Abstract

The distribution range of soil-rock mixtures (S-RM) in fault zones is wide, with significant differences in mechanical properties, making them the main sites for rock instability and support structure failure in mines. This paper takes the Sanshan Island fault zone as the engineering background, and uses a self-designed small-scale test device to conduct triaxial compression tests to study the strength and deformation failure laws of S-RMs with different rock block proportions (20%, 40%, 60%, and 80%). Combined with numerical simulation test results, the spatial transport laws and microscopic deformation failure characteristics of particles with different particle sizes in the S-RM are revealed. The main conclusions drawn are as follows: (1) For S-RMs with rock block proportions (RBP) of 20%, 40%, and 60%, there is a linear positive correlation between confining pressure and peak strength. When the RBP increases to 80%, there is a non-linear positive correlation between the confining pressure and peak strength of the S-RM sample. Under the same increase in confining pressure, the increase in peak strength of the sample decreases. The influence of confining pressure on the strength and deformation characteristics of S-RMs with high RBP is reduced. (2) During the process of increasing the RBP from 20 to 60%, there is a linear positive correlation between the RBP and peak strength of the S-RM sample. When the RBP increases to 80%, the peak strength of the sample experiences a sudden increase, with an increase of nearly 80 kPa in peak strength. When the RBP is high, the S-RM sample exhibits the mechanical properties of block rocks. (3) The cohesion and internal friction angle of the S-RM sample are positively correlated with the RBP. During the process of increasing the RBP from 20 to 80%, the cohesion increases from 83.12 kPa to 119.38 kPa, and the friction angle increases from 6° to 11°. (4) When the RBP is low (20% and 40%), as the experiment progresses, a significant conjugate shear deformation zone will form within the S-RM sample, and block rock particles will migrate towards this area and undergo shear slip failure between particles. When the RBP is high (60% and 80%), splitting failure mainly occurs at the bonding surface between block rock particles and soil particles inside the sample, and the contact force between particles is relatively large. The relevant research results have important social and economic value for revealing the fracture failure laws of rock masses in fault zones and ensuring the safe development of human engineering activities.

Similar content being viewed by others

Introduction

Faults are common geological structures in mining activities and have always been an important factor affecting mine safety production1,2,3. Due to the high degree of rock fragmentation, low strength, high degree of weathering, and abundant groundwater in fault zones, when mining tunnels or mining sites cross such geological conditions, engineering problems such as rock instability and damage, sudden water and mud influx, excessive deformation of support structures, and even failure of support structures are prone to occur4,5,6,7,8. On site investigations have found that most fault zones have continuous mixtures of fault breccia and fault mud with varying thicknesses, and their physical and mechanical properties differ greatly from those of soil and rock. It is necessary to conduct comprehensive and in-depth research on the strength characteristics, deformation features, and failure mechanisms of S-RMs in fault zones to ensure safe and efficient production in mines.

S-RM is a special geological material that is different from both soil and rock, its interior is composed of fine-grained soil particles and coarse-grained block rocks, resulting in unique structural, non-uniform, and discontinuous characteristics of S-RM9,10,11,12. Many scholars have studied the mechanical properties of S-RMs using theoretical analysis, physical experiments, and numerical simulation methods. In terms of indoor mechanical tests and numerical simulation tests of S-RMs, Ren et al.13,14,15 conducted laboratory direct shear tests to clarify the basic laws of controlling the shear strength of S-RMs with block rocks, and combined numerical experiments to reveal the influence characteristics of block rock structures on the bearing characteristics and shear band evolution of S-RMs. Hu et al.16 revealed the main controlling factors affecting the shear band thickness of S-RMs by comparing the variation characteristics of shear band thickness with rock block proportion and overlying pressure in direct shear tests and discrete element (PFC) numerical simulation tests. Hu et al.17,18 established a flexible servo triaxial loading model that reproduces the actual shape of some large-sized block rocks based on indoor large-scale triaxial tests and the coupling analysis method of PFC and FLAC, and analyzed the deformation and failure characteristics of S-RM samples, as well as the development laws of shear planes and contact force chains. Yang et al.19 constructed a particle discrete element numerical model of S-RM based on PFC software, explored the influencing factors of shear characteristics of S-RM, and analyzed the influence of factors such as particle size distribution, initial porosity, block size, and block shape on the shear characteristics of S-RM. Zhang et al.20 conducted discrete element triaxial test simulations on S-RMs under different confining pressures using a particle flow program based on the flexible bonding particle film method, and studied the effects of rock block proportion and spatial distribution on the mechanical properties and deformation failure laws of S-RMs. Xu et al.21 established a PFC compression geometry model to study the proportion of strong contact force chains of different types of red layer modified fillers during the entire loading process and the probability density distribution law at peak strength, revealing the inherent mechanism affecting the strength of red layer modified fillers. Sun et al.22,23,24 conducted compression deformation tests on S-RMs using a self-made large-scale push shear apparatus, and studied the influence of different forms of base cover effects on the deformation and failure of S-RMs. In terms of strength model and failure mechanism of S-RMs, Ren et al.25 comprehensively used DEM simulation and theoretical analysis to reveal and characterize the shear failure mechanism of S-RMs under medium and low volume rock block proportion conditions from multiple scales. Zhang et al.26 established a nonlinear strength criterion that can describe the mechanical characteristics of S-RMs by referring to the calculation format of the generalized Hoek Brown nonlinear strength criterion and the selection of empirical parameters. Li et al.27 proposed a nonlinear failure strength criterion for rocks based on the variation law of triaxial test strength. The above research combines various methods to study the strength, deformation, and influencing factors of S-RM, which is of great significance in related fields, such research work still needs to be further strengthened and improved28,29,30,31. Fault zones are geological bodies commonly encountered in underground engineering activities such as mining, and are also the main places where geological disasters such as rock instability and failure occur32,33,34. However, research on the mechanical properties of S-RMs inside fault zones is rare, especially the micro deformation and failure mechanisms and failure modes of S-RMs, as well as their relationship with macroscopic mechanical parameters. The Jiaodong Peninsula is one of the most important gold producing areas in China, with three types of gold deposits developed: quartz veins, altered veins, and breccia veins, all strictly controlled by fault structures. Fault mud and fault breccia are widely developed, making them ideal places for studying S-RMs in fault zones35. The research results are also of great significance for ensuring mine safety production and preventing geological disasters. This article takes the Sanshan Island fault zone in the northwest of the Jiaodong Peninsula as the engineering background. In the second section of the paper, physical experiments were conducted to analyze the main mineral components and mass fractions of each particle size component of the S-RM in the fault zone. S-RM samples with different RBPs were made for conducting triaxial compression tests. A self-designed small-scale experimental device was introduced, and the experimental plan was explained. In the third section of the paper, the indoor triaxial compression test results of S-RMs were presented, and the strength parameters and deformation laws of S-RMs with different RBPs (20%, 40%, 60%, and 80%) were analyzed, and the shear strength parameters were obtained. In the fourth section of the paper, numerical simulation experiments were conducted to reveal the spatial transport patterns and microscopic deformation and failure characteristics of particles of different sizes in S-RMs. In the fifth section of the paper, a summary of the research findings was provided. The research results have important social and economic value for revealing the fracture failure laws of rock masses in fault zones and ensuring the safe development of human engineering activities.

Triaxial compression test of S-RM

Test materials and sample preparation

The Sanshan Island Fault Zone is a typical regional fault structure and the main ore controlling structure in the region. The Sanshan Island fault zone runs in an NNE direction with a dip angle of nearly 90°. The main fault zone is 3 ~ 6 m wide, with metamorphic rocks on the hanging wall and granite on the lower wall, filled with gray brown fault mud and blocky gravel (i.e. soil rock mixture) in the middle, its natural moisture content was determined to be 9.5%. This article takes the Sanshan Island fault zone as the engineering background, and studies the strength and deformation failure mechanism of S-RMs with different RBPs in the fault zone through laboratory experiments and numerical simulation experiments. Before conducting mechanical experiments, XRD powder diffraction experiments and electron microscopy scanning experiments were first carried out to study the mineral composition and mass fractions of various particle size components of the S-RM in the fault zone. The results indicate that the main components of the fault mud in the Sanshan Island fault zone include sericite, quartz, and mixed layers of illite and montmorillonite, as shown in Fig. 1, which have strong cementing properties. The specific content percentages of each component are shown in Fig. 2. The blocky gravel within the fault zone is mainly composed of diorite, which is widely distributed and has a regular morphology.

Next, we will start making S-RM samples for conducting triaxial compression tests. Firstly, it is necessary to determine the critical particle size \(d\). In the S-RM sample, particles smaller than this particle size are considered soil, while particles larger than this particle size are considered block rocks. Hu et al.36 conducted laboratory experiments to statistically analyze the particle size, surface fractal dimension, and morphological characteristics of S-RM, and constructed a formula for calculating the critical particle size of S-RMs, \(d = 0.05L_{c}\). In the formula, \(d\) is the critical particle size; \(L_{c}\) is the inner diameter of the mold used for making S-RM samples. The S-RM sample used in this experiment was made by compaction method, and the internal dimensions of the steel mold used were a diameter of 50 mm and a height of 100 mm. Therefore, the critical particle size can be calculated to be 2.5 mm. In addition, it is necessary to determine the maximum particle size of the block rocks that can be used when constructing S-RM samples. According to ASTM and relevant experimental specifications37,38, it is required that the maximum particle size in the S-RM sample should not exceed 1/6 of the diameter of the mold used to make the sample. Based on the size of the steel mold used in this experiment, the maximum particle size is determined to be 8.3 mm.

On site investigation found that at the same height level, the distribution of fault mud matrix within the fault zone is relatively uniform, and the mineral composition, cementation form, and structural characteristics of fault mud at different locations are not significantly different. This is because fault gouge is the product of shear sliding, fragmentation, grinding, and clay mineralization of rock masses in fault zones, with a long formation period and an overall tendency towards stability. For the block rocks and angular gravel within the fault zone, their spatial distribution varies greatly, with blocks of different particle sizes overlapping and interlocking, which has a significant impact on the stability of the fault zone. Based on this, combined with previous research results39,40, the ratio of the mass of block rocks to the total mass of S-RM samples is defined as the rock block proportion (RBP), and S-RM samples with different RBPs are made to study their strength and deformation characteristics through laboratory experiments. In order to achieve the research objectives of this paper, four types of S-RM with different RBPs were prepared, namely 20%, 40%, 60%, and 80%.

In addition, through screening tests, the mass fractions of each particle size component in the S-RM with different RBPs in the fault zone were determined. The specific results are shown in Fig. 3. It can be seen that when the RBP is 20%, the mass fraction curve of each particle size composition is the smoothest, indicating that under this RBP condition, particles of different sizes are continuously distributed in the S-RM, and each level occupies an appropriate proportion. For the S-RM samples with RBP of 40%, 60%, and 80%, the mass fraction curve bends and sinks inward in the middle, indicating that under the above RBP conditions, the distribution of particles of different sizes inside the sample is uneven, the content of particles of the middle size is relatively small, the mass fraction of particles of different sizes changes greatly, and the grading is poor. The parameters of different mass fraction components in the S-RM samples are shown in Table 1.

As mentioned earlier, this paper mainly studies the strength and deformation failure laws of S-RM in fault zones under different stress environments and RBP conditions by conducting triaxial compression tests. Therefore, when making S-RM samples, in addition to different RBPs, other parameters should be ensured to be the same. By conducting compaction tests, it was found that when the particle density of soil in S-RM with different RBPs was 1.82 g/cm3, the compactness of the samples was the best. The required compaction times for preparing S-RM with different RBPs under this soil particle density condition were determined. The specific results are shown in Fig. 4.

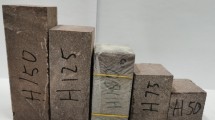

The next step is to prepare S-RM samples, which includes the following steps. (1) Drying of soil and washing of rocks. After air drying, soil particles are beneficial for maintaining the original mineral and particle composition inside the soil relatively constant. After washing, the surface floating soil of the block rock can be removed, enhancing the bonding strength with the block rock. (2) Screening. By screening the soil and rock blocks, a comprehensive analysis of particle size distribution can be obtained, which facilitates the preparation of S-RM samples according to different experimental requirements. (3) Add water and stir. According to the compaction curve of the soil, the optimal moisture content is calculated to be 9%, which means that 90 g of water needs to be added for every 1000 g of soil. Then, mix the soil with the block rocks to achieve initial uniformity of moisture in the S-RM. (4) Seal and moisturize. Seal and store the evenly mixed S-RM sample in a glass container for 3 days to ensure thorough wetting and uniformity. (5) Prepare S-RM samples. Apply lubricating oil evenly on the inner surface of the steel mold for sampling purposes. Place the S-RM sample in three layers in the mold, compact them separately, and roughen the interface. (6) Demoulding samples. Before disassembling the mold, first repair the part of the S-RM sample that exceeds the mold with a utility knife, then remove the mold and take out the sample. (7) Maintenance. To convert more free water in the S-RM sample into bound water, the S-RM sample was wrapped in plastic wrap and cured in a cool place for 28 days. The S-RM sample prepared through the above steps is shown in Fig. 5.

Test instruments and test plans

To complete the triaxial compression test of the S-RM, the author designed a small-scale test device on their own, as shown in Fig. 6. The main stress frame of the device is modified from a point load gauge and equipped with a hydraulic jack at the bottom. During the experiment, the S-RM sample is placed in a specially designed Hooke pressure chamber, which can achieve flexible and equal stress loading on the confining pressure, with a loading range of 0 ~ 400 kPa. When the confining pressure is loaded to the predetermined value, then apply axial load until the sample is completely destroyed, equipped with a dial gauge to read the axial load value. In addition, permeable plates are installed on both the upper and lower cushion blocks, and fluid structure coupling tests can also be conducted.

In order to study the mechanical properties and deformation failure characteristics of S-RMs with different RBPs, four types of S-RM samples with different RBPs (20%, 40%, 60%, and 80%) were prepared in this study for triaxial compression tests. The S-RM in the fault zone is located between the upper and lower rock masses of the fault. Under the influence of geological tectonic movements or human mining engineering activities, the upper and lower rock masses of the fault will undergo deformation and migration, which will cause changes in the stress state of the S-RM in the fault zone, and the deformation and failure characteristics under external loads will also be different. Therefore, it is proposed to conduct triaxial compression tests under different confining pressures, with confining pressures selected as 100 kPa, 200 kPa, and 300 kPa, respectively. To achieve the above research objectives, a total of 12 S-RM samples were prepared and divided into 4 groups. For each sample, name it according to its test conditions, as shown in Table 2. For example, for sample "20–100", it means that the RBP of the sample is 20%, and a triaxial compression test is conducted under a confining pressure of 100 kPa. The same applies to other samples and will not be repeated. It should be noted that during the experiment, the axial load was controlled by strain, with a compression rate of 1.50 mm/min. The condition for the end of the experiment was that the axial deformation reached 15% of the sample height.

Experimental results and analysis

Mechanical properties of S-RMs under different confining pressures

The triaxial compression test results of S-RMs with different RBPs are shown in Fig. 7. It can be seen that during the experiment, with the application of axial load, the stress–strain relationship curve basically develops linearly in the early stage of the experiment, and the stress increases rapidly. At this stage, the deformation of S-RM specimens is mainly composed of two parts: Elastic compression between soil particles and compression of initial pores within the sample. In the middle of the experiment, the stress–strain relationship curve gradually tilted towards the horizontal axis, and the rate of stress growth also began to slow down. As the axial load increases, the S-RM sample is compacted, the pores disappear, the elastic bonding structure between soil particles is destroyed, and they are squeezed and embedded into each other, gradually transitioning from elastic state to plastic state, resulting in plastic failure and a decrease in bearing capacity. In the later stage of the experiment, the stress–strain relationship curve basically transitions to a nearly horizontal state. At this time, the internal structure of the S-RM sample is destroyed, the stress reaches its peak, and the strain continues to increase.

From Fig. 7, it can also be seen that for S-RMs with RBP of 20%, 40%, and 60%, there is a linear positive correlation between confining pressure and peak strength. Under the condition of equal increase in confining pressure, the increase in peak strength of the samples is also basically equal. This is because under the constraint of confining pressure, particles of different sizes in the S-RM sample are squeezed and interlocked, forming a skeleton structure that jointly bears axial loads. When the RBP is 80%, there is a non-linear positive correlation between the confining pressure and peak strength of the S-RM sample. Under the condition of equal increase in confining pressure, the increase in peak strength of the sample decreases. This indicates that for S-RMs with high RBP, the influence of confining pressure on their strength and deformation characteristics is reduced.

Mechanical properties of S-RMs under different RBPs

The triaxial compression test results of S-RMs with RBP of 20%, 40%, 60%, and 80% under confining pressures of 100 kPa, 200 kPa, and 300 kPa are shown in Fig. 8. It can be seen that for S-RM samples with RBP of 20% and 40%, the trend of stress–strain relationship curve changes slowly under axial load, and after a short period of elastic deformation, it quickly enters the plastic deformation stage, begins to tilt towards the horizontal axis, and the peak strength is also low. For S-RMs with RBP of 60% and 80%, the stress–strain relationship curve shows a steep trend, and the elastic deformation stage is relatively long before entering the plastic deformation stage, with a higher peak strength. This is because when the RBP is low, the S-RM sample is mainly filled with soil particles, and the block rocks are wrapped by soil particles and suspended in the sample. The strength parameters and deformation failure laws of the sample are similar to those of the soil. Under external loads, soil particles are compressed and loose, quickly entering a plastic state. As the RBP increases, the S-RM sample gradually becomes occupied by block rocks, and interlocking structures are formed between the block rock particles, enhancing the bearing capacity. At this time, the mechanical parameters of the sample are similar to those of block rocks.

In addition, it can be seen from Fig. 8 that under different confining pressure conditions, when the RBP increases from 20 to 60%, the peak strength of the S-RM sample is linearly positively correlated with the RBP. Under the same increase in RBP, the peak strength increase of the sample is basically the same. However, when the RBP increased to 80%, there was a sudden increase in the peak strength of the S-RM sample. The peak strength of S-RMs under different experimental conditions is shown in Table 3. Taking the test results at a confining pressure of 200 kPa as an example, the peak strength increased by 41.21 kPa when the RBP increased from 20 to 40%, 44.02 kPa when the RBP increased from 40 to 60%, and 75.94 kPa when the RBP increased from 60 to 80%. This indicates that when the RBP increases to 80%, the S-RM sample is basically completely filled with block rock particles, and the sample also exhibits the mechanical properties of block rocks.

Based on the above analysis, it can be concluded that the strength parameters of S-RMs are positively correlated with confining pressure and RBP. However, for S-RM samples with higher RBP, the influence of confining pressure gradually decreases.

Strength parameters of S-RMs

Assuming that the strength parameters of the S-RM samples comply with the Mohr Coulomb criterion, for S-RM samples with different RBPs, combined with the results of triaxial compression tests, Mohr stress circles are drawn in a Cartesian coordinate system, as shown in Fig. 9.

In addition, according to the Mohr Coulomb criterion, the shear strength parameters of S-RM with different RBPs can be obtained by drawing the strength envelope. Among them, the intersection point between the envelope line and the vertical axis is the cohesive force, and the slope of the envelope line is the tangent of the internal friction angle. As shown in Fig. 9, for S-RMs with different RBPs, the strength envelope curve is basically a straight line with a certain slope, which also proves that the failure process of S-RMs can be described by the Mohr Coulomb criterion.

As shown in Table 4, the cohesion and internal friction angle of the S-RM sample are positively correlated with the RBP. This is because when the RBP is low, under external loads, the failure of the S-RM sample is mainly manifested as the adsorption force between soil particles being pulled apart, and the chain effect being destroyed. At this time, the shear strength parameter is relatively low. As the RBP increases, under external loads, the contact area between the block rocks becomes larger, resulting in a higher strength of the bite step and a larger shear strength parameter.

Analysis of micro deformation and failure mechanism of S-RM

This section intends to use particle flow numerical simulation technology to establish a two-dimensional discrete element model of S-RM samples based on indoor experiments, and conduct flexible biaxial loading tests to further explore the macroscopic mechanical behavior, mechanical properties, and deformation and failure mechanisms of S-RMs.

Flexible biaxial test of S-RM based on discrete element method

When conducting indoor mechanical tests, the S-RM sample was placed in a loading chamber, and the upper and lower ends of the sample were loaded through rigid loading plates. Latex film was used as the boundary condition for the lateral loading body to apply confining pressure to the sample. In order to maintain consistency with the boundary conditions of indoor experiments, a flexible servo method is used to apply confining pressure during particle flow numerical simulation experiments. The two lateral rigid walls used to apply confining pressure in traditional numerical simulation experiments are replaced by two columns of particle strings connected by a linear contact bonding model. This type of boundary can achieve only force transmission without torque transmission. During the experiment, the required confining pressure value is applied by continuously adjusting the radial velocity of the particles. Firstly, determine the average stress \(\sigma^{mea}\) on the current particle unit, then determine a better servo factor \(G\). Finally, subtract the target stress \(\sigma^{req}\) from the current stress \(\sigma^{mea}\), that is, multiply the stress difference by a servo coefficient as a velocity value: \(\overrightarrow {v} = G\left( {\sigma^{mea} - \sigma^{req} } \right)\).

The numerical simulation test of flexible biaxial loading of S-RMs can be divided into two parts: Model construction and model loading. The model construction includes three steps, namely sample preparation, preloading, and generation of flexible membrane. The flexible membrane and end loading plate are shown in Fig. 10.

In this section, numerical simulation experiments were conducted to study the spatial transport patterns and microscopic deformation and failure characteristics of particles of different sizes in S-RMs under external loads (axial loading under a confining pressure of 200 kPa). It should be noted that when establishing a numerical model for S-RMs, the mass fraction of particles with different particle sizes is the same as when conducting indoor tests. In addition, in order to ensure that the numerical model of the S-RM has the same physical and mechanical properties as the S-RM samples used in indoor tests, combined with the characteristics of the linear end bonding model, (1) the contact bonding model degenerates into a linear contact model after bonding failure; (2) Kratio (stiffness ratio) affects the Poisson’s ratio of elastic deformation, and the two are linearly correlated; (3) Emod (effective modulus) controls the elastic modulus, and the two are linearly correlated; (4) The friction coefficient only works after bond failure, and the determined micromechanical parameters through repeated calculations and deductions are shown in Table 5. The numerical models of S-RMs with different RBP are shown in Fig. 11.

Based on the discrete element numerical models of S-RMs with different RBP established above, a flexible biaxial loading numerical simulation test was conducted under a confining pressure of 200 kPa. The numerical simulation test results were plotted in the same coordinate system as the indoor triaxial compression test results conducted under the same confining pressure conditions, as shown in Fig. 12. It can be seen that the numerical simulation test result curve is more tortuous and fluctuates more violently compared to the indoor triaxial compression test result curve. This is because the numerical simulation test records the test data of the entire triaxial compression test process of the S-RM, while the indoor test only records some data points during the test process. At the same time, the discrete element method simulates soil and rock blocks in S-RMs by generating particles, and uses contact stiffness models, sliding models, and contact bonding models to calculate the interactions between particles. Overall, the numerical simulation test results are consistent with the indoor triaxial compression test results, which basically reflect the shear characteristics of the rock and soil mass, this also proves the rationality of using this model to study the micromechanical properties of S-RMs.

Analysis of failure modes of S-RMs with different RBPs

Figure 13 shows the internal particle morphology of S-RMs with different RBPs when the axial strain reaches 15%. From an overall perspective, under external loads, when the S-RM samples with different RBPs ultimately fail, both ends are compressed and the middle is extruded outward, forming a “drum” shaped failure form. Differently, when the RBP is low (20% and 40%), during the loading process, the block rock particles in the sample do not come into contact, and the soil particles are uniformly deformed under compression. Coupled with the confinement effect of confining pressure, shear slip failure occurs, and the bulging surfaces on both sides of the sample are relatively flat. When the RBP is high (60% and 80%), during the loading process, a locally dense area of block rocks is formed in the sample, and the contact area between block rock particles increases, and they are squeezed and interlocked with each other, forming an interlocking structure. At the same time, due to the mismatch in deformation modulus between block rock particles and soil particles, there are many cracks at the interface between soil particles and block rock particles, resulting in shear splitting failure, and the bulging surfaces on both sides of the sample are also relatively tortuous. From this, it can be seen that with the change of RBP, under external loads, the interlocking form and spatial transport law of particles inside the S-RM sample are different, resulting in significant changes in its deformation and failure mode.

Microscopic failure mechanism analysis of S-RMs with different RBPs

The maximum deformation cloud map of particles in the S-RM sample is shown in Fig. 14. The displacement magnitude at different positions in the sample is represented by different color intervals, transitioning from the red interval to the blue interval, indicating a gradual decrease in deformation. It can be seen that for S-RMs with different RBPs, significant deformation occurs on both the upper and lower surface positions under external loads, while the deformation in the middle of the sample is relatively small. Meanwhile, as the experiment progressed, the block rock particles in the sample gradually migrated towards the middle. For S-RM samples with RBP of 20% and 40%, due to shear slip failure of soil particles in the samples, obvious conjugate shear deformation bands are formed in the samples, forming a 45° angle with the axial direction. For S-RM samples with RBP of 60% and 80%, the content of block rocks in the samples is relatively high, and splitting failure occurs at the interface between soil particles and block rock particles. Therefore, the conjugate shear deformation zone is not obvious, especially for S-RM samples with RBP of 80%.

Figure 15 shows the cloud map of the maximum contact force distribution between particles in the S-RM sample. It can be seen that for the S-RM sample with a RBP of 20%, a "funnel-shaped" area is formed in the middle of the sample, and the boundary of this area is basically consistent with the position of the conjugate shear deformation zone in Fig. 14 (the contact force is larger in the locally dense block rock area). The contact force between particles in the area is larger, while the indirect contact force between particles in other areas is smaller, with a peak value of 7.03 × 105 Pa. When the RBP increases to 40%, a "funnel-shaped" area also forms in the middle of the S-RM sample, but the boundary is not clear, with a peak value of 7.65 × 105 Pa. When the RBP reaches 60%, due to the larger distribution range of block rocks in the sample, the corresponding contact force at the corresponding position is also larger, and the contact force on the outer side of the sample is smaller, with a peak value of 12.1 × 105 Pa. When the RBP reaches 80%, the contact force between particles is evenly distributed within the sample, with a peak value of 14.8 × 105 Pa.

From the above analysis, it can be concluded that for S-RMs with low RBP, under external loads, a significant conjugate shear deformation band will form within the sample, leading to shear slip failure. When the RBP is high, the block rock particles form a skeleton structure inside the sample, squeezing and biting each other, forming an interlocking structure, making the overall bearing capacity of the sample stronger. Under external loads, splitting failure occurs.

Conclusion

This paper takes the Sanshan Island Fault as the engineering background. Firstly, physical experiments were conducted to analyze the main mineral composition, structural characteristics, and mass fractions of various particle size components of the S-RM within the fault zone. Then, using a self-designed small-scale test device, laboratory triaxial compression tests were conducted to study the strength parameters and deformation laws of S-RMs with different RBPs (20%, 40%, 60%, and 80%), and the shear strength parameters were obtained. Finally, numerical simulation experiments were conducted to reveal the spatial transport patterns and microscopic deformation and failure characteristics of particles of different sizes within the S-RM. The following conclusion has been reached:

-

(1)

The main components of the fault mud in the Sanshan Island fault are sericite, quartz, etc., with strong cementation. The blocky gravel is mainly composed of diorite, with regular morphology and widespread distribution. When the RBP is 20%, particles of different sizes are continuously distributed in the S-RM, with each level occupying an appropriate proportion and a continuous grading. When the RBP is 40%, 60%, and 80%, the content of intermediate particles in the sample is relatively low and the grading is poor.

-

(2)

For S-RMs with RBPs of 20%, 40%, and 60%, there is a linear positive correlation between confining pressure and peak strength. When the RBP increases to 80%, there is a non-linear positive correlation between the confining pressure and peak strength of the S-RM sample. Under the same increase in confining pressure, the increase in peak strength of the sample decreases. The influence of confining pressure on the strength and deformation characteristics of S-RMs with high RBP is reduced.

-

(3)

During the process of increasing the RBP from 20 to 60%, there is a linear positive correlation between the RBP and peak strength of the S-RM sample. When the RBP increases to 80%, the peak strength of the sample experiences a sudden increase, with an increase of nearly 80 kPa in peak strength. When the RBP is high, the S-RM sample exhibits the mechanical properties of block rocks.

-

(4)

The cohesion and internal friction angle of the S-RM sample are positively correlated with the RBP. During the process of increasing the RBP from 20 to 80%, the cohesion increases from 83.12 kPa to 119.38 kPa, and the friction angle increases from 6° to 11°.

-

(5)

When the RBP is low (20% and 40%), as the experiment progresses, a significant conjugate shear deformation zone will form within the S-RM sample, and block rock particles will migrate towards this area and undergo shear slip failure between particles. When the RBP is high (60% and 80%), splitting failure mainly occurs at the bonding surface between block rock particles and soil particles inside the sample, and the contact force between particles is relatively large.

The relevant research results have important social and economic value for revealing the fracture failure laws of rock masses in fault zones and ensuring the safe development of human engineering activities.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Wen-gang, H. U. A. N. G. et al. Residual coal distribution in China and adaptability evaluation of its resource con- ditions to underground coal gasification. Sustain. Energy Technol. Assess. 49(11), 1–13 (2022).

Tsubakihara, Y. & Kishida, H. Frictional behaviour between normally consolidated clay and steel by two direct shear type apparatuses. J. Jpn. Soc. Soil Mech. Foun. Eng. 33(2), 1–13 (1993).

Dove, J. E. & Frost, J. D. Peak friction behavior of smooth geomembrane-particle interfaces. J. Geotech. Geoenviron. Eng. 125(7), 544–555 (1999).

Xiao-dan, L. E. I. Study on shear properties and rock block breakage characteristics of S-RMs[D] (Chongqing University, 2018).

He-ping, X. I. E., Hong-yan, M. I. A. O. & Hong-wei, Z. H. O. U. Development strategy of mining discipline in china during the 14th five-year plan period. Bull. Natl. Sci. Found. China 35(6), 856–863 (2021).

Hai-yan, L. I. et al. The seepage-flowing conversion mechanism of the fault lagging water inrush and its numerical simulation. J. Min. Saf. Eng. 34(2), 323–329 (2017).

Hong-wei, W. A. N. G. et al. Mechanical model for the calculation of stress distribution on fault surface during the underground coal seam mining. Int. J. Rock Mech. Min. Sci. 144(8), 104765 (2021).

Lian-jing, M. A. et al. Research on water inrush mechanism of fault coupling bed separation with fully-mechanized sublevel caving of ultra-thick coal seam. J. China Coal Soc. 44(2), 567–575 (2019).

Ping-song, Z. H. A. N. G. et al. Monitoring and analysis of deformation characteristics of fault structure under mining condition. J. Min. Saf. Eng. 36(2), 351–356 (2019).

Wen-hui, T. A. N. et al. Influence of rock block proportion on seepage characteristics of S-RM in fault zone. J. Yangtze River Sci. Res. Inst. 39(8), 86–92 (2022).

Cheng-jin, D. E. N. G. et al. Experimental study on permeability of sand gravel after compaction. Hydro-Sci. Eng. 9(3), 121–129 (2023).

Lacey, M. et al. Effects of pore and grain size on water and polymer flooding in micromodels. Energy Fuels 31(9), 9026–9034 (2017).

REN Ming-hui, ZHAO Guang-si, PU Hai, et al. Structural effects on shearing properties of loose cohesionless S-RM and development of strength model. Chin. J. Rock Mech. Eng. 43 (2024)

Rui-lin, Hu. et al. Research on engineering geomechanics and structural effect of S-RM. J. Eng. Geol. 28(2), 255–281 (2020).

Tsesarsky, M., Hazan, M. & Gal, E. Estimating the elastic moduli and isotropy of block in matrix rocks by computational homogenization. Eng. Geol. 200, 58–65 (2016).

Feng, H. U. et al. Impact on rock block breakage characteristics to the thickness of shear band of soil-rock mixture. J. Eng. Geol. 32(1), 39–51 (2022).

Shi-xing, H. U. et al. Triaxial test and PFC-FLAC coupling simulation study on material parameters and deformation characteristics of S-RM. Chin. J. Rock Mech. Eng. 40(Supp. 2), 3344–3356 (2021).

Yi-liang, T. U. The macro and meso mechanical characteristics and nonlinear elastoplastic constitutive model of soil-rock aggregate[D] (Chongqing University, 2017).

Zhong-ping, Y. A. N. G. et al. Particle discrete element numerical study on factors of shear strength characteristics for soil-rock mixture. J. Eng. Geol. 28(1), 39–50 (2020).

Qiang, Z. H. A. N. G. et al. Discrete element simulation of large-scale triaxial tests on soil-rock mixtures based on flexible loading of confining pressure. Chin. J. Geotech. Eng. 41(8), 1545–1554 (2019).

Hua, X. U. et al. Compression test and numerical simulation research on improved red beds subgrade fillers in Sichuan-Tibet railway. Rock Soil Mech. 42(8), 2259–2268 (2021).

Yong-shuai, S. U. N. & Rui-lin, H. U. Experimental study of different shape bedrock surfaces about deformation and failure of soil and rock mixture. Chin. J. Rock Mech. Eng. 35(Supp. 1), 2907–2914 (2016).

Uesugi, M. & Kishida, H. Influential factors of friction between steel and dry sands. Soil. Found. 26(2), 33–46 (1986).

Hai-peng, D. E. N. G. et al. Study on mechanical characteristics and failure behavior of S-RM upon combined FDEM numerical simulation. Mech. Eng. https://doi.org/10.6052/j.issn.1000-4750.2023.06.0451 (2023).

Ming-hui, R. E. N. et al. Structural effects of shearing properties of loose cohesionless soil-rock mixture and development of strength model. Chin. J. Rock Mech. Eng. 43(7), 1707–1721 (2024).

Zhen-ping, Z. H. A. N. G. et al. A non-linear ultimate strength criterion for soil-rock mixture based on rock block proportion. Chin. J. Rock Mech. Eng. 40(8), 1672–1686 (2021).

Xiu-lei, L. I. et al. A non-linear failure strength criterion for rocks based on the peak value of deviatoric stress from triaxial tests. J. China Coal Soc. 44(Supp. 2), 517–525 (2019).

Yu-yong, J. I. A. O., Hao, W. A. N. G. & Jiang-feng, M. A. Research on biaxial test of mechanical characteristics on soil-rock aggregate (SRA) based on particle flow code simulation. Chin. J. Rock Mech. Eng. 34(S1), 3564–3573 (2015).

Huan-ling, W. A. N. G. et al. Research on strength of S-RM based on particle discrete element method. China Civ. Eng. J. 53(9), 106–114 (2020).

Zhong-ping, Y. A. N. G. et al. Differentiation characteristics and mechanism of hydraulic erosion of S-RMs with different rock contents. Chin. J. Rock Mech. Eng. 43(1), 133–145 (2024).

Ming-nian, W. A. N. G. et al. Prediction method for fine particle loss of sandy soil under seepage erosion. Chin. J. Undergr. Sp. Eng. 17(6), 1704–1712 (2021).

Li, L. I. A. N. G. et al. Experimental investigation of internal stability of widely graded coarse granular soil and criteria of internal stability Chin. J. Undergr. Sp. Eng. 16(3), 835–843 (2020).

Wei-yi, L. I. et al. Simulation of seepage erosion in gap graded sand soil using CFD-DEM. Rock Soil Mech. 42(11), 3191–3201 (2021).

Zhi-quan, H. U. A. N. G. et al. Experimental study in influencing factors of dynamic shear module and damping ratio of fault gouge. J. Eng. Geol. 25(1), 50–57 (2017).

Gu-xian, L. V. et al. Study on the multi-level controlling rule for tectonic system in Jiaodong gold-centralized area. Geotecton. Et. Metallog. 31(2), 193–204 (2007).

Wen-jie, X. U., Rui-lin, H. U. & Zhong-qi, Y. U. E. Meso-structure character of S-RMs based on digital image. J. Liaoning Tech. Univ. 27(1), 51–53 (2008).

Shang-xin, F. E. N. G. et al. Experimental study of mesostructural change of S-RMs based on NMR technology. Rock Soil Mech. 39(5), 1–9 (2018).

Xing-wang, S. H. I., Xin-bang, G. U. A. N. & Yun, B. I. A. N. Study on fractal characteristics and fractal evaluation model of landslide hazards in Yunnan Province. J. Nat. Dis. 30(3), 209–216 (2021).

Yang, L. U. et al. Experimental study and mechanism analysis of permeability performance of clayey S-RMs. Rock Soil Mech. 42(6), 1540–1548 (2021).

Zezhi, D. E. N. G., Enyue, J. I. & Gang, W. A. N. G. Experimental study on internal erosion behaviors under fluctuating hydraulic condition using transparent soil. Rock Soil Mech. 43(10), 2726–2734 (2022).

Acknowledgements

Funded by the Research Fund of Shandong University of Aeronautics of PhD Research Launch Project (No. 2023Y45), the Colleges and Universities Youth and Innovation Science and Technology Support Plan of Shandong Province(No.2021KJ024).

Funding

Shandong University of Aeronautics of PhD Research Launch Project, 2023Y45, the Colleges and Universities Youth and Innovation Science and Technology Support Plan of Shandong Province, 2021KJ024.

Author information

Authors and Affiliations

Contributions

In this paper, Pengfei WANG and Xueyang XING are mainly responsible for writing the manuscript, while Yongcheng JIN is responsible for preparing all the figures, and Changhong LI and Jianbiao BAI are responsible for organizing the literature materials. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, Pf., Xing, Xy., Jin, Yc. et al. Experimental study on mechanical properties of S-RM with different rock block proportions in fault zone. Sci Rep 15, 4757 (2025). https://doi.org/10.1038/s41598-025-87633-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-87633-0