Abstract

Water splitting is a promising pathway for hydrogen production, providing an environmentally friendly fuel source. More recently, great attention has been given to transition metal dichalcogenides (TMDCs) because of their interesting chemical and physical properties. In particular, tungsten disulfide (WS2) has garnered significant attention as a catalyst for this application due to its unique layered 2D structure. In this study, few-layered WS2 and phosphorus-doped WS2 (WS2/P) nanoflakes are synthesized on SiO2/Si substrates as electrocatalysts for hydrogen evolution reactions (HER) in acidic conditions. Analyses of the synthesized WS2 and WS2/P films reveal that the few-layered WS2 is of high quality, exhibiting continuity and uniformity. The presence of a strong peak in the photoluminescence spectrum confirms the mono/few layer nature of the synthesized samples. In additionally, scanning force microscopy in quantitative imaging mode reveals that the thinnest layers observed on the substrate have a height of 1.35 nm, indicating the presence of double-layer WS2. The WS2/P electrocatalyst demonstrates superior HER performance compared to pristine WS2, showing a low overpotential of 245 mV at 10 mA.cm−2 and a small Tafel slope of 123 mV.dec−1. Furthermore, WS2/P exhibits a greater electrochemical surface area and excellent catalytic stability under acidic conditions. Consequently, few layer phosphorus-doped WS2 proves to be a highly suitable electrocatalyst for hydrogen production compared to the WS2.

Similar content being viewed by others

Introduction

One of the attractive approaches toward replacing fossil fuels and thus solving the energy crisis is related to generating hydrogen fuel by water splitting1,2. When water is energized, it engages in a complex interplay of reactions known as water splitting, wherein it is divided into its constituent elements of hydrogen and oxygen. These processes involve two half-reactions at two different electrodes in the process: the hydrogen evolution reaction (HER) and the oxygen evolution reaction (OER)3,4,5. These half-reactions contribute to the whole water-splitting process for generating clean energy from water as a renewable resource. In the electrochemical process, hydrogen is released at the cathode through a double electron transfer mechanism. In acidic electrolytes, this reaction is represented as 2H3O+ + 2e− → 2H2O + H2, while in alkaline electrolytes, the reaction is represented as 2H2O + 2e− → 2OH− + H21,6. Since the process of water electrolysis should be continuous and effective, a catalyst is required. Moreover, it would increase the rate of reaction with low overpotential and high energy efficiency7,8. Although platinum-group metals are currently employed as advanced catalysts for the HER, but their rarity, and high cost prevent the widespread development of electrochemical water-splitting systems9,10. Hence, finding a catalyst abundant on Earth with high HER activity and low overpotential is vital. In recent years, transition metal-based dichalcogenides (TMDCs), such as MoS211, WS212,13,14,15,16, CoS217, FeS18, and Ni3S219, recognized for their high specific surface areas20, have gained attention as catalysts for HER21.

The TMDCs have garnered renewed attention due to a variety of new physical phenomena22,23,24,25. Two-dimensional (2D) TMDCs are increasingly seen as potential alternatives for catalytic applications26,27. These materials possess graphite-like layered structures, with weakly bound neighboring layers held together by van der Waals forces, and the intralayer framework is bonded, dominated by the S-Metal-S covalent bond21. This enables the structure to provide numerous active sites, thereby enhancing the electron transportation rate to active centers, hence improving activity and selectivity for redox reactions, which then accelerates catalytic reactions28,29,30. Among the TMDCs, WS2 is regarded as an effective catalyst for HER due to its high catalytic activity, particularly in acidic and alkaline environments. It facilitates the necessary chemical reactions for producing hydrogen gas from water. Additionally, WS2 exhibits favorable electrical conductivity, which enhances electron transfer during the HER, improving overall efficiency while maintaining relative stability under various conditions. Notably, compared to noble metal catalysts such as platinum, WS2 is more abundant and less expensive, making it a more sustainable option for large scale hydrogen production. To enhance the catalytic activity of these materials, the applied strategies involve heteroatom doping31,32,33, surface engineering34, non-metal doping35, and chemical processes to increase sulfur vacancies36.

Metal and non-metal doping are popular methods for enhancing catalytic performance37,38. Das et al.39 demonstrated that varying concentrations of Zn-doped WS2 exhibit improved electrochemical activity compared to pure WS2. Specifically, the Zn-doped WS2 variant showed high HER performance with an onset potential of 180 mV at a current density of 10 mA.cm−2 and a low Tafel slope of 70 mV.dec−1. Additionally, it was reported by Pan et al.40 that the bandgap of WS2 nanosheets was effectively reduced through doping with Te. These Te-doped WS2 nanosheets exhibited excellent HER catalytic performance with an overpotential of 213 mV to drive a current density of 10 mA.cm−2 and a small Tafel slope of 94 mV.dec−1. However, the experiments for this process often require challenging conditions. In contrast, non-metal doping typically involves less harsh conditions, generating further interest and research in this area37.

Phosphorus (P) doping can be incorporated into the S-W-S nano-layer, which reduces the electronic transition barrier, increases the density of active centers, and subsequently enhances HER33. Indeed, phosphorus creates new active sites for reactions, enhancing the catalyst’s ability to adsorb reactants and stabilize reaction intermediates. These phenomena are crucial for HER. The combination of P with WS2 can generate synergy that optimizes both the electronic and geometric properties of the catalyst41. Currently, the usual methods for preparing layered two-dimensional materials include mechanical exfoliation42,43, physical vapor deposition (PVD)44, and chemical vapor deposition (CVD)45,46. Among the methods, CVD is supposed to be one of the most promising techniques for large-scale preparation because of its high efficiency, low cost, and good quality of synthesis47,48. Additionally, CVD is a reliable approach for controlling sample quality49. To synthesize TMDCs via CVD, metal oxide powders like Tungsten oxide powder (WO3) are commonly used as tungsten sources50,51. Establishment of a low growth temperature to achieve few layer WS2 is achieved by addition of halide salts such as sodium chloride (NaCl) or potassium iodide (KI) during CVD synthesis. These promoters form volatile tungsten oxyhalides when reacting with tungsten oxide at rather low temperatures. This promotes WS2 nucleation and lateral growth on substrates through further reactions of these volatile intermediate products with gaseous sulfur. Following this principle, monolayer WS2 crystals on SiO2/Si substrates have been successfully grown at a relatively low temperature of 700–850 °C by several research groups utilizing NaCl or KI as a growth promoter with CVD52,53,54,55. Moreover, in order to enhance the quality of WS2, a trace amount of hydrogen is typically mixed into the argon (Ar) flow used in the CVD method. The mixed H2 in the Ar/H2 atmosphere serves as the reducing reagent during the reaction process56. The following are the chemical reactions happening in the synthetic process:

-

2WO3 + 2NaCl → WO2Cl2 + Na2WO4.

-

WO2Cl2 + 4H2 + 3 S → WS2 + 2HCl + 2H2O + H2S.

Researchers have synthesized WS2 using various methods to electrocatalyze HER; however, the growth of 2 H-WS2 few layers with high continuity and uniformity on SiO2/Si substrates has not been reported using a one-step CVD method57,58. In this work, we propose a simple and universal CVD method to fabricate high-quality (continuous and uniform) WS2 layered structures, including occasional few layers, by utilizing NaCl as a growth promoter. Furthermore, while many methods have recently been employed to enhance the electrocatalytic performance of WS239,59,60, there are very few reports focusing on the promotion of P-doped WS2 for HER61,62. Herein, micrometer-sized flakes of few layer WS2 doped with phosphorus are synthesized through a one-step CVD process by simultaneously evaporating WO₃, sulfur, and phosphorus. The resulting films are then evaluated as catalysts for the HER using electrochemical tests. Furthermore, characterizations of the WS2 and WS2/P nanoflakes are conducted using various techniques including Photo-luminescence spectroscopy (PL), Raman spectroscopy, UV–Visible (UV–Vis) spectrophotometry, I-V characteristics, X-ray diffraction (XRD), Scanning force microscopy (SFM) in quantitative mode, Field emission scanning electron microscopy (FESEM), and Energy dispersive X-ray spectroscopy (EDX). All these techniques are employed to evaluate the optical, electrical, and structural properties of the WS2 and WS2/P nanoflakes.

Experimental

P-type silicon wafers (prime), each measuring 2.5 × 1 cm2, apply as substrates in this study. The substrates are first cleaned by being dipped into a sonicated bath of acetone, ethanol, and deionized water one after the other, each for 10 min. Subsequently, the substrates are briefly immersed in hydrofluoric acid (HF) with a concentration of 33% to remove native oxides, and the etched substrates are then rinsed in deionized water three times. The cleaned substrates are then placed in an oven set to 80 °C for a duration of 5 min to dry. Next, a 60 nm thick SiO2 buffer layer is deposited on the substrates [Si (100)] using a single-zone furnace (TF5/25-1250) under Ar and O2 atmospheres at 970°C63. Without the SiO2 layer, silicon would react and disrupt the desired reaction for producing WS2.

The growth of WS2 and WS2/P nanoflakes is carried out by CVD in a three-zone furnace (TF5/25,3,1500). Tungsten oxide powder (WO3) with a purity of 99.99% is supplied by BDH Chemicals Ltd, Poole, England. In each experiment, the weights of WO3, sulfur, and NaCl (as the growth promoter) powders are 100 mg, 2000 mg, and 6 mg, respectively, while the phosphorus amounts are varied between 10 mg and 20 mg. WO3 and NaCl powders are thoroughly mixed and placed in separate ceramic (Al2O3) crucibles. The SiO2/Si substrates are placed on the ceramic boat containing mixtures of the WO3 and NaCl powders, with approximately 10 mm distance between the substrate surface and the powder. The crucibles are then placed inside a horizontal quartz tube with a diameter of 1.5 inches.

In the three-zone furnace, the crucible of the WO3/NaCl powder is placed in the high-temperature zone, phosphorus in the middle zone, and sulfur powder in the lower-temperature part located near the entrance of the Ar as shown in Fig. 1a. This arrangement allows for the simultaneous sublimation of WO3, sulfur, and phosphorus, ensuring their delivery to the proper reaction zone, simultaneously. The WS2 and WS2/P nanoflakes are deposited on the silicon substrates laid face down on the top side of the crucible with WO3 in the hot zone at 850 °C.

To pull out residual gases, the chamber is purged with Ar gas for 30 min at a flow rate of 100 sccm. Subsequently, the first heating zone is ramped up to 220 °C at a ramping rate of 10 °C/min, while the middle zone containing the phosphorus source is increased to 210 °C. The temperature in the third heating zone of the furnace is ramped from room temperature to 850 °C at a rate of 38 °C/min. The growth of WS2 and WS2/P occurs for 10 min in an Ar-H2 gas mixture, with flow rates of 30 sccm for Ar and 15 sccm for H2. Finally, the furnace is purged with 30 sccm of Ar for an additional 5 min.

After the growing process, the CVD system is allowed to cool down to room temperature, which is an essential step for ensuring the successful formation of WS2. Finally, after the system cools spontaneously to room temperature and the synthesized sample is removed, the ceramic crucibles are placed in a quartz tube. The furnace temperature is then increased from room temperature to 1100 °C at a rate of 38 °C/min, followed by a 1 h hold at this temperature to clean the system.

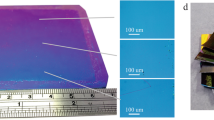

The crystalline structures are determined with the obtained XRD patterns using a Unisantis XMD 300. Room temperature PL spectroscopy, using an excitation wavelength of 532 nm, is employed to examine the optical attributes of WS2 and WS2/P nanoflakes with different phosphorus concentrations. The number of layers can be determined using Raman spectroscopy conducted with a RENISHAW instrument through a Raman Microscope with an excitation laser wavelength of 633 nm. The morphology is investigated with a Field emission scanning electron microscopy (FESEM) with a model of MIRA3 TESCAN-XMU and Scanning force microscopy (SFM) is carried out using JPK Nanowizard 3 in quantitative imaging and AC modes. Optical absorption is determined using UV–Vis spectroscopy employing a Perkin Elmer spectrometer (LQS-ID-006). The HER performance of the WS2 and WS2/P is estimated in N2-saturated acidic environment through a standard three-electrode system. The electrochemical measurements are taken using AUTOLAB–PGSTAT101 and Palmsens (Palmsens 4) electrochemical workstation with the three-electrode system purged with N2 prior to each test for 20 min64. An acid electrolyte of H2SO4 solution of 0.5 M concentration is taken up, while an Ag/AgCl electrode in 3.0 M of KCl acts as a reference electrode and a platinum electrode as the counter electrode. The working electrode comprises the WS2 or WS2/P nonoflakes on the SiO2/Si substrate with an area of about 0.4 cm2. The edges of the electrode are coated with Au using DC magnetron sputtering, as shown in Fig. 1b. Linear sweep voltammetry (LSV) is conducted at a 5 mV.S−1 scan rate in this paper. Double-layer capacitance (Cdl) is evaluated with cyclic voltammetry (CV) curves at various scan rates.

Results and discussion

Optical images of nanoflakes

The optical images of the synthesized WS2 and WS2/P films are depicted as shown in Fig. 2a, b, respectively. In Fig. 2a, a standard triangular WS2 crystal is observed, indicating the successful synthesis of WS2 nanoflakes. Furthermore, as illustrated in Fig. 2a, few layer WS2 is formed continuously and uniformly, demonstrating the high quality and proving of the synthesized nanoflakes. It is worth noting that phosphorus doping reduces the homogeneity of the WS2 structure.

XRD analysis

Figure 3 illustrates the crystal structure features of the WS2 thin films grown with different amounts of phosphorus.

The XRD measurements of the WS2 and WS2/P catalysts reveal that phosphorus is doped in the lattice. Due to the similar atomic radii of S and P, this doping provides very minimal lattice parameter variation. Characteristic peaks observed at 2θ = 14.43° (P = 0.02 gr), 14.47° (P = 0.01 gr), and 14.51° (P = 0) correspond to the (0 0 2) plane of WS2 nanoflakes, while peaks at 2θ = 69.33° (P = 0.02 gr), 69.35° (P = 0.01 gr), and 69.37° (P = 0) are associated with the Si peak. Additionally, a peak at 2θ = 19.70° is attributed to phosphorus65. The reduction in peak intensity at around 14.43° compared to the intensity of the Si peak, as well as the increase in the full width at half maximum (FWHM) after phosphorus doping, confirms the decreased homogeneity of the WS2 structure.

Photoluminescence spectroscopy

PL spectroscopy is added to further characterize the WS2 and WS2/P nanoflakes. As depicted in Fig. 4, a single strong peak is observed, centered at around 637 nm (~ 1.94 eV) for WS2 and 635 nm (~ 1.95 eV) for WS2/P. These wavelengths align closely with those reported for CVD-synthesized mono/few layer WS266,67. Moreover, the transition from an indirect band gap to a direct band gap is evident as the material transitions from multilayer WS2 to monolayer WS268,69,70,71. Additionally, according to other reports72,73, the full width at half maximum (FWHM) of PL spectra depend on the quality of the thin film. They reported that synthesized thin films with an FWHM of less than 24.8 nm demonstrate a high quality of the WS2 structure. According to PL results, FWHM of WS2/P crystals are around 22.3 nm (P = 0), 19.2 nm (P = 0.01 gr) and 18.1 nm (P = 0.02 gr), respectively.

Raman spectroscopy

Raman spectroscopy, similar to the methods above, is engaged in identifying the number of layers that WS2 structures have. For WS2 clearly two vibrational modes, E2g1 and A1g, are appearing on two different positions. The E2g1 mode is connected with the in-plane vibration of W and S atoms, whereas the A1g mode is related to the out-of-plane vibration of S atoms as illustrated in Fig. 5a. The number of layers is estimated through the value of Δ, which is the distance between these two modes74. In Fig. 5b, the E2g1 and A1g peaks for the WS2 synthesized in this study are observed at 352.46 and 419.23 cm−1, respectively, resulting in a frequency difference (Δ) of about 66.77 cm−1. According to other reports, a frequency difference equal to 66.77 cm−1 points towards bilayer as well as mono layer structures of WS274,75. Therefore, this value confirms that the grown WS2 in this work has a WS2 layered structures including occasional monolayers. The results is in agreement with the PL spectroscopy results.

Scanning force microscopy (SFM)

Scanning force microscopy (SFM) is a precise method for nanomechanical investigations, capable of measuring the topographical variations and nanomechanics of an interface. We used SFM to understand the extent of the interfacial growth of the WS2 with phosphorus doping at the SiO2 layer on the Si wafer substrate. For this, scanning force microscopy in quantitative imaging mode (SFM-QI) in addition to the tapping mode SFM (SFM-TM) were used. SFM-QI is capable of measuring the thickness of the layers and the variations of the topography in addition to measurements of the interfacial adhesion (pull off force), deformation, indentation and stiffness of structures at nanoscale. SFM-TM allows for a rather quick survey of the interface of the single type matter only and can demonstrate artificial height variations if the chemistry of the sample interface varies76. Therefore, due to higher height measurement precision, flexibility, and avoidance of the usual measurement artifacts seen in “SFM-TM”, we utilize SFM-QI in this study as the main experimental mode of investigation of the grown structures at the substrate interface. We use SFM-TM as a safe measurement tool for mapping the topography of the chemically similar regions of the sample, e.g., on WS2 crystals only.

An optical microscope coupled with the SFM-QI always demonstrated randomly placed triangular-shaped structures that were grown over the interface of the SiO2 layer of the Si Wafer. We probed the regions at the interfaces of triangularly shaped structures and their edges at the substrate interface, in addition to the regions with the lowest optical contrast in reflected light microscopy, see Fig. 6a. SFM-QI height images were measured at constant setpoint forces at the sample interface during experiments, and height variations were measured at contact points of the tip and sample interface at minimal forces, or undeformed height measurement. It was observed that the triangular structures are pyramidal in topography and contain many stepped terraces, often observed in the case of two-dimensional crystal structures. The smallest step height of the terraces was found to be 0.65 nm from height profiles (Fig. 6b). This value is reproducibly observed throughout the structures and their thinnest step terraces. Furthermore, spherical objects typically larger than 10 nm in height were observed to be occasionally present at the edges of terraces and triangular structures at the substrate. The thinnest layers found over the substrate were found to have a height of 1.35 nm (Fig. 6c) which is twice the thinnest terrace steps observed at the interface of larger triangular structures; these thin layers are also seen with the lowest reflection contrast through the optical microscopes. We assign the experimentally obtained 0.65 nm height of terraces observed in SFM height images to the thickness of a single layer WS2 sheet. Therefore, the 1.35 nm of the thinnest layers observed at the immediate substrate interface implies a double-layer WS2 (Fig. 6f). Moreover, SFM-QI (Fig. 6d, e) and SFM-TM modes provide evidence that the thinnest film grown by the method introduced in this study is much thinner than other studies employing CVD growth methodology, which often is 1.9 nm (~ 3 WS2 layers ) at the substrate interface77.

(a) Optical microscope image of the location of the flakes with minimal contrast of SiO2 layer on Si wafer, (b) SFM-TM height image of the pyramidal layered flakes assigned to WS2. (c) Height profile line as shown in (b), each step is 0.6 nm. (d) SFM-QI Pull off or Adhesion force image at the edge area of the flakes with low optical contrast. (e) SFM-QI height image of the edge of the flake seen as low contrast in the (a). (f) Height Distribution of the rectangular area seen in (e), showing the height of the low optical contrast area to be 1.35 nm, which is assigned to a bi-layer structure of the WS2 at the SiO2 layer of the Si wafer.

Morphological analyses by FESEM

Figure 7 illustrates the surface morphology of deposited thin films of WS2 and P-doped WS2 deposited on the substrates. FESEM images reveal that WS2 and WS2/P are uniformly grown on SiO2 substrate. Figure 7a, b show WS2 films, while Fig. 7c, d display WS2/P films with 10 mg of phosphorus. These images illustrate that the grown WS2 flakes exhibit a triangular shape, consistent with findings by Neileth et al.78. Additionally, the FESEM images indicate that the size of the triangles slightly increases after phosphorus doping, potentially providing a higher specific surface area and exposing more reaction sites for catalysis61. Furthermore, the thin films deposited on the substrates exhibit noticeable color contrast compared to bare substrates.

The Energy Dispersive X-ray spectroscopy (EDX) is a great tool to determinate the chemical constitution of unknown materials by identifying characteristic peaks in the EDX spectrum. In Fig. 8a, b, the EDX spectra of WS2 nanoflakes are presented both before and after phosphorus doping, with an amount of 10 mg. These images provide significant information regarding the distribution of elements across the surface of the nanoflakes. The EDX results verify the homogenous distribution of W, S, and P elements. Specifically, for WS2, the atomic percentages of W and S are measured at 33.59% and 66.41%, respectively. Upon phosphorus doping (WS2/P), the atomic percentages of W, S, and P are recorded as 32.96%, 65.77%, and 1.28%, respectively. The detailed elemental mapping in Fig. 8c, d further elucidates the spatial distribution of these elements. Notably, both WS2 and WS2/P exhibit uniform dispersion of W, S, and P, underscoring the successful incorporation of phosphorus into the nanoflakes, matrix. This thorough characterization enhances our understanding of the structural and compositional properties of the catalysts, laying the groundwork for further analysis and optimization in HER applications.

UV–Vis analysis

The investigation of semiconductor optical properties involves the analysis of UV–Visible absorption spectra within the wavelength range of 400–900 nm. In the optical absorption spectra presented in Fig. 9a, distinctive absorption peaks are observed for WS2. These peaks, located at 533 nm (2.33 eV) and 647 nm (1.92 eV), relate to the transitions from the spin-split valence band to the conduction band and d–d type transitions at the center of the Brillouin zone, respectively79,80,81. With phosphorus doping, these absorption peaks have a blue-shift to 526 nm (2.36 eV) and 636 nm (1.95 eV). This blue-shifting phenomenon, conventionally associated with the quantum confinement effect, is indicative of the modified electronic structure in P-doped WS281. Furthermore, it should be noted that in the case of P-doped WS2, peaks are considerably suppressed, which can be explained by a lower transitional possibility due to the creation of phosphorus atoms in the WS2 lattice.

Influence of phosphorus doping on WS2 I-V characteristics

The impact of phosphorus doping on the WS2 films is evident from the I-V characteristics analysis. Figure 9b illustrates the distinctive I-V curves of the WS2 and WS2/P captured under dark conditions. These curves depict the electrical behavior of the materials, showcasing their current-voltage characteristics. WS2/P exhibits a notably higher current compared to WS2, indicating an enhanced electrical performance induced by the phosphorus doping. This enhancement in current flow suggests an improvement in the electron mobility within WS2/P, a crucial factor contributing to its enhanced catalytic activity for the HER. This difference in behavior of current observed for WS2 and WS2/P treated manifests itself as a signature of the huge impact that phosphorus doping may have on the electrical properties of the film, thus motivating its potential use in various applications.

Electrochemical characterization

The HER performance of both WS2/P and WS2 catalysts was investigated under N2-saturated acidic media using a standard three-electrode setup. Figure 10a presents the linear sweep voltammograms (LSVs) of P-doped WS2 and WS2 films, acquired at a scan rate of 5 mV.s−1. Comparative analysis reveals that WS2/P exhibits outstanding catalytic activity for HER. Specifically, to attain a current density of 10 mA.cm−2, WS2/P requires an overpotential of 245 mV, which is smaller compared with that of WS2 (375 mV), obviously reflecting its superior catalytic performance. This enhanced electrocatalytic activity is primarily attributed to the doping with phosphorus. To emphasize the excellent HER properties of the synthesized electrodes, we compared the overpotential values (j = 10 mA.cm−2) of various nanostructured WS2. The results indicate that 1-T WS2 exhibits a lower overpotential compared to the 2-H phase. Additionally, based on microscopic images and morphological analysis, we synthesized the 2-H structure, which demonstrates a lower overpotential than previous reports concerning this structure (Table 1).

Tafel plots were derived from their corresponding LSV curves for further insight into the catalytic kinetics, as depicted in Fig. 10b.

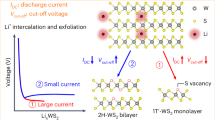

The Tafel slope, obtained from the Tafel law expressed as [η = b log(j) + a], provides valuable insights into the electrochemical kinetics of the WS2/P catalyst. In this equation, j represents the current density, η denotes the overpotential, and b signifies the Tafel slope83. The Tafel slope derived for WS2/P is 123 mV.dec−1, which is pretty low in comparison with that of WS2 (225 mV.dec−1). This lower Tafel slope indicates a larger charge transfer coefficient, which characterizes the better charge transfer ability84. Figure 10c indicates that hydrogen can be continuously generated for 7 h in an acidic solution, demonstrating the strong stability of the WS2 and WS2/P catalysts. Throughout the hydrogen production process, WS2/P exhibits a higher current, confirming that phosphorus doping enhances hydrogen production and improves the electrocatalytic properties of WS2. This further verifies the exceptional HER kinetics of WS2/P. As observed, the current reaches a steady state with a time delay. During this period, the current decreases from 10.5 mA.cm−2 until it stabilizes at values for WS2 and WS2/P. This initial decrease in current during the stability test can be attributed to a higher activation energy barrier for the electrochemical reactions occurring at the electrode surface. As the system stabilizes, the current decreases until the reaction kinetics reach a steady state. Additionally, when potential is applied, reactants from the electrolyte may begin to adsorb onto the electrode surface. This adsorption process can temporarily decrease the current until the surface becomes saturated or reaches an equilibrium state. The XRD spectra of the electrodes, both before and after testing, indicated that the peak position around 14.5° did not change significantly, suggesting that the crystalline structure remains unchanged after HER process.

To estimate electrochemically active surface areas (ECSA), cyclic voltammetry (CV) measurements were performed on few-layer WS2 and WS2/P catalysts for calculating double-layer capacitance (Cdl). ECSA can be calculated using the equation ESCA = Cdl/Cs, where Cs represents the specific capacitance62.

The CV test included multiple scan rates between 10 and 100 mV.s−1, within a potential range of 0.1 to 0.6 (V versus RHE). Figure 11a, b demonstrate the performance of the WS2 and WS2/P electrodes at various scan rates, respectively. Departure from the expected rectangular shape indicates that pseudocapacitance contribution can not be excluded, which is likely due to reversible redox reactions where the tungsten oxidation state shifts from + 4 to + 3, associated with the intercalation of electrolyte (H+) ions from the electrolyte into WS2. The curves also reveal that phosphorus doping enhances the current density.

The electrochemical active surface area (ECSA) is assessed by analysis of the CV curves, as shown in Fig. 11c where the slope represents the value of the Cdl, the double-layer capacitance. WS2/P exhibits a linear slope of 0.2 mF.cm−2, which is considerably greater than that of WS2 (0.03 mF.cm−2), suggesting a higher number of active surface sites available for electrochemical hydrogen evolution85. In conclusion, through meticulous adjustment of hydrogen and argon gas flow rates and the precise use of NaCl as a promoter, uniform and continuous synthesis of WS2 few-layers suitable for the HER can be achieved. Additionally, phosphorus doping improves the efficiency of the synthesized catalysts by promoting the development of numerous nanosheet structures on their surfaces, thereby exposing more active sites and improving electrolyte diffusion.

Conclusion

In summary, our study successfully synthesized WS2 and WS2/P layered structures, including occasional mono/few layers, in a single step using the CVD method on SiO2/Si substrates. This work demonstrates their efficacy as catalysts for the HER. The optical images and SEM results show that high-quality mono/few layer WS2 is formed continuously and uniformly. Using an optical microscope coupled with SFM-QI, we found that the thinnest layers on the substrate have a height of 1.35 nm, which is twice the height of the thinnest terrace steps observed at the interface of larger triangular structures. Regarding the optical images and PL spectra of the thin films, it is confirmed that the light brown areas exhibit stronger PL peaks around 635 nm, indicating the presence of monolayer WS2 and WS2/P. Additionally, Raman spectroscopy and XRD measurements confirm the presence of both few layer and monolayer WS2 structures on the SiO2/Si substrates.

Furthermore, we have demonstrated that phosphorus doping can effectively modify the electronic structures of WS2, resulting in remarkable HER catalytic capabilities while minimally affecting its crystalline structure. When comparing WS2/P with intrinsic WS2, we observe a significant enhancement in electrocatalytic performance, with WS2/P exhibiting a notably smaller overpotential of 245 mV versus RHE at a current density of 10 mA.cm−2. This result highlights that phosphorus doping improves the electrocatalytic performance of transition metal chalcogenides for HER applications. Overall, our research provides a new strategy for the systematic design of doped transition metal chalcogenides as effective electrocatalysts for HER, significantly contributing to the advancement of sustainable energy technologies.

Data availability

(1) All data generated or analyzed during this study are included in this published article and its supplementary information files. (2) The Excel datasets used during the current study are available from the corresponding author on reasonable request.

References

Voiry, D. et al. Enhanced catalytic activity in strained chemically exfoliated WS2 nanosheets for hydrogen evolution. Nat. Mater. 12 (9), 850–855 (2013).

Yu, Y. et al. High phase-purity 1T’-MoS2- and 1T’-MoSe2-layered crystals. Nat. Chem. 10 (2018).

Kim, J. et al. Mesoporous Rh nanoparticles as efficient electrocatalysts for hydrogen evolution reaction. J. Ind. Eng. Chem. 96, 371–375 (2021).

Suryanto, B. H. R. et al. Overall electrochemical splitting of water at the heterogeneous interface of nickel and iron oxide. Nat. Commun. 10 (1), 5599 (2019).

Zhuang, Z. et al. Three-dimensional open nano-netcage electrocatalysts for efficient pH-universal overall water splitting. Nat. Commun. 10 (1), 4875 (2019).

Dubouis, N. & Grimaud, A. The hydrogen evolution reaction: from material to interfacial descriptors. Chem. Sci. 10 (40), 9165–9181 (2019).

Kweon, D. H. et al. Ruthenium anchored on carbon nanotube electrocatalyst for hydrogen production with enhanced faradaic efficiency. Nat. Commun. 11 (1), 1278 (2020).

Choi, H. W. et al. Morphology adjustable CoxN with 3D mesoporous structure and amorphous N-doped carbon for overall water splitting. Appl. Surf. Sci. 529, 147177 (2020).

Zhou, X. et al. A review of hollow Pt-based nanocatalysts applied in proton exchange membrane fuel cells. J. Power Sources. 232, 310–322 (2013).

Tran, P. D. et al. Copper molybdenum sulfide: a new efficient electrocatalyst for hydrogen production from water. Energy Environ. Sci. 5 (10), 8912–8916 (2012).

Li, R. et al. Nitrogen doped MoS2 nanosheets synthesized via a low-temperature process as electrocatalysts with enhanced activity for hydrogen evolution reaction. J. Power Sources 356, 133–139 (2017).

Laszczyńska, A. & Tylus, W. Improving the Electrocatalytic performance for the hydrogen evolution reaction in the Electrodeposited Ni-Based matrix by incorporating WS2 nanoparticles. J. Electrochem. Soc. 170 (7), 076502 (2023).

Kumatani, A. et al. Electrochemical imaging correlated to hydrogen evolution reaction on transition metal dichalcogenide, WS2. J. Vacuum Sci. Technol. B 41 (5) (2023).

Han, A. et al. One-step synthesis of single-site vanadium substitution in 1T- WS2 monolayers for enhanced hydrogen evolution catalysis. Nat. Commun. 12 (1), 709 (2021).

Wu, L. et al. Enhancing the electrocatalytic activity of 2H- WS2 for hydrogen evolution via defect engineering. Phys. Chem. Chem. Phys. 21 (11), 6071–6079 (2019).

Ni, Z. et al. Recent advances in layered tungsten disulfide as Electrocatalyst for Water Splitting. ChemCatChem 12 (20), 4962–4999 (2020).

Ganesan, P. et al. Cobalt sulfide nanoparticles grown on Nitrogen and Sulfur Codoped Graphene Oxide: an efficient Electrocatalyst for Oxygen reduction and evolution reactions. ACS Catal. 5 (6), 3625–3637 (2015).

Jing, Z. et al. Nickel-doped pyrrhotite iron sulfide nanosheets as a highly efficient electrocatalyst for water splitting. J. Mater. Chem. A 8 (39), 20323–20330 (2020).

Hao, Q. et al. Dual tuning of nickel sulfide nanoflake array electrocatalyst through nitrogen doping and carbon coating for efficient and stable water splitting. Catal. Sci. Technol. 9 (12), 3099–3108 (2019).

Cai, Z. X. et al. Tailored catalytic nanoframes from metal-organic frameworks by anisotropic surface modification and etching for the hydrogen evolution reaction. Angew Chem. Int. Ed. Engl. 60 (9), 4747–4755 (2021).

Hussain, S. et al. One-Pot synthesis of W2C/ WS2 hybrid nanostructures for improved hydrogen evolution reactions and supercapacitors. Nanomaterials 10, 1597 (2020).

Zheng, W. et al. Light emission properties of 2D transition metal dichalcogenides: fundamentals and applications. Adv. Opt. Mater. 6 (21), 1800420 (2018).

Manzeli, S. et al. 2D transition metal dichalcogenides. Nat. Rev. Mater. 2 (8), 17033 (2017).

Shi, J. et al. Physical properties and potential applications of two-dimensional metallic transition metal dichalcogenides. Coord. Chem. Rev. 376, 1–19 (2018).

Kang, K. et al. High-mobility three-atom-thick semiconducting films with wafer-scale homogeneity. Nature 520 (7549), 656–660 (2015).

Zang, Y. et al. Tuning orbital orientation endows molybdenum disulfide with exceptional alkaline hydrogen evolution capability. Nat. Commun. 10 (1), 1217 (2019).

Niu, S., Cai, J. & Wang, G. Two-dimensional MoS2 for hydrogen evolution reaction catalysis: the electronic structure regulation. Nano Res. 14 (6), 1985–2002 (2021).

Lin, J. et al. Enhanced electrocatalysis for hydrogen evolution reactions from WS2 nanoribbons. Adv. Energy Mater. 4 (2014).

Huang, Y. et al. Publisher correction: atomically engineering activation sites onto metallic 1T-MoS2 catalysts for enhanced electrochemical hydrogen evolution. Nat. Commun. 11 (1), 2878 (2020).

Maslana, K. et al. High catalytic performance of tungsten disulphide rodes in oxygen evolution reactions in alkaline solutions. Appl. Catal. B. 266, 118575 (2020).

Sun, C. et al. N-doped WS2 nanosheets: a high-performance electrocatalyst for the hydrogen evolution reaction. J. Mater. Chem. A 4 (29), 11234–11238 (2016).

Jiang, A. et al. Vanadium doped WS2 nanosheets grown on carbon cloth as highly efficient electrocatalyst for hydrogen evolution reaction. Chem. Asian J. 13 (2018).

Paudel, D. R. et al. Fe and P doped 1T-phase enriched WS2 3D-dendritic nanostructures for efficient overall water splitting. Appl. Catal. B 286, 119897 (2021).

Shi, Z. et al. Phosphorus-Mo2C@carbon nanowires toward efficient electrochemical hydrogen evolution: composition, structural and electronic regulation. Energy Environ. Sci. 10 (5), 1262–1271 (2017).

Zhu, Q. et al. Two-dimensional layered materials: high-efficient electrocatalysts for hydrogen evolution reaction. ACS Appl. Nano Mater. 3 (7), 6270–6296 (2020).

Wang, H. et al. Addressable surface engineering for N-doped WS2 nanosheet arrays with abundant active sites and the optimal local electronic structure for enhanced hydrogen evolution reaction. Nanoscale 12 (44), 22541–22550 (2020).

Wang, S. et al. Ultrastable in-plane 1T-2H MoS2 heterostructures for enhanced hydrogen evolution reaction. Adv. Energy Mater. 8, 1801345 (2018).

Jing, Z. et al. Engineering unique Fe(SexS1-x)2 nanorod bundles for boosting oxygen evolution reaction. Chem. Eng. J. 418, 129426 (2021).

Das, A. et al. Zinc doping induced WS2 accelerating the HER and ORR kinetics: a theoretical and experimental validation. Catal. Today 423, 113921 (2023).

Pan, Y. et al. Enhanced electrochemical hydrogen evolution performance of WS2 nanosheets by Te doping. J. Catal. 382, 204–211 (2020).

Ouyang, C., Wang, X. & Wang, S. Phosphorus-doped CoS2 nanosheet arrays as ultra-efficient electrocatalysts for the hydrogen evolution reaction. Chem. Commun. 51 (75), 14160–14163 (2015).

Huang, F., Jian, J. & Wu, R. Few-layer thick WS2 nanosheets produced by intercalation/exfoliation route. J. Mater. Sci. 51 (22), 10160–10165 (2016).

Li, H. et al. Evidence for charging and discharging of MoS2 and WS2 on mica by intercalating molecularly thin liquid layers. Phys. Status Solidi (A) 221(1), 2300302 (2024).

Lee, S. et al. γ-GeSe: a new hexagonal polymorph from group IV–VI monochalcogenides. Nano Lett. 21 (10), 4305–4313 (2021).

Fu, Q. et al. Controllable synthesis of high quality monolayer WS2 on a SiO2/Si substrate by chemical vapor deposition. RSC Adv. 5 (21), 15795–15799 (2015).

Shan, J. et al. Enhanced photoresponse characteristics of transistors using CVD-grown MoS2/ WS2 heterostructures. Appl. Surf. Sci. 443, 31–38 (2018).

Zhou, J. et al. A library of atomically thin metal chalcogenides. Nature 556 (7701), 355–359 (2018).

Kim, M. et al. High-crystalline monolayer transition metal dichalcogenides films for wafer-scale electronics. ACS Nano. 15 (2), 3038–3046 (2021).

Barbosa, A. N. et al. Straightforward identification of monolayer WS2 structures by Raman spectroscopy. Mater. Chem. Phys. 243, 122599 (2020).

Shen, J. et al. Isomeric compound dendrites on a monolayer WS2 substrate: morphological engineering and formation mechanism. ACS Appl. Nano Mater. 4 (8), 8408–8416 (2021).

Huang, Y. et al. The synthesis of WS2 atomic layers under varying source-substrate distance. J. Phys. Conf. Ser. 1885 (3), 032075 (2021).

Li, S. et al. Halide-assisted atmospheric pressure growth of large WSe2 and WS2 monolayer crystals. Appl. Mater. Today 1 (1), 60–66 (2015).

Shi, B. et al. High-efficiency synthesis of large-area monolayer WS2 crystals on SiO2/Si substrate via NaCl-assisted atmospheric pressure chemical vapor deposition. Appl. Surf. Sci. 533, 147479 (2020).

Xie, Y. et al. NaCl-assisted CVD synthesis, transfer and persistent photoconductivity properties of two-dimensional transition metal dichalcogenides. MRS Adv. 3 (6), 365–371 (2018).

Zhang, G. et al. Synthesis of centimeter-scale WS2 membrane by chemical vapor deposition. J. Mater. Sci.: Mater. Electron. 33 (2022).

Li, X. et al. Role of hydrogen in the chemical vapor deposition growth of MoS2 atomic layers. Nanoscale 7 (18), 8398–8404 (2015).

Kim, H. U. et al. Wafer-scale and low-temperature growth of 1T- WS2 film for efficient and stable hydrogen evolution reaction. Small 16 (6), 1905000 (2020).

Nguyen, T. P. et al. Facile synthesis of WS2 hollow spheres and their hydrogen evolution reaction performance. Appl. Surf. Sci. 505, 144574 (2020).

Schulpen, J. J. P. M. et al. Nb Doping and Alloying of 2D WS2 by atomic layer deposition for 2D transition metal dichalcogenide transistors and HER electrocatalysts. ACS Appl. Nano Mater. 7 (7), 7395–7407 (2024).

Kuraganti, V. T. Heavily-doped multifunctional WS2 semiconductor as an efficient bifunctional electrocatalyst and supercapacitor electrode (2024).

Wang, F. et al. Phosphorus incorporation activates the basal plane of tungsten disulfide for efficient hydrogen evolution catalysis. Nano Res. 15 (4), 2855–2861 (2022).

Sun, L. et al. 1 T-Phase enriched P doped WS2 nanosphere for highly efficient electrochemical hydrogen evolution reaction. Chem. Eng. J. 429, 132187 (2022).

Reyhani, A. et al. Effect of ni, pd and Ni–Pd nano-islands on morphology and structure of multi-wall carbon nanotubes. Appl. Surf. Sci. 253 (20), 8458–8462 (2007).

Gan, Q. et al. Structure and electrocatalytic reactivity of cobalt phosphosulfide nanomaterials. Top. Catal. 61 (9), 958–964 (2018).

Lisitsyn, V. et al. Nanodefects in YAG:Ce-based phosphor microcrystals. Crystals 9, 476 (2019).

Dong, L. et al. Facile access to shape-controlled growth of WS2 monolayer via environment-friendly method. 2D Mater. 6, 015007 (2019).

Madenoğlu, B. et al. CVD growth of monolayer WS2 through controlled seed formation and vapor density. Mater. Sci. Semicond. Process. 93, 158–163 (2019).

Cai, S. et al. Photoluminescence characterization of the grain boundary thermal stability in chemical vapor deposition grown WS2. Mater. Res. Express. 4 (10), 106202 (2017).

Barbosa, A. N. Tungsten disulfide: new approaches for characterization and surface modification (Department of Physics, Catholic University of Rio de Janeiro, 2020).

Kim, M. S. et al. Biexciton emission from edges and grain boundaries of triangular WS₂ monolayers. ACS Nano 10 (2), 2399–2405 (2016).

Mortazavi, S. Z. et al. Micro-photoluminescence spectroscopy of two distinct types of WS2 monolayers using fs-Ti: Sapphire laser under vacuum and ambient conditions and multivariate calibration models. J. Lumin. 263, 119988 (2023).

Li, K. & Wang, W. Effects of substrates on the optical properties of monolayer WS2. J. Cryst. Growth 540, 125645 (2020).

McCreary, K. M. et al. Synthesis of large-area WS2 monolayers with exceptional photoluminescence. Sci. Rep. 6, 19159 (2016).

Zeng, H. et al. Optical signature of symmetry variations and spin-valley coupling in atomically thin tungsten dichalcogenides. Sci. Rep. 3, 1608 (2013).

Shuai, Q. et al. Identifying the number of WS2 layers via Raman and photoluminescence spectrum. In Proceedings of the 2017 5th International Conference on Mechatronics, Materials, Chemistry and Computer Engineering (ICMMCCE 2017) (Atlantis Press, 2017).

Nemes-Incze, P. et al. Anomalies in thickness measurements of graphene and few layer graphite crystals by tapping mode atomic force microscopy. Carbon 46 (11), 1435–1442 (2008).

Romanov, R. I. et al. Thickness-dependent structural and electrical properties of WS2 nanosheets obtained via the ALD-grown WO3 sulfurization technique as a channel material for field-effect transistors. ACS Omega 6 (50), 34429–34437 (2021).

Stand, N., Mendoza, C. D. & Freire, F. L. Synthesis of WS2 by chemical vapor deposition: role of the alumina crucible. Crystals 12 (6), 835 (2022).

Ghorai, A. et al. Highly luminescent WS2 quantum dots/ZnO heterojunctions for light emitting devices. ACS Appl. Mater. Interfaces 9 (1), 558–565 (2017).

Seo, B. et al. Electronic supplementary information (ESI) for preferential horizontal growth of tungsten sulfide on carbon and insight into active sulfur site for the hydrogen evolution reaction (2018).

Hazarika, S. J. & Mohanta, D. Exfoliated WS2 nanosheets: optical, photocatalytic and nitrogen-adsorption/desorption characteristics. Bull. Mater. Sci. 41 (6), 163 (2018).

He, Q. et al. Vertically aligned ultrathin 1T- WS2 nanosheets enhanced the Electrocatalytic Hydrogen Evolution. Nanoscale Res. Lett. 13 (1), 167 (2018).

Jiang, B. et al. Auto-programmed synthesis of metallic aerogels: core-shell Cu@Fe@Ni aerogels for efficient oxygen evolution reaction. Nano Energy 81, 105644 (2021).

Yu, P. et al. Earth abundant materials beyond transition metal dichalcogenides: a focus on electrocatalyzing hydrogen evolution reaction. Nano Energy. 58, 244–276 (2019).

Xie, L. et al. WS2 moiré superlattices derived from mechanical flexibility for hydrogen evolution reaction. Nat. Commun. 12 (1), 5070 (2021).

Acknowledgements

The authors gratefully acknowledge the financial support of Imam Khomeini International University. Dr. Mohammad Fardin Gholami and Prof. Dr. Jürgen P. Rabe acknowledge the support of the Cluster of Excellence “Matters of Activity. Image Space Material” funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) under Germany’s Excellence Strategy—EXC 2025-390648296.

Author information

Authors and Affiliations

Contributions

1. Elham Rahmani: Conducting experiments and writing the article. 2. Ali Reyhani: Supervisor1, presenting the initial idea and guidance in conducting experiments and collaborating in writing and revising the article. 3. Mohammad Reza Khanlary: Supervisor2, revising the article. 4. Seyedeh Zahra Mortazavi: adviser, revising the article. 5. Mohammad Reza Mohammadi and Holger Dau: Doing Raman analyses and revising the article. 6. Mohammad Fardin Gholami, Alireza Beig Mohammadi, Jürgen P. Rabe: Doing AFM analyses and revising the article. 7. Mehrdad Zarabadipoor: Collaborate in HER analyses. 8. Majid Soleimani: Collaborate in HER analyses and revise the article.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Rahmani, E., Reyhani, A., Khanlary, M.R. et al. Phosphorus doped few layer WS2 flakes grown by chemical vapor deposition for hydrogen evolution reactions. Sci Rep 15, 6350 (2025). https://doi.org/10.1038/s41598-025-90341-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-90341-4