Abstract

To investigate the movement law of overlying strata in the fully mechanized top-coal caving face of extra-thick coal seams and further achieve the effective prevention and control of rock burst. Taking the 12,240 working face of Gengcun Coal Mine as the engineering background, initially, the calculation formula for the collaborative deformation load of hard rock strata and the formula for the instability scale of hard rock strata are employed to precisely ascertain the position and instability scale of the key strata. Subsequently, a UDEC calculation model is established to comprehensively investigate the instability characteristics of the overlying hard rock strata. Simultaneously, a meticulous analysis of the working resistance of the on-site supports is carried out to validate the theoretical computations. Eventually, in light of the research findings, a rational determination of the cutting scale is made so as to offer a scientific foundation and efficacious guidance for the execution of roof pre-splitting blasting operations. The research results show that within 50 m above the 12,240 working face, there is one low-position hard strata and three medium-position hard strata. Under the influence of mining, the displacement field of the overlying hard strata is symmetrically distributed with respect to the central axis of the goaf. The stress rise areas on both sides of the goaf present a “hyperbolic” distribution, and the stress of the goaf roof and floor is released, showing an “elliptical parabolic belt” distribution. The periodic instability occurred about 8 m after the initial instability of the low-level hard rock layer, and the periodic instability occurred about 20 m after the initial instability of the middle hard rock layer 1. The goaf of the 12,220 working face in the north of the working face is a crucial reason for the support resistance of the upper part of the 12,240 working face being greater than that of the middle part and the middle part being greater than that of the lower part. When the working face advances 20–30 m, a distinct pressure accumulation area emerges in the middle of the working face and is regularly distributed as the working face advances. The monitoring results indicate that microseismic events are concentrated in the basic roof and medium-position strata 1, and energy events of 103 J are prone to occur. The basic roof and medium-position strata 1 are the key points for rock burst prevention of the working face. A roof cutting scale of no more than 10 m for the low-position hard strata can effectively reduce the rock burst risk. The research results provide theoretical support for roof pre-splitting and rock burst prevention of the 12,240 working face in Gengcun Coal Mine and can offer guidance for the prediction and prevention and control of rock burst risk in mines and working faces under similar conditions.

Similar content being viewed by others

Introduction

The reserves of ultra-thick coal seams account for 20% to 50% of the total recoverable coal reserves in the world’s major coal-producing countries, and the production of ultra-thick coal seams accounts for approximately 32% of the total coal production1,2. The use of fully mechanized top-coal caving mining for extra-thick coal seams has the characteristics of high efficiency and low cost3. The high extraction height of fully mechanized top-coal caving mining leads to more intense overlying rock movement compared to other mining processes such as layered mining. The distribution range of mining stress is large, and the impact on the overlying rock and coal seam floor is extensive4,5,6. Under the mining conditions of thick coal seams, the large-scale movement of rock layers and the manifestation of mining pressure have always been hot and difficult issues in scientific research and on-site construction7,8. Many scholars at home and abroad have achieved a large number of results in the field of overburden movement. Mangal, Aveek, et al.9,10,11 used retrospective analysis and on-site application and monitoring methods to study the geological mechanics issues related to the interaction between the dynamic support and the roof in fully mechanized top coal caving mining. At the same time, they studied the effect of roof support under thick coal seam conditions, providing theoretical support for the study of thick coal seam mining methods and overlying rock movement laws in thick coal seam fully mechanized top coal caving working faces. German scholars W Hack and G Gillitzer proposed the “pressure arch hypothesis”, which provides a preliminary theoretical basis for the study of rock fracture12,13. Guo W et al.14 studied the mechanism of bending deformation of overlying strata, mechanical parameters of alluvial layers, and their impact on surface subsidence through theoretical analysis and numerical simulation analysis. Academician Qian Minggao proposed the mechanical model of “masonry beam” and the theory of “key layer”, laying the foundation for the theory of mine pressure and rock control in China15. Based on the mechanical analysis and similar simulation test results of the fracture morphology of different layers of rock strata, Zuo Jianping et al.16 proposed a “hyperbolic-like” model for the overall movement of mining overlying strata and provided the expression and physical meaning parameter system for the overall movement inside and outside the mining overlying strata. Yu Bin et al.17 proposed the concept of large space mining and established a mechanical model of the far-field hard roof fracture structure in large space mining, revealing the strong rock pressure control mechanism of the instability caused by the far-field hard roof fracture. Guo, Linning et al.18 used numerical simulation methods to evaluate the stability of goaf, providing ideas for numerical simulation research on the instability of hard rock layers. Wang Ming et al.19,20,21,22,23 conducted numerous studies on the uniaxial compressive properties of rocks, which played a promoting role in accurately calculating the instability scale of hard rock layers and analyzing the activity characteristics of overlying rock layers. Ronghai et al.24,25,26,27 analyzed the structural characteristics, formation conditions, instability scale, and energy released by the instability of hard rock layers by constructing a model of the unstable structure of hard rock layers. They also provided corresponding calculation formulas to determine the control effect of hard rock layer instability on rockburst. Chu Zhixiang28 studied the mining pressure manifestation law and roof control technology during the backfilling process of thick coal seam island fully mechanized mining face through laboratory experiments, theoretical analysis, numerical simulation research, and field measurements. Pan Liting29 determined the pre-splitting and cutting scale of the roof rock layer instability in the 13,230 working face of Gengcun Coal Mine, providing theoretical support for the targeted implementation of rock burst prevention and control measures in Gengcun Coal Mine.

In the aforementioned research, scholars have carried out an extensive and comprehensive investigation into the overlying rock structure of the working face, the manifestation of working face pressure, as well as the laws governing roof movement. The research predominantly centers around the formation mechanism of overlying hard rock layers and the control technology of the roof. However, there is a relative paucity of reports concerning the instability characteristics of key strata within the overlying rock layers. As a distinct geological condition, thick coal seams can exert an influence on the occurrence of rockbursts. Consequently, how to explore the prevention and control technology of rockbursts in hard rock layers of working faces under thick coal seam conditions has emerged as an urgent issue that demands resolution.

Therefore, this article adopts the key layer perspective as the fundamental starting point. Through theoretical analysis, the key layer is precisely determined. Employing numerical simulation methods, a UDEC mining instability model is established to ascertain the instability scale. Based on the alterations in support resistance of the working face and the microseismic activity characteristics of the overlying rock layer, the movement law of the key layer is defined. Subsequently, the cutting scale of the hard rock layer is determined. Furthermore, the impact of key layer instability on the prevention and control of rockbursts in the mine working face is analyzed in depth, thereby furnishing guidance for the prevention and control of hard roof slabs in the mine working face. The ultimate aim is to offer valuable guidance for the prediction and prevention of rockbursts in the 12,240 working face and similar working faces of Gengcun Coal Mine.

Mine overview and analysis of the occurrence of overlying rock strata on the working face

Mine overview

The Gengcun Coal Mine is situated in Mianchi County, Sanmenxia City, Henan Province. The mine field lies on the northern flank of the Yima syncline, exhibiting an overall southward-dipping monocline structure. The geological conditions of the Gengcun Coal Mine are complex, and the F16 fault is a regional thrust fault that traverses the southern part of the Yima mining area. The coal seam of the Gengcun Coal Mine has a moderate tendency towards impact and is classified as a rockburst mine.

The Gengcun Coal Mine mainly extracts the 2–3 coal seams and is currently mining in 12 mining areas with an average burial depth of 547.45 m and an average coal thickness of 15.28 m. It is an ultra-thick coal seam and employs a comprehensive mechanized top-coal caving mining method. The 12,240 working face is situated on the west wing of mining area 12. The northern part of the working face is the 12,220 working face that has already been mined out. The western part of the working face is adjacent to the protective coal pillar of Xinhua Avenue in Mianchi County. The southern part of the working face is the 2–3 coal entity that has not yet been mined. The planar position of the 12,240 working face is illustrated in Fig. 1.

Analysis of the occurrence of overlying rock layers on the working face

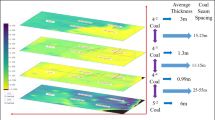

The stratigraphic column of the 12,240 working face drilling in Gengcun Coal Mine is shown in Fig. 2. As shown in Fig. 2, the top of the coal seam is a 2.69-m-thick sandy mudstone. Within a range of 100 m above the coal seam, there are three rock layers with a thickness greater than 10 m, from bottom to top: a fine-grained sandstone with a thickness of 13.45 m at a distance of 47.64 m from the coal seam roof, a sandy mudstone with a thickness of 24.5 m at a distance of 61.09 m from the coal seam roof, and a medium-grained sandstone with a thickness of 33.65 m at a distance of 94.29 m from the coal seam roof.

Uniaxial compressive strength (UCS) is an important mechanical parameter for evaluating the stability of rock engineering30. Wang Ming et al.31,32,33,34 obtained corresponding effective formulas or parameters through different algorithms and prediction methods, and conducted various experiments, providing important basis for rock engineering related research. The determination of UCS can provide theoretical support for accurately calculating the instability scale of hard rock layers and determining numerical simulation parameters.There are multiple layers of thick gravel layers above the working face. They are hard and difficult to collapse under the influence of mining. They are prone to accumulate energy, and the instability of the hard rock layers can easily cause rockburst, affecting the safe production of the mine35. The physical and mechanical parameters of the overlying rock strata on the 12,240 working face are shown in Table 1.

Determination of key layers in overlying strata and calculation of instability scale

The existence of key layers is prone to energy accumulation and is also the main target layer for rockburst control12,36. Based on the actual occurrence of coal and rock in the 12,240 working face, combined with the borehole column chart and the physical and mechanical parameters of the overlying rock layers, the load of each overlying rock layer is calculated layer by layer from bottom to top using the formula for the coordinated deformation load of hard rock layers and the formula for the instability scale of hard rock layers37,38. The layers of each hard rock layer are determined and solved as shown in Eq. (1).

In the formula: \(x_{i} = \frac{{b_{i} \sqrt {3a_{i}^{2} + b_{i}^{2} } - b_{i}^{2} }}{{2a_{i} }}\), \(y_{i} = \frac{{a_{i} \sqrt {a_{i}^{2} + 3b_{i}^{2} } - a_{i}^{2} }}{{2b_{i} }}\);

b1i-The initial instability scale of the i-th hard rock layer, m;

ai-The length of the hard rock layer hanging along the working face direction, m;

qi-The load on the i-th hard rock layer, MPa;

Msi-Ultimate bending moment of the i-th hard rock layer, \(M_{si} = \frac{1}{6}\sigma_{si} h_{i}^{2}\), N·m;

hi-The thickness of the i-th hard rock layer, m;

σsi-The tensile strength of the i-th hard rock layer, MPa.

Accurately calculating the step distance is beneficial for predicting the time and location of roof pressure, guiding the effective adoption of emergency measures, and reducing the risk of roof accidents. Since the ultimate span formed by bending moment is smaller than that formed by shear stress, the step spacing is usually calculated using bending moment39. The initial and periodic instability scales of low and medium hard rock layers are solved as shown in Eqs. (2) and (3).

In the formula: h-Rock thickness, m;

RT-Tensile strength, Pa;

q-Overlying rock load, Pa.

According to the aforementioned formula, the key layer levels and instability scales above the 12,240 working face are calculated and presented in Table 2.

Theoretical calculations indicate that there are a low-level hard rock layer and mid-level rock layers 1, 2, and 3 above the 12,240 working face. The low-level hard rock layer is 2.69 m away from the working face and serves as the basic roof. The energy generated by the instability of the basic roof will directly impact the working face24. Consequently, the basic roof of the 12,240 working face is the focal point of this study.

After determining the key strata and instability scale of the overlying rock layers on the 12,240 working face, we further utilized the UDEC numerical simulation method to delve deeper into the instability characteristics of these key strata and the overlying hard rock layers under the influence of mining. This investigation encompassed aspects such as displacement changes, stress distribution patterns, and instability patterns, aiming to gain a more comprehensive understanding of the inherent relationship between rock movement status and the risk of rockburst occurrence.

Analysis of the Instability Characteristics of Overlying Hard Rock Layers under the Influence of Mining Activities

Establishment of the UDEC numerical simulation model

The UDEC numerical simulation method can intuitively obtain the effect of rock fracture and collapse40,41,42. To study the displacement and stress distribution characteristics of the overlying strata under the mining of thick coal seams, a UDEC numerical model was established with the 12,240 working face of Gengcun Coal Mine as the reference object. The length of the model was calculated to be 600 m and the height was 188 m. According to the results of on-site stress testing, a stress of 12.17 MPa is applied horizontally in the model, and a stress of 13.69 MPa is applied vertically.To consider boundary effects, a 50-m coal pillar was left on the left side, with a uniform load of 10.18 MPa applied to the upper part and boundary constraints imposed. The coal rock mass was modeled using the Mohr Coulomb constitutive model, and the joints were modeled using the Coulomb slip constitutive model. The physical and mechanical parameters of the overlying rock on the 12,240 working face are shown in Table 1. The numerical model has a mining step spacing of 4 m and 100 mining steps, totaling 400 m of mining. The numerical calculation model is shown in Fig. 3.

Analysis of overburden displacement

As the working face progressed, corresponding displacement cloud maps of the overlying strata were obtained. Record the displacement values at different positions in the cloud map, and analyze the displacement characteristics of the overlying strata during the mining process of the 12,240 working face using the UDEC built-in measurement tool. The displacement cloud maps of the working face advancing 20 m, 40 m, 80 m, and 120 m are shown in Figs. 4, 5, 6, 7.As depicted in the figure, when the working face advances by 20 m, the maximum displacement of the overlying rock increases from 0.28 m to 1.03 m, and the basic roof commences to collapse. When the working face advances to 40 m, the instability and collapse of the basic roof lead to the overlying rock layer losing support. At this time, the structure of the middle hard rock layer 1 remains intact and there is no detachment phenomenon. When the working face advances to 80 m, the displacement field of the overlying rock further enlarges, and the peak height of the overlying rock failure reaches 32 m. The median rock layer 3 separates, and the median hard rock layers 1 and 2 collapse. As the working face continues to progress, the overlying rock layers keep on failing.

Overlying strata stress analysis

The variation law of the stress cloud diagram in the vertical direction of the working face is presented in Figs. 8, 9, 10, 11. The stress increase zones on both sides of the goaf display a “hyperbolic” distribution, and the deformation and displacement of the rock layers on both sides intensify. The stress release of the roof leads to its subsidence, affecting the stability of the roadway. The degree of stress release varies in different directions, resulting in an elliptical distribution of the pressure relief area. As the working face continues to excavate, the range of this area will gradually expand. According to the stress cloud diagram it can be observed that when the working face advances to 20 m, the stress of the low-level hard rock layer is released, but it does not collapse. When the working face advanced to 40 m, there was a significant alteration in the vertical stress distribution along the strike, and most of the rock layers underwent varying degrees of stress release. The pressure relief area above the goaf was higher than the median hard rock layer by 3. When the working face was mined to 72 m, a compacted area emerged in the goaf behind the working face, and its stress level returned to the original rock stress level. The numerical simulation results have verified the control effect of the key layer on the overlying rock layer, making it difficult for the overlying rock layer of the 12,240 working face to collapse normally and increasing the risk of rock burst in the working face.

Analysis of the instability characteristics of hard rock strata

During the process of advancing the working face, if the low-level hard rock layer and the mid-level hard rock layer are unstable simultaneously, the energy released by the rock layers will overlap with each other, augmenting the risk of rock burst in the working face43.

The instability law of low-level hard rock layers is demonstrated in Fig. 12. When the working face advances to 20 m, the displacement of the low-level hard rock layer markedly increases and commences to collapse, indicating the initial instability of the low-level hard rock layer. When the working face advances to 28 m, 36 m, and 44 m respectively, the displacement of the low-level hard rock layer significantly augments, indicating periodic instability. According to the numerical simulation results, it can be concluded that after the initial instability of low-level hard rock layers, periodic instability will occur every 8 m.

Cloud Diagram of Instability of Low-Level Hard Rock Formations. Figure (a) Displacement Cloud Diagram when the Working Face Advances by 20 mL, Figure (b) Displacement Cloud Diagram when the Working Face Advances by 28 m, Figure (c) Displacement Cloud Diagram when the Working Face Advances by 36 m, Figure (d) Displacement Cloud Diagram when the Working Face Advances by 44 m.

The instability law of the middle hard rock layer 1 is presented in Fig. 13. When the working face advanced to 56 m, the displacement of the median hard rock layer 1 markedly increased and commenced to collapse, indicating the initial instability of the median hard rock layer 1. When the working face advances to 80 m, 104 m, and 128 m, the displacement of the median hard rock layer 1 significantly augments, leading to periodic instability. According to the numerical simulation results, it can be concluded that there will be a periodic instability every 20 m after the initial instability of the medium hard rock layer.

Cloud Diagram of the Instability Law of Medium-Hard Rock Layer 1. Figure (a) Displacement Cloud Diagram when the Working Face Advances by 56 m, Figure (b) Displacement Cloud Diagram when the Working Face Advances by 80 m, Figure (c) Displacement Cloud Diagram when the Working Face Advances by 104 m, Figure (d) Displacement Cloud Diagram when the Working Face Advances by 128 m.

After conducting a detailed analysis of the instability characteristics of overlying hard rock layers under the influence of mining through UDEC numerical simulation, in order to verify the accuracy of the simulation results and gain a deeper understanding of the actual rock movement during mining, we will combine on-site monitoring data, including support work resistance monitoring data, calculation of energy released from the instability of hard rock layers, and microseismic activity monitoring data, to further study the movement laws of overlying rock layers and the prevention and control effects of rockburst in the 12,240 working face.

On-site monitoring data and analysis of prevention and control effects

On-site support work resistance monitoring plan and analysis

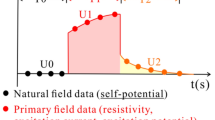

To enhance the observation of mining pressure on the working face and predict the periodic pressure on the working face, so as to adjust the mining speed of the working face in a timely manner. Design and install support work resistance monitoring stations on the working face, microseismic sensors are deployed along one side of the return airway and the transport airway and extending deep into the coal seam at intervals of 20 m, with one KJ653 pressure monitoring station installed every 10 units (15 m). During the mining process of the working face, record the changes in the pressure gauge values of the measuring station along with the progress of the working face, and analyze the mining pressure law of the working face. The layout diagram of the mining pressure observation station on the working face is shown in Fig. 14.

Continuously monitor the mining pressure within a range of 170 m in the working face, dividing the working face into three measuring areas: the upper part is from bracket No. 10 to No. 60, the middle part is from bracket No. 70 to No. 120, and the lower part is from bracket No. 130 to No. 180. Obtain the resistance cloud diagram of the hydraulic support, and employ mathematical statistical methods to analyze the changes in ground pressure during the process of advancing the working face44.

The resistance cloud diagram of the hydraulic support on the 12,240 working face is presented in Fig. 15. In the early stage of mining on the working face, the working resistance of the support is as high as 13–17 MPa. As the working face advances, the resistance of the support on the working face exhibits a trend of first increasing, then decreasing, and finally increasing again. The working resistance of the upper support is relatively high, and the goaf of the 12,220 working face in the north of the working face is an important reason for the upper support resistance > middle support resistance > lower support resistance of the 12,240 working face. When the 12,240 working face advances to 20–30 m, a pressure accumulation zone appears in the middle. As the working face continues to advance, the pressure accumulation zone of the central support appears regularly, indicating that the periodic instability of the overlying rock layer leads to the manifestation of pressure on the working face.

The criterion for judging the periodic pressure on the working face is the sum of the average end-of-cycle resistance of the support and its mean square error44, and the calculation formula is as follows:

wherein, \(\sigma_{P}\) is the variance of the average value of the end-of-cycle resistance; \({\text{n}}\) is the measured number of cycles; \(P_{ti}\) is the measured end-of-cycle resistance of each cycle; \(\overline{{P_{t} }}\) is the average value of the end-of-cycle resistance.

The criterion for the pressure on the working face

Bracket 30# is strategically positioned in the upper area, and the data it yields is highly conducive to disclosing the circumstances in the vicinity of specific geological structures or boundary conditions. Bracket 90#, being centrally located, is capable of reflecting the relatively average and archetypal state of the area. Support 150# plays a pivotal role in dissecting data fluctuations that occur under the influence of the lower strata. Consequently, the data of the upper 30#, middle 90#, and lower 150# supports were selected for data sorting and analysis. The end-of-cycle resistance curves of some supports at the 12,240 working face are shown in Figs. 16, 17, 18 .

The basic top pressure data for the upper, middle, and lower parts of the working face are presented in Tables 3, 4. According to data organization and analysis, the average initial step distance of the working face is 23.75 m; the step distance for cyclic compression is 6.55–6.77 m, with an average of 6.72 m. Compared with other mine working faces, the development of fault fissures makes the basic roof cycle of the 12,240 working face relatively small, increasing the instability of the roof.

Calculation of energy release and instability control scale for unstable hard rock layers

Through theoretical calculations, numerical simulations, and field measurements, it was found that the initial instability scales of low-level hard rock layers were 20.25 m, 20 m, and 23.75 m respectively, and the periodic instability scales were 8.27 m, 8 m, and 6.72 m respectively. Compare the theoretical calculation results, numerical simulation results, and on-site measurement results. The comparison results are shown in Table 5.

To achieve the anti-erosion control of the 12,240 working face in Gengcun, it is necessary to analyze the energy released by the instability of hard rock layers based on the determination of the instability law of the overlying key layers. The deviation between theoretical calculations and numerical simulation results is relatively small. In order to maximize the control of instability energy, the instability scale obtained from theoretical calculations is selected, and the formula for releasing energy from the instability of hard rock layers is used for calculation29.

(1) Calculation of initial instability energy release

(2) Calculation of periodic instability energy release

In summary, the initial instability release energy of low-level hard rock layers is 1.11 × 10⁶ J, and the periodic instability release energy is 1.19 × 103 J. The initial instability release energy is higher than the critical energy of 4 × 104 J for the occurrence of rockburst in Gengcun Coal Mine. Therefore, it is necessary to take measures to control the scale of structural instability of hard rock layers, reduce the scale of instability, lower the energy released after the initial instability of low-level hard rock layers, and reduce the risk of rockburst occurrence45. According to the calculation formula (7) 37 for the initial instability control scale of low-level hard rock layers, the reference values for the initial instability scale control and energy release of low-level hard rock layers in the 12,240 working face are shown in Table 6.

According to the above calculation results, when the initial instability scale of the low-lying hard rock formation is controlled at 10 m, the energy released by the initial instability is 3.26 × 104 J, which is less than the critical energy (4 × 104 J). The working face is in a relatively stable state. When the hard rock formation is unstable, it is not prone to releasing a large amount of energy, which is not likely to cause a sudden increase in the pressure on the working face, reducing the risk of rock burst.

Monitoring of microseismic activity and analysis of prevention and control effects

In order to reduce the impact risk caused by the instability of hard rock layers, the 12,240 working face of Gengcun Coal Mine adopted the method of blasting pressure relief on site in April 2024. Three blast holes are arranged within a 50-m range from the roof in a square area on the working face, with a spacing of 10 m between each hole, covering low and medium hard rock layers, to destroy the continuity of the roof rock layer and promote its crack development. At this moment, the working face has advanced to approximately 80 m. The schematic diagram of the on-site drilling and blasting layout is shown in Fig. 19.

Microseismic monitoring was carried out within a 50-m area before and after drilling and blasting. Microseismic sensors are deployed along one side of the return airway and the transport airway46,47,48, extending deep into the coal seam at intervals of 20 m. As of July 2024, the distribution characteristics of microseismic activity on the top and bottom plates of the working face in the monitoring area are shown in Fig. 20. Microseismic events are concentrated in the basic roof and median rock layer 1 and are prone to occur with energy events of 103 J, indicating that the instability of the basic roof and median rock layer 1 has a significant impact on the working face. Microseismic events occur less frequently and more sporadically in the median hard rock layer 3 and above, which conforms to the periodic instability law. According to Fig. 20(a), (b), and (c), it can be seen that the microseismic events of the roof decrease after the roof pre-splitting blasting, and the maximum energy of microseismic decreases from 9.6 × 103 J to 6.9 × 103 J, indicating that the 10 m cutting scale reduces the impact of hard rock instability and fracture on the mining face.

Distribution Characteristics of Microseismic Activities on the Roof and Floor, (a) Statistics of Microseismic Events on the Roof and Floor, (b) Spatial Distribution of Microseismic Events before Roof Pre-splitting Blasting, (c) Spatial Distribution of Microseismic Events after Roof Pre-splitting Blasting.

Conclusion

-

(1) Gengcun Coal Mine has a tendency towards rockburst. On the 12,240 working face, the average coal thickness is 15.28 m, belonging to an extremely thick coal seam. There are multiple layers of thick gravel layers above the working face, and the instability of the overlying hard rock layers under the influence of mining can easily give rise to rockburst.

-

(2) Utilizing the formula for calculating the deformation load of hard rock layers and the formula for the instability scale of hard rock layers, it was ascertained that there exists one low-level hard rock layer and three mid-level hard rock layers within 50 m above the 12,240 working face of Gengcun Coal Mine, and their initial and periodic instability scales were obtained.

-

(3) By establishing the UDEC mining instability model, it is determined that a periodic instability occurs approximately 8 m after the initial instability of the low-level hard rock strata, and a periodic instability occurs approximately 20 m after the initial instability of the mid-level hard rock strata.

-

(4) The initial instability release energy of the low-level hard rock layer exceeds the critical energy of 4 × 104 J for the occurrence of rockburst in Gengcun Coal Mine. Based on the research findings, choosing a roof pre-splitting blasting cutting scale of no less than 10 m can effectively mitigate the impact risk of the 12,240 working face. The research results offer theoretical support for the roof pre-cracking and anti-impact measures of the 12,240 working face in Gengcun Coal Mine and serve as a guide for predicting and preventing the risk of rockburst in mines and working faces under similar conditions.

Data availability

All data generated or analysed during this study are included in this published article.

References

WU Chao, WANG Zhiqiang, LIU Yaoru, et al. Study on Stability and Control Technology of Narrow Coal Pillar Surrounding Rock in Vertical Layered Section of Extra-thick Coal Seam[J/OL]. Journal of Coal Science and Technology: 1–17 [2024–06–17].

Wang, Z. et al. Analysis of China’s coal resource endowment and the international reserves pattern[J]. Ch. Popul. Resour. Environ. 20(S1), 318–320 (2010).

Wang, J. Application status and development trends of comprehensive mining technology for extremely thick and hard coal seams[J]. Coal Sci. Technol. 42(01), 1–4 (2014).

Wang, J. 40 Years of top-coal caving mining in China and prospects[J]. J. China Coal Soc. 48(01), 83–99 (2023).

HOU Yunbing, HE Shangsen, XIE Shengrong. Study on Damage and Fracture Law of Basic Roof Between Close Coal Seams[J]. Rock and Soil Mechanics 38(10) 2989–2999+3008 (2017)

Deng, W. & Kang, T. Microseismic monitoring of roof fracture in the first fully mechanized caving face of extremely thick coal seam under goaf[J]. Saf. Coal Min. 48(04), 59–62 (2017).

CHANG Xueyun. Physical Simulation and Discontinuous Deformation Analysis of Strata Movement and Mine Pressure Behavior under Extremely Thick Coal Seam Mining Conditions[D]. China University of Mining and Technology, 2021.

Dou, L. et al. Present situation and problems of coal mine rock burst prevention and control in China[J]. J. China Coal Soc. 47(1), 152–171 (2022).

Aveek, M. & Paul, P. S. Rock mechanical investigation of strata loading characteristics to assess caving and requirement of support resistance in a mechanized powered support longwall face. Int. J. Min. Sci. Technol. 26(6), 1081–1087 (2016).

Mangal, A. Strata stability investigation and convergence monitoring (SSICM) in thick-seam depillaring with caving by cable bolting method. Min. Metall. Explor. 38(2), 927–944 (2021).

Akash Chaurasia, Gabriel Walton, Sankhaneel Sinha, Timothy J. Batchler, Kieran Moore, Nicholas Vlachopoulos, Bradley Forbes e.Large-scale laboratory investigation of pillar-support interaction Journal of Rock Mechanics and Geotechnical Engineering

Qian, M., Shi, P. & Xu, J. Mine Pressure and Strata Control[M] (China University of Mining and Technology Press, 2010).

Wang, S. R. et al. Mechanics evolution characteristics analysis of pressure-arch in fully-mechanized mining field[J]. J. Eng. Sci. Technol. Rev. 7(4), 40–45 (2014).

Guo, W. et al. Effect of overburden bending deformation and alluvium mechanical parameters on surface subsidence due to longwall mining[J]. Bull. Eng. Geol. Environ. 80, 2751–2764 (2021).

Qian, M., Miao, X. & XU, J. Theoretical study on key strata in rock control[J]. J. Coal Ind. 03, 2–7 (1996).

Zuo, J. et al. “Hyperbolic-like” theoretical model and verification of overall movement of mining rock strata-from two-dimensional “hyperbolic-like” to three-dimensional “hyperbolic-like” model[J]. J. Coal Ind. 49(04), 1731–1751 (2024).

Yu, B. et al. Theory and technical system of vertical and horizontal control of hard top plate wells in large space mining sites[J]. J. Coal Ind. 48(05), 1875–1893 (2023).

Guo, L., Hou, K., Sun, H. & Yang, Y. Stability evaluation of the goaf based on combination weighting and cloud model. Adv. Civil Eng. 2024(1), 3884586 (2024).

Wang, M. & Wan, W. A new empirical formula for evaluating uniaxial compressive strength using the Schmidt hammer test. Int. J. Rock Mech. Min. Sci. 123, 104094 (2019).

Wang, M., Zhenxing, Lu., Wan, W. & Zhao, Y. A calibration framework for the microparameters of the DEM model using the improved PSO algorithm. Adv. Powder Technol. 32, 358–369 (2021).

Wang, M., Wan, W. & Zhao, Y. Prediction of uniaxial compressive strength of rocks from simple index tests using random forest predictive model [J]. Comptes Rendus Mecanique 348(1), 3–32 (2020).

Wang, M., Wan, W. & Zhao, Y. L. Experimental study on crack propagation and coalescence of rock-like materials with two pre-existing fissures under biaxial compression. Bull. Eng. Geol. Environ. 79(6), 3121–3144 (2020).

Wang, M., Zhenxing, Lu., Zhao, Y. & Wan, W. Experimental and numerical study on peak strength, coalescence and failure of rock-like materials with two folded preexisting fissures[J]. Theor. Appl. Fract. Mech. 125, 103830 (2023).

Rong, H. et al. Structural instability motion law of hard overlying rock and its impact on impact ground pressure[J]. J. Min. Rock Control Eng. 4(06), 16–26 (2022).

Rong, H. et al. Insights into fundamental problems of rockburst under the modern structure stress field[J]. Sci. Rep. 12(1), 20299 (2022).

Rong, H. et al. Numerical simulation of blasting behavior of rock mass with cavity under high in-situ stress[J]. Sci. Rep. 14(1), 16046 (2024).

Rong, H. et al. Research on rockburst prevention systems based on the attenuation law of coal and rock vibration wave energy[J]. Sci. Rep. 14(1), 6452 (2024).

Chu, Z. Study on the Mechanism of Strong Mine Pressure and Roof Control in the Isolated Working Face of Shuiyu Coal Mine[D] (China University of Mining and Technology, 2021).

Pan, L. Study on the Attenuation Law of Rock Mass Vibration Energy and the Scale of Pre-splitting and Roof Cutting for Rockburst Mines[D] (Liaoning Technical University, 2023).

Wang, M., Zhenxing, Lu., Zhao, Y. & Wan, W. Peak strength, coalescence and failure processes of rock-like materials containing preexisting joints and circular holes under uniaxial compression: Experimental and numerical study. Theor. Appl. Fract. Mech. 125, 103898 (2023).

Wang, M., Zhenxing, Lu., Zhao, Y. & Wan, W. Calibrating microparameters of DEM models by using CEM, DE, EFO, MFO, SSO algorithms and the optimal hyperparameters. Comput. Part. Mech. 11, 839–852 (2024).

Wang, M. Discussion on “Study on mechanical and fracture characteristics of rock-like specimens with rough non-persistent joints by YADE DEM simulation”. Comput. Geotech. 167, 105966 (2024).

Wang, M., Zhenxing, L., Zhao, Y. & Wan, W. Numerical study on the strength and fracture of rock materials with multiple rough preexisting fissures under uniaxial compression using particle flow code. Comput. Part. Mech. https://doi.org/10.1007/s40571-024-00811-1 (2024).

Wang, M., Zhenxing, L., Zhao, Y. & Wan, W. A calibration framework for DEM models based on the stress-strain curve of uniaxial compressive tests by using the AEO algorithm and several calibration suggestions. Comput. Part. Mech. https://doi.org/10.1007/s40571-024-00820-0 (2024).

Yu, M. et al. Investigation on fracture models and ground pressure distribution of thick hard rock strata including weak interlayer[J]. Int. J. Min. Sci. Technol. 32(1), 137–153 (2022).

Yang, S., Wang, J. & Li, L. Deformation and fracture characteristics of key strata based on the medium thick plate theory[J]. J. Ch. Coal Soc. 45(8), 2718–2727 (2020).

Yunpeng, L. Study on the Instability Characteristics of Hard Rock Structure and Hydraulic Fracturing Control Technology[D] (Liaoning Technical University, 2019).

Jialin, X. U. & Minggao, Q. I. A. N. Method for determining the location of key strata in overburden strata[J]. J. Ch. Univ. Min. Technol. 05, 21–25 (2000).

Minggao, Q. I. A. N., Deren, Z. H. U. & Zuotang, W. A. N. G. Fracture patterns of the old roof strata and their effects on the pressure on the working face[J]. J. Ch. Univ. Min. Technol. 02, 12–21 (1986).

Hao, Z. et al. Numerical simulation and analysis of overburden movement patterns in protective layer mining based on UDEC[J]. Ch. Min. 07, 81–84 (2007).

Alshkane, Y. M., Marshall, A. M. & Stace, L. R. Prediction of strength and deformability of an interlocked blocky rock mass using UDEC[J]. J. Rock Mech. Geotech. Eng. 9(3), 531–542 (2017).

Zheng, Y. et al. Study on the mechanisms of flexural toppling failure in anti-inclined rock slopes using numerical and limit equilibrium models[J]. Eng. Geol. 237, 116–128 (2018).

Yu, B. et al. Engineering study on fracturing high-level hard rock strata by ground hydraulic action[J]. Tunnell. Undergr. Sp. Technol. 86, 156–164 (2019).

YU Bin, ZHU Weibing, GAO Rui, et al. The structure and mechanism of overburden strata in large-space mining areas of ultra-thick coal seams using fully mechanized top coal caving mining[J]. Journal of Coal Science and Technology (3) 2016

Rong, H. et al. Quantitative monitoring of underground fault activity and its impact on rockburst[J]. J. Coal Sci. Technol. 52(2), 10–22 (2024).

Dai, J. et al. Seismicity associated with hydraulic fracturing in Changning shale gas field, China: Constraints from source mechanisms, stress field and fluid overpressure thresholds. J. Rock Mech. Geotech. Eng. https://doi.org/10.1016/j.jrmge.2024.08.008 (2024).

Dai, J. et al. Regional characteristics of seismicity associated with hydraulic fracturing in the southern sichuan basin of China. Rock Mech. Rock Eng. https://doi.org/10.1007/s00603-024-03891-w (2024).

Stability Evaluation of the Goaf Based on Combination Weighting and Cloud Model Linning Guo, Kepeng Hou, Huafen Sun, Yong Yang.

Funding

This work was supported by the National Natural Science Foundation of China Project No. 51904145, Basic scientific research project (youth project) of Liaoning Provincial Department of Education in 2022 No. LJKQZ20222322, the 2024 Liaoning Province Special Program for Guiding Municipal Science and Technology Development - Liaoning Provincial Natural Science Foundation Joint Program, the Engineering Laboratory of Deep Mine Rockburst Disaster Assessment Open Project No. LMYK2020006, the Liaoning Natural Science Foundation Program Guidance Plan No. 2019-ZD-0045, and the Liaoning Provincial Department of Education Project No. LJ2019JL007.

Author information

Authors and Affiliations

Contributions

H.R. and Longyue He wrote the main manuscript text. Xiangzhi Wei, Suihan Yang and Linlin Chen were responsible for figure and table making and data analysis. Yadi Wang, Shilong Wei and Jincheng Li collect materials and summarize typesetting. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Declarations

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Rong, H., He, L., Wang, Y. et al. Overlying strata movement law and rockburst prevention & control for fully mechanized top coal caving face in extra-thick coal seams. Sci Rep 15, 4750 (2025). https://doi.org/10.1038/s41598-025-89133-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-89133-7