Abstract

The wavelet transform (WT) has gained significant attention for its ability to identify damage details within strain modes. However, edge damage in structures often remains obscured and unrecognizable when WT is applied, primarily due to edge effects. Intelligent algorithms used to assess structural damage severity often face challenges such as premature convergence and a tendency to settle on local optima. To address these challenges, damage location is analyzed using WT with a fitting extension of the original vibration signal, effectively mitigating edge effects. Additionally, an immune-genetic algorithm, integrating genetic and immune algorithms, is employed to overcome limitations of traditional intelligent algorithms in damage severity identification. The two-stage method’s effectiveness was validated through finite element simulations of fixed beam and frame structures, as well as vibration tests of fixed and cantilever beams, for locating and assessing edge damage. This method showed clear advantages, including precise damage characterization, noise robustness, and high sensitivity to edge damage.

Similar content being viewed by others

Introduction

Structural health monitoring (SHM) has become essential for ensuring the safety, reliability, and longevity of engineering structures, widely used in fields like civil engineering, aerospace, and machinery1,2,3,4. Boundary conditions critically influence the dynamic characteristics of structures. Damage to these conditions can severely compromise structural performance and potentially cause catastrophic failures. Thus, it is crucial to develop accurate and efficient methods for identifying boundary damage.

Structural damage alters physical parameters such as stiffness, damping, and mass, which in turn affect modal parameters like natural frequency, vibration modes and damping5,6. Therefore, structural damage can be evaluated by analyzing changes in these modal parameters. Based on this principle, many researchers have improved damage detection accuracy by analyzing fluctuations in vibration characteristics to identify structural damage and assess structural lifespan7,8.

A vibration mode shape represents the deformation distribution of a structure in a specific vibration mode describing the vibration state of discrete points in the structure for that mode. Some researchers have integrated natural frequency and vibration mode for the purpose of damage detection. Sun et al.9. used normalized uniform load surface curvature to identify damage in beam structures. Their method outperformed the uniform load surface curvature method and the mode shape curvature method in locating single and multiple damage locations. However, this method is limited to beam structures governed by the Bernoulli–Euler beam theory. Mustafa et al.10. proposed an energy-based damping assessment method for localizing damage. Ay et al.11. evaluated the damage-induced changes in overall damping behavior of free-vibrating dynamical systems using a statistical framework.

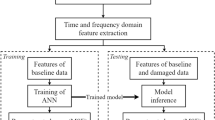

In recent years, WT analysis has become a crucial signal processing tool for detecting structural damage in civil engineering systems12,13. When combined with intelligent algorithms, WT aids in selecting key features and assigning weight thereby improving damage identification accuracy. Many researchers have utilized a two-stage approach that combines WT with intelligent algorithms for structural damage detection14,15,16. Guo et al.17,18. used WT and an improved particle swarm optimization algorithm to identify damage, severity, and non-uniform damage in beams. Researchers19 developed WT-based radial basis function networks (WT-RBFNs) for robust damage detection of marine fiberglass rectangular laminated composite plates (RLCPs). They20 also proposed a WT-based convolutional neural network (WT-CNN) technique, demonstrating high accuracy in predicting and detecting damage locations in RLCPs .

Applying WT to structural vibration data inevitably leads to singularities in wavelet coefficients at the structure’s edges, regardless of damage presence. This edge effect makes it impossible to identify edge damage using wavelet coefficients. To address this, scholars have proposed methods such as signal truncation6, extrapolating the signals21, filling zero22 and data coupling methods23. However, these methods may result in the distortion of the original signals and a considerable increase in the computational load.

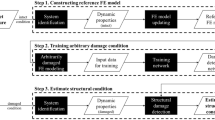

The paper is organized as follows: Section "Wavelet-immune genetic algorithm (WIGA)" introduces the WIGA based on signal fitting extension and immunogenetic algorithm. The displacement modal signal of the structure is fitted and extended, and the second-order difference of the fitted and extended signal is calculated. Then the WT is applied to locate the edge damage. Subsequently, an objective function composed of natural frequency and mode shape with certain weights is introduced to determine the edge damage severity by IGA. In Section "Numerical verification", the proposed method is validated using numerical simulation analysis of fixed beam and frame structure. In Section "Experimental validation", structural damage detection experiments are carried out on fixed beam and cantilever beam. Finally, conclusions are drawn.

Wavelet-immune genetic algorithm (WIGA)

Damage location detection

At the moment of damage, the mass of the beam structure with the microdamage is basically the same, so it can be considered that the structural damage is essentially the reduction of stiffness EI. The stiffness of the damaged location and adjacent location is not equal, i.e., \(EI(v^{ + } ) \ne EI(v^{ - } )\). When \(v = x\), the deformation condition and internal force balance condition of the position still meet the following conditions17,18:

Vertical displacement:

Rotation angle:

Bending moment:

Shearing force:

where w is deflection, and the superscripts + and − are used to denote the quantities just at the right and left of the discontinuous point.

According to Eqs. (3) and (4), microdamage will also cause the curvature mode and strain mode on both sides of the damage location to be unequal. In addition, the curvature mode and strain mode, far away from the damage location of the structure, will not change greatly, so the curvature mode and strain mode of the structure will mutate at the damage location. Previous research studies show that the strain mode is more sensitive to the microdamage of the structure, so the strain mode of the damaged structure will be analyzed by the continuous WT in this study, and the singular point (modulus maximum point) of the structural strain mode signal will be used to identify the damage location of the structure.

Strain is the first derivative of displacement, and thus each displacement mode corresponds to the corresponding strain mode. The strain mode reflects the inherent characteristics of the structure. To measure strain, the curvature mode can be used for indirect measurement. According to the material mechanics, the bending static relation of the beam can be obtained as23.

where i is the section position of measuring point, Mi is the bending moment of section I, EiIi is the flexural rigidity of section I, li is the radius of curvature at section I, ρi is the curvature of section i. According to the approximate equation of bending deformation of the beam:

where x is the coordinate along the length direction of the straight beam and y is the bending deflection of the beam. According to Eqs. (5) and (6), the difference equation of three equidistant continuous measuring points along the beam can be obtained 23.

where i + 1, i, and i − 1 are three adjacent continuous measuring points with equal distance along the beam, yi is the bending deflection of section i, y i+1 and y i − 1 are the bending deflections of section i − 1 and section i + 1 f. the measuring points, respectively, and Δ is the distance of two adjacent measuring points. The strain εi of the measuring point i of the beam can be expressed as

where h0 is the distance between the surface of the measuring point on the beam and the neutral layer, and Eq. (8) shows the direct relationship between the curvature mode and the strain mode of the beam.

Signal fitting extension

Signal fitting is a common mathematical method that aims to identify a polynomial function whose expression is as close as possible to the actual signal data. The fitting of a curve to a signal allows the fitted function to predict the topological signal and reveal the relationship between the data. Empirical formulas for fitting curves can be categorized as polynomial, exponential, trigonometric, and Fourier, among others. When fitting data, the use of a fitting tool with a similar pattern to the signal to be fitted will result in more accurate fitting results. According to the principle of structural dynamics, the free vibration equation of an equal-section Euler beam is as follows:

whereδ is the density of material, EI is the sectional stiffness, S is the area of the section, u(x,t) is the transverse displacement of position x at moment t. The generalized solution of Eq. (9) can be obtained using the method of separated variables as:

where H1,H2,H3,H4 are determined by the boundary conditions of the beam, and they determine the beam’s vibration pattern and amplitude, a is frequency parameter,φ(x) is vibration pattern. From Eqs. (9) and (10), it can be seen that the vibration pattern of the beam structure is in the form of trigonometric function. Therefore, a higher fitting accuracy can be obtained by using trigonometric functions or Fourier functions to fit the vibration profile of the beams. The fitting extension diagram of vibration signal of an undamaged beam is shown in Fig. 1:

Root mean square error (RMSE) reflects the accuracy of data fitting, a smaller RMSE indicates higher precision. Polynomial, Gaussian, trigonometric, and Fourier function fits were employed to fit vibration signal using the fitting extension method, and their RMSE of fitting were 0.03895, 0.06387, 0.00231, and 0.00835, respectively. It can be observed that the fitting with trigonometric and Fourier functions exhibits a high degree of accuracy. The fitting extension signal is subjected to WT, and then the wavelet coefficients of the same length as the original signal are intercepted to obtain Fig. 2:

As illustrated in Fig. 2, the wavelet coefficients near the ends are not mutated, and the edge effect is effectively mitigated. The fitting extension of the signal preserves the damage information at the endpoint of the original signal, but does not cause the damage information to be replicated in the extended signal and affect the identification of the damage location. Since the wavelet coefficients in the damaged element and nearby units are similar in scale, which is not conducive to the intuitive judgment of the damage location, this paper employs the treatment of coefficient squares to highlight the location of the damaged element.

Damage severity

The damage severity was quantified by measuring the reduction in stiffness.

where EI is the sectional stiffness of non-destructive beam, and EIS is the stiffness of damaged section, γ is the damage severity. In accordance with the established stiffness formula for a beam with a rectangular cross-section, the following can be derived:

where d is the damage depth corresponding to the damage severity and h is the height of the beam section. it can be obtained:

In accordance with Eq. (13), the element damage depth corresponding to the severity of damage can be calculated.

Immune genetic algorithm (IGA)

Genetic Algorithm (GA) is an optimization algorithm inspired by the process of natural selection and genetics. It mimics the biological evolution process, where individuals compete, reproduce, mutate, and survive, to iteratively find better solutions. GA is widely applied in function optimization, combinatorial optimization, and solving complex problems24. There are three types of selection mechanisms: roulette wheel selection, tournament selection and rank selection, the one used in this paper is roulette wheel selection. Common crossover operators are single-point crossover, multi-point crossover, uniform crossover. In this paper, two-point crossover is adopted. Two crossover points are randomly chosen within the gene sequence of parent individuals. The gene segments between these points are exchanged to create new offspring. The mutation operator introduces random changes in genes to maintain diversity in the population and avoid local optima. In this paper, bit flip mutation is adopted, which targets binary coding by flipping a bit of a gene at random (0 to 1 or 1 to 0).

In order to enhance the efficacy of the genetic algorithm (GA), while maintaining its capacity for global search and diversity of individuals, and overcoming the limitations of its simplistic "precociousness," some scholars have introduced the concept of biological immunity into the domain of genetic algorithms. This entails the incorporation of immune algorithm (IA) into the GA, which serve to simulate the behavior of biological immunity, thereby forming a novel type of intelligent algorithm known as the immune genetic algorithm (IGA).

The IGA takes the objective function of the problem to be solved as the antigen, the feasible solution of the problem as the antibody, and the characteristic information of the problem as the abstraction of the vaccine. According to the principle of biological immunity, when the immune system detects the presence of an antigen, it will cause the cells to differentiate, and the differentiated immune cells will produce specific antibodies corresponding to the antigen, which contain the characteristic information of the antigen. The introduction of the concept of vaccine in GA is equivalent to using the characteristic information of the problem to guide the evolution of the population in a direction that is more conducive to solving the problem. This largely avoids the randomness and precocity that are inherent to the GA. The specific steps of IGA are as follows25:

-

(1)

Random generation of initial population A1.

-

(2)

The vaccine is extracted by utilizing some characteristic information or priori knowledge of the problem being asked. The priori knowledge can be the range of values of some components of the optimal individual, or the relationship between the components.

-

(3)

Terminate the algorithm if the best individual in the current population satisfies the termination condition, otherwise proceed to the next step.

-

(4)

Perform a crossover operation on the current k-th generation population Ak to obtain the population Bk.

-

(5)

A mutation operation on population Bk forms population Ck.

-

(6)

Vaccination of population Ck forms population Dk.

-

(7)

Perform an immune selection operation on population Dk to obtain a new generation of population Ak+1 and return to step (3).

The vaccine is the modification of genes at some of its loci in accordance with prior knowledge so that the individual has a higher fitness with a higher probability26. To vaccinate the population Ck = (x1, x2,…, xn) means to select an individuals randomly according to the proportion a. The vaccination operation must adhere to the following law: if the genes at each locus of individual x are different from the genes of the optimal individual y, the probability that individual x turns into y is 0; conversely, if the genes at each locus of individual x are the same as the genes of the optimal individual y, the probability that individual x turns into y is 1. Immune selection is the process of randomly selecting a number of individuals for vaccination and immune testing after each genetic manipulation. If the fitness of the individuals following genetic manipulation is less than that of the parent individuals, indicating that degradation has occurred, the parent individuals will be included in the subsequent iteration. Conversely, if the fitness of the individuals following genetic manipulation is greater than that of the parent, they will serve as the parents of the new generation with a certain probability.

Objective function

Based on the comprehensive consideration of the global and local structural properties, the objective function shown in Eq. (14) is constructed by using the regularized frequency variation function and the weighted sum of the displacement mode variation function:

The objective function of the intelligent algorithm for detecting the severity of structural damage can be constructed based on the structural modal parameters, such as the natural frequency and vibration mode shape. As previously stated, the natural frequency, as an overall parameter of the structure, is not sensitive to the local damage information, and may have the same frequency in different damage cases, which is not conducive to the accurate identification of the damage extent. In contrast to the natural frequency, the mode shapes are more responsive to local information. To enhance the detection accuracy, an objective function can be constructed by integrating the natural frequency and the modal vibration pattern. This function can be adjusted by introducing a weight coefficient to regulate the contribution of the two parameters to the objective function. The expression of the objective function is as follows: 17:

where \(f_{i}^{test}\) and \(f_{i}^{cal}\) are the actual measured natural frequency and the frequency calculated by the algorithm through modeling at the i-th order, respectively, \(\phi_{ij}^{test}\) and \(\phi_{ij}^{cal}\) are the measured and calculated displacement modes at the j-th node in the i-th order mode, respectively. \(G_{\omega }\) and \(G_{\phi }\) are the weighting coefficients of the natural frequency and displacement modes, which are set as 1. m is the total number of orders of the frequencies taken, n is the total number of orders of the displacement modes taken, and k is the number of the summary points.

As illustrated in Eq. (14), the objective function quantifies the severity of damage by modeling the modal parameters under random damage severity with an intelligent algorithm and comparing them with the actual measured modal parameters. The closer the modal parameters under the damage severity assumed by the algorithm are to the actual measured structural modal parameters, the closer the assumed damage severity is to the real damage severity. The objective function of identifying the minimum value of the difference between the modal parameters transforms the damage identification problem into an optimization problem, thereby enabling the intelligent algorithm to utilize its powerful optimization abilities to accurately identify the damage severity of the structure. The complete flowchart of the WIGA localization process for damage and severity identification is presented in Fig. 3.

Numerical verification

Selection of mother wavelet

The selection of an appropriate mother wavelet is of paramount importance for the successful application of WT in damage identification. Previous research has demonstrated that scholars employ different criteria for selecting the mother wavelet, depending on the specific application conditions27,28. There criteria include regularity, symmetry, wavelet selection criterion (WSC)29, the ability to reconstruct the analyzed signal, the number of vanishing moments and effective support30,31. In most cases, the mother wavelet is determined through a trial-and-error approach32.

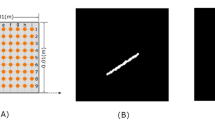

In order to select the most appropriate mother wavelet, a numerical simulation of a fixed beam containing single damage is carried out using the finite element software Ansys2024R1, and SOLID185 is used for the beam element. The model of the beam is depicted in Fig. 4. The beam length is 1274 mm, the cross-section size b × h = 60 mm × 80 mm, the element length is 26 mm, and a total of 49 elements are used for the division of the beam. The damage element is located in the middle of the span, at element 25. According to the definition in Section "Damage severity", the damage severity and depth of the element are 10% and 2.76 mm respectively. The other material parameters are presented in Table 1.

Commonly utilized mother wavelets include the Haar, Db3, Mexh, and Bior wavelets, among others. Given that the first-order displacement mode can provide more precise vibration information and is relatively straightforward to obtain in the test, the first-order mode is employed in this paper for analysis. The second-order difference of the first-order displacement modes obtained from the numerical simulation is employed to obtain the strain modes. The wavelet coefficient of the beams is generated by utilizing distinct wavelet bases to perform continuous WT on the strain modal data through the wavelet toolbox in MatlabR2019b. From Fig. 5, it can be observed that the Db3 wavelet is capable of effectively identifying damage in the span of the beam, with more symmetrical distortion at the two ends. Therefore, the Db3 wavelet is selected as the mother wavelet in this study.

Identification of edge damage in fixed beam

In order to ascertain the efficacy of WIGA in identifying the edge damage of fixed beams, five scenarios, as depicted in Table 2, have been devised. In these scenarios, elements close to the end of the beam are regarded as edge elements, as illustrated in Fig. 6. The parameters of the beams are maintained consistent with those presented in Section "Selection of mother wavelet", and the damage depth and severity of the beams are presented in Table 2:

The first-order displacement modes of the fixed beams were obtained by employing the finite element software Ansys2024R1 for the modal analysis of different scenarios. The displacement modal signals were extended by the data fitting extension method in Section "Signal fitting extension", and the extended data were processed by the method in Section "Damage location detection" to obtain the strain modes of the structure. Subsequently, the WT of the strain modes is conducted using the Db3 wavelet. Finally the data with the same length as the original signal is intercepted, thereby generating the squared wavelet coefficients under each scenario, as illustrated in Fig. 7:

As shown in Fig. 7, the wavelet coefficients in scenario 1 lack singularities, indicating no damage within the beam span. After mitigating the edge effect, no singularities are observed at either end of the beam, which signifies the absence of damage at both ends of the beam as well. The fitting RMSE is 2.31 × 10–3. Scenarios 2 and 3 show distinct wavelet singularities near node 1. In scenario 2, the modulus maximum occurs at node 2, indicating damage in element 1. In scenario 3, the modulus maximum is at node 3, corresponding to damage in element 2. The fitting extension eliminates the edge effect near node 50 for scenarios 2 and 3, and the fitting RMSEs are 5.47 × 10–4 and 1.3 × 10–4 for scenarios 2 and 3, respectively.

Singularities at both ends of scenarios 4 and 5 indicate edge damage. In scenario 4, the modulus maximum is at node 2 on the left and node 49 on the right, identifying damage in elements 1 and 48. In scenario 5, In scenario 5, the modulus maximum is at node 3 on the left and node 50 on the right, indicating damage in elements 2 and 49. The fitting extension mitigates the edge effects near the two ends, and the fitting RMSEs for scenarios 4 and 5 are 1.85 × 10-3and 7.36 × 10–4, respectively.

The damage severities of scenarios 2 and 4 are set to 10% and 5% in element 1, respectively. It can be observed that the wavelet coefficients of scenario 2 is significantly larger than that of scenario 4. Meanwhile, both scenarios 3 and 5 are set with 20% damage in elements 2 and 49, respectively. However, the wavelet coefficient modulus maximums notably disparate. It can be demonstrated that a comparison of the severity of damage can only be made when the damage occurs at the same location in both conditions. When damage occurs at different locations, the maximum coefficient cannot compare severity but can still indicate damage location.

To evaluate the performance of IGA in damage detection, this section compares GA, IA, and IGA in identifying the damage severity of scenarios listed in Table 2. Parameter settings for each algorithm are based on empirical values and tuning trials. The population size is set to 50, and the maximum number of iterations is 100 for all three algorithms. For GA, the crossover probability is set to 0.5, and the mutation probability to 0.01. For IA, the immune selection probability is 0.3, the clone multiplicity is 5, and the population update ratio is 0.2. For IGA, the mutation probability is 0.01, the crossover probability is 0.5, the cloning rate is 0.6, and the cloning inhibition rate is 0.01. MATLAB was used to model the fixed beams numerically for each scenario, generating modal data. These data, along with results from ANSYS finite element analysis, were imported into the algorithm to calculate damage severity. To minimize random errors, the average of ten calculations was used as the identification result for each scenario, as shown in Figs. 8 and 9:

As illustrated in Fig. 8, the GA, IA, and IGA are all effective in identifying edge damage in all scenarios. Furthermore, the higher the damage, the more uniform the identification accuracy of these three algorithms. When identifying 5% damage in scenario 4, notable discrepancies are observed among the algorithms. IGA achieves the closest result to 5%, likely due to smaller damage leading to less noticeable changes in the structure’s modal information. As a result, more calculations are needed for detection, which increases computation time, as shown in Fig. 9. Scenario 4 with 5% damage severity exemplifies this. It can also be observed in Fig. 9 that the running time of IGA is lower than that of GA and IA, and the discretization of its computation time is also smaller than that of GA. Considering both accuracy and efficiency, IGA outperforms GA and IA in detecting edge damage in fixed beams.

Among the ten calculations of the three algorithms, the one with the fastest iteration convergence speed is selected, and the corresponding iteration curves are presented in Fig. 10. GA shows a rapid initial adaptation decline due to its robust searchability. However, it remains relatively stagnant between the 10th and 50th iterations, and between the 50th and 75th iterations. The algorithm converges only after the 75th iteration. Following the introduction of prior antigenic knowledge, the IA exhibits a markedly lower affinity at the outset, with a tendency to converge after the 38th iteration following a brief period of stagnation. In contrast, IGA converges within 10 iterations, showing a significantly faster rate than GA and IA. Additionally, IGA shows no signs of premature stagnation.

Frame edge damage detection

Figure 11 depicts a model of a one-story one-span frame structure comprising rigidly connected beams and columns. The columns are fixed to the ground. Both the beam’s length and the column’s height are 1000 mm, with cross-sectional dimensions of b × h = 40 mm × 60 mm. Additional material parameters are listed in Table 1. The frame structure was modeled using the finite element analysis software Ansys2024R1. The structure was divided into 150 elements, with each element having a length of 20 mm. Four damage elements were defined near two nodes. Their locations and severity of the damage elements are shown in Table 3 and Fig. 11. Damage was simulated by reducing the stiffness of the affected elements. The damage, characterized as transfixion along the thickness, was modeled using Eq. (13) to compute the damage depth based on severity. Squared wavelet coefficients were derived using the processing method described in Section "Identification of edge damage in fixed beam", as shown in Fig. 12.

Figure 12 shows that the squared wavelet coefficients of the frame’s beam reach maximum values at nodes 1, 2, 43, and 44. This indicates that the damage elements are located at elements 1 and 43. The identification results align with the model damage settings. The fitting extension accurately detects damage at the frame beam edges, with a fitting RMSE of 6.315 × 10–4. Additionally, the squared wavelet coefficients for element 1 is larger than that for element 43, consistent with their damage severities.

The maximum value of the squared wavelet coefficients appears at nodes 1 and 2 of the frame’s right column. This indicates that damage is present in element 1 of the right column of the frame. Similarly, the maximum squared wavelet coefficient at nodes 2 and 3 of the left column suggests damage in element 2. It can be observed that there is no wavelet singularity at the two fixed supports, and the edge effect at the fixed supports is suppressed by the fitting extension process.

The frame model in this section differs from the fixed beam model in Section "Identification of edge damage in fixed beam" regarding structure, element count, and damage distribution. Consequently, continuing to utilize the parameters of the IGA in Section "Identification of edge damage in fixed beam" will not be able to better balance the accuracy and computational efficiency of the algorithm. The empirical parameter values and parameter attempts to adjust have been employed to set the parameters of the IGA for calculating the frame model in this section as follows: the population size is 100; the number of iterations is 100; the variance probability is 0.05; the crossover probability is 0.7; the cloning rate is 0.4; and the inhibition rate of cloning is 0.01. MATLAB was employed to numerically model the frame structure to obtain the corresponding modal data, which were imported into the algorithm program to calculate the damage severity along with the modal data calculated by ANSYS finite element software. A total of ten calculations were performed, and the results of identification are shown in Fig. 13.

The results of the calculations indicate that the errors of the four damage severity detection results are all below 3%. The largest error, 2.72%, occurred in damage 2, with a damage severity of 5.14%. The smallest error, 0.75%, occurred in damage 3, with a damage severity of 19.85%. It can be observed that when the IGA is employed to identify the severity of damage, the greater the severity of damage, the higher the identification accuracy. This is due to the fact that the frame model is more complex than the fixed beam, which has a more complex structural form, a greater number of element nodes, and a higher number of damages recognized in a single pass. Consequently, the error in the detection of the same severity of damage is generally higher than that of the fixed beam edge damage. Furthermore, the time required for damage detection in the frame is longer than that required for the fixed beam edge damage detection.

Experimental validation

The efficacy of the IGA approach in identifying edge damage in fixed beams and frame structures is demonstrated by numerical simulations in Section "Numerical verification". To further substantiate the effectiveness of the method in real structures, the following experiments on fixed beams and cantilever beams will be conducted. The damage is a transfixion notch with a width of 26 mm, as depicted in Fig. 14a, and the depth of the damage is determined by the specified damage severity, as defined by Eq. (13). Figure 14 depicts the experimental setup for acquiring the vibration signal of the structure. The steel used in the test is Q235, and Table 1 presents the main material parameters of the beams.

The tests were conducted using high-sensitivity 1A110E type IEPE piezoelectric transducers to collect the displacement modal data of the beam. In accordance with the design scenarios, the beam was divided into discrete segments along its length, with each segment measuring 26 mm in length. Due to the constraints of the available vibration transducer, a distance of 13 mm was left at both ends as the mounting position of the transducer. The transducers were positioned on the mid-axis of the upper surface of the beam. Due to the limited number of transducers, vibration data for all nodes was acquired through multiple batches of testing. The first-order displacement modes of the beam were obtained by tapping the beam with a force hammer of type GST (LC-04A) using the unmeasured-force method, and then analyzed using the DH5922D test system.

Identification test of edge damage in fixed beam

The parameters of the fixed beams are maintained in accordance with those established in section "Identification of edge damage in fixed beam". Following the acquisition of the first-order displacement modes of the beams through the dynamic test and analysis system, the second-order difference is employed to derive the strain modes. Subsequently, the wavelet coefficients of the beams are then obtained through the utilization of the wavelet toolbox in Matlab 2019b, which performs noise reduction and WT on the strain modes. The natural frequencies of the three scenarios recorded in the test are 97 Hz, 101.807 Hz and 102.539 Hz respectively.

Figure 15 depicts the wavelet coefficients in their original form, prior to the application of fitting extension process. It is evident that scenario 1 exhibits pronounced edge effects, which render it challenging to ascertain the presence of damage at the edges. The edge effect in scenario 2 precludes the identification of damage at the end of the beam, which ultimately leads to the failure of damage identification in element 1. In scenario 3, a clear wavelet singularity is observed in the span, which indicates the presence of damage in the span. However, due to the edge effect, this also results in the failure of damage identification in element 1.

Figure 16 depicts the squared wavelet coefficients following the fitting extension process. The RMSEs of the three scenarios, as determined by the fitting process, are 3.35 × 10–3, 9.1 × 10–3, and 1.26 × 10–2, respectively. It is evident that the RMSE of the experimental data is greater than that of the numerical simulation, due to the influence of noise in the test environment. A comparison of Figs. 15 and 16 reveals that the fitting extension for scenario 1 eliminates the edge effect and does not exhibit any wavelet singularity, indicating that scenario 1 is a lossless beam. In contrast, scenario 2 exhibits a maximum wavelet coefficient at node 1, which suggests the presence of damage in element 1. Furthermore, the edge effect is suppressed at the right end of the beam, indicating that there is no damage around right end. In scenario 3, two wavelet coefficient singularities are observed, the first at node 1 and the second at node 26. These observations indicate the presence of damage at these two nodes. Moreover, since the damaged element also affects the stiffness of the surrounding units, the greater the damage, the more pronounced the influence of the range. Consequently, in the vicinity of node 26, there are wavelet singularities at several nodes. Nevertheless, the maximum value is observed at node 26, which is indicative of the damage.

The second-order difference results in the reduction of data from 50 nodes to 48, which in turn leads to the loss of edge signals. While the location of the damage can be roughly determined, it is not precise. However, the fitting extension can serve to complement the 50 data points and thereby facilitate the precise localization of the damaged element. From the preceding discussion, it can be seen that after the fitting extension the of experimental data, the influence of the edge effect on the damage identification can be significantly reduced, and the damage can be more accurately localized. Moreover, this approach does not affect the localization of the damage in the span.

The severity of damage was identified using GA, IA, and IGA for the two scenarios presented in Table 4. The parameters of each algorithm were maintained consistent with those described in section "Identification of edge damage in fixed beam", and 10 calculations were performed for each scenario. Figure 17 illustrates that GA, IA, and IGA are capable of identifying the severity of damage for both scenarios. However, the calculations of IGA and IA are more accurate than those of GA, and IGA has a smaller dispersion in identifying the severity of damage. Furthermore, it can be observed that the computational time of the three algorithms increases with the number of damages. Among the three algorithms, the computational time of IGA is shorter, and its computational time is also more stable compared to GA and IA.

Identification test of edge damage in cantilever beam

The cantilever beam has a length of 1066 mm and section size of b × h = 60 mm × 80 mm, which is divided into 41 elements. The material parameters are maintained consistent with those of the fixed beam (Fig. 18). Subsequently, the first-order displacement modes of the beam were obtained through the dynamic test and analysis system. The second-order difference was then employed to obtain the strain modal, and the wavelet coefficients of the beam were derived by utilizing the wavelet toolbox in Matlab 2019b to perform noise reduction and WT of the strain modes. The fundamental parameters utilized in the IGA were established as follows: population size of 50, iteration number of 100, variance probability of 0.02, crossover probability of 0.35, clone rate of 0.5, and clone suppression rate of 0.03. The natural frequency of scenario 1 recorded in the test is 23.193 Hz.

The severity of damage was identified using IGA for the scenarios presented in Table 5. Figure 19 illustrates the squared wavelet coefficients comparing the wavelet coefficients without and with the fitting extension. In the absence of the data fitting extension, wavelet singularities appear at both the free and fixed ends of the beam. However, these singularities cannot confirm whether they result from damage or edge effects. After applying the fitting extension, the singularity at the free end disappears, while the singularity at the fixed end remains. This confirms damage at the fixed end but not at the free end. Both methods successfully identified spanning damage. However, without the fitting extension, the second-order difference produced two missing data points. Consequently, the complete information regarding the beam was not retained. The result is that the wavelet coefficient value with fitting extension can be used to determine that the span damage is in element 15, which matches the design damage location. In contrast, the wavelet coefficient value without fitting extension has the span damage in element 14, which deviates from the design damage location.

Figure 20 shows the results of IGA in determining damage severity in cantilever beams. It is evident that IGA is capable of accurately identifying the damage severity in both edge and span damage scenarios for cantilever beams. As with the previous discussion, IGA also exhibits some limitations in accuracy. The error and dispersion of IGA in recognizing 20% damage are smaller than those observed in the detection of 5% damage. This indicates that as the damage severity increases, the detection accuracy also increases.

Conclusions

While many studies have investigated structural damage detection using WT and intelligent algorithms, significant challenges persist. One challenge is the influence of edge effect, which hinders the ability to discern the edge damage of a structure. Additionally, these algorithms are prone to premature convergence, limiting their effectiveness. This study introduces data fitting extension into the process of damage identification. The WT is utilized to overcome the influence of noise and obtain the location of structural damage, which is then combined with IGA to identify the damage severity of the structure. The feasibility of the method for detecting edge damage is investigated through numerical simulation cases of fixed beams and frame structures. The applicability of the method for identifying real structures is verified by experimentally obtaining the displacement modes of fixed beams and cantilever beams. The study draws the following conclusions:

-

(1)

The fitting extension of data can effectively circumvent the influence of the edge effect of the WT in recognizing damage, and can accurately identify the edge damage location of the structure without affecting the non-boundary damage. Furthermore, the fitting extension of data can also compensate for the missing signal caused by the second-order difference, ensuring there is no misalignment when using wavelet coefficients to localize the damage.

-

(2)

In terms of computational efficiency and accuracy, IGA is superior to GA and IA in identifying the degree of structural damage.

-

(3)

Additionally, the IGA exhibits limitations in its capacity to discern the severity of damage of the test beam. As the severity of damage increases, the accuracy of its detection also rises. Nevertheless, the detection outcomes remain of considerable practical utility.

The method exhibits considerable potential in both theoretical and experimental contexts but faces several limitations. First, the damage form and severity observed in real structures often deviate from the transfixion damage modeled in the tests. Second, the methodology to acquiring structural modal information needs further refinement.

Data availability

Data is provided within the manuscript or supplementary information files.

References

Deng, Z., Huang, M., Wan, N. & Zhang, J. The current development of structural health monitoring for bridges: A review. Buildings 13, 13061360 (2023).

Zhang, J. et al. Missing measurement data recovery methods in structural health monitoring: The state, challenges and case study. Measurement 231, 114528 (2024).

Huang, M. S. et al. Two-stage damage identification for bridge bearings based on sailfish optimization and element relative modal strain energy. Struct. Eng. Mech. 86, 715–730 (2023).

Ding, Z. H., Yao, R. Z., Huang, J. L., Huang, M. & Lu, Z. R. Structural damage detection based on residual force vector and imperialist competitive algorithm. Struct. Eng. Mech. 62, 709–717 (2017).

Hou, R. & Xia, Y. Review on the new development of vibration-based damage identification for civil engineering structures: 2010–2019. J. Sound Vibr. 491, 115741 (2021).

Fan, W. & Qiao, P. Vibration-based damage identification methods: A review and comparative study. Struct. Health Monit. 10, 83–111 (2011).

Zhang, H., Sun, J., Rui, X. & Liu, S. Delamination damage imaging method of CFRP composite laminate plates based on the sensitive guided wave mode. Compos. Struct. 306, 116571 (2023).

Zhou, Z., Zhao, J. & Guan, D. Q. A simple and convenient fatigue analysis method considering the effect of plasticity on fatigue. J. Build. Eng. 65, 105625 (2022).

Sun, S. H., Jung, H. J. & Jung, H. Y. Damage detection for beam-like structures using the normalized curvature of a uniform load surface. J. Sound Vibr. 332(6), 1501–1519 (2013).

Mustafa, S., Matsumoto, Y. & Yamaguchi, H. Vibration-based health monitoring of an existing truss bridge using energy-based damping evaluation. Bridge Eng. 23(1), 04017114 (2017).

Ay, A. M., Khoo, S. & Wang, Y. Probability distribution of decay rate: a statistical time-domain damping parameter for structural damage identification. Struct. Health Monit. 18(1), 66–86 (2019).

Saadatmorad, M., Talookolaei, R.-A.J., Pashaei, M.-H., Khatir, S. & Wahab, M. A. Pearson correlation and discrete wavelet transform for crack identification in steel beams. Mathematics 10, 2689 (2022).

Katunin, A., Lopes, H. & dos Araújo Santos, J. V. Identification of multiple damage using modal rotation obtained with shearography and undecimated wavelet transform. Mech. Syst. Signal Proc. 116(1), 725–740 (2019).

Chen, C. et al. Reconstruction of long-term strain data for structural health monitoring with a hybrid deep-learning and autoregressive model considering thermal effects. Eng. Struct. 285, 116063 (2023).

Sun, H., Song, L. & Yu, Z. Bridge damage localization and quantification using deep learning and FEM static simulation. Mech. Syst. Signal. Pr. 211, 111177 (2024).

Chen, Z., Liu, Q., Ding, Z. & Liu, F. Automated structural resilience evaluation based on a multi-scale transformer network using field monitoring data. Mech. Syst. Signal Pr. 222, 111813 (2025).

Guo, J., Guan, D. Q. & Zhao, J. W. Structural damage identification based on the wavelet transform and improved particle swarm optimization algorithm. Adv. Civ. Eng. 14, 8869810 (2020).

Guo, J., Guan, D. Q. & Pan, Y. R. Research on damage identification of nonuniform microcrack in beam structures. Adv. Civ. Eng. 2021, 8877821 (2021).

Saadatmorad, M., Jafari-Talookolaei, R.-A., Pashaei, M.-H., Khatir, S. & Abdel Wahab, M. A robust technique for damage identification of marine fiberglass rectangular composite plates using 2-D discrete wavelet transform and radial basis function networks. Ocean Eng. 263, 112317 (2022).

Saadatmorad, M., Jafari-Talookolaei, R.-A., Pashaei, M.-H. & Khatir, S. Damage detection on rectangular laminated composite plates using wavelet based convolutional neural network technique. Compos. Struct. 278, 114656 (2021).

Rucka, M. & Wilde, K. Neuro-wavelet damage detection technique in beam, plate and shell structures with experimental validation. J. Theor. Appl. Mech. 48(3), 32–96 (2010).

Xu, W., Cao, M. S. & Ostachowicz, W. Two-dimensional curvature mode shape method based on wavelets and Teager energy for damage detection in plates. J. Sound Vibr. 347, 266–278 (2015).

Zhao, J. W. & Zhou, Z. A wavelet based data coupling method for spatial damage detection in beam-type structures. PLOS One https://doi.org/10.1371/journal.pone.0290265 (2023).

Huang, M.-S., Gül, M. & Zhu, H.-P. Vibration-based structural damage identification under varying temperature effects. J. Aerospace Eng. 31, 04018014 (2018).

Peng, J. & Shi, S. L. Research on gas emission quantity prediction model based on EDA-IGA. Heliyon 9(7), e17624 (2023).

Monteiro, L. H. A., Gandini, D. M. & Schimit, P. H. T. The influence of immune individuals in disease spread evaluated by cellular automaton and genetic algorithm. Comput. Meth. Programs Biomed. 196, 105707 (2020).

Meng, F., Li, G., Kageyama, K. & Su, Z. Optimal mother wavelet selection for Lamb wave analyses. J. Intell. Mater. Syst. Struct. 20, 1147–1161 (2009).

Jahangir, H. Hasani, H: Wavelet-based damage localization and severity estimation of experimental RC beams subjected to gradual static bending tests. Structures 34, 3055–3069 (2021).

Saadatmorad, M., Khatir, S., Cuong-Le, T., Benaissa, B. & Mahmoudi, S. Detecting damages in metallic beam structures using a novel wavelet selection criterion. J. Sound Vib. 578, 118297 (2024).

Ovanesova, A. V. & Suarez, L. E. Applications of wavelet transforms to damage detection in frame structures. Eng. Struct. 26, 39–49 (2004).

Zhong, S. & Oyadiji, S. O. Crack detection in simply supported beams using stationary wavelet transform of modal data. Struct. Control. Health Monit. 18, 169–190 (2011).

Jaiswal, N. G. & Pande, D. W. Investigation on selection of optimal mother wavelet in mode shape based damage detection exercise. Procedia Eng. 181, 531–537 (2017).

Acknowledgements

This study was supported by the National Natural Science Foundation of China (Grant No.5138079) and Hunan Graduate Scientific Research Innovation Project of China (Grant No. CX20200815) and Hunan Graduate Scientific Research Innovation Project of China (Grant No. CX20210737).

Author information

Authors and Affiliations

Contributions

Jianwei. Zhao. and Liang. Gong. worote the main manuscript text. Zhuo. Zhou prepared all the figures. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhao, J., Zhou, Z., Guan, D. et al. Structural edge damage detection based on wavelet transform and immune genetic algorithm. Sci Rep 15, 4376 (2025). https://doi.org/10.1038/s41598-025-87712-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-87712-2