Abstract

Understanding the mechanical properties of Rosa sterilis S.D. Shi is important for the design and improvement of related mechanical equipment for planting, picking, processing, and transporting Rosa sterilis S.D. Shi. Compression damage is a common form of mechanical damage in agricultural products, especially during automated mechanical production. Therefore, this study establishes a three-dimensional model of seedless prickly pear fruit based on image processing technology and analyzes the compressive mechanical properties of seedless prickly pear under different directions through experiments combined with finite element method simulation. In both simulation and actual results, the average correlation coefficients were found to be 0.99 and 0.98 for the vertical compression direction and the horizontal compression direction, respectively. The above results show that our finite element compression model can provide a comprehensive understanding of the mechanical properties of Rosa sterilis S.D. Shi fruits under different directional loads. There is significant directional sensitivity in the compression resistance of Rosa sterilis S.D. Shi fruits have horizontal compression resistance greater than vertical compression resistance. The results of this study are of great significance for the development of mechanized automation in the Rosa sterilis S.D. Shi industry and for ensuring the quality of Rosa sterilis S.D. Shi fruits.

Similar content being viewed by others

Introduction

Seedless prickly pear (Rosa sterilis S.D. Shi), also known as golden prickly pear, light branch seedless prickly pear, hitchhiking prickly pear, etc1. , is a perennial climbing small shrub in the genus Rosaceae. By the end of 2023, the planting scale of Rosa sterilis S.D. Shi will reach 2.1 million mu, and the production of fresh fruit will get more than 300,000 tons. Due to its large scale, the post-harvest commercialization of fruits has developed towards automation and mechanization, but more technical support needs to be needed. During mechanical automation, random compression and impact between fruits, between fruits and the walls of rigid containers or conveyor parts, and the free fall of fruits on sorting and packaging equipment affect the appearance and edibility of the fruits. Therefore, ensuring the quality of Rosa sterilis S.D. Shi fruits and understanding the mechanical properties of Rosa sterilis S.D. Shi fruits have become an important research topic.

Agricultural products and fruits’ compression and impact contact mechanics are essential to biomaterial mechanics. It focuses on the behavior of biophysical bodies when subjected to contact forces or displacements. A rigid plate-probe compression test usually characterizes the mechanics of agricultural products and fruits2. Compression mechanical properties are essential characteristics of farming fruits. To predict fruit damage, many studies have investigated the relationship between external loads and the amount of fruit damage. For example, the effect of mechanical damage caused by compression on the storage time of mandarin oranges was studied by periodically squeezing the mandarin oranges in a mesh3. Changes in surface pressure and bruising of “Golden Delicious” apples when impacted by different rigid plates of varying drop heights4. Using a texture analyzer to apply five distinct stress levels to the grapes, it was found that the higher the degree of mechanical compression, the more serious the loss of grape quality5. The three-dimensional model of Rosa roxburghii fruit was reconstructed using a three-dimensional laser scanner6, and the stress, strain, and strain energy of Rosa roxburghii fruit was investigated by compression test and finite element simulation, which indicated that Rosa roxburghii fruit was more resistant to damage in the horizontal direction than in the vertical direction; however, the study was limited to single Rosa roxburghii fruit, and the conclusions of the study lacked generalizability7. However, to date, more detailed information on the quality changes of Rosa sterilis S.D. Shi fruits are lacking under different loading conditions (such as speed, loading direction, and compression force). It is worth noting that there have been very few studies on the effects of compression damage on fruit damage, mechanical behavior, and quality attributes. Previous research on the mechanics of agricultural fruit has focused on simple geometric mechanism analysis. However, a more accurate study of these agricultural fruits requires micron-level segmentation, and the Finite Element Method (FEM) is one of the better methods for this.

The finite element method is a numerical technique widely used in engineering to solve complex problems and analyze the stress distribution of stressed objects8. This method divides a stressed object into small elements of a certain geometry9. The stress distribution of the object is calculated by calculating each small element, and mechanical models and equations are used to simulate and predict the response and damage of the fruit under external forces8,10. The FEM method was used to simulate the drop tests of peaches11,12 and apples13, and the analytical results were in good agreement with the damage results obtained from the tests, which confirmed the feasibility of finite element analysis in the study of mechanical damage to fruits14. This method has been widely used in food for material impact and compression damage. The analysis of mechanical damage to fruits can be considered from the perspective of the maximum stress points after the fruit is stressed. Using this line of thinking on tomato fruits, a multi-scale model was developed to correlate the entire fruit. A large number of simulations were performed using FEM to find the maximum and minimum stress points of the internal structure of the tomato fruit after compression. It was determined that the stress distribution under the influence of the internal structure significantly impacts mechanical damage15. These studies are primarily based on models of linear materials. The serrated rheological phenomenon16in the force-deformation curve of the fruit makes the fruit more viscoelastic17, which is a nonlinear phenomenon caused by the stress relaxation characteristics18 of biological materials. Therefore, it is necessary to use experimental methods to compare with simulation methods and to calculate the improved damage model by incorporating the damage data measured after the compression test19,20.

In this study, a method for reconstructing the three-dimensional model of Rosa sterilis S.D. Shi fruit based on image processing technology is proposed, which eliminates the influence of shadows and fruit surface thorns on image contour feature extraction during image acquisition. Using finite element analysis software (Ansys workbench), the compression mechanics test of the fruit was simulated, and the stress distribution, strain distribution, and curve relationship between force and compression displacement of the Rosa sterilis S.D. Shi fruit under compression load was obtained. Comparative analysis with actual compression experiments verified the authenticity of the finite element method for simulating the compression of Rosa sterilis S.D. Shi. This study fills a gap in the existing knowledge base on the effects of compression damage on the fruit of Rosa sterilis S.D. Shi provides practical insights for improving the processing efficiency of Rosa sterilis S.D. Shi.

Materials and methods

Materials

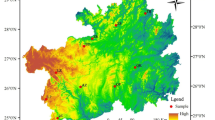

The experiment used Guizhou Rosa sterilis S.D. Shi was picked in the orchard of Shibing County, Qiandongnan Miao and Dong Autonomous Prefecture, Guizhou Province, on October 11, 2023. There was no rainfall before or during the harvest. The harvest time is when the Rosa sterilis S.D. Shi is commercially ripe (155–160 days after unfolding the leaves, with a soluble solid content of 7 ± 0.5%). After harvest, the fruit is placed in a storage box at 20 °C and 90% relative humidity within 24 h. To ensure that the Rosa sterilis S.D. Shi remains at commercial maturity for as long as possible during storage, ventilate the storage box by opening it during the night or early morning when the temperature is lower, to expel the ethylene produced by the Rosa sterilis S.D. Shi and reduce its ripeness. The following day, seedless Rosa sterilis S.D. Shi fruits without visible disease were selected and removed for physical parameter determination and compression mechanics testing after removing all Rosa sterilis S.D. Shi fruits, let stand for 15 min to exclude interference from the storage environment. In addition, to select samples of similar size, the three-dimensional dimensions and mass of the fruit were measured using a vernier caliper and electronic balance, and other parameters were measured, as shown in Table 1.

Plant guideline statement

We confirm that all the experimental research and field studies on plants (either cultivated or wild), including the collection of plant material, complied with relevant institutional, national, and international guidelines and legislation. The Rosa sterilis S.D. Shi in this study is not a United Nations endangered species. All of the material is owned by the authors and/or no permissions are required.

Determination of mechanical parameters

During the compression test, the electronic universal testing machine generates a graph of the force and deformation of the compressed specimen (force-deformation curve). To determine the modulus of elasticity and Poisson’s ratio of the specimen and use them as input parameters for the finite element model, the modulus of elasticity and Poisson’s ratio are determined using the following method in the compression experiment.

-

(1)

Select a sample of 10 Rosa sterilis S.D. Shi fruits without seeds, measure the initial length and initial diameter, place them on the test bench in order, determine and mark the position of the compression contact points on the upper and lower surfaces, and measure and calculate the maximum and minimum radii of curvature R of the compression contact points on the upper and lower surfaces.

where A, B, and D are the contact points of the analog altimeter probe on the surface of the sample, point C is the midpoint of the line segment AB, AB is the chord length, in mm; and CD is the perpendicular to the chord, in mm, as shown in Fig. 1.

-

(2)

Calculate the value of cosθ, and use the value of cosθ to look up Table 2 to obtain the values of KU and KL.

where R is the radius of curvature of the upper contact point and R’ is the radius of curvature of the lower contact point.

-

(3)

Poisson’s ratio is a constant defined as the relationship between the amount of deformation of an elastic material in the transverse and longitudinal directions. Use a flat plate with a diameter of 10 cm to press down at a constant speed, with a maximum downward pressure of 5 mm. Record the maximum force, the length after compression, and the diameter after compression, and calculate the Poisson’s ratio.

where µ is the Poisson’s ratio (dimensionless); εa is the axial strain, mm/mm; εr is the radial strain, mm/mm; l0 is the original length before compression, mm; l1 is the final length after compression, mm; D0 is the original diameter before compression, mm; and D1 is the final diameter after compression, mm, as shown in Fig. 2. According to the requirements of the American Society of Agricultural Engineers (ASAE) standard, each mechanical test was repeated 10 times.

-

(4)

According to Hertz’s theory, the modulus of elasticity is defined as the ratio of stress to strain in the elastic range under the assumptions of small deformations and the equivalent density of a uniformly elastic material. Calculate the modulus of elasticity of the fruit by entering the above data into Eq. 5 respectively.

where E is the modulus of elasticity in compression, MPa; F is the acting force, N; µ is the Poisson’s ratio; D is the deformation, mm; RU and RL are the minimum and maximum radii of curvature of the compression contact point on the upper surface of the fruit, respectively, mm; R′U and R′L are the minimum and maximum radii of curvature of the compressed contact points on the lower surface of the fruit, respectively, in mm. This parameter is calculated using Eq. (1). KU and KL are constants determined by the radii of curvature of the upper and lower flat plates at the point of contact with the surface of the fruit. Their values are obtained by linear interpolation according to the values of cosθ in Table 2, where cosθ is determined by Eq. (2). The mechanical parameters of the fruit samples, such as the elastic modulus, Poisson’s ratio, and maximum breaking force, were determined in a compression experiment.

The mechanical parameters of the fruit samples, such as the elastic modulus, Poisson’s ratio, and maximum breaking force, were determined in a compression experiment. These indicators need to be used as input parameters for the finite element model. Table 3 shows the elastic modulus and Poisson’s ratio of Rosa sterilis S.D. Shi samples.

Compression mechanical test

Ten Rosa sterilis S.D. Shi fruits in perfect condition with removed seeds within the shelf life were selected for repeated compression testing. The fruits were divided into two groups and subjected to compression testing in the horizontal and vertical directions, respectively—the equipment for the compression testing of Rosa sterilis S.D. Shi was a computer-controlled electronic universal testing machine, as shown in Fig. 3 (Shenzhen Wansheng Equipment Co., Ltd., model: TSE104B).

The test process is shown in Fig. 4. Rosa sterilis S.D. Shi was placed at different angles, both horizontally at 0° parallel to the compression plate and vertically at 90° perpendicular to the compression plate, in a universal material testing machine equipped with a force sensor (American Transducer Company, test force resolution: 1/200000, test force display error: less than ± 0.5%). Each test specimen was placed between two parallel rigid plates with a diameter of 50 mm. The lower rigid plate was stationary, while the upper rigid plate compressed the test specimen at a loading speed of 2.5 mm/min (quasi-static loading) until the fruit broke.

3D modeling of Rosa sterilis S.D. Shi fruit

An important factor affecting the results of the final finite element simulation is a realistic description of the original product geometry. The first step in simulating a compression scenario using the finite element method is to create a high-precision geometric model of the Rosa sterilis S.D. Shi fruit. This study uses image processing technology to extract as many of the main features of Rosa sterilis S.D. Shi as possible and construct a high-precision 3D geometric. Pictures of Rosa sterilis S.D. Shi fruits were taken using a G1X optical camera (G series, canon) at 90° intervals. After denoising and segmentation of the image data, the Laplace-of-Gauss edge extraction operator is used to extract the fruit contours. Extracts corner points based on contours as candidate feature points and select feature points. The solid grid is constructed using the outline of the fruit as the first feature chain and the characteristic points as the second feature chain. Finally, the mesh is converted into a solid model in UG12, as shown in Fig 0.5.

Finite element simulation

The meshing is directly related to the accuracy and authenticity of the finite element simulation. When meshing, there are usually two types of meshes: tetrahedral and hexahedral. Although tetrahedral meshes increase the number of mesh elements, they are more accurate when analyzing the stress of complex geometric models. Hexahedral meshes are suitable for meshing simple geometric shapes. In the finite element analysis of this experiment, the seedless Rosa sterilis S.D. Shi fruit is an irregular and complex geometric model, while the upper and lower pressing heads are cylindrical models. Therefore, tetrahedral meshes and hexahedral meshes were combined in the finite element analysis to mesh the overall model. During the meshing process, tetrahedral meshes were used to divide the solid of the seedless Rosa sterilis S.D. Shi fruit and hexahedral meshes were used to divide the upper and lower pressing heads.

The fineness of the mesh determines the fineness of the solution model, and under reasonable mesh delineation, the more cells in the mesh, the more subdivided the solid model will be and the finer the solution model will be. But the corresponding solution time is longer. Therefore, it is necessary to consider the balance between the model fineness and the solution time when dividing the grid, not only to subdivide the solid model of Rosa sterilis S.D. Shi fruit as much as possible, but also not to affect the solution speed too much.

As can be seen in Fig. 6, the same mesh size is set for the model as a whole, and the effect of mesh sizes of 4.0 mm, 2.0 mm, 1.0 mm, and 0.5 mm on the simulation results is compared. From this Fig., it can be visualized that the number of grid cells increases significantly as the grid size decreases, and the computational power of the solution process follows the increase. The mesh quality is 0.4639, 0.7103, 0.8271 and 0.8984 respectively. The decrease in mesh size is parabolically related to the increase in mesh quality. As the mesh size decreases, the mesh quality increases. However, when the mesh size is reduced from 1.0 mm to 0.5 mm, the improvement in mesh quality is smaller, but the solution time increases significantly. Therefore, a mesh with a size of 1 mm was used to delineate the 3D model of Rosa sterilis S.D. Shi is a better meshing method. Mesh transformation: fast, mesh smoothing: medium, and physical preference: nonlinear were defined in the simulation settings. After meshing, 179,986 elements and 323,044 nodes were obtained. The indenter and the flat plate are made of a structural steel material that is much stronger than the Rosa sterilis S.D. Shi fruit and is considered as an ideal rigid body. Three-dimensional linear hexahedral mesh cells were used to delineate the indenter and plate, with a total of 440 elements and 7261 nodes. The mesh quality after meshing was 0.8524. The meshing was optimized to ensure that a better cell mesh was obtained in a shorter solution time, thus ensuring that the meshing was effective. The solution time for each cell mesh is 0.01 s and is divided into 100 sub-steps. Seedless Rosa sterilis S.D. Shi fruits in different compression positions were simulated using a nonlinear finite element model. In the finite element simulations, the fruit samples were compressed uniaxially in the horizontal and vertical directions, respectively. Rosa sterilis S.D. Shi fruits were considered as uniformly distributed isotropic linear elastomers with elastic modulus taken as 4. 5 × 106 Pa and Poisson’s ratio of 0.38. The form of surface contact between the fruit and the flat plate was selected as frictional contact (friction coefficient of 0.3). As shown in Fig. 7, the lower plate is set as a fixed constraint, and the upper plate is loaded vertically downward with a displacement load of 2.5 mm/min.

Results and discussion

Analysis of Rosa sterilis S.D. Shi fruit compression test

Since many fruits behave differently in both horizontal and vertical compression tests2122, pressure loading in both horizontal and vertical directions was designed to obtain plots of loading force versus displacement of the flat plate indenter (Fig. 8).

In Fig. 8, all the force-displacement curves show approximately linear changes at the beginning stage. With the increase of compression displacement, the curves undergo a certain degree of bending. All the curves do not show apparent biological yield points but directly rupture when the load increases to a certain value. From the overall point of view, all the force-displacement curves have similar trends. The point at which the value of the compressive load is located at the time of fruit rupture is known as the compressive resistance, and the compressive resistance2322 is regarded as an evaluative index for determining the failure of the material of the fruit samples. Before the compression load values reached the compression resistance, the fruits showed no damage under visual observation24. After the compression load value reaches the compression resistance, the fruit ruptures, and the force of the Rosa sterilis S.D. Shi fruit sample on the compression flat plate decreases instantly, and the value of the loading force detected by the sensor decreases rapidly. According to the compression mechanical test in different directions, it can be seen that the compression resistance of the compression test in the horizontal direction is greater than that of the compression test in the vertical direction, and the resistance of Rosa sterilis S.D. Shi fruits to compression loads show anisotropy in the vertical and horizontal directions.

Finite element analysis of compressive mechanical properties

Statistical comparison is an effective tool to determine the significant differences between groups. The compression force-displacement curves of Rosa sterilis S.D. Shi obtained by finite element analysis was compared and analyzed with the force-displacement curves obtained by actual compression mechanical tests. The mechanical behavior of fruits was analyzed when compressive loads were applied by a flat plate indenter. In the above analysis, the equivalent forces were analyzed using the von Mises yield criterion, which is commonly used to estimate material yield behavior.

To verify the validity of the finite element model, the force-displacement curves obtained from the finite element simulation were compared with those obtained from the compression experiments of individual Rosa sterilis S.D. Shi fruits to verify the validity of the finite element model. Figure 9 shows the force-displacement curves obtained from experiments and finite element simulations of compressing a single Rosa sterilis S.D. Shi fruit. The scatter plots of the predicted and measured forces match the forces measured from the compression tests in both the vertical and horizontal directions. The correlation coefficient R2 = 0.99 in the horizontal direction and R2 = 0.93 in the vertical direction. The finite element method is highly informative in the simulation of a single Rosa sterilis S.D. Shi fruit as an object. Given the differences in individual samples and to attenuate the specificity of the test results, the force-given displacement curves obtained from finite element simulations were compared with the average force-displacement curves obtained from compression experiments on ten groups of Rosa sterilis S.D. Shi fruits.

By comparing the compression force-displacement curves of Rosa sterilis S.D. Shi obtained from the finite element analysis with ten sets of compression mechanical tests; the average force-displacement curves were obtained (Fig. 10). With the enlarged sample size, the test values of force-displacement were still highly correlated with the experimental values ( R2 = 0.99, 0.98), suggesting that the orthogonal anisotropy of Rosa sterilis S.D. Shi fruits in the horizontal and vertical directions are universal and do not occur by chance. Similarly, Khodabakhshian and Emadi concluded that the nonlinear behavior of fruits increases with increasing compression displacement. The distribution of equivalent stresses (Von Mises) for different displacements of the specimen in vertical compression is shown in Fig. 11.

When the samples were placed vertically with displacements of 2.0, 4.0, and 6.0 mm, the maximum equivalent stresses of the fruit were 0.92, 1.00, and 2.05 MPa, respectively. The results confirmed that the larger the displacement, the stress inside the fruit increased, and the stress distribution area also spread out in the internal stress cloud map of the fruit with the increase of compression displacement, and the stress distribution range at the same contour expanded. As shown by the internal stress cloud diagram of the fruit (Fig. 12), the shape of the fruit stalk and calyx of Rosa sterilis S.D. Shi is prominent when placed vertically, and the stress will be concentrated in the stress point where the fruit is in contact with the upper and lower plates, and the flesh of Rosa sterilis S.D. Shi is pressed out of the pear juice, and the color at the upper and lower contact points of the fruit becomes darker. In addition, there is a stress concentration at the site of the largest diameter of the annular cavity inside the fruit. However, in the mechanical tests in the vertical compression direction, the beginning of the rupture was mostly at the side of the fruit from the largest diameter to the vertical crack, which may be because the peeling material was not taken into account.

When the fruit is compressed horizontally, the same as the vertical compression finite element test scheme is set up with three levels of displacement loads of 2 mm, 3 mm, and 5 mm, and the maximum equivalent stresses can reach 0.93 MPa, 2.07 MPa, and 4.61 MPa at these three levels of displacement loads (Fig. 12). The stress map of horizontal compression is similar to that of vertical compression, with the maximum equivalent stress point appearing in the region adjacent to the stress point, and the stress distribution starts from the contact point between the plate and the fruit, gradually spreads outward and penetrates deep into the fruit with the increase of the displacement load. The above comparison between the stress distribution of finite element simulation and the actual compression test situation fully verifies the authenticity of the finite element method for the compression simulation of Rosa sterilis S.D. Shi.

To control the quality of Rosa sterilis S.D. Shi fruits during the grading process, it is necessary to consider the orientation of fruit placement from harvest to consumption when an operator is handling large quantities of Rosa sterilis S.D. Shi fruit, or when a large number of boxes need to be stacked, using the longitudinal axis of the Rosa sterilis S.D. Shi fruit as the direction of stacking reduces the loss of the Rosa sterilis S.D. Shi fruit.

Conclusions

This study aims to investigate the compression resistance and internal mechanical stress distribution of Rosa sterilis S.D. Shi fruits under different directional loads. The three-dimensional model of Rosa sterilis S.D. Shi fruit, which was successfully established by image processing technology, effectively retained the shape characteristics of the fruit, with a smooth surface and no noise interference. Simulation results using the static mechanics module of the finite element analysis software Ansys Workbench software showed the compression behavior of Rosa sterilis S.D. Shi fruits in the vertical and horizontal directions were highly consistent with the experimental data, with correlation coefficients of 0.93 and 0.99, respectively, and the correlation coefficients of the average values of the actual compression test and the force-displacement curves of the finite element simulation were 0.99 and 0.98, respectively, and the stress cloud diagrams also corresponded to the location of fruit rupture by compression. Fruits were prone to rupture when the load exceeded 5 mm in the horizontal direction and 8 mm in the vertical direction, showing obvious anisotropy. Therefore, the finite element method is universal in analyzing the deformation behavior of Rosa sterilis S.D. Shi fruits, and it applies to the study of other deformation behaviors (e.g., tensile, shear), which provides the scientific basis for the design of related mechanical equipment. This is not only a cost-effective method for identifying and predicting fruit damage in agricultural products under static loading conditions but also helps to gain insight into the deformation behavior of Rosa sterilis S.D. Shi during agricultural production.

Data availability

All data generated/analyzed during the course of the study are available from the corresponding author.

Change history

20 March 2025

A Correction to this paper has been published: https://doi.org/10.1038/s41598-025-94280-y

References

Du, L., Wu, H., Zhou, H. & Yang, C. Research on the resources of Guizhou Rosa plants. J. Guizhou For. Sci. Technol. 46, 19–21. https://doi.org/10.16709/j.cnki.gzlykj.2018.01.005 (2018).

Li, Z., Miao, F. & Andrews, J. Mechanical models of compression and impact on fresh fruits. J. Compr. Rev. Food Sci. Food Saf. 16, 1296–1312 (2017).

Tian, H., Chen, H. & Li, X. Mechanical damage caused by compression and its effects on storage quality of Mandarin. J. Foods 13 (2024).

Zhu, J. et al. Effects of compression damage on mechanical behavior and quality attributes of apple fruit: Technical papers. J. Food Sci. Technol. Res. 28, 53–65 (2022).

Zhu, S. et al. The impact of mechanical compression on the postharvest quality of ‘Shine Muscat’ grapes during short-term storage. J. Agron. 13 (2023).

Xie, Z. P., Lang, Y. C. & Chen, L. Q. Geometric modeling of Rosa roxburghii fruit based on three-dimensional point cloud reconstruction. J. Food Qual. 2021. https://doi.org/10.1155/2021/9990499 (2021).

Lang, Y. C., Xie, Z. P. & Chen, L. Q. Finite element simulation of mechanical properties of Rosa roxburghii under compression loading. J. Food Process Eng. 45. https://doi.org/10.1111/jfpe.13939 (2022).

Rashvand, M., Akbarnia, A., Abbaszadeh, R., Karimi, D. & Jafari, A. Measurement bruise volume of olive during impact test using FEM and quality evaluation of extracted olive oil. Food Sci. Nutr. 9, 5493–5508. https://doi.org/10.1002/fsn3.2508 (2021).

Zulkifli, N., Hashim, N., Harith, H. H. & Shukery, M. F. M. Finite element modelling for fruit stress analysis—A review. Trends Food Sci. Technol. 97, 29–37. https://doi.org/10.1016/j.tifs.2019.12.029 (2020).

Du, D., Wang, B., Wang, J., Yao, F. & Hong, X. Prediction of bruise susceptibility of harvested kiwifruit (Actinidia chinensis) using finite element method. Postharvest Biol. Technol. 152, 36–44. https://doi.org/10.1016/j.postharvbio.2019.02.013 (2019).

Ahmadi, E., Ghassemzadeh, H. R., Sadeghi, M., Moghaddam, M. & Neshat, S. Z. The effect of impact and fruit properties on the bruising of peach. J. Food Eng. 97, 110–117. https://doi.org/10.1016/j.jfoodeng.2009.09.024 (2010).

Kabas, O. & Vladut, V. Determination of drop-test behavior of a sample peach using finite element method. Int. J. Food Prop. 18, 2584–2592. https://doi.org/10.1080/10942912.2014.994069 (2015).

Scheffler, O. C., Coetzee, C. J. & Opara, U. L. A discrete element model (DEM) for predicting apple damage during handling. Biosyst. Eng. 172, 29–48. https://doi.org/10.1016/j.biosystemseng.2018.05.015 (2018).

Chen, H. et al. Integration of puncture loading and finite element simulations to predict the mechanical responses for kiwifruit.J. J. Postharvest Biol. Technol. 217, 113102–113102 (2024).

Li, Z. G., Li, P. P., Yang, H. L. & Liu, J. Z. Internal mechanical damage prediction in tomato compression using multiscale finite element models. J. Food Eng. 116, 639–647. https://doi.org/10.1016/j.jfoodeng.2013.01.016 (2013).

Ji, H., Shao, W. & Meng, X. Experimental study on the mechanical behavior and creep characteristics of Kiwi fruit compression. J. Anhui Agric. Sci. 38, 1107–1109. https://doi.org/10.13989/j.cnki.0517-6611.2010.03.107 (2010).

Mei, R., Bao, L. & LIU, X. Geometric proof of the Mises yield criterion in the teaching of plasticity mechanics. J. Mech. Pract. 44, 955–959 (2022).

Sirisomboon, P., Tanaka, M. & Kojima, T. Evaluation of tomato textural mechanical properties. J. Food Eng. 111, 618–624. https://doi.org/10.1016/j.jfoodeng.2012.03.007 (2012).

Gao, M. J., Guo, W. C., Huang, X. L., Du, R. Y. & Zhu, X. H. Effect of pressing and impacting bruises on optical properties of kiwifruit flesh. Postharvest Biol. Technol. 172. https://doi.org/10.1016/j.postharvbio.2020.111385 (2021).

Mao, P. X., Xie, Z. P., Wang, J. H., Guo, J. L. & Sun, M. Y. Study on the mechanism of local compression bruising in kiwifruit based on FEM. J. Food Process Eng. 46 https://doi.org/10.1111/jfpe.14469 (2023).

Wang, J., Teng, B. & Yu, Y. Pear dynamic characteristics and firmness detection. J. Eur. Food Res. Technol. 218, 289–294 (2004).

Azadbakht, M. et al. Assessing kiwifruit quality in storage through machine learning. J. Food Process Eng. 47. https://doi.org/10.1111/jfpe.14681 (2024).

Razavi, S. M. A. & BahramParvar, M. Some physical and mechanical properties of kiwifruit. Int. J. Food Eng. 3. https://doi.org/10.2202/1556-3758.1276 (2007).

Caglayan, N. et al. Determination of time-dependent stress distribution on a potato tuber during drop case. J. Food Process Eng. 41. https://doi.org/10.1111/jfpe.12869 (2018).

Acknowledgements

The authors thank the anonymous reviewers for their insights, comments, and suggestions.

Funding

Guizhou Provincial Department of Education’s “Hundred Schools and Thousand Enterprises Technology Research and Development” Project, China.

Author information

Authors and Affiliations

Contributions

W.S.Q.: Investigation; statistical analysis; visualization; writing – original draft. M.P.X.: Co-authored this article; Data analysis; Experimental assistance; Project administration; formal analysis; resources. F.W.X.: Project administration; formal analysis; resources. Y.Y.F.: Project administration; formal analysis; resources. Y.Y.L. and H.X.Y.: Formal analysis; resources. X.Z.P.: Funding acquisition; supervision; writing–review and editing. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this Article was revised: In the original version of this Article, Peixuan Mao was incorrectly assigned as a corresponding author. Full information regarding the correction made can be found in the correction for this Article.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, S., Mao, P., Feng, W. et al. Study of the mechanical compression properties of Rosa sterilis S.D. Shi based on FEM. Sci Rep 15, 3712 (2025). https://doi.org/10.1038/s41598-025-87112-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-87112-6