Abstract

Municipal solid waste incineration fly ash (MSWIFA) is of great value in resource utilization. Harmless pretreatment is a crucial prerequisite for the resource utilization of MSWIFA. The detoxification process is a crucial step in the harmless pretreatment of MSWIFA. This includes polychlorinated dibenzo-p-dioxins and dibenzofurans (PCDD/Fs), which are among the most toxic substances to humans and other living organisms. Low-temperature degradation technology has broad prospects in engineering applications due to the advantages of low technical difficulty and operating costs. This work conducts a pilot test on the degradation of 17 toxic PCDD/Fs in MSWIFA at low temperatures. The pilot test investigates the effects of reaction temperature and oxygen content on the degradation of PCDD/Fs in MSWIFA. Furthermore, based on the perspective of MSWIFA resource utilization, an analysis and a proposal are made to judge the degradation effect of low-temperature thermal treatment technology on PCDD/Fs in MSWIFA. Further, taking the soil sludge field as the application scenario, the application feasibility of MSWIFA after detoxification is analyzed. The flotation process markedly reduces both the carbon content and the levels of PCDD/Fs in MSWIFA. The hydrothermal method facilitates the degradation of dioxins in fly ash while introducing oxygen significantly lowers the reaction temperature required for fly ash treatment. This can enhance the degradation rate and reduce the demands on reaction equipment. The results indicate that the low-temperature thermal treatment technology can effectively degrade PCDD/Fs in MSWIFA, satisfying the requirements of some application scenarios. Notably, evaluating the effect of low-temperature thermal treatment technology on the degradation and detoxification of PCDD/Fs in MSWIFA should satisfy the residue requirements of different industries and achieve a certain detoxication efficiency.

Similar content being viewed by others

Introduction

Municipal solid waste primarily originates from the waste generated by human and animal activities within urban areas, as well as discarded materials that are no longer in use. With continuous urbanization, more domestic garbage is generated in the cities. To solve the problem of urban garbage and alleviate land occupation, the incineration of waste has become one of the most efficient and environmentally friendly methods. However, the municipal solid waste incineration fly ash (MSWIFA) is classified as hazardous waste due to the presence of potentially toxic elements (PTEs), such as polychlorinated dibenzo-p-dioxins and dibenzofurans (PCDD/Fs), heavy metals, and chlorine salts1,2.

In China, the most commonly used method for landfill disposal after solidification/stabilization is cement solidification combined with chemical stabilization3. This method operates on the fundamental principle of chemically stabilizing the hazardous wastes present in MSWIFA. Thus, they can be converted into a substance characterized by low solubility, limited migration, and reduced toxicity. The dangerous wastes are subsequently encapsulated in a durable cement matrix through the process of cement solidification, thereby mitigating the potential leaching of hazardous constituents within the waste4. However, this method does not convert hazardous waste into harmless substances, posing a potential risk of dangerous waste leakage while using cement. Therefore, the safe treatment method should convert fly ash’s PCDD/Fs and chlorine salts into nontoxic and pollution-free substances. On this basis, the heavy metals are stabilized or collected separately and are centrally processed. For example, treating MSWIFA with the mechanochemical (MC) method demonstrates effective degradation of PCDD/Fs. The processed MSWIFA can then be used as supplementary cementitious materials (SCMs), providing filling and pozzolanic effects that enhance the performance of MSWIFA concrete blocks5. Huang et al.6 stated that harmless pretreatment is a crucial prerequisite for the resource utilization of MSWIFA.

The detoxification process is a vital step in the harmless pretreatment of MSWIFA. The PCDD/Fs are among the most toxic substances to human beings and other living organisms. PCDD/F usually refers to the group of polychlorinated planar aromatic compounds with similar structure and physical and chemical properties, which include 75 polychlorinated dibenzo-p-dioxins (PCDDs) and 135 polychoral-dibenzofurans (PCDFs). In 2001, PCDD/Fs have been listed in the Stockholm Convention7.

Present studies on dioxin degradation mainly focus on the following degradation technologies: plasma, mechanical chemical, photocatalytic, biodegradation technology, and thermal degradation technologies8. Low-temperature thermal treatment technology is the most suitable method due to the simple process and low energy consumption. As early as 1987, Hagenmaier et al.9 revealed that dioxins could be degraded under low temperatures and anaerobic conditions. This method could achieve the desired detoxification effect of dioxins at low temperatures (300 ~ 600°℃) and was studied in the last few decades. The current study on low-temperature thermal treatment technology for PCDD/Fs primarily focuses on optimizing the parameters of the thermal treatment process (such as pyrolysis atmosphere, reaction temperature, and reaction time). Li et al.10,11 conducted a correlation analysis on the influence of experimental process parameters (reaction temperature, reaction time, and oxygen contents) on the degradation stage of low-temperature thermal treatment. Similarly, Li et al.10,11 reviewed the degradation techniques for treating PCDD/Fs in MSWIFA.

The analysis shows that low-temperature thermal treatment technology has enormous potential in large-scale applications and is more in line with the goal of low-carbon emissions reduction. However, representative research findings reveal significant differences in the effectiveness of low-temperature thermal degradation (LTTD) of dioxins in MSWIFA12,13,14,15,16,17,18,19. This difference may be attributed to the reaction temperature, time, and atmosphere20. On this basis, some research findings may prove other reasons for this difference. The composition of MSWIFA significantly affects the degradation effect of PCDD/Fs. Some metal compounds21, transition metal oxides22, or metal elements19 may promote the degradation of PCDD/Fs.

Nevertheless, CuCl2 has a catalytic effect on the synthesis of PCDD/Fs. Thus, it is necessary to control the generation of CuCl2 by reducing the oxygen content, which is beneficial for reducing the regeneration of PCDD/Fs23. Furthermore, the above studies12,13,14,15,16,17,18,19 indicate that the different composition of MSWIFA is closely related to the process of flue gas before entering the dust collector. Compared to the flue gas leaving the incinerator after cooling and directly entering the dust collector12, the flue gas first contacts activated carbon and Ca(OH)2 before entering the dust collector16. This can reduce PCDD/Fs, chloride salts, and metal oxides in the MSWIFA collected from the dust collector.

This inevitably led to a noticeable alteration in the composition of MSWIFA. Moreover, the MSWIFA employed in the experiment might undergone a screening process. The MSWIFA used in the experiment first removed the large particles, and then removed soluble chlorides that might poison catalysts using deionized water before pyrolysis18,19.

All the samples in the above studies experienced degradation effects as small amounts of MSWIFA were used under laboratory conditions. Correspondingly, pilot tests were conducted to achieve engineering applications. Chen et al.24 mixed MSWIFA with sewage sludge for thermal treatment. Huang et al.25 added MSWIFA to the iron ore sintering process. Zhang et al.26 coupled the coal-fired power plant process with solid waste combustion. Xiao et al.27 and Yu et al.28 added economizers to the flue gas purification system.

However, the above research pointed out that the above measures only inhibited the generation of PCDD/Fs during the combustion process and the regeneration of dioxins during the flue gas purification process. There were no significant degradation effects on the already generated PCDD/Fs. Furthermore, some findings revealed that the actual engineering scale conditions could not achieve the same degradation effect as the laboratory research scale. Hung et al.29 studied laboratory-scale and pilot tests on removing PCDD/Fs from sludge soil. The research results indicated that under laboratory scale, the dioxins’ removal efficiency (RE) was higher than 97% at temperatures of 400 ℃. However, under the conditions of pilot tests, the RE of PCDD/Fs at a temperature of 500 ℃ was less than 93%. Even under high-temperature conditions (750 ℃), the RE of PCDD/Fs did not exceed 97%.

Xue et al.30 proposed a collaborative thermal treatment method that combined MSWIFA with electrolytic manganese slag to detoxify PCDD/Fs at relatively low temperatures. This method leveraged the synergistic effects of manganese oxides, ammonia gas, and the thermal field, exploring the degradation pathways and mechanisms of PCDD/F congeners. The technique’s effectiveness was validated through a comparative analysis of concentrations and fingerprint profiles. This study provided a new low-temperature thermal treatment method. However, its feasibility and cost-effectiveness in practical applications, particularly in different types of waste and real-world operational environments, remained unclear. Furthermore, the stability and activity of manganese oxides as catalysts needed further evaluation.

In contrast, Gao et al.31 introduced a dual-strategy LTTD method involving pre-dechlorination and maintaining a reducing atmosphere, which demonstrated higher efficiency in PCDD/Fs detoxification. The process removed soluble chlorines and metals through pre-dechlorination and hydrolyzed CaClOH to Ca(OH)₂, further enhancing PCDD/Fs detoxification. When combined with activated carbon to inhibit PCDD/F reformation, the method achieved detoxification efficiencies of 99.4 and 97.4% under 1 and 2% oxygen, respectively. This innovative method is more efficient than traditional LTTD but faces challenges in ensuring the completeness and stability of the pre-dechlorination process. Ensuring the stable operation and maximization of effectiveness, especially under low oxygen concentrations, remains a significant challenge. Although both studies have made significant progress in LTTD, particularly in PCDD/F degradation mechanisms and efficiency, neither fully addresses the applicability and scalability of these techniques in different environments.

In summary, two key conclusions can be drawn from the current state of low-temperature thermal treatment technology for the degradation of PCDD/Fs in MSWIFA. First, the composition of MSWIFA used in laboratory-scale studies may differ from that of fly ash generated in actual waste incineration processes. Meanwhile, there is insufficient evidence to confirm that the degradation effect observed in laboratory conditions is consistent with that in real-world engineering applications. Second, there is a lack of pilot-scale studies on the degradation of PCDD/Fs in MSWIFA under low-temperature conditions, making it difficult to assess the practical effectiveness of low-temperature thermal treatment technology in engineering applications. To address this gap, this work conducts pilot tests to evaluate the degradation of PCDD/Fs in MSWIFA under low-temperature conditions (reaction temperature and oxygen content). It aims to explore the impact of low-temperature thermal treatment on PCDD/Fs degradation and provide technical support for the resource utilization of fly ash.

This work proposes the following scientific hypotheses based on the existing research background and technical challenges. Hypothesis 1: Low-temperature thermal treatment can effectively degrade PCDD/Fs in fly ash. Within an appropriate temperature range, low-temperature thermal treatment technology can decompose PCDD/Fs in fly ash through pyrolysis and catalytic oxidation processes. This can achieve degradation effects comparable to, or even better than, traditional high-temperature methods. Hypothesis 2: The degradation effect of low-temperature thermal treatment is closely related to the application scenario. The composition of fly ash and the concentration of pollutants may vary depending on the source and treatment method. Therefore, the degradation effect of low-temperature thermal treatment is influenced by these factors.

Hypothesis 3: The generation of secondary pollutants during low-temperature thermal treatment can be controlled through technological optimization. It can be assumed that the formation of secondary pollutants can be reduced during degradation by improving the treatment process and introducing catalysts or adsorbent materials. Thus, the environmental friendliness and feasibility of the technology can be enhanced. Hypothesis 4: Low-temperature thermal treatment has advantages in terms of economic viability and sustainability. Compared to high-temperature treatments, low-temperature thermal treatment requires less energy consumption, which helps reduce the overall operational costs when processing fly ash. Furthermore, as the technology continues to improve, large-scale applications of low-temperature thermal treatment may demonstrate greater economic potential in cost control and long-term operations. Therefore, it can be assumed that low-temperature thermal treatment technology offers greater cost-effectiveness and sustainability than traditional methods, making it particularly suitable for large-scale and long-term applications.

The main objectives of this work are as follows. First, based on pilot test experiments, the degradation effect of PCDD/Fs by low-temperature thermal treatment technology under different reaction temperatures and oxygen concentrations is investigated, evaluating the potential for its application in practical engineering. Second, the influence of various treatment conditions on the RE of PCDD/Fs is analyzed to verify the effectiveness of low-temperature thermal treatment technology and provide a scientific basis for the resource utilization of fly ash. Finally, the feasibility of reusing fly ash after detoxification, particularly in fields such as soil and sludge, is explored in conjunction with the resource utilization of fly ash after low-temperature thermal treatment.

In addition, the innovative contributions of this work are as follows. (1) The pilot test fills the gap in the engineering application of low-temperature thermal treatment technology for PCDD/Fs degradation in MSWIFA, providing data support for the further promotion of this technology; (2) The degradation effects of PCDD/Fs under various low-temperature conditions are assessed. Meanwhile, the relationship between these effects and resource utilization is explored, offering practical guidelines for fly ash treatment and application scenarios; (3) The impact of oxygen concentration and reaction temperature on the degradation effect is analyzed in-depth, providing a reference for optimizing the low-temperature thermal treatment process and improving degradation effects. Through these objectives and contributions, this work not only offers new insights into the application of low-temperature thermal treatment technology in fly ash degradation but also paves the way for the resource utilization of MSWIFA.

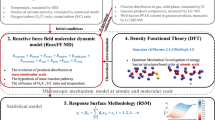

Theoretical and experimental basis

Generation and catalytic reaction mechanisms of PCDD/Fs

Currently, three primary mechanisms for the emission of PCDD/Fs during combustion are widely accepted within the scientific community:

Firstly, PCDD/Fs naturally present in the waste material, if not sufficiently destroyed during combustion, can directly remain in the flue gas produced. These undegraded PCDD/Fs are then released into the atmosphere, causing environmental pollution. The study by Lu et al.32 verified this phenomenon. It revealed the buffering effect of the economizer on PCDD/Fs, which contrasts with the widely recognized memory effect. Through 36 full-scale experimental datasets under three typical operating conditions, the study uncovered the underlying mechanism. The results showed that the buffering effect, including interception and release, could remove an average of 82.9% of PCDD/Fs from the flue gas and modulate the concentration distribution of PCDD/Fs. The interception effect was dominant and followed the condensation law.

Secondly, a series of cyclic precursors, structurally similar to PCDD/Fs, are generated under incomplete combustion conditions. These precursors are primarily chlorinated aromatic hydrocarbons. During combustion, these precursor molecules undergo complex molecular disassembly or recombination reactions, eventually converting into PCDD/Fs. This process is called the gas-phase (homogeneous) reaction that generates PCDD/Fs.

Lastly, PCDD/Fs can also be synthesized on the surface of solid fly ash through heterogeneous catalysis. During combustion, residual carbon, oxygen, hydrogen, chlorine, and other elements, along with metal catalysts in the fly ash, form catalytic active sites on the ash surface. These active sites catalyze the formation of intermediate products of PCDD/Fs or directly catalyze the conversion of PCDD/Fs precursor compounds in the gas phase. This is because, firstly, the presence of chlorine in fly ash is considered one of the key factors catalyzing the formation of PCDD/Fs. Xing et al.33 indicated that chlorine could interact with metal catalysts in fly ash, such as Fe and Cu, to form reactive catalytic centers, thereby promoting PCDD/Fs synthesis. On the surface of fly ash, chlorine can combine with metal surfaces through chlorination reactions, forming metal chloride complexes. These chlorides not only enhance the efficiency of PCDD/Fs formation but may also accelerate the reaction rate by providing reactive sites. Secondly, metal catalysts play an important role in PCDD/Fs synthesis. According to Xiao et al.34, metals such as Fe and Cu could act as catalysts to promote the formation of PCDD/Fs. Under high-temperature conditions, Fe may react with chlorine in fly ash to form intermediate products like FeCl2, which further participate in PCDD/Fs formation. Cu may promote redox reactions, increasing the concentration of free radicals in the reaction system, thus intensifying PCDD/Fs synthesis.

Subsequently, under incomplete combustion conditions, a series of cyclic precursor compounds with structural similarities to PCDD/Fs are generated. These precursor compounds are primarily chlorinated aromatic hydrocarbons, such as chlorobenzene, dichlorobenzene, chlorophenol, and polychlorinated biphenyls (PCBs). During the combustion process, these chlorinated aromatic compounds undergo a series of complex decomposition or reorganization reactions, ultimately converting into PCDD/Fs. This process, known as gas-phase (homogeneous) reactions, involves a sequence of chlorination and rearrangement reactions, leading to the formation of PCDD/Fs.

Chlorobenzene is one of the key precursor compounds for the formation of PCDD/Fs. At high temperatures, chlorobenzene and its derivatives are prone to further chlorination or decomposition, forming PCDDs and PCDFs. Also, PCBs and chlorophenols are considered potential precursors for PCDD/Fs. In particular, the presence of chlorine groups in chlorophenols provides possible reaction sites for the formation of PCDD/Fs. This process occurs under high temperature and low oxygen conditions. At the same time, it involves molecular reactions in the gas phase, where these precursor compounds form secondary reaction products in the gas phase during combustion. When combined with the action of metal catalysts, the conversion mechanisms of these chlorinated aromatic hydrocarbons become more complex, potentially catalyzing the formation of PCDD/Fs in the later stages of combustion.

The catalytic degradation of PCDD/Fs mainly follows two reaction pathways. The first pathway is the dechlorination reaction. In this step, the C-Cl bonds in the PCDD/Fs molecules break, removing chlorine atoms from the molecules. As the dechlorination reaction progresses (i.e., the continuous cleavage of C-Cl bonds), PCDD/Fs molecules gradually transform into dechlorinated products of dibenzo-p-PCDD/Fs (DD) and dechlorinated products of dibenzofuran (DF).

The second pathway is the oxidation reaction. In this process, DD and DF, which have already been converted via dechlorination, as well as other potential intermediate products, are involved. These intermediates include various monobenzene ring organic compounds formed from the C-O bond cleavage of PCDDs and PCDFs, which undergo further reactions in the presence of active components. Then, these monobenzene ring organic compounds undergo ring cleavage and decompose into aliphatic hydrocarbon intermediates. Simultaneously, DD and DF may generate biphenyl-type organic compounds under the influence of active components. Under certain conditions, both degradation pathways can proceed simultaneously, but their dominance is influenced by factors such as temperature, catalyst type, and reaction atmosphere. Specifically, under low-temperature conditions, dechlorination reactions typically dominate, while oxidation reactions are more prominent at high temperatures. In some cases, dechlorination and oxidation reactions may promote each other, particularly under specific catalysts and reaction conditions.

The aforementioned monocyclic organic compounds, bicyclic organic compounds, and aliphatic hydrocarbon intermediates are not the final degradation products. They further participate in oxidation reactions and, through oxidative processes, are progressively transformed into simpler inorganic substances such as CO₂, H₂O, and HCl. These final products signify that the PCDD/Fs molecules have been completely degraded, achieving harmless disposal.

Preparation of monolithic catalysts

In the catalytic technology field, monolithic catalysts have garnered widespread attention due to their high efficiency and stability. Four common structural types of monolithic catalysts, as displayed in Fig. 1, encompass honeycomb, flat-plate, corrugated plate, and cloverleaf structures.

The honeycomb monolithic catalyst is known for its distinctive honeycomb-like structure, encompassing a series of parallel, independent hexagonal or other-shaped channels. This design increases the geometric surface area of the catalyst and promotes the uniform distribution of fluids within the catalyst bed, thereby enhancing catalytic efficiency. Additionally, the honeycomb structure offers excellent mechanical strength and thermal stability, enabling it to withstand harsh operating conditions such as high temperatures and pressures. Honeycomb monolithic catalysts are widely utilized in automotive exhaust purification, industrial waste gas treatment, and other applications.

The flat-plate monolithic catalyst includes several parallel plates, creating narrow channels between them. The flat-plate structure is characterized by its simple geometric shape and ease of manufacture. Although the flat-plate catalyst’s surface area may be smaller compared to the honeycomb structure, the fluid flow within its channels is more uniform, facilitating thorough mixing and mass transfer of reactants. Flat-plate monolithic catalysts are suitable for treating low-concentration or specific types of waste gases, such as those found in indoor air purification.

The corrugated plate monolithic catalyst combines the benefits of both flat-plate and honeycomb structures. Its channels are formed by a series of wavy plates. This design not only increases the surface area of the catalyst but also promotes turbulent fluid flow within the channels, facilitating the mixing and mass transfer of reactants. Moreover, this design exhibits good mechanical strength and thermal stability, allowing the catalyst to withstand high pressures and temperatures. This type of catalyst is particularly suitable for the treatment of high-concentration or complex waste gases, such as those from petrochemical industries.

The cloverleaf monolithic catalyst features unique cloverleaf-shaped channels, formed by a series of interlocking cloverleaf patterns. Each channel is curved and has a substantial surface area. This structure provides more complex fluid flow pathways, promoting thorough mixing and mass transfer of reactants. Additionally, cloverleaf monolithic catalysts exhibit exceptional corrosion resistance and thermal stability, enabling them to maintain stable catalytic performance in harsh operating environments. These catalysts are especially effective for treating waste gases that contain corrosive components or require high-temperature and high-pressure conditions.

Pilot-test experiment system

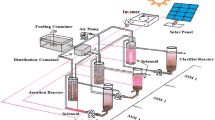

Design of pilot-test experiment system

Compared with laboratory-scale experiments, the pilot test is more convenient for extracting and formulating improvement strategies. The low-temperature degradation system for PCDD/Fs in MSWIFA is expanded and renovated based on the waste treatment transition facility in Xiong’an New Area (China), located in northern China. This facility has a daily waste disposal capacity of approximately 300 tons. Solid waste is processed using a “crushing & vertical rotary pyrolysis gasification” method to ensure stable and efficient combustion. The flue gas purification system consists of an SNCR, a semi-dry reaction tower, a lime slurry, an activated carbon injection system, a bag-type dust collector, and a deacidification tower. The core process of the garbage incineration technology involves the entry of domestic waste into the pyrolysis gasification furnace via the feeding device. Moreover, the SNCR system mainly uses urea solution as a reducing agent during the combustion process. The flue gas from the pyrolysis gasification furnace enters the secondary combustion chamber for further combustion. The temperature in the secondary combustion chamber is higher than that of the pyrolysis gasification furnace. After passing through the secondary combustion chamber, the flue gas in the secondary combustion chamber becomes high-temperature flue gas and remains in a high-temperature state. It is then cooled by a cooling tower before entering a semi-dry reaction tower to remove some heavy metals and harmful gases. Subsequently, the lime slurry and activated carbon are sprayed into the flue gas to further remove the heavy metals, PCDD/Fs, and acidic gases. The flue gas continues to pass through the bag-type dust collector to remove the fly ash before entering the deacidification tower. Moreover, deep removal of acidic gases is achieved by spraying alkaline liquid into the deacidification tower. Finally, the flue gas passing through the deacidification tower can meet the national emission standards.

It is worth noting that the existing transitional facilities still adopt the landfill method for the MSWIFA collected in the bag-type dust collector, without any detoxification treatment. To some extent, this results in a waste of resources. Furthermore, as the flue gas passes through the semi-dry reaction tower and the lime slurry and activated carbon injection system, it captures some toxic substances such as PCDD/Fs and heavy metals. This leads to even detoxification of the MSWIFA collected in the bag-type dust collector, which cannot remove PCDD/Fs captured by the adsorption of activated carbon. The composition of MSWIFA has already changed. Hence, the design of the pilot test system for the low-temperature degradation system for PCDD/Fs in MSWIFA improves the above issues.

First, the existing technique is expanded to combine the flue gas purification process and the MSWIFA thermal treatment process using the waste heat of flue gas. Second, it ensures that the collection of MSWIFA generated by waste incineration. The pilot test’s overall idea is to introduce 100 m3/h of flue gas (temperature 800–1000 ℃) from the outlet of the secondary combustion chamber ash hopper of the existing transition facility. The high-temperature flue gas is converted into low-temperature flue gas (below 200 ℃) through the custom-designed water-cooled heat exchanger. The high-temperature water vapor generated in the heat exchanger transfers heat to a waste heat collection device. The low-temperature flue gas is then directed to the semi-dry reaction tower after passing through the custom-designed bag-type dust collector. The MSWIFA collected by the dust collector is transferred to a specially designed low-temperature degradation system for PCDD/Fs in MSWIFA. During the thermal treatment, a waste heat collection device provides heat for the reaction, while the gas generated during the thermal treatment are also routed to the semi-dry reaction tower. Figure 2 shows the pilot-test experiment system of the low-temperature degradation system for PCDD/Fs in MSWIFA. Figure 3 denotes the custom-designed water-cooled heat exchanger and bag-type dust collector.

Low-temperature degradation system for PCDD/Fs in MSWIFA

Given the low concentration of PCDD/Fs in fly ash and the complex composition of the samples, which contain numerous substances that may cause interference, a series of complex and meticulous pretreatment steps must be performed prior to analysis. The pretreatment techniques form a critical component of the analytical process for PCDD/Fs compounds. The quality and efficiency of these steps directly impact the accuracy, sensitivity, analysis speed, and cost-effectiveness of the entire analytical procedure.

The detection pretreatment process for PCDD/Fs in fly ash samples and solutions involves five key stages. The first step is acid washing to remove surface impurities. This is followed by an extraction process aimed at effectively isolating and enriching the target analytes. Nitrogen evaporation is then conducted to reduce the sample volume and increase the concentration of the analytes. The next stage is the purification process, which further removes potential interferences. Lastly, nitrogen evaporation is performed again to ensure that the sample achieves the required concentration and volume for analysis. The pretreatment steps for PCDD/Fs in both fly ash and solution samples are illustrated in Fig. 4.

In Fig. 4, during the acid washing process, 3 g of dried fly ash samples are precisely weighed and placed in a glass fiber filter (specification: 25 mm, Whatman GF/A). Next, a tracer reagent, consisting of 0.1 g of diphenyl ether (a typical extraction tracer with 99% purity), is added. Then, the filter containing the sample and tracer is placed in a beaker, and 30 mL of 2 mol/L hydrochloric acid (ACS grade, purchased from Sigma-Aldrich) is added. To ensure full reaction between the fly ash sample and hydrochloric acid, the beaker is gently shaken, and the reaction temperature is maintained at room temperature (25 °C). Additional hydrochloric acid is added as needed to ensure complete contact between the sample and the acid solution. This step facilitates a strong reaction between hydrochloric acid and the organic matter in the fly ash, forming an acid solution.

After the acid-washing reaction, the acid-treated solution is filtered using the glass fiber filter. The filtration device used is a pure glass funnel (specification: 90 mm), and the filtered solution is rinsed with 100 mL of deionized water to remove any residual hydrochloric acid and soluble impurities. Subsequently, the filter is washed with 100 mL of acetone (99% purity, purchased from Fisher Scientific) to remove any remaining water and other volatile impurities. This ensures the cleanliness of both the sample and filter.

The cleaned glass fiber filter and sample are returned to the previously used beaker and transferred to a drying apparatus for complete drying. The drying device is an incubator (model: Binder ED 115, accuracy ± 0.5 °C). The samples are dried at 105 °C for 12 h to ensure the removal of all moisture from the sample, providing a dry sample for subsequent analysis.

During the extraction phase, two methods are employed: liquid–liquid extraction and Soxhlet extraction.

-

(1) Liquid–liquid extraction: For the ammonium chloride leachate and the liquid phase after acid washing, 60 mL of dichloromethane (99% purity, purchased from Merck) is used for three consecutive extractions. After each extraction, the mixture naturally separated into two layers: the organic phase and the aqueous phase. To remove moisture and impurities from the aqueous phase, the organic phase is dried with anhydrous sodium sulfate (99.5% purity, Sigma-Aldrich), ensuring the purity of the anhydrous extract. Finally, the extract is transferred to a round-bottom flask (250 mL, Pyrex) for subsequent analysis.

-

(2) Soxhlet extraction: For solid samples, traditional Soxhlet extraction is used. The Soxhlet extractor (model: Soxhlet Extractor, purchased from Labconco) is pre-cleaned. Meanwhile, a mixed solvent of dichloromethane (99% purity, Merck) and n-hexane (99% purity, Sigma-Aldrich) in a 1:1 ratio is prepared. The dried fly ash sample is placed in a glass fiber filter and tightly sealed with glass wool to prevent sample loss during extraction. The filter containing the sample is then placed in the Soxhlet extractor, and 250 mL of toluene (99% purity, Fisher Scientific) is used to heat and extract the sample for 18 h. During this process, toluene dissolved the organic contaminants in the sample, including PCDD/Fs, and continuously extracted them through the cyclic process.

During the concentration step, the extracts are combined and concentrated to 1–2 mL using a rotary evaporator. Following concentration, solvent exchange is performed with n-hexane, and the solution is adjusted to a final volume of 10 mL in a centrifuge tube. In the purification stage, various techniques such as sulfuric acid purification, silica gel column chromatography, and alumina column chromatography are employed to purify the sample. A 13C-labeled purification standard is added before the purification process. It is important to note that the sample should appear colorless after multi-layer silica gel column purification. If the solution retains color or shows a breakthrough in the column, further multi-layer silica gel column purification is necessary to ensure the sample’s purity and accuracy.

The low-temperature degradation system for PCDD/Fs in MSWIFA (LTDS-PM) is a custom-designed system. It includes an MSWIFA storage bin, a feeding mechanism, a rotary power unit, a sealing component, a heating unit, an inert gas filling system, a tail gas cooler, and an MSWIFA cooler, as indicated in Fig. 5. The volume of the fly ash storage bin is 0.18 m3. The pilot test bench can display the temperature of the reaction area. It can also adjust the continuous feeding screw speed via a Proportion Integration Differentiation (PID) control panel and a Liquid Crystal Display. The adjustable ranges of the reaction temperature and reaction time are 200 ~ 600 °C and 30 ~ 120 min, respectively.

The MSWIFA collected in the custom-designed bag-type dust collector is first stored in the MSWIFA storage bin. As the experiment begins, the MSWIFA is placed in the fly ash storage bin. The feeding and rotary power parts work together to send fly ash into the furnace. The rotary power part evenly distributes fly ash in the furnace, and consequently, the fly ash can be evenly heated. Then, it can set the reaction condition through the control part. After that, the heating part starts heating the fly ash and simultaneously the gas-filled part adjusts the oxygen content. During the reaction, the control part always adjusts and maintains the reaction temperature and oxygen content according to the feedback parameters. When the reaction ends, the heating part and gas-filled part stop working. The rotary power part works again to send the reacted fly ash to the fly ash cooler, which can be convenient for sampling and detection. The gas produced during the reaction is cooled by the tail gas cooler and returned to the semi-dry reaction tower. This process can collect the gas. The main purpose is to detect the content of PCDD/Fs in the gas and verify whether the PCDD/Fs in MSWIFA are degraded or transferred to the gas phase.

Debugging and experimental design of pilot-test experiment system

One of the biggest highlights of this pilot-test experiment system is the utilization of the waste heat from the high-temperature flue gas to provide heat for the LTDS-PM. The advantage is that it can fully utilize the waste heat resources of flue gas and avoid energy waste. However, the experimental process needs to maintain a stable reaction temperature. Therefore, before the experiment begins, it is necessary to debug the pilot-test experiment system to determine the temperature range that the flue gas can maintain during the reaction process.

First, it takes a certain amount of MSWIFA from the bag-type dust collector of the original flue gas purification system and places it into the furnace of LTDS-PM, with a filling amount accounting for about two-thirds of the furnace volume. Because the control of oxygen content during the reaction process is mainly achieved by increasing the inert gas content, there is inevitably a gas flow process within the furnace. This may lead to a change in reaction temperature, so it is necessary to maintain the fluidity of the gas in the furnace during debugging. In this process, the heating part does not work and the gas-filled part fills the air into the furnace at different flow rates. The airflow rates in the furnace are 10, 20, 30, 40, 50 and 60 L/min respectively. The corresponding rate of each flow rate lasts for 4 h. The debugging process runs continuously for 24 h.

The results of debugging show that the gas flow rate can change the heating temperature. Yet the heating temperature change is also affected by the total amount of high-temperature flue gas and its temperature. After 24 h, the high-temperature flue gas of the pilot test system can make the temperature range of LTDS-PM between 344 and 352 ℃. This pilot test explores the degradation of PCDD/Fs in MSWIFA under low temperature and low oxygen conditions. Based on the above debugging results, this experiment tested the effect of different temperatures and oxygen content on the thermal degradation of PCDD/Fs in MSWIFA. Existing research results prove that low temperature and inert gas environments are conducive to the degradation of PCDD/Fs. The downside is that most studies do not quantify the inert gas environment but pay more attention to the influence of temperature. A completely oxygen-free environment is not the most suitable environment for dioxin degradation. Zeinali35 showed that limited oxygen content could promote the decomposition of PCDD/Fs molecules.

In summary, this experiment first tests the degradation effect of temperature under low-oxygen conditions and then measures the degradation effect of oxygen content under low-temperature conditions. Table 1 lists the experimental conditions of PCDD/Fs degradation. The test result shows that the flue gas can maintain the temperature of the reaction process between 344 and 352 ℃. Consequently, the reaction temperature is set at 350 ℃ to study the degradation of PCDD/Fs using the oxygen content.

Detection and analysis

The MSWIFA formed by the flue gas is transported continuously into the MSWIFA storage bin in LTDS-PM The minimum mass volume of the designed MSWIFA storage bin is 220 kg. Meanwhile, the mass of MSWIFA stored before the experiment starts is 237 kg. The amount of MSWIFA filled in each experiment is consistent with the debugging process, about two-thirds of the furnace volume (approximately 15 kg).

The ash hopper outlet of the secondary combustion chamber can be closed after the experiment begins. The MSWIFA is fed into the furnace from the MSWIFA storage bin and stops feeding when the filling amount reaches two-thirds of the furnace volume. After each experiment, the samples from the MSWIFA collection are removed and placed into sampling bottle. The furnace is then cleaned before the next set of experiments. In each experiment group, the gas produced during the reaction is also collected, with an approximate volume of 2 Nm3.

The MSWIFA and gas samples were handed over to Shandong Gaoyan Testing Technology Service Co., Ltd. for PCDD/Fs content testing.

Results and discussion

The toxicity of PCDD/Fs is related to the substitution of chlorine atoms at 8 positions. The most concerning is the homologous compounds of PCDD/Fs with chlorine atoms at the four coplanar substitution positions 2, 3, 7, and 8, totaling 17 types. Therefore, the detection of PCDD/Fs in the original MSWIFA mainly focuses on the 17 homologs mentioned above. The result reveals that 17 PCDD/Fs homologs are detected in the original MSWIFA. Figure 6 shows the contents of 17 PCDD/Fs homologs in the original MSWIFA. In the original MSWIFA, the total content of 17 PCDD/Fs homologs is 3929.3 ng/kg. The lowest content of 17 PCDD/Fs homologs is 2,3,7,8-TCDD accounting for about 0.5%. The highest content of 17 PCDD/Fs homologs is 1,2,3,4,6,7,8-HpCDD, accounting for about 25.4%. The total amount of PCDFs is more than the total amount of PCDDs, accounting for 50.6% of the total content of 17 PCDD/Fs homologs. The toxic equivalent (I-TEQ) of the 17 PCDD/Fs homologs in the original MSWIFA is calculated to be 353.1 ng-TEQ/kg.

The RE and DE of 17 PCDD/Fs homologs in the original MSWIFA are defined.

mtotal represents the total mass of 17 PCDD/Fs in the original MSWIFA (ng/kg); mar denotes the total mass of 17 PCDD/Fs in MSWIFA after thermal degradation reaction (ng/kg); subscript ‘ar’ indicates after the reaction. In the same way, mtotal, TEQ refers to the total toxic equivalent (TEQ) mass of 17PCDD/Fs in the original MSWIFA (ng-TEQ/kg); mar, TEQ stands for the total TEQ mass of 17 PCDD/Fs in MSWIFA after thermal degradation reaction (ng-TEQ/kg).

Reaction temperature

The oxygen content and reaction time were set to 500 ppm and 1 h, respectively. The reaction temperatures are 100, 200, 300, 350, 400, and 450 ℃, respectively for Experiments 1 to 6.

The results shown in Fig. 7 indicate that the reaction temperature has a significant impact on the RE and DE of PCDD/Fs. However, neither of them increases monotonically with rising temperature. Experimental results reveal that at 450 °C, both RE and DE reach their highest values, with 99% efficiency for each. However, at lower temperatures (e.g., 100 °C), RE and DE are relatively low, at only 43 and 39%, respectively. These results suggest that the degradation of PCDD/Fs is not solely dependent on an increase in temperature, but rather there exists an optimal reaction temperature range.

Regarding the relationship between reaction temperature and degradation effects, it can be inferred that temperature exerts a complex influence on the RE of PCDD/Fs. At lower temperatures (e.g., 100°℃), the reaction rate is slower, and the thermal energy is insufficient to disrupt the chemical structure of PCDD/Fs, leading to poor degradation. At higher temperatures, although the reaction rate is faster, excessively high temperatures may promote the formation of by-products, reducing RE. Additionally, excessively high temperatures may cause chlorides and other harmful substances to recombine during the reaction, generating new pollutants that affect the final degradation outcome. Therefore, it is hypothesized that there exists an optimal temperature range in which a balance is achieved between the reaction rate and degradation effect. In Fig. 7, the degradation effect is most significant when the reaction temperature ranges between 350 and 450°℃, with both RE and DE remaining at high levels. This phenomenon indicates that moderate temperature conditions are beneficial for the complete degradation of PCDD/Fs while avoiding the formation of by-products at higher temperatures. Consequently, for the process optimization of low-temperature thermal treatment in PCDD/Fs, attention should be given to maintaining the temperature within this optimal range to achieve efficient and environmentally friendly degradation outcomes.

Table 2 shows the results of 17 PCDD/Fs residues after the reactions (Experiments 1 to 6). According to Table 2, the above reasons are mainly due to the degradation effect of the homologs of the different PCDD/Fs under various temperature conditions. At reaction temperatures from 100 to 450 ℃, the largest RE values of the PCDD/Fs are 1,2,3,4,7,8,9-HpCDF, 1,2,3,4,7,8,9-HpCDF, 1,2,3,7,8- PeCDF, 1,2,3,7,8,9-HxCDF, 2,3,4,6,7,8-HxCDF and 2,3,4,6,7,8-HxCDF; the RE values are 55.3, 93.6, 84.2, 99.5, 99.6, and 99.8%, respectively. In contrast to this, the lowest RE values of the PCDD/Fs are 1,2,3,7,8,9-HxCDD, 2,3,7,8-TCDF, OCDD, 2,3,7,8-TCDD, OCDD and OCDF, where the RE values are 7.1, 11.5, 57.3, 76.1, 89.9, and 96.9%, respectively. The RE of PCDDs is slightly higher than that of PCDFs at 200℃ (Experiment 2). However, the RE of PCDFs is slightly higher than that of the PCDDs under the remaining five temperature conditions (Experiment 1, Experiments 3 to 6).

Furthermore, a closer examination of the data in Table 2 reveals that the RE of certain PCDD/F isomers decreases as the reaction temperature increases. For example, for isomers such as 1,2,3,4,7,8-HxCDF, 1,2,3,6,7,8-HxCDF, 2,3,4,6,7,8-HxCDF, 1,2,3,7,8,9-HxCDF, 1,2,3,4,6,7,8-HpCDF, 1,2,3,4,7,8,9-HpCDF, OCDF, 1,2,3,4,7,8-HxCDD, 1,2,3,4,6,7,8-HpCDD, and OCDD, the residual amount at a reaction temperature of 400 °C is higher than that at 350 °C. This phenomenon suggests that for certain PCDD/F isomers, incomplete reactions or the formation of by-products may occur at higher temperatures, leading to a decrease in RE.

For other isomers, such as 1,2,3,4,6,7,8-HpCDF, 1,2,3,4,7,8,9-HpCDF, OCDF, 1,2,3,7,8-PeCDD, and OCDD, the residual amount gradually decreases with increasing temperature, indicating better degradation at higher temperatures. This result supports the effectiveness of low-temperature thermal treatment, suggesting that the unique degradation behaviors of certain isomers need to be considered during process optimization.

These results highlight the complex interplay between temperature and the structural characteristics of PCDD/F isomers. Some isomers with stronger structural stability may require higher temperatures to achieve complete degradation, whereas those with simpler chemical structures or higher reactivity may be effectively degraded at lower temperatures. Therefore, in practical applications, the optimization of low-temperature thermal treatment technology should consider the degradation characteristics of different PCDD/F isomers to enhance overall treatment efficiency.

In conclusion, the data in Table 2 further confirm the complex impact of reaction temperature on the degradation of PCDD/Fs and reveal the varying degradation behaviors of different isomers under low-temperature thermal treatment. These findings provide valuable experimental evidence for future optimization of low-temperature thermal treatment processes. Meanwhile, it offers important insights for further research into the degradation mechanisms and treatment technologies for dioxin-like pollutants in fly ash.

Figure 8 compares the RE of PCDD/F isomers at different reaction temperatures, leading to several important conclusions. First, the impact of temperature on the RE of different isomers shows significant variability. For example, at 200 and 300 °C, the RE difference for OCDD is the largest, reaching 28.9%, while the RE difference for 1,2,3,4,7,8-HxCDD is the smallest, only 0.4%. This indicates that temperature has a stronger influence on the RE of OCDD than on 1,2,3,4,7,8-HxCDD. Similarly, at 350 and 400 °C, the RE difference for OCDF is the largest, at 6.7%, while the RE difference for 1,2,3,4,7,8,9-HpCDF is the smallest, at 0.9%. These data suggest that at lower reaction temperatures (e.g., 200 and 300 ℃), the RE differences of PCDD/Fs are generally larger. In contrast, at higher temperatures (e.g., 350 and 400 ℃), the RE differences are smaller.

These results demonstrate that the RE of different PCDD/F isomers reacts differently to temperature variations. It can be inferred that the structural characteristics of these isomers, particularly the number and position of chlorine substituents, determine their sensitivity to temperature changes. For instance, PCDD/F isomers with high chlorination (e.g., OCDD and OCDF) exhibit larger changes in RE at lower temperatures, while those with fewer chlorine substituents show less sensitivity to temperature changes. Moreover, the RE of PCDFs is generally higher than that of PCDDs. This may be due to the smaller molecular structure and lower thermal stability of PCDFs compared to PCDDs.

In the lower temperature range (200 and 300 ℃), the RE of PCDFs is significantly affected by temperature changes, especially for PCDFs with high chlorination. At these temperatures, high-chlorinated PCDFs typically exhibit higher RE. This phenomenon further supports the effectiveness of low-temperature thermal treatment for the degradation of high-chlorinated PCDFs. This effect stabilizes at higher temperatures (e.g., 350 and 400 ℃), and the RE differences become smaller. This may be because at higher temperatures, the reaction rate is faster and the degradation process tends to be stable.

Overall, the results from Fig. 8 illustrate the degradation characteristics and temperature sensitivity of PCDD/F isomers under various temperature conditions. Notably, at lower temperatures (200 and 300 °C), high-chlorinated PCDFs show pronounced changes in RE, while the RE differences for PCDDs are relatively small. This finding is significant for optimizing the low-temperature thermal treatment process, particularly in the degradation of high-chlorinated PCDD/Fs, as it suggests that temperature range selection should be carefully considered to maximize RE. Furthermore, future research could explore the degradation mechanisms of PCDD/Fs with varying degrees of chlorination under different operational conditions, providing theoretical support for the development of future treatment technologies.

The above analysis proves that the residues and toxicity of 17 PCDD/Fs in MSWIFA are reduced after the reaction. However, it does not fully clarify whether the PCDD/Fs are degraded by the reaction or transferred to the gas phase. Therefore, it is essential to analyze the gas collected through the gas sampling points to determine whether the PCDD/Fs in MSWIFA are degraded or simply transferred. Table 3 lists the PCDD/Fs content in the gas phase.

The data in Table 3 exhibit that the transfer of PCDD/Fs to the gas phase occurs under conditions of low-temperature degradation. At the reaction temperatures of 100, 200, and 300 ℃, the contents of PCDD/Fs in the gas phase change greatly, indicating that some PCDD/Fs do not degrade at low temperatures. As the reaction temperature increases, the PCDD/Fs content in the gas phase decreases continuously. When the reaction temperature reaches 350 ℃, the PCDD/Fs content in the gas phase has almost no significant change.

Notably, the PCDD/Fs concentration in the gas phase is very low under the reaction conditions of 350 and 400°℃. However, it does not meet the national emission standard (< 0.1 ng-TEQ/m3, GB18485-2014). The conclusion can be drawn based on the analysis of Tables 2, 3. At a reaction temperature of 450°℃, an oxygen content of 500 ppm, and a reaction time of 1 h, the PCDD/Fs concentration in MSWIFA can be reduced to below 50 ng-TEQ/kg. This meets the requirements of the “Technical Specifications for Pollution Control of Municipal Solid Waste Incineration Fly Ash (Trial Version HJ 1134-2020)”. Moreover, the PCDD/Fs concentration in the gas phase can also be reduced to below 0.1 ng-TEQ/m3, thus satisfying the national emission standards. This indicates that, with proper control of temperature, oxygen content, and reaction time, the system can effectively meet the prescribed emission standards. However, further optimization is required at the lower temperatures of 350 and 400 °C to fully comply with the standards.

Oxygen content

The atmospheric conditions include nitrogen atmosphere 1, with an oxygen content of approximately 0.35%. Nitrogen atmosphere 2 has an oxygen content of approximately 0.1%. Nitrogen atmosphere 3 contains approximately 650 ppm oxygen. Nitrogen atmosphere 4 has an oxygen content of approximately 500 ppm. Finally, nitrogen atmosphere 5 has an oxygen content of approximately 320 ppm. These conditions correspond to Experiments 7, 8, 9, 4, and 10, respectively. At the same time, the reaction temperature and time are 350 ℃ and 1 h, respectively. The ppm is used as a unit of volume fraction, in which 1 ppm = 0.0001%.

Figure 9 presents an analysis of the impact of oxygen content on the RE and DE of 17 PCDD/Fs isomers. Five different nitrogen atmospheres are used in the experiments, with oxygen contents of approximately 0.35%, 0.1%, 650 ppm, 500 ppm, and 320 ppm. The reaction temperature and time are set at 350 °C and 1 h, respectively.

The results from Fig. 9 illustrate that as the oxygen content decreases, the changes in RE and DE are not significant. At the same time, RE and DE remain above 90% under all experimental conditions. Notably, at an oxygen content of 650 ppm, both RE and DE reach their maximum values, exceeding 99%. At an oxygen content of 0.35%, RE and DE are at their lowest values, 95.8 and 91.8%, respectively. More importantly, RE and DE do not continuously increase with the decrease in oxygen content; rather, optimal oxygen content is observed, suggesting that a low-oxygen environment does not indefinitely enhance RE.

This finding illustrates that oxygen content has an optimizing effect on the RE of PCDD/Fs, with an optimal value for oxygen concentration. At higher oxygen contents (e.g., 650 ppm), oxygen likely provides sufficient oxidative conditions for the degradation reaction, thus improving RE. However, as the oxygen content further decreases, insufficient oxygen may limit the progress of the oxidation reaction, resulting in slower or stagnated increases in RE. At extremely low oxygen concentrations (e.g., 0.35%), RE significantly decreases, likely due to the lack of oxygen inhibiting the reaction and preventing complete degradation of PCDD/Fs.

These results highlight the importance of optimizing oxygen content for the effectiveness of the low-temperature thermal treatment process. Too low an oxygen concentration may lead to decreased RE, while too high an oxygen concentration may not necessarily further improve RE. Therefore, an appropriate oxygen concentration range should be selected in practical applications to maximize RE and minimize energy consumption. Additionally, further studies could explore the combined effects of oxygen concentration and other reaction conditions (e.g., temperature, reaction time) on the degradation mechanism of PCDD/Fs, providing more theoretical support for process optimization. In conclusion, the results from Fig. 9 demonstrate the crucial role of oxygen content in the low-temperature thermal treatment process for RE of PCDD/Fs. It reveals the existence of an optimal oxygen concentration, beyond which excessively low and high oxygen contents can negatively affect RE.

Table 4 suggests the results of the 17 PCDD/Fs residues under different oxygen content. Similar to the effect of temperature, the different PCDD/Fs homologs have different RE values under diverse oxygen content conditions. As the oxygen contents are reduced from 0.35% to 320 ppm, the RE values of 2,3,4,6,7,8-HxCDF, 1,2,3,7,8, 9-HxCDF, 2,4,6,7,8-HxCDF, 1,2,3,7,9-HxCDF and 1,2,3,4,6,7,8-HpCDF in PCDD/Fs homologs increase significantly, reaching 98.6, 99.8, 99.9, 99.5, and 99.8%, respectively. The PCDD/Fs homologs with the smallest RE value across all conditions is 2,3,7,8-TCDD, with values of 41.5, 61.8, 96.9, 76.1, and 96.2%, respectively. When oxygen contents are 0.35 and 0.1%, the RE values of PCDDs are slightly higher than that of the PCDFs. However, when oxygen contents are reduced to 650 ppm, 500 ppm, and 320 ppm, the RE values of PCDFs are slightly higher than that of PCDDs.

The RE of PCDD/Fs decreases as oxygen content drops. Interestingly, unlike the effect of temperature, the RE of all 17 PCDD/Fs homologs at 650 ppm is higher than that of 500 ppm. Figure 10 shows the RE comparison of the PCDD/Fs homologs with oxygen content of 650 and 500 ppm. Under these conditions, the RE difference of 2,3,7,8-TCDD is the largest, reaching 20.8%, while the RE difference of 1,2,3,7,8, 9-HxCDF is the smallest, at 0.4%. Notably, with the exception of 2,3,7,8-TCDD, the maximum RE difference among the remaining 16 PCDD/Fs homologs does not exceed 5%.

In summary, the low-oxygen condition is more suitable for the removal of high chlorine substituents in PCDFs, and the change of oxygen contents has the least effect on the RE of 2,3,7,8-TCDD. Compared with the impact of temperature on the degradation effect of PCDD/Fs homolog, the variation in oxygen content has no significant effect on the variation range of PCDD/Fs homolog degradation effect.

Similarly, to verify whether PCDD/Fs in MSWIFA is degraded or transferred to the gas phase, the content of PCDD/Fs in gases collected by gas sampling points is analyzed. Table 5 outlines the PCDD/Fs content in the gas phase.

In Table 5, the oxygen content has almost no obvious influence on the PCDD/Fs content in the gas phase. This is significantly different from the effect of temperature variation on the PCDD/Fs content in the gas phase. Under the five oxygen content conditions, the PCDD/Fs content is in the range of 0.7 ~ 0.9 ng-TEQ/m3 in the gas phase. By comparing Tables 3, 5, it can be concluded that there is more operability range to adjust the oxygen content than to adjust the reaction temperature. This can inhibit the transfer of PCDD/Fs in MSWIFA to the gas phase during low-temperature degradation.

However, despite the very low PCDD/Fs content in the gas phase under the five experimental conditions, the emissions still do not meet the national discharge standard (< 0.1 ng-TEQ/m3, GB18485-2014). This indicates that, in practical applications, although PCDD/Fs emissions are lower under some experimental conditions, the system does not fully comply with the standard in all cases. Therefore, further optimization of the reaction conditions, particularly the regulation of oxygen content, reaction temperature, and reaction time, help better meet the national emission standards. In summary, under the experimental conditions, the optimal conditions are a reaction temperature of 450 °C, an oxygen content of 500 ppm, and a reaction time of 1 h. While emissions still do not fully meet the national standards, the system demonstrates strong regulatory potential. Moreover, with further optimization, the system can potentially achieve full compliance with emission standards in more practical industrial applications.

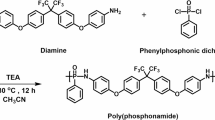

Impact of ammonium leaching on the distribution of PCDD/Fs in fly ash

Figures 11, 12 show the PCDD/Fs content in the original fly ash and ammonium leachate residue, respectively. The PCDD/Fs content in the ammonium leachate residue is remarkably higher compared to the original fly ash. This phenomenon can be attributed to the transfer of PCDD/Fs to the leachate residues through an enrichment effect during the ammonia leaching process. This facilitates the migration of PCDD/Fs from fly ash to the leachate residues. Specifically, during the ammonia chloride leaching process, PCDD/Fs primarily remain in the solid phase (fly ash and leachate residues), with very little migrating into the liquid phase (leachate). Consequently, the ammonia leaching process effectively immobilizes PCDD/Fs in the solid phase, reducing the possibility of these toxic substances migrating into the liquid phase.

Figure 13 illustrates the distribution of flotation products from the ammonium leachate residue. The loss on ignition (LOI) of the ash residue is notably high, reaching 11.9%, a significant phenomenon caused by the introduction of large amounts of powdered activated carbon into the system. This measure ensures that the PCDD/Fs emission concentration from the waste incineration process remains below the regulatory threshold of 0.1 ng TEQ/Nm3. The powdered activated carbon is injected into the flue gas before it enters the bag filter, where it absorbs harmful substances in the flue gas. As a result, the carbon content in the incineration fly ash of some solid waste can range from 11.4 to 91.2%.

Analysis confirms that the powdered activated carbon injected into the solid waste, along with incompletely combusted carbonaceous substances, form the primary carbon sources in the fly ash. Through flotation technology, up to 65.2% of the carbonaceous components can be effectively removed from the fly ash residue, thereby reducing the LOI of the fly ash residue to 4.8%. Compared to traditional methods of removing unburned carbon from municipal solid waste incinerator fly ash, this flotation technique shows significantly higher efficiency in carbon removal. This is the fact that unburned carbon particles often undergo oxidation, forming more oxygen-containing functional groups on their surfaces. These changes reduce their original hydrophobicity, making it more challenging to remove these particles during the froth flotation process.

This finding suggests that the combination of ammonia leaching and flotation technology in the treatment of PCDD/Fs in fly ash helps remove toxic substances from the solid phase. Also, it improves the recycling efficiency of the fly ash residue. In particular, flotation technology effectively removes unburned carbon, significantly reducing the LOI of the fly ash. The application of this integrated treatment technology reduces harmful substances in fly ash. Concurrently, it provides a new idea to enhance resource recovery, particularly in waste treatment scenarios requiring low carbon emissions and high pollution control. In conclusion, these experimental results confirm the DE and RE of PCDD/Fs in fly ash treatment using ammonia leaching and flotation technology. A detailed analysis of the distribution of PCDD/Fs in fly ash can further optimize the treatment process, achieving more efficient waste resource recovery while reducing environmental pollution risks.

Resource utilization analysis of the degradation effect of PCDD/Fs in MSWIFA under low temperature

The degradation RE and DE of each group of experiments are different. Considering the cost factors in the engineering application process, the complete degradation of PCDD/Fs is expensive. In addition, there is still a lack of a unified standard to evaluate the effect of low-temperature thermal treatment of PCDD/Fs in MSWIFA. Therefore, this section discusses from the perspective of MSWIFA resource utilization. Combining with the existing research and national standards in related fields, a method for judging the effect under low-temperature thermal treatment of PCDD/Fs is proposed. Further, the results of this pilot test are evaluated.

Direct introduction is the most common way MSWIFA gets to landfills. According to the ‘Standard for pollution corrode on the landfill site of municipal solid waste, (GB 16889-2008)’, the amount of PCDD/Fs in MSWIFA entering landfill site should not exceed 3 μg-TEQ/kg. The I-TEQ of the 17 PCDD/Fs homolog mixtures in the original MSWIFA is 353.1 ng-TEQ/kg, much smaller than 3 μg-TEQ/kg.

Although direct disposal of MSWIFA in landfills does not cause significant environmental pollution, its potential for resource utilization remains largely untapped. According to the ‘Technical Specification for Pollution Control of Fly Ash from Municipal Solid Waste Incineration (Trial Version HJ 1134–2020)’, when treated MSWIFA is exploited, the residual amount of PCDD/Fs in it should not exceed 50 ng-TEQ/kg. In experiments 4 to 6, reaction temperatures of 350, 400, and 450°℃, with an oxygen content of 500 ppm and a reaction time of 1 h, meet this requirement. When the reaction temperature is 350 ℃ and the reaction time is 1 h, the oxygen content in experiments 4 and 7 to 10 also meets the threshold. However, the ‘Technical Specification for Pollution Control of Fly Ash from Municipal Solid Waste Incineration (Opinion Soliciting Draft)’ states that after treatment, the residual amount of PCDD/Fs should not exceed 50 ng-TEQ/kg and the DE no less than 99%. Based on this standard, reaction temperatures of 400 and 450°℃, with an oxygen content of 500 ppm and a reaction time of 1 h, meet the above requirements. In contrast, the reaction temperature is 350 ℃ and the reaction time is 1 h, the oxygen content of 650 ppm and 320 ppm also satisfy the criteria. Therefore, lower residue levels do not necessarily equate to higher DE, a point that is also evident in numerous other studies.

Table 6 summarizes representative research results from the past two decades (excluding studies that used additives such as catalysts that could affect the reaction). Only four studies12,14,15,17 achieved PCDD/Fs residue levels below 50 ng-TEQ/kg. Among these, three studies12,14,15 met the requirements for both PCDD/Fs residues and detoxication efficiency. In addition, some studies obtained a high detoxication efficiency (more than 95%), but the PCDD/Fs residues after detoxification remained above 50 ng-TEQ/kg. Conversely, other studies with lower detoxification efficiencies (below 90%) achieved PCDD/Fs residues under 50 ng-TEQ/kg. The main reason for these variations is that the sources and total amount of MSWIFA used across studies, which leads to large differences in the PCDD/Fs content in MSWIFA.

The above analysis indicates that a simple comparison of the residues after detoxification does not fully capture the effectiveness of low-temperature thermal treatment technology. Similarly, evaluating detoxification efficiency without considering the residues of dioxins may result in an inaccurate assessment of the resource recovery potential of MSWIFA post-detoxification. To address this, the analysis applies the guidelines outlined in the “Technical Specification for Pollution Control of Fly Ash from Municipal Solid Waste Incineration (Opinion Soliciting Draft)” to judge the degradation effect of low-temperature thermal treatment technology on PCDD/Fs in MSWIFA. This approach ensures compliance with the residual requirements of various industries and provides a more accurate measure of detoxification efficiency.

Finally, the results of this pilot test are classified according to the specific application background. After detoxification, MSWIFA can be used as an asphalt mixture, cement raw material, and glass ceramic raw material6. However, further treatment is still needed for the MSWIFA post-detoxification. In contrast, the direct use of MSWIFA as road filling materials and soil amendment36 is more convenient and cost-effective for resource utilization. Therefore, the resource utilization scenarios are defined in the field of soil sludge. The application scope of the results of this experiment is based on the “Environmental Quality Standard for Soils (GB 15618-2008)”. The requirements for the content of PCDD/Fs in soil environments for different uses in the “Environmental Quality Standard for Soils (GB 15618-2008)” are as follows. (1) Secondary Agricultural land < 4 ng-TEQ/kg; (2) Secondary Residential land < 8 ng-TEQ/kg; (3) Secondary Commercial and Industrial land < 10 ng-TEQ/kg. Table 7 shows the summary of the availability of the experimental results in the field of soil sludge. In Table 7, AL, RL, CL, and IL indicate Secondary Agricultural land, Secondary Residential land, Secondary Commercial land, Secondary Industrial land. Table 7 illustrates that the degradation effect of low-temperature thermal treatment technology on PCDD/Fs in MSWIFA can satisfy the application standards of relevant industries while achieving extremely high DE.

Analysis of PCDD/Fs degradation products

In addition to evaluating the RE and TEQ of PCDD/Fs, the types of degradation products and their environmental impact are also analyzed in depth. To fully understand the degradation mechanism of PCDD/Fs and the potential environmental risks of the products, gas chromatography-mass spectrometry (GC-MS) is employed for qualitative and quantitative analysis of the degradation products under different conditions. The nature of the degradation products directly influences both the effectiveness of the degradation process and environmental safety, making the analysis of these products crucial.

Based on the GC-MS analysis results, various intermediate and final products are generated during the degradation of PCDD/Fs. These include chlorinated aromatic hydrocarbons, non-chlorinated aromatic hydrocarbons, and partially degraded PCDD/Fs congeners. The types of these products are closely related to the degradation temperature, catalyst type, and reaction conditions. Specifically, the degradation products can be classified into three categories based on their toxicity characteristics and recyclability:

-

Low-toxicity products: These encompass chlorinated aromatic hydrocarbons and low-chlorinated PCDD/Fs compounds. These products have relatively low toxicity and exhibit some potential for resource recovery.

-

High-toxicity products: These include certain aromatic chlorides and poly-chlorinated aromatic hydrocarbons, which may have significant negative impacts on the environment and ecosystems and require further degradation.

-

Toxic intermediate products: These products are typically formed during the degradation process and their toxicity and recyclability depend on the specific degradation conditions.

This work provides a detailed analysis of the degradation products under different temperature and catalyst conditions. By adjusting the reaction temperatures (400, 600, 800°℃) and introducing various types of catalysts (such as activated carbon and metal catalysts), significant changes are observed in the types of degradation products. These changes also affect their environmental safety. Under high-temperature conditions, the degradation products contained fewer toxic components, primarily forming low-toxicity chlorinated and non-chlorinated aromatic compounds. In contrast, under low-temperature conditions, more toxic products are generated, especially in the absence of catalysts.

Table 8 presents the TEQ values of the degradation products under different operating conditions, along with their environmental safety assessments. The TEQ values are calculated to quantify the potential environmental threat posed by each product. The results indicate that under high-temperature conditions, the TEQ values of the degradation products are lower, demonstrating better environmental safety. However, under lower temperatures, the TEQ values of the degradation products are relatively higher, suggesting that further optimization of the degradation conditions is necessary to reduce toxicity.

In addition to environmental safety, this work also focuses on evaluating the resource recovery potential of the degradation products. GC-MS analysis reveals that certain degradation products, such as aromatic hydrocarbons, can be used in industrial production after further processing. The recovery potential of these compounds is significant for improving resource utilization efficiency and reducing environmental pollution. Table 9 shows various degradation products’ recovery potential and possible industrial applications under different degradation conditions.

Literature comparison and application prospect discussion

This work focuses on the thermal degradation characteristics of PCDD/Fs in MSWIFA and demonstrates that the reaction temperature significantly affects both the RE and RE. Compared to existing literature, this work further confirms that the optimal temperature range for degrading PCDD/Fs is between 350 and 450°℃, which aligns with the findings of Naghdi et al.37. This indicates that this temperature range is ideal for the efficient degradation of persistent organic pollutants. However, for certain PCDD/F congeners (such as 1,2,3,4,7,8-HxCDF), a decrease in degradation rate is observed at higher temperatures. This phenomenon is consistent with the study of Shen et al.38, which emphasizes the differences in thermal stability among congeners and the risk of secondary pollutants forming at elevated temperatures.

Furthermore, this work delves into the degradation behavior differences of various PCDD/F congeners at different temperatures, particularly highlighting the stronger resistance of certain congeners at higher temperatures. This observation agrees with the conclusions of Ma et al.39,they noted that certain PCDD/F congeners exhibited greater stability under high-temperature conditions, resulting in lower removal rates during degradation. Compared to previous studies, this work refines the degradation mechanisms of different congeners at high temperatures, providing more detailed guidance on temperature control.

The innovation of this work lies in its systematic study of the thermal degradation behavior of PCDD/Fs under various reaction temperatures, which identifies the critical impact of temperature control on RE. Additionally, by analyzing actual reaction data, this work examines the reasons behind the degradation differences of specific congeners in response to temperature changes. Compared to existing literature, this work advances the understanding of the thermal treatment of hazardous gases in MSWIFA through refined experimental design and data analysis. This offers theoretical support for the optimization of future waste treatment systems.

Furthermore, the experimental temperature range and RE analysis method employed in this work provide more precise operating conditions for the thermal treatment of MSWIFA. This is of significant importance for enhancing the environmental friendliness of waste treatment in practical engineering applications.

In terms of practical applications, the findings of this work are highly operable and meaningful. First, based on the optimal reaction temperature range (350 to 450 ℃) identified in this work, the operational conditions of existing MSWIFA systems can be optimized to improve the RE of PCDD/Fs and reduce the formation of by-products. Second, the results of this work play a crucial role in advancing the cost–benefit analysis of MSWIFA technology. While increasing temperature may raise energy consumption, the ability to efficiently remove harmful substances can, in the long term, reduce potential environmental pollution and societal costs during the treatment process. From a scalability perspective, the temperature optimization strategy proposed in this work can be applied to MSWIFA systems of various scales. Due to the simplicity of temperature control and the enhancement of reaction efficiency, this technology demonstrates good potential for large-scale application. Additionally, based on the data from this work, future engineering systems can further adjust equipment configurations to reduce operational costs and improve overall system performance.

In conclusion, this work provides new theoretical foundations for optimizing MSWIFA technology and offers practical guidance for its application in real-world engineering. Future research can further explore the thermal degradation characteristics of different types of waste to optimize the cost-effectiveness and sustainability of the treatment system.

Conclusions

This work presents a pilot test experiment on the degradation of 17 toxic PCDD/Fs in MSWIFA under low-temperature conditions. By effectively utilizing the waste heat from high-temperature flue gas to drive degradation reactions, the experiment enhances energy utilization efficiency. Moreover, it offers a new direction for upgrading and renovating existing technologies. The pilot test investigates the effects of reaction temperature and oxygen content on the degradation of PCDD/Fs in MSWIFA. Furthermore, an analysis and proposal are provided on how to assess the degradation effect of low-temperature thermal treatment technology on PCDD/Fs in MSWIFA. Finally, drawing from research in the field of sludge soil, it is demonstrated that low-temperature thermal treatment technology can enhance the resource recovery potential of MSWIFA. The main findings and conclusions are as follows:

-

(1) The variation in reaction temperatures affects the degradation effect of PCDD/Fs. In contrast, the variation of oxygen content under low oxygen conditions has little degradation effect of PCDD/Fs. To inhibit the transfer of PCDD/Fs in MSWIFA to the gas phase during low-temperature degradation, there is more operability range to adjust the oxygen content than to adjust the reaction temperature.

-

(2) The optimum degradation temperature of 17 PCDD/Fs homolog varies. The PCDD/Fs homologs with the highest RE all belonged to the high chlorine substituents. Among these high chlorine substituents, RE is superior to PCDFs, and the RE of PCDDs is smaller. The RE of high chlorine substituents is greatly affected by temperature changes, where PCDFs are more obvious than PCDDs. The low oxygen condition is more suitable for removing high chlorine substituents in PCDFs, and the change of oxygen contents has the least effect on the RE of 2,3,7,8-TCDD.

-

(3) Based on the perspective of MSWIFA resource utilization, the analysis and comparison are as follows. Evaluating the effect of low-temperature thermal treatment technology on the degradation and detoxification of PCDD/Fs in MSWIFA should satisfy the residue requirements of different industries and achieve certain detoxication efficiency.

-

(4) The hydrothermal degradation of PCDD/Fs in the flotation concentrate under different atmospheric conditions involves complex chemical changes. These may include dechlorination, oxidative ring cleavage, re-synthesis, chlorination reactions, and precursor formation. Whether the PCDD/Fs concentration increases or decreases depends on the interactions between these reactions.