Abstract

We demonstrate a thulium (Tm)-doped fibre amplifier using a Ho: GdVO4 solid-state laser as the master oscillator operating at 2048.53 nm. In experiment, a novel spatial coupling system was used, combining a single lens with a curved end cap to simplify the structure and reduce losses. The integrated fibre end cap design effectively protected the fibre core from damage caused by high-energy short-pulse seed lasers. The power amplifier (PA) stage adopted backward pumping to directly achieve pure laser output. In continuous wave (CW) mode, a maximum laser output power of 33.4 W was obtained under a maximum pump power of 151 W injection at 18 °C. The slope efficiency of the amplification stage was 19.5%. The output laser wavelength was 2048.57 nm, and the full width at half maximum (FWHM) was 0.14 nm. In Q-switched mode, a maximum single pulse energy of 3.86 mJ was obtained at a pulse repetition frequency (PRF) of 5 kHz with a pulse width of 22.1 ns, corresponding to a peak power of 174.7 kW and an average output power of 19.3 W. No nonlinear optical effects, such as stimulated Raman scattering (SRS) or stimulated Brillouin scattering (SBS) was observed throughout the experiment, and the fibre amplifier output remained stable. Ultimately, the maximum single pulse energy obtained by a 2.05 μm backward-pumped Tm-doped fibre amplifier (TDFA) at a PRF of 5 kHz and a pulse width of 22.1 ns was 3.86 mJ.

Similar content being viewed by others

Introduction

Lasers in the 2 μm wave band have significant applications in various fields, including biomedicine, optical communications, remote sensing and the processing of nonmetallic materials1,2,3,4,5,6,7. For example, the absorption wave bands of human tissues lie between 1.94 and 2.05 μm8,9. Therefore, high energy TDFAs can be used as laser scalpels, which can rapidly coagulate blood, cause minimal damage to human tissues and effectively achieve hemostasis. High-power lasers at 1.95 μm are suitable as efficient pump sources for holmium (Ho)-doped lasers because they match well with the absorption peaks of holmium ions10,11. TDFAs also exhibit a wide range of molecular vibrational absorption resonances with many gases (e.g., water vapour and CO212) near the 2 μm wave band, making them ideal for use in coherent Doppler wind LiDAR and spectroscopy13,14,15,16,17,18. To date, the high gain region of Tm-doped fibres in the 1.9–2.0 μm wave band has been extensively studied, whereas relatively few studies have focused on longer wavelengths. Lasers in the 2050 nm wave band have a wide range of applications in the military and defense sectors. Among these, TDFAs operating in this wave band can be used to pump zinc germanium phosphide optical parametric oscillators (ZGP OPOs) to generate 3–5 μm infrared lasers19. This band laser is the radiation band of high-speed aircraft such as fighters. It has specificity and exclusiveness, so it is often used in the field of photoelectric countermeasures.

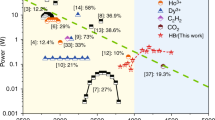

Many applications typically require TDFA with high energy and peak power. Currently, techniques capable of generating high-energy pulses in the 2 μm wave band include Q-switching, dissipative soliton resonance (DSR) mode locking and gain-switching. In 2010, Tang et al.20 used the gain-switched technique to achieve pulsed laser output from a two-stage Tm-doped fibre laser, employing a Tm: YLF solid-state laser. The laser linewidth was 25 nm, with a central wavelength of 2020 nm. At a PRF of 500 Hz, the output laser had a pulse width of 75.4 ns, a peak power of 138 kW, and a single-pulse energy of 10.4 mJ. As far as we know, this report presents the highest single-pulse energy output in the 2 μm band to date. However, this high-energy output was obtained under low PRF and large pulse width conditions. In 2015, Yang et al.21 demonstrated a nanosecond all-fibre MOPA with linearly polarized output at 2040 nm using a gain-switched Tm-doped fibre laser with in-band pumping as the seed source. After two-stage amplification, an average power of 70 W was achieved at a pulse repetition frequency of 10 kHz, with a pulse width of 114 ns, resulting in a pulse energy of 7 mJ and a peak power of 53.8 kW. Notably, the amplifier system designed by Yang et al. featured a relatively wide pulse width and lower peak power. In 2016, Dai et al.22 constructed a TDFA pumped by a Ho: GdVO4 solid-state laser via the Q-switching technique, producing a peak power of 56.8 kW and a single pulse energy of 0.66 mJ at a wavelength of 2048 nm with a PRF of 10 kHz. In 2019, Zheng et al.23 built an all-fibre 9-cavity mode-locked dual-cladding TDFA operating in DSR mode and obtained an average output power of 104.3 W with a pulse energy of 0.33 mJ. In 2022, Dominik Lorenz et al.24 demonstrated a polarization-maintaining (PM) fibre amplifier based on the gain-switching technique at a wavelength of 2047 nm. A single pulse energy output with a pulse width of 50 ns and an energy of 0.396 mJ was obtained at a PRF of 50 kHz. Compared with DSR mode locking, Q-switching can generate higher single pulse energy and peak power. Q-switching is used in a more flexible range, including solid-state lasers and fibre lasers, whereas DSR mode-locking technology is usually used in fibre lasers and can work in only a specific wavelength range with less wavelength flexibility and selectivity. Compared with Q-switching, gain-switching struggles to achieve large pulse outputs and is unsuitable for applications requiring high peak power and energy. Gain-switching produces pulses that are typically long, with pulse shapes that do not meet the expected requirements and require further tuning. In summary, to generate high single pulse energy, Q-switching is usually preferred. Currently, master oscillator power amplifier (MOPA) systems are commonly used for power scaling. The seed source in MOPA systems is based on acousto-optic Q-modulation (AO-Q) technology. This technology is widely applied in solid-state lasers but is less frequently reported in fibre lasers.

In this paper, we report a 2.05 μm Tm-doped fibre laser pulse amplification system based on a MOPA structure with a Ho: GdVO4 solid-state laser as the master oscillation stage. The MOPA system achieved an average output power of 19.3 W and a peak power of 174.7 kW at a PRF of 5 kHz at 2048.57 nm. The pulse width was 22.1 ns, and the single pulse energy was as high as 3.86 mJ. The FWHM was 0.14 nm.

Experimental

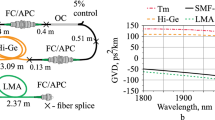

We designed a TDFA based on a spatially coupled MOPA structure, which consists of three parts: a master oscillator of AO-Q Ho: GdVO4, a spatial coupling system, and a power amplifier of a Tm-doped fibre. The structure of the master oscillation amplification system based on spatial coupling is schematically shown in Fig. 1 below.

AO-Q Ho: GdVO4 master oscillator

We used a self-made AO-Q Ho: GdVO4 solid-state laser25 as the main oscillator. In the experiments, we used a fully unpolarized fibre laser with a linewidth of 0.1 nm, an operating wavelength of 1940.25 nm, and a beam quality factor of M2 = 1.47 pumping26 for the Ho: GdVO4 crystal. The master oscillator output had a center wavelength of 2048.53 nm and a full width at half maximum (FWHM) of 0.2 nm. A maximum single pulse energy of 0.94 mJ, a minimum pulse width of 7.3 ns, a peak power of 129 kW and an average output power of 4.7 W were obtained at a PRF of 5 kHz. A beam quality factor of M2 = 1.01 was achieved at the maximum absorbed pump power.

The laser pulses output from the Ho: GdVO4 master oscillator were detected by a HgCdTe high-speed response photodiode and recorded by a 350 MHz digital oscilloscope. The pulse durations were 7.3, 10.9, 14.2 and 20.5 ns, and the PRFs were 5, 10, 15 and 20 kHz, respectively. The shapes of single pulses and pulse sequences at different PRFs are shown in Fig. 2. As the PRF increasing, the accumulated time of the inverse population turns shorter, causing a decrease in inverse population density. This results in an increase in pulse width.

Spatial coupling system

The spatial coupling system employed an integrated fibre end cap structure, as illustrated in Fig. 3. The curved surface of the end cap acts as a lens to simplify the spatial coupling system. In the experiment, the use of coupling lenses was minimized by fusing the end cap. The reverse use of the end caps allows the laser to enter the fibre core more uniformly, reducing localized excessive power densities due to uneven beams or spot variations. This not only protects the core, but also improves the overall performance of the fibre system. We used simulation to obtain the optimal position of the coupling lens L1 as well as the end cap to ensure that the laser can be coupled into the fibre smoothly and efficiently. The novel spatial coupling system consists of a single lens and a curved end cap. This system is essentially equivalent to “two-lens” (the single lens and the curved front surface of the end cap). To couple the seed laser into the fibre end cap, a “two-lens” system is required to collimating and converging laser. We adopt an integrated fibre-endcap design with curvature, which can replace one of the lenses. This design simplifies the system structure and reduces the difficulty of optical path alignment.

la represents the distance from the laser-emitting surface to the coupling lens L1, lb represents the distance from L1 to the end cap, and lc represents the length of the end cap, which is 16.9 mm. The refractive index of air is n1 = 1, the refractive index of the end cap is n2 = 1.437, and the refractive index of the passive fibre core is n3 = 1.44. The end cap has a convex curvature radius of R = 5.07 mm and a diameter of 6 mm. f represents the focal length of the coupling lens L1, which is 250 mm.

Through the calculation of the beam parameter product (BPP) condition, to couple the laser into the fibre core, the waist spot radius should meet 7.32 < ω0 < 7.81 μm, and the far-field divergence angle half-angle should meet 0.084 < θ < 0.09 rad.

We performed beam transformation via the Gaussian beam q-parameter ABCD matrix method on the basis of the measured beam waist radius and far-field divergence angle. Before the experiment, beam propagation was simulated, as shown in Fig. 4a.

Simulation of the beam radius distribution in the coupled system. (A represents the variation curve of the beam radius when the laser is transmitted from the exit surface of the laser to a distance of L1. B represents the curve of the beam radius as a function of the distance from L1 to the end cap surface. C represents the curve of the variation in the beam radius with the distance from the end cap surface to the fibre core. D shows a schematic diagram of the variation curve of the beam radius with the laser light entering the optical fibre).

As shown in Fig. 4a, a thin lens L1 with a focal length of 250 mm was inserted at a distance of 120 mm from the output end of the seed source, and the beam radius was 0.784 mm. The fused curved optical fibre end cap was placed 330 mm from the output end of the seed source, and the beam radius was 1.034 mm. As shown in Fig. 4b, after the laser was coupled into the end cap, the laser beam radius decreased rapidly. When it reached the fusion point between the optical fibre and the end cap, the laser beam radius became 7.421 μm. At this time, the high energy laser meets the coupling conditions.

In the optical fibre spatial coupling experiment, a laser four-sided etched cladding light stripper is fused to the pigtail of the optical fibre end cap, as shown in Fig. 5. The fibre end cap was fixed on a five-dimensional adjustment frame to couple the beam by adjusting its position and angle. The passive fibre (Nufern, Inc.) has a core size of 25 μm (NA = 0.09), an inner cladding diameter of 400 μm, a length of 2.4 m, and an output end cut at 8°.

In coupling tests, with continuous seed laser injection, a 4.1 W laser output was obtained at a maximum injection of 6.2 W, resulting in a coupling efficiency of 66.1%. When pulsed seed laser was injected, the average output power and coupling efficiency at different PRFs of 5, 10, 15, and 20 kHz and injection average powers are shown in Table 1. In the experiment, we used a five-dimension adjuster to adjust the coupling system multiple times, with the coupling efficiency remaining around 60%. The experiment showed no clear correlation between PRF and coupling efficiency.

In the experiment, the fibre core at the fusion splice point of the fibre end cap was broken at a PRF of 5 kHz when the seed power exceeded 2.8 W, the pulse width was 11 ns, and the energy of a single pulse was 0.56 mJ, corresponding to a peak power of 51 kW. The core fragmentation experiment revealed that the maximum peak power that the fibre end face can withstand was 51 kW and the single pulse energy was 0.56 mJ at a PRF of 5 kHz. In addition, the use of end caps, which is equivalent to the closure of the fibre end face, reduces the refractive index difference of the medium on both sides of the end face, however, the bare fibre end face can withstand the peak power, and the single pulse energy is even lower than this value.

The shape of the single pulse after seed laser coupling injection into the fibre was measured in the experiment via a HgCdTe high-speed response detector and recorded with a 350 MHz digital oscilloscope. The pulse width was found to be broadened but not significantly. The pulse durations were measured to be 11.7, 15.6, 18.6 and 22.6 ns at PRFs of 5, 10, 15 and 20 kHz, respectively. The single pulse shapes for different PRFs are shown in Fig. 6. Compared with the single pulse shape of the laser output from the oscillating stage in Fig. 2, the pulse widths are broadened, ranging from 2 to 5 ns. In multimode fibres, different modes propagate at different speeds. This causes mode dispersion. As a result, pulse broadening occurs. And the material dispersion of the fibre would also broaden the pulse. At the splice point between the passive fibre and the curved end cap, variations in the refractive index led to pulse broadening.

Tm-doped fibre power amplifier

The 2.05 μm seed laser passes through a spatial optical isolator into the end cap coupling system of the amplification stage. The pump source of the amplification stage consists of two laser diodes (LDs) with a wavelength of 790 nm (nLight, Inc.), each with a maximum output power of 75 W. The pump light is introduced into the gain medium via a (2 + 1)×1 fibre combiner. A 25/400/550 µm large mode field, double-clad, Tm-doped fibre (Nufern Inc.) with a length of 3.8 m and a pump absorption coefficient of 3.6 dB/m was selected as the gain fibre for the amplification stage. The laser amplification system adopts the backward pumping method, which eliminates the fibre stripper or dichroic mirror at the output end of the laser, making the amplification system simple and compact. Heat dissipation of the Tm-doped fibre is needed in the experiment. The Tm-doped fibre is surrounded by a copper heat sink U-shaped groove and coated with high-thermal-conductivity silicone grease for fixation and heat dissipation. The heat sink uses water circulation to dissipate heat, and the water temperature is controlled at approximately 15 °C. The minimum circumference diameter of the Tm-doped fibre is around 18 cm, and the fusion points on both sides are straightened and placed in the U-shaped groove of the heat sink. The minimum coiling diameter of the fibre was selected to be around 18 cm. This was based on the following reason: The smaller the coiling diameter, the more the leakage of higher order mode laser power in the fibre. When the minimum coiling diameter of the fibre was reduced to around 18 cm, higher order modes were effectively filtered out, and the energy loss during transmission was minimized. At the other end of the active fibre, we fuse and splice a passive fibre for laser output. In the experiment, a passive fibre is fused at the end of the Tm-doped fibre to export the laser. The 25/400/550 µm large mode field double-clad undoped fibre (Nufern Inc.) is selected as the passive fibre, and the output end is cut by 8° to eliminate the Fresnel reflection of the fibre end face.

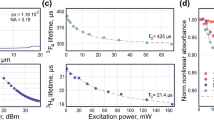

Firstly, we investigated the CW output performance of the TDFA. Experimentally, under a maximum CW seed power injection of 4.1 W, the relationship between the amplifier’s output laser and the pump laser is depicted in Fig. 7a. With a maximum pump power injection of 151 W, the amplifier’s output laser achieved a power of 33.4 W. The slope efficiency of the amplifier was 19.5%. Owing to the gain range of the Tm-doped fibre being from 1.6 to 2.1 μm and 2.05 μm being at the end of the gain curve, the slope efficiency of the amplifier was lower at 2.05 μm than at 1.9 μm. Using a Bristol 721B spectrum analyser with an infrared spectral resolution of 6 GHz, the output laser center wavelength of the fibre amplification stage was measured to be 2048.57 nm at the maximum pump power with an FWHM of 0.14 nm, as shown in Fig. 7b.

Secondly, we examined the output performance of the Q-switched mode in the TDFA. The amplified laser output was measured under the injection of pulsed seed laser at various repetition frequencies. At PRFs of 5, 10, 15 and 20 kHz, corresponding to seed laser average powers of 1.6, 3.2, 3.5 and 3.8 W, respectively, the relationship curves between the average output power of the amplified-stage pulse laser and the pump power were measured, as shown in Fig. 7c. Under the maximum 151 W pump injection, laser outputs of 19.3, 20.5, 21.8 and 23.4 W were obtained at PRFs of 5, 10, 15 and 20 kHz, respectively, with slope efficiencies of 12.2%, 12.3%, 12.6% and 13.4%, respectively. The slope efficiency of the pulsed laser was experimentally found to be lower than that of the continuous laser, as the pulsed laser generated a greater thermal effect during operation, reducing its slope efficiency. Additionally, as the PRF decreased, the pulse energy increased, resulting in a more significant thermal effect, which also led to a decrease in slope efficiency.

The Q-switched laser pulses were detected via a high-speed HgCdTe detector and recorded with a 350 MHz digital oscilloscope. At various PRFs, the output pulse sequences of the TDFA remained stable. The single pulse shape was symmetric, with consistent intensity and width. At repetition frequencies of 5, 10, 15 and 20 kHz, the pulse durations were 22.1 ns, 26.2 ns, 28.2 ns and 31.8 ns, respectively. The amplified single pulse shapes at various PRFs are shown in Fig. 8. The figure shows that as the PRF decreases, the pulse width increases. When the seed pulse passes through the Tm-doped fibre amplifier, the amplifier’s gains are limited. Gain saturation occurs at higher input pulse energies. The gain saturation effect causes the leading edge of the pulse to experience higher gain. The trailing edge suffers from reduced gain due to energy depletion. This results in pulse broadening.

The amplified single pulse shape (Fig. 8) has an average broadening of approximately 9.9 ns compared with the coupled single pulse shape (Fig. 6). The pulse broadening of the amplified output laser was around 10 ns at different PRFs, with no significant difference observed. The coupled single pulse shape (Fig. 6) shows an average broadening of approximately 3.9 ns compared with the seed laser single pulse shape (Fig. 2). These pulse broadenings are closely related to the fibre length. The fibre length attached to the fibre end cap was 2.4 m, with a broadening of approximately 1.63 ns per meter; the fibre length used in the amplification stage was 4.8 m, with a broadening of approximately 2 ns per meter. It is evident that the fibre length is the primary factor causing pulse broadening. In this experiment, the pulse broadening related to the fibre length was caused mainly by the dispersion of the fibre material. To minimize the pulse broadening of the output laser, the length of the fibre used in the amplification stage should be reduced as much as possible.

Through calculations, we determined the single pulse energy and peak power at various PRFs, as shown in Fig. 9. At a PRF of 5 kHz, the maximum single pulse energy was 3.86 mJ, and the peak power was 174.7 kW. At a PRF of 10 kHz, the maximum single pulse energy was 2.05 mJ, and the peak power was 78.2 kW. At a PRF of 15 kHz, the maximum single-pulse energy was 1.45 mJ, and the peak power was 51.5 kW. At a PRF of 20 kHz, the maximum single pulse energy was 1.16 mJ, and the peak power was 36.3 kW. The figure shows that as the PRF decreases, both the single pulse energy and peak power increase. At a lower PRF, the longer time intervals between pulses allow the laser’s gain medium to absorb and store more pump energy. This accumulation process enables each pulse to release more energy, resulting in higher peak power. However, as the PRF increases, the intervals between pulses shorten, leading to insufficient energy accumulation and, consequently, a decrease in single pulse energy and peak power.

No nonlinear optical effects, such as SRS or SBS, were observed throughout the experiment, and the fibre amplifier output remained stable. The polarization states of the continuous and pulsed laser outputs were measured at maximum output power via an attenuator and a Glan prism. The polarization (P) ranged from 0.2 to 0.3 for the continuous laser output from the amplification stage, and P ≤ 0.06 for the pulsed light. This indicates that the amplification stage output had been depolarized, particularly for pulsed light, which had been completely depolarized. Using nonpolarization-maintaining fibres to transmit and amplify polarized light makes the eventual depolarization of the laser predictable.

Conclusion

In summary, this paper reports a high peak power, high single pulse energy and stable MOPA system based on a Tm-doped fibre laser. In the CW mode, a 33.4 W laser output power with a slope efficiency of 19.5% was obtained at a maximum pump power of 151 W. The output wavelength was 2048.57 nm, corresponding to an FWHM of 0.14 nm. In the Q-switched mode, the pulse duration of the TDFA was measured at PRFs of 5, 10, 15 and 20 kHz, and the single pulse energy and peak power were calculated. Under a maximum pump power of 151 W, the maximum single pulse energy was 3.86 mJ at a PRF of 5 kHz, the shortest pulse duration was 22.1 ns, and the corresponding peak power was 174.7 kW. Ultimately, the maximum single pulse energy obtained by a 2.05 μm backward-pumped TDFA at a PRF of 5 kHz, and a pulse width of 22.1 ns is 3.86 mJ. The laser produced by the TDFA can be used for ZGP OPOs pumping to obtain 3–5 μm and 8–12 μm lasers.

Data availability

The datasets generated and analysed during the current study are available from the corresponding authors on reasonable request.

References

Moulton, P. F. et al. Tm-doped fiber lasers: fundamentals and power scaling. IEEE J. Sel. Top. Quant. Electron. 15(1), 85–92 (2009).

Sudesh, V. et al. Latest developments in high-power tunable CW narrow line thulium fiber laser for deployment to the ISTEF. Laser Technol. Defense Secur. V SPIE 7325, 64–71 (2009).

Richardson, D. J. et al. High power fiber lasers: current status and future perspectives. JOSA B 27(11), B63–B92 (2010).

Jackson, S. D. Towards high-power mid-infrared emission from a fibre laser. Nat. Photon. 6(7), 423–431 (2012).

Wang, X. et al. 102 W monolithic single frequency Tm-doped fiber MOPA. Opt. Exp. 21 (26), 32386–32392 (2013).

Shah, L. et al. Thulium fiber laser and application development. Laser Technol. Defence Secur. X SPIE 9081, 85–90 (2014).

Mingareev, I. et al. Principles and applications of trans-wafer processing using a 2 µm thulium fiber laser. Int. J. Adv. Manuf. Technol. 84, 2567–2578 (2016).

Alfano, R. R. et al. Mar. Method for picosecond and femtosecond laser tissue welding. U.S. Patent. No. 8,974,444 (2015).

Fried, N. M. et al. High-power thulium fiber laser ablation of urinary tissues at 1.94 µm. J. Endourol. 19(1), 25–31 (2005).

Yang, C. et al. Passively Q-switched Ho: YLF laser pumped by Tm3+-doped fiber laser. Opt. Laser Technol. 77, 55–58 (2016).

Hemming, A. et al. High power operation of cladding pumped holmium-doped silica fibre lasers. Opt. Exp. 21(4), 4560–4566 (2013).

Pal, A. et al. All-fiber tunable laser in the 2 µm region, designed for CO2 detection. Appl. Opt. 51(29), 7011–7015 (2012).

Henderson, S. W. et al. Eye-safe coherent laser radar system at 2.1 µm using tm, Ho: YAG lasers. Opt. Lett. 16(10), 773–775 (1991).

Henderson, S. W. et al. Coherent laser radar at 2 µm using solid-state lasers. IEEE Trans. Geosci. Remote Sens. 31(1), 4–15 (1993).

Gibert, F. et al. 2-µm high-power multiple-frequency single-mode Q-switched Ho: YLF laser for DIAL application. Appl. Phys. B Opt. 116(4), 967–976 (2014).

Yang, C. et al. 140 W high power all-fiber laser at 1940 nm with narrow spectral line-width by MOPA configuration. Appl. Phys. B Opt. 122, 1–5 (2016).

Liu, Y. et al. Advances in multipass cell for absorption spectroscopy-based trace gas sensing technology. Chin. Opt. Lett. 21(3), 033001 (2023).

Qiao, S. et al. Super tiny quartz-tuning-fork-based light-induced thermoelastic spectroscopy sensing. Opt. Lett. 48(2), 419–422 (2023).

Liu, G. et al. 161 W middle infrared ZnGeP2 MOPA system pumped by 300 W-class Ho: YAG MOPA system. Opt. Lett. 46(1), 82–85 (2020).

Yulong, T. et al. High-power gain-switched Tm3+-doped fiber laser. Opt. exp. 18(22), 22964–22972 (2010).

Yang, J. et al. High-power highly linear-polarized nanosecond all-fiber MOPA at 2040 nm. IEEE Photon. Tech. L. 27(9), 986–989 (2015).

Dai, T. Y. et al. Amplification of a Q-Switched Ho: GdVO4 oscillator in Thulium-Doped large-Mode-Area Fiber. J. Russ. Laser Res. 37, 401–406 (2016).

Zheng, Z. et al. 0.33 mJ, 104.3 W dissipative soliton resonance based on a figure-of-9 double-clad Tm-doped oscillator and an all-fiber MOPA system. Photon. Res. 7(5), 513–517 (2019).

Lorenz, D. et al. Three-stage MOPA 2 µm fiber laser for ZGP OPO pumping. Nonlinear Freq. Gener. Conversi. Mater. Dev. XXI SPIE 11985, 106–111 (2022).

Yang, C. et al. A good beam quality Ho: GdVO4 laser pumped by thulium-doped fiber laser at 1940 nm. Microw. Opt. Technol. Lett. 66(1), e33900 (2024).

Yang, C. et al. High-efficiency continuous-wave Tm-doped fiber laser with a single fiber Bragg grating at 1942 nm. Laser Phys. 33(12), 125104 (2023).

Acknowledgements

Jilin Provincial Natural Science Foundation (NO. 20220101359JC); Science and Technology Research Project of Jilin Provincial Department of Education (No. JJKH20210818KJ); National Natural Science Foundation of China (No. 62075018); the 111 Project of China (D17017).

Author information

Authors and Affiliations

Contributions

Bowen Z, Xin L and Junyu H tested the lasers. Chao Y and Bowen Z designed the laser. Bowen Z, Yongliang L, Keyan D and Youlun J were responsible for fabrication of the laser. Bowen Z wrote the main manuscript text with Chao Y and Xin L. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yang, C., Zheng, B., Huang, J. et al. 2.05 μm high-energy thulium-doped fibre amplifier based on backward pumping. Sci Rep 15, 5664 (2025). https://doi.org/10.1038/s41598-025-89987-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-89987-x