Abstract

To address the buckling of flat steel plate webs in traditional concrete-filled steel plate composite coupling beams, this study proposes a novel composite coupling beam with axial rib corrugated webs. The corrugated plates provide greater out-of-plane stiffness compared to flat steel plates. Cyclic loading tests are conducted on specimens with a span-to-depth ratio of 1.5:1. The working mechanism of the coupling beam is investigated through stress–strain analysis of the steel plates and internal force analysis of the coupling beam. A calculation method based on an equivalent section is proposed for the ultimate shear capacity of the beam. The design of stiffener plates at the connection between the coupling beam and the wall piers is also discussed. The results show that the proposed coupling beam exhibits excellent energy dissipation performance. Additionally, the proposed shear capacity calculation method is highly applicable, with an error margin within 10%.

Similar content being viewed by others

Introduction

Concrete-filled double-skin composite walls have been widely used as lateral resisting members in high-rise buildings1,2. These walls not only reduce the dead weight of the structure but also enhance construction efficiency3. Based on the shape of the outer steel plates, composite walls can be categorized into two types: double-skinned flat steel plate composite walls4,5 and double-skinned profiled steel plate composite walls6,7. Eom et al.8 conducted in-plane cyclic testing on isolated and coupled double-skinned composite shear walls with flat steel plates. The failure modes of the specimens primarily included tensile fracture of the welds at the bottom of the shear wall and coupling beams, as well as the local buckling of the steel plates9.

Corrugated or profiled steel plates are also employed as outer plates for composite walls due to their greater out-of-plane stiffness compared to flat steel plates. Hossain et al.10,11,12,13 conducted systematic research on profiled double-skin composite shear walls, including experimental, numerical and theoretical analyses of these walls under axial loads, cyclic loads, and combined loads. The advantages of the composite beam can be further enhanced by strengthening the interface connection between steel plate and concrete through reliable shear connectors. Zhou et al.14 conducted low-cycle loading tests on 15 corrugated double-skin composite shear wall specimens with varying shear span ratios, axial compression ratios, corrugated directions, corrugated shapes, and connection types. Their findings revealed that vertical corrugated composite shear walls exhibit superior seismic performance compared to horizontal corrugated composite walls. Similarly, Zhao et al.15 also adopted corrugated double-skin composite shear walls with vertical ribs. In their study, the two corrugated steel plates of the specimens were connected and tightened using bolts. Four specimens, including flat plate composite walls and corrugated plate composite walls, were tested under axial compressive forces and reversed cyclic lateral loads. The results demonstrated that, compared to flat steel plate composite shear walls, corrugated composite walls possess higher initial stiffness, ductility ratios, and energy dissipation capacities, even with double fastening bolt spacing.

Nowadays, most relevant studies focus on the double-skin composite shear wall itself, while research on coupling beam forms suitable for this structural system remains limited. The bearing capacity and deformation capacity of reinforced concrete coupling beams may be insufficient to match the performance of composite shear wall structures. Although corrugated web steel coupling beams exhibit high stiffness and energy dissipation capacity, they are also associated with higher costs. In current research on corrugated web steel coupling beams, the ribs are typically oriented perpendicular to the flange, resembling an open accordion. Compared to traditional flat steel beams with stiffeners, these corrugated web coupling beams demonstrate superior energy dissipation capacity, bearing capacity, and particularly improved performance in addressing buckling issues. Shahmohammadi and Hajsadeghi et al.16,17,18 investigated the influence of web shape (flat, trapezoidal, curved, zigzag), thickness, corrugation number, and web angle on the energy dissipation capacity of coupling beams through the analysis of 160 finite element models. Vertical ribbed corrugated web shear links can also be installed in the middle of beams in steel moment-resisting frames as energy dissipation fuses19. Wang et al.20 proposed a novel vertical ribbed corrugated web composite beam, which was applied in the Xingkang Dadu River Bridge in Luding, China. However, vertical ribbed corrugated web coupling beams exhibit the accordion effect, characterized by negligible axial stiffness, which is unfavorable for resisting axial forces and bending moments through the flange section. To address this issue, Zuo et al.21 proposed an axial ribbed web steel coupling beam, where the ribs are oriented parallel to the beam flange. Since the axial ribbed corrugated steel plate itself can bear axial forces, this coupling beam exhibits greater axial stiffness.

There are limited studies on concrete-filled steel plate composite coupling beams, which are structurally similar to concrete-filled double-skin composite walls. These beams possess suitable strength, stiffness and deformation capacity, making them well-matched to the double-skin composite shear wall structural system. Nie et al.22,23,24 conducted quasi-static loading tests on steel–concrete composite beam specimens with outer flat steel plates. The results indicated that the failure modes of the steel plates primarily included cracking of the end plate and local buckling.

To address this issue, this study proposes an axial rib corrugated web steel–concrete composite beam. The web plates are arranged with ribs oriented along the beam’s axial direction (i.e., the horizontal direction), and the interior space is filled with high-damping concrete25. This configuration endows the beams with excellent bearing capacity and ductility. Quasi-static loading tests are conducted on the specimens to investigate their failure modes and hysteresis characteristics. Subsequently, the working mechanism of the coupling beam is analyzed through strain–stress analysis, and a simplified design formula for the ultimate shear capacity is proposed. Additionally, the connection forms between the coupling beam and the wall pier are discussed.

Experimental program

Test specimens

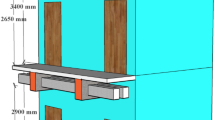

As shown in Fig. 1, two horizontal corrugated coupling beams, HCCB-1 and HCCB-2, are designed. The primary difference between the two specimens is the orientation of the corrugated web: in HCCB-1, the troughs of the corrugated web are located at the flange, whereas in HCCB-2, the crests are positioned at the flange.

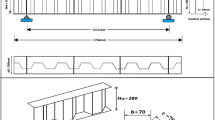

The cross-sectional schematic of the corrugated steel plate used for the coupling beam web is shown in Fig. 2. The dimensions of the corrugated steel plate are as follows: the width of both the horizontal sub-panels a1 and the inclined sub-panels a2 is 105 mm, the corrugation depth d is 84 mm, the thickness is 10 mm, and the corrugation angle δ is 53°. The global and local stability performance of this corrugated steel plate is verified. According to Section D.2.2 of the Eurocode26 on the shear capacity of corrugated steel plates, the reduction factors for global buckling χcg and local buckling χcl can be calculated using Eqs. (1) and (2), respectively. The definitions and calculation methods for λcg and λcl are provided in the standard. The value of χc > 1 indicates that the corrugated steel plate yields prior to buckling, thereby satisfying stability requirements.

The geometry and sectional details of the specimen are shown in Fig. 3. The middle part of the specimen represents the coupling beam, and the ends are end plates simulating wall piers. A scale ratio of 1:2 is used. Consequently, the cross-sectional dimensions of the corrugated plate in Fig. 2 are proportionally scaled down. The width, height and span of the outer contour of the coupling beam are 200 mm, 400 mm, and 600 mm, respectively. The main parameters of the specimens are detailed in Table 1.

To prevent premature failure of the joints at the ends of the beam, six studs and stiffened plates are welded on both sides to enhance the shear and bending capacities. Taking HCCB-1 as an example, the specific construction is illustrated in Fig. 3. Symbols 1 and 2 denote the stiffeners and studs, respectively. Symbol 3 indicates the two Φ25 holes in the left end plate: one hole is for pouring concrete, and the other is for venting air to ensure proper concrete density. After concrete pouring is completed, the round holes in the end plate will be sealed with steel plates.

In this study, the material used for the outer steel plates of the composite beam is Q235. Based on the previous experiments, the yield strength of the 5 mm thick steel plate used for the flange and web, as well as the 10 mm diameter stud are 354 N/mm2 and 636 N/mm2, respectively. Both specimens are cast with high-damping concrete, which is prepared by adding a mixture of styrene acrylate emulsion and carboxyl styrene-butadiene emulsion with 12% cement mass and polypropylene fiber with 0.2% volume content to ordinary C50 concrete27. The mean cubic compressive strengths of the concrete in HCCB-1 and HCCB-2 are 37.8 N/mm2 and 36.2 N/mm2, respectively.

Loading and measuring

The test setup, shown in Fig. 4, includes the specimen, loading beam, loading frame and actuator. A drift-controlled cyclic loading program is applied, as shown in Fig. 5. The test is terminated when the shear force drops below 85% of the peak shear force.

Taking HCCB-1 as an example, the arrangement of displacement and strain gauges is shown in Fig. 6. Since the loading frame and loading beam are not rigid bodies, their in-plane rotation and out-of-plane deformation affect the horizontal movement of the loading frame. Consequently, the measured horizontal displacement is larger than the actual value, resulting in a smaller calculated stiffness. To eliminate the influence of the undesirable deformation caused by the loading device, the diagonal displacement is used to define the chord angle \(\theta\). The chord angle is calculated as follows

where \({{\Delta}}\) is the diagonal displacement of the specimen, \({{\Delta}}_{{\text{h}}}\) is the horizontal displacement transformed from \({{\Delta}}\), \(\gamma\) is the angle between the diagonal displacement gauge and the beam span direction, and \(l_{{\text{b}}}\) is the span, as shown in Fig. 6a.

Test results and analysis

Test phenomenon

During the cyclic test of HCCB-1, several distinct phenomena are observed: (1) When \(\theta = \pm \,0.0050\;{\text{rad}}\), the shear force reaches 0.6 times the peak shear force \(V_{{\text{p}}}\), and the flange near the stiffeners begins to buckle locally. At the same time, small cracks appear in the corner of the welded joint of the flange and web. (2) When \(\theta = \pm\, 0.02\;{\text{rad}}\), the shear force reaches \(V_{{\text{p}}}\), a continuous tearing sound is heard, the cracks gradually expand across the width of the flange and the height of the web, tending towards transfixion. (3) When \(\theta = \pm\, 0.03\;{\text{rad}}\), the cracks at the end continue to extend toward the middle of the flange and web, and the sound of concrete crushing can be heard. (4) When \(\theta = \pm \,0.05\;{\text{rad}}\), the shear force decreases to \(0.7V_{{\text{p}}}\), the cracks at the end of the flange are fully penetrated, as shown in Fig. 7. No significant out-of-plane deformation is observed in the web, except for local buckling near the cracks. This indicates that the corrugated web of HCCB-1 effectively prevents out-of-plane buckling.

The tearing near the four corners of HCCB-1 is located in the sections where the stiffeners connect to the flanges. This indicates that the stress concentration near stiffeners causes premature cracking of the flanges, which further impairs the deformation and energy dissipation capacity of the specimen. To reduce stress concentration and delay cracking, the stiffeners of HCCB-2 are weakened before the test. The weakened stiffeners are shown in Fig. 8.

Figure 9 illustrates the damage pattern of HCCB-2. Cracks are primarily concentrated in the flanges connected to the stiffeners, particularly on the lower left and upper right sides, where complete fractures occur. These cracks eventually extend to the middle of the web. Due to machining defects, the welding on the upper right side tears, leading to tearing of the end web during loading stages. This affects the bearing capacity of HCCB-2.

As shown in Fig. 9, obvious local buckling occurs diagonally along the lower left and upper right sides. The cracking of the welding on the upper right side reduces the out-of-plane stiffness of the corrugated steel web. Additionally, severe cracking in the web at the same location further reduces its out-of-plane stiffness and exacerbates the local buckling.

Hysteresis curves and skeleton curves

The hysteresis curves of the two specimens, shown in Fig. 10a, exhibit full and symmetric spindle shapes. After the steel plate crack, when the specimens are unloaded and then reloaded to θ = 0, the tangent stiffnesses of the hysteresis curves begin to increase gradually, corresponding to the pinching phenomenon. This is primarily due to the cracks opening and closing during unloading and reloading.

The skeleton curve, obtained by connecting the peak points of the first cycle at all loading levels in the hysteresis curve, is shown in Fig. 10b. The skeleton curves can be clearly divided into three stages: elasticity, plasticity and destruction. Note that the corrugated webs of specimens HCCB-1 and HCCB-2 have the same rib direction, but the flange width of HCCB-2 is larger. As a result, the skeleton curves of the two specimens are similar, and both exhibit good deformation ability (with a chord angle of approximately 0.05 rad). However, the peak bearing capacity of HCCB-2 is slightly higher than that of HCCB-1.

Bearing capacity and ductility factor

The shear and chord angles of the characteristic points on the skeleton curves are obtained using the geometric drawing method28. The point at which the descending section of the skeleton curve reaches 85% of the peak shear force is defined as the limit point. Table 2 summarizes the characteristic parameters of the skeleton curves, including the shear force and chord angle in yield (\(V_{{\text{y}}}\) and \(\theta_{{\text{y}}}\)), peak (\(V_{{\text{p}}}\) and \(\theta_{{\text{p}}}\)) and ultimate (\(V_{{\text{u}}}\) and \(\theta_{{\text{u}}}\)) states, as well as the ductility factor (\(\mu\)), defined as the ratio of \(\theta_{{\text{p}}}\) to \(\theta_{{\text{y}}}\). The chord angles in the positive (+) and negative (−) loading directions are close, indicating similar steel plate damage on both sides. The peak shear force and corresponding chord angle of HCCB-2 are higher than those of HCCB-1, indicating that HCCB-2 has better deformation ability.

Energy consumption

The energy dissipation per loading cycle E, cumulative energy dissipation Ecum and equivalent viscous damping coefficient \(\xi_{{{\text{eq}}}}\) are shown in Fig. 11. The ultimate deformation capacity of specimens HCCB-1 and HCCB-2 is roughly similar, with chord angles of approximately 0.05 rad. However, HCCB-2 exhibits stronger energy dissipation capacity than HCCB-1. The equivalent viscous damping coefficients at the ultimate states are 0.29 for HCCB-1 and 0.35 for HCCB-2, both indicating excellent energy dissipation performance.

Analysis of working mechanism

In this section, the stress distribution in the flange along the span direction and in the web along the height is investigated. By integrating the stress distribution of the web along its height and using the internal force balance equation of the coupling beam, the contributions of the force of the outer steel plates and the filled concrete are investigated. Finally, the formula for the ultimate shear capacity is derived.

Stress and strain analysis of steel plates

A Cartesian coordinate system oxyz is established on the neutral surface of the beam, as shown in Fig. 12, with the beam’s span aligned along the x-direction. For the strain rosette of the web, the normal and shear strains in the x–y plane can be calculated using Eq. (4).

where, \(\varepsilon_{{{\text{sx}}}}\), \(\varepsilon_{{{\text{sy}}}}\), and \(\gamma_{{{\text{sxy}}}}\) represent the normal strains of the web in the x- and y-directions and the shear strain in the x–y plane, respectively. Meanwhile, \(\varepsilon_{1}\), \(\varepsilon_{2}\), and \(\varepsilon_{3}\) are the corresponding measured values obtained from the test.

Figure 13 illustrates the shear-strain hysteresis curves of typical measuring points on the outer steel plates at the fracture section of HCCB-1. As the shear force increases, the hysteretic loops of shear-normal strain and shear-shear strain gradually expand outward. Based on the shear strain variation shown in Fig. 13d, shear deformation remains dominant during loading, consistent with the test design. The strain development pattern of HCCB-2 is similar to that of HCCB-1.

After the outer steel plates of the coupling beam yield, the increase in shear force on the hysteretic curve is relatively small, but the change in strain is significant, primarily due to plastic strain.

Figure 13 clearly shows that the increase in plastic strain of the steel plate is much larger than that of elastic strain. Therefore, in the subsequent analyses, it is assumed that the strain increment of the outer steel plates after yielding is equal to their plastic strain increment.

To determine the shear force and chord angle at the yield point of the outer steel plate, the yield strain is first calculated. Specifically, the steel flange is analyzed under a uniaxial stress state, while the web is analyzed under a plane stress state. The shear force and corresponding chord angle of the flange (\(V_{{{\text{yf}}}}\) and \(\theta_{{{\text{yf}}}}\)) and web (\(V_{{{\text{yw}}}}\) and \(\theta_{{{\text{yw}}}}\)) in the yield state are shown in Table 3. It can be seen that the flange of HCCB-1 yields before the web, while the opposite is true for HCCB-2. Additionally, the shear forces at flange yield \(V_{{{\text{yf}}}}\) and web plate yield \(V_{{{\text{yw}}}}\) are lower than the yield shear force \(V_{{\text{y}}}\) determined by the geometric drawing method. After the specimen is fully yielded, the increase in bearing capacity primarily results from steel hysteresis strengthening and the contribution of the concrete.

Based on the measured strain data, the stress distribution of the flange along the beam span under different load levels is calculated, as shown in Fig. 14. The vertical coordinate represents the location along the beam span. For HCCB-1, Fig. 14a, b show that \(\sigma_{{{\text{sx}}}}\) is linearly distributed along the span before the flange yields. After the flange yields and approaches \(V_{{\text{p}}}\), both ends of the specimen yield rapidly, while \(\sigma_{{{\text{sx}}}}\) near the mid-span region grows slowly and does not reach the yield state. The stress distribution of the HCCB-2 steel flange along the span is similar to that of the HCCB-1. However, under higher loading levels, the flange near both ends of HCCB-2 exhibits a wider yield range.

During the loading process, the neutral axis is located in the middle of the beam span, indicating that the boundary conditions of the specimen are sufficiently rigid to accurately simulate the working condition of the coupling beam.

The stress distribution of the web along the beam height is shown in Fig. 15. For HCCB-1, Fig. 15a shows that after the steel flange yields and approaches the peak load \(V_{{\text{p}}}\), \(\sigma_{{{\text{sx}}}}\) of the web near the compression flange gradually converts from compressive to tensile stress.

Figure 15b illustrates that the shear stress \(\tau_{{{\text{sxy}}}}\) remains roughly constant along the beam height before the web yields. After the flange yields and approaches \(V_{{\text{p}}}\), \(\tau_{{{\text{sxy}}}}\) near the tension side decreases, becoming much smaller than the shear stress near the compression side.

The above analysis indicates that the web near the tension side is primarily dominated by tensile action, with a weak shearing effect. In contrast, the web near the compression side exhibits significant shear stress while also experiencing compressive action due to the concrete’s contribution to compression resistance. This stress distribution enables the web to more effectively resist external forces. The shear stress \(\tau_{{{\text{sxy}}}}\) of each specimen near the peak load has reached the yield point, indicating a pronounced shearing effect.

Table 3 presents the ratio of the yield shear force to the peak shear force (\({{V_{{\text{y}}} } \mathord{\left/ {\vphantom {{V_{{\text{y}}} } {V_{{\text{p}}} }}} \right. \kern-0pt} {V_{{\text{p}}} }}\)) of specimens HCCB-1 and HCCB-2, which are 0.71 and 0.91, respectively. As shown in Fig. 15, when the specimen is near yielding, the measuring points of the web near the flange have already reached yield. Therefore, it can be concluded that the yield of the outer steel plate occurs before the overall yield of the specimen.

Analysis of coupling beam internal force

Given the relatively complex stress state of the filled concrete, the internal force analysis is first conducted on the outer steel plates. Subsequently, the internal force components of the filled concrete are determined through the force balance relations of the composite beam, and the working mechanism is studied based on these results.

The axial force \(N_{{{\text{st}}}}\), bending moment \(M_{{{\text{st}}}}\) and shearing force \(V_{{{\text{st}}}}\) of the outer steel plates are obtained by integrating the stress distribution along the height of the beam using Eqs. (5) to (7).

where \(t_{{{\text{sf}}}}\) and \(t_{{{\text{sw}}}}\) are the thicknesses of the flange and web steel plates, respectively. \(\sigma_{{{\text{sxf1}}}}\) and \(\sigma_{{{\text{sxf2}}}}\) are the axial normal stresses of the upper and lower flanges of the coupling beam, respectively, while \(\sigma_{{{\text{sx}}}}\) is the normal stress of the web. Note that for \(N_{{{\text{st}}}}\), positive and negative signs indicate tension and compression, respectively. For simplicity, it is assumed that the stress distribution between the two strain measured points of the steel web is linear.

The axial force \(N_{{{\text{co}}}}\), bending moment \(M_{{{\text{co}}}}\) and shearing force \(V_{{{\text{co}}}}\) of the internal concrete can be calculated using the internal force balance equations given by Eqs. (8) to (10).

where, \(N_{{{\text{co}}}}\) is the axial force of the filled concrete, with positive and negative signs indicating compression and tension, respectively. \(V_{{{\text{co}}}}\) and \(M_{{{\text{co}}}}\) are the shear force and bending moment of the concrete, respectively. \(d\) is the distance from the mid-span to the strain measurement point at the beam end, and \(V\) is the total shear force of the coupling beam.

The evolution curves of \(V_{{{\text{st}}}}\), \(M_{{{\text{st}}}}\) and \(N_{{{\text{st}}}}\) under various loading levels are shown in Fig. 16a–c.

Figure 16a shows that before the coupling beam yields, \(V_{{{\text{st}}}}\) increases linearly with the increase in the coupling beam’s shear force. After yielding, the growth rate of \(V_{{{\text{st}}}}\) slows down, and even a decrease occurs, primarily due to steel plate cracking. Throughout the loading process, the outer steel plates bear most of the shear force. However, the increase in shear force at higher loading levels is mainly due to the filled concrete.

Figure 16b shows that \(M_{{{\text{st}}}}\) does not exhibit a significant decline as the loading level increases.

Figure 16c indicates that before the coupling beam yields, the growth rate of \(N_{{{\text{st}}}}\) remains relatively unchanged; after yielding, \(N_{{{\text{st}}}}\) decreases and then slightly increases.

The proportions of the shear force and bending moment borne by the outer steel plates under each load level are shown in Fig. 17a, b. Figure 17a indicates that when the coupling beam yields, the shear force borne by the outer steel plates of specimens HCCB-1 and HCCB-2 accounts for 91% and 94% of the total shear force, respectively. Near the peak shear \(V_{{\text{p}}}\), the shear force proportions of the outer steel plates tend to be similar, accounting for 60% and 63% of the total shear force, respectively.

Figure 17b shows that at the yield points of HCCB-1 and HCCB-2, the bending moments of the outer steel plates \(M_{{{\text{st}}}}\) account for 61% and 92% of the total of the coupling beams, respectively. When the shear force approaches the peak value, the bending moments of the outer steel plates account for 66% and 92% of the total bending moments, respectively. The bending moment of the outer steel plates after yielding is greater than that of the shearing force. Besides, it can be known that before the beam yields, the outer steel plates mainly undertake the internal force components, and the effect of the filled concrete is small. After the coupling beam yields, the outer steel plates are cracked. The internal concrete mainly bears the subsequent internal force increase, and the internal filling concrete plays a greater role.

The curves of the ratio of the shear force to the axial force of the outer steel plates under each load level are shown in Fig. 19a. When the shearing force is low, the ratio fluctuates significantly. This may be due to the small strain values at low load levels, where measurement errors can have a substantial impact on the results. As the peak shear force is approached, \({{V_{{{\text{st}}}} } \mathord{\left/ {\vphantom {{V_{{{\text{st}}}} } {N_{{{\text{st}}}} }}} \right. \kern-0pt} {N_{{{\text{st}}}} }}\) ratios for specimens HCCB-1 and HCCB-2 are 0.85 and 0.87, respectively. According to the test phenomenon, the ratio of the height \(h_{{\text{b}}}\) to the distance between the cracked sections of the outer steel sheets \(l^{\prime}_{{\text{b}}}\), as shown in Fig. 18, is 0.87. When the loading level is close to the peak shear force, these two ratios are generally consistent, i.e., \({{V_{{{\text{st}}}} } \mathord{\left/ {\vphantom {{V_{{{\text{st}}}} } {N_{{{\text{st}}}} }}} \right. \kern-0pt} {N_{{{\text{st}}}} }} = {{h_{{\text{b}}} } \mathord{\left/ {\vphantom {{h_{{\text{b}}} } {l^{\prime}_{{\text{b}}} }}} \right. \kern-0pt} {l^{\prime}_{{\text{b}}} }}\).

Figure 19b shows the curves of the ratio of the shear force \(V_{{{\text{co}}}}\) to the axial force \(N_{{{\text{co}}}}\) of the filled concrete under each load level. The ratios of \(V_{{{\text{co}}}}\) to \(N_{{{\text{co}}}}\) for specimens HCCB-1 and HCCB-2 are 0.51 and 0.56, respectively, when the peak shear force is approached. The concrete high-span ratio (\({{h_{{\text{c}}} } \mathord{\left/ {\vphantom {{h_{{\text{c}}} } {l_{{\text{b}}} }}} \right. \kern-0pt} {l_{{\text{b}}} }}\)) of the specimen is 0.65, which is close to the ratio of \({{V_{{{\text{co}}}} } \mathord{\left/ {\vphantom {{V_{{{\text{co}}}} } {N_{{{\text{co}}}} }}} \right. \kern-0pt} {N_{{{\text{co}}}} }}\). This indicates the following relationship:

Calculation of ultimate shear capacity

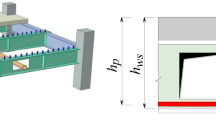

To calculate the bearing capacity of the beam, the corrugated cross-section of the specimen is approximated as a rectangular section, as shown in Fig. 18. The equivalent thickness of the steel web \(t_{{{\text{eqsw}}}} = \alpha t_{{{\text{sw}}}}\), where α is determined by the ratio of the actual side length L of the corrugated web to its vertical projection length \(h_{{\text{b}}}\). The equivalent width \(b_{{{\text{eqc}}}}\) of the concrete is calculated by maintaining the cross-sectional area of the filled concrete and the height of the section. The equivalent thickness \(t_{{{\text{eqsf}}}}\) of the steel flange is calculated based on the principle of flange area equivalence.

Based on the internal force analysis of the steel plates and the filled concrete, the following basic assumptions are made for calculating the ultimate shear capacity:

-

1.

The tensile strength of concrete in the tension zone is neglected, while the compressive and shear strengths in the compression zone are considered.

-

2.

The ratio of the shear force to the axial force of the filled concrete is assumed to be equal to the high-span ratio of the filled concrete, as shown in Eq. (11).

-

3.

Based on the stress assumptions for the composite beam proposed by Hu29, the axial force and shear force in concrete can be calculated using Eqs. (12) and (13). These calculations are performed in accordance with the stress distribution of the concrete depicted in Fig. 20 and Eq. (11).

$$N_{{{\text{co}}}} = f_{{\text{c}}} b_{{\text{c}}} x_{{\text{c}}} \cos^{2} \gamma$$(12)$$V_{{{\text{co}}}} = f_{{\text{c}}} b_{{\text{c}}} x_{{\text{c}}} \cos \gamma \sin \gamma$$(13)where \(x_{{\text{c}}}\) is the height of compression zone of the concrete, \(b_{{\text{c}}}\) is the width of the filled concrete.

-

4.

As shown illustrated in Fig. 21, the outer steel plates of the equivalent section reach full-section plasticity at the fracture location. Additionally, the normal stress and shear stress are evenly distributed along the beam height. The normal stress of the steel plate is considered equal to the yield strength of steel.

$$\begin{aligned} N_{{{\text{st}}}} & = 2\left[ { - f_{{{\text{yw}}}} x_{{\text{s}}} + f_{{{\text{yw}}}} \left( {h_{{\text{b}}} - x_{{\text{s}}} } \right)} \right]t_{{{\text{sw}}}} + \left( {f_{{{\text{yf}}}} - f_{{{\text{yf}}}} } \right)b_{{\text{c}}} t_{{{\text{sf}}}} \\ & = 2f_{{{\text{yw}}}} t_{{{\text{sw}}}} h_{{\text{b}}} - 4f_{{{\text{yw}}}} t_{{{\text{sw}}}} x_{{\text{s}}} \\ \end{aligned}$$(14)$$V_{{{\text{st}}}} = 2\tau_{{\text{s}}} t_{{{\text{sw}}}} h_{{\text{b}}}$$(15) -

5.

The ratio of the shear force to the axial force borne by the outer steel plates is equal to the ratio of the beam height \(h_{{\text{b}}}\) to the distance \(l^{\prime}_{{\text{b}}}\) between the cracked sections on both sides.

$${{V_{{{\text{st}}}} } \mathord{\left/ {\vphantom {{V_{{{\text{st}}}} } {N_{{{\text{st}}}} }}} \right. \kern-0pt} {N_{{{\text{st}}}} }} = {{h_{{\text{b}}} } \mathord{\left/ {\vphantom {{h_{{\text{b}}} } {l^{\prime}_{{\text{b}}} }}} \right. \kern-0pt} {l^{\prime}_{{\text{b}}} }}$$(16)Substituting Eq. (14) and Eq. (15) into Eq. (16) leads to:

$$f_{{{\text{yw}}}} h_{{\text{b}}} - 2f_{{{\text{yw}}}} x_{{\text{s}}} - \tau_{{\text{s}}} l^{\prime}_{{\text{b}}} = 0$$(17)where \(f_{{{\text{yw}}}}\) is normal stress of steel web, with compression assumed to be positive. Additionally, \(\tau_{{\text{s}}}\) is the shear stress of the steel web and \(x_{{\text{s}}}\) is the height of the compression zone of the steel web.

-

6.

The upper limit of the height of the compression zone of the concrete \(x_{{\text{c}}}\) is recommended to be 0.55hb29.

Based on the internal force balance analysis of the outer steel plates and the filled concrete, the equilibrium relations for the composite beam are obtained:

Equation (21) can also be used to calculate the moment at the end of the specimen.

The values of \(x_{{\text{c}}}\), \(x_{{\text{s}}}\) and \(\tau_{{\text{s}}}\) are calculated by simultaneously solving Eqs. (17), (18) and (21). These values are then substituted into Eq. (19) to determine the ultimate shear capacity of the composite beam.

When \(x_{{\text{c}}}\) obtained by Eq. (22) exceeds \(x_{{\text{c,max}}}\), it is set equal to \(x_{{\text{c,max}}}\) according to assumption (6), effectively reducing the axial force borne by the concrete. Additionally, according to the axial force balance relationship between the steel plate and the filled concrete, the axial force of the steel web is also reduced. Based on assumption (5), the shear effect of the steel web is not fully utilized, which contradicts the actual situation. Therefore, when \(x_{{\text{c}}} > x_{{\text{c,max}}}\), assumption (5) is no longer applicable. Instead, it is assumed that the normal stress and shear stress of the outer steel web are \(f^{\prime}_{{{\text{yw}}}}\) and \(\tau_{{\text{s}}}\), respectively, and the stress distribution satisfies the von Mises yield equation:

Then the equations system (22) can be modified to:

The values of the \(x_{{\text{c,max}}}\), \(x_{{\text{s}}}\), \(\tau_{{\text{s}}}\) and \(f^{\prime}_{{{\text{yw}}}}\) are calculated by solving Eq. (24), and these values are then substituted into Eq. (19) to determine the ultimate shear capacity of the composite beam.

The calculated bearing capacity \(V_{{{\text{cal}}}}\) and the measured value \(V_{{{\text{test}}}}\) are shown in Table 4. Note that the test value represents the mean result of both positive and negative loading. The ratio of \({{V_{{{\text{cal}}}} } \mathord{\left/ {\vphantom {{V_{{{\text{cal}}}} } {V_{{{\text{test}}}} }}} \right. \kern-0pt} {V_{{{\text{test}}}} }}\) ranges from 0.96 to 1.05, indicating that the proposed method accurately calculates the ultimate shear capacity of the composite beam. Notably, the height of the filled concrete compressive zone in HCCB-2 exceeds the limit value of \(0.55h_{{\text{b}}}\), and \({{V_{{{\text{cal}}}} } \mathord{\left/ {\vphantom {{V_{{{\text{cal}}}} } {V_{{{\text{test}}}} }}} \right. \kern-0pt} {V_{{{\text{test}}}} }}\) ratio is 1.10. According to assumption (6), when the height of the concrete compressive zone is revised to \(0.55h_{{\text{b}}}\), the ratio of \({{V_{{{\text{cal}}}} } \mathord{\left/ {\vphantom {{V_{{{\text{cal}}}} } {V_{{{\text{test}}}} }}} \right. \kern-0pt} {V_{{{\text{test}}}} }}\) is 1.05, demonstrating improved accuracy. At this point, \(f^{\prime}_{{{\text{yw}}}} = 0.897f_{{{\text{yw}}}}\).

The calculated bearing capacity \(V_{{{\text{cal}}}}\) of HCCB-2 is larger than the measured \(V_{{{\text{test}}}}\) due to defects in the specimen processing. However, the error is controlled within 10%, which is acceptable.

Influence of stiffener plates at the connection

To validate the reduction in stress concentration within the steel flange of specimen HCCB-2, attributed to the weakened stiffener plates as shown in Fig. 8, finite element analysis is conducted on three distinct models: the model without stiffener plates (HCCB-2a), the model before stiffener plate reduction (HCCB-2b), and the model after stiffener plate reduction (HCCB-2c). The boundary conditions of the finite element models are set as follows: one end is fixed, while the other end is coupled with the center point of the end face, and the same displacement loading pattern as in the experiment is applied. Note that HCCB-2c is the finite element model of specimen HCCB-2. A comparison between the experimental results of specimen HCCB-2 and the corresponding finite element model HCCB-2c is shown in Fig. 22. The elastic stiffness of both is essentially consistent. The negative loading yield shear force of HCCB-2 is slightly greater than that of HCCB-2c, while the positive loading yield shear force is slightly smaller than that of HCCB-2c. Overall, this comparison essentially confirms the validity of the finite element model.

Figure 23 illustrates the hysteretic curves and skeleton curves for these three models with different connections. It is evident that stiffeners have a minimal impact on the hysteretic performance of the coupling beam models. Specifically, the load-bearing capacity of the model without stiffeners (HCCB-2a) is approximately 8% less than that of the model with stiffeners (HCCB-2b).

A comparative analysis of the von Mises stress and equivalent plastic strain distributions in the outer steel plates of each model is conducted. Figures 24 and 25 present the von Mises stress and plastic equivalent strain contour plots, respectively, for the outer steel plates at the peak chord rotation of the HCCB-2 specimen. In the HCCB-2a model, stress in the outer steel plate is primarily concentrated at the end section of the steel flange. In contrast, for the HCCB-2b and HCCB-2c models, stress is predominantly concentrated at the junction between the steel flange and the stiffener plates. This indicates that stiffener plates effectively mitigate stress concentration at the end beam and wall connection nodes, thereby protecting the beam and wall junctions. Compared to the HCCB-2b model, the stress concentration in the outer steel plate of the HCCB-2c model is reduced, suggesting that the reduction of the stiffener plates has a delaying effect on the cracking of the steel flange in the HCCB-2 model.

Table 5 shows the maximum plastic equivalent strain on the failure section of the outer steel flange for models at chord rotations of 0.03 rad and 0.04 rad. The values in parentheses indicate the change rate relative to the HCCB-2b model without stiffener reduction. It is observed that compared to the HCCB-2b model, the maximum plastic equivalent strain of the steel flange in the HCCB-2c model is significantly lower, while in the stiffener-less HCCB-2a model, it is markedly higher. This suggests that reducing stiffeners significantly enhances the plastic development of the steel flange.

Conclusion

In this study, a novel steel–concrete composite coupling beam with axial rib corrugated webs is proposed. Through the experimental research and analysis of the working mechanism, the following conclusions are obtained:

-

1.

The equivalent viscous damping coefficients for HCCB-1 (trough at flange section) and HCCB-2 (crest at flange section) at the ultimate states are 0.29 and 0.35, respectively. Both demonstrate substantial energy dissipation capacity, with HCCB-2 performing better.

-

2.

The steel web in the tension zone primarily experiences tension and contributes minimally to shear effects. Conversely, the steel web in the compression zone exhibits significant shear effect. Before yielding, the outer steel plates bear the majority of the internal forces, with the filled concrete playing a minor role. Upon yielding, the increase in internal forces is predominantly supported by the filled concrete.

-

3.

Based on the internal force analysis of the outer steel plates and the filled concrete, a calculation formula for the ultimate shear capacity is developed. Verification results indicate excellent agreement between the theoretical formula and experimental results.

-

4.

Reducing the stiffener plates at the connection between the coupling beam and the wall pier helps achieve a more uniform stress distribution in the flange.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author (Email: ffsun@tongji.edu.cn) or first author (Email: yue_liu@tongji.edu.cn) on reasonable request.

References

Li, J., Wang, Z., Li, F., Mou, B. & Wang, T. Experimental and numerical study on the seismic performance of an L-shaped double-steel plate composite shear wall. J. Build. Eng. 49, 104015 (2022).

Guo, L., Wang, Y. & Zhang, S. Experimental study of rectangular multi-partition steel-concrete composite shear walls. Thin-Walled Struct. 130, 577–592 (2018).

Hilo, S. J. et al. A state-of-the-art review on double-skinned composite wall systems. Thin-Walled Struct. 97, 74–100 (2015).

Qian, J., Jiang, Z. & Ji, X. Behavior of steel tube–reinforced concrete composite walls subjected to high axial force and cyclic loading. Eng. Struct. 36, 173–184 (2012).

Nie, J., Ma, X., Tao, M., Fan, J. & Bu, F. Effective stiffness of composite shear wall with double plates and filled concrete. J. Constr. Steel Res. 99, 140–148 (2014).

Hilo, S. J., Badaruzzaman, W. H. W., Osman, S. A. & Al-Zand, A. W. Axial load behavior of a composite wall strengthened with an embedded octagon cold-formed steel. Appl. Mech. Mater. 754–755, 437–441 (2015).

Rafiei, S., Hossain, K. M. A., Lachemi, M., Behdinan, K. & Anwar, M. S. Finite element modeling of double skin profiled composite shear wall system under in-plane loadings. Eng. Struct. 56, 46–57 (2013).

Eom, T. S., Park, H. G., Lee, C. H., Kim, J. H. & Chang, I. H. Behavior of double skin composite wall subjected to in-plane cyclic loading. J. Struct. Eng. 135(10), 1239–1249 (2009).

Nie, J. et al. Experimental study on seismic behavior of high-strength concrete filled double-steel-plate composite walls. J. Constr. Steel Res. 88, 206–219 (2013).

Hossain, K. M. A. & Wright, H. D. Performance of double skin-profiled composite shear wall-experiments and design equations. Can. J. Civil Eng. 31, 204–207 (2004).

Hossain, K. M. A. & Wright, H. D. Finite element modelling of the shear behavior of profiled composite walls incorporating steel–concrete interaction. Struct. Eng. Mech. 21, 659–676 (2005).

Hossain, K. M. A. & Wright, H. D. Behaviour of composite walls under monotonic and cyclic shear loading. Struct. Eng. Mech. 17, 69–85 (2004).

Hossain, K. M. A. & Wright, H. D. Experimental and theoretical behaviour of composite walling under in-plane shear. J. Constr. Steel Res. 60, 59–83 (2004).

Zhou, J., Chen, Z., Liao, H. & Tang, J. Seismic behavior of corrugated double-skin composite wall (DSCW) with concrete-filled steel tubes: Experimental investigation. Eng. Struct. 252, 113632 (2021).

Zhao, Q., Li, Y. & Tian, Y. Cyclic behavior of double-skin composite walls with flat and corrugated faceplates. Eng. Struct. 220, 111013 (2020).

Shahmohammadi, A., Mirghaderi, R., Hajsadeghi, M. & Khanmohammadi, M. Application of corrugated plates as the web of steel coupling beams. J. Constr. Steel Res. 85, 178–190 (2013).

Hajsadeghi, M., Zirakian, T., Keyhani, A., Naderi, R. & Shahmohammadi, A. Energy dissipation characteristics of steel coupling beams with corrugated webs. J. Constr. Steel Res. 101, 124–132 (2014).

Zirakian, T., Hajsadeghi, M., Lim, J. B. P. & Bahrebar, M. Structural performance of corrugated web steel coupling beams. Proc. Inst. Civ. Eng. Struct. Build. 169(10), 756–764 (2016).

Mansouri, A. & Sharif, M. M. Development of a corrugated web shear link for steel moment-resisting frames. J. Constr. Steel 193, 107281 (2022).

Wang, S., Liu, Y., He, J., Xin, H. & Yao, H. Experimental study on cyclic behavior of composite beam with corrugated steel web considering different shear-span ratio. Eng. Struct. 180, 669–684 (2019).

Zuo, J., Zhu, B., Guo, Y., Wen, C. & Tong, J. Experimental and numerical study of steel corrugated-plate coupling beam connecting shear walls. J. Build. Eng. 54, 104662 (2022).

Nie, J., Hu, H. & Eatherton, M. R. Concrete filled steel plate composite coupling beams: Experimental study. J. Constr. Steel Res. 94, 49–63 (2014).

Hu, H., Nie, J. & Eatherton, M. R. Internal force and deformation of concrete-filled steel plate composite coupling beams. J. Constr. Steel Res. 92, 150–163 (2014).

Hu, H., Nie, J. & Wang, Y. Shear capacity of concrete-filled steel plate composite coupling beams. J. Constr. Steel Res. 118, 76–90 (2016).

Wang, M., Song, X. & Wang, Z. Experimental study on seismic behavior of high-damping concrete with concealed shear wal. Earthq. Eng. Eng. Vibr. 05, 153–161 (2013).

Eurocode. Design of Steel Structures. Part 1.5: Plated Structural Elements. (European Committee for Standardization, 2003).

Wang, M., & Song, X. A New Type of Energy Dissipation Low-Rise Shear Wall with Concealed Bracings and Steel Plate, China, ZL201220022614.6 (P) (2012). (in Chinese).

Guo, Z. & Shi, X. Principle and Analysis of Reinforced Concrete 337 (Tsinghua University Press, 2003) (in Chinese).

Hu, H. Outsourcing Steel-Concrete Composite Coupling Beam and Its Application in Shear Wall Structure (Tsinghua University, 2014) (in Chinese).

Acknowledgements

Financial support from the Jiangxi key technological research and development program of China (No. 20224BBG71024) and the National Natural Science Foundation of China (No. 52378531) is greatly acknowledged.

Author information

Authors and Affiliations

Contributions

Yue Liu: Investigation, Data curation, Writing-original draft. Feifei Sun: Funding acquisition, Supervision, Conceptualization, Methodology. LianHong Jiao: Data curation, Supervision. HongKe Pan: Funding acquisition, Supervision. Defeng Xu: Supervision, Validation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liu, Y., Sun, F., Jiao, L. et al. Investigation of cyclic behavior of steel–concrete composite coupling beams with axial rib corrugated webs. Sci Rep 15, 8566 (2025). https://doi.org/10.1038/s41598-025-91414-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-91414-0