Abstract

Steel Shear Walls (SSWs) are known as structures that dampen the seismic loads like earthquakes in every construction, especially in tall buildings. The SSW contains three critical elements; beam, column, and infill plate. These elements have a significant effect on the seismic performance of the SSWs. The infill plate of SSW is important due to the absorption of the induced external energies. The current research paper studied different configurations of the sandwich panels with trapezoidal corrugated cores as the stiffeners inside the infill plate of the SSWs numerically in the presence of cyclic loading conditions. Two directions the horizontal and vertical are considered for the stiffeners. Also, various numbers of rows and columns are assumed for the stiffeners. The initial model was validated with the published experimental data. According to the average values that obtained, the horizontally and vertically oriented sandwich panels increase the plastic dissipation energy of the SSWs by around 156% and 196%, respectively. The outputs derived from this study will help to increase the SSWs’ strength in the built constructions by using sandwich panels inside them. Because the sandwich panels have low weight and high strength compared to the other stiffening systems.

Similar content being viewed by others

Introduction

A shear wall is a structural component that resists forces applied laterally, or in a direction perpendicular to the wall’s plane1. Shear walls resist loads because of cantilever action in thin wall situations when there is greater flexural deformation2. Put otherwise, shear walls are the vertical components of the system that resist horizontal forces. The infill steel plate in the Steel Shear Walls (SSWs), which is joined to the steel beams and columns by any connecting method, is frequently the main component resistant to lateral forces3. This structural system has a high initial stiffness, strong ductility, and a high ultimate strength4. Furthermore, the industry is embracing it because of its many advantages, such as its strong seismic performance, lightweight nature, rapid construction, and adaptable structural building design5. As a result, the SSWs are widely employed across numerous nations and have a reputation for being highly resilient to wind loads and earthquakes. One of the applications of the SSWs is using them inside the bridges6. Also, using some materials such as polystyrene geofoam7 or fiber reinforced polymers8 inside the SSWs can be useful in damping the exerted loads. Besides, other types of SSWs’ configurations can be implemented; soil-steel composite bridges, which are an innovative and cost-effective alternative to traditional reinforced concrete bridges. These advanced structural solutions offer remarkable advantages, including rapid construction, reduced costs, and the ability to meet stringent design and safety requirements comparable to conventional bridge designs9.

As a matter of fact, the infill plate is considered the core of much research that has been conducted, recently. Here, some of the studies on the SSWs are briefly described to provide a better understanding of them. The increased length of the infill plate allowed for better energy dissipation, and Mansouri et al.‘s10 confirmation demonstrated that the infill plate successfully dissipated the higher applied energy levels. Using 57 computer models, Paslar et al.11 investigated the connection between a steel plate shear wall’s border sections and the infill plate. The obtained results showed that, in comparison to the column-only connected joint, the beam-only connected connection decreased the shear force resistive in the shear wall. Lu et al.12 suggested that the seismic load-resisting mechanism in steel structures is self-centering steel plate shear walls with slits. Finite element research confirmed the reported shear walls’ capability. When compared to normal shear walls, Azandariani et al.‘s study13 showed how successful the partial plate-column connection is in steel plate shear walls. The main considerations for the CSSWs in the field of corrugated infill plates are the corrugation shape14, corrugation angle15, fillet size, junction sorts16, etc. Three kinds of SPSWs were postulated by Emami et al.17: flat infill plates, horizontal corrugated infill plates, and vertical infill plates. In comparison to flat steel shear walls, the results showed that the corrugation pattern might enhance the cyclic properties of the SPSWs. Notably, corrugated geometries within structural systems, particularly trapezoidal core configurations, demonstrate significant potential for optimizing energy absorption mechanisms in sandwich panel assemblies under static loading18 and impact loading conditions19. Abbas and Allawi20 conducted a comprehensive experimental and numerical investigation of composite concrete-steel plate shear walls subjected to axial loading. The research findings revealed significant variations in structural behavior based on aspect ratio. Specifically, walls with a high aspect ratio demonstrated notably reduced performance (large flexural deformations) compared to walls with a low aspect ratio.

Different forms of infill plates, such as X-shaped infill plates, have recently been introduced, and a thorough analysis of their responses to seismic loading conditions has been conducted. A unique version of SPSW with X-shaped restrainers was created by Cao et al.21. The test findings indicate that the addition of restraints can reduce the out-of-plane buckling of the steel plate, offer a more comprehensive hysteresis curve, and improve the structure’s energy dissipation capacity. Yu et al.22 looked into the hysteresis characteristics of steel plate shear walls with cross-shaped supports. The results demonstrated that using cross-bracing instead of welding out-of-plane stiffeners can improve the overall shear resistance, energy dissipation, and ductility. Valizadeh et al.23 built a thin SPSW with a circular hole in the center of the infill plate. The results showed that this kind of SPSW maintained constant hysteresis performance even at huge displacements.

Here, different sandwich panels with trapezoidal cores are considered stiffeners in the infill plates. Then, the seismic performance of them is studied through the finite element method. To verify the modeled SSWs, the published experimental results are implemented. Different responses are evaluated and reported in the results and discussions section. As stated earlier, the current research paper is conducted numerically, thus, some experimental data are needed. The next section contains the data about the performed experiments and related results. The findings of this research offer valuable insights for enhancing the structural integrity of sandwich wall (SSW) systems in architectural and construction applications. Sandwich panels present a compelling alternative to traditional stiffening systems, characterized by their exceptional strength-to-weight ratio.

Experimental data

Any numerical study needs some basic information and the current paper uses the experimental data and given results by Emami et al.17. In17, the researcher examined the seismic performance of three types of Steel Shear Walls (SSWs); flat, horizontal corrugated, and vertical corrugated. The results indicated that the corrugation pattern in the infill plate can improve the cyclic behavior of the SSWs. The flat SSW that is tested in17 is presented in Fig. 1. The SSW consists of three main elements and the mechanical properties of them are reported in Table 1.

Flat SSW that is prepared and tested by Emami et al.17.

More detailed information about the dimensions and types of elements that have been used in the presented SSW can be found in17. One of the most important aspects of cyclic tests is the cyclic loading sequences that should be applied to the designed structure. The applied cyclic loading that is applied to the prepared SSW is depicted in Fig. 2. Based on this figure, the displacement values are increased sequentially to provide the earthquake phenomenon. Emami et al.17 used AC154 protocol for applying the earthquake loading condition.

Cyclic loading condition that was considered by Emami et al.17.

The main concepts of this paper are classified in the next section to supply the targets and models.

Models and target

Using stiffeners in the infill plate of SSWs can be an appropriate task because these mechanisms absorb higher amounts of induced energies on the SSWs. As it is clear from the literature review, most of the used stiffeners were in different shapes, while, using sandwich panels inside the shear walls was proposed for the first time. It should be noted that sandwich panels have low weight and high strength compared to the other types of stiffeners and they can be consisted of various types of cores even the lattice ones24. In this context, a trapezoidal stiffener (as depicted in Fig. 3) is incorporated within the infill plate of the Steel Shear Wall (SSW). This geometric configuration can be characterized as a sandwich panel, typically comprising two exterior shells and a corrugated core. Initially, it is anticipated that such sandwich panels will demonstrate superior capacity for absorbing external energy compared to traditional structural configurations.

The presented configuration in Fig. 3 is used in different manners inside the SSWs. Figure 4; Table 2 show the modeled configurations and nomenclature of the samples, respectively. As seen in Fig. 4, one, two, three, and four configurations of the presented sandwich panel are implemented inside the SSW. Besides, these manners are used in two directions of horizontal and vertical.

Now, the modeled samples are imported to the finite element analysis process and seismic loading sequences are applied to them to see how the sandwich panels act in the SSWs in the presence of the seismic loading conditions. Then, various cyclic characteristics of the outcomes are evaluated and reported. The next section relates to the finite element method and detailed information.

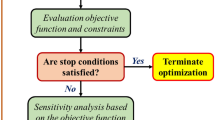

Finite element method

The Finite Element Method (FEM) is a widely used numerical method for solving differential equations in mathematical modeling and engineering25. Typical research areas include the traditional fields of electromagnetic potential, heat transfer, fluid flow, mass transport, and structural analysis26. Information from other knowledge domains, such as design, production, and IT, is integrated with FEM expertise. It is an analyst’s responsibility to assess and verify designs. Three steps make up the initial phases of FEM: issue classification, discretization, and modeling. In the FEM environment (Abaqus CAE27), the designed SSWs were subjected to the seismic loading sequences28. Several SSW variants were built in the FEM’s part modulus in order to achieve this. Since the shear wall consisted of multiple parts, including a beam, infill plate, and column, the manufactured elements were put together. It was also anticipated that they would possess the materials’ mechanical qualities (see Table 1). Based on the mechanical characteristics of the elements, the isotropic assumption was considered for the mentioned elements. Also, the mechanical properties of the SSW’s elements were assumed point by point from the stress-strain curves of the basic material. While the bottom of the SSW was permanent (fully fixed in different directions), the upper beam on one side was loaded cyclically (Fig. 5a). These considerations were according to the main experimental procedures stated in section II. The purpose of this process was to ensure the boundary conditions. To analyze problems involving severe plastic deformation and cyclic loading with load reversal, it is essential to use explicit dynamic steps in the simulation. Thus, the dynamic explicit solver was assumed to evaluate the cyclic characteristics such as hysteresis behavior. The previously outlined procedures were used to mesh apart the intended shear walls (see Fig. 5b). The right number and sizes of S4R element types were also determined for the shear walls using the mesh convergence analysis by considering the reaction forces of a basic model. The frame components’ final diameters were 5 cm, while the infill plate’s diameter was 2.5 cm. In these sizes, the change in the reaction forces was minor, hence, they were selected in meshing apart the models.

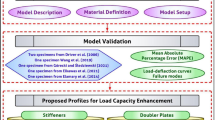

Verification of FEM

Researchers can assess the precision of a Finite Element Method (FEM) model by comparing its simulated outcomes with experimental data. Following the FEM implementation according to the guidelines outlined in section IV, the hysteresis curves for the USSW were generated through the model and subsequently compared with the experimentally obtained results17. This comparative analysis enabled researchers to validate the accuracy and reliability of the FEM results. Figure 6 presents a visual representation of both the empirical and theoretical hysteresis curve evaluations. The comparative analysis demonstrated that the FEM model could predict the Flat Steel Shear Wall’s hysteresis curves with remarkable precision, exhibiting minimal deviation from the experimental data. It is noteworthy that the discrepancy between the experimental and numerical results was approximately 20% for the worst condition (i.e., when the maximum load was applied from the presented curves in Fig. 2). This suggests that employing the simulated steel shear wall (Fig. 4; Table 2) with various corrugation patterns could produce the required results. The findings presented in the next section and its pertinent subsections will also be a reliable resource for engineers and construction designers.

Hysteresis curves of the experimental results17 and FEM.

Results and discussion

This section consists of the evaluated results from the FEM and corresponding discussions. different contours are prepared and presented in this section to see how the sandwich panels with the corrugated cores and their orientation affect the stress and strain distributions.

Stress distribution

Stress distribution is a way to find the stress concentration zones. These zones can be identified as failure vicinities from the mechanical strength point of view. The stress distributions for different studied SSWs’ configurations (see Table 2) are evaluated and depicted in Fig. 7. In this figure, the stresses are depicted in the Pa unit. One of the extracted data from this figure is the higher amounts of stress in the corners of the SSWs. Based on the stated reason earlier in this paragraph, the joining point between the columns and beams is the most susceptible zone to failure.

Conversely, as the number of sandwich panels within the infill plate increases, the stress values demonstrate a notable reduction. This indicates that steel shear walls with stiffening system of sandwich exhibit superior performance under cyclic loading conditions compared to the USSW sample. Furthermore, an important observation from the stress distribution contours is that vertically oriented sandwich panels yield enhanced performance, both in terms of stress distribution pattern and overall stress value magnitudes.

The out-of-plane distribution is discussed in the next subsection.

Out-of-plane displacement and plastic strain

It is crucial to recognize that during seismic loading sequences, different sections of the shear walls, particularly the middle of the infill plate, experience the out-of-plane displacement phenomenon. This characteristic can potentially lead to structural failure or even fracture of the infill plate. Figure 8 illustrates the out-of-plane displacement distribution across the modeled Steel Shear Walls (SSWs). Based on the results presented in the figure, vertically oriented sandwich panels with corrugated cores demonstrate lower out-of-plane displacement compared to their horizontally oriented counterparts. While the Unstiffened Steel Shear Wall (USSW) sample exhibits higher out-of-plane displacement relative to stiffened SSWs with sandwich panels, the SSSW-H2 configuration paradoxically shows even greater out-of-plane displacement than the USSW.

Notably, as depicted in Fig. 8, the concentration of out-of-plane displacement is predominantly located in the middle of the USSW’s infill plate. Incorporating sandwich panels as stiffeners in the SSWs offers a significant advantage by providing more effective dispersion of the out-of-plane displacement contour, potentially mitigating the risk of structural failure.

As a matter of fact, higher out-of-plane displacement led to earlier failure. Hence, vertically oriented sandwich panels have better cyclic performance in comparison to horizontally oriented ones.

Following the analysis of out-of-plane displacement contours, the plastic strain contours derived from finite element simulations are presented. As illustrated in Fig. 9, which depicts the plastic strain distributions of the studied SSWs, the plastic strain is uniformly distributed across the entire infill plate of the USSW sample.

However, implementing a sandwich panel stiffening system offers a notable improvement by providing a more effective dispersion of plastic strain distribution over the infill plate. Consequently, the concentration of plastic strain is redirected towards the corners of the structure. This redistribution enables the columns to play a more significant role in managing and controlling the seismic loading sequences, potentially enhancing the overall structural resilience and performance during dynamic loading conditions.

Till now, the presented results and corresponding discussions relate to static loading conditions. next results discuss about the cyclic behavior of the studied SSWs.

Hysteresis and strength

When a structural component is subjected to cyclic loading with varying amplitudes, the hysteresis behavior emerges. This phenomenon results in diverse cyclic performances within structures. Following the application of seismic loading sequences to the modeled SSWs, the hysteresis curves are obtained and visualized in Fig. 10.

Two critical aspects of the hysteresis curves are the maximum force and total enclosed area. These characteristics illuminate how designed systems absorb exerted energy under cyclic loading conditions. Analyzing Fig. 10 reveals that the hysteresis curve of the USSW demonstrates the lowest internal area compared to the stiffened SSWs. Incorporating stiffening sandwich panels within the infill plates significantly enhances energy absorption capacity. The primary rationale behind this enhancement lies in the sandwich panels’ extensibility and inherent resistance to failure. Moreover, the geometric configuration and internal structure of the sandwich panels function as stress-absorbing zones, necessitating substantially higher stress application to induce significant structural compromise.

Consequently, utilizing sandwich panels as a stiffening system emerges as an effective methodology for augmenting SSWs’ structural strength. Additional considerations include the orientation and quantity of sandwich panels. Comparative analysis between vertical and horizontal panel orientations indicates that vertically oriented configurations yield superior peak loads and larger internal areas. This observation suggests that vertically oriented sandwich panels require greater exerted energies for deformation, whereas horizontally oriented panels exhibit more pronounced deformation under compressive loading conditions.

Given the complexity of comparing hysteresis curves across different sandwich panel quantities, the strength of the modeled SSWs is comprehensively evaluated and presented in Fig. 11.

Figure 11 shows the strength-drift angle curves obtained for the USSW and stiffened SSWs under the assumed loading conditions. By joining the peak loads in the hysteresis curves, the maximum strength of the SSW can be calculated. Also, the drift angle is calculated by dividing the horizontal displacement of the SSW into the column’s length.

Based on Fig. 11, the minimum and maximum strength values correspond to the SSSW-V3 and SSSW-H4 samples, respectively. Furthermore, the minimum drift angle is associated with the USSW sample, which can be attributed to the sample’s inherently brittle mechanical behavior. It is noteworthy that three of the sandwich panels demonstrate superior performance from a strength perspective. However, an increase in the number of sandwich panels may lead to an escalation of stress concentration zones, consequently resulting in reduced strength when four panels are utilized.

Plastic dissipation energy

When a structure is subjected to seismic loading sequences, the designed construction dissipates and absorbs a portion of the applied forces as energy. A higher energy absorption capacity indicates that the structure possesses enhanced capability to attenuate and dampen external dynamic loads.

There are two mechanisms for absorbing external energies: fracture and plastic deformation. This implies that the external energies must be dissipated within the system. When exerted energies generate micro-cracks within the structure, subsequent loading sequences can propagate these micro-cracks, ultimately leading to fracture. Conversely, when external loads induce plastic deformation through the material’s inherent plasticity, the plastic deformation transforms into plastic dissipation energy. This phenomenon mitigates structural failure and enhances the cyclic life of the designed construction. Consequently, the plastic dissipation energies of the studied sandwich structures in the current research are extracted and presented in Figs. 12 and 13.

In Fig. 12, the plastic dissipation energies versus the drift angles are plotted. The SSSW-V3 sample has the best performance from this figure’s point of view. To provide a better understanding of the presented results in Fig. 12, the maximum values of the plastic dissipation energies are evaluated and illustrated as bar charts in Fig. 13.

Based on Fig. 13, the average plastic dissipation energy for the horizontally and vertically oriented sandwich panels is 16.08 and 18.61 KJ, respectively. The least plastic dissipation energy relates to the USSW sample with the value of 6.28 KJ. According to the average values that mentioned earlier, the horizontally and vertically oriented sandwich panels increase the plastic dissipation energy of the SSWs by around 156% and 196%, respectively. Considering the horizontal sandwich panels, the best behavior is detected for the SSSW-H3 sample, however, the SSSW-H4 sample shows the worst performance. On the other side, the SSSW-V3 and SSSW-V1 presented the best and worst conditions from the plastic dissipation point of view, respectively.

To elucidate the results, several critical aspects must be considered: the stretch phenomenon and stress concentration zones. These aspects potentially influence the maximum plastic dissipation energies obtained. When comparing horizontal and vertical sandwich panels, the stretching of vertically oriented sandwich panels as stiffening systems results in higher plastic dissipation energy. This is because when seismic loads are applied to the sandwich structure, horizontal displacement is anticipated, causing vertical stiffeners to undergo stretching while horizontal stiffeners experience compression. As previously noted, steel serves as the primary material for both the SSWs and stiffeners, and steel exhibits superior plastic deformation characteristics during stretching. Consequently, vertically oriented stiffeners demonstrate higher plastic dissipation energy and enhanced cyclic performance compared to their horizontally oriented counterparts.

The stress concentration zones in the SSSW-H4 and SSSW-V4 may be realized as the reason for reducing the plastic dissipation energy in the studied SSWs.

The research findings demonstrate that incorporating sandwich panel stiffeners within structural sandwich walls (SSWs) offers significant potential for improving structural reliability and seismic performance of built environments. While the integration of these innovative stiffeners presents substantial benefits, several critical challenges must be carefully addressed. The welding processes associated with sandwich panel installation can induce residual stresses within the SSWs, necessitating comprehensive post-fabrication treatments to mitigate potential structural compromises. Critically, the utilization of sandwich infill plates presents a dual advantage. These lightweight structural elements not only enhance the overall mechanical performance of the walls but also substantially reduce the total structural weight. From a seismic engineering perspective, this weight reduction is particularly advantageous, as lighter structures demonstrate improved dynamic response and enhanced resilience during seismic events.

A critical component of scientific research involves comparative analysis with previously published investigations. Tan et al.29 investigated cyclic behavior enhancement of SSWs through the implementation of buckling restrainers on infill plates. Comparative analysis between their findings and the present study revealed distinct performance characteristics: while their research demonstrated maximum displacements of approximately 30 mm, the current investigation utilizing sandwich panel integration achieved substantially higher displacement values, corroborated by drift angle measurements. Significantly, Sadeghi et al.30 investigated the combination of grid stiffeners and metallic yielding dampers in SSWs through finite element analysis. Their integrated system demonstrated superior seismic performance compared to the sandwich panel configuration examined in the present study. Nevertheless, the sandwich panel system exhibited comparable performance metrics relative to their published results. Additionally, Tong et al.31 conducted research utilizing ultra-high toughness cementitious composites in SSWs, analyzing their cyclic performance characteristics. The results obtained in the present investigation demonstrated comparable performance parameters to those reported in their study.

A significant economic advantage of the proposed methodology lies in its manufacturing efficiency compared to alternative approaches. The fabrication of sandwich panels requires only conventional machining processes, minimizing production complexity and associated costs.

Conclusions

Using Steel Shear Walls (SSWs) in steel constructions as an energy-damping system is an appropriate task. SSW has some elements named beam, column, and infill plate. This research addresses a significant advancement in SSW design by investigating the application of sandwich panels with corrugated cores as stiffening elements within the infill plate. By employing numerical modeling techniques, the study systematically examines the cyclic behavior of these enhanced structural configurations under two distinct panel orientations; horizontal and vertical. Through numerical analysis, the research seeks to contribute meaningful knowledge to the field of structural engineering, offering potential strategies for improving the seismic resilience and energy dissipation capabilities of steel construction systems. Key objectives include:

-

FEM simulation was validated through experimental verification. The comparative analysis demonstrated an excellent correlation between computational modeling and empirical results, thereby establishing the model’s credibility and reproducibility.

-

Using stiffening systems inside the infill plate provides good dispersion of the stress and strain contours in comparison to the unstiffened SSW.

-

Vertically oriented stiffeners demonstrated superior mechanical characteristics compared to their horizontally oriented counterparts. This notable performance difference can be attributed to the complex material stretching phenomenon occurring within the structural configuration.

-

The samples which have three stiffeners inside the infill plate present a better performance from the hysteresis point of view.

-

The sandwich panels inside the SSWs acted like a damping system which absorbed the exerted energy by consuming the exerted cyclic loads in the form of plastic dissipation energy.

-

The average plastic dissipation energy for the horizontally and vertically oriented sandwich panels is 16.08 and 18.61 KJ, respectively. The least plastic dissipation energy relates to the USSW sample with the value of 6.28 KJ.

While the current research provides numerical insights into the structural sandwich wall performance, future investigations should prioritize experimental validation to comprehensively address the proposed methodological approach which compromises the manufacturing challenges. Using various shapes of structures that increase the energy absorption process will be a valuable issue. The transition from numerical modeling to experimental implementation will inevitably reveal nuanced challenges inherent in practical applications.

Data availability

The data that support the findings of this study are available from Shuna Zhang but restrictions apply to the availability of these data, which were used under license for the current study, and so are not publicly available. Data are however available from the authors upon reasonable request and with permission of Shuna Zhang.

References

Resmi, R. & Roja, S. Y. A review on performance of shear wall. Int. J. Appl. Eng. Res. 11, 369–373 (2016).

Goel, R. K. & Chopra, A. K. Period formulas for concrete shear wall buildings. J. Struct. Eng. 124, 426–433 (1998).

Kim, H-S. & Lee, D-G. Analysis of shear wall with openings using super elements. Eng. Struct. 25, 981–991 (2003).

Roberts, T. M. Seismic resistance of steel plate shear walls. Eng. Struct. 17, 344–351 (1995).

Eatherton, M. Design and construction of steel plate shear walls. Proc. Eighth US Natl. Conf. Earthq. Eng. 18–22 (2006).

Maleska, T. & Beben, D. Effect of the soil cover depth on the seismic response in a large-span thin-walled corrugated steel plate bridge. Soil. Dyn. Earthq. Eng. 166, 107744 (2023).

Maleska, T., Beben, D., Vaslestad, J. & Sergei Sukuvara, D. Application of EPS Geofoam below soil–steel composite bridge subjected to seismic excitations. J. Geotech. Geoenviron. Eng. 150, 4024115 (2024).

Du, Y. et al. Behavior of steel plate shear walls reinforced with stiffened FRP plates. Thin-Walled Struct. 204, 112236 (2024).

Maleska, T. & Beben, D. Behaviour of soil–steel composite bridges under strong seismic excitation with various boundary conditions. Materials (Basel) 16, 650 (2023).

Mansouri, I., Arabzadeh, A., Farzampour, A. & Hu, J. W. Seismic behavior investigation of the steel multi-story moment frames with steel plate shear walls (2020).

Paslar, N., Farzampour, A. & Hatami, F. Infill plate interconnection effects on the structural behavior of steel plate shear walls. Thin-Walled Struct. 149, 106621 (2020).

Lu, J., Zhang, H. & Yu, S. Study on seismic behaviors of self-centering steel plate shear walls with slits. J. Constr. Steel Res. 185, 106878 (2021).

Azandariani, M. G. et al. Investigation of performance of steel plate shear walls with partial plate-column connection (SPSW-PC). Steel Compos. Struct. Int. J. 39, 109–123 (2021).

Yu, Y., Lin, S., Zhao, F., Tian, P. & Jiang, L. A built-up type horizontally corrugated steel plate shear wall with a special shape. Eng. Struct. 250, 113458 (2022).

Bahrebar, M. et al. Perforated Steel Plate Shear Walls with Curved Corrugated webs under Cyclic Loading. Structures vol. 24 600–609 (Elsevier, 2020).

Biswal, A., Prasad, A. M. & Sengupta, A. K. Study of shear behavior of grouted vertical joints between precast concrete wall panels under direct shear loading. Struct. Concr. 20, 564–582 (2019).

Emami, F., Mofid, M. & Vafai, A. Experimental study on cyclic behavior of trapezoidally corrugated steel shear walls. Eng. Struct. 48, 750–762 (2013).

Lashgaroo, M., Dadrasi, A., Parvaneh, V. & Taghipoor, H. Optimizing energy absorption and peak force in metal/glass fiber sandwich panels with trapezoidal cores. Sci. Rep. 14, 25371 (2024).

Sefidi, M., Taghipoor, H. & Damghani Nouri, M. Experimental crashworthiness analysis of corrugated-core sandwich panels under impact loading. Ships Offshore Struct. 1–14 (2024) .

Abbas, J. L. & Allawi, A. A. Experimental and numerical investigations of composite concrete–steel plate shear walls subjected to axial load. Civ. Eng. J. 5, 2402–2422 (2019).

Cao, Z., Wang, Z., Du, P., Liu, H. & Fan, F. Research on steel plate shear walls stiffened with X-shaped restrainers: hysteretic behavior and effect of height-to-thickness ratio of steel plate. Thin-Walled Struct. 144, 106316 (2019).

Yu, J-G., Feng, X-T., Li, B. & Hao, J-P. Cyclic performance of cross restrained steel plate shear walls with transverse braces. Thin-Walled Struct. 132, 250–264 (2018).

Valizadeh, H., Sheidaii, M. & Showkati, H. Experimental investigation on cyclic behavior of perforated steel plate shear walls. J. Constr. Steel Res. 70, 308–316 (2012).

Sefidi, M. & Taghipoor, H. Analysis of deformation and failure mechanism of sandwich beams with lattice core under three-point bending load. Sci. Rep. 14, 13302 (2024).

Rao, S. S. The Finite Element Method in Engineering (Elsevier, 2010).

Larson, M. G. & Bengzon, F. The Finite Element Method: Theory, Implementation, and Applications vol. 10 (Springer Science & Business Media, 2013).

Manual, A. S. U. Abaqus 6.11. Http://130149 89, v6 (2012).

Zienkiewicz, O. C. & Taylor, R. L. The Finite Element Method set (Elsevier, 2005).

Tan, J-K. et al. Experimental study on cyclic shear performance of steel plate shear wall with different buckling restraints. Structures 35, 469–82 (2022).

Sadeghi, M., Shoja, S., Ardakani, M. A. S. & Jahangiri, M. Innovative improvement towards steel plate shear walls employing the grid stiffeners along with the metallic yielding dampers. J. Constr. Steel Res. 223, 109080 (2024).

Tong, J. et al. Cyclic test and analysis of UHTCC-enhanced buckling‐restrained steel plate shear walls. Earthq. Eng. Struct. Dyn. 53, 4006–4031 (2024).

Author information

Authors and Affiliations

Contributions

Shuna Zhang: Conceptualization, Data curation, Writing - original draft, Writing - review & editing.Peng Zhang: Conceptualization, Data curation, Writing - original draft, Writing - review & editing.Shaopeng Wang: Conceptualization, Data curation, Writing - original draft, Writing - review & editing.Amir Ghiasvand: Conceptualization, Data curation, Writing - original draft, Writing - review & editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, S., Zhang, P., Wang, S. et al. Numerical study on the cyclic behavior of the stiffened steel plate shear walls containing sandwich panels with corrugated core. Sci Rep 15, 4832 (2025). https://doi.org/10.1038/s41598-025-87709-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-87709-x

Keywords

This article is cited by

-

Lateral performance of the ODCSSWs under cyclic loading

Sādhanā (2025)