Abstract

This study examined the electrodissolution mechanism of five impure sphalerite samples, which differ significantly in purity levels, along with their partially oxidized counterparts in a 0.5 M H2SO4. Partially oxidized samples were prepared through an incomplete leaching of sphalerite using H2SO4 with Fe2(SO4)3.H2O as an oxidizing agent. The original sphalerite samples and the partially oxidized samples were referred to as SP and POS samples, respectively. Analyses using XRD, SEM, Raman spectroscopy, and electrochemical techniques suggested presence of elemental sulfur and a metal-deficient layer on the surface of the POS samples. Cyclic voltammetry revealed that the sample with the highest iron content exhibited the highest electrochemical response, while the sphalerite with the highest lead concentration had the lowest activity. Electrochemical impedance spectroscopy (EIS) studies showed that impedance values were higher in the POS samples compared to the PS samples, indicating a correlation within the passivation phenomenon. In conclusion, these findings suggested that the sphalerite dissolution process is primarily controlled by charge transfer and kinetic polarization. This understanding can lead to the development of more selective and sustainable extraction methods and improving the overall economic viability of zinc hydrometallurgical operations.

Similar content being viewed by others

Introduction

Zinc is the world’s fourth most consumed metal after iron, aluminum, and copper. Zinc metal is increasingly recognized as a critical mineral in many critical mineral lists globally due to its essential role in various industrial and technological applications. As a vital component in galvanization, zinc protects steel from corrosion, thereby extending the lifespan of infrastructure and vehicles. Its importance extends to producing alloys, such as brass and bronze, and its use in die-casting for the automotive and construction industries. Furthermore, zinc is crucial in manufacturing batteries, including zinc-air and zinc-carbon types, integral to energy storage solutions. The growing demand for sustainable and renewable energy technologies underscores zinc’s significance, as it is essential for developing efficient energy storage systems.

Approximately 90% of zinc has been produced by processing sphalerite since 2016 1,2. Despite its simple crystal structure and formula, sphalerite incorporates a large number of elements, such as Fe, Ge, Ga, Si, and so on, with economic values into its structure. These elements often replace zinc in the crystal structure of sphalerite, which significantly influences the dissolution kinetics of sphalerite3,4,5.

The most common process for producing zinc from sulfide concentrates is the process of roasting-leaching electrowinning (RLE), through which more than 80% of zinc worldwide is obtained6,7,8. The significant challenges of the RLE process are the production of zinc ferrite9 and the emission of sulfur dioxide gas (SO2)8,10,11. It should be noted that the RLE process is energy-intensive and necessitates the purchase of costly sequestration units to reduce air pollution12.

Instead of the RLE process, two alternative methods have been proposed: the high-pressure leaching process4,13and direct atmospheric leaching14,15,16,17. The pressure leaching process produces less pollution and has a higher recovery rate of zinc, but the equipment maintenance costs are high, and it is more challenging to work with4,18. Direct atmospheric leaching of zinc sulfide concentrate has many advantages over the RLE process; the most significant of these is the production of solid elemental sulfur rather than toxic gaseous SO2. However, the biggest challenge of the direct leaching process is mainly the low kinetics due to the formation of a passive layer or an iron-free layer on the sphalerite surface during the leaching stage19,20,21,22.

One of the most critical parameters in sphalerite dissolution is selecting the appropriate leaching agent and its optimal concentration. Sphalerite has been dissolved using various acid lixiviants agents such as sulfuric acid20,23, hydrochloric acid24, and nitric acid25,26. To increase the kinetics of the sphalerite leaching reaction, suitable oxidants, like Fe2(SO4)3, FeCl3, and Fe(NO3)315,16,20,27, rising temperature, decrease in particle size, pure oxygen, and mechanical activation have been used4,8,28,29.

Generally, when ferric sulfate is added to the leaching solution of sphalerite and sulfuric acid, it dissociates to produces ferrous ions (Fe2+) according to Eq. (1) 18,30 :

If oxygen is introduced, then ferrous ions are oxidized back to the ferric ion (Fe3+), which help to maintain the appropriate oxidant level according to Eq. (2):

The sulfur element is crucial in determining both the rate of the leaching process and the overall yield. The type of sulfur layer formed in the residue (porous or non-porous) depends on the oxidant used in the leaching media, which influences the kinetics of zinc dissolution16,22. However, the mechanisms behind the formation of secondary phases and the extent to which these layers impact sphalerite leaching remain unclear. Electrochemical studies offer valuable insights into the nature of formation and dissolution mechanisms of secondary mineral phases during the leaching process. This understanding is vital for the development of hydrometallurgical methods31. Furthermore, different impurities present in zinc sulfide concentrate can alter the leaching mechanism. Consequently, conducting an electrochemical survey of various sources and compositions of sphalerite could provide additional mechanism information throughout the leaching process.

Several studies have been conducted to assess the electrochemical performance of sphalerite dissolution using techniques such as cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS)19,32,33. CV and EIS are effective electrochemical methods for identifying the oxidation-reduction mechanism of materials and studying the layers formed on the particle surface. Regarding electrochemistry, sphalerite dissolution involves two half-reactions: anodic and cathodic34. The anodic half-reaction is carried out according to Eq. (3), wherein E22 represents the potential at 22 °C:

Similarly, the cathodic half-reaction is carried out according to Eq. (4):

Karimi et al. reported that the anodic behavior of sphalerite can be divided into two distinct parts: passive zone dissolution and active zone dissolution. In the inactive zone, a passive layer is formed where sphalerite is oxidized, resulting in the formation of zinc and elemental sulfur ions on the surface of sphalerite. In contrast, in the active zone, sphalerite dissolves without forming a passive layer19. Ahlberg et al. conducted cyclic voltammetry (CV) experiments to investigate the oxidation of sphalerite over a voltage range of −1 to 1 V. They performed these experiments in various acidic media, including HCl, HC1O4 and H2SO4at temperatures ranging from 23 to 85 °C. Their findings revealed that the sphalerite sample with a low iron content of 0.8% exhibited no significant electrochemical activity when subjected to these acidic conditions whereas a sphalerite sample with a high iron content of 8.2% showed significant electrochemical activity35. According to Srinivasan et al., the primary products of the anodic oxidation of sphalerite are sulfur and sulfate ions. These products undergo reduction to H2S during the reverse cycle. The researchers also noted that the dissolution current increased with acid concentration and scan rate36.

In recent decades, the environmental limitations of the RLE method, such as roasting, have led to the development of alternative methods for dissolving sphalerite, such as atmospheric leaching in an acidic environment. This approach produces elemental sulfur instead of sulfur dioxide gas, significantly reducing environmental pollution. This method can operate effectively in the presence of high-concentration impurities, extract zinc from low-grade sources, and is more cost-effective and environmentally friendly than the RLE method. This research used an atmospheric leaching method to partially leach sphalerite samples with various concentrations of different impurities. Five sphalerite samples were collected from various mines in Iran, without any prior enrichment. The electrochemical activity of the passive layer formed (i.e., elemental sulfur, iron hydroxides and other metal sulfides) and their oxidation rate were analyzed using cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) and compared with the pre-leaching samples. Investigating the electrochemical behavior of the sulfur layer and other secondary phases during atmospheric leaching is crucial as it allows a reliable prediction of the reaction mechanism and optimizes the leaching process for enhanced metal recovery. Additionally, studying the atmospheric leaching of different types of sphalerite with varying iron and lead content is of utmost importance. Sphalerite often contains iron as a substitute for zinc in its crystal structure, and it can significantly influence the leaching kinetics as it impacts the electrochemical properties of the mineral, including its reactivity and the formation of secondary phases such as iron hydroxides or sulfides. High iron content may lead to passivation of the mineral surface, thereby slowing down the leaching process. On the other hand, if present in sphalerite, lead can form insoluble lead compounds during leaching, which can also influence the leaching rate and efficiency. The partial leaching of different impure sphalerites was performed by ferric sulfate Fe2(SO4)3 and H2SO4, acting as oxidants and lixiviants agents, respectively. These partially oxidized sphalerites will be referred to as “POS samples,” and the pre-leaching samples will be referred to as “SP samples.” It should be noted that Scanning electron microscopy (SEM), Raman spectroscopy, and X-ray diffraction analysis (XRD) were used to characterize the SP and POS samples.

Materials and methods

Sample preparation and characterization

Five sphalerite samples (Table 1) were obtained from various mining sites in Iran. They differed significantly in Zn, Fe, S, Ga, and Pb content. Impure sphalerites were crushed and followed by milling to −100 μm particle size. Then, the samples were pulverized to −25μm using a laboratory mortar and pestle to make the carbon paste electrodes (CPE) and for leaching experiments19. The particle size distribution was determined using a laser particle sizer (Fraunhofer Hydro, 2000 S, as illustrated in Fig. S1.

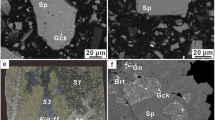

The composition of samples was characterized by inductively coupled plasma optical emission spectrometry (ICP-OES) using a Vista-Pro Varian. For this purpose, 0.1 g of the feed or leaching residue samples were digested in aqua regia (a mixture of hydrochloric acid and nitric acid in a volume ratio of 3:1) and analyzed using ICP-OES. Atomic absorption spectroscopy (AAS) analysis was also performed for comparison purposes using a Varian AA 240Z atomic absorption spectrometer. For all AAS measurements, 0.1 g of the feed or leaching residue sample was mixed with an acid solution consisting of 15 mL HCl, 5 mL HNO₃, and 1–2 mL HF. This mixture was heated at 120–180 °C for 24 h before AAS analysis. The X-ray diffraction (XRD) spectra, X-ray fluorescence (XRF), and Raman spectra of samples were analyzed by Bruker D8-Advance with a CuKα beam, Perkin Elmer Optima 4300 XRF, and Teksan_N1-541, respectively. The surface morphology and mineralogy of samples were characterized using an optical microscope and scanning electron microscopy (SEM) using a Hitachi S4160 SEM equipped with energy-dispersive X-ray spectroscopy (EDS), as shown in Fig. 1.

Sulfuric acid (Merck Co., Germany) and iron (III) sulfate monohydrate (Biochem Chemopharma Co., France) were employed as sphalerite leaching reagents. In addition, all solutions were prepared with specified concentrations using deionized (DI) water.

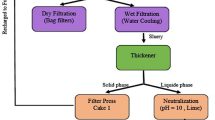

Leaching

Based on our previous studies, the highest zinc metal recovery was achieved in a 0.5 M sulfuric acid solution at 80 °C. To replicate these conditions, 100 mL of 0.5 M sulfuric acid solution was prepared by mixing 97.3 mL of deionized water with 2.7 mL of H₂SO₄ for each sample. The prepared acidic solution was transferred to a 250 mL Erlenmeyer flask. Once the solution reached 80 °C, a predetermined amount of iron (III) sulfate was added, varying for each sample as indicated in Table S1. After the iron (III) sulfate had completely dissolved, 5 g of sphalerite was added. Upon completion of the 15-minute leaching process, the leach liquor was filtered, and the POS was washed several times with DI water. The POS was dried in an oven at 70 °C and accurately weighed before further characterization. The conditions of atmospheric leaching of sphalerite are summarized in Table S1.

Following each experiment, concentrations of metals were analyzed in the POS samples by the AAS, and leaching recovery was calculated using the following Eq. (5):

Where, Cfeed (g) and Cresidual (g) are content of the metals in the SP and POS samples, respectively.

Electrochemical experiments and electrode preparation

Electrochemical experiments were conducted at room temperature, 21 ± 1 °C, using a three-electrode system: a working electrode (WE), which is a carbon paste electrode with a surface area of 0.8 cm2; a counter electrode (CE), which is composed of graphite and a reference electrode (RE), which is a glass Ag/AgCl electrode (Metrohm Ag) filled with 3 M KCl solution and saturated with AgCl (197 mV vs. SHE at a temperature of 20 °C), specifications of these electrodes are shown in Table S237. All cyclic voltammetry experiments were carried out using a potentiostat/galvanostat (Auotolab PGSTAT30) connected to a computer and controlled by Nova software (Version 2.1) at a scan rate of 20 mV/s over a potential range of − 500 to 900 mV vs. Ag/AgCl. Additionally, in order to prepare the carbon paste electrode, 0.15 g of sphalerite (x < 25 μm) and 0.25 g of graphite (Aldrich, x < 25 μm) were ground in a lab mortar and pestle. The resulting powder was mixed with 0.1 g of silicone oil (viscosity 100 kcSt, Merck Co., Germany) as a non-conducting binder to create a homogenous paste19,38. The resulting homogeneous paste was pressed into a 3 ml plastic syringe with a 0.8 cm2surface area, and a copper wire was inserted into the paste to connect the electrode to the potentiostat electrically. All electrochemical experiments were carried out using fresh electrolytes with a volume of 100 ml to reduce the error rate to a minimum. The electrolytes used in all experiments were 0.5 M sulfuric acid in DI water19,32,38,39. Following each experiment the carbon paste electrode was pushed out of the tube with the plunger after each test and was polished on a clean piece of paper in order to refresh the surface for the next experiment. It is worth noting that the potential scan in the open circuit potential (OCP) started in the anodic direction. To stabilize and obtain reproducible results, the CVs were performed in 5 cycles for each sample, shown in Fig. S2 to Fig. S6. In addition, the EIS technique was performed at an oxidation potential of 550 mV vs. Ag/AgCl in 0.5 M acid sulfuric media to better understand the electrochemistry of sphalerite behavior. The amplitude of the AC overvoltage was kept at 10 mV vs. Ag/AgCl in all electrochemical impedance spectroscopy experiments and in the frequency range of 0.01 to 100,000 Hz. Nevertheless, all electrochemical experiments were repeated at least three times to ensure the reproducibility of the results.

Results and discussion

Samples characterization

Table 1 shows the relatively high purity of the sphalerite samples and the significant difference in the amount of iron and lead. According to the result, the samples’ iron, lead, and zinc contents ranged from 0.20 to 8.95%, 0.05–1.94%, and 56.53–65.13%, respectively. Also, it is noted that the analyses of zinc (Zn) using AAS and XRF were in agreement with each other. Furthermore, the samples contained between 2068 and 7129 mg/L Cd, 26.5 to 635 mg/L Cu, 54 to 3094 mg/L Mn, 5 to 44.9 mg/L Ga, 4.9 to 74.7 mg/L Sr, and 3 to 22.1 mg/L Ag, according to the ICP-OES analysis as shown in Table 1. The presence of these impurities in sphalerite minerals is entirely consistent with previous research by other scientists4,28. Based on Fig. S1 and Table 1, it is evident that the iron content in impure sphalerites influences particle grindability and thus the D80 values. Since the work index and hardness of iron are significantly higher than those of sphalerite, the samples with higher iron content showed greater resistance to crushing and therefore larger D80 values. For instance, SP-5 contains more iron than SP-1. As a result, under the same grinding duration, SP-5 showed a D80 value of 25.7 μm compared to 17.9 μm for SP-1.

Polished sections were prepared from the different impure sphalerites for optical mineralogical studies and SEM-EDS analysis. Figure 1a shows the optical microscopy view and SEM-EDS analysis of all sphalerite samples. The samples with the lower Fe content, SP-1 and SP-3, were light yellowish under the microscope. Samples SP-2 and SP-4 with higher Fe concentrations show brownish colors. The highest Fe-content sample, SP-5, was dark brownish-black in color. Finally, it is clear that the amount of sphalerite impurities affects its color and that this result is consistent with Symonds’s work40. The SEM results show that the surfaces of samples SP-3 and SP-4 are smoother than those of samples SP-1 and SP-2. In contrast, sample SP-5 appears different, which could be due to its high iron content (Fig. 1b). EDS analysis was used to analyze the amount of zinc, iron, sulfur, manganese, and cadmium on the surface of the samples (Fig. 1c). According to the results, the zinc content was consistent with the analyses in Table 1. However, the amount of iron was lower than the analyzed amount, which could be due to the following reasons: either the particles containing iron are located separately from the sphalerite particles, or the iron in the sphalerite structure is placed in the subsurface layers.

Leaching results

Table 2 depicts the results of the POS efficiencies in acidic ferric media. The Zn leaching recovery of the samples varied between 30.6 and 36.2%. The highest and lowest Zn recoveries were found for POS-1 and POS-4 samples, respectively. POS-1, which had the lowest iron content, achieved the highest recovery under similar conditions. Conversely, it was expected that POS-5, with the highest iron content and lowest zinc content, would have the lowest recovery, but this was not the case. According to Eq. (1), in the atmospheric leaching method, sphalerite is oxidized in an environment containing sulfuric acid and iron (III), resulting in the production of zinc and iron (II) ions, as well as elemental sulfur. It is important to note that iron (III) ions play a critical role in the oxidation of sphalerite. During the dissolution of sphalerite, blowing oxygen facilitates the oxidation of iron (II) to iron (III). Since iron (III) is a strong oxidizing agent, it facilitates the dissolution of sphalerite and the reduction of iron (III) back to iron (II) creating a cyclical redox process. This process provides insights into the reaction’s kinetics, activation energy, and electrochemical parameters. In other words, the iron (III) ions form elemental sulfur around the sphalerite particles, significantly impacting the kinetics and outcomes of the leaching process19. It is hypothesized that the thickness of the sulfur layer formed on the sphalerite during the initial leaching stages is thin and has no effect on the leaching kinetics. However, as the leaching time increases, so does the thickness of the passive layer, and the permeability (the oxidant’s contact with the particle) decreases dramatically. Our experiments aimed to partially leach sphalerite to allow the formation of a passive layer on the sphalerite mineral surface, so the electrochemical behavior of the passive layer is evaluated using electrochemical techniques (e.g., CV and EIS) and compared with the SP samples.

XRD analysis of SP and POS samples

The X-ray diffractograms of the SP samples are illustrated in Fig. 2. The graphs showed almost similar peaks for each sample. It is readily apparent that most of the samples are pure sphalerite, while the SP-2 and SP-3 samples showed some impurities of quartz and galena (G). Moreover, all samples showed a weak peak of pyrite at 59°. The prominent peaks in these samples are sphalerite, observed at three values of 28.8, 47.5, and 56.2°. In terms of the crystal system, all samples were similar and shared a cubic system.

Figure 2 also shows the X-ray diffraction patterns of the POS samples. As shown, galena and quartz peaks were removed in the POS-2 and POS-3 samples. In Sample 2, the phase change observed in galena may be attributed to its dissolution, potentially involving the transformation of galena (lead sulfide) into lead sulfate. In addition, the intensity of the sphalerite peaks has decreased, indicating the reduction of its contents in the leach residue. In Fig. 2, two weak peaks associated with the element sulfur were detected at 2θ equals 23.38 and 26.76°, respectively. These weak peaks are related to elemental sulfur due to the low zinc efficiencies in the short leaching process. Generally, elemental sulfur is formed by oxidation of sphalerite or other sulfide minerals (i.e., galena) with iron (III) in acid media.

SEM and EDS analysis of POS samples

Figure 3 shows the SEM and EDS-map results of the POS samples. As shown in Fig. 3a, bright cores were covered by thin dark layers in SEM micrographs, and this result is entirely consistent with previous works16,41. Based on Fig. 3b, it was determined that the bright core and dark layers were sphalerite and elemental sulfur, respectively, where the thickness of the sulfur layer was very thin. According to the sphalerite oxidation reactions, elemental sulfur forms as a by-product on the particle surface and becomes thicker as the leaching process progresses. By comparing Figs. 1b and 3a, it can be noted that the nearly smooth surface of the samples after partial leaching tests demonstrates negligible corrosion.

As depicted in Fig. 3, it was observed that as the iron content in the samples increased, the thickness of the passive sulfur layer decreased. It should be noted that EDS analysis (Fig. 3c) proved the presence of impurities such as lead, iron, sulfur, aluminum, and silica in the samples. In addition, the amount of zinc in the POS samples decreased compared to the SP samples.

Raman spectroscopy analysis of SP and POS samples

Figure 4 depicts the Raman spectra of the SP and POS samples. Recent Raman studies of sphalerite revealed six bands at 176, 215, 300, 335, 350, and 665 cm−142. Generally, the Raman spectrum of sphalerite is divided into two optical phonons: longitudinal optical and transverse optical (TO)43. Previous research has discovered that longitudinal optical modes 176, 215, 350, and 665 cm−1 are associated with Zn-S vibration, and Raman peaks 300 and 335 cm−1 are associated with Fe-S vibration modes. Also, two peaks at 154 and 220 cm−1can be attributed to elemental sulfur formed on the sphalerite surface19,21,44. Based on the previous data, intensities in the Raman peaks around 300, 330, and 350 cm−1change with their iron contents42,45.

According to Fig. 4, the SP-1 sample showed only Zn-S vibration at 352 cm−1, and no trace of the iron peak was detected, which could be due to the high purity of sample SP-1. The Raman spectrum of the SP-3, SP-4, and SP-5 samples were virtually the same, showing Zn-S and Fe-S vibrations at 352 and 301 cm−1, respectively. The situation in the SP-5 sample appeared slightly different, most likely due to the increase in iron concentration, as no peak was detected. In general, the Raman results were consistent with the initial analysis of the samples. On the other hand, the Raman spectra of the POS samples (POS-1 to POS-5) show four peaks at 155, 220, 301, and 352 cm−1, whereas the intensity of the peaks at 300 and 350 cm has been dramatically reduced compared to the SP samples. Furthermore, the appearance of bands at 150 and 220 cm−1confirms the formation of elemental sulfur on the surface of oxidized sphalerite. Generally, the Raman spectra were consistent with previously reported data and suggested the formation of elemental sulfur on the surface of partially oxidized minerals19,21,42.

Cyclic voltammetry study

Cyclic voltammograms of the SP and POS samples are shown in Fig. 5. The CV experiments were carried out at 22 °C with a sweep potential of −500to 900 mV vs. Ag/AgCl in 0.5 M sulfuric acid19. To accurately compare CV plots, only one scan of each sample is illustrated in the measured CV window. It should be noted that the responses in the second to fifth scans of cyclic voltammetry were similar to those of the first scan. As shown in Fig. 5, there are differences in electrochemical behavior among SP samples, especially in anodic oxidation peaks. There is not much difference in the samples’ cathodic behavior if the CV plots’ cathodic current is ignored.

Generally, sphalerite oxidation occurs in three potential ranges: low (around 350 mV vs. Ag/AgCl), medium (around 550 mV vs. Ag/AgCl), and high (more than 700 mV vs. Ag/AgCl), which are illustrated in Fig. 5 as A1, A2, and A3, respectively. In the anodic peak A1 at the range of 350 mV vs. Ag/AgCl, sphalerite dissolves with low current density. During its oxidation, zinc ion enters the solution and elemental sulfur forms on sphalerite particles, according to Eq. (3). Following increasing potential, the anodic peak A2 at 500–550 mV vs. Ag/AgCl is attributed to the zinc sulfide oxidation and partial oxidation of elemental sulfur. Indeed, according to Eqs. (3) and (6), sphalerite is oxidized to zinc and elemental sulfur, and a thin passive layer covers its surface. Furthermore, the anodic peak A3 recorded at a potential of more than 700 mV vs. Ag/AgCl shows direct sphalerite oxidation according to Eq. (7), so the passive layer is undetected in this range of potential19,46.

Based on the cyclic voltammetry results of the SP samples in Fig. 5, the electrochemical behavior of sphalerite containing high impurities was overshadowed by the oxidation of other sulfides. For instance, the A1 peak disappeared in the SP-2, SP3, and SP-4 samples, and also the A1 and A2 oxidation peaks disappeared in the SP-5 sample. The absence of the A1 peak in samples SP-2 to SP-5 may be due to the high current intensity relative to sample SP-1, which was due to the oxidation of impurities such as iron sulfide, lead sulfide, cadmium sulfide, and so on. Therefore, the electrochemical activity of impure sphalerites strongly depends on the other sulfides that co-exist in the mineral, especially iron content. Besides, according to the increase in current density in SP-4 and SP-5 samples (high percentage of iron), it can be said that samples containing high iron showed a higher leaching rate compared to low-level iron samples. As a result, significant electrochemical activity can be detected in sphalerite with a high iron content. In fact, iron plays the role of a catalyst in the electrochemistry of sphalerite. This result is entirely consistent with previous literature35,47. It has already been reported that the depletion rate of iron atoms in the leaching process is much faster than that of zinc atoms21,48.

It is worth noting that the sharp peak recorded at the potential of 900 mV vs. Ag/AgCl for all SP samples showed the oxidation of zinc sulfide to zinc cation and sulfate anion, according to Eq. (7). The surface passivation is usually eliminated at elevated positive potentials (higher than 700 mV vs. Ag/AgCl) owing to the direct oxidation of zinc sulfide or the decomposition of metal-deficient layers49.

Based on the Pb impurity in impure sphalerites, it was expected that the SP-2 sample would show significant electrochemical activity in the initial cycles. Based on Ahlberg and Asbjornsson’s finding, at the first cycle, galena increases sphalerite’s electrochemical activity, but at higher cycles, galena is oxidized and produces insoluble lead sulfate on the surface of the particles, according to Eq. (8). In addition to elemental sulfur, the produced lead sulfate acts as a passive layer and strongly affects the electrochemical activity of sphalerite35,50.

The cyclic voltammetry responses of the POS samples illustrated in Fig. 5 are related to the electrochemical activity of the oxidized samples. Overall, the current density of oxidation peaks drastically decreased, indicating the formation of a passive layer due to the leaching process. Indeed, the passive layer of sulfur or iron-free sphalerite acted as a barrier against product electron transfer and diffusion, thereby preventing oxidation acceleration. It has been reported that the recovery of zinc sulfide during the leaching process is proportional to the electrical conductivity of elemental sulfur formed on the surface. Therefore, electron transfer must occur on the sphalerite surface to increase efficiency51. It should be noted that the reduction in electrochemical activity is more visible in samples with low levels of impurities. In mathematical terms, compared to SP samples, the current density of POS-1, POS-2, POS-3, POS-4, and POS-5 samples has decreased by 63.33%, 68.62%, 40.38%, 23.51%, and 35.29%, respectively. The POS-2 had the most significant decrease in electrochemical activity, which can be attributed to the high concentration of lead in the sample and the formation of lead sulfate on the sphalerite surface during the leaching process. Conversely, the POS-4 and POS-5 samples had a lower reduction of electrochemical activity than the other samples due to their high iron content.

The reverse scan observed the cathodic peak C1 at 400 mV vs. Ag/AgCl. This reduction peak in the SP-1 sample was recorded at lower potentials, which could be due to the higher purity of the SP-1 sample. Based on the other research, peak C1 is usually assigned to reducing ferric oxy-hydroxides to Fe2+ species, given in Eq. (9) 51,52. As mentioned, the SP-3 sample showed two cathodic peaks in which the peak C2 can be related to the reduction of the elemental sulfur to H2S or the reduction of the metal-deficient layer, as shown in Eq. (10) 51,53.

Electrochemical impedance spectroscopy study

EIS experiments were carried out at 550 mV vs. Ag/AgCl to more accurately study the electrochemical oxidation of the SP and POS samples and the formation and dissolution of the passive layer on their surface. Figure 6 shows the Nyquist diagrams of the SP and POS samples.

The standard potential for Fe(II)-Fe(III) couple reactions on sphalerite surface is well known, according to Eq. (11):

Where E0is the standard electrode potential of the Fe(III)/Fe(II) couple (573 mV vs. Ag/AgCl at 25 °C)54; aFe3+ and aFe2+ are the corresponding chemical activities of Fe(III) and Fe(II) ions and also R, T, n, and F represent the ideal gas constant, the temperature in Kelvin, the number of transferred electrons and the Faraday constant, respectively. Therefore, the EIS measurements of SP and POS were recorded near the standard potential of ferric/ferrous couples (i.e., 550 mV vs. Ag/AgCl).

It can be understood from Fig. 6 that Nyquist diagrams of SP and POS samples showed two overlapping semicircles and the values of the real impedance (diameter of the semicircle on the X axis) increased substantially after the leaching process in the POS-1 to POS-4 samples. This was due to the forming of a passive layer or an intermediate compound with low dissolution kinetics on the electrode surface. However, the situation differed slightly in the POS-5 sample because the value of real impedance increased somewhat compared to the SP sample (SP-5). This can be due to the high iron content in this sample, which differs from the surface composition of low-level iron sphalerite samples. Furthermore, the high iron content samples had a lower resistance, which increased sphalerite dissolution. This led to a higher current density, which agrees with the CV results (Fig. 5)55.

The Nyquist diagrams were consistent with an equivalent electrical circuit consisting of two-time constants in parallel for the passive barrier layer and the double layer, which is shown in Fig. 7. To fit the spectra in the equivalent circuits, a constant-phase element (CPE with the abbreviation of Q) was used instead of a pure capacitor due to the surface roughness of the working electrode and a lack of ideal capacitance response. Each CPE has two parameters, Y0 and n. The former is the admittance, and the latter is the surface roughness coefficient. The n value fluctuates between 0 and 1, and an ideal capacitor has a value of 1. The Rs, Rp, and Qp parameters are associated with the passive layer’s solution resistance, resistance, and CPE, respectively. Additionally, the Rct and Qdl belong to the charge transfer resistance and electrical double-layer capacitance, respectively. The values of these parameters for all samples are tabulated in Table 3.

Based on Table 3, the values of total impedance (|Z|) of all samples increased after the leaching process. It should be noted that the solution resistance (Rs) did not increase much in all the experiments, and the resistances of the surface passive layer (Rp) and charge transfer (Rct) caused an increase in total impedance (|Z|). This indicates that charge transfer and kinetic polarization mainly control the sphalerite dissolution process at 550 mV vs. Ag/AgCl. Table 3 shows that the ‘Rp’ values of the SP and POS samples varied from 5 kΩ.cm2 to 33 kΩ.cm2 and from 8.4 kΩ.cm2 to 35.3 kΩ.cm2, respectively. Similarly, the ‘Rct’ values of the SP and POS samples varied from 2.5 kΩ.cm2 to 79 kΩ.cm2 and from 2.9 kΩ.cm2 to 220.3 kΩ.cm2, respectively.

As mentioned above, the formation a passive layer on the surface of the particles led to an increase in impedance in the POS samples. This passive layer, identified as either elemental sulfur or the iron-free surface of sphalerite, was confirmed by SEM images, XRD, and Raman analysis. This result is in agreement with previous works on the formation of a passive barrier layer20,22,23,47. On the other hand, besides the sulfur layer, the intermediate compounds formed by the reactions (in this work, the iron-free sphalerite surface layer) with low dissolution kinetics may be another reason for the significant increment in total impedance21. In this case, sphalerite samples with lower iron content have higher impedance values both before and after the leaching process21,48,56. As shown in Table 3, the Y0 of Qp values for POS-1 to POS-5 samples had decreased. These results confirm the reduction in diffusion phenomena between the electrode surface and the unreacted surface of impure sphalerites and vice versa. In addition, when fewer species penetrate under the passive layer, the capacitance of the electric double layer also decreases, so the Y0 of Qdlvalues for POS-1 to POS-5 samples decrease57.

As mentioned above, the dissolution kinetics of sphalerite samples increased according to the iron content. Based on the SP-5 from Fig. 6, it can be understood that the total impedance increment, even after leaching (POS-5), was not significant. The reason is that the iron content on the electrode’s surface is not entirely removed after the leaching process. Thus, the remaining iron on the electrode’s surface resulted in a low impedance21,55,58. Furthermore, the value of ‘n’ has increased from 0.81 in sample SP-5 to 0.86 in sample SP-15, indicating that the sulfur layer has been compacted.

Conclusions

The electrochemical activity and oxidation rate of five partially leached sphalerite samples and their original counterparts were analyzed using cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) in 0.5 M sulfuric acid solutions. Understanding the electrochemical mechanism of the sulfur layer and secondary phases is crucial, as they are the controlling factors in atmospheric leaching. The initial and oxidized samples were labeled as SP and POS samples, respectively. The POS samples were prepared through incomplete leaching in a ferric acid sulfate medium. The CV results showed that the electrochemical behavior of SP samples depended on the oxidation of other sulfides, particularly the Fe and Pb content. On the other hand, the electrochemical responses of POS samples were significantly reduced due to the formation of a passive film on the sphalerite surface during the leaching process. The passive layer was characterized using SEM, XRD, and Raman analyses, which indicated the presence of elemental sulfur and a metal-deficient layer. The CV results revealed that sphalerite with high iron content (SP-5) exhibited the highest dissolution rate, while POS-2, which had a high lead content, showed the lowest electrochemical activity. Nyquist diagrams of SP and POS samples showed two overlapping semicircles corresponding to two different charge transfer phenomena. After the leaching process, the real impedance values increased substantially in the POS-1 to POS-4 samples. Conversely, the real impedance value in the high iron-containing sphalerite sample (POS-5) showed a smaller increase compared to the other oxidized samples. Furthermore, the increase in the resistance of the double layer in POS samples is consistent with the passivation phenomenon. A schematic of the methodology used in this study and key results are shown in Fig. 8.

This research will significantly contribute to the ongoing effort to develop more selective and sustainable methods for extracting zinc. It aims to reduce the formation of undesirable by-products and improve the overall economic viability of zinc hydrometallurgical operations.

Data availability

All data generated or analysed during this study are included in this published article [and its supplementary information files].

References

Summaries, M. C. Mineral Commodity summaries; USGS Unnumbered Series. US Geol. Survey: Rest. VA., 200 (2021).

Henning, A. J. Mechanisms and Kinetics of Atmospheric Sphalerite Oxidative and non-oxidative Leaching (Stellenbosch University, 2018).

Nitta, E. et al. Crystal chemistry of ZnS minerals formed as high-temperature volcanic sublimates: Matraite identical with sphalerite. J. Mineral. Petrol. Sci. 103, 145–151 (2008).

Ye, L. et al. Trace and minor elements in sphalerite from base metal deposits in South China: a LA-ICPMS study. Ore Geol. Rev. 39, 188–217 (2011).

Abdollahi, H. et al. Acid bioleaching of select sphalerite samples of variable Zn-and Fe-contents. Hydrometallurgy, 105897 (2022).

Zhang, K. et al. Recovery of gallium from leach solutions of zinc refinery residues by stepwise solvent extraction with N235 and cyanex 272. Hydrometallurgy 205, 105722 (2021).

Han, J. et al. Recovery of zinc and iron from high iron-bearing zinc calcine by selective reduction roasting. J. Ind. Eng. Chem. 22, 272–279 (2015).

Tian, L., Zhang, T., Liu, Y., Lv, G. & Tang, J. Oxidative acid leaching of mechanically activated sphalerite. Can. Metall. Q. 57, 59–69 (2018).

Hazaveh, P. K., Karimi, S., Rashchi, F. & Sheibani, S. Purification of the leaching solution of recycling zinc from the hazardous electric arc furnace dust through an as-bearing jarosite. Ecotoxicol. Environ. Saf. 202, 110893 (2020).

Aydoğan, S., Aras, A. & Canbazoğlu, M. Oxidative ammonia leaching of sphalerite concentrate. J. Fac. Eng. Arch. Selcuk Univ. 20, 55–62 (2005).

Cheikh, M., Magnin, J. P., Gondrexon, N., Willison, J. & Hassen, A. Zinc and lead leaching from contaminated industrial waste sludges using coupled processes. Environ. Technol. 31, 1577–1585 (2010).

Sahu, S., Sahu, K. & Pandey, B. Leaching of zinc sulfide concentrate from the ganesh-himal deposit of Nepal. Metall. Mater. Trans. B. 37, 541–549 (2006).

Gupta, C. K. & Mukherjee, T. Hydrometallurgy in Extraction Processes (CRC, 2017).

Aydogan, S. Dissolution kinetics of sphalerite with hydrogen peroxide in sulphuric acid medium. Chem. Eng. J. 123, 65–70 (2006).

Nikkhou, F., Xia, F. & Deditius, A. P. Variable surface passivation during direct leaching of sphalerite by ferric sulfate, ferric chloride, and ferric nitrate in a citrate medium. Hydrometallurgy 188, 201–215 (2019).

Picazo-Rodríguez, N. G. et al. Direct acid leaching of sphalerite: An approach comparative and kinetics analysis. Minerals 10, 359 (2020).

Nikkhou, F., Kartal, M. & Xia, F. Ferric Methanesulfonate as an effective and environmentally sustainable lixiviant for zn extraction from sphalerite (ZnS). J. Ind. Eng. Chem. 96, 226–235 (2021).

Sadeghi, N., Moghaddam, J. & ILKHCHI, M. O. Kinetics of zinc sulfide concentrate direct leaching in pilot plant scale and development of semi-empirical model. Trans. Nonferrous Met. Soc. China. 27, 2272–2281 (2017).

Karimi, S., Ghahreman, A., Rashchi, F. & Moghaddam, J. The mechanism of electrochemical dissolution of sphalerite in sulfuric acid media. Electrochim. Acta. 253, 47–58 (2017).

Karimi, S., Rashchi, F. & Moghaddam, J. Parameters optimization and kinetics of direct atmospheric leaching of Angouran Sphalerite. Int. J. Miner. Process. 162, 58–68 (2017).

Karimi, S., Rashchi, F. & Ghahreman, A. The evaluation of sphalerite surface formed during oxidative leaching in acidic ferric sulfate media. J. Sustain. Metall. 7, 1304–1313 (2021).

Nikkhou, F., Xia, F., Deditius, A. P. & Yao, X. Formation mechanisms of surface passivating phases and their impact on the kinetics of galena leaching in ferric chloride, ferric perchlorate, and ferric nitrate solutions. Hydrometallurgy 197, 105468 (2020).

Dutrizac, J. The dissolution of sphalerite in ferric sulfate media. Metall. Mater. Trans. B. 37, 161–171 (2006).

Aydogan, S., Aras, A. & Canbazoglu, M. Dissolution kinetics of sphalerite in acidic ferric chloride leaching. Chem. Eng. J. 114, 67–72 (2005).

Adebayo, A., Ipinmoroti, K. & Ajayi, O. Leaching of sphalerite with hydrogen peroxide and nitric acid solutions. J. Miner. Mater. Charact. Eng. 5, 167–177 (2006).

Copur, M. Solubility of ZnS concentrate containing pyrite and chalcopyrite in HNO ~ 3 solutions. Chem. Biochem. Eng. Q. 15, 181–184 (2001).

Ghassa, S. et al. Optimization of pyrite bio-oxidation to produce ferric reagent for sphalerite leaching. J. Hazard. Toxic. Radioact. Waste 26, 04021035 (2022).

Aram, R., Abdollahy, M., Pourghahramani, P., Darban, A. K. & Mohseni, M. Dissolution of mechanically activated sphalerite in the wet and dry milling conditions. Powder Technol. 386, 275–285 (2021).

Xu, Z., Jiang, Q. & Wang, C. Atmospheric oxygen-rich direct leaching behavior of zinc sulphide concentrate. Trans. Nonferrous Met. Soc. China. 23, 3780–3787 (2013).

Lampinen, M., Laari, A. & Turunen, I. Kinetic model for direct leaching of zinc sulfide concentrates at high slurry and solute concentration. Hydrometallurgy 153, 160–169 (2015).

Debernardi, G. & Carlesi, C. Chemical-electrochemical approaches to the study passivation of chalcopyrite. Miner. Process. Extr. Metall. Rev. 34, 10–41 (2013).

Karimi, S., Ghahreman, A. & Rashchi, F. Kinetics of Fe (III)-Fe (II) redox half-reactions on sphalerite surface. Electrochim. Acta. 281, 624–637 (2018).

Shi, S. Y., Fang, Z. H. & Ni, J. R. Electrochemical impedance spectroscopy of marmatite–carbon paste electrode in the presence and absence of Acidithiobacillus ferrooxidans. Electrochem. Commun. 7, 1177–1182 (2005).

Bobeck, G. E. & Su, H. The kinetics of dissolution of sphalerite in ferric chloride solution. Metall. Trans. B. 16, 413–424 (1985).

Ahlberg, E. & Ásbjörnsson, J. Carbon paste electrodes in mineral processing: An electrochemical study of sphalerite. Hydrometallurgy 36, 19–37 (1994).

Srinivasan, G. & Iyer, S. V. Cyclic voltammetric studies on sphalerite electrodes. Bull. Electrochem. 16, 5–9 (2000).

Ebrahimi, E. et al. Solvometallurgical recycling of spent LiNixCoyMnzO2 (NCM) cathode material using ternary choline chloride-ethylene glycol-p-toluenesulfonic acid deep eutectic solvent. Hydrometallurgy 222, 106184 (2023).

Khodadadmahmoudi, G. et al. Green extraction of nickel and valuable metals from pyrrhotite samples with different crystallographic structures through acidophilic bioleaching. J. Environ. Manag. 317, 115394 (2022).

Ma, Y., Yang, Y., Skinner, W. & Chen, M. Electrochemical and spectroscopic analysis of enargite (Cu3AsS4) dissolution mechanism in sulfuric acid solution. Hydrometallurgy 194, 105346 (2020).

Symonds, R. Scanning electron microscope observations of sublimates from Merapi Volcano, Indonesia. Geochem. J. 27, 337–350 (1993).

Souza, A. D. D., Pina, P. D. S., Leão, V. A., Silva, C. A. D. & Siqueira, P. D. F. The leaching kinetics of a zinc sulphide concentrate in acidferric sulphate. Hydrometallurgy 89, 72–81 (2007).

Vázquez-Sánchez, E. E., Robledo-Cabrera, A., Tong, X. & López-Valdivieso, A. Raman spectroscopy characterization of some Cu, Fe and Zn sulfides and their relevant surface chemical species for flotation. Physicochemical Probl. Mineral. Process. 56 (2020).

Buzatu, A., Buzgar, N., Damian, G., Vasilache, V. & Apopei, A. I. The determination of the Fe content in natural sphalerites by means of Raman spectroscopy. Vib. Spectrosc. 68, 220–224 (2013).

White, S. N. Laser Raman spectroscopy as a technique for identification of seafloor hydrothermal and cold seep minerals. Chem. Geol. 259, 240–252 (2009).

Bîrgăoanu, D., Damian, G. & Buzatu, A. The Fe content in the sphalerites from the Breiner-Băiuț deposit. Rom J. Min. Depos. 91, 37–42 (2018).

Nava, D. & González, I. Electrochemical characterization of chemical species formed during the electrochemical treatment of chalcopyrite in sulfuric acid. Electrochim. Acta. 51, 5295–5303 (2006).

Estrada-De los Santos, F., Rivera-Santillán, R., Talavera-Ortega, M. & Bautista, F. Catalytic and galvanic effects of pyrite on ferric leaching of sphalerite. Hydrometallurgy 163, 167–175 (2016).

Weisener, C. G., Smart, R. S. C. & Gerson, A. R. A comparison of the kinetics and mechanism of acid leaching of sphalerite containing low and high concentrations of iron. Int. J. Miner. Process. 74, 239–249 (2004).

Mikhlin, Y. et al. in Electrochem. Soc. Proc. 96–107.

Ahlberg, E. & Asbjörnsson, J. Carbon paste electrodes in mineral processing: An electrochemical study of galena. Hydrometallurgy 34, 171–185 (1993).

Cruz, F. L., Oliveira, V. A., Guimarães, D., Souza, A. D. & Leão, V. A. High-temperature bioleaching of nickel sulfides: Thermodynamic and kinetic implications. Hydrometallurgy 105, 103–109 (2010).

Mikhlin, Y. Reactivity of pyrrhotite surfaces: An electrochemical study. Phys. Chem. Chem. Phys. 2, 5672–5677 (2000).

Almeida, C., l., M. & Giannetti, B. F. The electrochemical behavior of pyrite–pyrrhotite mixtures. J. Electroanal. Chem. 553, 27–34 (2003).

Bard, A. J., Inzelt, G. & Scholz, F. Electrochemical Dictionary (Springer, 2012).

Crundwell, F. K. Effect of iron impurity in zinc sulfide concentrates on the rate of dissolution. AIChE J. 34, 1128–1134 (1988).

Buckley, A., Wouterlood, H. & Woods, R. The surface composition of natural sphalerites under oxidative leaching conditions. Hydrometallurgy 22, 39–56 (1989).

McCafferty, E. Introduction to corrosion science (Springer, 2010).

Pawlek, F. Research in pressure leaching. J. South Afr. Inst. Min. Metall. 69, 632–654 (1969).

Acknowledgements

The authors would like to acknowledge the staff of the Institute of Electrochemistry and Mineral Processing Laboratory of the University of Tehran for their technical support. In addition, we are grateful to the Electrochemistry and Corrosion Group in the Faculty of Chemical at the K.N.Toosi University of Technology for facilities and technical assistance.

Author information

Authors and Affiliations

Contributions

G. K.: Conceptualization, Investigation, Methodology, Software, Formal analysis, Data curation, Writing - original draft, Writing - review and editing, Visualization, Funding acquisition, Resources. S. K.: Conceptualization, Investigation, Methodology, Validation, Writing - Review and Editing. H. A.: Conceptualization, Supervision, Resources. M. K.: Investigation, Software, Data curation, Writing - Review and Editing, A. R.: Funding acquisition, Equipment. L. A.: Writing – Review, Editing, and Supervision. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Khodadadmahmoudi, G., Karimi, S., Abdollahi, H. et al. Electrochemical insights into the direct dissolution of impure sphalerites and their partial oxidation in an acidic environment. Sci Rep 15, 3005 (2025). https://doi.org/10.1038/s41598-025-87270-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-87270-7