations. This proactive approach not only safeguards personnel, materials, and structures but also aligns with the concept of sustainable mining practices. Furthermore, the integration of machine learning in vibration prediction contributes to operational efficiency and cost savings while minimizing environmental impact. The predictive capabilities of these models can help optimize blasting schedules and techniques, reducing unnecessary vibrations that could lead to structural damage or hazardous conditions.

Overall, this research underscores the potential of machine learning to advance safety standards and promote sustainable mining practices. By leveraging these technologies, the mining industry can move toward a safer, more efficient future, ensuring that environmental and human factors are prioritized in operational decision-making.

Practical implication

The integration of Internet of Things (IoT) and machine learning technologies into mining operations presents a transformative opportunity for enhancing safety, efficiency, and sustainability. This research demonstrates not only the feasibility of employing these advanced technologies for real-time monitoring of blast-induced ground vibrations but also highlights their potential for broader application across various facets of mining operations.

-

1.

Enhanced Safety Monitoring: The continuous monitoring capabilities offered by IoT devices enable proactive identification of hazardous conditions. By utilizing machine learning algorithms to analyze vibration data, mining companies can predict and mitigate risks associated with blasting operations. This predictive capability allows for timely interventions that safeguard personnel and infrastructure.

-

2.

Operational Efficiency: The application of machine learning for data analysis facilitates better decision-making processes in mining operations. By leveraging historical data and real-time inputs, companies can optimize blasting schedules, reduce operational downtime, and enhance overall productivity. The ability to analyze large datasets quickly and accurately leads to significant cost savings and resource optimization.

-

3.

Environmental Sustainability: Implementing IoT and machine learning technologies contributes to the sustainability goals of the mining industry. By monitoring ground vibrations and other environmental parameters, companies can minimize their ecological footprint. These technologies support compliance with environmental regulations and enhance the industry’s reputation as it moves toward more responsible practices.

-

4.

Long-term Technological Evolution: As the mining industry continues to embrace digital transformation, the long-term potential of IoT and machine learning will expand. Future developments in sensor technology and data analytics are likely to enhance the capabilities of these systems, allowing for even greater integration and automation in mining operations. This evolution will pave the way for smart mines that can autonomously monitor and adjust operations in real-time.

-

5.

Industry-wide Impact: The insights gained from this research are applicable not only to individual mining operations but can also serve as a blueprint for the entire industry. As more companies adopt IoT and machine learning technologies, the mining sector will benefit from enhanced safety standards, improved operational practices, and a commitment to sustainability. The widespread adoption of these innovations can foster a cultural shift within the industry, prioritizing safety and environmental stewardship.

Future work

While this study has demonstrated the promising application of IoT and machine learning techniques in monitoring and predicting blast-induced ground vibrations in surface mining, there are several avenues for further research and enhancement. Future work could focus on the following areas:

-

1.

Expansion of IoT Deployment: The integration of additional IoT sensors, including advanced sensor networks and real-time data acquisition systems, could enhance the accuracy and granularity of the vibration data. By expanding the coverage of sensor nodes across diverse mining environments, we could better capture the spatial and temporal variations of ground vibrations, leading to more robust and adaptive predictive models.

-

2.

Integration with Deep Learning Techniques: While this study focused on traditional machine learning algorithms, incorporating deep learning models, such as neural networks and deep reinforcement learning, could offer significant improvements in handling large, complex datasets generated by IoT systems. These models could potentially uncover hidden patterns in the data, enabling even more accurate predictions and real-time decision-making capabilities.

-

3.

Real-time Adaptive Systems: Developing real-time, adaptive prediction systems that continuously learn and improve from new data streams is another promising direction. By leveraging online learning techniques, the system could dynamically adjust its models based on incoming data, improving the system’s resilience and predictive accuracy over time.

-

4.

Predictive Maintenance and Risk Mitigation: Future work could extend this research to include predictive maintenance algorithms for equipment and machinery based on vibration patterns. By linking vibration data with the health of mining equipment, we could create more comprehensive systems for risk mitigation, enabling proactive maintenance scheduling and reducing equipment failures during blasting operations.

-

5.

Environmental Impact Monitoring: Another area for future exploration is the integration of environmental impact monitoring, where IoT and machine learning can be used to track the effects of blast-induced vibrations on nearby ecosystems and infrastructure. Machine learning models could be trained to predict potential damage to structures or the environment, offering early warnings for preventative measures.

By further extending the integration of IoT with advanced machine learning and deep learning techniques, these efforts could significantly enhance the predictive power, safety, and efficiency of blast-induced vibration monitoring systems in surface mining operations.

Conclusions

The successful development and implementation of an IoT-based ground vibration monitoring device in limestone mines marks a significant advancement in mining safety technology. Through rigorous validation, the IoT system demonstrated a remarkable level of agreement with the industry-standard Minimate Blaster, with maximum percentage errors during validation as low as 2.924%. These results underscore the promising potential of IoT-based blast vibration monitoring systems in enhancing safety protocols during blasting operations in mines. Furthermore, the integration of machine learning algorithms, including Support Vector Regression (SVR), Gradient Boosting Regression (GBR), and Random Forest (RF), for predicting ground vibration levels offers unprecedented insights into risk management and safety enhancement within the mining industry. Despite challenges such as data nonlinearity and outliers, the Random Forest model emerged as a standout performer, showcasing robust predictive capabilities and significantly outperforming other models. While acknowledging the limitations of the IoT-based monitoring system, including its lower data sampling rate, these findings highlight the transformative impact of IoT and machine learning technologies in optimizing safety, efficiency, and sustainability in mining operations. Moving forward, future research endeavors can focus on addressing current limitations, refining predictive models, and exploring novel techniques for data analysis and interpretation, further advancing the capabilities of IoT-based monitoring systems in ensuring safer and more sustainable mining practices.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Yamaguchi, T. et al. Study on the propagation of Blast-Induced Ground Vibration and its control measure in open pit mine. In: (eds Drebenstedt, C. & Singhal, R.) Mine Planning and Equipment Selection. Springer International Publishing; :979–986. https://doi.org/10.1007/978-3-319-02678-7_94 (2014).

Ak, H., Iphar, M., Yavuz, M. & Konuk, A. Evaluation of ground vibration effect of blasting operations in a magnesite mine. Soil Dyn. Earthq. Eng. 29 (4), 669–676. https://doi.org/10.1016/j.soildyn.2008.07.003 (2009).

Akinbinu, V. A. Assessment of blast induced vibrations based on regulatory criteria (a case study of limestone mines, Nigeria). IJMME 9 (2), 81. https://doi.org/10.1504/IJMME.2018.091966 (2018).

Arthur, C. K., Temeng, V. A. & Ziggah, Y. Y. Multivariate Adaptive Regression splines (MARS) approach to blast-induced ground vibration prediction. Int. J. Min. Reclam. Environ. 34 (3), 198–222. https://doi.org/10.1080/17480930.2019.1577940 (2020).

Khan et al. Blockchain-enhanced sensor-as-a-Service (SEaaS) in IoT: leveraging blockchain for efficient and secure Sensing Data transactions. Information 15, 10 (2024).

Ragam, P. & Nimaje, D. S. Selection and evolution of MEMS accelerometer sensor for measurement of blast-induced peak particle velocity. IEEE Sens. Lett. 2 (4), 1–4. https://doi.org/10.1109/LSENS.2018.2872624 (2018).

Gou, Y. et al. Attenuation assessment of blast-induced vibrations derived from an underground mine. Int. J. Rock Mech. Min. Sci. 127, 104220. https://doi.org/10.1016/j.ijrmms.2020.104220 (2020).

Yan, Y., Hou, X. & Fei, H. Review of predicting the blast-induced ground vibrations to reduce impacts on ambient urban communities. J. Clean. Prod. 260, 121135. https://doi.org/10.1016/j.jclepro.2020.121135 (2020).

Ainalis, D., Kaufmann, O., Tshibangu, J. P., Verlinden, O. & Kouroussis, G. Modelling the source of blasting for the numerical simulation of blast-induced ground vibrations: a review. Rock. Mech. Rock. Eng. 50 (1), 171–193. https://doi.org/10.1007/s00603-016-1101-2 (2017).

Kumar, S., Chandra Dutta, S., Goswami, K. & Mandal, P. Vulnerability assessment of building structures due to underground blasts using ANN and non-linear dynamic analysis. J. Building Eng. 44, 102674. https://doi.org/10.1016/j.jobe.2021.102674 (2021).

Temeng, V. A., Arthur, C. K. & Ziggah, Y. Y. Suitability assessment of different vector machine regression techniques for blast-induced ground vibration prediction in Ghana. Model. Earth Syst. Environ. 8 (1), 897–909. https://doi.org/10.1007/s40808-021-01129-0 (2022).

Agrawal, H. & Mishra, A. K. Modified scaled distance regression analysis approach for prediction of blast-induced ground vibration in multi-hole blasting. J. Rock Mech. Geotech. Eng. 11 (1), 202–207. https://doi.org/10.1016/j.jrmge.2018.07.004 (2019).

Agrawal, H. & Mishra, A. K. An innovative technique of simplified signature hole analysis for prediction of blast-induced ground vibration of multi-hole/production blast: an empirical analysis. Nat. Hazards. 100 (1), 111–132. https://doi.org/10.1007/s11069-019-03801-2 (2020).

Ragam, P. & Nimaje, D. S. Monitoring of blast-induced ground vibration using WSN and prediction with an ANN approach of ACC dungri limestone mine, India. J. Vibroeng. 20 (2), 1051–1062. https://doi.org/10.21595/jve.2017.18647 (2018).

Sehrawat, D. & Gill, N. S. Smart sensors: analysis of different types of IoT sensors. In: 3rd International Conference on Trends in Electronics and Informatics (ICOEI). IEEE; 2019:523–528. (2019). https://doi.org/10.1109/ICOEI.2019.8862778

Ullo, S. L. & Sinha, G. R. Advances in smart environment monitoring systems using IoT and sensors. Sensors 20 (11), 3113. https://doi.org/10.3390/s20113113 (2020).

Raheja, N. & Kumar Manocha, A. IoT based ECG monitoring system with encryption and authentication in secure data transmission for clinical health care approach. Biomed. Signal Process. Control. 74, 103481. https://doi.org/10.1016/j.bspc.2022.103481 (2022).

Krishnamurthi, R., Kumar, A., Gopinathan, D., Nayyar, A. & Qureshi, B. An overview of IoT sensor data processing, fusion, and analysis techniques. Sensors 20 (21), 6076. https://doi.org/10.3390/s20216076 (2020).

Nguyen, H., Choi, Y., Bui, X. N. & Nguyen-Thoi, T. Predicting Blast-Induced Ground vibration in open-pit Mines using vibration sensors and support Vector Regression-based optimization algorithms. Sensors 20 (1), 132. https://doi.org/10.3390/s20010132 (2019).

Asl, P. F., Monjezi, M., Hamidi, J. K. & Armaghani, D. J. Optimization of flyrock and rock fragmentation in the Tajareh limestone mine using metaheuristics method of firefly algorithm. Eng. Comput. 34 (2), 241–251. https://doi.org/10.1007/s00366-017-0535-9 (2018).

Montesinos López, O. A., Montesinos López, A. & Crossa, J. Support vector machines and support vector regression. In: Multivariate Statistical Machine Learning Methods for Genomic Prediction. Springer International Publishing; :337–378. doi:https://doi.org/10.1007/978-3-030-89010-0_9 (2022).

Otchere, D. A., Ganat, T. O. A., Ojero, J. O., Tackie-Otoo, B. N. & Taki, M. Y. Application of gradient boosting regression model for the evaluation of feature selection techniques in improving reservoir characterisation predictions. J. Petrol. Sci. Eng. 208, 109244. https://doi.org/10.1016/j.petrol.2021.109244 (2022).

Venkatesh, M., Srinu, M., Gudivada, V.K., Dash, B.B. & Satpathy, R. An efficient IoT security solution using deep learning mechanisms. In: Intelligent Computing and Applications: Proceedings of ICDIC 2020 (pp. 109-117). Singapore: Springer Nature Singapore. (2022).

Kiran, T.R., Srisaila, A., Shankar, G.S., Sowjanya, B. & Lakshmanarao, A. Machine learning approach for diabetes prediction using genetic algorithm based feature selection. In: 2024 3rd International Conference for Innovation in Technology (INOCON) (pp. 1-5). IEEE. https://doi.org/10.1109/INOCON60754.2024.10511558 (2024).

Zhou, S. & Mentch, L. Trees, forests, chickens, and eggs: when and why to prune trees in a random forest. Stat. Anal. 16 (1), 45–64. https://doi.org/10.1002/sam.11594 (2023).

Author information

Authors and Affiliations

Contributions

M.A, H.V, A.K.T, S.P, L.Y. conceptualized the research and wrote the manuscript - M.A, H.V, E.P.V - conducted the experimental, L.Y, N.V.R.S.R, K.S.M- Edited the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical considerations

This study does not involve human participants or images that could lead to their identification. Therefore, informed consent was not required.

Statement Regarding Fig. 4

We confirm that Fig. 4 in our manuscript is part of our study project, and the individual shown is a member of our lab team. We have obtained their informed consent for the use of their image in this online open-access publication. As such, there are no privacy concerns or issues related to identifying information in the image.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Aruna, M., Vardhan, H., Tripathi, A.K. et al. Enhancing safety in surface mine blasting operations with IoT based ground vibration monitoring and prediction system integrated with machine learning. Sci Rep 15, 3999 (2025). https://doi.org/10.1038/s41598-025-86827-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-86827-w

Keywords

This article is cited by

-

Predicting the blast-induced ground vibration with support vector regression optimized by five swarm algorithms

Earth Science Informatics (2025)