Abstract

In the background of increasing depth of metal mining, the issue of airflow temperature field during the construction of ultra-deep shaft is very important, in view of the fact that there is still very little research related to this content at home and abroad, so this aspect of the research is very necessary in the process of the development of deep shaft mining. This paper focuses on the study of the patterns of change in the airflow temperature field during the construction of ultra-deep shaft, based on Newton’s law of cooling and the first law of thermodynamics, and from the perspective of fluid dynamics, it puts forward a new theory - the theory of equilibrium enthalpy interface, which qualitatively and quantitatively derives the critical conditions of the three changes in the wind temperature of ultra-deep shaft and uses numerical simulation to study the content of the theory. The results of the study show that when the airflow runs from bottom up in the ultra-deep shaft, the change of airflow temperature is not a simple linear relationship, but a curve relationship similar to a cubic function, showing a law of decreasing first, then increasing and then decreasing. In addition, the equilibrium enthalpy interface theory elucidates the energy conversion relationship and process behind the change law of the airflow temperature field in the ultra-deep shaft. This study has explored the theoretical aspects of the airflow temperature field during the construction period of ultra-deep shaft, and also laid the foundation for the subsequent ventilation and cooling work of shaft construction.

Similar content being viewed by others

Introduction

Currently, there are 66 metal mines in China with a depth exceeding one kilometer, while internationally, there are more than 100 mines that go deeper than one kilometer. Among them, some deep mining operations have reached depths of 3,000 to 5,000 m. The problem of high temperatures associated with deep mining, which is exacerbated by the increasing depth of extraction, has become increasingly prominent1.

From the empirical data collected at various mines across the globe, it is observed that the working place depth at the President Steyn Gold Mine in South Africa exceeds 3,000 m, with the virgin rock temperature reaching as high as 63 °C. The Robinson Gold Mine, with a mining depth of 2,700 m, records virgin rock temperature of 41.1 °C. In the northern part of Australia, the Mount Isa Copper Mine exhibits the virgin rock temperature of 60 °C at a depth of 2,000 m. The Petrov Coal Mine in the former Soviet Union reaches a depth of 1,200 m, with the virgin rock temperature hitting 52 °C. In Germany, the Ibbenbüren Coal Mine has a mining depth of 1,530 m, with the bottom rock temperature soaring to 60 °C. The Creighton Mine in Canada shows the virgin rock temperature of 48 °C at a depth of 2,400 m2,3.

In China, the rock temperature of Sanshandao gold mine and Shaling gold mine in Shandong reached 50–53℃ and the underground wind temperature reached 43℃ at the depth of 1500 m. The underground temperature of Xincheng gold mine reached 35℃ at a depth of 1100 m4. The underground mining areas of the Hongtoushan Copper Mine and the Dongguashan Copper Mine have temperatures that have already reached 40 °C. As the depth of mining increases, both the virgin rock temperature and the airflow temperature in many mines at depth significantly rise, severely deteriorating the underground working environment and posing threats to the health and safety of the personnel. This has led to mining engineering activities being constrained by the deep thermal environment of the mines5. Consequently, the high-temperature thermal hazards in the deep mines have garnered research attention worldwide since the last century.

International research on mine air temperature commenced in 1740. International research on mine thermal hazards commenced in 1740, primarily with geothermal measurements conducted in mines near Belfort. During the 18th century, France and the United Kingdom carried out geothermal surveys in metal mines, establishing a relationship between geothermal temperatures and the depth of mining operations. In 1919, South Africa initiated studies on the thermodynamic laws of mine air currents. In 1923, Germany investigated the periodic changes in the thermal environment within the surrounding rock, introducing the concept of the thermal regulation zone. Subsequently, the Soviet Union and South Africa, among other nations, developed theoretical frameworks for calculating the thermodynamic state of air currents within mines. In 1951, scholars from the United Kingdom and Japan derived theoretical solutions for the temperature field of the rock’s thermal regulation zone. During the 1970s, Germany proposed a thermodynamic calculation method for the air temperature at mining places. In the 1980s, the German Mining Research Institute conducted field tests and analyses on the heat transfer properties of rocks, introducing the concept of the equivalent thermal conductivity coefficient. Since the 1990s, the United States has put forward new methodologies for analyzing the thermal conductivity of surrounding rocks. These advancements have significantly contributed to the understanding and management of thermal hazards in mining environments, ensuring safer and more efficient extraction operations6,7.

With the rapid development of science and computer technology, since the middle of the last century, Chinese scholars had successively summarised the heat exchange law of mine wind flow, put forward the method of thermal calculation of airflow and the mathematical model of mine wind temperature prediction, given the statistical method and empirical formulae for determining the heat exchange coefficient of mine wind flow, and researched the related problems of mine heat exchange calculation8. After that, the mine wind temperature solution technology has also made progress, forming a wind temperature calculation method using B-P neural network to improve the solution accuracy. After entering the 21st century, some scholars proposed the analytical formula and theoretical solution of unstable convective heat transfer coefficient by analysing the heat exchange process between the mine wind flow and the wall of the roadway9. In 2003, some scholars published an article on the heat exchange of mine wind flow and proposed a method for calculating the heat of mine wind flow; after 2005, some scholars published papers to study the effect of water evaporation on wind temperature10. These theoretical results of mine wind flow temperature and humidity in the new period have provided a scientific basis for the prediction of the thermal environment in the mine and the effective management of thermal hazards in the mine, and so far formed a discipline theoretical system of mine wind temperature research based on the theories of thermodynamics, ventilation, and heat transfer11.

From the aforementioned research trajectory, it is evident that an increase in the depth of mining operations leads to a significant rise in the temperature of deep mine airflow, which severely deteriorates the underground working environment12,13. This not only poses a threat to the health of miners but also affects the normal progression of mining and excavation activities, resulting in a decrease in labor productivity and an increase in the rate of underground accidents14. In the process of deep shaft construction, it is an important premise to find out the change law of airflow temperature field in ultra-deep shaft.

This paper conducts a targeted study on the patterns of change in the airflow temperature field within the shaft during the construction of ultra-deep shaft. Given the scarcity of research on this topic both domestically and internationally, there is a lack of relevant reference materials for deep vertical shaft projects during the shaft excavation phase, which underscores the significance of this study. Consequently, to better address the high-temperature thermal hazards during the construction of ultra-deep shaft, it is essential to understand the conditions of the airflow temperature within the shaft, providing a theoretical foundation for subsequent practical engineering applications. By identifying the key locations and parameters of high-temperature areas within ultra-deep shaft, this study lays the groundwork for subsequent shaft cooling efforts. The research findings are expected to contribute to the development of effective strategies for managing thermal conditions in deep mining operations, thereby enhancing the safety and efficiency of ultra-deep shaft construction projects.

Analysis of model

In accordance with the ventilation methods and path characteristics during the construction of ultra-deep shaft, it is imperative to employ artificial forced mechanical intervention to ensure the circulation of the airflow system, with fresh air intake through the ventilation ducts and return air within the shaft. The Model of Shaft Airflow is shown in Fig. 1.

The Model of Shaft Airflow (a). Fresh ground airflow is delivered to the working site at the bottom of the shaft (d) via the Air blower (b) and the Air duct (c). The airflow, indicated by green arrows, is introduced into the bottom of the shaft through the air duct and is expelled to the ground by red arrows. During this process, the airflow undergoes heat exchange with the shaft in wall (e).

During this process, the interior of the shaft exhibits characteristics such as high humidity, elevated temperatures, and a directional phase change in heat transfer between the airflow and the shaft walls at varying depths15. These characteristics result in a multitude of complex influencing factors for the study of the airflow temperature field in ultra-deep shaft, making mathematical modeling based on actual engineering conditions extremely challenging and not conducive to quantitative research. As a result, there is a paucity of research on this subject, with most studies being qualitative and simplistic in nature, offering only a general analysis.

Fresh airflow is pressurized from the ground by a ventilation fan and delivered through the air duct to the shaft excavation working place during the construction of ultra-deep shaft. Subsequently, the airflow is expelled from the shaft to the ground, ensuring air circulation at the excavation place and the expulsion of harmful gases.

As the fresh airflow travels through the air duct to the bottom of the shaft, it is subjected to the pressure of the air column within the shaft due to the influence of Earth’s gravity, resulting in a compression effect. During this process, the potential energy of the airflow is converted into internal energy, leading to an increase in wind temperature16.

During the process where the airflow at the bottom of the shaft is expelled to the ground, the geothermal effect causes the surrounding rock of the shaft to transfer heat from the deeper strata to the shaft walls through thermal conduction. The temperature of the shaft walls exhibits a gradient increase. The airflow within the shaft is influenced by the dual effects of heat transfer from the surrounding rock and water vapor, and the airflow temperature field exhibits a specific variation law.

Theoretical principles

Given that the heat exchange between the shaft and the airflow is a complex process influenced by various environmental factors, it is nearly impossible to establish a mathematical model based entirely on real conditions. Therefore, to meet the needs of the research, we have made some idealized assumptions regarding the calculation scenarios:

Due to the limitations imposed by the ventilation fan and practical engineering constraints, the airflow velocity within the air duct is relatively low, and the Mach number of the airflow is minimal. The elastic modulus of the shaft airflow is considerably large, allowing for the treatment of the airflow as incompressible. Thus, theoretically, it is feasible to consider the increase in internal energy solely in terms of the conversion of potential energy. However, as the depth of the shaft increases, changes in airflow density can no longer be disregarded, making it necessary to take this into account.

Furthermore, the high humidity levels underground mean that the impact of water vapor on heat transfer cannot be ignored. Therefore, considering the airflow within the shaft as a non-viscous, uniform velocity, ideal gas-like medium that accounts for changes in pressure and density will enhance the accuracy and realism of the computational model.

Based on the aforementioned analysis, we propose the Equilibrium enthalpy interface theory, grounded in Newton’s law of cooling and the first law of thermodynamics, to explain and analyze the patterns of change in the shaft airflow temperature field17. This theory focuses on the enthalpy energy transformation of the shaft airflow as the primary variable of study, employing integral and differential mathematical methods to compare the contribution levels of each influencing factor. Consequently, we derive energy transformation equations for the airflow temperature field and critical classification conditions based on varying shaft depths.

Derivation and analysis of the energy equation

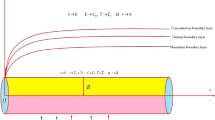

The airflow field within the shaft is regarded as an energy system18,19. One-Dimensional Flow Energy Exchange Model for Shaft Airflow is shown in Fig. 2.

According to the first law of thermodynamics, changes in the system’s energy can occur through two pathways: heat exchange with the surroundings and work done by or on the surroundings. This is represented by the following equation:

In the equation, \(\:E\) represents the energy of the system, \(\:{\dot{Q}}_{\text{i}\text{n}}\) denotes the heat exchanged with the surroundings, and \(\:{\dot{W}}_{\text{o}\text{u}\text{t}}\) signifies the work done by the system on the surroundings. Expressed in a general form:

Wherein, \(\:e\) represents the energy per unit mass of the fluid.\(\:\:\text{S}\text{y}\text{s}\) representative system.

According to the Reynolds Transport Theorem:

\(\:{{\Phi\:}}_{\text{s}\text{y}\text{s}}\) is mechanical properties of the system, \(\:{{\Phi\:}}_{\text{c}\text{v}}\) is mechanical properties of the control volume, \(\:cs\) is the boundaries of control volume, \(\:\overrightarrow{V}\) is fluid velocity, \(\:\text{d}A\) is microelement area of the control surface.

From the aforementioned equation, the first law of thermodynamics can be used to derive the one-dimensional energy equation for airflow temperature field of the shaft as follows:

Wherein,\(\:\:\dot{m}\) is fluid flow per unit time, the airflow energy \(\:e\) encompasses internal energy, kinetic energy, and potential energy, leading to the energy relationship equation:

\(\:\widehat{u}\) is the internal energy; \(\:\frac{{V}^{2}}{2}\) is the kinetic energy, \(\:gz\) is the gravitational potential energy.

The work exchange \(\:{\dot{W}}_{\text{o}\text{u}\text{t}}\) between the shaft airflow and the surroundings (shaft wall) needs to be facilitated through the application of force, which primarily consists of volume force and surface force. The volume force is mainly considered gravity, and this part has been calculated in gravitational potential energy, so the calculation will not be repeated.

Surface force predominantly exist at the two interfaces where the fluid within the control volume interacts with the external environment. One is the fluid contact surface at the entrance and exit of the section, and the other is the vertical shaft in wall and airflow contact surface.

a. The force exerted by the fluid within the control volume at the inlet, acting upon the external airflow:

The work done by the airflow within the control volume on the external airflow per unit time is:

The negative sign indicates that direction of the force is opposite to the direction of air velocity, which means that the airflow at the bottom of the shaft does negative work externally, and in fact the airflow entering the control volume is doing pushing work on the internal airflow.

At the outlet, the work done by the airflow within the control volume on the external airflow unit time is:

The total work done by the airflow within the control volume to the external environment at the inlet and outlet is:

Utilizing the flow rate equation \(\:\dot{m}=\rho\:AV\) and the continuity equation \(\:{\dot{m}}_{\text{i}\text{n}}={\dot{m}}_{\text{o}\text{u}\text{t}}\), the aforementioned formula is transformed into:

b. Since the shaft wall is parallel to the direction of airflow movement, the pressure does not perform work. The wall is stationary, and the viscous shear stress does no work on the fluid, \(\:{\dot{W}}_{\text{v}}=0\). However, within the airflow, work can be done through viscous shear stress, converting mechanical energy into internal energy. But this part belongs to internal force work, not to external work research category.

The work exchange relationship between the airflow within the control volume and the external environment is given by:

By substituting the energy relationship equation and the work exchange relationship between the airflow and the external environment into the one-dimensional energy equation for airflow temperature field of the shaft, obtain:

Employing \(\:q\) to denote the heat transfer per unit mass, we can derive the one-dimensional integral form of the energy equation for airflow temperature field of the shaft as follows:

where \(\:\widehat{u}\) is the internal energy per unit mass of fluid; \(\:\frac{p}{\rho\:}\) is the pressure potential energy per unit mass of fluid; \(\:\frac{{V}^{2}}{2}\) is the kinetic energy per unit mass of fluid; \(\:gz\) is the gravitational potential energy per unit mass of fluid.

Since \(\:h=\widehat{u}+p/\rho\:\) represents the enthalpy of the airflow, the one-dimensional integral form of the energy equation for airflow temperature field of the shaft can be rewritten as:

The above equation is the main energy equation used to discuss the energy change of shaft airflow temperature field in this paper, and it is the flow equation of compressible airflow field derived based on the assumptions of this study.

Composition of the energy equation

When the velocity of the airflow in the shaft does not change significantly, the main energy factors that affect the shaft airflow temperature field are considered to be:

a. Based on Newton’s law of cooling, the heat enthalpy value transfer from the shaft wall to the shaft airflow (It is the heat exchange quantity per unit mass of airflow with the surroundings \(\:q\) in the energy equation)20.

Wherein, \(\:{C}_{p}\) denotes the specific heat capacity at constant pressure for air (airflow), \(\:{T}_{B}\) represents the temperature of the shaft in wall, and \(\:{T}_{f}\) signifies the average temperature of the airflow within the control volume.

-

a.

b. The change in gravitational potential energy \(\:g{\Delta\:}z\) as the airflow ascends from the bottom of the shaft to the ground.

-

b.

c. The variation in enthalpy value during the airflow’s operation, which, due to the high humidity environment in ultra-deep shaft, includes sensible heat and latent heat.

Wherein, \(\:{C}_{d}\) represents the specific heat capacity at constant pressure for dry air, \(\:Y\) denotes the latent heat of vaporization for ice at zero degrees, \(\:{\Delta\:}\text{d}\) signifies the change in moisture content, \(\:{T}_{out}\) is the airflow temperature at the exit of the control volume, and \(\:{T}_{in}\) is the airflow temperature at the entrance of the control volume.

Equilibrium enthalpy interface theory

Through the above theoretical deduction and Eq. (14) (15) (16), we take the enthalpy transfer and change of shaft airflow as the main research object, and put forward the equilibrium enthalpy interface theory to analyze the characteristics of the variation of airflow temperature field during the construction of ultra-deep shaft.

Critical condition for Equilibrium Enthalpy Interface I:

The theoretical diagram of the equilibrium enthalpy interface at the boundary of the first control volume is shown in Fig. 3.

Critical condition for Equilibrium Enthalpy Interface II:

The theoretical diagram of the equilibrium enthalpy interface at the boundary of the second control volume is shown in Fig. 4.

Critical condition for Equilibrium Enthalpy Interface III:

\(\:{T}_{B}={T}_{f}\),\(\:q<0\)

The theoretical diagram of the equilibrium enthalpy interface at the boundary of the third control volume is shown in Fig. 5.

Numerical simulation and results

To further study the Equilibrium Enthalpy Interface Theory, our team selected the engineering geological parameters of a gold mine in Shandong Province, China, as the background conditions for numerical simulation. To ensure that the results of the simulation study more closely align with actual engineering situations, it is necessary to make some idealized assumptions about the simulation subject21.

The shaft airflow is regarded as a quasi-ideal gas, characterized as compressible, non-viscous, with density varying with pressure. The airflow velocity is held constant, and the control volume’s airflow inlets and outlets are defined by the theoretical cross-sectional area of the shaft22. The simulation parameters are based on actual engineering parameters. This study employs the typical turbulent k-ε model for non-isothermal flow fields in Comsol Multiphysics software for steady-state control23. The governing equations are as follows:

Using the actual engineering and environmental parameters of the sample mine as the background conditions for numerical simulation24,25, the specific settings are presented in Table 1:

The model diagram and meshing are shown in Fig. 6:

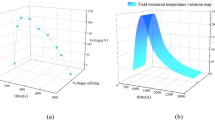

The numerical simulation results at three different temperatures are depicted in Figs. 7 and 8.

-

(a)

Variation of radial equivalent surface temperature of shaft at different inlet air temperatures.

-

(b)

Variation of axial section temperature inside the shaft at different inlet air temperatures.

-

(c)

Variation of tangential velocity of wind flow inside the shaft at different inlet air temperatures.

-

(d)

Variation of pressure on shaft wall by airflow at different inlet temperatures.

Wind flow in the bottom of the shaft through the air duct discharge began to run upward, with the continuous influx of wind, wind speed gradually increased, wind pressure gradually decreased, surface of shaft began to heat transfer to the airflow, the change rate of sensible heat \(\:\frac{d{{\Delta\:}h}_{sensible}}{dt}\) will lead to an increase in the temperature of the airflow, the change rate of latent heat \(\:\frac{d{{\Delta\:}h}_{latent}}{dt}\) and the change rate of gravitational potential energy \(\:g\cdot\:\frac{d{\Delta\:}z}{dt}\) will lead to a decrease in the temperature of the airflow. As the contact area between surface of shaft and the airflow increases, the humidity of the airflow decreases, the saturation capacity of water vapour decreases, the heat absorption capacity decreases, the latent heat part of the ratio decreases, and the sensible heat part of the ratio increases. As surface temperature of shaft decreases and the airflow temperature increases, the maximum value of the airflow temperature is reached. Until surface temperature of shaft \(\:{T}_{B}\) and airflow temperature \(\:{T}_{f}\) is equal, the direction of heat transfer began to change, the airflow temperature began to decrease, through the airflow radial equivalent surface and axial equivalent surface temperature results can be seen in the numerical simulation of the wind temperature change law and the balance of the enthalpy interface theory is consistent with the conclusions of the theoretical derivation, the high temperature zone of the airflow in the shaft is not located in the bottom, but is located in the middle position of the shaft.

Three colours are used to indicate the temperature change of the airflow at three temperatures, including the temperature, location, and temperature rise in the low and high temperature zones. In addition, the blue area is the area of maximum exothermic capacity of the outside world to transform the airflow in the control volume.

Discussion

Research on the variation law of the airflow temperature field as the airflow moves from the ground to the bottom of the shaft is relatively abundant and well-understood. However, studies on the variation law of the airflow temperature field during the construction of the shaft, particularly as the airflow moves from the bottom of the shaft to the ground. There are fewer studies related to the changing law of airflow temperature field, most of which are more general and do not yield clear scientific conclusions26.

The Equilibrium Enthalpy Interface Theory proposed in this study provides a clear explanation and analysis of the variation law in the shaft airflow temperature field. It derives the one-dimensional energy equation for shaft airflow and the energy relationship formula for the control volume within the shaft from classical principles. The study establishes a one-dimensional flow energy exchange model for shaft airflow and ultimately formulates the one-dimensional integral form of the energy equation for shaft airflow. Building upon a summary of the objective primary energy factors affecting the airflow temperature field and their interrelationships, the study utilizes the characteristic relationships of the three interfaces of the Equilibrium Enthalpy Theory and the analysis of the energy transformation process to elucidate the variation law of the shaft airflow temperature field.

The airflow starts to run upwards after being discharged from the wind pipe at the bottom of the shaft, and the heat transfer effect of the shaft wall towards the airflow is gradually enhanced from zero, and the sensible heat leads to an increase in the temperature of the airflow. At the same time, the airflow upward expansion exothermic, latent heat consumes part of the heat, the airflow temperature is gradually reduced. When the heat flow density is equal, the first critical condition is arrived. At this point, the airflow temperature drops to a very small value (local relative), which is the position of equilibrium enthalpy interface I.

After that, with the increasing contact area between the shaft wall and the airflow, the humidity of the airflow decreases, the saturation capacity of water vapour decreases, the heat-absorbing capacity decreases, the latent heat portion decreases and the sensible heat portion increases. The rate of change of gravitational potential energy is constant, and the exothermic capacity of the external environment for the conversion of the airflow in the control volume gradually increases to the maximum value, and the temperature of the airflow continues to increase and the rate of change reaches the maximum (the slope of the curve is the maximum), which is the position of the equilibrium enthalpy interface II.

In the process of the airflow continues to run to the ground, due to the decreasing temperature gradient of the ultra-deep shaft wall and the increasing temperature of the airflow, the temperature difference is gradually reduced, and the heat exchange capacity is reduced. When the wall temperature of the shaft is equal to the temperature of the airflow, the heat transfer no longer occurs, and at this time the temperature of the airflow reaches maximum value (local relative). Subsequently, the direction of energy transfer between the shaft and the airflow changes, the control volume starts to release heat to the external environment, and the temperature of the airflow starts to decrease.

Future research will continue to focus on the derivation of the one-dimensional differential forms of the energy equation and the internal energy equation for shaft airflow. so that the process of enthalpy-energy transformation inside the wind flow will be understood more deeply, and the influencing factors and sources of this transformation relationship will be clearly seen from the microelementary point of view27. In summary, this study holds significant research value for understanding the variation law of the airflow temperature field during shaft construction. and it has important practical implications for guiding engineering practices28.

Conclusion

From the theoretical derivation and simulation results, it can be seen that the airflow in the shaft running from bottom to top, the change of wind temperature is not a simple linear relationship but rather a curvilinear one that decreases, then increases, and finally decreases again. This pattern is distinct from the conclusions presented in many sources29,30,31. Overall, the image of this variation pattern shows a similar cubic function, and the reason for this phenomenon is the complex energy conversion relationship between the temperature of the shaft wall and the enthalpy of the airflow.

From the results of the study, it can be seen that the location of the high temperature zone corresponding to the shaft airflow is near the depth of 1375 m change to 1622 m when the intake air temperature is in the range of 293.15 K to 313.15 K. This indicates that the increase of the intake air temperature leads to the descend of the high temperature zone within the shaft.

Meanwhile, when the inlet air temperature is in the range of 293.15 K to 313.15 K, the increase of inlet air temperature at the bottom of the shaft changes from 15.43 K to 2.48 K, and the magnitude decreases significantly. The effect of geothermal heat in the shaft leads to the weakening of the kinetic energy of heat transfer.

During the ventilation process of ultra-deep shaft construction period, the airflow in the process of rising, the temperature will appear in the local minima and maxima. Among them, the point of maximum value is very important, because it is the real high temperature area of the shaft airflow temperature field. From the results, the conditions of the selected three groups of inlet wind temperature samples, the high temperature area of the shaft airflow is located in the depth of 1375 m, 1466 m, 1622 m, respectively, and these research achievements are very critical to the management of high temperature thermal hazards in the ultra-deep shaft construction project.

Data availability

All data generated or analyzed during this study are included in this published article and its supplementary information files.The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.First author: Zhao Siyu, Corresponding author: Zhao Xingdong E-mail address: NEU537zhaoxingdong@126.comSincerely yours.

References

He Manchao. Present Situation and Prospect of rock Mechanics in deep Mining Engineering99–105 (Chinese Society of Rock Mechanics and Engineering, 2004).

Zhao, X., Zhao, S. & Li, A. Design and analysis of a new type of mobile ice cooling equipment for deep mine. Sci. Rep. 13, 20375 (2023).

Wang Yunmin, L. & Gang, X. Yu, et al. Research Status and Prospect of Thermal Environment Regulation of the Deep Mine of China in the past 20 years. Metal Min., (03):1–13. (2023).

Liu Kai, Z. et al. Analysis of the deep thermal environment and temperature testing of the surrounding rock at Xincheng Gold Mine. Metal Min., (06):157–161. (2016).

Roy, S., Mishra, D. P. & Bhatacharjee, R. M. Heat stress in Underground Mines and its control measures: a Systematic Literature Review and retrospective analysis. Min. Metall. Explor. 39 (2), 357–383 (2022).

Xu, Y. et al. Synergetic mining of geothermal energy in deep mines: an innovative method for heat hazard control. Appl. Therm. Eng. 210, Article118398 (2022).

Gao Wenzhe. Underground mining technology and development trend of underground mining. World Nonferrous Met., (03): 32–33. (2021).

Cai Meifeng, X., Dinglong & Ren Fenhua. Current status and development strategy of metal mines. Chin. J. Eng. 41 (4), 417–426 (2019).

He Qilin, R. & Kebin Prediction of air temperature of air-intake shafts in developing coal mine. Coal Eng. 8 (8), 47–48 (2002).

Zhang Xiaoming, H. et al. Numerical simulation of airflow temperature and humidity for partly wet roadway model. China Saf. Sci. J. 30 (1), 21–26 (2020).

Liu Jingxian, L. et al. Present situation and prospect of mine geothermal hazard control technology. Metal Mine, :1–15. (2023).

Kyuro, S., Hiroshi, M., Toru, O. & Hiroshi, K. A prediction system for airflow temperature and humidity in underground ventilation networks. Shigen-to-Sozai 108, 378–388 (1992).

Bascompta, M., Rossell, J. M. & Sanmiquel, L. Anticoi. Temperature prediction model in the main ventilation system of an underground mine. Appl. Sciences-basel. 10, 7238 (2020).

Habibi, A., Kramer, R. B. & Gillies, A. D. S. Investigating the effects of heat changes in an underground mine. Appl. Therm. Eng. 90, 1164–1171 (2015).

Gnielinski, V. New equations for heat and mass transfer in turbulent pipe and channel flow. Int. J. Chem. Eng. 16, 359–368 (1976).

Cebeci, T. P. Bradshaw. Momentum Transfer in Boundary Layers (Hemisphere Publishing Corporation, 1977).

ChengK.C. Some observations on the origins of Newton’s law of cooling and its influences on thermo fluid science. Appl. Mech. Rev. 62 (6), Article060803 (2009).

Bian, X. T., Wang, Q. S., Chen, Z. Y., Su, X. R. & Yuan, X. Hybrid RANS/LES study of complex turbulence characteristics and flow mechanisms on the highly-loaded turbine end wall. Aerosp. Sci. Technol., 94 (2019). Article 105404.

Ding, P. X., Chen, K. & Zhou, X. Q. Numerical investigation of turbulent flow and mixed convection around a wavy cylinder. Int. J. Therm. Sci., 179 (2022). Article 107692.

Zaitsev, A., Shalimov, A. & Borodavkin, D. Unsteady coupled heat transfer in the air and Surrounding Rock Mass for Mine excavations with distributed heat sources. FUILDS 8 (2), 67 (2023).

Guo, P. Y., Su, Y., Pang, D. Y., Wang, Y. W. & Guo, Z. B. Numerical study on heat transfer between airflow and surrounding rock with two major ventilation models in deep coal mine. Arab. J. Geosci. 13 (16), 756 (2020).

Sasmito, A. P., Kurnia, J. C., Birgersson, E. & Mujumdar, A. S. Computational evaluation of thermal management strategies in an underground mine. Appl. Therm. Eng. 90, 1144–1150 (2015).

LILLEY,G. Turbulent drag and heat transfer in high-speed gas flows. Nature 206, 227–228 (1965).

Liu, Z., Wang, X. L., Cheng, Z. F., Sun, R. R. & Zhang, A. L. Simulation of construction ventilation in deep diversion tunnels using Euler-Lagrange method. Comput. Fluids. 105, 28–38 (2014).

Li, Z. et al. Impact of the water evaporation on the heat and moisture transfer in a high-temperature underground roadway. Appl. Therm. Eng. 28, 101551 (2021).

Loredo, C., Banks, D. & Roqueni, N. Evaluation of analytical models for heat transfer in mine tunnels. Geothermics 69, 153–164 (2017).

Kang, F., Li, Y. & Tang, C. Numerical study on airflow temperature field in a high-temperature tunnel with insulation layer. Appl. Therm. Eng. 179, 115654 (2022).

Wang, J. Z., Du, C. F. & Wang, Y. Study on the influence of ventilation parameters on the airflow temperature in excavation roadway and ventilation duct. Appl. Therm. Eng. 28, 101387 (2021).

Zeng, Y., Liu, K., Zhou, X. & Fan, L. Tunnel temperature fields analysis under the couple effect of convection-conduction in cold regions. Appl. Therm. Eng. 120, 378–392 (2017).

Bao, T., Meldrum, J., Green, C., Vitton, S. & Liu, Z. Bird. Geothermal energy recovery from deep flooded copper mines for heating. Energy Convers. Manage. 183, 604–616 (2019).

Wang, K., Li, Q., Wang, J. & Yang, S. Thermodynamic characteristics of deep space: hot hazard control case study in 1010-m-deep mine. Appl. Therm. Eng. 28, 101656 (2021).

Author information

Authors and Affiliations

Contributions

Xingdong Zhao directed the study. Siyu Zhao wrote the paper. Siyu Zhao and Ang Li performed the computations and analysis. Lei Deng revised the logic of the article and gave suggestions for revision.Figures 1, 2, 3, 4, 5, 6 and 7 of < Study on the change rule of airflow temperature field in ultra-deep mining shaft > were drawn by first author Siyu Zhao.All images can be published in all formats.All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Siyu, Z., Xingdong, Z., Ang, L. et al. Study on the change rule of airflow temperature field in ultra-deep mining shaft. Sci Rep 15, 6999 (2025). https://doi.org/10.1038/s41598-025-88247-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-88247-2