Abstract

Major exploitation phases in quarries involve stone fragmentation by blasting and crushing. Considering the nature of stone aggregates and their applications in engineering works, technological characterizations are fundamental to the adequate selection of these stone products. The present work aimed to characterize stones with different compositional, structural, and textural aspects in a quarry belonging to the Limeira Intrusion, state of São Paulo, Brazil. Distinct samples of aphanitic stone (basalt), diabase, and two monzodiorites were collected. Routine technological tests were performed to qualify the stone aggregates, aiming at their use in Portland cement concrete and asphalt pavements, as well as to meet the greater commercial demands for coarse aggregate produced by the local mineral industry and railway ballast. The values obtained in the physical-mechanical tests evidence no limitations to the use of these types of stone in engineering works. Alterability was low, which highlights the suitability of the two varieties of stones predominantly found in the deposit (diabase and medium-grained monzodiorite) for use as railway ballast. Growing demand for crushed stone considering the implementation of important transport infrastructure works in the region. The fines generated in diametral compression tests with fast loading rates were also quantitatively analyzed. An increase in fines was observed related to higher strengths. This behavior is corroborated by the literature and also by field observations. Some restrictions were detected in the reaction tests with binders. In the adhesiveness test of coarse aggregate to bituminous coating, all the stones presented unsatisfactory results, although the basalt presented much less detachment from the asphalt binder. The alkali-aggregate reactivity tests proved that only one monzodiorite is non-reactive, and the other lithotypes have an R1 reactivity level. These results are related to the variation in petrographic characteristics. Therefore, technological studies associated with the geological context in quarries with some lateral and vertical heterogeneity are essential to assist in the selection of stony materials most suitable for more specific commercial demands.

Similar content being viewed by others

Introduction

The Limeira Intrusion, located in the central-eastern region of the state of São Paulo, Brazil, has been mined for over 40 years, with two quarries producing aggregates whose main demands are concrete and paving. This intrusion is correlated with the Mesozoic basaltic flows of the SGF Serra Geral Formation that are part of the PMP Paraná Magmatic Province. The origin of the PMP is related to the rupture of Gondwana and the opening of the South Atlantic Ocean, resulting in over 600,000 km³ of lava and many associated intrusive bodies1.

Due to the extensive area of occurrence in Brazil, important infrastructure works, such as dams, highways, and railways, for example, were implemented in basaltic rock masses and/or used SGF stones as construction material. Therefore, these materials have been studied from the perspective of engineering geology for decades, as exemplified in the literature2,3,4,5 and technical studies6,7,8,9,10. In the case of the Limeira Intrusion, it differs from basaltic flows due to its textural characteristics and, in particular, its geochemical composition, which makes it one of the most differentiated SGF intrusive bodies, containing up to 55% silica11.

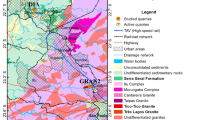

According to Faria12 and Santos13, the Limeira Intrusion Fig. 1A) is composed of a wide lithological variety including aphanitic stones, diabases, monzodiorites, and quartz-monzodiorites, associated with fractional crystallization processes, intruded into sandstones and siltstones of the Itararé Sub-Group. Rhyolite and rhyodacite veins cutting the monzodiorites are also typical, representing the portions originated by hydrothermalism. Regarding the geometry of the intrusive body Fig. 1B, C), it is referred to as a lopolith14.

Regardless of the genesis or form of occurrence of these rock masses, from a geotechnical perspective, the structural features are related to the presence and type of discontinuities, spatial orientation, and spacing, as well as to the characteristics of the intact rock such as mineralogy, texture, degrees of alteration and microcracking, mechanical strength, alterability, that together define their technological quality. Therefore, two fundamental aspects must be highlighted, although sometimes neglected in engineering practice: (i) the geological-structural evaluation of a quarry must precede the sampling and technological testing stages; (ii) there is no homogeneous rock mass, but rather one with greater or lesser geological variability. In other words, every study must begin with a detailed geological description of the quarry, especially the heterogeneities of the rock mass in terms of exploitable stones.

Concerning rock masses intended to produce aggregate for use in engineering works, their structural conditioning determines the adjustments and efficiency of the blasting and crushing stages. However, the properties of the intact rock significantly influence the quality of the crushed products. Due to their importance, these cause-and-effect relationships associated with geological variability and performance in use, respectively, have been extensively studied15,16,17,18,19. Other examples20,21 report deterioration of stone aggregates used in engineering works, caused by inadequate or insufficient in situ investigation of the diabase quarries studied. Since they provide consistent data on the geotechnical variability of the quarry in terms of the distribution and quantity of materials, the investigations guide the sampling of the stones for their qualification using laboratory tests.

(A) Geological context of the study area, (B) Google Earth satellite image with visited field points (https://earth.google.com/web/search/pedreira+basalto+4+limeira+sp/@-22.61573785,-47.35788902,464.90719386a,1434.78509095d,35y,360 h,0t,0r/data=CiwiJgokCZHUXk1nnDbAEdfTqHqxnjbAGcqyf6dyrEfAIfEHBVjyrkfAQgIIAToDCgEwQgIIAEoNCP___________wEQAA), (C) Illustration of geological profiles of the Limeira Intrusion (SP), modified from12.

With regard to the basic stones of the Sill Whin in the United Kingdom, field and laboratory investigations22,23 indicated that hydrothermal processes were responsible for the decline in the quality of some geological materials studied for use as aggregate. In the case of the Prospect Hill laccolith mined in a quarry in Australia24,25, detailed field inspection of the magmatic differentiation processes of the rock mass supported its exploitation via selective mining and careful blending of the materials to produce aggregates with appropriate qualities. In other words, a geological-geotechnical investigation should well represent the heterogeneity of the rock mass and, thus, allow an adequate evaluation of stones for quarrying and the optimization of the necessary investments in the deposit26,27,28, including more specific studies of stones in the production of aggregates aiming at a more rational exploitation of natural resources and minimization of environmental impacts resulting from these mining activities29,30,31.

Based on these premises, the main focus of this work is related to the physical-mechanical, chemical-mineralogical, and textural properties of different stone materials in terms of the notable geological variability characteristic of an active quarry in the Limeira Intrusion, with emphasis on the studies of stone aggregates in a geotechnical context of their performance in engineering works demands, notably in hydraulic concrete, paving and also as railway ballast.

Materials and sampling

The industrial processes of blasting and, especially, crushing adopted do not take into account the geological variability existing in the studied quarry. Therefore, field observations and descriptions were made in the mining fronts where stones are exploited for various engineering applications to define the portions of the rock mass with the best quality, that is, those with a low degree of weathering and hydrothermal alteration Fig. 2). In terms of the properties of intact rock, emphasis was placed on sites with ample exposure of the fresh rock. Subsequently, new observations allowed the selection of the sectors for the collection of blocks and irregular fragments of the dismantled material, based on the three most representative lithotypes of the quarry, namely an aphanitic stone, a diabase, and monzodiorites of different grain sizes32.

The APH aphanitic stone Fig. 2A-B) is petrographically characterized by a very fine-grained, aphanitic, rim basalt that occurs in bands of 1 to 3 m in contact with sandstones of the Itararé Sub-Group. Underlying the aphanitic material, there are DIA dia-bases Fig. 2C-D) with fine to medium phaneritic texture, up to approximately 30 m from the edges of the geological body. Their central (innermost) portion is composed of medium to medium-coarse-grained monzodiorites (MONM and MONMC) and crossed by thin (mm to cm) frequent rhyolite veins, the latter being more common in the coarser terms Fig. 2E-F). The quartz-monzodiorite lithology, which occurs at greater depths, as in the neighboring quarry, was not observed in the field.

Details showing the careful inspection of mining fronts of the quarry in terms of sample representation for technological testing: (A) Face “East” showing contact between dark aphanitic stone and (light) siltstones of the Itararé Sub-Group, (B) Detail of irregular block of aphanitic stone; (C) Face “North”: partial view of bench exposing diabase: note in the foreground the blocks of stone collected; (D) Observe fine phaneritic texture typical of diabase; (E) Face “South”: bench showing rock mass with more pronounced fracturing pattern; (F) Detail of MONMC monzodiorite typically crossed by aplitic veins.

Crushed stones were produced in a laboratory to establish the exact origin of the material, which is different from what occurs in industrial-scale crushing in quarries, which contain mixtures of stones with different qualities due to the heterogeneities presented by the rock mass. After crushing, the materials were sieved, homogenized, and quartered, with aliquots separated for mechanical and accelerated alteration tests with sodium sulfate/ethylene glycol and binders (adhesiveness and alkali-aggregate reactivity). The selected stone blocks, measuring approximately 40 × 40 cm, were also taken to the laboratory to obtain cylindrical test specimens using a diamond drill (external diameter of 63.5 mm and internal diameter of 56.2 mm) cooled with water, to determine uniaxial and diametral compressive strengths.

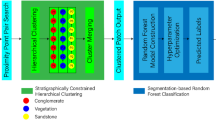

The methodological flowchart is illustrated in Fig. 3: (I) Geological field recognition to define the quarry sector to be studied; (II) Collection of stone samples in desmantling fronts (blocks and irregular fragments), laboratory preparation of aggregates, petrographic analysis and determination of physical indices; (III) Determination of the values for mechanical properties (UCS Uniaxial compressive strength, BTT Brazilian tension test, LAA Los Angeles abrasion, MD Micro-Deval abrasive wear, T Treton toughness index and ACV Aggregate Crushing Value, alterability (SSA Soundness by use of sodium sulfate and EG ethyleneglycol) and binder reactions tests (AA Adhesion to asphalt and AAR Alkali aggregate reactivity); (IV) Integrated assessment of data obtained in technological characterization.

Test methods

Petrographic analyses, physical-mechanical testing procedures, alterability, and binder reactions tests followed the guidelines of the ASTM American Standard Testing Materials38,41, ABNT Brazilian Association of Technical Standards33,34,38,40,41,43,44 and ISRM International Society for Rock Mechanics and Rock Engineering35,36. Tables 1 and 2 present the synthesis of these tests and their respective technical standards, type/amount of sample, and execution procedures.

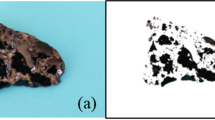

During the dismantling and crushing stages for aggregate production, crushed stones of various particle sizes are produced, including “fines” (with a diameter smaller than 4.75 mm), sometimes in excessive amounts that require quantitative studies on the particle size ranges resulting from the process. For these estimates, the present study also investigated the production of fines in diametral compression tests with fast loading rates, lasting around 10 and 20 s46,47, different from the conditions established by the ISRM (Table 1). The loading rates (7 and 3.5 kN/s APH and DIA; 5 and 2.5 kN/s MONM and MONMC) were previously tested on pilot specimens. A plastic package was used to cover the experimental apparatus to collect the fragments resulting from the ruptures Fig. 4). After the tests were completed, the fragments with diameters of 4.75 mm were sieved, resulting in mass loss rates for each sample.

The technological characterization of the two most frequent and representative lithologies of the quarry, DIA diabase, and MONM medium-grained monzodiorite, included complementary tests, notably Los Angeles abrasion (Graduation F: particles ranging from 50 to 25 mm) and accelerated alteration with immersion cycles in ethyleneglycol followed by drying in an oven. Thus, it is understood that they were duly evaluated concerning their use also as railway ballast.

Results and discussions

The results of the tests performed are presented following the order of the methodology used in the study.

Petrographic analysis and physical indices

Petrographic studies were essential for identifying primary and hydrothermal mineralogy, texture, granulation, degrees of microcracking, and stone alteration, among other geological information about the studied stones. The main macro- and microscopic features observed using this important method of technological characterization of stone aggregates are presented in Table 3 and Fig. 5.

The APH basalt presents, texturally, very fine-grained crystals with hypocrystalline character and plagioclase and augite phenocrysts immersed in a glassy matrix with low crystallinity minerals, and hydrothermal alteration can be observed in the phenocrysts. As shown in Fig. 5A, the matrix is formed by volcanic glass, opaques, and alteration minerals (saussorite, carbonate, and chlorite/smectite), with clear late to post-magmatic hydrothermal alteration processes in this stone. The DIA diabase occurs as a transition material from APH to the MON monzodioritic core of the intrusion. It exhibits dark gray coloration, massive and phaneritic, with holocrystalline character, and with euhedral to subhedral plagioclase crystals dominant in the stone matrix and smaller minerals in its surroundings constituting the intergranular texture. Hydrothermal alteration in DIA diabase is less intense than in APH, marked by partial replacement of augite with chlorite/smectite aggregates, saussuritization, and albite exsolutions in plagioclase Fig. 5B).

The MONM monzodiorite occurs as the main lithology, considering the current configuration of the studied quarry. It is massive, with a phaneritic texture and grain size ranging from fine to coarse Fig. 5C-D). In the case of MONMC monzodiorite, it is crossed by veins ranging from mm to cm of rhyolitic composition, consisting of holocrystalline stones, with very fine to fine-grained texture (crystals up to 0.5 mm), and essentially quartz-feldspathic matrix Fig. 5E). The hydrothermal alteration in MONMC is less intense and non-pervasive. However, in the portions connected to the aplitic veins, normally composed of quartz, albitized plagioclase, and completely chloritized pyroxenes, forming chlorite and hornblende, hydrothermalism is intense Fig. 5F).

Photomicrographs (A to D crossed and E-F parallel nicols): (A) Details showing hydrothermal processes and devitrification in the aphanitic stone APH; (B) Mineralogical matrix of the DIA diabase affected by hydrothermal alteration in the clinopyroxene and plagioclase crystals. References in Table 3 (Gls, Pl, Cpx, Op); (C, D) Intergranular texture with trans- and intramineral fissures in the MONM and MONMC monzodiorites; (E, F) Details showing the aspect of the vein with quartz-feldspathic composition and very fine-grained, and chlorite/smectite agglomerates, and alteration processes (Ssz + Alb) at the interface between the MONMC and the rhyolite vein.

In the context of the variations in the mineralogical, textural, and structural components of the studied stones, together with the chemistry reported in the literature, they are related to the magmatic differentiation processes that occurred mainly through fractional crystallization in terms of the evolution of this igneous body in the Limeira Intrusion11,13,14. This is essential knowledge for a better understanding of the possible behaviors of stone aggregates produced on an industrial scale for use in engineering works.

Regarding late-magmatic (hydrothermal) phases, the processes of expulsion of differentiated liquids in the solidification phases may have originated the aplitic veins, in addition to promoting mineral alterations and replacements, such as the chlorite aggregates that occur in all the stones of the intrusion12. These aggregates are associated with the partial or total replacement of clinopyroxene crystals, the replacement of the glassy matrix, causing devitrification in the APH stone. In the case of plagioclase, albitization occurs, mainly in the stones with larger grain sizes in the central portion of the intrusion, such as the MONMC monzodiorite.

Table 4 presents a summary of the results that comprise the physical properties, which are directly related to the petrographic characteristics, such as mineralogical composition, texture, structures, and crystal size of the four magmatites studied.

The stones presented high apparent specific gravity values and porosity below 1%. These are typical for crystalline rock materials, with a low degree of weathering and with specific microcracking conditions, i.e., materials that are physically good and satisfactory for stones in applications as aggregate. Even so, some nuances affect the manufacture of asphalt concretes, mainly due to the increasing content of felsic minerals as the distance from the intrusion edge increases. This geological variation results in changes in the dry apparent specific gravity between the lithotypes tested, making this property important in the planning and operations of the industry, converging with the latent need for geological zoning in the quarry to meet an increasingly demanding consumer market.

Mechanical properties

Table 5 summarizes the test results that comprise the mechanical properties. The intact stone properties reflected the characteristics of materials with relatively high strength and stiffness. The results demonstrated a downward trend in the uniaxial compressive strength and indirect tensile strength for the stones with larger grain sizes, because of the increase in crystal size. The APH basalt proves to be an extremely resistant stone, even considering the heterogeneities of the material that presents microcracks, related to the hydrothermal mineralogical phases, while the other three lithotypes are considered very resistant stones. For the DIA diabase, the strength compared to the finer-grained stone (APH) is lower, which is expected since it is a fine-grained holocrystalline stone. In terms of strength values, MON monzodiorites do not show major changes in the results obtained; they are materials with very similar behavior, showing very consistent values since they are stones with the same textures and slightly varied grain sizes.

The modulus of elasticity (E) and Poisson’s ratio (ν) vary less, showing a certain inclination towards lower deformability as the grain size increases. In any case, the materials have very high stiffness, presenting moduli of elasticity above 100 GPa. The Poisson’s ratio of the APH basalt is lower mainly due to the difference in crystal size since it is composed partly of glassy material and has a large part of minerals arranged in a very fine matrix. In comparison, the DIA diabase has crystals between 0.5 and 1 mm and is, therefore, more prone to the opening of microcracks, which causes greater radial expansion of the test specimen. Further, towards the center of the geological body, MON monzodiorites can even have coarse minerals (> 5 mm), making it plausible that greater deformations occur on the lateral faces of the test specimens. The values for both monzodiorites present small differences and are close to those of DIA diabase.

Regarding the accelerated BTT tests, at rates of 7 to 5 kN/s, ruptures in less than 10 s, the BAS showed a greater gain in strength and greater production of fines than the other lithotypes Fig. 6A). There is a tendency for correlation between the values of the LM 4.75 mm index and the strength values (R2 = 0.56), with the best-fitting curves obtained by exponential equations, indicating that the higher the loading rate, the greater the amount of fines produced. On the other hand, at rates of 3.5 and 2.5 kN/s, ruptures in less than 20 s, there was no clear differentiation in the production of fines between the lithotypes, but a similar trend in the results can be seen, with greater strength and greater production of fragments smaller than 4.75 mm Fig. 6B).

The production of fines during fast BTT depended on the loading rate used. In general, at higher rates, 7 to 5 kN/s, compared to lower rates, 3.5–2.5 kN/s, there was a greater production of materials passing through sieve 4 (4.75 mm), as illustrated in Fig. 7. These results are in agreement with those indicated by other authors44,45 and also by field observations, where more resistant stones generate more fragments in tensile tests when loaded at high rates.

Similarly, the results of the geomechanical properties of intact stone, the tests on aggregates demonstrated the same excellence for the study applications. The LAA tests, a widespread routine method for characterizing aggregates that essentially evaluate the durability of rock fragments under friction and impact stresses, were performed in three particle size ranges (B, C, and F). The results of the LAA indices also prove the quality of the materials, with small percentages of mass loss (11.8–17.4%).

The results of mass loss by the Micro Deval test were less than 10%. The values of the particle size range B were higher than range A but were below any limit of the American standard D692839, not limiting the use of these materials in any application. As previously observed in other mechanical tests, these results indicate a downward trend in strength for stones with larger grain sizes. Even though the MONM monzodiorite presented less mass loss than the MONMC, which has relatively larger crystals, this may also be influenced by other variables such as the heterogeneity of the crushed stone tested. Given the surface wear the test promoted in the stone fragments, the roughness of the aggregates was greatly altered, so that the crushed stone at the end of the test had practically smooth surfaces with few irregularities, that is, without angular edges (Fig. 8). This behavior is corroborated in experiments by other authors55.

The Treton impact test is widely adopted to qualify ballast materials, as it fragments the aggregates with successive drops of a hammer, a situation similar to dynamic loading on railways. Therefore, it is a very aggressive test. The APH basalt has a lower index than the coarser-grained stone (6 and 13.4%, respectively), and this is the test that shows the greatest influence of texture and particle size on the results.

Regarding the crushing test, the stony materials tested showed low mass loss rates (11.5–14.6%), once again proving the excellent quality of the materials. The results were very similar (Fig. 9), and the resistances are directly correlated with the grain size of the stones, i.e., stones with finer crystals are more resistant.

LAAB, C Los Angeles abrasion in grades B and C, MDA, B Micro-Deval abrasion in grades A and B; T: Treton impact strength; ACV: abrasive crushing value. In dashed lines, limits recommended by standard.

Alterability and binder reaction tests

In order to evaluate the performance of materials in applications in concrete (hydraulic and asphalt), base and sub-base, and railway ballast (in the case of DIA and MOMM), the tests below are essential and may present results that indicate the need to use additives to improve the stability and durability of the materials in question. Table 6 presents a summary of the test results that comprise the properties of alterability and binder reaction tests.

The results of the durability in sodium sulfate solution for the APH basalt indicate very low loss values (0.68%), just over 1% for the DIA diabase. In the case of the MONM and MONMC monzodiorites, the difference in this test is more evident, with a tendency towards lower strength in the case of MONMC, which presented the highest total corrected loss, 2.01%. In general, the results were relatively low and followed a trend of greater changes in stones with larger grain sizes. There is also a direct relationship in water absorption since this test saturates the aggregates in sodium sulfate solution. At a more detailed level, macroscopic aspects of mass losses were observed with some ease (Fig. 10) only in the cycling of samples 19–9.5 mm of the MOMMC monzodiorite (loss of 1.63% in the aforementioned grain size range).

Regarding the immersion of the most common stones in the quarry in ethyleneglycol, both the DIA diabase and the MONM monzodiorite showed no visible modifications, with very low mass losses (1.8% and 0.49%, respectively), probably because DIA is a stone with a compact texture and also little porosity, in addition to both having mineralogical composition and alteration products that tend not to react with ethyleneglycol. From the alterability point of view, such aspects are important when considering the potential use of these stones as aggregate without binders, as is the case for railway ballast. For comparison purposes, other materials exploited in quarries with certain geographical proximity, Terra Nova granite (13.3% SSA)56, basic intrusives (41.0% EG)57, and basalts related to the SGF (10.5% EG)58 are examples of stones that indicated high rates of mass loss in accelerated alteration tests, even exceeding normative recommendations. This fact gains relevance taking into account the progress of relevant railway infrastructure projects for passenger transport in the eastern region of the state of São Paulo, the richest in Brazil.

On the other hand, the tests in the presence of binders clearly showed certain behaviors that require greater care. Regarding the adhesiveness of coarse aggregates to the bituminous binder, the results for all lithotypes were unsatisfactory, so there were displacements of binders in all cases. It is worth noting that this test includes a visual assessment43, that is, if any part of the aggregate surface fails to adhere properly to the binder, the material is classified as unsatisfactory. Anyway, in the case of the APH basalt, there was better adhesion to the binder than in comparison to the other materials studied (Fig. 11). This is mainly due to the mineralogical composition of the stones, but textural and crystal size differences were also noted. Just as the chemical classification of the stones should also be considered, data from other studies corroborate these results, since it is known that intermediate and/or acidic stones tend to present worse adhesion to the binder58,59. In engineering practice, the asphalt cement chosen for testing is typically the one intended for use. If necessary, adjustments such as doping for enhanced adhesion are also considered, especially if the stone materials previously showed unsatisfactory results. It is important to note that when these materials are used in road paving, their performance can vary based on the binder that is used. Therefore, without proper differentiation or homogeneous application, they may behave unpredictably.

In terms of the use of crushed stone for the manufacture of Portland cement concrete, a property that gains relevance is the alkali-aggregate reactivity58,59,60,61,62. In the present study, this property was evaluated by the accelerated test method44,45. Figure 12 illustrates a comparative overview of the average expansion of mortar bars up to the age of 30 days, tested by the accelerated method, and the APH, DIA, and MOMM samples showed a potentially reactive behavior, with expansions above the limit of 0.19% established by NBR 15577-4 standard44.

The comparative evaluation of the AAR tests shows a certain contamination by deleterious minerals. In the case of the MONMC monzodiorite, this was caused by the presence of aplitic veins, which contain microcrystalline quartz, a reactive mineral. The results observed for this lithology were those of greater expansion in the mortar bars. However, considering the essential (primary) mineralogy of the stone material in question, no other reactive phases were identified. Regarding the more internal magmatites of the intrusion, the MONM monzodiorite did not present a mineral phase considered to be at risk for AAR, and the same behavior was observed in the expansion profile of this stone in the test (innocuous to AAR). These analyses related to the two stones at the center of the intrusion show that the possibility of contamination of MONMC by reactive minerals may reach a significant part of the rock mass. This is due to the distribution of aplitic veins that occur from the transition edge (diabase) to the intrusion core14, therefore this hypothesis requires attention regarding the use of crushed stone for the manufacture of concrete.

The APH basalt, which mainly presents the glassy matrix considered as a potentially reactive mineralogical phase, has a positive result for the possibility of AAR in the mortar bar tests. In the DIA diabase, which had the same result of expansion above the limit of 0.19%, no minerals that could react with Portland cement alkalis, producing expansive gel, were microscopically identified. Other researchers58 also analyzed stones that presented behavior similar to diabase, without presenting reactive minerals in petrographic analysis and with positive results in accelerated tests. According to these authors, the AAR tests might not solely assess the expansion of mortar bars from expansive gel formation. They might also capture the swelling of smectite clay minerals due to water absorption. Thus, there is a need for more detailed petrographic and mineralogical analysis of the clay minerals present in the stone.

In summary, only the MONM monzodiorite had a negative result for this test, considered potentially innocuous with grade R0, therefore the only material without restrictions in any concrete with this aggregate. The APH basalt, the DIA diabase, and the MONMC monzodiorite were classified as grade R1 and potentially reactive. Given this information, some mitigation methods have been suggested44,64 but the potential reactivity of these stones should be reassessed using the accelerated concrete prism method (in 90 days) and the long-term concrete prism method (1 year), which are well-documented in the literature65,66,67,68. In general, this research indicates the need for extended testing for ARR in concrete used for specific applications, particularly in environments with high exposure to water. Thus, as in the adhesion studies, these results emphasize the need for differentiated application of stony materials or stone homogenization.

Conclusions

The geological, petrographic, and laboratory studies aimed at the technological characterization of stones from different facies from the studied quarry that is part of the Limeira Intrusion (São Paulo State, Brazil) allowed considerations to be made regarding the qualification of these stones. This investigation emphasizes the critical role of selecting and using materials that meet engineering and construction standards. These insights are essential for choosing suitable aggregates for civil engineering applications.

These studies were contextualized with genetic models of the rock mass, providing an understanding of the variation in the properties of the main lithologies mapped in the pit exposures. Two key geological processes were observed: fractional crystallization and late-magmatic hydrothermalism. Some of these magmatic differentiation processes were identified in the field and confirmed by petrographic analysis, and these processes largely contribute to the differences in technological properties of the main lithologies. Therefore, they play a crucial role in interpreting the results and drawing correlations between the results of an intense sequence of technological tests carried out. The main highlights are:

-

In terms of the physical properties of stones, technological differences are mostly related to the content of ferromagnesian minerals they contain. Stones in the edge (APH) and transition zone (DIA) usually show higher apparent specific gravity. Despite these minor variations in the values obtained, they are decisive in the type of stone used and the dosage of materials in the asphalt plant. This underscores the need for geological contextualization in aggregate characterization tests. While obtaining physical measurements from the rocks is straightforward, without insights into their petrographic makeup and origin, the data lacks the depth needed for meaningful industry application.

-

The mechanical and alteration properties of the stones were evaluated and found to have good to excellent indices. These rocks are characterized by high strength, fine to medium grain sizes, and specific textural properties, such as grain size and microcracking conditions, combined with low porosity, which influence the results in the main technological tests. Among all stones examined, those with the highest representation in the rock mass (DIA and MOMM) are particularly suitable for use as railway ballast. This suitability is especially relevant considering the advancement of important government projects that focus on railway infrastructure for passenger transport in São Paulo, the wealthiest state in Brazil.

-

The tensile strength of stones in the studied quarry is significantly influenced by their mineralogical and textural characteristics, especially the grain size variations. The APH stone, characterized by its very fine-grained aphanitic structure, showed a strength of 15.3 MPa, whereas the MONMC had a result of 12.7 MPa, both typical average values according to standard Brazilian methods. In rapid ruptures of up to 10 s, the effect of grain size increases, differentiating the strength values of the stones. The initial strength difference of 2.6 MPa increased to 7.8 MPa, suggesting a relationship between mineralogical properties, loading rates, and strength results. As loading rates escalate, the production of fines also increases due to higher rupture rates, leading to a greater post-rupture load. These findings offer valuable insights that could enhance the study of fines production during the crushing phase, where the characteristics of the intact rock are of significant importance.

-

The aggregates from the quarry studied are mainly used in hydraulic and asphalt concretes. Therefore, it was crucial to examine how binders interact with these stones. This investigation highlighted the potential necessity for additives to improve the adhesiveness (in asphalts) and mitigate possible AAR. To achieve this, more detailed control of the dismantling and processing stages in the field is required. The minerals reactive with Portland cement are volcanic glass and quartz (apophase) from rhyolite veins, and it is worth emphasizing that the reactivity of the stones is directly related to the concrete, especially concerning its environmental exposure. Additionally, the adhesiveness depends on both the mineralogical composition and the grain size of the stones.

-

In this sense, there are several promising avenues for future research, including conducting further long-term testing, such as concrete prism tests, and developing strategies to address issues related to AAR and adhesiveness issues.

-

In the case of other intrusive geological formations22,23, no unsatisfactory resistances resulting from magmatic differentiation processes were detected. Nevertheless, results from AAR and adhesion tests indicate that the stones found in the Limeira intrusion possess unique characteristics. Similar to the approach suggested for the Prospect Hill laccolith materials24, options such as blending or selective mining may facilitate their optimal application in hydraulic and bituminous concrete production.

Data availability

All data generated or analysed during this study are included in this published article.

References

Frank H. T., Gomes M. E. B. & Formoso M. L. L. Revisão Da Extensão areal e do volume Da Formação Serra geral, Bacia do Paraná, América Do Sul. Pesquisas Em Geociências 36(1), 49–57 (2009). https://doi.org/10.22456/1807-9806.17874

Frascá, M. H. B. O. Assessment of alterability of basalt used for riprap by petrographic examination. J. Rock Mech. Geotech. Eng. 11(1), 208–213 (2019). https://doi.org/10.1016/j.jrmge.2018.06.009.

Paiva, C. E. L., Pereira, M. L., Ribeiro, R. P. & Santos, R. S. Evaluation of ballast materials used in Brazilian railways based on their resistance to wear. In Proceedings of the International Conference on Road and Rail Infrastructure, CETRA, Zadar: International Road Federation, 1–8 (2018). https://doi.org/10.5592/CO/CETRA.2018.763

Oliveira, P. C., Patias, J. & Zuquette, L. V. A study of the alterability of basaltic lithotypes from the Itaipu dam site (southern Brazil). Bull. Eng. Geol. Environ. 74(4), 1331–1348 (2015). https://doi.org/10.1007/s10064-014-0716-3

Gomes, R. L. & Rodrigues, J. E. Quality ranking of twelve columnar basalt occurrences in the Northern portion of the Paraná Basin—Brazil. Eng. Geol. 91(2–4), 265–278 (2007). https://doi.org/10.1016/j.enggeo.2007.02.004

Marrano, A. & Paraguassú, A. B. Caracterização tecnológica das rochas basálticas da Usina Hidrelétrica Canoas I, rio Paranapanema, SP/PR, Brasil. Solos e Rochas 21(3), 143–164 (1998). https://doi.org/10.11606/D.18.2016.tde-26072016-144438

Frazão E. B. A importância Das características tecnológicas Da Pedra Para Lastro ferroviário. Solos E Rochas 10(3), 11–20 (1987).

Frazão, E. B. & Paraguassu, A. B. Basalts from Três Irmãos Hydroelectric Dam, São Paulo State, Brazil: A review of methodology for alterability evaluation. In International Congress International Association of Engineering Geology, Lisboa, Portugal. v. 5, 3583–3589 (1994).

Andriolo, F. R., Sgarboza, B. C. & Saad, M. N. A. The use of unsound basalt as concrete aggregate. Bull. Eng. Geol. Environ. 30(1), 171–175 (1984). https://doi.org/10.1007/BF02594302

IPT. Caracterização tecnológica do material rochoso do lastro dos trechos Gal. Luz (RS) – Lages (SC) e Mafra (SC), Ponta Grossa (PR). Instituto de Pesquisas Tecnológicas do Estado de São Paulo. Relatório nº 8300 (1975).

Machado, F. B., Nardy, A. J. R., De Melo, R. P., De Oliveira, M. A. F. & Squisato, E. As Rochas intrusivas Da Formação Serra geral Na Porção Leste Da Bacia do Paraná no Estado de São Paulo: Aspectos petrográficos e geoquímicos–resultados preliminares. Geociências (SP), 24(1): 5–17. ISSN: 1980900X, 01019082.

Faria, C. A. Evolução magmática do sill de Limeira: Petrografia e Geoquímica, Master’s Dissertation, University of São Paulo) (2008). https://doi.org/10.11606/D.44.2008.tde-04122008-152040

Santos, L. M. A. D. Geometry and stratigraphy of the Limeira tholeiitic intrusion, Paraná¡ magmatic province (SP-Brazil), Master’s Dissertation. University of São Paulo. https://doi.org/10.11606/D.44.2019.tde-21012019-140838

Lino, L. M., Cavallaro, F. D. A., Vlach, S. R. D. F. & Coelho, D. C. 2D magnetometric modeling of a basic-intermediate intrusion geometry: Geophysical and geological approaches applied to the Limeira intrusion, Paraná magmatic Province (SP, Brazil). Braz. J. Geol. 48(20), 305–315 (2018). https://doi.org/10.1590/2317-4889201820180099

Vouffo, M., Tiomo I. D., Fanmi, H. K., Djoumen, T. K. & Ngapgue, F. Physical and mechanical characterization of pyroclastic materials in Baleng area (Bafoussam, West-Cameroon): Implication for use in civil engineering. Case Stud. Constr. Mat. 16, e00916 (2022). https://doi.org/10.1016/j.cscm.2022.e00916.

Yılmaz, A. Engineering properties of basalt aggregates in terms of use in granular layers of flexible pavements. Case Stud. Constr. Mat. 17, e01182 (2022). https://doi.org/10.1016/j.cscm.2022.e01182.

Germinario, L. & Török, Á. Variability of technical properties and durability in volcanic tuffs from the same quarry region – examples from Northern Hungary. Eng. Geol. 262, 105319 (2019). https://doi.org/10.1016/j.enggeo.2019.105319.

Vignaroli, G., Belardi, G. & Serracino, M. Multi-scale geological evaluation for quarrying activities in ophiolitic rocks: Implications for asbestos-related legislation. Bull. Eng. Geol. Environ. 72(3–4), 285–302 (2013). https://doi.org/10.1007/s10064-013-0475-6

Räisänen, M. & Mertamo, M. An evaluation of the procedure and results of laboratory crushing in quality assessment of rock aggregate Raw materials. Bull. Eng. Geol. Environ. 63(1), 33–39. https://doi.org/10.1007/s10064-003-0218-1.

Fookes, P. G. Geomaterials. Quart. J. Eng. Geol. Hydrog. 24(1), 3–15. https://doi.org/10.1144/GSL.QJEG.1991.024.01.02

Fookes, P. G., Gourley, C. S. & Ohikere, C. Rock weathering in engineering time. Quart. J. Eng. Geol. Hydrog. 21(1), 33–57 (1988). https://doi.org/10.1144/GSL.QJEG.1988.021.01.03

Dearman, W. R., Irfan, Y., Money, M. S., Turk, N. & Hussen, T. I. Quality variations in Whin sill aggregates from Northumberland, England. Bull. Eng. Geol. Environ. 29(1), 355–359 (1984). https://doi.org/10.1007/BF02594435.

Dearman, W. R., Turk, N., Irfan, Y. & Rowshanei, H. Detection of rock material variation by Sonic velocity zoning. Bull. Eng. Geol. Environ. 35(1), 3–8 (1987). https://doi.org/10.1007/BF02590472

McNally, G. H. Soil and rock construction materials. (CRC Press, 1988). https://doi.org/10.4324/9780203476574

Minty, E. J. Quarried rocks and products. In: Pells PJN (ed) Engineering Geology of the Sydney Region. E-book. 1st ed. 331–344 (Routledge). https://doi.org/10.1201/9780203757390-16

Atac, B., Deniz, A., Serkan, T. & Alp, B. S. Study of the optimal aggregate blending model for quarries. Environ. Earth Sci. 75(19), 1304 (2016). https://doi.org/10.1007/s12665-016-6126-z

Dalgic, S. Effects of geologic conditions on rock quarry operations, Istanbul, Turkey. Environ. Eng. Geosci. 12(4), 315–329 (2006). https://doi.org/10.2113/gseegeosci.12.4.315

Räisänen, M. & Torppa, A. Quality assessment of a geologically heterogeneous rock quarry in Pirkanmaa County, Southern Finland. Bull. Eng. Geol. Environ. 64(4), 409–418 (2005). https://doi.org/10.1007/s10064-005-0006-1

Jamshidi, A. A laboratory study on the durability of limestone wastes in harsh environments for their suitability as aggregate in concrete. Case Stud. Constr. Mater. 20, e03274 (2024). https://doi.org/10.1016/j.cscm.2024.e03274.

Wagh, V. P., Sukhija, M. & Gupta, A. Investigation on bonding between aggregates and asphalt binder containing warm mix additives. Constr. Build. Mater. 409, 133797 (2023). https://doi.org/10.1016/j.conbuildmat.2023.133797.

Van Blerk, P. G. L., Fletcher, E., Costello, S. B. & Henning, T. F. P. Ethylene glycol accelerated weathering test: an improved, objective aggregate durability test method. Transp. Res. Rec. 2655(1), 27–35 (2017). https://doi.org/10.3141/2655-05.

Curtis Neto, J. A. Technological studies of rocks from Limeira Intrusion, aiming at application as aggregates in engineering works. MSc Dissertation. Engineering School of São Carlos. University of São Paulo. 166 (2019). https://doi.org/10.11606/D.18.2019.tde-18122019-095732

ABNT (2009) NBR 7389-2: Aggregates - Petrographic Analysis of Aggregate for Concrete Part 2: Course Aggregate. Brazilian Technical Standards Association, Rio de Janeiro.

ABNT (2018a) NBR 15577-3: Aggregates - Alkali-aggregate Reactivity Part 3: Petrographic Analysis for Evaluation of the Potential Reactivity of Aggregates With Alkali Compounds from Concrete. Brazilian Technical Standards Association, Rio de Janeiro.

ISRM, Suggested Methods for Determining Water Content, Porosity, Density, Absorption and Related Properties and Swelling and Slake-Durability Index Properties. International Society for Rock Mechanics and Rock Engineering (1977).

ISRM, Suggested Methods for Determining the Uniaxial Compressive Strength and Deformability of Rock Materials. International Society for Rock Mechanics and Rock Engineering (1979).

ISRM, Suggested methods for the quantitative description of discontinuities in rock masses. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 15, 319–368 (1978).

NBR 16974: Coarse aggregate - Abrasion Test in the Los Angeles Machine. Brazilian Technical Standards Association, Rio de Janeiro (2022).

ASTM, D6928: Standard Test Method for Resistance of Coarse Aggregate To Degradation by Abrasion in the Micro-Deval Apparatus. American Society for Testing and Materials, West Conshohocken (2017).

ABNT, NBR 5564: Railway – Ballast – Requirements and Test Methods. Brazilian Technical Standards Association, Rio de Janeiro (2021).

ABNT, NBR 9938: Aggregates - Determination of Strength To Crushing of Coarse aggregate - Test Method. Associação Brasileira de Normas Técnicas, Rio de Janeiro (2013).

ASTM, C88/C88M: Standard Test Method for Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate. American Society for Testing and Materials, West Conshohocken (2018).

ABNT, NBR 12583: Coarse aggregate - Determination of Bituminous Coating. Brazilian Technical Standards Association, Rio de Janeiro (2017).

ABNT. NBR 15577-4: Aggregates—Alkali-aggregate reactivity. In Part 4: Determination of Expansion on Mortar Bars by Accelerated Mortar-Bar Method. Brazilian Technical Standards Association, Rio de Janeiro, Brazil (2018).

ASTM. C1260. Standard Test Method for Potential Alkali Reactivity of Aggregates (Mortar-Bar Method); American Society for Testing and Materials, West Conshohocken, USA (1994).

Bohloli, B., Gustafson, G. & Ronge, B. A laboratory study on reducing the quantity of rock fines at failure: Application to rock blasting and crushing. Bull. Eng. Geol. Environ. 60(4), 271–276 (2001). https://doi.org/10.1007/s100640100102.

Bohloli, B. & Hoven, E. A laboratory and full-scale study on the fragmentation behavior of rocks. Eng. Geol. 89(1–2), 1–8 (2007). https://doi.org/10.1016/j.enggeo.2006.05.010

DNER. DNER-EM 037/97. Agregado Graúdo Para Concreto De Cimento. Departamento Nacional de Estradas de Rodagem, Rio de Janeiro, 6 (1997).

ABNT, NBR 7211. Aggregates for Concrete. Requirements. Brazilian Technical Standards Association, Rio de Janeiro (2022).

ASTM, C33M-23. Standard Specification for Concrete Aggregates. American Society for Testing and Materials, West Conshohocken (2023).

DNIT, 031/2006. Pavimentos flexíveis - Concreto Asfáltico. Especificação De Serviço. Departamento Nacional de Infra-Estrutura de Transportes, Rio de Janeiro (2006).

ABNT. NBR 11803. Materials for Base and Subbase for Graded Crushed Stones Treated With Cement. Requirements. Brazilian Technical Standards Association, Rio de Janeiro (2013).

DIN. EN 13450: Aggregates for Railway Ballast. Deutsches Institut für Normngen, Berlin (2013).

SABS. SANS 1083: Aggregates from Natural sources - Aggregates for Concrete. South African Bureau Standards, Pretoria (2014).

Wu, J., Wang, L., Hou, Y., Qian, Z., Meng, L. & Zhao, Q. Simulation on the Micro-Deval test for the aggregate wear properties measurement. Const. Build. Mat. 20, 445–454 (2018). https://doi.org/10.1016/j.conbuildmat.2018.03.264

Remédio, M. J., Ribeiro, R. P., Curtis Neto, J. A. Correlations between petrography and technological properties of rocks: Application as railway ballast. Geociências 37(3), 669–681.2018.

Santos, R. S., Ribeiro, R. P., Paraguassú, A.B., Xavier, G. C. Railroad ballast of granites and basic rock in tropical regions: Relationships between petrography, physical-mechanical properties and alterability. Transportes 29(2), 1–17 (2021). https://doi.org/10.14295/transportes.v29i2.2369

Alves, D. T., Ribeiro, R. P., Xavier, G. X., Monteiro, S. N., Azevedo, A. R. G. Technological studies for railway ballast in granites and basic rocks from the Eastern region of the state of São Paulo, Brazil. Scientific Reports (accepted)

Wojahn, R. E., Clemente I. M., Back, A. H., Nummer, A. V., Pinheiro, R. J. B. Evaluation of technological properties of granite composition aggregates from two deposits in the state of Rio Grande do Sul. Anuário do Instituto de geociências (UFRJ) 1, 1 (2021). https://doi.org/10.11137/1982-3908_2021_44_36308

Back, A. H., Ceccato, H. D., Pinheiro, R. J. B., Nummer, A. V. & Sagrilo, A. V. Evaluation of the characteristic behavior of volcanic rocks from Serra geral formation and its use in pavements constructions. Geociências 40, 1136–1136 (2021). https://doi.org/10.5016/geociencias.v40i04.15845

Gregerová. M., Stulírová, J., Frýbort, A., Grosek, J. Impact of light mica on the intensity of the alkali-silica reactions in cement concrete pavements containing cataclased granite aggregates. Case Stud. Constr. Mat. 21, e03521 (2024). https://doi.org/10.1016/j.cscm.2024.e03521

Neville, A. Properties of Concrete 844. (Longman Group, 1995).

Quitete, E. B., Menezes,P. M. L., Miranda, A. O. Reatividade potencial de Diabásio, Rocha Semelhante Ao Basalto? Abordagem microestrutural. In Congresso Brasileiro Do Concreto, 55, 2013, Gramado. 55º Congresso Brasileiro Do Concreto. São Paulo: IBRACON, (2013).

Francklin Jr, I., Ribeiro, R. P., Corrêa, F. A. Quartzite mining waste: Diagnosis of ASR Alkali-Silica reaction in mortars and Portland cement concrete. Materials 14, 7642 (2021). https://doi.org/10.3390/ma14247642

Wallau, W., Pirskawetz, S., Voland, K., Meng, B. Continuous expansion measurement in accelerated concrete Prism testing for verifying ASR-expansion models. Mater. Struct. 51, 79 (2018). https://doi.org/10.1617/s11527-018-1205-0

Sanches, L.; Kuperman, S.C.; Helene, P. Using the accelerated Brazilian concrete Prism test (ABCPT) to evaluate alkali aggregate reaction (AAR). IBRACON Struct. Mater. J. 4, 575–581 (2011). https://doi.org/10.1590/S1983-41952011000400004

Shi, Z., Park, S., Lothenbach, B. & Leemann, A. Formation of Shlykovite and ASR-P1 in concrete under accelerated alkali-silica reaction at 60 and 80° C. Cem. Concr. Res. 137, 106213 (2020). https://doi.org/10.1016/j.cemconres.2020.106213

Tiecher, F., Venquiaruto, S. D., Silva, L. B., Dal Molin, D. C. & Gomes, M. B. The reactivity of the aggregates from Southern region of Brazil. IBRACON Mat. J. 3, 73–81 (2007).

Acknowledgements

The authors would like to thank Engineering Geology and Road laboratories (EESC-USP) for the opportunity and for all the infrastructure offered to carry out the physical-mechanical and alterability tests. The authors acknowledge the Brazilian governmental research agencies CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior) and CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico).

Funding

The participation of J.A.C. and R.P.R. was sponsored, respectively, by CAPES research fellowships and by CNPq through the research fellowship PQ2 316330/2021-3.

Author information

Authors and Affiliations

Contributions

Rogério P. Ribeiro : Wrote the main manuscript text; Conceptualization; methodology, formal analysis; Project Administration.João A. C. Neto: Wrote the main manuscript text; Conceptualization, methodologyFernando A. Corrêa: Conceptualization, methodology; formal analysis; João P. Monticelli: Wrote the main manuscript text; formal analysis.José C. Ribeiro: Wrote the main manuscript text; formal analysis.Sérgio N. Monteiro: Writing—review and editing; Resource Acquisition; Project Administration; Review of technical language.Afonso R. G. de Azevedo: Writing—review and editing; Resource Acquisition; Project Administration; Review of technical language.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Statement in the methods

All methods were performed in accordance with the relevant guidelines and regulations.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ribeiro, R.P., Neto, J.A.C., Corrêa, F.A. et al. Characterization of Limeira intrusion stones for aggregate use in engineering applications. Sci Rep 15, 7611 (2025). https://doi.org/10.1038/s41598-025-91292-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-91292-6