Abstract

With the increasing depletion of shallow mineral resources, deep mining has become important; however, basic research on deep resource development remains insufficient, and basic laws are unclear. In particular, comprehensive research on the pore structure characteristics of deep coal bodies at different scales is needed, and how burial depth affects pore structure characteristics should be investigated. Herein, this study performed mercury intrusion porosimetry, liquid nitrogen method, and low-temperature carbon dioxide adsorption method to systematically determine the pore structure characteristics of deep coal and comprehensively analyze coal pore complexity based on the Menger Sponge, Frenkel–Halsey–Hill (FHH), and density function models. The influence of depth on coal pore structure was also discussed. In the study zone, the stage pore volume was mainly concentrated in the macroporous (43.6–83.4%) and mesoporous Sect. (16.3–54.7%) and sparsely distributed in the microporous Sect. (0.3–2.1%). The accumulated pore volume decreased with an increase in coal sample burial depth, with a gentle curve in the micropore section and obvious fluctuations in the mesopore and macropore sections. The main distribution of stage surface area was in the mesoporous Sect. (79.5–91.8%), followed by the microporous (7.8–19.8%) and macroporous Sect. (0.3–0.6%). The accumulated surface area curve fluctuated greatly in the mesoporous and microporous sections, and that in the macroporous section was relatively flat with limited distribution. According to the Menger Sponge model, the fractal dimensions of the macroporous (Dmac) and mesoporous (Dmes) sections ranged from 2.4 to 2.8 and 3.7–3.9, respectively, with obvious fractal characteristics; Dmes was higher than Dmac, indicating that the structure of small and medium-sized micropores is more complex and irregular. The fractal dimension in the high-pressure zone of the FHH model (DHP) ranged from 2.8 to 2.9, and that in the low-pressure zone (DLP) ranged from 2.1 to 2.4, indicating that coal pore structure under low-pressure conditions is relatively simple. The fractal dimension of the density functional model ranged from 2.5 to 3.0, closer to 3, indicating that the pores are relatively complex and rough. A single-variable analysis revealed a strong correlation between burial depth and aperture parameters. This is the first study to reveal the relationship between burial depth and aperture parameters. Moreover, characterization of critical depth based on aperture structure was performed, providing a feasible method for quantifying “critical depth.” Our results enrich our understanding of the structure of deep coal bodies and serve as a reference for deep mining engineering.

Similar content being viewed by others

Introduction

Coal is a highly heterogeneous porous medium1, and its surface is the main site for gas adsorption and desorption processes. Studying the fractal characteristics and pore structure of coal is particularly crucial for gas prediction, development, and disaster management in deep coal. Characterization methods for coal pore structure include liquid nitrogen adsorption2, mercury intrusion porosimetry (MIP)3, and low-temperature carbon dioxide adsorption4. Here, this type of method involves injecting or adsorbing fluid into coal pores under a certain pressure to calculate the volume of fluid within the coal pores. Recently developed electron microscopy and X-ray methods, such as field emission scanning electron microscope5, optical microscopy6, environmental scanning electron microscopy7, atomic force microscopy8, other microscopic observations, nuclear magnetic resonance9, X-ray computed tomography10, and small angle X-ray scattering11, have provided new ideas for studying coal pores. However, they have limitations, such as low accuracy, large errors, and adaptability, thus requiring combination with traditional methods. The combination of pore characterization methods and fractal geometry theory12,13 can accurately characterize the roughness of coal, providing a precise description of coal pore structure complexity. For example, Cheng et al.14 used the Menger Sponge model to study the alterations in pore structure of low-rank coal before and after acidification using H2S aqueous solution. Cai et al.15 determined the fractal characteristics of coal pores using classical geometric and thermodynamic fractal models, establishing the relationship between fractal dimension and coal pore characteristics. Moreover, Zhang et al.16 used the Sierpinski model to analyze the fractal characteristics of reservoir pores in 56 coal samples from 14 mining zones on the eastern edge of the Ordos Basin, revealing the relationship between pore volume fractal dimension and permeability of coal reservoir seepage pores. Zhang et al.17 utilized the Frenkel–Halsey–Hill (FHH) model to study the fractal characteristics of different structure samples in the No. 3 coal seam of the Qinshui Basin and investigate how they influence methane adsorption and diffusion in coal. Lastly, based on the theory of microporous filling and pore size distribution, Xiong et al.18 investigated the fractal characteristics of coal and shale microporous structures. Most studies have focused on the pore structure of shallow coal seams, and there is limited research on the comprehensive characterization and fractal laws of deep coal bodies. The main manifestation is that there are abundant achievements in the structural characteristics of shallow coal bodies, while there is very little research on the pore structure of 800-m deep coal; The pore structure within coal is intricate and complex, making it difficult to accurately characterize using a single method. Therefore, a comprehensive analysis of the full pore size of macropores, mesopores, and micropores is needed; however, a single fractal model is not sufficient to fully evaluate the complexity of coal pores, a comprehensive evaluation of the fractal characteristics of the full pore structure is needed.

To address these limitations, this study performed various testing methods, including MIP, liquid nitrogen adsorption, and low-temperature carbon dioxide adsorption, to (1) comprehensively characterize the pore structure of deep coal, (2) analyze the full pore-size distribution and pore fractal characteristics of various coal rank coals, and (3) investigate how coal burial depth influences pore structure. Our results provide new insights on deep mining.

Methods

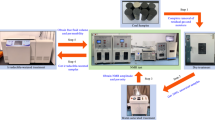

Characterization of coal samples

Fresh coal samples were obtained from 8 various locations in the Kailuan and Fushun mining zones according to the “Sampling of coal petrology” protocol (GB/T 19222 − 2003). Industrial analysis indicators of coal were measured according to the “Proximate analysis of coal” (GB/T 212–2008). Basic information on the coal sample is listed in Table 1.

Characterization methods

MIP method

MIP is based on capillary resistance. Mercury has no wetting ability on coal and can only enter its pores by overcoming capillary resistance under external pressure. Capillary resistance depends on the pore radius, and the total volume of pores larger than a certain radius is determined based on the volume of mercury injected into coal under a certain mercury pressure. The distribution of pores of various sizes in coal is calculated by measuring the volume of mercury injected under various pressures19.

According to the “Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and gas Adsorption, Part 1: Mercury Porosimetry” (GB/T 21650.1–2008), an appropriate amount of coal sample is weighed for mercury intrusion testing. Prior to testing, the sample will be fully dried at 378 K for 10 h. The instrument will be vacuumed and degassed for 12 h to eliminate gas interference.

Liquid nitrogen method

Nitrogen undergoes multi-layer adsorption on mesopore and macropore surfaces of coal. When the temperature of liquid nitrogen is 77.35 K, the amount of nitrogen adsorbed on a certain surface of coal and its relative pressure follow the Kelvin equation. Theoretical models, such as the Barret–Joyner–Halenda (BJH) model, density function theory (DFT), and Brunauer–Emmett–Teller (BET) models, can be used to determine the surface area and pore volume distribution of coal samples20.

The experimental conditions were relative pressure of 0.010-0.0 995, test temperature 77.35 K, nitrogen purity 99.99%. The protocol was performed in accordance with the “Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and gas Adsorption, Part 2: Analysis of Mesopores and Macropores by gas Adsorption” (GB/T 21650.2–2008).

Carbon dioxide method

The MIP and liquid nitrogen adsorption method can effectively characterize the mesoporous and macroporous structures of coal but not the microporous structure. Liquid nitrogen (77.35 K) adsorption and filling of micropores require lower pressure, while liquid argon (87.30 K) filling of micropores requires a slightly higher pressure than liquid nitrogen. However, there is a diffusion restriction problem that hinders gas molecules from entering the micropores. Choosing a low-temperature CO2 (273.15 K) adsorbent can effectively address the diffusion limitation at a saturated vapor pressure of 3.48 MPa, thus characterizing micropores within 2 nm. Hence, the low-temperature CO2adsorption method can be utilized to determine the pore volume, surface area, porosity, and other parameters of micropores with pore width > 2 nm21.

The procedure was performed according to the “Pore size distribution and porosity of solid materials by mercury porosimetry and gas adsorption, Part 3: Analysis of micropores by gas adsorption” (GB/T 21650.3–2011). The sample (~ 2 g) was weighed, placed in a sample tube, and vacuumed for 12 h. After degassing, using 99.99% high-purity CO2 as adsorbent, adsorption testing was conducted at 273.15 K.

Fractal models of coal pores

Menger sponge model

The Menger Sponge model assumes that a regular and ideal microcube component is used to simulate the fractal dimension of porous media. By combining it with the Washburn equation, the relationship between mercury injection pressure and volume, pore size, and fractal dimension can be obtained as follows22,23:

where V is the amount of mercury injected (ml/g); P is the mercury injection pressure (MPa), r is the pore size (nm), and D is the fractal dimension. Then, the fractal dimension can be obtained based on the functional relationship between \(\:log(dV/dP)\) and \(\:logP\).

FHH model

Pfeifer and Avnir24,25first proposed the FHH model, while Avnir and Jaroniec26created an adsorption model for gas molecules in the capillary condensation region of non-uniform porous media based on adsorption potential theory27. The functional equation is expressed as:

where V is the volume of nitrogen gas (ml/g), D is the fractal dimension, P0 is the steam pressure (MPa), P is the adsorption equilibrium pressure (MPa), and C is a constant. Thus, the fractal dimension can be calculated based on the functional relationship between \(\:lnV\) and \(\:ln\left[ln\left({P}_{0}/P\right)\right]\).

Density functional model

Jaroniec et al.28 found that in nanopores, the pore size distribution density function \(\:J\left(r\right)\) and pore size r follow a linear relationship, which can be expressed as:

where \(\:J\left(\text{r}\right)\) is the pore size distribution density function, D is the fractal dimension, r is the aperture (nm), and C is a constant.

Thus, the fractal dimension can be determined based on the functional relationship between \(\:{ln}J\left(r\right)\) and \(\:{ln}r\).

Results

Full aperture characterization results

According to the IUPAC classification criteria29, pores larger than 50 nm are macropores, those smaller than 2 nm are micropores, and those between 2 nm and 50 nm are mesopores. The full pore size distribution characteristics of the coal samples are shown in Table 2; Figs. 1–2.

In Table 2, the stage pore volume was mainly concentrated in the macroporous (43.6–83.4%) and mesoporous Sect. (16.3–54.7%), with sparse distribution in the microporous Sect. (0.3–2.1%). In Fig. 1(a), the pore volume distribution curve in the microporous section was relatively flat, containing three peaks, the maximum of which was at 5.80 × 10–4 ml/g. The pore volume distribution in the mesoporous section was relatively wide, with multiple peaks, the maximum of which was at 5.36 × 10–3 ml/g. Lastly, the distribution of pore volume in the macroporous section was the most extensive, with a maximum at 0.1322 ml/g for the full pore size of ~ 91,000 nm.

In Fig. 1(c), the pore volume distribution in the microporous section was sparse, having a maximum peak value of 1.11 × 10−3 ml/g. The pore volume distribution in the mesoporous section was relatively wide, containing multiple peaks, the maximum of which was at 7.27 × 10−3 ml/g. The distribution of pore volume in the macroporous section was the most extensive, with a maximum at 0.2408 ml/g for the entire pore size of ~ 91,000 nm. As shown in Fig. 1(b) and 1(d), from KL-04 to KL-01 and from FU-04 to FU-01, respectively, the accumulated pore volume decreased with an increase in coal sample burial depth. The curve of the micropore section was flat, while the mesopore and macropore sections had large fluctuations, indicating that the pore volume is concentrated in these areas.

Table 2; Fig. 2 show the distribution of the surface area of the full aperture. The surface area of each sample stage was mainly distributed in the mesoporous Sect. (79.5–91.8%), followed by the microporous Sect. (7.8–19.8%), and sparsely distributed in the macroporous Sect. (0.3–0.6%) (Table 2). In Fig. 2(a), the mesoporous section has the widest distribution of surface area, with a high peak frequency. The maximum peak value near 3.4 nm was 5.6337 m2/g, and the surface area oscillated and decreased with an increasing pore size. There were three peaks within the microporous section, the maximum of which at 1.9392 m2/g. The overall surface area within the macroporous section was flat and sparsely distributed, with a maximum surface area of 0.053 m2/g. The surface area distribution in Fig. 2(c) was similar to that in Fig. 2(a), with a maximum of 4.2347 m2/g, 8.3348 m2/g, and 0.079 m2/g for the microporous, mesoporous, and macroporous sections, respectively.

Calculation of fractal dimension of deep coal

Menger sponge model

In Table 3, Dmac ranged from 2.4 to 2.8, and Dmes ranged from 3.7 to 3.9. The fractal dimension is generally between 2 and 3. When the mercury pressure inside the coal exceeds 10 MPa, the coal matrix undergoes deformation due to compression, resulting in a pore fractal dimension greater than 330. Overall, the fractal dimension of the mesoporous section was higher than that of the macroporous section, indicating that the pore structure of small and medium-sized micropores is more complex and irregular.

FHH model

The fractal curve of the FHH model is bounded by “\(\:\text{P}/{\text{P}}_{0}=0.5\)“, and when “\(\:\text{P}/{\text{P}}_{0}<0.5\)”, the Van-Der-Waals forces between nitrogen molecules and coal molecules dominate the adsorption; When “\(\:\text{P}/{\text{P}}_{0}>0.5\)”, nitrogen will condense on the surface of coal pores, producing capillary condensation phenomenon, and the surface tension formed by capillary condensation is mainly controlled. In Table 4, DHP ranged from 2.8–2.9, and DLP ranged from 2.1–2.4, indicating that, in the low-pressure zone, the pore structure of coal is relatively simple.

Density functional model

From Table 5, the fractal dimension D of the carbon dioxide method ranged from 2.5 to 3.0, which is close to 3, suggesting that the pore structures are relatively complex and rough.

Discussion

Relationship between burial depth and pore volume

The relationship of burial depth with total pore volume (Fig. 3) and stage pore volume (Fig. 4) was evaluated.

In Fig. 3, the influence of coal seam burial depth on the total pore volume is obvious. With an increase in burial depth, the total pore volume constantly decreased. Combined with Fig. 4(a), the largest proportion of macropore volume in the Kailuan mining zone showed a monotonically decreasing trend with an increase in burial depth. This suggests that as the coal seam burial depth increases, the coal body produces compaction effect owing to complex factors such as temperature and pressure, and the coal seam pore structure becomes denser, resulting in a decrease in the number of macropores. Meanwhile, the second largest proportion of mesopores showed a monotonically increasing trend in pore volume, indicating that after the compression of macropore space, the pore structure changed, and the macropores in the coal gradually transformed into mesopores and micropores.

Figure 4(b) shows that the proportion of the macropore volume in the Fushun mining zone gradually decreased with increasing burial depth, whereas that of the mesopore and micropore volume gradually increased. At 660 m, this trend was reversed. Overall, an increase in burial depth reduced the total pore volume, with the largest proportion of macropores having a lower proportion. Meanwhile, the mesopores and micropores have a relatively increased pore volume, indicating a turning critical depth for pore structure transformation. This depth affects pore structure parameters. From the fitting results, the relationship between burial depth and pore volume can be expressed by quadratic function.

Influence of burial depth on surface area

The relationship between burial depth and surface area is shown in Figs. 5 and 6.

In Fig. 5, as burial depth increases, the surface area of coal samples in the Kailuan mining zone constantly decreased. In Fig. 6(a), with increasing burial depth, the mesoporous section with the highest proportion of surface area first decreased and then increased; meanwhile, in the micropore section with the second highest proportion, the trend was opposite, indicating that the surface area also undergoes a transformation along with changes in pore structure. The influence of burial depth on surface area in the Fushun mining zone is controlled by the critical depth. Below 620 m, there was a monotonically increasing trend, and beyond the depth of the inflection point, it has a similar trend to the Kailuan mining zone, that is, a decreasing trend with an increase in burial depth. Thus, the relationship between the burial depth and surface area is expressed as a quadratic function.

Influence of burial depth on fractal dimension

According to the fractal models, the relationship between burial depth and fractal dimension was plotted (as shown in Figs. 7, 8 and 9).

The burial depth and fractal dimension of coal in the Kailuan and Fushun mining zones showed a quadratic trend. From the Menger Sponge and density functional models, a “convex parabola” was noted, whereas from the FHH model, a “Concave parabola” was observed. Thus, there was a strong association between burial depth and fractal dimension. After reaching the critical burial depth, the regularity and complexity of the pores also changed accordingly pwing to changes in the pore structure.

Using a single-variable analysis, a strong correlation between burial depth and aperture parameters was found, both of which can be characterized by quadratic function formulas. There is a critical burial depth on the curve, and the trends in aperture parameter changes on both sides of this burial depth were completely different.

Therefore, the general formula expressing the relationship between burial depth and aperture parameters is as follows:

where \(\:\varOmega\:\) represents aperture parameters (includes pore volume, surface area, fractal dimension, among other); H is the depth of occurrence (m); and A, B, C are constants.

Challenges and future prospects

Chinese coal mines have reached deep mining depths; however, there remains no clear and quantitative definition of critical deep. In this study, there was a strong correlation between coal pore parameters and burial depth, which can be quantitatively characterized by pore size parameters. After reaching a certain turning critical burial depth, the pore structure underwent obvious changes, which are controlled by factors such as temperature, self-weight pressure, and structural stress at a certain burial depth. Therefore, aperture parameters can be selected as indicators for determining the critical depth in deep mining. The characterization of critical depth based on pore structure not only affects the gas adsorption, diffusion, and migration laws inside a coal body, but also relates to coalbed methane extraction and utilization, gas extraction and emission, and gas disaster prevention and control engineering. Thus, our findings are of great significance for future deep engineering research.

However, determining the universal critical burial depth is difficult, and most tests on the pore structure parameters of coal from different mining zones and burial depths need to be conducted to more accurately determine the burial depth of most mining zones. This requires continuous research and collaboration among scholars.

Conclusions

This study comprehensively characterized the pore structure of deep coal bodies, analyzed the full pore-size distribution and pore fractal characteristics of coal at different burial depths, and evaluated the influence of coal burial depth on pore structure. Our main conclusions are as follows:

(1) In the study zone, the stage pore volume of coal is mainly concentrated in the macroporous (43.6–83.4%) and mesoporous Sect. (16.3–54.7%), with sparse distribution in the microporous Sect. (0.3–2.1%). The cumulative pore volume decreased with an increase in burial depth, indicating that with an increase in coal seam burial depth, the coal body produces a compaction effect under complex factors, such as temperature and pressure, and the pore structure of the coal seam becomes denser, resulting in decreased cumulative pore volume. In the study zone, the stage surface area of coal was mainly distributed in the mesoporous Sect. (79.5–91.8%), followed by microporous (7.8–19.8%) and macropore Sect. (0.3–0.6%). These results imply that the adsorption performance of coal is mainly controlled by the mesopores and micropores.

(2) The Menger Sponge model has obvious fractal characteristics, with a macroporous section Dmac ranging from 2.4 to 2.8 and a mesoporous section Dmes ranging from 3.7 to 3.9. The fractal dimension of the mesoporous section was higher than that of the macroporous section, suggesting that the structure of small and medium-sized micropores is more complex and irregular. The DHP in the high-pressure zone of the FHH model ranged from 2.8 to 2.9, and the DLP in the low-pressure zone ranged from 2.1 to 2.4, with obvious fractal characteristics. The pore structure of coal under low-pressure conditions was relatively simple. The fractal dimension of the density functional model ranged from 2.5 to 3.0 (closer to 3), indicating that the pores are relatively complex and rough.

(3) The system analyzed the influence of burial depth on pore volume, surface area, fractal dimension, and other pore size parameters. From a single-variable analysis, the burial depth and pore size parameters were strongly correlated, both of which can be characterized by quadratic function formulas. There was a critical burial depth on the curve change, and the trends in pore size parameter on both sides of this critical burial depth were different. The general formula for the relationship between burial depth and aperture parameters can be expressed as \(\:\varOmega\:=A+B\cdot H+C{\cdot H}^{2}\).

(4) Based on the distribution law and fractal characteristics of multi-level pore size in deep coal seams, a burial depth effect was revealed, and characterization of critical depth based on pore size structure was proposed, providing a feasible method for quantifying “critical depth.” This finding serves as a reference for studying pore connectivity, gas adsorption, and gas migration laws of deep coal seams and advances the research of future deep coal and gas co-mining technology, coal and gas outburst prevention and control engineering, and quantitative delineation of deep mining.

Data availability

All data generated or analysed during this study are included in this published article. The datasets used and/or analysed during the current study available from the corresponding author on reason able request.

References

Li, Q., Qin, Y. & Ren, S. Structural characterization analysis and macromolecular model construction of coal from Qinggangping coal mine. Sci. Rep. 13, 14365 (2023).

Zhang, D. et al. Effect of particle size on CO adsorption and thermodynamic analysis. J. Loss Prev. Process. Ind. 84, 105127 (2023).

Skowera, K. Fusion of differential analysis of volumetric strain method (dilatometric thermoporometry) and mercury intrusion porosimetry method for pore space characterization in carbonate rocks. Struct. Environ. 15, 90–98 (2023).

Changtao, Y., Shuyuan, L., Hailong, W., Fei, Y. & Xinyi, X. Pore structure characteristics and methane adsorption and desorption properties of marine shale in Sichuan Province, China. RSC Adv 8, 6436–6443 (2018). (2018).

Ken, B. S. & Nandi, B. K. Desulfurization of high sulfur Indian coal by oil agglomeration using linseed oil. Powder Technol. 342, 690–697 (2019).

Li, Q. et al. Effects of natural micro-fracture morphology, temperature and pressure on fluid flow in coals through fractal theory combined with lattice boltzmann method. Fuel 286, 119468 (2021).

Wang, Y., Xia, W., Yang, J. & Zhu, B. Low-temperature oxidation process of anthracite particle surface. J. China Univ. Min. Technol. 41, 578–581 (2012).

Yang, R. et al. Pore-scale analysis of coal structure and mechanical properties evolution through liquid nitrogen thermal shock. Nat. Gas Ind. B. 8, 596–606 (2021).

Li, Y. et al. Characterizing water vapor adsorption on coal by nuclear magnetic resonance: influence of coal pore structure and surface properties. Energy 282, 128420 (2023).

Liu, D., Zhao, Z., Cai, Y., Sun, F. & Zhou, Y. Review on applications of xray computed tomography for coal characterization: recent progress and perspectives. Energy Fuels. 36, 6659–6674 (2022).

Zhou, Z. et al. Solvent extraction of superfine pulverized coal. Part 3. Small angle X-ray scattering characterization. Fuel 353, 129201 (2023).

Mandelbrot, B. How long is the coast of Britain? Statistical self-similarity and fractional dimension. Science 156, 636–638 (1967).

Mandelbrot, B. On the geometry of homogeneous turbulence, with stress on the fractal dimension of the iso-surfaces of scalars. J. Fluid Mech. 72, 401–416 (1975).

Cheng, X. et al. Experimental research on the effect of H2S solution on pore structure of low-rank coal. J. China Coal Soc. 45, 1436–1444 (2019).

Cai, Y., Liu, D., Yao, Y., Li, J. & Liu, J. Fractal characteristics of coal pores based on classic geometry and thermodynamics models. Acta Geol. Sin. 85, 1150–1162 (2011).

Zhang, S. et al. Fractal characteristics of coal reservoir seepage pore, east margin of Ordos Basin. J. China Univ. Min. Technol. 38, 713–718 (2019).

Zhang, K., Meng, Z., Jin, Y. & Wang, B. Fractal characteristics of pore structures on different coal structures and its research significance. Coal Sci. Technol. 51, 198–206 (2022).

Xiong, Y. H. et al. Fractal analysis of micropore structures in coal and shale based on low-temperature CO2 adsorption. Nat. Gas Geosci. 31, 1028–1040 (2020).

Lin, J., Ye, J. & Zou, W. Effect of pore fluid on microstructure in expansive soil. J. Huazhong Uni Sci. Technol. 48, 12–17 (2020).

Li, X. et al. Study on nanopore structure of soil and quantitative characterization based on mercury intrusion, liquid nitrogen adsorption, CO2 adsorption, and SEM. Arab. J. Geosci. 15, 210 (2022).

Wedler, C. & Span, R. Micropore analysis of biomass chars by CO2 adsorption: comparison of different analysis methods. Energy Fuels. 35, 8799–8806 (2021).

Menger, K. Grundzüge Einer Theorie Der Kurven. Sel. Math. 95, 277–306 (1926).

Menger, K. Über die dimension von punktmengen: II. Teil. Monats Math. 34, 137–161 (1926).

Pfeifer, P. & Avnir, D. Chemistry in noninteger dimensions between two and three. I: Fractal theory of heterogeneous surfaces. J Chem Phys 79, 3558–3565 (1983). (1983).

Pfeifer, P., Avnir, D. & Erratum Chemistry in noninteger dimensions between two and three. I. fractal theory of heterogeneous surfaces. J. Chem. Phys. 80, 4573–4573 (1984).

Avnir, D. & Jaroniec, M. An isotherm equation for adsorption on fractal surfaces of heterogeneous porous materials. Langmuir 5, 1431–1433 (1989).

Jaroniec, M. Evaluation of the fractal dimension from a single adsorption isotherm. Langmuir 11, 2316–2317 (1995).

Jaroniec, M., Gilpin, R. K. & Choma, J. Correlation between microporosity and fractal dimension of active carbons. Carbon 31, 325–331 (1993).

International Union of Pure and Applied chemistry. Physical chemistry division commission on colloid and surface chemistry, subcommittee on characterization of porous solids: Recommendations for the characterization of porous solids (Technical Report). Pure Appl Chem 66, 1739–1758. (1994).

Chen, X., Zhao, S., Si, Z., Qi, L. & Kang, N. Fractal characteristics of pore structure of coal with different metamorphic degrees and its effect on gas adsorption characteristics. Coal Sci. Technol. 48, 118–124 (2020).

Acknowledgements

The authors would like to express gratitude to the Key Laboratory of Rock Mechanics and Geohazards of Zhejiang Province for the facilities and resources invested in the project, as well as the strong support and assistance provided by the laboratory staff.

Author information

Authors and Affiliations

Contributions

Qi Li: conceptualization, funding acquisition, methodology, writing – original draft, writing – review & editing; Xiaoxia Zhang: project administration, resources, translation, writing – original draft; Zhengzong Wang: conceptualization, supervision, validation, visualization, writing – review & editing; Lei Qiao: data curation, investigation; Shitan Shao: formal analysis, software. All authors contributed to the development of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, Q., Zhang, X., Wang, Z. et al. Research on comprehensive characterization of deep coal full aperture structure and burial depth effect. Sci Rep 15, 4510 (2025). https://doi.org/10.1038/s41598-025-88593-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-88593-1