Abstract

The study employed an Artificial Neural Network (ANN) to predict the performance and emissions of a single-cylinder SI engine using blends of Gasoline, Ethanol, and Methanol (GEM) ranging from E10 to E50 equivalence, achieving less than 5% error compared to experimental values. Furthermore, Response Surface Methodology (RSM) was utilized to optimize the engine’s performance, identifying the optimal operating conditions of 2992.9 rpm engine speed and an E20-equivalent GEM blend. Under these conditions, the engine exhibited a brake thermal efficiency (B_The) of 34.63%, a brake specific fuel consumption (BSFC) of 243.7 g/kW-hr, and minimal emissions of 1.5% CO, 108.13 ppm HC, and 1211.8 ppm NOx, with an overall desirability of 0.820, indicating a highly favorable combination of performance and emissions characteristics.

Similar content being viewed by others

Introduction

Internal combustion engines play a pivotal role in energy and transportation, boasting high power-to-volume ratios and efficiency. Yet, their use of fossil fuels generates exhaust emissions that contribute to environmental pollution. With global fossil fuel reserves dwindling and demand rising, the search for alternative fuels is imperative. Renewable alcohols like ethanol and methanol are promising substitutes for spark ignition (SI) engines, as they blend well with gasoline. Ethanol is typically derived from biomass like sugarcane and corn, while methanol can be sourced from various renewables, including agricultural by-products and municipal waste. Waluyo et al.1examined stable blends of gasoline, methanol, and ethanol (G-100 to G-10, 5–90% v/v methanol), finding that some blends separated into layers, necessitating the addition of ethanol for homogenization. Kumbhar and Khot2 conducted experiments on an SI engine using ethanol-gasoline blends (E0, E20, E40, and E60) with a partial n-pentane addition, concluding that E20 at 24˚ bTDC yielded promising results without engine modifications. Mohammed et al.3 studied ethanol-gasoline blends’ effects on power, efficiency, and exhaust gases, noting improvements in these parameters with higher ethanol concentrations.

Various studies have explored ethanol and methanol blending with gasoline, with volume fractions ranging from 3 to 85%, resulting in enhanced engine performance and reduced emissions. Ethanol’s widespread use is limited due to its impact on the food sector, while methanol, derived from biological and agricultural waste, presents a promising alternative that could significantly extend lighter alcohols’ availability in transportation. Turner et al.4 introduced ternary blends of Gasoline, Ethanol, and Methanol (GEM) with iso-stoichiometric air-fuel ratios similar to conventional gasoline-ethanol blends, maintaining identical lower heating values and octane numbers. Sileghem et al.5investigated equivalent E85 GEM blends on a 1.8 L SI PFI 4-cylinder engine, reporting similar brake thermal efficiency, volumetric efficiency, and heat release rates as binary E85 blends. Chaichan6 demonstrated that an E85 equivalent G37 E20 M43 blend (37% gasoline, 20% ethanol, 43% methanol) reduced CO, HC, and NOx concentrations compared to pure gasoline.

ANN and RSM are powerful tools for predicting and optimizing engine performance and emissions. ANNs excel at capturing complex relationships in data, while RSM determines optimal input combinations to maximize or minimize desired outputs. Studies have shown the efficacy of both ANNs and RSM in predicting engine performance and emissions across various fuels and conditions. For instance, Najafi et al.7 used an ANN to predict engine characteristics of gasoline-ethanol blends with high accuracy. Kapusuz et al.8 employed ANNs to study lighter alcohol blends with gasoline, finding accurate performance and emissions predictions. Ardebili et al.9 optimized gasoline-fuel oil blend performance using RSM, achieving efficiency and emission improvements. Yusri et al.10 optimized gasoline-2-butanol blends using RSM, showing efficiency gains. Some studies have combined ANN and RSM to predict and optimize engine performance, with Uslu and Celik11 using this approach for gasoline-isopropyl alcohol blends. Overall, these tools are effective for predicting and optimizing engine performance and emissions, with the potential for reducing development time and cost.

Materials and methods

Iso-Stoichiometric blends

The test fuels consist of commercial gasoline, ethanol and methanol of 99.7% purity. Table 1 presents the fundamental physicochemical properties of pure gasoline, ethanol, and methanol. The mathematical formulation of iso-stoichiometric GEM blends adheres to the methodology established by Pearson et al.12 in which volume fractions of each component in GEM blends are chosen in such a way that their stoichiometric AFR to be identical as conventional binary gasoline-ethanol blends. Table 2 represents the ternary Gasoline, Ethanol, and Methanol (GEM) blends have an identical air-fuel ratio and lower heating value as conventional binary gasoline-ethanol blends.

Engine tests and procedure

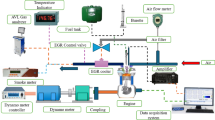

The study involved experimentation on a Honda GX 200 single-cylinder, four-stroke spark ignition engine with port fuel injection. A dynamometer of eddy current type applied loads to the engine at varying speeds and loads. Figure 1 depicts the experimental setup. Data collection and analysis utilized the ‘I.C.Engine soft 9.0’ software. An open Electronic Control Unit (ECU) from Performance Electronics Ltd, PE3 series system, controlled the engine’s spark and fuel injection timing, linked to a Windows-based system via Ethernet. The PE software on a computer managed ignition timing for each engine cycle. Ethanol and methanol were blended with gasoline before being added to the fuel tank. Experiments were conducted under dry ambient conditions, maintaining engine load by adjusting speed from 1700 to 3300 rpm. Engine stability was ensured at each speed by adjusting the throttle.

Engine performance and emissions data were recorded once the engine stabilized at each speed. Exhaust emissions (CO, NOx, HC) were measured using an AVL Digas 444 N gas analyzer, employing Non-Dispersive Infrared (NDIR) absorption, Chemiluminescence, and Flame Ionization techniques. Exhaust gases were purged completely from the stabilizing tank after each reading to maintain measurement accuracy. Each engine test speed underwent three repetitions for performance tests and emission measurements, with averaged data values used for analysis.

Modeling and prediction using ANN

The ANN method began to gain popularity in many fields with impressive speed along with the development of high-speed computers. Researchers are experimenting with different alternative fuels by blending with conventional fuels in different volume proportions and under different operating conditions to study its effect on engine emissions and performance. Nevertheless, these tests require longer durations and costlier affair8. Thereupon, research investigators start using mathematical models to achieve the same but through fewer trails. In this instance, ANN is useful because they lessen the total experimentation. Artificial neural networks have proven to be valuable in forecasting the performance of IC engines, and there have been significant advancements made to this field11. In this research, neural networks were used to model engine parameters such as B_The, BSFC, Vol_Eff, and emission parameters (CO, HC, NOx) based on input variables such as engine speed and GEM blend. Under various operating conditions, ANN model is very useful for predicting performance and emission parameters from engines.

Artificial neural network modeling framework

Objective functions

The primary objective of the ANN model in this study is to predict engine performance and emissions. The outputs are represented by the response variables yk (k = 1,2,…,m) as Brake Thermal Efficiency (B_The), Brake-Specific Fuel Consumption (BSFC), volumetric efficiency (Vol_Eff), Carbon Monoxide (CO), Hydrocarbons (HC), and Nitrogen Oxides (NOx). The error between the predicted values (y*) and the experimental values (yk) is minimized using the Mean Squared Error (MSE)14:

Where ‘m’ is the number of output parameters.

The objective is to adjust weights and biases of the network to minimize MSE, ensuring accurate predictions of the target responses.

Constraints

The ANN training is constrained by the following:

Dataset partitioning

Three subsets are usually created from the dataset, each of which has a specific function in the modeling process. By letting it discover patterns and connections in the data, the model is trained using the training set, which makes up 70% of the total data. During training, the model’s performance is assessed and its overfit to the training data is prevented by using the validation set, which makes up 15% of the dataset. In order to provide an objective evaluation of the final model’s performance and its capacity for generalization on unknown data, the testing set—which also comprises 15% of the data—is put aside for this purpose.

Normalization

Inputs and outputs are normalized to ensure all data lie in the range [0, 1] using minimum-maximum values normalization:

Where \(\:{x}^{*}\) is a normalized value of the datasets.

Stopping criteria

Training is stopped when specific criteria are met to ensure the model achieves optimal performance without unnecessary computation. One such condition is when the mean squared error (MSE) on the validation set shows no improvement over a predefined number of iterations, indicating that further training may not enhance the model’s ability to generalize. Another criterion is reaching the maximum number of iterations or epochs, a safeguard to prevent infinite training cycles and to limit computational resources. Lastly, training ceases when the gradient descent algorithm achieves a predefined tolerance level of 10−7, signifying that the model parameters have converged sufficiently close to an optimal solution and further updates would result in negligible improvements. These conditions collectively balance the trade-off between computational efficiency and model performance.

Training procedure

The ANN model is trained using the Levenberg-Marquardt Algorithm, which combines gradient descent and Gauss-Newton methods for optimization.

Weight and bias initialization

Weights (wij) and biases (bj) are initialized randomly at the beginning of the training process.

Forward Propagation

For each input x, calculate activations at each hidden neuron (hj)

and calculate output at each output neuron (yk)

Error calculation

Compute the error (ek) as:

Weight and Bias updates

Adjust weights using

where.

J: Jacobian matrix of errors with respect to weights.

µ: Damping factor.

e: Error vector.

Back propagation

The error is propagated backward through the network to update the weights of each layer. This process, known as back-propagation, involves calculating the gradient of the loss function with respect to each weight by applying the chain rule of differentiation. Starting from the output layer, the error signal is computed and passed backward through the network, layer by layer. At each layer, the weights are adjusted in proportion to the computed gradients, scaled by the learning rate, to minimize the loss function. This iterative process enables the network to progressively refine its parameters and improve its predictive accuracy.

Dataset generation

Experimental data from the SI engine were used as the input dataset. The dataset comprises:

-

Input Parameters: Engine speed (x1) and GEM blend ratio (x2).

-

Output Parameters: Performance and emissions responses (y1,y2,… ym).

Testing and validation

Validation

During training, the validation set monitors over-fitting. If the error on the validation set increases while the training error decreases, training is stopped.

Testing

After training, the testing set is used to evaluate model performance. The testing error (MSE) is computed as:

Algorithm: ANN training and prediction

Step 1

Load and preprocess the dataset (normalize inputs and outputs).

Step 2

Initialize weights and biases randomly.

Step 3

Partition the dataset into training, validation, and testing subsets.

Step 4

Perform the following for each epoch.

-

Forward propagate the input data.

-

Calculate the error using the MSE function.

-

Back propagate the error and update weights and biases.

-

Monitor the validation error.

Step 5

Stop training if stopping criteria are met.

Step 6

Test the model using the testing subset.

Step 7

Predict responses for unseen inputs using the trained mode.

Operating parameters optimization using RSM

RSM is a multivariate system that utilizes mathematical and statistical methods to establish relationships between response variables and significant input variables. Its objective is to model and optimize these responses. In this study, engine speed and GEM blends were considered as input variables, while B_The, BSFC, Vol_Eff, HC, CO, and NOx were regarded as output response variables. The study employed Design of Experiments (DoE) with a multilevel factorial design using Minitab 17 software. The performance of the model was evaluated using Analysis of Variance (ANOVA). The main objective of this work was to determine the optimal operating parameters of the engine to maximize B_The and Vol_Eff while minimizing BSFC, HC, CO, and NOx, utilizing the desirability approach of RSM.

Multi objective optimization using RSM

The multi-objective optimization in this study aims to maximize engine performance while minimizing emissions. The responses are optimized using RSM. The steps and mathematical details are as follows [26]:

Objective functions

Let the response variables be B_The, BSFC, Vol_Eff, HC, CO, and NOx represented as yk for k = 1,2,3….m.

The desirability function Dk is defined for each response based on its optimization goal.

For maximization (B_The and Vol_Eff):

For minimization (BSFC, CO, HC, NOx):

where ‘r’ is the weight determining the importance of the response.

The overall desirability ‘D’ is the geometric mean of the individual desirability

where wk is the weight attached to each response.

Each response yk is modeled as second order polynomial:

where i is the linear coefficient, j is the quadratic coefficient, β is the regression coefficient, k is the number of factors.

Results and discussion

This study focuses on formulating and testing E10, E20, E30, E40, and E50 binary blends, along with their equivalent GEM blends. The experiments varied the engine speed from 1700 to 3300 RPM while maintaining a constant 5 kg engine load. Results for the GEM blends are compared with pure gasoline. The second part of the study introduces ANN and RSM models to predict and optimize engine performance and emissions using GEM blends.

Experimental engine test results

Table 3 presents the test data obtained from the engine test results. Experimental observations showed that blending of ethanol and methanol to gasoline has positive effect on positive effect on engine behavior. And also it was observed that iso-stoichiometeric GEM blends have similar performance characteristics as conventional binary gasoline-ethanol blends due to similarity in air-fuel ratios and heating values of fuels.

The present study focuses on the formulation and testing of binary gasoline-ethanol (E10, E20, E30, E40, and E50) blends and their equivalent ternary gasoline-ethanol-methanol (GEM) blends in a spark-ignition (SI) engine. These blends are evaluated in terms of engine performance metrics, including Brake Thermal Efficiency (B_The) and Brake Specific Fuel Consumption (BSFC), volumetric efficiency (Vol_Eff) and emission parameters, such as carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx).

A detailed comparative analysis between the GEM blends and pure gasoline is provided, highlighting the potential advantages and trade-offs of using these alternative fuel formulations. The study’s primary objective is to predict and optimize engine performance and emission characteristics for GEM blends through modeling techniques using Artificial Neural Networks (ANN) and Response Surface Methodology (RSM). These models are utilized to optimize the engine’s operational parameters, providing insights into how GEM blends can be effectively utilized to achieve better performance and lower emissions. The accuracy and reliability of these models are validated against experimental data to ensure robustness and practical applicability.

The influence of ternary blending on fuel properties has been meticulously analyzed, with a particular focus on the air-fuel ratio (AFR) and lower heating value (LHV). These properties are critical as they directly impact combustion efficiency, engine performance, and emission behavior. Table 2 in the manuscript provides a comprehensive overview of how these properties vary across different ternary blend formulations. It is important to note that this manuscript does not include combustion analysis, such as cylinder pressure dynamics, rate of pressure rise, or heat release rate. While combustion analysis is crucial for a holistic understanding of fuel behavior in SI engines, it has been deliberately excluded from the scope of this study. The findings of the current research lay a foundation for future investigations into the combustion characteristics of GEM blends, which could be explored in subsequent studies.

This study underscores the potential of GEM blends as viable alternatives to conventional gasoline, with an emphasis on their impact on engine performance, emissions, and fuel properties. By leveraging predictive and optimization models, it bridges experimental findings with practical applications, paving the way for further advancements in sustainable fuel technologies.

Experimental B_The for different rpm’s and blends

The Radar chart of Variation in different blends ( E10, E20,E30,E40 and E50) at various speeds in rpm ( 1700, 2100, 2500, 2900 and 3300 ) for B_The, BSFC, CO, HC and NOx are presented from the Fig. 2 (a, b,c, d and e) to Fig. 6 (a, b,c, d and e)respectively. For all the blends, trends are observed in similar pattern ( i.e. for 1700 rpm min B_The is observed and as rpm increases B_The also increases. The Maxium B_The is witnessed uniformly at 2900 rpm for all blends. Further all discussions were made for 2900 rpm. The radar chart for B_The is showing similar trend for all the cases. It can be observed from the Fig. 2(c) that B_The is increasing with increase in engine speed. The similar trend is observed by Turner et al.4. The E30 blend is witnessed maximum B_The compared to pure gasoline.

Experimental BSFC for different rpm’s and blends

Variation of different blends ( E10, E20,E30,E40 and E50) at various speeds in rpm (1700, 2100, 2500, 2900 and 3300) for BSFC is presented in Fig. 3( a, b,c, d and e). For all the blends, trends are observed in Rhombus shape pattern in radar chart, it is noticed that for 2900 and 3300 rpm, approximately same BSFC has been noted. It is evident from Fig. 3 that BSFC declined as engine speed increased, and that pure gasoline uses less fuel than binary and ternary alcohol combined fuels alike. When alcohols are added to gasoline, the blended fuel’s heating value decreases, causing the engine to use more fuel to maintain the same speed and torque.

Experimental CO for different rpm’s and blends

Figure 4 represents CO emission for various blends and engine speeds. As alcohol mixed fuels have a lower carbon content than pure gasoline, the E30 equivalent blends emit less CO. Figure 4(a, b, c, d, and e) shows the variation of several blends (E10, E20, E30, E40, and E50) for CO emission at different speeds (1700, 2100, 2500, 2900, and 3300). The existence of oxygen concentration, which causes lean combustion, is another factor contributing to this decrease9. The E30B3 ternary blend exhibits the greatest decrease in CO because of the increased oxygen concentration of the methanol fuel, which promotes rapid and thorough burning.

Experimental HC for different rpm’s and blends

Figure 5shows how the HC emission varies for different blends (E10, E20, E30, E40, and E50) at different speeds (1700, 2100, 2500, 2900, and 3300). When the air fuel mixture is extremely rich or low, the unburned hydrocarbons cause a flame dampening effect close to the combustion chamber surface, which results in hydrocarbon emissions in the exhaust9.

Experimental NOx for different rpm’s and blends

The NOx emissions variation for gasoline and alcohol mixed fuels at varying speeds is depicted in Fig. 6. Because of the high temperatures inside the cylinder, it has been shown that increasing engine speed causes NOx emissions to rise. Figure 6shows that the NOx production is higher for E30 mixed fuels than for pure gasoline at all engine speeds. High oxygen concentrations cause a leaner effect when alcohol is added, and alcohols’ high laminar burning speeds enhance combustion and raise the temperature within the cylinder as compared to pure gasoline10. Therefore, when compared to pure gasoline, high in-cylinder temperatures encourage the creation of greater NOx for GEM mixtures.

Artificial neural network training and prediction

Artificial neural network architecture

Architecture of an ANN involves defining the layering organization, the number of neurons within each layer, and how neurons are connected to one another. Figure 7 illustrates three layers of neural network architecture featuring neurons that are fully connected to each other. The training algorithm controls the number of layers in the network. The back-propagation algorithm, for example, consists of an input layer, an output layer, and a hidden layer. During this study, Engine speed and GEM blends were taken as input data, whereas B_The, BSFC, Vol_Eff, HC, CO, and NOx as target data. Based on the experimentation, the number of neurons in the hidden layer is taken as 10.

Modeling using ANN

The neural network used in this study was modeled using the nntool neural network tool from MATLAB. The performance of the Artificial Neural Network (ANN) model relies heavily on training with a comprehensive set of experimental data, followed by validation and testing of the model. During the training phase, the network was trained extensively to generate an output prediction based on the given target data. The training process continued until the error between the predicted and target values reduced to a predefined threshold. The neural network architecture used in the study is depicted in Fig. 7. The ANN model was trained using the back-propagation algorithm, where network weights and biases were initialized arbitrarily using supervised learning. Gradient descent was employed to minimize the error between the network output and the desired target value. Before modeling, the input data and targets were normalized between 0 and 1 to ensure accurate results. The Levenberg-Marquardt (TrainLM) algorithm was used as the training instruction algorithm to train the data with different neurons and layers. The tangential sigmoid (TANSIG) function was found to be the most suitable transfer function for this model. Finally, a de-normalization method was applied to convert the results from the ANN model back to their original forms.

Artificial neural network training and prediction

A neural network model was developed using test data from engine tests for analyzing the different gasoline alcohol blends. (2–10-6) topology has been used, wherein 2 neurons for the input layer, 10 neurons for the hidden layer, and 6 neurons for the output layer. A network was trained on input and target variables, secondly, it was validated, then it was tested, and finally it was terminated with stopping criteria of 1000 iterations and minimum gradient 1 × 10−7. Correlation coefficient (R) is used to determine the correlation between output and target values; when R is close to 1, there is a strong correlation. After completion of training the network, the predictive ability of the trained network was carried out by simulating the data variables, which were not used for training. The comparison between the simulated output values with the experimental data was carried out and the error percentage was calculated for the justification of the developed ANN model. Figure 8 represents the ANN-trained model regression graphs for engine output parameters i.e. B_The, BSFC, Vol_Eff, CO, HC, and NOx. The values of Correlation coefficient (R) are in the range of 0.995 and 0.998 for the engine performance and emission parameters. This is due to the trained ANN model predicts output values equivalent to the experimental target data values are close with each other. Tables 4 and 5 show the 15 simulation data set variables outputs as predicted (Pred) comparing with experimental data (Exp) and its differences are calculated in terms of error %. The error % value observed less than 5% which indicates a strong relationship between the experimental and predicted values.

RSM based analysis

The purpose of using RSM is to develop a model using experimental test data. The objective of a model is to optimize the operating parameters of the engine fuelled with different GEM blends. The engine speed and GEM blends were taken as input parameters and B_The, BSFC, Vol_Eff, HC, CO, and NOx are responses. The investigation of the developed model was conducted using Analysis of variance (ANOVA).

Effect of input parameters on performance and emission characteristics

Three-dimensional wire frame surface plots were plotted based on the effect of input factors on different responses are shown from Figs. 9, 10, 11, 12, 13 and 14. Figure 9presents the change of B_The with engine speed and GEM blends. 2. The B_The of engine is found to increase up to E30 and its equivalent blends with maximum increase of 13.5% compared to gasoline and with further addition of ethanol and methanol in E40 and E50 equivalent blends leads to decrease in B_The with minimum increase of 1.6% for E50 equivalent GEM blends. The reduction in B_The is by reason of reduction in calorific value of the blended fuels with increase in ethanol and methanol percentages12. Figure 10 reveals the change in BSFC with input parameters. The BSFC of engine is observed to be decreased for E10 and E20 equivalent GEM blends compared to gasoline with maximum decrease of 4.1% for E20 equivalent blends. Further increment of ethanol and methanol proportions to gasoline in E30, E40 and E50 equivalent GEM blends results increase in BSFC with maximum of 18.8% for E50 equivalent GEM blend. Figure 11 shows the variation of Vol_Eff with engine speed and different blends. According to the figure, Vol_Eff of the engine increases up to E30 equivalent blends and shows a decreasing trend at E40 and E50 equivalent blends. Figures 12 and 13shows surface plot of HC and CO emissions with engine speed and GEM blends as input parameters. HC emissions are lowered because of raise in alcohol percentage in gasoline with maximum reduction of 48.9% compared to gasoline for E50 equivalent blends. CO emissions also reduce with increase in ethanol and methanol percentage in gasoline with maximum reduction of 53.4% compared to gasoline for E50 blends. Similar trends for exhaust emissions were reported by researchers15,16. Figure 14 shows the variation of NOx with engine speed and different blends. Table 6 represents comparison of B_The, BSFC, Vol_Eff (%) of experimental and ANN predicted values whereas Table 4 depicts Comparison of CO, HC and NOx experimental and ANN predicted values NOx emissions are found to decrease for E10, E20 and their equivalent GEM blends compared to neat gasoline with maximum reduction of 13.6%. With further increase in alcohol proportion in gasoline for E30 to E50 binary and their equivalent GEM blends, NOx emissions observed to be increased. Maximum increase in NOx emissions are observed for E50 equivalent blends with increase by 26.6%. The variation in NOxemissions are due to combined effects of excess availability of oxygen inside combustion chamber and high in-cylinder temperatures17.

Table 5 shows the ANOVA results for the developed model in expressions of p, R2, R2 (Adj), and R2 (pred). The obtained results indicate that the developed model is consistent with a p-value less than 0.05 and the regression statistics like R2 (goodness for fit) and R2 –Adj (goodness of predictions) are in agreement with others. At 95% confidence level, p less than 0.05 suggest that the factors withstand considerable influence in ANOVA analysis. A high value of R2, close to 100%, is essential and a reasonable agreement with R2 (Adj) and R2 (Pred) are necessary. According to the ANOVA results of the data in Table 5 showed that the values of R2, R2 (Adj), and R2 (Pred) are in the range of 92.64–99.34%, which indicates that the developed regression equations are precise for predicting and optimizing the experimental test results. Equation 1 to 6 provide the second-order polynomial equation derived using multiple regression analysis of the experimental data to determine the response of B_The, BSFC, Vol_Eff, CO, HC, and NOx to input parameters.

Response optimization

RSM optimizer has been employed to optimize the performance and emission parameters of SI engines by comparing different combinations of engine speed and GEM blends. The detailed criteria of optimization are given in Table 7.

Optimization results

Multi-objective optimization was implemented to ascertain the best engine working conditions based on the criteria of maximizing the B_The, Vol_Eff while minimizing the BSFC, CO, HC, and NOx for given input factors (speed and GEM blends) using RSM. Figure 15 shows the optimum values of B_The, BSFC, Vol_Eff, CO, HC, and NOx emissions are 34.63%, 243.7 g/kW-hr, 70.39%, 1.5%, 108.13ppm, and 1211.8 ppm respectively when the engine input parameters of the test engine were made to operate at an engine speed of 2992.9 rpm for 7.5 GEM blended fuel. The composite desirability value generally varies from 0 to 1 and a higher value prefers for better optimization. In the present work, the value has been observed to be 0.8206. The GEM blend 7.5 refers to a group of E20 equivalent blends. The optimized results need to be verified by conducting validation experiments. Table 7 represents the optimization criteria response factors.

Experimental validation

To validate the RSM optimum results, engine experiments were carried out at 2990 RPM for E20_Eq blended fuel. The information regarding the engine experimental responses are shown in Table 8. Based on the experimental data, it is determined that the optimized values had an error less than 4% in agreement with the experimental values.

Conclusions

The study investigates the effects of E10 to E50 binary blends and their equivalent Gasoline-Ethanol-Methanol (GEM) blends on the performance and emissions of a single-cylinder four-stroke SI engine. Engine tests were conducted at constant load with speeds ranging from 1700 to 3300 rpm. Artificial Neural Network (ANN) modeling was used to predict engine performance and emissions, while Response Surface Methodology (RSM) was employed to optimize operating parameters for maximizing efficiency and minimizing emissions.The formulated E10 to E50 equivalent GEM blends were designed to have identical air-to-fuel ratios and lower heating values as conventional binary gasoline-ethanol blends. The study found that the Brake Thermal Efficiency (B_The) of the engine increased up to E30 and its equivalent blends, with a maximum increase of 13.5% compared to gasoline. However, further addition of ethanol and methanol in E40 and E50 equivalent blends led to a decrease in B_The, with a minimum increase of 1.6% for E50 equivalent GEM blends. The Brake Specific Fuel Consumption (BSFC) of the engine decreased for E10 and E20 equivalent GEM blends compared to gasoline, with a maximum decrease of 4.1% for E20 equivalent blends. However, the BSFC increased with further increments of ethanol and methanol proportions to gasoline in E30, E40, and E50 equivalent GEM blends, with a maximum increase of 18.8% for E50 equivalent GEM blend. Hydrocarbon (HC) emissions were lowered due to the increase in alcohol percentage in gasoline, with a maximum reduction of 48.9% compared to gasoline for E50 equivalent blends. Carbon monoxide (CO) emissions also reduced with an increase in ethanol and methanol percentage in gasoline, with a maximum reduction of 53.4% compared to gasoline for E50 blends. Nitrogen oxides (NOx) emissions decreased for E10, E20, and their equivalent GEM blends compared to neat gasoline, with a maximum reduction of 13.6%. However, with further increases in alcohol proportion in gasoline for E30 to E50 binary and their equivalent GEM blends, NOx emissions were observed to increase, with the maximum increase observed for E50 equivalent blends at 26.6%. The ANN model regression graphs for predicting engine output parameters (B_The, BSFC, Vol_Eff, CO, HC, and NOx) showed regression values (R) ranging from 0.997 to 0.998, indicating a favorable relationship between the predicted and target data. RSM was used to perform multi-objective optimization by maximizing B_The and Vol_Eff for a given input factor (speed and GEM blends) while minimizing BSFC, CO, HC, and NOx emissions. The optimum values of B_The, BSFC, Vol_Eff, CO, HC, and NOx emissions were achieved at an engine speed of 2992.9 rpm for E20_Eq GEM blended fuel, with values of 34.63%, 243.7 g/kW-hr, 70.39%, 1.5%, 108.13 ppm, and 1211.8 ppm respectively, and a desirability of 0.826. The optimized results were validated through conformity experiments, showing that the difference between the experimental and RSM predicted values was less than 4%.

Data availability

All data used to support the findings of this study are included within the article.

Abbreviations

- ANN:

-

Iota carrageenan

- ANOVA:

-

Analysis of Variance

- A/F:

-

Air Fuel ratio

- BSFC:

-

Brake-specific fuel consumption

- B_The:

-

Brake thermal efficiency

- CO:

-

Carbon monoxide

- DoE:

-

Design of experiments

- Exp:

-

Experimental values

- GEM:

-

Gasoline-Ethanol-Methanol

- HC:

-

Hydrocarbons

- NOx:

-

Nitrogen oxides

- ppm:

-

parts per million

- Pred:

-

Predicted values

- RSM:

-

Response surface methodology

- RPM:

-

Revolutions per minute

- RON:

-

Research octane number

- p-value:

-

Probability value

- R2 :

-

Coefficient of determination

- R2-(Adj):

-

Adjusted R2 value

- R2-(Pred):

-

Predicted R2 value

References

Waluyo, B., Setiyo, M. & Wardana, I. N. G. Fuel performance for stable homogeneous gasoline-methanol-ethanol blends. Fuel 294, 120565 (2021).

Kumbhar, S. V. & Khot, S. A. Experimental investigations of ethanol-gasoline blends on the performance, combustion, and emission characteristics of spark ignition engine spark ignition (SI) engine with partial addition of n-pentane. Materials Today: Proceedings, 77, pp.647–653. (2023).

Mohammed, M. K., Balla, H. H., Al-Dulaimi, Z. M. H., Kareem, Z. S. & Al-Zuhairy, M. S. Effect of ethanol-gasoline blends on SI engine performance and emissions. Case Studies in Thermal Engineering, 25, p.100891 (2021).

Turner, J. W. et al. ac GEM ternary blends: testing iso-stoichiometric mixtures of gasoline, ethanol and methanol in a production flex-fuel vehicle fitted with a physical alcohol sensor (No. 2012-01-1279). SAE Technical Paper. (2012).

Sileghem, L., Coppens, A., Casier, B., Vancoillie, J. & Verhelst, S. Performance and Emissions of iso-stoichiometric Ternary GEM Blends on a Production SI Engine117pp.286–293 (Fuel, 2014).

Chaichan, M. T. Gasoline, ethanol and methanol (GEM) ternary blends utilization as an alternative to conventional Iraqi gasoline to suppress emitted sulfur and lead components to environment. Al-Khwarizmi Eng. J. 12 (3), 38–51 (2016).

Najafi, G. et al. Performance and exhaust emissions of a gasoline engine with ethanol blended gasoline fuels using artificial neural network. Appl. Energy. 86 (5), 630–639 (2009).

Kapusuz, M., Ozcan, H. & Yamin, J. A. Research of performance on a spark ignition engine fueled by alcohol–gasoline blends using artificial neural networks. Appl. Therm. Eng. 91, 525–534 (2015).

Ardebili, S. M. S., Solmaz, H. & Mostafaei, M. Optimization of fusel oil–gasoline blend ratio to enhance the performance and reduce emissions. Appl. Therm. Eng. 148, 1334–1345 (2019).

Yusri, I. M. et al. Application of response surface methodology in optimization of performance and exhaust emissions of secondary butyl alcohol-gasoline blends in SI engine. Energy. Conv. Manag. 133, 178–195 (2017).

Uslu, S. & Celik, M. B. Prediction of engine emissions and performance with artificial neural networks in a single cylinder diesel engine using diethyl ether. Eng. Sci. Technol. Int. J. 21 (6), 1194–1201 (2018).

Pearson, R. J. et al. Iso-stoichiometric fuel blends: Characterization of physicochemical properties for mixtures of gasoline, ethanol, methanol and water. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of automobile engineering, 229(1), pp.111–139. (2015).

Yusoff, M. N. A. M. et al. Comparative assessment of ethanol and isobutanol addition in gasoline on engine performance and exhaust emissions. J. Clean. Prod. 190, 483–495 (2018).

Amine, M. & Barakat, Y. Properties of gasoline-ethanol-methanol ternary fuel blend compared with ethanol-gasoline and methanol-gasoline fuel blends. Egypt. J. Pet. 28(4), 371–376 (2019).

Wu, C. W., Chen, R. H., Pu, J. Y. & Lin, T. H. The influence of air–fuel ratio on engine performance and pollutant emission of an SI engine using ethanol–gasoline-blended fuels. Atmos. Environ. 38 (40), 7093–7100 (2004).

Bayraktar, H. Experimental and theoretical investigation of using gasoline–ethanol blends in spark-ignition engines. Renew. Energy. 30 (11), 1733–1747 (2005).

Masum, B. M. et al. Effect of ethanol–gasoline blend on NOx emission in SI engine. Renew. Sustain. Energy Rev. 24, 209–222 (2013).

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University, Saudi Arabia for funding this work through the Research Group Program under Grant No: RGP 2/127/45.

Funding

This work does not received funding from any funding agencies.

Author information

Authors and Affiliations

Contributions

Farooq Shaik . Vinay Kumar D . Channa Keshava Naik N and Radha Krishna. Written Original Manuscript , Methodology and reviewed T. M. Yunus Khan . Abdul Saddique Shaik . Abdulrajak Buradi and Addisu Frinjo Emma. Data curation and resources.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shaik, F., Kumar, D.V., Naik, N.C.K. et al. Predictive modeling and optimization of SI engine performance and emissions with GEM blends using ANN and RSM. Sci Rep 15, 4585 (2025). https://doi.org/10.1038/s41598-025-88486-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-88486-3

Keywords

This article is cited by

-

Performance, combustion, emission and optimization characteristics of biodiesel–n-butanol blends enriched with Ni2O3 nanoparticles in a diesel engine

Scientific Reports (2026)

-

Thermodynamics based modeling of various in-cylinder processes and spark ignition engine cycle with a focus on sub-models assessment

Scientific Reports (2025)