Abstract

Methanogenic archaea (methanogens) possess fascinating metabolic characteristics, such as the ability to fix molecular nitrogen (N2). Methanogens are of biotechnological importance due to the ability to produce methane (CH4) from molecular hydrogen (H2) and carbon dioxide (CO2) and to excrete proteinogenic amino acids. This study focuses on analyzing the link between biological methanogenesis and amino acid excretion under N2-fixing conditions. Among five hydrogenotrophic, autotrophic methanogens, Methanothermobacter marburgensis was prioritized and further cultivated in closed batch cultivation mode under N2-fixing conditions. M. marburgensis was grown on chemically defined minimal medium with different concentrations of ammonium in a H2/CO2/N2 atmosphere. This enabled the quantification of ammonia uptake, N2-fixation, amino acid excretion and the conversion of H2/CO2 to CH4. To quantify N2-fixation rates in a mass balance setting a novel method has been established. The method utilizes the pressure drop below a certain threshold pressure in closed batch cultivation mode – the threshold pressure for N2-fixation (THpN2fix). Using the THpN2fix method, volumetric N2-fixation rates of M. marburgensis as high as 0.91 mmol L−1 h−1 were determined. Excretion of amino acids was found with highest detected values of glutamic acid, alanine, glycine and asparagine. The highest total amino acid excretion of 7.5 µmol L−1 h−1 was detected with H2/CO2/N2 at an ammonium concentration of 40 mmol L−1. This study sheds light on the link between methanogenesis, biological N2-fixation, and proteinogenic amino acid excretion. The concomitant production of amino acids and CH4 could become of biotechnological relevance in an integrated approach coupling biomethanation and N2-fixation in a biorefinery concept.

Similar content being viewed by others

Introduction

The greenhouse gasses (GHGs) carbon dioxide (CO2), methane (CH4) and nitrous oxide (N2O) accumulate in the atmosphere of Earth where they contribute heavily to global warming and climate change. The accumulation of GHGs mainly results from anthropogenic combustion of fossil fuels, industrial processes and agriculture1,2,3. One example for high CO2 emissions in industrial processes is the production of ammonia via the Haber-Bosch process. The Haber-Bosch process catalyzes the reaction of molecular hydrogen (H2) and molecular nitrogen (N2) to ammonia and demands a metal catalyst, high temperature (400–500 °C) and high pressure (150–350 bar) and therefore results in 1.5 tons CO2 per ton NH3 produced4,5,6. From a nitrogen perspective, 174 million tons of NH3 are produced each year globally applied as artificial fertilizers to ensure an increased harvest of crops4,7. Thus, biological nitrogen N2-fixation (diazotrophy), to fertilize soil and produce substances relevant for human nutrition, such as amino acids, is one solution to reduce global CO2 emission tremendously. Due to the highly stable triple bond between the nitrogen atoms, it is difficult for microorganisms to fix N2 directly from the environment. Although this makes N2 unavailable as a biological nitrogen source for most organisms, some microorganisms from the domain of Archaea and Bacteria developed the trait to fix N2. This process is coupled to highly expensive metabolic costs of 16 ATP per N2 fixed8,9,10.

In Bacteria, diazotrophy is found in symbiotic and free-living species. The symbiosis ranges from the known example between legumes and intracellular diazotrophs, such as Azobacter spp. or Pseudomonas spp., to symbiotic relationships between diazotrophic bacteria and sponges, gymnosperms, or even insects11. Among the Archaea diazotrophy occurs among the methanogenic archaea (methanogens)12,13,14,15. Methanogens are anaerobic microorganisms and known for the ability to generate methane (CH4) as the end product of their energy metabolism. According to their substrate utilization spectrum, methanogens can be divided into different metabolic groups: hydrogenotrophic (H2, formate or simple alcohols), aceticlastic (acetate), methylotrophic (compounds containing a methyl group), H2-dependent methylotrophic (methylated compounds with H2 as electron donor), and methoxydotrophic (methoxylated aromatic compounds). Some methanogens are able to grow autotrophicly and hydrogenotrophicly by reducing CO2 with H2 to CH4, and play a crucial role in the global carbon cycle16. The first proof of diazotrophy in methanogens was shown in Methanosarcina barkeri strain 227 (DSM 1538)17 and Methanothermococcus thermolithotrophicus DSM 209518. Since then, diatrozophy has been further studied in M. thermolithotrophicus10,18, Methanococcus maripaludis19,20,21, M. barkeri22, Methanosarcina mazei23,24, Methanocaldococcus sp.14 and in Methanothermobacter marburgensis18. One way to make use of diazotrophy in biotechnology could be to store the fixed N2 in nitrogen containing metabolic end products, such as proteinogenic amino acids.

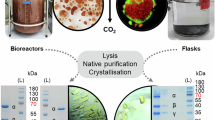

Proteinogenic amino acids are applied in a variety of industrial sectors, such as food and feed, agriculture, pharmaceuticals, or packaging and housing. The production of amino acids through bacterial fermentation has marked an important branch of biotechnology for several decades25. Through genetic engineering of the main microorganisms for amino acid production, Escherichia coli and Corynebacterium glutamicum, were turned into highly optimized microbial cell factories for commercial production of amino acids26,27,28,29,30,31,32. However, the metabolic potential of archaea with regard to amino acid excretion has up to now been vastly overlooked33,34,35,36. In the emerging research and development field of Archaea Biotechnology33,34, the production of proteinogenic amino acids, which are important nutritional compounds, could be linked to the production of CH4, which is an important biofuel35. Several studies already showed the biotechnological potential of methanogens in biomethanation37,38,39,40,41,42,43,44,45,46,47. Moreover, methanogens were recently reported to excrete proteinogenic amino acids35,48,49,50,51. However, to our knowledge, the interplay between diazotrophy, amino acid production and CH4 production has not been described yet in the scientific literature.

The aim of our research was to examine the physiological and biotechnological characteristics of biological CO2- and N2-fixation in connection to proteinogenic amino acid excretion and CH4 production. Among five methanogens, M. marburgenis was prioritized to investigate N2-fixation, CH4 production, and amino acid excretion characteristics in closed batch cultivation mode at different NH4+ concentrations. Moreover, to unambiguously prove biological N2-fixation in a closed batch system and in a mass balance setting, a method for proving biological N2-fixation by methanogens without N-labelling techniques was also developed. The method focusses on headspace gas conversion in an isobaric setting in closed batch cultivation mode by undercutting a certain pressure – the theoretical threshold (THpN2fix). Since M. marburgensis was reported to be able to grow solely on N219 and is able to excrete proteinogenic amino acids35 we hypothesized that M. marburgensis utilizes N2 as the sole source of nitrogen for proteinogenic amino acid production and excretion.

Materials and methods

Strains

The selection of hydrogenotrophic, autotrophic, diazotrophic methanogens was based on literature screening of the following articles13,17,18,19,35,36,52. From the analysis the following strains were selected for the experiments: Methanothermobacter marburgensis DSM 2133, Methanobacterium thermaggregans DSM 3266, Methanocaldococcus villosus DSM 22612, and Methanothermococcus okinawensis DSM 14208. All strains were taken from the strain collection of the Archaea Physiology & Biotechnology Group, Department of Functional and Evolutionary Ecology of the University of Vienna and had initially been obtained from the Deutsche Sammlung für Mikroorganismen und Zellkulturen GmbH (DSMZ) (Braunschweig, Germany). Methanococcus maripaludis S0001 was provided by Barny Whitman, University of Georgia, Athens, USA.

Gases and chemicals

H2 (5.0), CO2 (5.0), N2 (5.0), H2/CO2 (20 Vol.-% CO2 in H2) (4:1), H2/CO2/N2 (11.13 Vol.-% N2 and 11.13 Vol.-% CO2 in H2) (7:1:1) were used for closed batch experiments. For gas chromatography (GC), N2/CO2 (20 Vol.-% CO2 in N2), CH4 (4.5) and the standard test gas (Messer GmbH, Wien, Austria) (containing 0.01 Vol.-% CH4, 0.08 Vol.-% CO2 in N2) were additionally used. All gases, except the standard test gas, were purchased from Air Liquide (Air Liquide GmbH, Schwechat, Austria).

Media

M. villosus and M. okinawensis were grown in a chemically defined medium53. M. thermaggregans and M. marburgensis were cultivated in a minimal medium37,54 designated M. marburgensis medium (MM). M. maripaludis was grown in McN medium40,55.

Media were aliquoted into 117 mL serum bottles (VWR, Austria) to a total working volume of 50 mL and closed with blue rubber stoppers (20 mm, butyl rubber, CLS-3409-14, Chemglass Life Sciences, USA) and aluminum crimp caps (Ochs Laborbedarf, Bovenden, Germany). Before utilization, blue rubber stoppers were boiled 10 times for 30 min in Milli-Q water. To ensure anaerobic conditions the atmosphere in the headspaces of the closed serum bottles were changed before autoclavation by vacuuming and gassing with the respective gas mixture (H2/CO2 (4:1) or H2/CO2/N2 (7:1:1)) up to 2 bar rel. (3 bar abs.) repeating the procedure five times53. After autoclavation, sterile L-Cysteine-HCl·H2O, sterile NaHCO3 solution and/or sterile Na2S·9H2O were added to the sterile media in an anaerobic glove box (Coy Laboratory Products, Grass Lake, USA) prior to inoculation. For gassing, sterile syringe filters (w/0.2c µm cellulose, 514 − 0061, VWR International, USA) and sterile needles (disposal hypodermic needle, Gr 14, 0.60 × 30 mm, 23 G × 1 1/4′′, RX129.1, Braun, Germany) were used.

MM medium40 with varying NH4+ concentrations in regard to the usually provided NH4+concentration of 40 mmol L− 138,54 was prepared to examine N2-fixation characteristics of M. marburgensis. Moreover, the MM medium was prepared (as indicated) by omitting Na2CO3 to ensure that CO2 will be the sole source of carbon for growth and biomethanation37. To reach equal Na+ concentrations to the initial MM medium recipe, Na2CO3 was substituted by equal molarities of NaCl (Supplementary Table 1). To replace L-cysteine monohydrate, a diluted HCl solution was used to retrieve the pH value. Medium without Na2CO3 was manually adjusted before gassing and autoclavation to pH 6.8 by titrating with 10 mol L−1 NaOH.

Cultivations

Cultures were incubated in a water bath (GFL 1083, Burgwedel, Germany) at 65 °C (M. marburgensis, M. thermaggregans and M. okinawensis) or in a shaking air incubator at 37 °C (M. maripaludis) (GFL 3033, Burgwedel, Germany) and 80 °C (M. villosus) (ZWYR-2102 C, LABWIT Scientific Pty Ltd, Australia). For the purpose of N2-fixation all closed batch experiments were performed in a H2/N2/CO2 (7:1:1) gas mixture (unless otherwise indicated, for positive control). This study includes three different setups. The first setup is a screening experiment to prioritize the most suitable strain regarding N2-fixation. The second setup focuses to prove N2-fixation with destructive sampling technique. The third setup combines N2- and CO2-fixation and the excretion of amino acids.

To prioritize the most suitable strain, M. marburgensis, M. maripaludis, M. thermaggregans, M. villosus and M. okinawensis were grown in triplicates (n = 3) with one zero control to an OD578 of approximately 0.7. As the MM medium contains the highest NH4+ concentrations, it was additionally examined if growth of M. marburgensis was affected by reducing the amount of NH4+ to 10% of the original media NH4+ concentration. To remove residual nitrogenous compounds from the media, pre-cultured cells were washed (see below) before inoculation with reduced medium without NH4+. For a complete N-free media all cultures were washed three times, for all other experiments one time to none.

Experiments with only M. marburgensis were performed in quadruplicates (n = 4) or octuplicates (n = 8) at different NH4+ concentrations (0%, 1%, 5%, 7.5%, 10%, 25%, 50% and 100%) in relation to original media composition of 40 mmol L−1. A pre-culture with 10% of the initial NH4+ concentration of 40 mmol L−1 served as inoculum. To reduce the possibility of a NH4+ carryover some experiments as indicated were performed with one additional washing step. Washing of cells was performed by anaerobic transfer of 0.9 mL cell-culture into a 1.5 mL Eppendorf reactions tube (Eppendorf AG, Hamburg, Germany). The sample was centrifuged (5415 R, Eppendorf AG, Hamburg, Germany) at full speed (16,100 rcf) for 20 min. Supernatant was discarded and the pellet was resuspended in the respective medium. The closed batch experiment with 0% NH4+ served as negative control and gassed with H2/CO2 (4:1) as positive control. After every incubation time the serum bottles were left at room temperature for 45 min to cool down to reach isobaric conditions53. For the destructive sampling experiments, the cultures were not put back into the water bath for incubation.

For growth and N2-fixation experiments liquid samples of 0.75 mL were withdrawn from the serum bottles. Then growth was measured spectrophotometrically via OD (λ = 578 nm, blanked with Milli-Q water) (Beckman Coulter, DU 800 Spectrophotometer, California, USA). To sample and quantify amino acids, liquid samples of 1 mL were taken and centrifuged at full speed (16,100 rcf) for 30 min (5415 R, Eppendorf AG, Hamburg, Germany). The supernatant of each experiment was stored in a sterile Eppendorf tube at −20 °C until further analysis.

Gas quantification

The relative pressure in bar within the serum bottle was measured with a digital manometer (LEO1-Ei, 1–3 bar rel., Keller GmbH, Winterthur, Switzerland). Gaseous substance (n / mol) in the serum bottles headspace was calculated via the ideal gas law. A non-inoculated serum bottle, gassed simultaneously with all other serum bottles served as a positive pressure control. As removing the needle releases some gas, pressure from this measurement indicated the “real pressure” and served as baseline for the calculations of N2-fixation. Headspace volume was determined in earlier experiments53 and adjusted after every OD measurement by the extracted sample volume of 0.75 mL. All measurements were performed at room temperature. Afterwards, the atmosphere was flushed and re-pressurized to 2 bar rel. (3 bar abs.). This procedure was repeated after every incubation or until the theoretical threshold (THpN2fix) was undercut. GC analyses were performed as previously described56. To obtain the actual amount of N2 the pressure inside the serum bottles was multiplied by 0.11392 based on the exact percentage of N2 (11.392 Vol.-%) in the gas mixture, then multiplied with the normalized gas composition gained from GC measurement. The values of the zero control served as N2 baseline. N2 uptake rate (NUR / mmol L−1 h−1) was calculated by dividing the deviation of N2 before and after incubation (ΔN2) by volume of the liquid medium and the time since last incubation (Δt).

The specific nitrogen uptake (qN2 / mmol h−1 g−1) was determined by dividing the NUR by the biomass concentration (x / g L−1) calculated with an experimentally determined coefficient53.

CO2 uptake rate (CUR / mmol L−1 h−1), H2 uptake rate (HUR / mmol L−1 h−1), CH4 evolution rate (MER / mmol L−1 h−1), carbon balance (C-balance), yields (Y(CH4/CO2) and Y(x/CO2)) and biomass productivity (rx / C-mmol L−1 h−1) was calculated as described elsewhere53.

Theory

Gas pressure and theoretical threshold (THpN2fix)

In a pure culture of a hydrogenotrophic, autotrophic methanogen full gas conversion must be considered53 for the optimal conditions of N2-fixation. The ideal gas composition for H2/CO2 (4:1) follows the stoichiometry (1):

The stoichiometry (2) of biological N2-fixation is:

To catalyze this reaction and to break the highly energetic triple bond of N2 (945 kJ mol−1), 16 ATP and 8 electrons are required. One molecule of H2 and ammonia (NH3) is formed after the reduction of N29. During artificial N2-fixation by the Haber-Bosch process, high pressure, high temperatures and a metal catalyst are necessary to form two molecules of NH3 out of three molecules of H2 and one molecule of N2. In theory, combining Eqs. (1) and (2) provides an ideal gas composition of seven parts of H2 and each one part of CO2 and N2 (3), with the possibility of full gas conversion by hydrogenotrophic, autotrophic, diazotrophic methanogens:

All serum bottles were purged and re-pressurized after every incubation. A gassing manifold was used to ensure equal pressure of approximately 3 bar (abs.) of one closed batch (replicates and 1 zero control). To measure the exact total pressure after re-pressurizing, the THpN2fix was calculated from the pressure of the zero controls. Under H2/CO2 gassing in a ratio of 4:1, the pressure can decrease to almost 0.6 bar abs., if all molecules of H2 and CO2 would be converted to CH453:

H2/CO2(4:1); 3 bar (abs.)

Expecting full conversion, and neglecting biomass production, CH4 would be about one fifth of the pressure in the 7:1:1 gas mixture (see Eq. 3):

H2/CO2/N2(7:1:1); 3 bar (abs.)

If autotrophic, hydrogenotrophic methanogenesis takes place at full conversion, but without N2-fixation, one part of CH4, three parts of H2 and one part of N2 would remain in the serum bottle headspace:

This leads to the theory, that a pressure below 1.66 bar (abs.) in this respective set-up is a clear indicator N2-fixation. To assure N2-fixation, gases was measured at the GC at a pressure of 1.5 (abs.).

Ammonium determination

NH4+ determination was performed using a modified procedure according to the method described before57. The oxidation solution, the colour reagent and the NH4Cl stock solution were prepared freshly before the measurement. As standards, nine different concentrations, ranging from 100 µmol L−1 to 1000 µmol L−1 of NH4Cl, were prepared. Samples were diluted with Milli-Q water to an end concentration between the standard ranges. Before the measurement, 300 µL of colour reagent and 120 µL oxidation solution were added immediately to the standards and samples and shortly mixed. After 30 min in the dark, measurement (λ = 660 nm) was performed using a 96 well plate (Microtest Plate 96 Well, F, Sarstedt AG & Co KG, Nümbrecht, Germany) with a plate photometer (Sunrise plate reader, Tecan Group AG, Männedorf, Switzerland). Regression curve R2 was always higher than 0.999.

Amino acid analysis

For amino acid analyses the supernatant of samples was diluted with Milli-Q water at the ratio of 1:4. Measurements were performed on Agilent 1260 Infinity Bioinert HPLC system containing a fluorescence detector, a column oven, an autosampler and a quaternary pump. 1 mL of sample was mixed with 75 µL borate buffer (0.4 N in water, pH = 10.2; Agilent Technologies) followed by 5 µL OPA reagent, (3-mercaptopropionic acid in 0.4 mol L−1 borate buffer and 10 mg mL−1 of o-phthalaldehyde (OPA); Agilent Technologies). 100 µL of the mixture was injected to HPLC system after 2 min at 27 °C. Fluorescent derivates (primary dissolved free amino acids) were separated at 25 °C and a flow rate of 0.8 mL min−1 on a Zorbax ECLIPSE AAA column (4.6 × 150 mm, 3.5 μm particle size, Agilent Technologies) with a Zorbax ECLIPSE AAA guard cartridge (4.6 × 150 mm, 5 μm particle size, Agilent Technologies). The excitation wavelength was 340 nm and emission 450 nm. The use of a gain factors 9 or 10 was depended on the expected concentration and pre-tested before. For identification and quantification of peaks a primary amino acid standard mix (AAS18, Sigma Aldrich) in different concentrations was prepared for each run according to the concentration range of the samples (100 nmol L−1 to 15 µmol L−1). AAS18 standard mix lacks five amino acids (asparagine (Asn), glutamic acid (Glu), gamma-aminobutyric acid (GABA), taurine (Tau), tryptophan (Trp); Sigma Aldrich) which were added. In total, 20 different AA could be measured with this method. Valine and methionine had to be excluded from evaluation as they were located within a signal noise “ammonium peak” and therefore hard to measure within experiments with high NH4+concentrations as in our experiments. The details of this method were as previously described36.

Results

Prioritization of strains

Growth of M. marburgensis, M. maripaludis, M. thermaggregans, M. villosus and M. okinawensis was analyzed in NH4+ containing and an NH4+ free medium with an H2/CO2/N2 headspace. This allowed us to screen for NH4+ uptake, N2-fixation, amino acid excretion and the conversion of H2/CO2 to CH4 in parallel. All methanogens, excluding M. thermaggregans, could be grown to an OD578 of 0.7 in NH4+ containing medium (Supplementary Fig. 1). No growth or decrease in pressure (∆p) was detected when cells were washed and afterwards used as inoculum for another NH4+ free medium (data not shown). However, when M. marburgensis was grown in NH4+ free medium, without a biomass washing procedure the organism showed very slow growth (up to OD578 of 0.3 ) compared to optimal growth conditions37 while its ∆p reached up to 2 bar (Fig. 1a). M. maripaludis obtained a ∆p up to 1 bar (Fig. 1b). All other organisms showed neither growth nor a high and unambiguous ∆p (Fig. 1, Supplementary Table 2) when cultivated with NH4+ carryover. Therefore, only M. marburgensis was prioritized for further experiments. A subsequent transfer of M. marburgensis from NH4+ free medium, however, with NH4+ carryover, to another NH4+ free medium was not successful (data not shown). These experiments indicated that a certain amount of NH4+ was necessary for growth of M. marburgensis even with N2 in the headspace.

N2-fixation ability of M. marburgensis

Growth and N2-fixation characteristics of M. marburgensis were monitored at different NH4+ concentrations in relation to original media composition of 40 mmol L−1 gassed with H2/CO2/N2. Therefore, pre-experiments were made to examine the effect on growth of NH4+ and carbonate (Supplementary Fig. 2, Supplementary Fig. 3). Due to chemical speciation reactions58, carbonate that is converted to CO2 serves as an additional carbon source for M. marburgensis. However, with an additional liquid-based carbon source our postulated theory to analyze THpN2fix as an indicator for N2-fixation would be contradicted. In both set-ups (Supplementary Fig. 2, Supplementary Fig. 3) 0% and 1% NH4+ concentration showed no or very little growth with no N2-fixation. All other tested NH4+ concentrations followed a similar growth behavior and reached stationary phase after about 120 h of incubation. Experiments with carbonate added to the media resulted in faster growth. The THpN2fix of 1.66 (abs.) was undercut several times during these experiments (Data Sheet 1: Pressure Drop CB, GC Sum). As the stationary phase of M. marburgensis was entered after about 120 h in the pre-experiments (Supplementary Fig. 2, Supplementary Fig. 3), growth and N2-fixation in the experiment was subsequently monitored until 141 h and additionally NH4+ concentrations of 2.5% and 7.5% have been included in the experiment (Fig. 2). End point measurements of NH4+ after 141 h showed that NH4+ limitation only occurred in 0% and in 5% NH4+ experiments (data not shown).

Growth kinetics of M. marburgensis during the THpN2fix methodology experiment without Na2CO3 in the medium and at different NH4+ concentrations in relation to original media composition (n = 4). Due to undercutting the THpN2fix in all four replicates of 5% NH4+ experiments at two subsequent time points, growth could not be monitored further since the method of destructive sampling has been employed for verifying THpN2fix independently twice through GC measurements.

THpN2fix was undercut in several samples at different time points between 40 and 77 h of incubation and the headspace gas composition has been analyzed via GC for determinations of NUR (Fig. 3). Highest NUR of 0.62 mmol L−1 h−1 after 40 h of incubation was obtained when 7.5% NH4+ concentration had been examined. Only at 0% and 1% NH4+ the pressure never undercut THpN2fix. The quantification of NUR through the theoretical background of the THpN2fix methodology could thus be verified (Fig. 3). It became visible that after the first time of undercutting THpN2fix and with every further incubation round, THpN2fix could hardly be reached anymore and the physiological ability for N2-fixation seemed to be reduced as NUR is decreased. Moreover, in addition to the THpN2fix methodology, N2-fixation of one replicate of the 10% NH4+, two replicates of the 7.5% NH4+, all replicates of the 5% NH4+ and one replicate of the 2.5% NH4+ cultures were analyzed via GC. Therefore, the destructive sampling method was used in order to independently prove N2-fixation of M. marburgensis by GC in addition to the already available proof of N2-fixation through the THpN2fix methodology (Fig. 3, Data Sheet 1: Sum NUR). The culture that was cultivated at 100% NH4+ did surprisingly not grow as expected from previous experiments (Fig. 2) and reached THpN2fix at a low mean value at the last measurement time-point (Fig. 3). The qN2 of M. marburgensis that was reached in both replicates of 7.5% NH4+ was 10.24 mmol h−1 g−1 at 40 h and 9.99 mmol h−1 g−1 at 77 h (Data Sheet 2: NUR_qN2). HUR, CUR, NUR, MER and the mass balances were calculated from GC measurements (Supplementary Table 3). NUR was always higher at earlier time points when THpN2fix was undercut for the first time. Full conversion of H2 and CO2 to CH4 did not occur in 0% and 1% replicates and therefore did not drop below THpN2fix. The ratios of HUR:CUR, calculated from HUR/CUR and C-balances under consideration of biomass production from the total of Y(CH4/CO2) and Y(x/CO2), were found to be partially inconsistent in measurements where NUR was higher.

NUR / mmol L−1 h−1 of M. marburgensis with different NH4+ concentrations calculated by the THpN2fix methodology. Negative values for NUR / mmol L−1 h−1 on the y-axis indicate N2-fixation. Sample size varies due to the time point of undercutting THpN2fix. The sample number (n) is indicated in brackets on the x-axis. In addition, the sampling time points (in h) and the values of the applied NH4+ concentration (in %) are also indicated on the x-axis.

Uptake of NH4 + and N2 for amino acid excretion

For visualization of N2-fixation and the simultaneous production of proteinogenic amino acids, experiments of M. marburgensis were performed with 0%, 5%, 7.5%, 10% and 100% NH4+, gassed with H2/CO2/N2. To reduce the possibility of a NH4+ carryover the experiments were performed with one washing step before inoculation in octuplicates (n = 8) and using a second zero (gas) control. Due to this additional biomass washing step slower growth compared to non-washed biomass experiments was observed (please compare growth curves shown in Fig. 2, Supplementary Fig. 2, Supplementary Fig. 3 to Supplementary Fig. 4). After 77.17 h of incubation the OD578 reached values between 0.17 and 0.20. As expected, the 100% NH4+ H2/CO2 positive control showed the highest OD578 value of around 0.25. Gas samples were taken after approximately 40, 59 and 77 h of incubation (Supplementary Fig. 4). An NH4+ uptake during N2-fixation is evident in all experiments (Supplementary Fig. 5), although NH4+ was never completely consumed. The highest uptake was achieved in the positive control (Data Sheet 1: NH4Cl Uptake). Highest NUR was calculated from 7.5% to 100% closed batch experiments after 40 h of incubation with 0.91 or 0.83 mmol L−1 h−1, respectively and from 10% after 59 h with 0.88 mmol L−1 h−1. The qN2 follows the same pattern (Supplementary Table 3). As a general trend, earlier sampling time points rather show higher NUR values, and later time points lower but more balanced NUR values. (Fig. 4). A detailed description of HUR, CUR, and MER is shown in Supplementary Table 3. MER during N2-fixing conditions and omission of carbon in the media could not reach the MER values previously described for closed batch experiments37,40,53.

Results of NURs during the amino acid excretion and N2-fixation time series experiment. The experiment was performed using destructive sampling procedure. M. marburgensis biomass was washed before inoculation. NUR / mmol L-1h-1 of M. marburgensis during growth on H2/CO2/N2 are shown as individual box plots indicating NH4+ concentration and the time point. The first number on the x-axis labelling indicates the percentages of NH4+ in the medium. The first number on the x-axis labelling indicated the sampling time point. The legend on the right-hand side of the graph indicates the respective group in colours (red: 5% NH4+, green: 7.5% NH4+, blue: 10% NH4+, magenta: 100% NH4+ as well as the time point of sampling (40 h, 59 h, 77 h). All results are n = 8. Thus, 93 out of 96 individual NUR results show N2-fixation whereas only 3 NUR results from 3 different set-ups do not show N2-fixation.

Independent of the NH4+ concentration almost all detectable proteinogenic amino acids were found in the supernatant (Fig. 5). The highest excreted amino acids are glutamic acid (Glu), alanine (Ala), glycine (Gly) and asparagine (Asn). The concentrations of Glu, Gly and Asn are constantly increasing during the time-course of the cultivation, whereas the trend for Ala is not entirely clear. It could be that Ala is partially consumed during the cultivation. All amino acid excretion experiments showed a clear NH4+ dependence, where amino acid concentrations at 5%, 7.5% and 10% of NH4+ is different to 100% NH4+ (in H2/CO2 and H2/CO2/N2) (Fig. 5). The highest amino acid excretions rates were detected for Glu with up to 4.59 µmol L−1 h−1 in 5% after 40 h and a smaller amount of Ala with up to 1.36 µmol L−1 h−1. Highest value of Gly was achieved in 100% after 40 h with 0.99 µmol L−1 h−1 (Data Sheet 1: HPLC Productivity).

Results of individual amino acid concentrations during the amino acid excretion and N2-fixation time series experiment. M. marburgensis biomass was washed before inoculation. Amino acid concentration / µmol L−1 of M. marburgensis during N2-fixation on H2/CO2/N2 shown as individual bar charts with standard deviation for each amino acid. The legend on the right-hand side of the graphs indicates the quantified amino acids. On the left-hand y-axis, the amino acid (AA) concentration / µmol L−1 is shown. NH4+ concentrations of the respective time series are indicated on the right-hand y-axis from top to bottom: 0%, 5%, 7.5%, 10%, 100% and 100%_41. 100%_41 denotes amino acid excretion during incubation with H2/CO2 (4:1). The sampling time is shown on the x-axis as headers from left to right. After biomass washing negligible amino acid concentration is measurable at time point 0 h. All results are n = 8.

Examining the total amount of excreted amino acids, an increasing excretion of amino acids over time with the highest concentration of 14.67 to 18.44 µmol L−1 in later time points was found (Data Sheet 1: AUR vs. AA). The presence of higher concentrations of NH4+in the media seems to serve as an inhibitor for amino acid production, which is in agreement to earlier findings36, as 100% experiments showed slightly lower excreted amino acid concentrations (Fig. 5, Data Sheet 1: HPLC Productivity). A comparison of the total uptake of NH4+ with the total amino acids excretion rate indicated that amino acid excretion rate increased with increasing AUR. Furthermore, during depletion of NH4+, the concentration of AA did not increase (Supplementary Fig. 5).

Discussion

Agriculture and the production of artificial N-fertilizers are an indirect source of GHG emissions through releasing N2O via nitrification of ammonia (NH3)2,4. To generate this ammonia fertilizer, the Haber-Bosch process is the main industrial procedure for synthetic N2-fixation and responsible for a release of 1.5 tons of CO2 per ton of NH3 produced6. Therefore, the identification of microbial strains optimized for molecular N2-fixation could reduce the amount of chemically produced ammonia via the Haber-Bosch process. Physiologically, an ideal strain for N2-fixation in a biorefinery concept should include certain properties, such as high specific growth rate, high specific CO2 conversion and high N2-fixing abilities. Furthermore, the strain should be cultivatable in chemically defined minimal medium exclusively with inorganic compounds and substrates. Among the methanogens, several candidates would fulfill these prerequisites. For this reason, suitable methanogens should be identified using a fast and simple screening methodology regarding their N2-fixation characteristics. Therefore, this study proposes a fast and easy detection method of diazotrophic characteristics of autotrophic, hydrogenotrophic methanogens using THpN2fix as proof of N2-fixation and concomitant amino acid production. Moreover, in the context of “power to gas” technology, biomethanation of CO243,44,45,48 in combination with N2-fixation for the excretion of amino acids could become of high economic interest48,49,50,51. To our knowledge there is no study yet that examined combined CO2- and N2-fixation regarding amino acid excretion. However, this study should only be seen as proof of principle. For a high throughput screening of THpN2fix and quantification of NUR, online measurements of the headspace pressure would be clearly desirable40,41. In addition, in-line or at-line measurements of biomass and of NH4+ concentrations would be needed to be able to examine the growth and production kinetics of methanogens under N2-fixing conditions.

Furthermore, methanogens may use carbonates as an additional carbon source59. A carbon source in the media would render the THpN2fix method as an indicator for N2-fixation impossible, as additional H2 utilization beyond the 4:1 ratio would potentially occur. For that reason, it was necessary to exclude carbonate from the media for the purpose of converting CO2 to CH4 only from the gas that had been supplied in the serum bottle headspace. Gassing with H2/CO2/N2 generally resulted in lower growth (Supplementary Fig. 4) when compared to gassing with only H2/CO2 (Supplementary Fig. 2, Supplementary Fig. 3). This could be explained via constrained growth by the expensive N2-fixing process9. Within this set-up, undercutting the THpN2fix while fixing N2 was successful in experiments where NH4+ was limiting, ranging between 2 and 10% and in a time frame from 40 to 77 h of cultivation (Fig. 3). The qN2 of M. marburgensis (Data Sheet 2: NUR_qN2) detected in this study are in the range 5–20% the maximum specific CH4 production rates54. This high physiological capacity of M. marburgensis for diazotrophic growth seems to agree with that of M. thermolithotrophicus10.

Regarding the capability of methanogens for N2-fixation, M. marburgensis harbours a nif gene cluster13 and the organism was already examined in continuous culture regarding its growth yield under N2-fixing conditions18. Thus, M. marburgensis has been shown to be capable to growing on NH4+-free medium solely using N2 as nitrogen source. However, here we show that NH4+ addition is required to enable N2-fixation of M. marburgensis and that there seems to be an optimal concentration of NH4+ between 2.5 and 10% for optimal N2-fixation. At higher concentrations of NH4+ (50% and 100%) (Fig. 3), the pressure rarely dropped below the THpN2fix, and it seemed that N2-fixation was slightly inhibited or at least reduced. This could be related to the fact that M. marburgensis is usually grown at NH4+ concentrations of 20 to 40 mmol L− 138,40,53,54 which acts as the preferred nitrogen source, or that the tested NH4+ concentrations above 20 mmol L−1 physiologically down-regulates the nitrogenase activity20,60. NH4+ switch off can occur in methanogens. This means that there is an inactivation of N2-fixation once a thermodynamically superior nitrogen source is available20. A switch-off of the nitrogenase activity with addition of NH4+ as a superior and more easily accessible nitrogen source, as seen in M. maripaludis60 could not be fully confirmed here. However, during growth of M. maripaludis on Ala only a partial switch-off of the nitrogenase activity has been observed60. Thus, it might be possible that in M. marburgensis the uptake of Ala allows for N2-fixation in the presence of NH4+ (Supplementary Fig. 5). N2 fixation in the presence of NH4+ was studied e.g., in M. barkeri17 and in M. maripaludis60, but in both studies N2-fixation in the presence of NH4+ had not been observed. Except for our study, N2-fixation in the presence of NH4+ has only been reported in a single experiment61. In experiments with washed M. marburgensis biomass compared to non-washed biomass, metabolic expensive N2-fixation was proven even with higher NH4+ concentrations (Figs. 3 and 4). This might have occurred due to the slow growth and introduced stress because of the washing step. Thus, amino acid excretion could also be the reason for the partially inconsistent and higher HUR:CUR ratio and C-balances (Supplementary Table 3).

The results presented in this study confirm that M. marburgensis is a diazotrophic organism. However, we could not yet confirm earlier findings that the sole N-source of M. marburgenis can be N219. In independent unpublished experiments with M. marburgensis using N2 as sole source of nitrogen, the organism did also not grow or produce CH4 (Nevena Maslać, personal communication). We show that the N2 is converted by M. marburgensis during growth on H2/CO2/N2 in chemically defined minimal medium into proteinogenic amino acids (Fig. 5) which are excreted into the growth medium. One could argue that the amino acids were not actively or passively excreted. However, in a previous study it has been shown that cell lysis was not a substantial source of amino acid excretion by M. marburgensis35. In this study a variety of amino acids were excreted by M. marburgensis with the highest total amount of up to 7.5 µmol L−1 h−1 in early time points (Data sheet 1: HPLC Productivity). Interestingly, Ala seems to be consumed in later time points of 5%, 7.5% and 10% experiments (Fig. 5). This finding might provide insight for the varying NUR (Fig. 4), as NH4+ could hinder nitrogenase enzyme activity, whereas the utilization of Ala could switch to an intermediate regulatory response60.

Amino acid excretion rates of M. marburgensis under N2-fixing conditions can currently not compete with the genetically engineered and high amino acid producing organisms C. glutamicum and E. coli26. Highest concentrations of Glu reached 0.045 g L−1 compared to genetically modified C. glutamicum of 40 g L−1 (Table 1). Nevertheless, they succeeded to create a modified C. glutamicum from a wild type with no L-Lysine production to 0.6 to 4.0 g L−1 h−128. Furthermore, conventional amino acid excreting cell factories are engineered to only overproduce one specific amino acid and are, unlike M. marburgensis, not able to fix atmospheric N2 for their production26,29. Moreover, the carbon and energy substrate for E. coli and C. glutamicum are carbohydrates and M. marburgensis utilizes CO2 and H2. With the synthetic biology tools that have become available to genetically enhance methanogens55,62,63,64,65,66, some of these organisms may become cell factories for proteinogenic amino acid production.

Conclusions

This study sheds new light on the link between methanogenesis, biological N2-fixation, and proteinogenic amino acid excretion. We show the inherent industrial potential of M. marburgensis for amino acid excretion under N2-fixing conditions. The THpN2fix method can be used to determine N2-fixation rates of hydrogenotrophic, autotrophic, diazotrophic methanogens – without the need for GC measurements. Moreover, the THpN2fix methodology may serve as the basis for establishing high-throughput screening of methanogens and other gas-fermenting organisms where a pressure drop or increase occurs. This study has implications for research in microbial physiology, ecology, and biotechnology of amino acid excretion, methanogenesis and N2-fixation and may serve as basis for developing applications in gas fermentation and Archaea Biotechnology.

Data availability

The datasets generated and/or analysed during the current study are available in the PHAIDRA repository of Universität Wien, https://doi.org/10.25365/phaidra.515; https://doi.org/10.25365/phaidra.516.

References

Griffis, T. J. et al. Nitrous oxide emissions are enhanced in a warmer and wetter world. Proceedings of the National Academy of Sciences 114, 12081–12085 (2017).

Reay, D. S. et al. Global agriculture and nitrous oxide emissions. Nat. Clim. Change. 2, 410–416 (2012).

Wang, M. et al. Can sustainable ammonia synthesis pathways compete with fossil-fuel based Haber–Bosch processes? Energy Environ. Sci. 14, 2535–2548 (2021).

Snyder, C. S., Bruulsema, T. W., Jensen, T. L. & Fixen, P. E. Review of greenhouse gas emissions from crop production systems and fertilizer management effects. Agric. Ecosyst. Environ. 133, 247–266 (2009).

Kandemir, T., Schuster, M. E., Senyshyn, A., Behrens, M. & Schlögl, R. The Haber–Bosch process revisited: on the real structure and Stability of Ammonia Iron under Working conditions. Angew. Chem. Int. Ed. 52, 12723–12726 (2013).

Pfromm, P. H. Towards sustainable agriculture: Fossil-free ammonia. J. Renew. Sustain. Energy. 9, 034702 (2017).

Hink, L., Nicol, G. W. & Prosser, J. I. Archaea produce lower yields of N2O than bacteria during aerobic ammonia oxidation in soil. Environ. Microbiol. 19, 4829–4837 (2017).

Fernandez, L., Bertilsson, S. & Peura, S. Non-cyanobacterial diazotrophs dominate nitrogen-fixing communities in permafrost thaw ponds. Limnol. Oceanogr. 65, S180–S193 (2020).

Hu, Y. & Ribbe, M. W. Nitrogenase assembly. Biochim. et Biophys. Acta (BBA) - Bioenergetics. 1827, 1112–1122 (2013).

Maslać, N., Sidhu, C., Teeling, H. & Wagner, T. Comparative transcriptomics sheds light on remodeling of Gene expression during Diazotrophy in the Thermophilic Methanogen Methanothermococcus thermolithotrophicus. mBio 13, e02443–e02422 (2022).

Kneip, C., Lockhart, P., Voß, C. & Maier, U. G. Nitrogen fixation in eukaryotes – new models for symbiosis. BMC Evol. Biol. 7, 55 (2007).

Bae, H. S., Morrison, E., Chanton, J. P. & Ogram, A. Methanogens are major contributors to Nitrogen fixation in soils of the Florida Everglades. Appl. Environ. Microbiol. 84, e02222–e02217 (2018).

Leigh, J. A. Nitrogen fixation in methanogens: the archaeal perspective. Curr. Issues Mol. Biol. 2, 125–131 (2000).

Lie, T. J. et al. A genetic study of Nif-Associated genes in a Hyperthermophilic Methanogen. Microbiol. Spectr. 10, e0209321 (2022).

Mehta, M. P. & Baross, J. A. Nitrogen fixation at 92°C by a Hydrothermal Vent Archaeon. Science 314, 1783–1786 (2006).

Lyu, Z., Shao, N., Akinyemi, T., Whitman, W. B. & Methanogenesis Curr. Biol. 28, R727–R732 (2018).

Murray, P. A. & Zinder, S. H. Nitrogen fixation by a methanogenic archaebacterium. Nature 312, 284–286 (1984).

Fardeau, M. L., Peillex, J. P. & Belaïch, J. P. Energetics of the growth of Methanobacterium Thermoautotrophicum and Methanococcus thermolithotrophicus on ammonium chloride and dinitrogen. Arch. Microbiol. 148, 128–131 (1987).

Kessler, P. S., McLarnan, J. & Leigh, J. A. Nitrogenase phylogeny and the molybdenum dependence of nitrogen fixation in Methanococcus maripaludis. J. Bacteriol. 179, 541–543 (1997).

Kessler, P. S., Daniel, C. & Leigh, J. A. Ammonia switch-off of Nitrogen fixation in the Methanogenic Archaeon Methanococcus maripaludis: mechanistic features and requirement for the Novel GlnB homologues, NifI1 and NifI2. J. Bacteriol. 183, 882–889 (2001).

Payne, D., Spietz, R. L., Newell, D. L., Dijkstra, P. & Boyd, E. S. Influence of sulfide on diazotrophic growth of the methanogen Methanococcus maripaludis and its implications for the origin of nitrogenase. Commun. Biol. 6, 1–13 (2023).

Lobo, A. L. & Zinder, S. H. Diazotrophy and Nitrogenase Activity in the Archaebacterium Methanosarcina barkeri 227. Appl. Environ. Microbiol. 54, 1656–1661 (1988).

Ehlers, C., Veit, K., Gottschalk, G. & Schmitz, R. A. Functional organization of a single nif cluster in the mesophilic archaeon Methanosarcina mazei strain Gö1. Archaea 1, 143–150 (2002).

Veit, K. et al. Global transcriptional analysis of Methanosarcina mazei strain Gö1 under different nitrogen availabilities. Mol. Genet. Genomics. 276, 41–55 (2006).

Kinoshita, S. Amino-acid production by the fermentation process. Nature 240, 211–211 (1972).

Becker, J. & Wittmann, C. Systems and synthetic metabolic engineering for amino acid production – the heartbeat of industrial strain development. Curr. Opin. Biotechnol. 23, 718–726 (2012).

Becker, J., Zelder, O., Häfner, S., Schröder, H. & Wittmann, C. From zero to hero–design-based systems metabolic engineering of Corynebacterium glutamicum for L-lysine production. Metab. Eng. 13, 159–168 (2011).

Ding, X. et al. High-level and -yield production of L-leucine in engineered Escherichia coli by multistep metabolic engineering. Metab. Eng. 78, 128–136 (2023).

Hirasawa, T. & Shimizu, H. Recent advances in amino acid production by microbial cells. Curr. Opin. Biotechnol. 42, 133–146 (2016).

Tuo, J., Nawab, S., Ma, X. & Huo, Y. X. Recent advances in screening amino acid overproducers. Eng. Microbiol. 3, 100066 (2023).

Wendisch, V. F. Metabolic engineering advances and prospects for amino acid production. Metab. Eng. 58, 17–34 (2020).

Kurpejović, E. et al. Metabolic engineering of Corynebacterium glutamicum for l-tyrosine production from glucose and xylose. J. Biotechnol. 363, 8–16 (2023).

Pfeifer, K. et al. Archaea Biotechnology. Biotechnol. Adv. 47, 107668 (2021).

Rittmann, S. K. M. R., Pfeifer, K., Palabikyan, H., Ergal, İ. & Schuster, B. Archaea Der Biotechnol. Biospektrum 27, 96–98 (2021).

Taubner, R. S. et al. Lipidomics and Comparative Metabolite Excretion Analysis of Methanogenic Archaea Reveal Organism-Specific Adaptations to Varying Temperatures and Substrate Concentrations. mSystems 8, e01159-22 (2023).

Taubner, R. S. et al. Membrane lipid composition and amino acid excretion patterns of Methanothermococcus okinawensis grown in the Presence of inhibitors detected in the Enceladian Plume. Life 9, 85 (2019).

Abdel Azim, A. et al. The physiology of trace elements in biological methane production. Bioresour. Technol. 241, 775–786 (2017).

Bernacchi, S., Rittmann, S., Seifert, H., Krajete, A., Herwig, C. & A. & Experimental methods for screening parameters influencing the growth to product yield (Y(x/CH4)) of a biological methane production (BMP) process performed with Methanothermobacter marburgensis. AIMS Bioeng. 1, 72–86 (2014).

Mauerhofer, L. M. et al. Physiology and methane productivity of Methanobacterium thermaggregans. Appl. Microbiol. Biotechnol. 102, 7643–7656 (2018).

Mauerhofer, L. M. et al. Hyperthermophilic methanogenic archaea act as high-pressure CH4 cell factories. Commun. Biology. 4, 289 (2021).

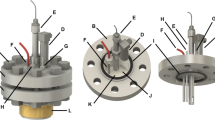

Pappenreiter, P. A., Zwirtmayr, S., Mauerhofer, L. M., Rittmann, S. K. M. R. & Paulik, C. Development of a simultaneous bioreactor system for characterization of gas production kinetics of methanogenic archaea at high pressure. Eng. Life Sci. 19, 537–544 (2019).

Rittmann, S. K. M. R. A critical Assessment of Microbiological Biogas to biomethane upgrading systems. Adv. Biochem. Eng. Biotechnol. 151, 117–135 (2015).

Rittmann, S. K. M. R., Seifert, A. H. & Krajete, A. Biomethanisierung — ein Prozess Zur Ermöglichung Der Energiewende? Biospektrum 20, 816–817 (2014).

Rittmann, S. K. M. R., Seifert, A. H. & Bernacchi, S. Kinetics, multivariate statistical modelling, and physiology of CO2-based biological methane production. Appl. Energy. 216, 751–760 (2018).

Seifert, A. H., Rittmann, S., Bernacchi, S. & Herwig, C. Method for assessing the impact of emission gasses on physiology and productivity in biological methanogenesis. Bioresour. Technol. 136, 747–751 (2013).

Seifert, A. H., Rittmann, S. & Herwig, C. Analysis of process related factors to increase volumetric productivity and quality of biomethane with Methanothermobacter marburgensis. Appl. Energy. 132, 155–162 (2014).

Rittmann, S., Seifert, A. & Herwig, C. Essential prerequisites for successful bioprocess development of biological CH4 production from CO2 and H2. Crit. Rev. Biotechnol. 35, 141–151 (2015).

Rittmann, S. K. M. R. et al. Method for Producing Amino Acids with Methanogenic Microorganisms in a Bioreactor. (2023).

Rittmann, S. K. M. R. et al. Method for Producing Amino Acids in a Bioreactor with Methanogenic Microorganisms. (2023).

Rittmann, S. K. M. R. et al. Method for Producing Amino Acids in a Bioreactor. (2023).

Rittmann, S. K. M. R. et al. Method for Fermentatively Producing Norvaline. (2023).

Belay, N., Sparling, R. & Daniels, L. Dinitrogen fixation by a thermophilic methanogenic bacterium. Nature 312, 286–288 (1984).

Taubner, R. S. & Rittmann, S. K. M. R. Method for Indirect quantification of CH4 production via H2O production using Hydrogenotrophic Methanogens. Front. Microbiol. 7, 532 (2016).

Rittmann, S., Seifert, A. & Herwig, C. Quantitative analysis of media dilution rate effects on Methanothermobacter marburgensis grown in continuous culture on H2 and CO2. Biomass Bioenerg. 36, 293–301 (2012).

Sarmiento, F. B., Leigh, J. A. & Whitman, W. B. Genetic systems for hydrogenotrophic methanogens. Meth Enzymol. 494, 43–73 (2011).

Reischl, B., Ergal, İ. & Rittmann, S. K.-M. R. Biohydrogen production characteristics of Desulfurococcus amylolyticus DSM 16532. Int. J. Hydrog. Energy. 43, 8747–8753 (2018).

Kandeler, E. & Gerber, H. Short-term assay of soil urease activity using colorimetric determination of ammonium. Biol. Fert Soils. 6, 68–72 (1988).

Wang, X., Conway, W., Burns, R., McCann, N. & Maeder, M. Comprehensive Study of the hydration and dehydration reactions of Carbon Dioxide in Aqueous Solution. J. Phys. Chem. A. 114, 1734–1740 (2010).

Kral, T. A., Bekkum, C. R. & McKay, C. P. Growth of Methanogens on a Mars Soil Simulant. Orig Life Evol. Biosph. 34, 615–626 (2004).

Lie, T. J. & Leigh, J. A. Regulatory response of Methanococcus maripaludis to alanine, an intermediate nitrogen source. J. Bacteriol. 184, 5301–5306 (2002).

Nishizawa, M., Miyazaki, J., Makabe, A., Koba, K. & Takai, K. Physiological and isotopic characteristics of nitrogen fixation by hyperthermophilic methanogens: key insights into nitrogen anabolism of the microbial communities in Archean hydrothermal systems. Geochim. Cosmochim. Acta. 138, 117–135 (2014).

Fink, C. et al. A Shuttle-Vector System Allows Heterologous Gene Expression in the Thermophilic Methanogen Methanothermobacter thermautotrophicus ∆H. mBio 12, e0276621 (2021).

Metcalf, W. W., Zhang, J. K., Apolinario, E., Sowers, K. R. & Wolfe, R. S. A genetic system for Archaea of the genus Methanosarcina: Liposome-mediated transformation and construction of shuttle vectors. PNAS 94, 2626–2631 (1997).

Nayak, D. D. & Metcalf, W. W. Cas9-mediated genome editing in the methanogenic archaeon Methanosarcina acetivorans. PNAS 114, 2976–2981 (2017).

Walters, A. D., Smith, S. E. & Chong, J. P. J. Shuttle Vector System for Methanococcus maripaludis with Improved Transformation Efficiency. Appl. Environ. Microbiol. 77, 2549–2551 (2011).

Li, J. et al. Genetic and metabolic engineering of Methanococcus spp. Curr. Res. Biotechnol. 5, 100115 (2023).

Sawada, K., Zen-in, S., Wada, M. & Yokota, A. Metabolic changes in a pyruvate kinase gene deletion mutant of Corynebacterium glutamicum ATCC 13032. Metab. Eng. 12, 401–407. https://doi.org/10.1016/j.ymben.2010.01.004 (2010).

Vogt, M. et al. Pushing product formation to its limit: Metabolic engineering of Corynebacterium glutamicum for l-leucine overproduction. Metab. Eng. 22, 40–52. https://doi.org/10.1016/j.ymben.2013.12.001 (2014).

Park, S.H. et al. Metabolic engineering of Corynebacterium glutamicum for L-arginine production. Nat. Commun. 5, 4618. https://doi.org/10.1038/ncomms5618 (2014).

Lv, Q. et al. Enhancing lglutamine production in Corynebacterium glutamicum by rational metabolic engineering combined with a two-stage pH control strategy. Biores. Technol. 341, 125799. https://doi.org/10.1016/j.biortech.2021.125799 (2021).

Zhang, Y. et al. Metabolic engineering of Corynebacterium glutamicum WM001 to improve l-isoleucine production. Biotechnol. Appl. Biochem. 68, 568–584. https://doi.org/10.1002/bab.1963 (2021).

Li, Y. et al. Metabolic engineering of Corynebacterium glutamicum for methionine production by removing feedback inhibition and increasing NADPH level. Antonie van Leeuwenhoek 109, 1185–1197. https://doi.org/10.1007/s10482-016-0719-0 (2016).

Zhang, X. et al. High-yield production of l-serine through a novel identified exporter combined with synthetic pathway in Corynebacterium glutamicum. Microbial Cell Factories 19, 115. https://doi.org/10.1186/s12934-020-01374-5 (2020).

Zhang, X., Jantama, K., Moore, J.C., Shanmugam, K.T. & Ingram, L.O. Production of l-alanine by metabolically engineered Escherichia coli. Appl. Microbiol. Biotechnol. 77, 355–366. https://doi.org/10.1007/s00253-007-1170-y (2007).

Acknowledgements

Ece Kocabiyk is acknowledged for helping with cultivations. Thanks to Logan Hodgskiss for proofreading the article. Open access funding by the University of Vienna.

Funding

The Österreichische Forschungsförderungsgesellschaft (FFG) funded this research through the NitroFix project (grant 859293).

Author information

Authors and Affiliations

Contributions

BR, BS and HP conducted closed batch experiments and GC measurements. BM and BR performed amino acid analysis, BR performed NH4+ measurements. BR visualized data. SK-MRR conceived, designed and supervised research. BR, BS, CF and SK-MRR wrote the manuscript. SK-MRR acquired funding.

Corresponding author

Ethics declarations

Competing interests

BR, CF and SK-MRR declare competing financial interests due to their employment at Arkeon GmbH. SK-MRR declares competing financial interests as shareholder of Arkeon GmbH. All other authors declare not to have any competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Reischl, B., Schupp, B., Palabikyan, H. et al. Quantitative analysis of amino acid excretion by Methanothermobacter marburgensis under N2-fixing conditions. Sci Rep 15, 3755 (2025). https://doi.org/10.1038/s41598-025-87686-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-87686-1

Keywords

This article is cited by

-

Quantitative analysis of amino acid excretion and consumption by Methanothermobacter marburgensis in fed-batch cultivation mode

Amino Acids (2026)

-

Method for automated high performance closed batch cultivation of gas-utilizing methanogens

AMB Express (2025)

-

A high-pressure bioreactor system for the cultivation of Methanothermobacter marburgensis on advanced growth media for sustainable energy applications

Scientific Reports (2025)

-

hEDTA and EDDS as sustainable and harmless alternatives to NTA as trace metal chelators in Methanothermobacter marburgensis cultivation

Extremophiles (2025)