Abstract

Dehydration of serpentine is an important prograde metamorphic reaction within the lithosphere and subduction zones, potentially causing profound changes in rock properties. Imaging these transitions in real time provides direct insight into the process. We have used in-situ transmission electron microscopy (TEM) to continuously monitor nanoscale transformations in lizardite from 20 to 600 °C. Phase transformation processes during dehydration are recorded and analyzed in real time, including the amorphization of lizardite, and the recrystallization of nanocrystalline forsterite and talc within amorphous dehydroxylate phases. These observations delimitate the role of dehydration temperature in controlling reaction kinetics and the nucleation of reaction products. Specifically, the higher the temperature, the faster the rate of lizardite dehydration, accompanied by faster and more extensive nucleation of nanocrystalline forsterite and talc. Furthermore, the lizardite crystal is observed to gradually shrink with dehydration while maintaining its structural integrity, leading to the expansion of nanoscale intergranular pores and the formation of interconnected pore networks.

Similar content being viewed by others

Introduction

Serpentine minerals are important components of the oceanic lithosphere, mantle wedge, and subducting oceanic plate. Their structure, mineralogy, and mechanical behaviour have significant implications for global and regional geodynamics1,2,3. The most critical process is serpentine dehydration, which occurs with increasing temperature. The substantial amount of fluid released during this dehydration process is believed to trigger arc partial melting and related magmatism4,5,6, and is considered responsible for intermediate-depth seismicity7,8,9.

The dehydration of serpentine is accompanied by drastic changes in the minerals and their microstructures. The dynamic transformations of minerals and structures at nanoscale in serpentine under reaction conditions remain unclear. In-situ X-ray diffraction (XRD) and in-situ Fourier-transform infrared spectroscopy (FTIR) have been successfully applied over the past two decades to investigate the physical and chemical transformations of serpentine with changing temperature10,11,12,13,14,15. However, these techniques do not allow observation of mineral morphology, microstructure, and porosity, which are crucial for better understanding the related transformations at the nanoscale and also the geophysics and geochemistry in Earth’s interior16,17,18,19,20,21,22. Transmission electron microscopy (TEM) is the available instrument to simultaneously provide high-resolution images, chemical analyses, and crystal diffraction data at submicrometric scale. Previous studies have employed analytical TEM to study naturally and/or experimentally dehydrated serpentinite under certain ambient conditions12,23,24,25, i.e., quenched samples, thus not in real-time. In-situ heating high-resolution TEM (HRTEM) is an emerging technique that allows tracking the entire process in real-time and is applied here to capture the mineral morphology, microstructure, porosity, and their real-time variations in dehydrating lizardite.

Results and discussion

Elemental variations at different temperatures

The sample was baked for 15 min at each of the following seven temperatures: 20, 200, 250, 300, 400, 500, 600 °C (Fig. 10 in “Methods”). After each baking stage, we selected the representative area shown in Fig. 1a for HAADF-STEM imaging and analyzed the chemical composition using EDS. Lattice fringes and the corresponding FFT (fast Fourier transform) of HRTEM images indicate that the area is composed of well-crystallized lizardite (Fig. 1b–d). The dehydration of lizardite is actually a process of dehydroxylation as below:

The proportions of H and O in the system continuously decrease, while Mg and Si stay constant during decomposition of lizardite. Due to the presence of Si in the sample holder (see “Methods” for experimental details), it is not possible to accurately determine the Si content in the sample. Therefore, the Mg/O ratio was chosen to analyze the release of H2O. From 20 to 600 °C, the entire area in Fig. 1a has been observed through the high-angle annular dark field-STEM (HAADF-STEM) (Fig. 2a) and analyzed by in-situ EDS (Fig. 2b). Based on the chemical composition obtained from EDS, it was found that the Mg/O ratio of the whole area in Fig. 2a increases with temperature and can be divided into two stages (Fig. 2c): (1) the first initial small increase occurring below 300 °C, which is ascribed to the loss of physically bound water observed in many dehydration experiments10,15. Within the temperature range of 250–300 °C, the constancy of the Mg/O ratio indicates that the physically adsorbed water has been completely released, and the decomposition of lizardite has not yet begun; (2) the other stage in the range of 400–600 °C corresponds to the decomposition of lizardite. It should be emphasized that the EDS analysis is not quantitative. The ideal Mg/O ratio of lizardite should be 0.33, and our experimental results are significantly lower than this value (Fig. 2c). However, as the temperature increases, the trend of the Mg/O ratio is real, independent of the actual values. Therefore, the rate of dehydration at different temperatures can be compared using the rate of increase in the Mg/O, \(\partial (Mg/O)/\partial t\). In this study, the rate of increase in the Mg/O for sample at 400, 500, and 600 °C is 0.0213/h, 0.0548/h, and 0.2154/h respectively, with a ratio of 1:2.5:10. Based on this result, we infer that the decomposition rate ratios of lizardite at 400, 500, and 600 °C are approximately 1:2.5:10. Previous studies conducted the dehydration of pure antigorite crystals using non-isothermal thermogravimetric analysis, providing dehydration reaction progress curves at different temperatures26. We calculated the slope of the reaction progress curves for antigorite reported in the aforementioned study to compare the dehydration rates and found that the dehydration rates at 400, 500, and 600 °C are approximately in the ratio of 1:3:9, which agrees well with our experimental results. Consistent with some previously reported studies15, we suggest that below 600 °C, the dehydration rates of antigorite and lizardite are controlled by temperature in a similar manner.

Nanoscale phase transformations monitored by in-situ HRTEM

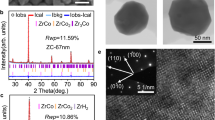

High-resolution TEM records the detailed phase transformations at the nanoscale in lizardite with heating. Figure 3a–d reveal the amorphization of lizardite from 20 to 400 °C. Lizardite becomes amorphous at 250 °C and remains amorphous up to 400 °C, which is verified by the corresponding FFT (insets in Fig. 3). Figure 4a–f reveal the formation process of new mineral phases in the amorphous lizardite. Additionally, the diffraction patterns in the FFT are visualized as a function of the azimuthal angle and distance in polar coordinates, with radial intensity profiles derived, and plotted in Fig. 4. After being heated up to 500 °C, few nanocrystalline dehydrated products (< 10 nm) slowly form in the amorphous materials (Fig. 4a,b), indicating that the lizardite has broken down. In the radial intensity profiles (Fig. 5), we observed a new characteristic peak at around 4.72 nm−1 (d = 2.14 Å) with heating, which also indicates the phase transformation of lizardite. Considering measurement errors and slight difference of standard d values, we cannot definitively determine whether 2.14 Å represent talc, forsterite, or both. Notably, reaction products cannot be observed in some areas due to the low reaction rate below 500 °C (Fig. 5).

(a) TEM image of untreated lizardite sample. (b) TEM image of lizardite sample at 200 °C; the lattice fringes of the lizardite are no longer clear, but there is still a show similar crystal nature to untreated lizardite in corresponding Fourier transform (inset). (c) TEM image of lizardite sample at 250 °C; sample become completely amorphous. (d) TEM image of lizardite sample at 400 °C; sample remains amorphous.

Sequence of HRTEM images and corresponding FFT showing nucleation of dehydration products, such as forsterite and talc, within amorphous lizardite. (a–c) 500 °C, (d–f) 600 °C. The d = 5.26 Å is closer to the standard d value of (001)talc (d = 5.229 Å) than that of (001)Fo (d = 5.159 Å), especially when considering the effect of thermal expansion on lattice.

Radial intensity profiles derived from the FFT images in Fig. 6, indicating the phase transition and crystallinity evolution of lizardite during the heating process.

While at 600 °C, nucleation of nanocrystallites is observed throughout the sample (Fig. 7). Continuous HRTEM observations reveal that the nucleation rate of dehydration products (mostly forsterites) becomes higher with increasing temperature. A large amount of nanocrystalline dehydrated products (~ 5–15 nm) forsterites and a few talcform in a short time, and they are highly crystalline and randomly oriented, as suggested by the corresponding Fourier transform (Fig. 4d–f and insets). The radial intensity profile also shows that the enhancement of characteristic peaks at 4.72 nm−1 (d = 2.14 Å) and 6.71 nm−1 (d = 1. 49 Å) is almost instantaneous (Fig. 5), indicating a significantly higher nucleation rate compared to 500 °C. Combined with EDS analysis (Fig. 2c), we suggest the extensive nucleation may signal rapid dehydration. The above observations indicate that the nucleation of dehydration products is controlled by temperature, i.e., the higher the temperature, the faster the nucleation. However, we have not observed a significant difference in the size of the dehydration products at different temperatures so far, which may be limited by the sample size and heating time in our experiments.

Two typical regions in Fig. 8 (I and II) are examined to study the detailed evolution process of nanocrystalline products. As shown in Fig. 8a–c, the nucleation of products is not instantaneous at 500 °C but slow, and then the nanocrystalline forsterite grows in-situ with time. Upon the elevation of the heating temperature to 600 °C, rapid nucleation of several nanocrystalline forsterites with different orientations is firstly observed. As heating proceeds, the lattices of these forsterites intersect and grow, and their crystal nature can be verified by the corresponding Fourier transform (Fig. 8d–f and insets). We envisage that if heated for long enough and the size of the sample is large enough, the size of these forsterites might continue to increase to that observed in natural dehydrated serpentinites.

Morphology evolution of lizardite with heating

The boundaries of lizardite crystals are detected by segmentation of HAADF-STEM images (Fig. 2a) through a triangle threshold algorithm27 (Fig. 9a). Because the heating duration at each temperature is fixed at 15 min, the area shrinkage rate at the corresponding temperature can be calculated by dividing the area change of the solid part by heating time. It should be noted that these HAADF-STEM images were taken after heating for 15 min, reflecting the state of lizardite after heating/decomposition at the corresponding temperature. The morphology evolution of lizardite is analysed and divided into the following three stages (Fig. 9b): (1) a slight thermal expansion observed during the induction period below 200 °C, with an area increasing of 0.5%, from 0.5099 to 0.5124 μm2; (2) a steady shrinkage period between 200 and 300 °C with minor area fluctuations. This period displays a shrinkage rate of 6.376 × 10–6 μm2/s, which is attributed to the dynamic process of the loss of physically bound water and the amorphization of lizardite. The first two stages do not involve thermal decomposition of lizardite without obvious structural transition or shape change; (3) a sharp shrinkage stage when the temperature is above 400 °C, which is attributed to the decomposition of lizardite. As shown in Eq. (1), under low-pressure conditions, the decomposition of lizardite results in a solid volume reduction of ~ 25%28. Our results show that although the structural integrity is retained without falling into small fragments, the solid part of the sample obviously shrinks with dehydration (Fig. 9a,b). The shrinkage rate approaches 1.696 × 10–5 μm2/s at 400 °C, followed by a “rapid nucleation” stage with the shrinkage rate reaching its maximum up to 2.970 × 10–5 μm2/s at 600 °C. This means that at 400 °C, the decomposition of lizardite will form porosity at a rate of 3.33 × 10–5/s, and this rate will increase to 5.82 × 10–5/s at 600 °C (area shrinkage rate divided by the initial area of the measured lizardite). The solid area is eventually reduced by about 15%, indicating the reaction progress is about 60% at the end of heating. Taking into account the non-uniformity in the thickness of the lizardite crystal, this is more likely to be the upper limit of the reaction progress. Another interesting finding is that the edge of intergranular pores expands outwards gradually with the shrinkage of lizardite, inducing a pair of pores to connect (highlighted in Fig. 9a). Figure 9c demonstrates the area variations of an intergranular pore. Thermal expansion of lizardite facilitates pore closure as the initial pore area ~ 2.919 × 10–3 μm2 gently decreases to ~ 2.671 × 10–3 μm2 when the temperature is below 200 °C. Accompanied by dehydration, the pore area increased rapidly from ~ 2.750 × 10–3 μm2 at 300 °C to ~ 5.336 × 10–3 μm2 at 600 °C, about twice the initial pore area.

Quantitative analysis of lizardite morphology during the heating process. (a) Contours of lizardite crystal colour-coded by temperatures, illustrating the shrinkage of the lizardite grain with increasing temperature. (b) Area variations of solid part under different temperatures. (c) Area variations of intergranular pore (inset) under different temperatures.

Implications

This paper describes the real-time mineralogical and morphologic evolution at the nanoscale of an actively dehydrating lizardite using in-situ heating HRTEM. Although our experiments were not conducted at the high pressures typical of the crust or subduction zones, previous studies have shown that pressure has no obvious effect on the dehydration kinetics of serpentine13,29. At different pressures, there is no significant difference in the rate of phase decomposition/crystallisation13. Some studies on serpentine dehydration conducted at ambient or lower pressures (≤ 200 MPa) have been used to explain the dehydration processes occurring deep within subduction zones26,30. Thus, our results may be applicable to naturally dehydrating systems in hot subduction zones and crustal metamorphic regimes, where serpentine breakdown into forsterite + talc + water is possible.

The sequence of phase transformations observed in the in-situ heating experiments, as described above, involves well-crystallized lizardite, poorly crystalline or amorphous lizardite, and subsequently nanocrystalline forsterite and talc. This sequence is consistent with those observed in high-velocity friction experiments and natural serpentinite shear zones24,25. Metamorphosed veins preserved in Erro-Tobbio meta-serpentinites also verify the presence of nanocrystalline olivine in the incipient dehydration stage of serpentinites23. This means that the formation of nanocrystalline phases could be identified here as the first step in the nucleation and growth of reaction products during serpentine dehydration. In particular, our results emphasize the role of dehydration temperature in controlling the nucleation and growth of reaction products, which likely determine the mechanical behavior of serpentinized rocks30,31,32,33. High temperatures are conducive to rapid and extensive nucleation of nanocrystalline reaction products, resulting in extreme grain size reduction. The nanoscale reaction products observed, with a grain-size distribution from 5 to 15 nm, are strikingly similar to those nanocrystalline grains generated in high-pressure faulting17,34. Such fine-grained aggregates are considered to drive nanometric flow and cause extreme weakening in rock during fault slip17. Only a small volume fraction of nanocrystalline phases is required to cause stress concentration, leading to large-scale shear localization35,36.

One of the interesting implications of our results pertains to the evolution of nanoscale structure in dehydrating serpentine, which is one of the key factors for understanding the mechanisms of fluid transport, mineral solubility, and chemical reactions22,37,38. We show that the solid part of lizardite gradually shrinks while maintaining its structural integrity during dehydration. The nanoscale intergranular pores gradually expand and induce the formation of interconnected pore networks. Lizardite-serpentinites inherently function as nanoporous media, with pore sizes ranging from sub − 10 to 100 nm39,40. Considerable interconnected porosity is expected in dehydrating serpentine, which might be a source of increased permeability41. Here, we provide the dynamic properties like area shrinkage rate and pore expansion rate, which are helpful for quantitatively investigating fluid migration in natural dehydration systems. However, we emphasize that these quantitative results are influenced by factors such as the sample’s chemical composition and grain size, which need to be further assessed in experiments. In addition, the elevated porosity and permeability during dehydration in natural systems would break down as the pore structure collapses due to brittle failure or creep28,42. Whether pore-fluid pressures build up depends on the relative dynamics of dehydration and drainage, and thus requires further research for different scenarios. For example, the dehydration of serpentine leads to the rapid development of interconnected pore networks, which is beneficial for the expulsion of water. Good drainage conditions facilitate further dehydration30 and may influence the characteristics of the reaction products43. In contrast, high confining pressures may quickly eliminate the porosity generated during the reaction process, thereby inhibiting the progress of dehydration41.

Methods

Preparation of lizardite

The samples used in the present experiments were serpentinized harzburgites, selected from drill cores recovered at the South Chamorro Seamount during ODP Leg 195, at Site 1200 (17G-1, 43–46). The average composition of the sample material44 is 39.01 wt% SiO2, 0.009 wt% TiO2, 0.42 wt% Al2O3, 8.92 wt% Fe2O3, 0.12 wt% MnO, 47.71 wt% MgO, 0.34 wt% CaO, 0.07 wt% Na2O and 0.05 wt% K2O.

In-situ TEM and EDS

The sample, after being crushed, was diluted with ethanol and homogenized with ultrasonic energy for 20 min to aid dispersion. The mixture of sample and ethanol was then sprayed over a silicon nitride film. The TEM investigation was performed using a 200 kV transmission electron microscope (JEOL, JEM-2100F) equipped with a Protochips in-situ heating test system. The Protochips sample holder is key for examining the same location because the sample on Protochips can be directly heated in every experiment run. We can therefore observe and record in-situ by TEM at any time during the heating period. Radiation damage of minerals by high-energy electrons during observation can be a problem, especially for beam-sensitive silicates like lizardite. Therefore, we examine the sample particles at moderate magnification to find regions with moderate and uniform thickness (Fig. 1a), supporting subsequent TEM observation and EDS analysis. Under our experimental conditions, the lizardite crystal remains stable under the electron beam in the first several acquisitions. The rate of increase of specimen temperature was controlled at 50 ℃/s. The sample was baked for 15 min at each of the following seven temperatures: 20, 200, 250, 300, 400, 500, 600 °C (Fig. 10). The TEM was conducted for in-situ observation during heating. The TEM is also equipped with semi-STEM control and ultra-thin window Oxford ISIS energy-dispersive X-ray spectrometer (EDS). After each baking stage, HAADF-STEM images were captured and chemical analysis for atoms heavier than C in the study area was conducted using EDS (stars in Fig. 10). Checked by repeated analysis, the analytical precisions of the major elements are all better than 0.5 wt.% (on the absolute value).

Data availability

Data are available upon reasonable request from the corresponding author.

References

Faccenda, M., Burlini, L., Gerya, T. V. & Mainprice, D. Fault-induced seismic anisotropy by hydration in subducting oceanic plates. Nature 455, 1097-U1098 (2008).

Hyndman, R. D. & Peacock, S. M. Serpentinization of the forearc mantle. Earth Planet Sci. Lett. 212, 417–432 (2003).

Ranero, C. R., Morgan, J. P., McIntosh, K. & Reichert, C. Bending-related faulting and mantle serpentinization at the Middle America trench. Nature 425, 367–373 (2003).

Grevemeyer, I., Ranero, C. R. & Ivandic, M. Structure of oceanic crust and serpentinization at subduction trenches. Geosphere 14, 395–418 (2018).

Hansen, S. M. et al. Seismic evidence for a cold serpentinized mantle wedge beneath Mount St Helens. Nat. Commun. 7, 6 (2016).

Rüpke, L. H., Morgan, J. P., Hort, M. & Connolly, J. A. D. Serpentine and the subduction zone water cycle. Earth Planet Sci. Lett. 223, 17–34 (2004).

Dobson, D. P., Meredith, P. G. & Boon, S. A. Simulation of subduction zone seismicity by dehydration of serpentine. Science 298, 1407–1410 (2002).

Jung, H., Green, H. W. & Dobrzhinetskaya, L. F. Intermediate-depth earthquake faulting by dehydration embrittlement with negative volume change. Nature 428, 545–549 (2004).

Peacock, S. M. Are the lower planes of double seismic zones caused by serpentine dehydration in subducting oceanic mantle?. Geology 29, 299–302 (2001).

Alizadehhesari, K., Golding, S. D. & Bhatia, S. K. Kinetics of the dehydroxylation of serpentine. Energy Fuels 26, 783–790 (2012).

Chollet, M., Daniel, I., Koga, K. T., Morard, G. & van de Moortèle, B. Kinetics and mechanism of antigorite dehydration: Implications for subduction zone seismicity. J. Geophys. Res.-Solid Earth 116, 9 (2011).

Gualtieri, A. F., Giacobbe, C. & Viti, C. The dehydroxylation of serpentine group minerals. Am. Miner. 97, 666–680 (2012).

Perrillat, J. P. et al. Kinetics of antigorite dehydration: A real-time X-ray diffraction study. Earth Planet Sci. Lett. 236, 899–913 (2005).

Trittschack, R., Grobéty, B. & Koch-Müller, M. In situ high-temperature Raman and FTIR spectroscopy of the phase transformation of lizardite. Am. Miner. 97, 1965–1976 (2012).

Viti, C. Serpentine minerals discrimination by thermal analysis. Am. Miner. 95, 631–638 (2010).

Brantut, N., Passelègue, F. X., Deldicque, D., Rouzaud, J. N. & Schubnel, A. Dynamic weakening and amorphization in serpentinite during laboratory earthquakes. Geology 44, 607–610 (2016).

Green, H. W., Shi, F., Bozhilov, K., Xia, G. & Reches, Z. Phase transformation and nanometric flow cause extreme weakening during fault slip. Nat. Geosci. 8, 484-U491 (2015).

Green Ii, H. & Burnley, P. A new self-organizing mechanism for deep-focus earthquakes. Nature 341, 733–737 (1989).

Karato, S. I. Rheology of the deep upper mantle and its implications for the preservation of the continental roots: A review. Tectonophysics 481, 82–98 (2010).

Ohuchi, T. et al. Intermediate-depth earthquakes linked to localized heating in dunite and harzburgite. Nat. Geosci. 10, 771 (2017).

Thielmann, M., Rozel, A., Kaus, B. J. P. & Ricard, Y. Intermediate-depth earthquake generation and shear zone formation caused by grain size reduction and shear heating. Geology 43, 791–794 (2015).

Plümper, O. et al. Fluid-driven metamorphism of the continental crust governed by nanoscale fluid flow. Nat. Geosci. 10, 685 (2017).

Plümper, O., John, T., Podladchikov, Y. Y., Vrijmoed, J. C. & Scambelluri, M. Fluid escape from subduction zones controlled by channel-forming reactive porosity. Nat. Geosci. 10, 150 (2017).

Tarling, M. S., Smith, S. A. F., Viti, C. & Scott, J. M. Dynamic earthquake rupture preserved in a creeping serpentinite shear zone. Nat. Commun. 9, 8 (2018).

Viti, C. & Hirose, T. Thermal decomposition of serpentine during coseismic faulting: Nanostructures and mineral reactions. J. Struct. Geol. 32, 1476–1484 (2010).

Liu, T., Wang, D. J., Shen, K. W., Liu, C. J. & Yi, L. Kinetics of antigorite dehydration: Rapid dehydration as a trigger for lower-plane seismicity in subduction zones. Am. Miner. 104, 282–290 (2019).

Zack, G. W., Rogers, W. E. & Latt, S. A. Automatic measurement of sister chromatid exchange frequency. J. Histochem. Cytochem. 25, 741–753 (1977).

Rutter, E. H., Llana-Funez, S. & Brodie, K. H. Dehydration and deformation of intact cylinders of serpentinite. J. Struct. Geol. 31, 29–43 (2009).

Rubie, D., Thompson, A. Kinetics of metamorphic reactions at elevated temperatures and pressures: an appraisal of available experimental data. In Metamorphic Reactions: Kinetics, Textures, and Deformation. (Springer, 1985).

Okazaki, K. & Katayama, I. Slow stick slip of antigorite serpentinite under hydrothermal conditions as a possible mechanism for slow earthquakes. Geophys. Res. Lett. 42, 1099–1104 (2015).

Rutter, E. & Brodie, K. Experimental, “sytectonic” dehydration of serpentinite under conditions of controlled pore water pressure. J. Geophys. Res. Solid Earth 93, 4907–4932 (1988).

Shao, T. B. et al. Potential link between antigorite dehydration and shallow intermediate-depth earthquakes in hot subduction zones. Am. Miner. 108, 127–139 (2023).

Takahashi, M. et al. On the transient response of serpentie (antigorite) gouge to stepwise changes in slip velocity under high-temperature conditions. J. Geophys. Res.-Solid Earth 116, 25 (2011).

Chester, J. S., Chester, F. M. & Kronenberg, A. K. Fracture surface energy of the Punchbowl fault, San Andreas system. Nature 437, 133–136 (2005).

Shi, F. et al. Metamorphism-facilitated faulting in deforming orthopyroxene: Implications for global intermediate-depth seismicity. Proc. Natl. Acad. Sci. U. S. A. 119, 11 (2022).

Sun, H. Y. & Pec, M. Nanometric flow and earthquake instability. Nat. Commun. 12, 9 (2021).

Cole, D., Striolo, A., Orcutt, B., Daniel, I., Dasgupta, R. The influence of nanoporosity on the behavior of carbon-bearing fluids. In Deep Carbon: Past to Present, 358–387 (2019).

Tutolo, B. M., Mildner, D. F. R., Gagnon, C. V. L., Saar, M. O. & Seyfried, W. E. Nanoscale constraints on porosity generation and fluid flow during serpentinization. Geology 44, 103–106 (2016).

Chogani, A. & Plümper, O. Decoding the nanoscale porosity in serpentinites from multidimensional electron microscopy and discrete element modelling. Contrib. Mineral Petrol 178, 17 (2023).

Malvoisin, B., Auzende, A. L., Kelemen, P. B., Oman Drilling Project Sci P. Nanostructure of serpentinisation products: Importance for water transport and low-temperature alteration. Earth Planet Sci. Lett. 576, 11 (2021).

Tenthorey, E. & Cox, S. F. Reaction-enhanced permeability during serpentinite dehydration. Geology 31, 921–924 (2003).

Leclère, H., Faulkner, D., Llana-Fúnez, S., Bedford, J. & Wheeler, J. Reaction fronts, permeability and fluid pressure development during dehydration reactions. Earth Planet Sci. Lett. 496, 227–237 (2018).

Proctor, B. & Hirth, G. Role of pore fluid pressure on transient strength changes and fabric development during serpentine dehydration at mantle conditions: Implications for subduction-zone seismicity. Earth Planet Sci. Lett. 421, 1–12 (2015).

Savov, I. P., Ryan, J. G., D’Antonio, M. & Fryer, P. Shallow slab fluid release across and along the Mariana arc-basin system: Insights from geochemistry of serpentinized peridotites from the Mariana fore arc. J. Geophys. Res.-Solid Earth 112, 30 (2007).

Acknowledgements

We thank the two anonymous reviewers for their constructive comments. This research work is funded by the National Natural Science Foundation of China (No. 92058211, No. 52074251 and 42121005), Shandong Province Department of Education for Taishan Scholars (No. tstp20221112), Laoshan Laboratory (No. LSKJ202203502), the Fundamental Research Funds for the Central Universities (No. 202012003), and 111 Project (No. B20048). We appreciate the samples and support provided by the ODP Leg 195 project.

Author information

Authors and Affiliations

Contributions

H.X. conceived the study. M.Q. carried out experiments and drafted the manuscript. H.X. funding acquisition, methodology and supervision. J. W., G. J., Z. H., W. Y. and Y.T. involved in the results investigation and discussion; J. L. and R. Z. contributed to image visualization and analysis. All the authors discussed the results and contributed to writing the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Qin, M., Xing, H., Wang, J. et al. In-situ observation of nanoscale transformations in dehydrating lizardite. Sci Rep 15, 4000 (2025). https://doi.org/10.1038/s41598-025-88077-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-88077-2