Abstract

Sponges are benthic filter-feeder invertebrates capable to produce a variety of high value bioactive compounds. Nevertheless, exploitation of sponges as bio-factories requires scalable and sustainable strategies to supply sponge biomass without threatening wild natural populations and to minimize the consumption of toxic organic solvents in metabolites extraction and purification procedures. Sponges farming in integrated facilities nearby fish mariculture cages represents a highly efficient strategy combining the production of sponge biomass with bioremediation. Here we report the results of the in situ rearing of the keratose sponge Sarcotragus spinosulus developed within three years in an innovative Integrated Multi-Trophic Aquaculture system in the Gulf of Taranto (Southern Italy, Mediterranean Sea), capable to supply large-scale sponge biomass with a minimal impact on wild populations. Moreover, we demonstrate the proof of concept that it is possible to produce polyprenyl hydroquinones, selected as well-known bioactive model metabolites, in good yields, high purity degree and low organic solvent consumption, by means of an innovative protocol based on the combination of supercritical carbon dioxide fluid extraction and gel permeation chromatography. Such a combination of eco-friendly techniques paves the way to eco-sustainable supply of bioactive compounds from marine organisms highly profitable in terms of working times, costs, solvents, and energy saving.

Similar content being viewed by others

Introduction

Marine organisms including micro- and macroalgae, corals, ascidians, and sponges make up a significant oceanic living biomass, and are valuable source of bioactive compounds with potential uses in pharmacology, nutraceuticals and energy conversion, among others1,2,3,4,5,6. Research on marine-derived products and eco-sustainable extraction methods is crucial for develop new marine-related economic activities and driving to innovation in Blue Economy. Up to date an extremely high number of bioactive molecules (e.g. antioxidant, anti-inflammatory, antitumor, immunosuppressive, antiviral) has been discovered, with marine sponges being the most extensively studied group7,8.

Porifera, or sponges, benthic invertebrates distributed worldwide mainly in marine ecosystems9, host a complex microbial community10,11,12,13 that produces bioactive secondary metabolites that help protect themselves from predators, infections, and biofouling14. While various methods are being explored to extract these compounds from sponge biomass and seawater15, the main challenge involves obtaining sufficient biomass and then develop eco-friendly compounds recovery protocols, especially when metabolite concentrations are low16,17. For this aim, the overexploitation of natural sponge populations is unconceivable and ethically inappropriate18,19,20,21,22,23. To address this challenge, in situ aquaculture of sponges has emerged as the best strategy for biomass production24,25,26 which exploit the natural ability of sponges to regenerate and survive after fragmentation27,28,29.

Since Porifera are efficient filter-feeders capable to adapt their diet according to available food30,31 and to retain up to 98% of suspended microparticles in seawater (i.e. bacteria, phyto or zooplankton, viruses, and organic particulate)32,33,34, they are proven to be excellent bioremediators of anthropized marine areas such as confined costal area whith mariculture pressure24,35. The combination of sponges’ in situ rearing, particularly in Integrated Multi-Trophic Aquaculture (IMTA) systems, with their bioremediation properties, may lead to an extremely virtuous production model that would not threaten or overexploit natural populations of sponges17,19,21,23,24.

This study presents an efficient three-year model for sponge biomass production using an Integrated Multi-Trophic Aquaculture (IMTA) system in the Gulf of Taranto, Italy. It was tested with the naturally spread horny sponge Sarcotragus spinosulus Schmidt, 1862 (class Demospongiae, order Dictyoceratida, family Irciniidae)35, a species with rearing feasibility29, microbial bioremediation capabilities36 and a source of polyprenyl hydroquinones, known for antibacterial, anti-inflammatory, and antioxidant properties37,38,39,40,41. These bioactive compounds, characterized by their hydrophobic nature due to long alkyl chains and insolubility in seawater, are typically extracted through complex and time-consuming methods that rely on toxic solvents like methanol and chloroform, as well as advanced chromatography techniques37,38,39,40,41,42.

In this context, Supercritical Carbon Dioxide (sCO2), Supercritical Fluid Extraction (SFE), and Gel Permeation Chromatography (GPC) are promising but underexplored extraction or purification techniques. SFE, often used in food processing43,44,45,46 and green extractions from algae and waste water47,48,49,50, preserves sensitive molecules by operating at lower temperatures. While not yet applied to marine sponges, sCO2's non-polar properties can be modified with co-solvents for extracting compounds like flavonoids or alkaloids51,52,53,54. Additionally, it leaves no solvent residue and offers environmental benefits by recycling CO2. On the other hand, GPC, more efficient than silica gel chromatography and with an equipment less cost-effective than the HPLC, purifies large quantities of high molecular weight compounds using fewer solvents, such as lipids, proteins or even pollutants55.

To date, to the best of our knowledge, there is only one study in which GPC has been applied to sponge extracts, specifically for isolating the alkaloid isobromotopsentin from a species of the genus Spongosorites, though the process involved long procedures and high solvent use56.

In this study we report the rearing outcomes of the keratose sponge S. spinosulus within an innovative IMTA plant and the efficiency of combining supercritical carbon dioxide fluid extraction with GPC to isolate polyprenyl hydroquinones from the obtained biomass, exploring the process effectiveness in terms of sustainability, organic solvents consumption, scalability and working times with respect to the classical procedures reported in literature for the isolation of the same compounds.

Materials and methods

Sponge mariculture

The sponge rearing was performed in the REMEDIA Life IMTA system29 located in the “Maricoltura Mar Grande” (MMG) aquaculture plant on the southwestern side of the Mar Grande of Taranto (40°25′56″ N; 17°14′19″ E) (Mediterranean Sea) (Fig. 1A).

(A) Map of the sponge mariculture site located in the REMEDIA Life Integrated MultiTrophic Aquaculture (IMTA) system at Maricoltura Mar Grande fish farm (generated by Google Earth: https://www.google.it/earth/); (B) Plant scheme showing the three long lines positioned around the fish cages containing the bioremediator organisms; (C) A photograph of the external long line (Photo by Miki Trani); (D) scheme showing the bioremediators positioned in the IMTA plant; (E) A specimen of the Keratose sponge Sarcotragus spinosulus reared in the IMTA plant (Photo by Caterina Longo).

The aquaculture plant consists of six fish cages (Ø 22 m), placed at 7–12 m depth, producing European seabass Dicentrarchus labrax (Linnaeus, 1758) and sea bream Sparus aurata, Linnaeus, 1758, to which three Long Lines (LLA, LLB, LLC) with bioremediators (sponges, polychaetes, macroalgae and mussels) were associated (Fig. 1B). Fishes were not handled or used in the present study. Long lines for the bioremediators rearing were supported by buoys to avoid the sinking of the structure due to the biomass growth (Fig. 1C). The sponge rearing modules consisted in a 7 m long tubular net like that used for mussels rearing, connected to the horizontal ropes, in which sponge explants were inserted at ~ 40 cm intervals, each counting a total of 12–15 explants (Fig. 1D).

Different demosponge species among those relatively common on the artificial and natural hard substrates of the area were selected, including the horny sponge Sarcotragus spinosulus Schmidt, 186235 (Fig. 1E). The donor sponges were collected by scuba divers near the MMG plant in accordance with the technique described by Corriero et al.27, from artificial substrates, such as iron poles and concrete boulders, avoiding the picking up on natural hard substrates. After collection, donor sponge specimens were cut into fragments of uniform volume (100 ± 10 mL) and inserted in the sponge rearing modules.

The donor specimen’s collection from the natural population was carried out in October 2018 at the start of the sponge rearing experimentation and it comprised three rearing cycles. The first sponge rearing cycle lasted three years from January 2019 to December 2021, the second cycle two years from January 2020 to December 2021, and the third cycle one year, from January to December 2021.

At the end of each year, sponge explants were divided in three quotes, the first one used for laboratory chemical experiments, the second one cut into fragments of uniform volume (~ 100 mL) and re-seeded for subsequent cycles, the last one kept in the farm as it was.

Overall, 172 modules (72 modules in the LLA, 56 in the LLB, 44 in the LLC) containing a total number of 2000 explants of sponges were positioned. With exception for the first Italian COVID 19 lockdown period (March–May 2020), modules were monthly monitored since January 2019 to December 2021, by checking health and growth of 30 randomly selected S. spinosulus explants. The explants well-being was assessed by visual observation of cutting surfaces. In the case of completely restored surfaces and absence of stress factors (presence of areas with bacterial microfilm or exposed skeletal tissue) the sponge fragments were considered in good condition, while those with evident signs of stress were considered damaged.

To avoid sponges’ suffocation due to fouling recruitment, modules were regularly cleaned since April 2019, operating in immersion to prevent sponge stress.

The percentage survival rate (S) was evaluated as the ratio between the number of living explants recorded each month (Nt) and the number of explants at the beginning of the experiment (N0).

Differences in survival rates were tested by analysis of variance (ANOVA) using PRIMER software.

For the evaluation of sponge growth, a nondestructive and un-stressful technique was adopted to estimate sponge volume. Each sponge explant was measured using the water displacement method, immersing it in a graduate beaker filled with sea water. This method allows the fragments to be kept out of the water for only a few seconds, thus limiting their stress. The growth assessment was performed evaluating the Specific Growth Rate (SGR) of sponge fragments as it follows:

where loge are the natural logarithms, Vt2 and Vt1 the average volume at the two different times, and (t2 − t1) the time interval in days.

Bioactive compounds recovery

Sponge laboratory analysis

Sarcotragus spinosulus explant samples collected for laboratory were firstly washed with distilled water, then cleaned from epi and endobionts and frozen for 24 h at − 20 °C. Then, sponges were freeze-dried for 72 h in a Scanvac Cool Safe lyophilizer (Labogene), at 0.5 torr, until reaching a constant weight ~ 75% lower than that of pristine samples. After manually crumbling into small pieces, dried sponges were reduced to a fine powder by an electric mixer, to increase the sample surface area and enhance the efficiency of extraction with supercritical fluid57.

Chemicals

Carbon dioxide (Supercritical Fluid Chromatography grade) was supplied by Rivoira (Milan, Italy). All solvents used for isolation and characterization of organic extracts were purchased from Sigma Aldrich. Anhydrous absolute ethanol was used as the CO2 polarity-modifier. The calibration mix for GPC, including corn oil (50 mg/mL), methoxychlor (2.000 mg/L), bis-2-ethylhexyl ester phthalic acid (10.000 mg/L), perylene (200 mg/L) and sulfur (800 mg/L) was supplied by Dr. Ehrenstorfer GmbH (Germany).

Supercritical fluid extraction

SFE was carried out in a Spe-ed SFE apparatus (Applied Separations, Allentown, USA) (see Figure S1, Supplementary Information). The freeze-dried sponge sample (84 g) mixed to Ottawa dispersing sand (105 g) was loaded into the extractor vessel (500 mL) and four extraction cycles were carried out. The first cycle was performed without co-solvent in a sequence of 3 min static time (i.e. s-CO2 is pumped inside the cell and kept in contact with the sample for 3 min) and 15 min dynamic time (i.e. s-CO2 flows through the cell in the presence of the sample), working at 250 bar pressure, 3 LPM CO2 flow (where 1 Liter Per Minute of expanded CO2 is equivalent to 2 mL of liquid CO2), 60 °C vessel temperature and 70°C temperature of the micrometric valve, that is 10°C higher than that of the oven to avoid possible obstructions. The second extraction cycle was performed using the same conditions, with the sole difference that ethanol was used as the co-solvent at 2 mL/min flow rate. The third and fourth steps were co-solvent assisted using 10 min static time. In all co-solvent assisted steps, the extraction in dynamic mode was performed at 2 mL/min EtOH flow rate, reaching 33% polarity modification. After the extraction, ethanol was removed by a Rotavapor R-100 (Büchi) at 200 mbar, 35 °C and 100 rpm, thus yielding a total ~ 5.6% (w/w) raw extract (4.513 g) from the large-scale system (500 mL vessel).

Gel permeation chromatography

The GPC set-up was purchased from Knauer, Berlin (see Figure S2, Supplementary Information). It consists in a manual injection valve (six ports-two positions), 15 sample loops controlled by two valves with 16 port multi-position, a pump head for normal phase, a 16 port multi-position valve for the collection with the 16th port devoted to waste. A fixed single wavelength (λ = 254 nm) UV detector was used to monitor the elution of separated substances. A glass column (450 mm length and 10 mm internal diameter) was packed with a styrene–divinylbenzene copolymer (10 g) commercially known as SX-3 Bio-Beads (3% cross linkage, 40–80 µm bead size, molecular weight exclusion limit ≤ 1000 Da). A mixture of cyclohexane/ethyl acetate (50/50, v/v) was used at 1 mL/min flow rate as the mobile phase, at low-pressure mode chromatography. Before experiments on sponge extracts, GPC calibration was carried out recording elution times of a standard solution (see Figure S3, Supplementary Information). Since elution rate depends on effective molecular dimension in solution, assuming all molecules like simple spheres, each GPC collection window defines a molecular mass range based on molecular masses of compounds in the standard, i.e. corn oil (900 Da), bis-2-ethylhexyl ester phthalic acid (400 Da), methoxychlor (345 Da), perylene (250 Da), and sulphur (256 Da).

GPC purification was not performed on overall SFE extract (4.513 g) since the first fraction (~ 89%, 4.039 g) extracted by the sole sCO2 apolar solvent was discarded. Only the fractions (~ 11%, 0.474 g) collected in the subsequent three extraction cycles with polar sCO2 and ethanol mixture were subjected to GPC, these being the most suitable to recover polar bioactive polyprenyl hydroquinone molecules. A 100 mg/mL solution of the raw extract (from the 2nd, 3rd, and 4th cycles) in cyclohexane/ethyl acetate mixture (120 mg in 1.2 mL) was loaded inside the loop of the GPC system (1 mL) for chromatography. The mixture of cyclohexane/ethyl acetate (1:1 vol) was used as the solvent working with 1 ml min−1 flow. Six aliquots were recovered at the following time intervals: (i) 0–6.8 min, (ii) 6.8–12.6 min, (iii) 12.6–18.0 min, (iv) 18.0–27.0 min, (v) 27.0–35.0 min, (vi) 35.0–53.0 min. The first GPC fraction provided by-products with molecular weight higher than 900 Da and it was discarded. The other fractions were then evaporated by rotavapor at 240 mbar, 35°C and 100 rpm yielding the following amounts, respectively: (ii) 22 mg at 6.8–12.6 min, (iii) 25 mg at 12.6–18.0 min, (iv) 49 mg at 18.0–27.0 min, (v) 2 mg at 27.0–35.0 min and (vi) 7 mg at 35.0–53.0 min.

NMR and ESI–MS spectroscopic characterization

1H, 13C and 2D NMR spectra were recorded at 500 and 125 MHz, respectively, using an Agilent Technologies 500/54 Premium Shielded spectrometer. Samples were locked to the deuterated solvent and chemical shifts (δ) were recorded in ppm with CDCl3 using the residual solvent peak as the internal reference (δH 7.26 ppm and δC 77.0 ppm). All NMR spectra were processed using MestReNova software (version 14.1.1) automatically correcting phases and baselines. High resolution mass spectrometry was carried out by a Shimadzu high performance liquid chromatography-ion trap-time of flight mass spectrometer (HPLC–ESI–MS–IT–TOF).

The flow rate of the methanol mobile phase was 0.3 mL/min. The autosampler thermostat temperature was fixed at 15.0 °C to maintain the stability of the sample and the injection volume was determined as 1.0 mL. Analysis conditions were set as it follows: 1.5 L/min nebulizing gas flow, 3.5 kV high voltage probe, 200 kPa drying gas pressure, 260 °C heat block temperature, and 240 °C desolvation line (CDL) temperature. The detector voltage of the TOF was set to 1.6 kV. The IT–TOF system was calibrated with sodium trifluoroacetate solution.

LCA analysis

Given that the extraction and purification of bioactive compounds from sponges are among the most environmentally impactful phases, whether starting from sponge biomasses obtained in situ or through ex situ methods58,59, a standardized Life Cycle Assessment (LCA) analysis was conducted exclusively on the protocol outlined in this study i.e. the use of supercritical carbon dioxide fluid for the extraction and the gel permeation chromatography for the purification.

The environmental assessment of the extraction and purification of polyprenyl hydroquinones from S. spinosulus in-situ reared, involved the classification and characterization stages of the LCA methodology (ISO 14040, 2006). The characterization factors utilized were based on the method outlined by the Centre of Environmental Science at Leiden University (CML, 2001 method), as detailed by Guinee et al.60 Specifically, the CML impact categories were chosen to facilitate direct comparisons with a previous LCA study on the same subject conducted by Perez-Lopez et al.59 which employed the traditional solvent extraction method (see Supplementary Information). The impact potentials considered, in accordance with the CML method, encompassed: Abiotic Depletion (AD), Abiotic Depletion fossil fuels (ADF), Global Warming (GWP), Ozone layer Depletion (ODP), Human Toxicity (HT), Freshwater aquatic Ecotoxicity (FEP), Marine aquatic Ecotoxicity (MEP), Terrestrial Ecotoxicity (TEP), Photochemical Oxidants Formation (POFP), Acidification (AP), and eutrophication (EP). The computational implementation of the inventories was carried out using SimaPro version 9.1.1.7 software.

Results and discussion

Sponge mariculture

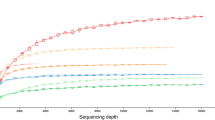

Sarcotragus spinosulus explants seeded in the IMTA plant and reared across three cycles showed noteworthy rearing performances, with high survival rates and increases in biomass. In the first rearing cycle, which lasted three years (2019–2021), the mean annual survival rate (mean ± SD) ranged from 82.9 ± 2.7% in 2019 to 93.9 ± 3.1% in 2021 (Fig. 2). The lowest value was registered in the first months of 2019 (51.4% in March), then it increased drastically from April onwards, up to values close to 100% by the end of the three rearing years. The critical phase registered at the beginning of the first rearing year could be linked to three main factors: manipulation (collection, cutting, and seeding), cutting surface healing and fouling recovery. While manipulation and surface healing are perceivable only in the first year of rearing, the settlement of fouling organisms affected the rearing modules during the entire period. In late spring 2019, sponges were found covered by recruits of Mytilus galloprovincialis Lamarck, 1819, Sabella spallanzanii (Gmelin, 1791) and other fouling organisms (e.g. colonial and solitary ascidians, mollusks, cnidarians, bryozoans and poriferans). Thus, since April 2019, when the first mucilage and fouling recruitment appeared, cleaning operations were carried out monthly until December 2021 to avoid explants suffocation.

A similar trend of growth and fouling settlement was observed in the second and third rearing cycles, confirming the critical early rearing phases and the necessity for periodic cleaning.

Analysis of variance showed significant differences in survival rate across the three years of the first rearing cycle (F = 16.44, p < 0.01). Tukey’s pairwise test showed a significant difference between 2019 and 2020 and between 2019 and 2021, with a significant reduction in mortality over time in the first rearing cycle. These significant differences were also highlighted in the second rearing cycle (ANOVA test, F = 11.26, p < 0.01).

As regards the estimation of sponge growth in the farm, initial biomass loss was observed in all cycles. However, despite the initial volume loss and stress induced by collecting and cutting sponges into uniform explants, growth mainly occurred in the first year of all rearing cycles (Fig. 3). Indeed, in the first year (2019) of the first cycle, the mean volume of explants showed a continuous positive trend, increasing from 100.0 ± 10.0 mL to 241.2 ± 11.8 ml (Fig. 3A) and remaining almost constant in the second (208.0 ± 8.1 in 2020) and third (211.3 ± 11.8 mL, 2021) rearing years, respectively. Similarly, the highest Specific Growth Rate (SGR) was recorded in the first year ranging from 5.1 to 9.6%. This rate declined in the subsequent years, with the highest monthly SGRs of 5.2% and 2.6% in 2020 and 2021, respectively (Fig. 3B).

A similar growth trend was observed in the second and third rearing cycles with sponge explants doubling in volume during the first year reaching 210.0 ± 11.3 and 209.2 ± 16.5 mL, respectively. Even in the second rearing cycle, at the end of the second rearing year, explants remained almost unchanged reaching 235.0 ± 20.6 mL of mean volume. Again, the highest SGRs for the second and third rearing cycles occurred during the first rearing year, with values of 7.5% in July 2020 and 14.9% in February 2021, respectively (Fig. 3B,C). These fluctuations in volume can be attributed to several factors such as natural physiological variation among monitored sponge explants, which is typical in both cultivated and wild populations.

The in situ rearing of S. spinosulus in the IMTA system allowed the development of an eco-friendly, straightforward, and valuable practice to obtain sponge biomass. Donor sponges were collected only at the beginning of the first rearing cycle, and subsequent cycles relied on reared explants, ensuring no further impact on wild populations.

S. spinosulus explants reared on vertical tubular net doubled their initial volume within the first 12 months, with mortality never exceeding 8%, which is considered acceptable in a rearing system. The first year of all three rearing cycles showed the best sponge growth, indicating the effectiveness of the rearing method, whether sponges were collected from the wild or from farmed explants. These results indicate that explants should not be kept in the farm for more than 12 months due to the considerable effort needed for fouling maintenance. Reseeding a portion of the explants annually ensures a continuos biomass production.

To the best of our knowledge no other studies have documented the in situ rearing performance of this species, except for our previous studies made in the same IMTA system29 and a Life Cycle Assessment (LCA) investigation of in situ Mediterranean mariculture structures for bioactive compounds production without detailed data on rearing performances59.

One of the main obstacles in exploiting bioactive compounds from marine species, particularly sponges, is the availability of large-scale systems for constant biomass supply61.

The rearing technique used for S. spinosulus involving vertical modules in the water column suspended by ropes (named long-lines) and supported by floating buoys, similar to traditional mussel farming method in Taranto seas62, proved successful. This approach reduces the need for underwater operators and lowers both economic and environmental costs. It should be emphasized that sponge rearing practices, like all aquacuture practices carried out in the natural environment, require constant maintenance to manage fouling organisms that inevitably settle on submerged structures, including sponge explants. Regular monitoring of explants well-being is also essential to evaluate the performance of the sponge rearing system. This type of rearing system can be efficiently managed by specialized personnel using small boats, which helps keep costs low while ensuring consistent sponge biomass production.

However, the production of potentially exploitable biomass is only one of the aspects linked to integrated aquaculture. A further relevant aspect is related to the possibility of restoring the water embody, allowing filter feeders such as porifera, to grow using aquaculture waste.

Coastal fish farming plants can have considerable environmental impact due to the release of organic wastes from farmed organisms and feed residues, causing an overall increase in organic matter, nutrients and harmful particles (e.g. bacteria, viruses, and also fecal pellets) including potentially pathogenic or antibiotic resistant bacterial load in sea water63,64. In this sense IMTA, combining the cultivation of fed aquaculture species with other organisms able to uptake organic and/or inorganic substances from sea water, offers an eco-friendly alternative to monoculture. IMTAs allow water quality improvement, promising high-quality ecosystem services, high economic return and social suitability also implying an improvement in human welfare. The bioremediators combination tested in the IMTA system, such as sponges, polychaetes, macroalgae and mussels, although needing different methodological approaches, represents a promising tool for ease species cultivation, high efficiency of the filtering system and diversification of valuable by-products29.

Although in situ sponge aquaculture has been recognized for a long time, its potential in IMTA systems remains largely underexploited24,26,65,66. Few sponge species have been tested for their rearing suitability, performance, production of bioactive compounds, or bioremediation capabilities in such systems21,67,68,69,70,71,72,73. In the Mediterranean, Geodia cydonium (Linnaeus, 1767) nearly doubled its weight in six months73, while Dysidea avara (Schmidt, 1862) doubled its size in four months69, and Chondrosia reniformis Nardo, 1847 achieved a 170% growth rate in twelve months67. Over two years, the “bath sponges”, Spongia officinalis (Linnaeus, 1759) and Hippospongia communis (Lamarck, 1814), increased their volume by 100–200%74. In the southwestern Pacific Ocean, Mycale hentscheli (Bergquist & Fromont, 1988) exhibited impressive growth, exceeding 2000% per year when co-cultured near a mussel farm75. The rearing performance of S. spinosulus in this study was more comparable to that of the “bath sponges” than to D. avara, despite all being classified as “horny sponges” with similar skeletal feature.

Bioactive compounds recovery

s-CO2 SFE extraction

The freeze-dried sponge powder samples were subjected to a series of SFE experiments, with the aim to optimize extraction conditions and performances. The experiments were made on a sample of dried sponges (9 g) loaded with Ottawa sand (10 g) in a small scale SFE vessel (25 mL). Table S1a (Supplementary Information) shows the experimental conditions used in each extraction cycle, including the expanded CO2 pressure, the oven temperature, the fluid flow rates, the static and dynamic time intervals, as well as the recovery yield in terms of weighting percentage of the raw extract. Such conditions were selected according to our previous work on the SFE extraction of polyphenols from wastes of wine production45, considering the expected similarity of polarity of these molecules with that of polyprenyl hydroquinones in sponge extracts. Each cycle was carried out in sequence, i.e. using the solid residue of the previous extraction cycle.

The use of sole sCO2 was investigated as the first experiment, although apolar CO2 is not suitable for an efficient extraction of compounds bearing hydrophilic polar groups such as polyprenyl hydroquinones76,77. As expected, the 1H NMR spectrum evidenced that the sole s-CO2 solvent, as well as hexane78, yielded a crude extract (about 0.5 g) mainly composed of a mixture of long chain fatty acids (~ 5.6% w/w) as confirmed by the presence of intense signals at δ 1.27 ppm typical of methylene protons of long fatty alkyl chains and in the range 0.8–0.9 ppm for terminal methyl groups (see Figure S4, Supplementary Information). However, the removal of fatty acids from extracts was anyway useful to streamline the matrix and allow easier isolation of bioactive molecules of interest. The addition of a co-solvent, such as ethanol, was envisaged to greatly improve the extraction efficiency of the target compounds.

Indeed, a second extraction cycle with ethanol co-solvent (2 mL/min) on the solid residue of the first extraction provided 0.044% of further extract and, extending the static time from 3 to 10 min, an improved 0.47% yield was achieved in the third cycle (see Table S1a, Supplementary Information), most likely as an effect of more prolonged time of contact between the supercritical fluid and the lyophilized sample powder79. A static time of 10 min was selected because longer period in a parallel experiment (data not shown) did not lead to further yield improvement.

Therefore, a fourth extraction cycle was repeated, using 10 min static and 15 min dynamic times for the same sample residue in the cell, yielding 0.083% of extract (see Table S1a, Supplementary Information). A fifth cycle eventually led to a negligible contribution to the extraction (< 0.001%). The estimated overall yield, considering the fractions from the 2nd, 3rd and 4th cycles of ethanol assisted s-CO2 SFE was therefore almost equal to 0.60%, this being a valuable result with respect to more conventional extraction procedures reported in the literature that suffer from the demand of significant amounts of organic solvents38. The percentage of ethanol was also increased during the dynamic period but, as shown in Table S1a (Supplementary Information) for the 6th cycle, it did not lead to a significant increase in yield.

Moreover, as reported in the literature, the co-solvent amount typically used for polar modification is 10–30% versus the volume of supercritical carbon dioxide43,46 and the use of higher amount of modifier would mean too high solvent consumption and, consequently, energy and work for the subsequent preparative steps.

After the optimization of SFE parameters, the extraction was scaled up loading 84.15 g of lyophilized sponge in a laboratory large scale cell vessel (500 mL), applying the same protocol defined at small scale. By this experiment, an overall 0.56% yield (474 mg of extract) was obtained for the extracts collected in the three subsequent co-solvent assisted extraction cycles performed on the residue of the first s-CO2 based extraction (Table S1b, Supplementary Information). The 1H-NMR analysis of the crude extract obtained with ethanol as co-solvent showed typical prenyl hydroquinone signals at δ 6.57–6.68 ppm (see Figure S5, Supplementary Information) and it was therefore subjected to further purification.

GPC purification

Considering the polarity of EtOH/s-CO2 mixture, the extract (474 mg) was expected to be rich of polar compounds of lower and higher molecular weight and, for this reason, it was subjected to GPC, this representing a proof of the principle that GPC is suitable for purification of biologically active compounds from marine sponges, with good potentialities versus more investigated chromatographic protocols. Literature shows that polyprenyl hydroquinones were isolated from the same S. spinosulus species via more complex and organic solvent consuming procedures based on solid–liquid extraction with a methanol/dichloromethane mixture followed by a reverse phase flash chromatography of raw extracts with a further semi-preparative high pressure liquid chromatography carried out with methanol and hexane on a fraction resulting from the first chromatographic separation38,40.

In our study, GPC was performed using a mixture of cyclohexane-ethyl acetate in 1:1 volume ratio (1 mL min−1) for both calibration and extract elution. This mixture was preferred to the most common cyclohexane-dichloromethane 7:3 (1 mL min−1), because acetyl acetate is less toxic than dichloromethane79,80.

Calibration allows to define the molecular weight ranges for collection: six intervals were identified using the elution times of each component of the standard mixture, i.e. (i) 0–6.8 min for the fraction with molecular weight higher than 900 Da; (ii) 6.8–12.6 min (corn oil), (iii) 12.6–18.0 min (bis-2-ethylhexyl ester phthalic acid), (iv) 18–27 min (methoxychlor), (v) 27–35 min (perylene) and (vi) 35–53 min (sulphur). After the GPC calibration, 100 mg mL−1 of the extract obtained from the co-solvent assisted SFE, were loaded in GPC for separation. The GPC chromatographic set-up used in this work has a loading capacity up to 100 mg. However, our group has recently developed a double-column GPC advanced system with loading capacity up to 1 g81, this making the combined SFE-GPC protocol very appealing for further scale-up application.

GPC led to the isolation of the following amounts of fractions at the different elution times (ii) 22 mg (6.8–12.6 min), (iii) 25 mg (12.6–18.0 min), (iv) 49 mg (18.0–27.0 min), (v) 2 mg (27.0–35.0 min), and (vi) 7 mg (35.0–53.0 min).

Characterization of the isolated GPC fractions via NMR and ESI–MS

After the evaporation of solvent, each fraction isolated via GPC was characterized by NMR and ESI–MS.

Figures S6 and S7 (Supplementary Information) show the 1H NMR spectra of the GPC fractions collected in 6.8–12.6 min and 12.6–18.0 min time intervals which are rich in fatty acids, showing a large singlet signal at δ 1.27 ppm that denotes the majority presence of long alkyl chains.

Conversely, the most interesting fraction was the fourth one (49 mg), eluted in the 18.0–27.0 min range, since the recorded 1H NMR spectrum allowed to identify a mixture of hexaprenyl hydroquinone and heptaprenyl hydroquinone (Fig. 4 and Table S2, Supplementary Information).

Indeed, according to the spectra reported in literature for these compounds41, signals of the chemical shifts corresponding to three aromatic protons indicate the presence of a monosubstituted hydroquinone, i.e. two doublets at δ 6.61 (J = 3.1 Hz) and at δ 6.67 (J = 8.4 Hz), and a double doublet at δ 6.57 ppm (J = 8.5 and 3.0 Hz). Furthermore, the signals corresponding to olefinic protons between δ 5.10 and 5.40 ppm, together with a large singlet resonating at δ 1.58 ppm ascribable to methyl groups on a double bond, suggest the presence of a polyprenyl tail. This isoprenoid chain would be linked to the hydroquinone ring in the 2’ position, as deduced from the weak four-bond correlation between the methylene protons in position 1 (δH 3.30 ppm) and the aromatic methine in 3’ (δH 6.61 ppm) observed in the COSY spectrum (Fig. 5, Table S2, and Figure S8, Supplementary Information). All these data were supported by two-dimensional heteronuclear HSQC correlation techniques.

Figures S9 and S10 (Supplementary Information) show the 1H NMR spectra of GPC subfractions eluted at 27.0–35.0 min and 35.0–53.0 min respectively. In both cases aromatic signals different from those observed for hexa and heptaprenyl hydroquinones were observed and, for this reason, both fractions were not considered.

The electrospray ionization mass spectrum (ESI–MS) of the fraction of our interest (18.0–27.0 min), ionization mode, also allowed to observe the peaks of the molecular ions of both hexa- and heptaprenylhydroquinone, ([HexaQ + H]+ = 519.415 [HeptaQ + H]+ = 587.481) as well as some of their cationic adducts ([HexaQ + Na]+ = 541.400 [HexaQ + K]+ = 557.391 [HeptaQ + Na]+ = 609.442 in Figure S11, Supplementary Information). This analysis confirmed the isolation of a mixture of both compounds (49 mg from 100 mg of extract fraction, i.e. 232 mg from 474 mg of overall extract obtained from 85.4 g of dried sponge) and the integrals of methylene protons of the isoprenoid side chain in the 1H NMR spectrum were used to evaluate a 1:3 molar ratio of hexaprenyl hydroquinone versus heptaprenyl hydroquinone.

This result is also profitable in terms of yields, since our combined SFE/GPC method affords an overall amount of bioactive compounds comparable to that obtained from other methods reported in literature38,39,40,41 (Table S3, Supplementary Information) but with the advantage that our protocol avails of lower amounts of organic solvents with a faster, more sustainable and costly effective experimental procedure. Indeed, as shown in the comparative Table S3 (Supplementary Information), in our method, SFE provided ~ 5.36% (w/w) yield of organic extract (4.51 g from 84.15 g of dried sponge) similarly to 5.13% yield (4.92 g from 95.9 g) reported by Bisio et al.39 and 4.71% by Tziveleka et al.40. A slightly higher yield of extraction (11%) was reported by Abed et al.41 but more toxic methanol and dichloromethane solvents were used. Moreover, in our case, it was possible to directly separate a first fraction of extract (4.04 g of the overall 4.51 g) rich in fatty acids using the sole sCO2 solvent, achieving a profitable preliminary purification of the subsequent subfraction that was extracted with sCO2 and ethanol. This pre-purified subfraction was then subjected to GPC purification.

The purification processes reported in the literature are mainly based on a series of steps. For example, Bisio et al. reported a purification method that, despite leading to separate samples of hexa and hepta prenylhydroquinones, was based on a first silica gel medium pressure liquid chromatography (MPLC) followed by a solid-phase extraction cartridge (reverse-phase) and further semi-preparative HPLC with significant consumption of organic solvents39. Our GPC protocol, although being less selective than HPLC, provided a mixture of the same metabolites in significantly higher yield (0.28% vs overall 0.055%38). Considering that both polyprenylhydroquinones of the mixture have very similar biological activity42, the lower selectivity of the SFE/GPC method is not envisaged as a detrimental aspect since it allows a higher eco sustainability in terms of solvent consumption, working times and costs of the experimental procedure.

LCA analysis

The LCA results for the SFE extraction and GPC isolation of 232 mg of polyprenyl hydroquinones mixture from S. spinosulus are shown in Table S4 (Supplementary Information). The data reveal that, in our protocol, while the extraction phase emerges as the main contributor to the environmental burden, the recorded values are very low. Notably, among the considered impact categories, marine aquatic ecotoxicity suffers from the highest contribution, accounting for 98% with respect to the other categories considered in the analysis.

The extraction and purification method of bioactive compounds from S. spinosulus described here, based on low consumption of organic solvents, allows minimizing the most impactful stages that classical extraction processes require, as reported by Perez-Lopez et al.,59. Hence, our method opens up new environmental-friendly perspectives for the large-scale valorization of sponge biomass cultivated in sustainable mariculture systems.

Conclusion

In conclusion, we have provided the proof of principle that it is possible to develop simple and valuable practices to obtain sponge biomass at large-scale in IMTA system, and to isolate bioactive compounds from reared sponges by an innovative eco-friendly combined strategy based on supercritical fluid extraction and gel permeation chromatography.

Our results highlight that in our IMTA system, the horny sponge Sarcotragus spinosulus reared on vertical tubular nets doubled its initial volume after the first 12 months. This finding is significant as it enables biomass production within relatively short timeframes, compatible with the fish farming cycles. Furthermore, the developed rearing technique contributes to constant biomass supply with minimal impact on sponge wild populations, as donor specimens were collected only at the start of the first rearing cycle.

An unprecedented protocol was set up and optimized to isolate bioactive polyprenyl hydroquinones from reared sponges. This protocol combines the eco-friendly supercritical fluid-based extraction—the first time this technique has been applied to to sponge-derived organic extracts- with advanced gel permeation chromatography (GPC). Notably, the GPC method reduces organic solvents consumption while purifying bioactive molecules.

Polyprenyl hydroquinones were obtained in good yields comparable to those of methods reported in literature38 which typically require higher solvent amounts and additional processing steps. Our combined strategy is advantageous in terms of solvent consumption, toxicity, processing time, and overall costs. Preliminary estimates indicate that producing 232 mg of polyprenyl hydroquinones required ~ 360 ml of s-CO2 (working in the overall four SFE cycles at 6 ml min−1 for 15 min) and 90 ml of ethanol for the extraction as well as ~ 127 ml of cyclohexane and ~ 127 ml of ethyl acetate for GPC. Such solvents are less toxic compared to those used in the literature in alternative procedures, and their volume values are significantly lower.

Life Cycle Assessment (LCA) data further confirm that production costs using this approach can be reduced compared to existing procedures. Moreover, the eco-sustainable strategy for producing polyprenyl hydroquinones from S. spinosulus could, in principle, be applied to other bioactive compounds from different sponge species, making it a promising model with broader applicability.

Overall, our integrated in situ rearing approach, combined with the green SFE/GPC protocol can addresses all the three main pillars of sustainable development: environmental, social and economic.

Future perspectives include further exploration of the innovative IMTA system developed in the REMEDIA Life project, which has already shown that integrating macroalgae and filter-feeder organisms, such as polychaetes, sponges, and mussels, into a rearing site significantly improves the environmental quality around fish cages82. Regarding the role of sponges in this system, ongoing and future research will focus on answering key questions, such as whether explants in the IMTA system grow faster than those cultivated at a control site distant from the fish farm. Additionally, it will be investigate whether the primary drivers of growth in these conditions are water parameters or the fish farm effluents. Also, future efforts will extend the application of the current extraction and purification methods to explore additional classes of biomolecules that can be derived from sponges.

Data availability

All data generated or analyzed in this present study are included in this published article or its supplementary information files.

Abbreviations

- SFE:

-

Supercritical fluid extraction

- GPC:

-

Gel Permeation chromatography

- IMTA:

-

Integrated multi-trophic aquaculture

- NMR:

-

Nuclear magnetic resonance

- LLA:

-

Long line A

- LLB:

-

Long line B

- LLC:

-

Long line C

- MMG:

-

Maricoltura del Mar Grande

- SGR:

-

Specific growth rate

- LPM:

-

Liter per minute

- HPLC–ESI–MS–IT–TOF:

-

High-performance liquid chromatography–electrospray ionization–mass spectrometry–ion trap–time-of-flight

- REMEDIA:

-

Remediation of Marine Environment and Development of Innovative Aquaculture

- LCA:

-

Life cycle assessment

- COSY:

-

COrrelation spectroscopy

- HSQC:

-

Heteronuclear single quantum coherence

References

Rocha-Martin, J., Harrington, C., Dobson, A. D. W. & O’Gara, F. Emerging strategies and integrated systems microbiology technologies for biodiscovery of marine bioactive compounds. Mar. Drugs. 12(6), 3516–3559. https://doi.org/10.3390/md12063516 (2014).

Ragni, R., Cicco, S., Vona, D., Leone, G. & Farinola, G. M. Biosilica from diatoms microalgae: smart materials from bio-medicine to photonics. J. Mater. Res. 32(2), 279–291. https://doi.org/10.1557/jmr.2016.459 (2017).

Cicco, S. R. et al. In vivo functionalization of diatom biosilica with sodium alendronate as osteoactive material. Mater. Sci. Eng. C. 104, 109897. https://doi.org/10.1016/j.msec.2019.109897 (2019).

Wali, A. F. et al. Natural products against cancer: Review on phytochemicals from marine sources in preventing cancer. Saudi Pharm. J. 27(6), 767–777. https://doi.org/10.1016/j.jsps.2019.04.013 (2019).

Qi, S.-H. & Ma, X. Antifouling compounds from marine invertebrates. Mar. Drugs. 15(9), 263. https://doi.org/10.3390/md15090263 (2017).

Langasco, R. et al. Natural collagenic skeleton of marine sponges in pharmaceutics: Innovative biomaterial for topical drug delivery. Mater. Sci. Eng. C. 70, 710–720. https://doi.org/10.1016/j.msec.2016.09.041 (2017).

Comprehensive Marine Natural Products Database (CMNPD), Taxonomy. https://www.cmnpd.org/visualization. Accessed 19 Jan 2024.

Blunt, J. W., Copp, B. R., Keyzers, R. A., Munro, M. H. & Prinsep, M. R. Marine natural products. Nat. Prod. Rep. 32(2), 116–211. https://doi.org/10.1039/C4NP00144C (2015).

Van Soest, R. W. M. et al. Global diversity of sponges (Porifera). PLoS One https://doi.org/10.1371/journal.pone.0035105 (2012).

Webster, N. S. & Taylor, M. W. Marine sponges and their microbial symbionts: Love and other relationships. Environ. Microbiol. 14(2), 335–346. https://doi.org/10.1111/j.1462-2920.2011.02460.x (2012).

Vacelet, J. & Donadey, C. Electron microscope study of the association between some sponges and bacteria. J. Exp. Mar. Bio. Ecol. 30(3), 301–314. https://doi.org/10.1016/0022-0981(77)90038-7 (1977).

Montalvo, N. F. et al. Integration of culture-based and molecular analysis of a complex sponge-associated bacterial community. PLoS One 9(3), e90517. https://doi.org/10.1371/journal.pone.0090517 (2014).

Pita, L., Rix, L., Slaby, B. M., Franke, A. & Hentschel, U. The sponge holobiont in a changing ocean: from microbes to ecosystems. Microbiome 6(1), 46. https://doi.org/10.1186/s40168-018-0428-1 (2018).

Walker, R. P., Thompson, J. E. & Faulkner, D. J. Exudation of biologically-active metabolites in the sponge Aplysina fistularis. II. Chem. Evid. Mar. Biol. 88, 27–32. https://doi.org/10.1007/BF00393040 (1985).

Mauduit, M. et al. In situ capture and real-time enrichment of marine chemical diversity. ACS Cent. Sci. 9(11), 2084–2095. https://doi.org/10.1021/acscentsci.3c00661 (2023).

Lee, Y.-K., Lee, J.-H. & Lee, H.-K. Microbial symbiosis in marine sponges. J. Microbiol. 39(4), 254–264 (2001).

Bergman, O. et al. Examination of marine-based cultivation of three demosponges for acquiring bioactive marine natural products. Mar. Drugs. 9(11), 2201–2219. https://doi.org/10.3390/md9112201 (2011).

Munro, M. H. G. et al. The discovery and development of marine compounds with pharmaceutical potential. Prog. Ind. Microbiol. 35, 15–25. https://doi.org/10.1016/S0079-6352(99)80093-9 (1999).

Osinga, R., Tramper, J. & Wijffels, R. H. Cultivation of marine sponges. Mar. Biotechnol. 1(6), 509–532. https://doi.org/10.1007/PL00011807 (1999).

Belarbi, E. H., Gómez, A. C., Chisti, Y., Camacho, F. G. & Grima, E. M. Producing drugs from marine sponges. Biotechnol. Adv. 21(7), 585–598. https://doi.org/10.1016/S0734-9750(03)00100-9 (2003).

van Treeck, P., Eisinger, M., Müller, J., Paster, M. & Schuhmacher, H. Mariculture trials with Mediterranean sponge species. Aquaculture. 218(1–4), 439–455. https://doi.org/10.1016/S0044-8486(03)00010-3.doi:10.1016/S0044-8486(03)00010-3 (2003).

Sipkema, D., Franssen, M. C. R., Osinga, R., Tramper, J. & Wijffels, R. H. Marine sponges as pharmacy. Mar. Biotechnol. 7(3), 142–162. https://doi.org/10.1007/s10126-004-0405-5 (2005).

Duckworth, A. Farming sponges to supply bioactive metabolites and bath sponges: A review. Mar. Biotechnol. 11(6), 669–679. https://doi.org/10.1007/s10126-009-9213-2 (2009).

Aguilo-Arce, J. et al. Sponges as emerging by-product of integrated multitrophic aquaculture (IMTA). J. Mar. Sci. Eng. 11(1), 80. https://doi.org/10.3390/jmse11010080 (2023).

Pronzato, R. & Manconi, R. Mediterranean commercial sponges: Over 5000 years of natural history and cultural heritage. Mar. Ecol. 29(2), 146–166. https://doi.org/10.1111/j.1439-0485.2008.00235.x (2008).

Maslin, M., Gaertner-Mazouni, N., Debitus, C., Joy, N. & Ho, R. Marine sponge aquaculture towards drug development: An ongoing history of technical, ecological, chemical considerations and challenges. Aquac. Rep. 21, 100813. https://doi.org/10.1016/j.aqrep.2021.100813 (2021).

Corriero, G. et al. Rearing performance of Spongia officinalis on suspended ropes off the Southern Italian Coast (Central Mediterranean Sea). Aquaculture. 238(1–4), 195–205. https://doi.org/10.1016/j.aquaculture.2004.04.030 (2004).

Padiglia, A., Ledda, F. D., Padedda, B. M., Pronzato, R. & Manconi, R. Long-term experimental in situ farming of Crambe crambe (Demospongiae: Poecilosclerida). PeerJ 6, e4964. https://doi.org/10.7717/peerj.4964 (2018).

Giangrande, A. et al. An innovative IMTA system: Polychaetes, sponges and macroalgae co-cultured in a Southern Italian in-shore mariculture plant (Ionian Sea). J. Mar. Sci. Eng. https://doi.org/10.3390/JMSE8100733 (2020).

Perea-Blázquez, A., Davy, S. K., Magana-Rodríguez, B. & Bell, J. J. Temporal variation in food utilisation by three species of temperate demosponge. Mar. Ecol. Prog. Ser. 485, 91–103. https://doi.org/10.3354/meps10316 (2013).

Ribes, M., Coma, R. & Gili, J. M. Natural diet and grazing rate of the temperate sponge Dysidea avara (Demospongiae, Dendroceratida) throughout an annual cycle. Mar. Ecol. Prog. Ser. 176, 179–190. https://doi.org/10.3354/meps176179 (1999).

Reiswig, H. M. Bacteria as food for temperate-water marine sponges. Can. J. Zool. 53(5), 582–589. https://doi.org/10.1139/z75-072 (1975).

Larsen, P. S. & Riisgåd, H. U. The sponge pump. J. Theor. Biol. 168(1), 53–63. https://doi.org/10.1006/jtbi.1994.1087 (1994).

Pile, A. J., Patterson, M. R. & Witman, J. D. In situ grazing on plankton < 10 μm by the boreal sponge Mycale lingua. Mar. Ecol. Prog. Ser. 141(1/3), 95–102 (1996).

Longo, C. et al. The co-occurrence of the demosponge Hymeniacidon perlevis and the edible mussel Mytilus galloprovincialis as a new tool for bacterial load mitigation in aquaculture. Environ. Sci. Pollut. Res. 23(4), 3736–3746. https://doi.org/10.1007/s11356-015-5587-z (2016).

Mercurio, M., Corriero, G., Gherardi, M., Baldacconi, R. & Elda, G. Sexual reproduction in Sarcotragus spinosulus from two different shallow environments. Mar. Ecol. 34(4), 394–408. https://doi.org/10.1111/maec.12039 (2013).

Trani, R. et al. Filtering activity and nutrient release by the keratose sponge Sarcotragus spinosulus Schmidt, 1862 (Porifera, Demospongiae) at the laboratory scale. J. Mar. Sci. Eng. 9(2), 178. https://doi.org/10.3390/jmse9020178 (2021).

Cimino, G., De Stefano, St. & Minale, L. Polyprenyl derivatives from the sponge Ircinia spinosula: 2-Polyprenylbenzoquinones, 2-polyprenylbenzoquinols, prenylated furans and a C-31 difuranoterpene. Tetrahedron. 28(5), 1315–1324. https://doi.org/10.1016/S0040-4020(01)93556-2 (1972).

Bisio, A. et al. Isolation of hydroxyoctaprenyl-1′, 4′-hydroquinone, a new octaprenylhydroquinone from the marine sponge Sarcotragus spinosulus and evaluation of its pharmacological activity on acetylcholine and glutamate release in the rat central nervous system. Nat. Prod. Commun. 9(11), 1581–1584. https://doi.org/10.1177/1934578X1400901113 (2014).

Tziveleka, L. A., Kourounakis, A. P., Kourounakis, P. N., Roussis, V. & Vagias, C. Antioxidant potential of natural and synthesised polyprenylated hydroquinones. Bioorg. Med. Chem. 10(4), 935–939. https://doi.org/10.1016/S0968-0896(01)00346-7 (2002).

Abed, C. et al. A new hydroxylated nonaprenylhydroquinone from the mediterranean marine sponge Sarcotragus spinosulus. Mar. Drugs. https://doi.org/10.3390/md9071210 (2011).

Wätjen, W. et al. Hexa-, hepta-and nonaprenylhydroquinones isolated from marine sponges Sarcotragus muscarum and Ircinia fasciculata inhibit NF-k B signalling in H4IIE cells. J. Pharm. Pharmacol. 61(7), 919–924. https://doi.org/10.1211/jpp.61.07.0011 (2009).

Byrne, F. P. et al. Tools and techniques for solvent selection: Green solvent selection guides. Sustain. Chem. Process. 4(1), 1–24. https://doi.org/10.1186/s40508-016-0051-z (2016).

Aresta, A., Cotugno, P., De Vietro, N., Massari, F. & Zambonin, C. Determination of polyphenols and vitamins in wine-making by-products by supercritical fluid extraction (SFE). Anal. Lett. 53(16), 2585–2595. https://doi.org/10.1080/00032719.2020.1749846 (2020).

Aresta, A., Cotugno, P., Massari, F. & Zambonin, C. Determination of trans-resveratrol in wines, spirits, and grape juices using solid-phase micro extraction coupled to liquid chromatography with UV diode-array detection. Food Anal. Methods 11(2), 426–431. https://doi.org/10.1007/s12161-017-1013-0 (2018).

Arumugham, T. et al. Supercritical carbon dioxide extraction of plant phytochemicals for biological and environmental applications–A review. Chemosphere. 271, 129525. https://doi.org/10.1016/j.chemosphere.2020.129525 (2021).

Wajs-Bonikowska, A., Stobiecka, A., Bonikowski, R. & Krajewska, A. A comparative study on composition and antioxidant activities of supercritical carbon dioxide, hexane and ethanol extracts from blackberry (Rubus fruticosus) growing in Poland. J. Sci. Food Agric. 97(11), 3576. https://doi.org/10.1002/jsfa.8216 (2017).

de Andrade Lima, M., Kestekoglou, I., Charalampopoulos, D. & Chatzifragkou, A. Supercritical fluid extraction of carotenoids from vegetable waste matrices. Molecules. 24(3), 466. https://doi.org/10.3390/molecules24030466 (2019).

Abrahamsson, V., Cunico, L. P., Andersson, N., Nilsson, B. & Turner, C. Multicomponent inverse modeling of supercritical fluid extraction of carotenoids, chlorophyll A, ergosterol and lipids from microalgae. J. Supercrit. Fluids. 139, 53–61. https://doi.org/10.1016/j.supflu.2018.05.007 (2018).

Zhou, J. et al. The application of supercritical fluids technology to recover healthy valuable compounds from marine and agricultural food processing by-products: A review. Processes. 9(2), 357. https://doi.org/10.3390/pr9020357 (2021).

Kuvendziev, S., Lisichkov, K., Zeković, Z., Marinkovski, M. & Musliu, Z. H. Supercritical fluid extraction of fish oil from common carp (Cyprinus carpio L.) tissues. J. Supercrit. Fluids. 133, 528–534. https://doi.org/10.1016/j.supflu.2017.11.027 (2018).

Maran, J. P., Manikandan, S., Priya, B. & Gurumoorthi, P. Box-Behnken design based multi-response analysis and optimization of supercritical carbon dioxide extraction of bioactive flavonoid compounds from tea (Camellia sinensis L.) leaves. J. Food Sci. Technol. 52, 92–104. https://doi.org/10.1007/s13197-013-0985-z (2013).

Santos, S. A., Villaverde, J. J., Silva, C. M., Neto, C. P. & Silvestre, A. J. Supercritical fluid extraction of phenolic compounds from Eucalyptus globulus Labill bark. J. Supercrit. Fluid. 71, 71–79. https://doi.org/10.1016/j.supflu.2012.07.004 (2012).

Kim, J., Choi, Y. M. & Yoo, K. P. Chapter two Supercritical fluid extraction of alkaloids. In Alkaloids: Chemical and Biological Perspectives Vol. 15 415–431 (Elsevier, London, 2001). https://doi.org/10.1016/S0735-8210(01)80016-9.

Lehnik-Habrink, P., Hein, S., Win, T., Bremser, W. & Nehls, I. Multi-residue analysis of PAH, PCB, and OCP optimized for organic matter of forest soil. J. Soils Sediments. 10(8), 1487–1498. https://doi.org/10.1007/s11368-010-0241-3 (2010).

Murray, L. M., Lim, T. K., Hooper, J. N. A. & Capon, R. J. Isobromotopsentin: A new bis (indole) alkaloid from a deep-water marine sponge Spongosorites sp. Aust. J. Chem. 48(12), 2053–2058. https://doi.org/10.1071/CH9952053 (1995).

da Silva, R. P. F. F., Rocha-Santos, T. A. P. & Duarte, A. C. Supercritical fluid extraction of bioactive compounds. TrAC Trends Anal. Chem. 76, 40–51. https://doi.org/10.1016/j.trac.2015.11.013 (2016).

Pérez-López, P. et al. Environmental solutions for the sustainable production of bioactive natural products from the marine sponge Crambe crambe. Sci. Total Environ. 475, 71–82. https://doi.org/10.1016/j.scitotenv.2013.12.068 (2014).

Pérez-López, P. et al. Life cycle assessment of in situ mariculture in the Mediterranean Sea for the production of bioactive compounds from the sponge Sarcotragus spinosulus. J. Clean. Prod. 142, 4356–4368. https://doi.org/10.1016/j.jclepro.2016.11.137 (2017).

Guinée, J.B., Gorrée, M., Heijungs, R., Huppes, G., Kleijn, R., de Koning, A., van Oers, L., Wegener, A., Suh, S., Udo de Haes, H.A., de Bruijn, H. & van Duin, R., In Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards (Kluwer Academic Publishers, 2002).

Murray, P. M. et al. Sustainable production of biologically active molecules of marine based origin. New Biotechnol. 30(6), 839–850. https://doi.org/10.1016/j.nbt.2013.03.006 (2013).

Caroppo, C. et al. Progress toward sustainable mussel aquaculture in Mar Piccolo, Italy. Ecol. Soc. https://doi.org/10.5751/ES-04950-170310 (2012).

Gowen, R. J. & Bradbury, N. B. The ecological impact of salmonid farming in coastal waters: a review. Oceanogr. Mar. Biol. Annu. Rev. 25, 563–575 (1987).

Ervik, A., Thorsen, B., Eriksen, V., Lunestad, B. & Samuelsen, O. Impact of administering antibacterial agents on wild fish and blue mussels Mytilus edulis in the vicinity of fish farms. Dis. Aquat. Organ. 18, 45–51. https://doi.org/10.3354/dao018045 (1994).

Gökalp, M. et al. The effect of depth on the morphology, bacterial clearance, and respiration of the Mediterranean sponge Chondrosia reniformis (Nardo, 1847). Mar. Drugs. 18(7), 358. https://doi.org/10.3390/md18070358 (2020).

Gökalp, M., Wijgerde, T., Murk, A. & Osinga, R. Design for large-scale maricultures of the Mediterranean demosponge Chondrosia reniformis Nardo, 1847 for collagen production. Aquaculture. 548, 737702. https://doi.org/10.1016/j.aquaculture.2021.737702 (2022).

Gökalp, M., Wijgerde, T., Sarà, A., De Goeij, J. M. & Osinga, R. Development of an integrated mariculture for the collagen-rich sponge Chondrosia reniformis. Mar. Drugs. 17(1), 29. https://doi.org/10.3390/md17010029 (2019).

Longo, C., Scrascia, M., Trani, R., Pierri, C., Cariglia, A., Cariglia, F. & Cariglia, M., ASMar: Assessment of Sponge Mariculture potential in polyculture system in the Manfredonia Gulf, from natural resources to IMTA toward bioremediation and animal welfare. In Aquafarm/Novelfarm Fiera, Pordenone, 19–20 February 2020, 1 (2020).

Osinga, R., Sidri, M., Cerig, E., Gokalp, S. Z. & Gokalp, M. Sponge aquaculture trials in the East-Mediterranean Sea: New approaches to earlier ideas. Open Mar. Biol. J. 4(1), 74. https://doi.org/10.2174/1874450801004010074 (2010).

Pronzato, R. Sponge-fishing, disease and farming in the Mediterranean Sea. Aquat. Conserv. Mar. Freshw. Ecosyst. 9(5), 485–493. https://doi.org/10.1002/(SICI)1099-0755(199909/10)9:5%3c485::AID-AQC362%3e3.0.CO;2-N (1999).

Pronzato, R. et al. Sustainable development in coastal areas: Role of sponge farming in integrated aquaculture. Aquac. Water Fish Cult. Shellfish Cult. Water Usage 26, 231–232 (1998).

Stabili, L. et al. Filtering activity of Spongia officinalis var. adriatica (Schmidt) (Porifera, Demospongiae) on bacterioplankton: Implications for bioremediation of polluted seawater. Water Res. 40(16), 3083–3090. https://doi.org/10.1016/j.watres.2006.06.012 (2006).

Müller, W. E. G. et al. Initiation of an aquaculture of sponges for the sustainable production of bioactive metabolites in open systems: Example, Geodia cydonium. Mar. Biotechnol. 1(6), 569–579. https://doi.org/10.1007/PL00011812 (1999).

Pronzato, R., Bavestrello, G., Cerrano, C., Magnino, G., Manconi, R., Pantelis, J., Sarà, A., & Sidri, M. Sponge farming in the Mediterranean Sea: New perspectives, Memoirs of the Queensland Museum. 44, 485–491 (1999).

Page, M. J., Northcote, P. T., Webb, V. L., Mackey, S. & Handley, S. J. Aquaculture trials for the production of biologically active metabolites in the New Zealand sponge Mycale hentscheli (Demospongiae: Poecilosclerida). Aquaculture. 250(1–2), 256–269. https://doi.org/10.1016/j.aquaculture.2005.04.069 (2005).

Sapkale, G. N., Patil, S. M., Surwase, U. S. & Bhatbhage, P. K. Supercritical fluid extraction. Int. J. Chem. Sci. 8(2), 729–743 (2010).

Hassim, N., Markom, M., Rosli, M. I. & Harun, S. Effect of static extraction time on supercritical fluid extraction of bioactive compounds from Phyllanthus niruri. J. Comput. Theor. Nanosci. 17(2–3), 918–924. https://doi.org/10.1166/jctn.2020.8742 (2020).

Hossaini, R. et al. Efficiency of short-lived halogens at influencing climate through depletion of stratospheric ozone. Nat. Geosci. 8(3), 186–190. https://doi.org/10.1038/ngeo2363 (2015).

MacMillan, D. S., Murray, J., Sneddon, H. F., Jamieson, C. & Watson, A. J. B. Replacement of dichloromethane within chromatographic purification: a guide to alternative solvents. Green Chem. 14(11), 3016–3019. https://doi.org/10.1039/C2GC36378J (2012).

Taygerly, J. P., Miller, L. M., Yee, A. & Peterson, E. A. A convenient guide to help select replacement solvents for dichloromethane in chromatography. Green Chem. 14(11), 3020–3025. https://doi.org/10.1039/C2GC36064K (2012).

Cotugno, P. et al. Advanced gel permeation chromatography system with increased loading capacity: Polycyclic aromatic hydrocarbons detection in olive oil as a case of study. J. Chromatogr. A 1639, 461920. https://doi.org/10.1016/j.chroma.2021.461920 (2021).

Stabili, L. et al. Environmental quality improvement of a mariculture plant after its conversion into a multi-trophic system. Sci. Total Environm. https://doi.org/10.1016/j.scitotenv.2023.163846 (2023).

Acknowledgements

This research contributes to achieves the goals of the project “ MASBIA: Marine Sponges as Bioremediators in Integrated Aquaculture (cod. 2023-UNBACLE-0245506)” funded by the ERC SEEDS UNIBA. This research contributes to achieves the goals of the UNIBA researcher’s consortium involved in the project “RESTART: RESources of TARanTo seas. L'utilizzo delle risorse del mare per il risanamento degli ecosistemi marini e lo sviluppo di bio-economia circolare” funded by the Horizon Europe Seeds UNIBA. Roberta Ragni is also supported by the Next Generation EU PNRR M4C2I1.3 research project PNRR Spoke 6 "ManoHCC: Three-dimensional matrices and engineered nanoparticles for locoregional treatment of hepatocellular carcinoma" (PNRR_BAC24LDECO_01, CUP E93C22001860006).

Funding

This research was funded by the European Commission, Life Environment program: REMEDIA Life project (LIFE16 ENV/IT/000343): Remediation of Marine Environment and Development of Innovative Aquaculture: exploitation of Edible/not Edible biomass.

Author information

Authors and Affiliations

Contributions

C.L.: conceptualization, investigation, methodology, formal analysis, writing original draft, project management and administration, funding acquisition; C.P., R.T., J.A.A., V.S., F.M., D.V., S.M., M.M., C.N.M. and G.D.: investigation, methodology, formal analysis; A.G., G.C. and C.Z.: conceptualization, supervision; P.C., R.R. and P.F.: conceptualization, investigation, methodology, formal analysis, writing original draft.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Longo, C., Pierri, C., Trani, R. et al. Toward a green strategy of sponge mariculture and bioactive compounds recovery. Sci Rep 15, 5999 (2025). https://doi.org/10.1038/s41598-025-90192-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-90192-z