Abstract

Automated fiber placement technology can be used to improve the rigidity and load-bearing capacity of hyperbolic surface components in industrial fields such as automobiles, ships, and aviation. However, because multiple layers of fibers need to be continuously placed to meet usage requirements, the production efficiency of fiber placement is low. To achieve time-optimal path parameterization (TOPP), this study optimizes the path discrete point quantity and time parameters of TOPP in order to maximize time optimization. Firstly, in order to ensure the accuracy of surface fiber placement, a trajectory error calculation method based on third-order conical spiral approximation is introduced to constrain trajectory accuracy. Additionally, the fiber placement path normal change that may affect the stability of fiber placement force is also constrained. The maximum trajectory error and maximum surface normal change are used as constraints for the maximum step length of the path discrete points to reduce redundant points. Secondly, in response to the non-optimization problem of time parameters in TOPP, a new TOPP approach based on reachability quadratic analysis is proposed. Through coarse searching for discrete points, time parameters that better fulfill the characteristics of time optimization are solved and fitted by a polynomial. Finally, the grid points are densified for velocity planning. This study conducted simulation experiments on hyperbolic surface placement with a 6-RUS as the experimental object. The results show that under the same placement path, the traditional method Path1 takes a total of 2.05 s, while Path2 takes a total of 2.29 s. The proposed method in this study takes Path1 1.55 s and Path2 1.76 s, respectively, reducing the time by 0.5 and 0.53 s compared to the traditional method.

Similar content being viewed by others

Introduction

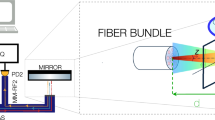

Automated Fiber Placement1,2,3,4,5 (AFP) has complex processing and high costs, especially when laying on curved surfaces in space. In addition to considering the spatial position, the orientation of the pressure roller must be taken into account to maintain the relative stability of the laying force during the laying process. Therefore, the 6RUS parallel mechanism6 is more suitable for composite material laying on curved surfaces due to its multi-DOF, high precision, and high reliability compared to the 6-DOF serial mechanism. In terms of laying quality, Rao et al. analyzed the effects of temperature, laying force, and laying speed on laying quality7. The experimental results showed that temperature, temperature-speed interaction, and laying force-temperature interaction have significant effects on laying quality. Cheng J analyzed the effects of pressure roller orientation on laying quality8. In terms of path planning, Tomáš Martinec et al. used matrix calculations to gradually calculate the rotation and translation matrices required for the end effector relative to the basic system’s local coordinate system in industrial robot automated laying to determine the generation of an economical path9. Yan L et al. proposed an exact cylinder path planning method using differential geometry10. Ruming He et al. further proposed a sparse point strategy based on a bi-normal error evaluation index after generating the path, which reduces data redundancy without causing drag overlap and further improves the efficiency of automated fiber placement11.

However, in automated fiber placement, speed planning has not received much attention, and extensive research has been conducted on parameterization methods for time-optimal path planning both domestically and internationally. Bobrow12 and Shin13 were the first to propose a numerical integration method, which is based on Pontryagin’s maximum principle14,15 and can directly compute the optimal solution. However, it is difficult to find the switching points between the acceleration and deceleration phases, and the stability significantly decreases as the complexity of constraints increases. Verscheure and Hauser proposed a convex optimization approach16,17, which optimizes the square of acceleration and velocity through path discretization, transforming the entire time-optimal problem into a convex optimization problem. This method provides high solution accuracy and stability but has slightly lower computational efficiency and is prone to getting stuck during the dynamic programming process. Pham proposed the Time-Optimal Path Parameterization based on the Reachability Analysis (TOPP-RA) algorithm, which is currently the fastest and most successful method for solving this problem. By dividing the trajectory into N grids, the time-optimal problem is transformed into a velocity-optimal problem18. Through multiple linear programming iterations, the algorithm achieves efficient and 100% successful solutions. Compared to numerical integration methods, there is no longer a need to search for dynamic singular points, resulting in an order-of-magnitude improvement in computation efficiency. By adding suction force constraints, the algorithm addresses the time-optimal problem in robot manipulation, and its feasibility is validated through experiments19. During the replication of the time-optimal experiment in automated fiber placement, it was found that the speed planning effectiveness of TOPP-RA is significantly affected by the sparsity of path discretization points and the coefficient matrix of polynomial trajectory fitting. Pham did not provide a detailed analysis of this issue.

Therefore, this paper focuses on two key research areas. Firstly, how to reduce redundant constraints and sparsify discretization points while maintaining accuracy. Secondly, optimizing the polynomial trajectory to improve smoothness and time optimality. Ultimately, the goal is to solve the time-optimal problem for hyperboloid surface fiber automated placement using the 6-RUS parallel mechanism.

The complex surface fiber placement process requires consideration of factors such as the laying force along the normal direction, laying speed, pre-impregnation temperature of the tape, and laying accuracy. Compared to flat surface placement, surface placement needs to ensure that the laying force remains relatively stable along the normal direction of the laying path. Therefore, it is necessary to pay attention to the offset of the normal vector of the laying path points. If the offset is too large, it can lead to a loss of precision in the end effector of the robot, affecting the effectiveness of fiber placement and reducing the mechanical performance of the surface.

In this paper, Section "Introduction" first introduces the basic concepts of the placement process, the configuration of the laying mechanism, and the control algorithm, analyzing the influencing factors under the speed planning of this algorithm. Section "Problem formulation" introduces constraints based on third-order helical trajectory error and normal vector offset. Under the premise of ensuring no overlap defects in the hyperboloid surface laying path, the grid points are sparsely processed, and the surface Cartesian space trajectory is transformed into a joint space trajectory through the inverse kinematics of the 6-RUS parallel mechanism. Section "Path parameterization planning method based on reachability quadratic analysis" proposes a time-optimal path parameter replanning method based on reachability quadratic analysis (TOPP-RQA). Section "Experiment of TOPP-RQA and grid point sparse method for laying of hyperboloid fibers in 6-RUS mechanism", through experiments, analyzes the effect of grid point density on TOPP-RA and compares the speed planning effects of TOPP-RQA and TOPP-RA, providing a more efficient approach for robotic automated fiber placement.

Problem formulation

Fiber laid path

The widely used fiber placement paths currently include 0°, 90°, and ± 45° orientations. The 0° orientation enhances the transverse load-bearing capacity of the curved surface, while the ± 45° orientation enhances the shear load-bearing capacity. The 90° orientation enhances the axial load-bearing capacity of the curved surface. These four orientations provide better strength and rigidity for the curved surfaces, meeting their specific requirements. The fiber placement models and paths are shown in Figs. 1 and 2. In Fig. 2, the spacing between the placement paths is controlled between 0.5 and 2.5 mm, following the standards of Boeing and Airbus. For the 90° orientation, the surface normal vector remains unchanged, and there is no displacement along the z-axis. For the 0° orientation, there is no displacement along the y-axis. Therefore, the difficulty of placement is relatively lower compared to the ± 45° orientations. Among these orientations, the ± 45° orientation is the most representative. Subsequent experiments will focus on analyzing this orientation.

After determining the layout path, the next step is to give the dynamics, maximum acceleration, and velocity constraints for TOPP to achieve efficient fiber layout.

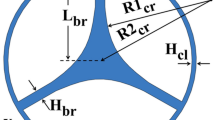

6-RUS pavement robot

Unlike flat laying, curved surface laying technology not only needs to consider the laying path but also the orientation at the discrete points on the path in order to ensure that the laying force of the end effector is always perpendicular to the curved surface, thereby maintaining the stability of the laying force.

Therefore, a 6-dof robot is required. This research project is based on a commissioned project from a company. The project requires laying hyperbolic surface fibers within a limited workspace of 1000 mm × 1000 mm × 1500 mm. Compared to serial mechanisms, a 6-RUS parallel robot can greatly save space by fixing the base above the workpiece. It can also provide better stiffness, and all six active arms are fixed to the base, greatly reducing structural loads and improving mechanism stability. Therefore, it is suitable as the research object for this project. The simplified diagram of the structure is shown in Fig. 3:

Theory of TOPP-RA

Currently, Pham has proposed the Time-Optimal Path Parameterization for Robotic Applications, which provides updated research findings in the field of TOPP. This method solves the problem by handling two quadratic linear programming problems and performing forward and backward grid searches on the discrete points of the path. It calculates the optimal velocity for each grid point.

The coordinates of the workpiece in the coordinate system of the double curved surface laying can be represented by a vector q ∈ R6, which corresponds to the six joints of the 6-RUS robot. The laying path can be represented by the function P(t). Assuming that P is a piecewise C2 continuous function, the path parameter in the path P can be represented as \(P(s(t))_{{s:[0,t] \to [0,s_{end} ]}}\).By transforming it into joint path parameters \(q(s(t))_{{s:[0,t][0,s_{end} ]}}\) through the kinematics of the 6-RUS parallel robot.

The generalized dynamic model of the 6-RUS robot can simplify the formula as follows:

In the formula : \({\mathbf{q}} = [q_{1} ,q_{2} ,q_{3} ,q_{4} ,q_{5} ,q_{6} ]^{{\text{T}}}\), \({\dot{\mathbf{q}}} = [\dot{q}_{1} ,\dot{q}_{2} ,\dot{q}_{3} ,\dot{q}_{4} ,\dot{q}_{5} ,\dot{q}_{6} ]^{{\text{T}}}\)\({\mathbf{\ddot{q}}} = [\ddot{q}_{1} ,\ddot{q}_{2} ,\ddot{q}_{3} ,\ddot{q}_{4} ,\ddot{q}_{5} ,\ddot{q}_{6} ]^{{\text{T}}},\) respectively represent joint acceleration, velocity, and position.\({{\varvec{\uptau}}} = [\tau_{1} ,\tau_{2} ,\tau_{3} ,\tau_{4} ,\tau_{5} ,\tau_{6} ]^{{\text{T}}}\) represent joint torque; M(q) represent inertia tensor matrix; C(q) represent kinetic force and elastic matrix) ; g(q) represent the gravitational terms and Coulomb friction force matrices.

q(s) can be obtained by continuous derivatives of :

From this point of view, the dynamics constraint can be regarded as a second-order cone constraint, and the path parameterization can be realized:

In the formula:

The first-order constraint can also be expressed as:

After path parameterization, the parameters are imported into the quadprog solver to solve the velocity feasible region for the solution.

The fitting of characteristic points of the laying path into a piece-wise geometric path function P can be discretized into M grid points, which allows us to obtain the path parameter s ∈ [ssta,send]. (ssta and send represent the starting point and the ending point of a path). The grid points can be represented as s0,s1,…,sN-1, sM, and the terms of the inner speed and acceleration of the intermediate stage i [si,si+1]are expressed as \(\dot{s}_{i}\) and \(\ddot{s}_{i}\). The grid-spacing velocity planning meets:

\(\Delta_{i}\) expressed that the space step length of the grid point joint is minimal.

In the process of trajectory planning, terminal executor moves according to the predetermined path speed, and \(\dot{s} \ge 0\) at any position, the total time of trajectory movement can be expressed as:

It translates time-optimal problem into a convex optimization problem and can be expressed as:

\(\tau_{\min } (s_{i} )\)、\(\tau_{\max } (s_{i} )\) represent the limits of joint torque at the i-th grid point (mainly affected by dynamic constraints), \(\ddot{s}_{i,\min }\)、\(\ddot{s}_{i,\max }\) represent the acceleration limit at the i-th grid point (a fixed value), \(\dot{s}_{i,\min }\)、\(\dot{s}_{i,\max }\) represent the speed limit of the i-th grid point (mainly affected by the curvature change between the continuous micro-segments connected by the grid point i-1,i,i + 1).To solve linear programming problems (LP) rapidly using quadprog solver by introducing constraints, can be achieved through TOPP-RA.

However, the effect of using the speed constraint and path discrete points in the speed planning of TOPP-RA in the actual layout process is not ideal, and the reasons for this are analyzed below.

Analysis of factors that influence TOPP-RA

In the process of laying hyperbolic surface fibers in 6-RUS manipulator, trajectory planning is required for the path. Therefore, it is necessary to collect discrete points on the path. The principle of the traditional equi-arclength method is to calculate the maximum step size that satisfies the global maximum trajectory error and the maximum normal rotation amount. The path is then divided equally according to this maximum step size.

In this study, a hyperbolic model with dimensions of 300 mm in length, 100 mm in width, and 30 mm in amplitude was selected as the experimental object. Taking two 45° laying paths shown in Fig. 4 as examples (Path1 in red and Path2 in orange), the equi-arclength method was used to discretize the paths and generate discrete points as the trajectory planning inputs for TOPP-RA. The equi-arclength method is characterized by high accuracy and dense distribution of discrete points. However, in fiber laying, multiple layers of fibers are required. Excessive density of discrete points can lead to data redundancy and reduce processing efficiency, as shown in Fig. 5.

In Fig. 5, the joint acceleration constraint is specified as 100 deg/s2. However, during the time interval from 1.6 s to 2 s, the optimal acceleration is not achieved. Factors that affect the TOPP-RA velocity planning include polynomial fitting trajectory constraints, maximum velocity constraint, maximum acceleration constraints, dynamic constraints, and kinematic constraints. However the main reason for this issue lies in the suboptimal trajectory parameters obtained from polynomial fitting. Two factors that affect the effectiveness of polynomial fitting are the number of discrete points and the time parameters. Excessive density of discrete points and unreasonable time parameters can lower the trajectory accuracy, resulting in unsatisfactory velocity planning by TOPP-RA.

Therefore, this paper proposes two optimizations to address this problem. Firstly, a discrete point sparsity strategy is proposed to meet the laying process requirements. Secondly, a rough planning-based optimization strategy for polynomial time parameters is proposed to improve the optimization of the trajectory.

Discrete point processing method

Trajectory error based on three-order helix approximation

During the process of discretization, it is necessary to consider the laying process to avoid phenomena such as bending and wrinkling. Taking into account the complexity of the spatial surface, this paper divides the error constraints into two categories: spatial trajectory error and surface normal vector deviation.

The spatial trajectory error can be represented by the chord error, as shown in Fig. 6. Given the surface equation S(x,y), where P(t) represents the laying path, the maximum distance between the discrete line segment PiPi+1 and the reference path is the spatial trajectory error in this paper, denoted as \(\delta_{r}\). The widely used approach for path approximation is the method of osculating circles. This method involves drawing a series of osculating circles on the surface of the workpiece to accurately represent the shape of the machining path. It is currently widely used in high-precision CNC machining.

Fiber placement is different from CNC machining, as it often involves freeform surfaces. The closely spaced circular method tends to have larger estimation errors for surfaces with varying curvatures and non-zero twists. Based on this, Du et al. proposed a high-precision estimation method for chord error based on third-order conical helix approximation20. Firstly, the helix can be described as follows:

In this formula, \(\alpha = \sin (b\ln s)/\sqrt {1 + b^{2} }\),

\(\beta = \cos (b\ln s)/\sqrt {1 + b^{2} }\),\(a \in (0,1],b \in \Re \backslash \{ 0\}\), s represent the arc length of the conical helix is then determined by Taylor expansion to determine approximate helix lines on the layout curve:

The spiral coefficient a,b can be derived according to the curvature \(\kappa (s)\), torsion \(\tau (s)\) and \(\kappa^{\prime}(s)\) as:

Any free curve can be approximated locally by a cone helix with a third-order approximation using a cone helix’s string error, therefore, the string error of the free curve can be estimated using a cone helix’s string error.

The surface spread also needs to consider the normal rotation amount of the discrete points. If the normal offset is too large, it will affect the stability of the 6-RUS parallel mechanism to apply vertical forces against the surface, therefore, while satisfying the string error, it also needs to constrain the normal offset \(\Delta \phi\) amount between the discrete points. In subsequent experiments, the maximum normal offset is taken as 2°.

Discrete point sparsity approach

When the laying surface is complex, it can lead to narrow spacing between the discrete points that satisfy the laying process for the local path. The traditional equal arc length discretization method would result in a significantly dense distribution of discrete points along the entire path, greatly affecting the quality of the laying. To address this issue, an improved path discretization algorithm is proposed, which takes into account trajectory error and normal offset.

The calculation error diagram, as shown in Fig. 7, illustrates that the curvature and torsion of the spatial curve can be obtained by considering three consecutive discrete points, while the first derivative of curvature can be obtained by considering four consecutive points, as indicated by formulas 11 and 12.

In this formula, h represents the discrete step size, and P(i) denotes the discrete points of the path.

The calculation of the spiral coefficient requires four discrete points to solve the curvature and torsion rate, among which the ∆θ is the offset of the normal vector and the δ is the trajectory error. The idea of this algorithm is to dilute the number of discrete points while ensuring the accuracy of the layout trajectory. The above algorithm flowchart is shown as follows, and the specific steps are listed in Table 1.

Approach feasibility verification

To ensure a laying process without overlapping defects, the machine positioning accuracy and repeat positioning accuracy are comprehensively considered. The maximum allowable trajectory error of 0.05 mm and the maximum normal variation of 2° are inputted into the sparse algorithm for discrete points. Before sparsification, the discrete points are shown in Fig. 8a as 501 points. After running the sparse algorithm, they are sparsified to 90 points, as shown in Fig. 8b, the third-order spiral errors obtained by the algorithm are all controlled below 0.05 mm, as shown in Fig. 9c. The discrete points are then subjected to an inverse kinematics solution using a 6-RUS parallel mechanism for joint time-optimal velocity planning. The maximum velocity constraint is set to 150 deg/s, and the maximum acceleration constraint is set to 100 deg/s2. In Fig. 9a, the algorithm without improvement is shown, and the trajectory takes 3.89 s. In Fig. 9b, the trajectory takes 3.71 s using the proposed sparse algorithm in this paper, reducing the time by 0.18 s. This demonstrates the feasibility of the method.

Due to the uneven spacing of the sparse points after sparsification, the trajectory obtained from polynomial fitting is not sufficiently smooth. This ultimately results in new vibrations in velocity at certain positions. To address this issue, a quadratic search-based time-optimal path parameter optimization strategy is proposed in Sect. "Path parameterization planning method based on reachability quadratic analysis" of this paper.

Path parameterization planning method based on reachability quadratic analysis

To perform trajectory planning for the 6-RUS robot in fiber laying, it is necessary to fit the discrete points of the path to constrain its geometric shape. Polynomial fitting is one of the simplest and most direct methods for this task. However, since the accuracy of polynomial fitting depends on the time parameters, finding the appropriate time for each node is a problem that needs to be addressed in this paper. First, let’s introduce the polynomial fitting method used in this paper.

Polynomial fitting method of TOPP-RA

To achieve better smoothness and continuity in the laying path and preserve the geometric features, this paper uses a 7th-order polynomial to fit the discrete points of the laying path for trajectory planning. The parameterization of joint angles q concerning time is represented as follows:

where i represents the i-th line segment connecting the discrete points, so W is a coefficient matrix. Taking its first and second derivatives separately, we get:

After solving the polynomial coefficient matrix W, velocity and acceleration at any point on the path can be obtained, thereby providing geometric constraints for TOPP-RA. However, due to the uneven mapping of the discrete points on the laying path to the positions of each joint, it is not possible to adjust the time parameters. This ultimately leads to a decrease in trajectory accuracy and smoothness, affecting the effectiveness of velocity planning. Below, a method for adjusting the time parameters is proposed to solve the problem.

Time-optimal path parameterization planning method based on reachability quadratic analysis (TOPP-RQA)

To solve the issue of non-uniform spacing between discrete points on the laying path and suboptimal time parameters leading to non-smooth polynomial trajectories and significant errors, this paper further proposes a quadratic programming method based on the concept of TOPP-RA. By solving a quadratic linear program, we obtain time parameters that comply with the discrete point spacing. We then perform quadratic fitting by replacing the original coefficient matrix W with the new coefficient matrix Wnew. Finally, we densify the trajectory grid points and perform time-optimal velocity planning.

The sparsity or density of the TOPP-RA grid points affects the sensitivity of velocity planning. Theoretically, the number of grid points M should not be smaller than the number of discrete points N in the input path. Otherwise, it would result in a loss of path information in velocity planning and lead to under-constrained trajectory distortion. Therefore, the number of grid points should not be a constant value. The number of discrete points N and the number of grid points M should satisfy the following condition:

k represent the experience coefficient, the larger the value of k, the longer the solution time and the better the solution effect.

After selecting N discrete points from the laying path, the next step is to perform polynomial fitting with a given set of time parameters. At this stage, the coefficient matrix W obtained is not yet optimal. Following the forward and backward recursive velocity search method of TOPP-RA, we perform a coarse search with the number of grid points equal to the number of discrete points N. Then, the optimal time obtained from this search is used as the time parameter for another fitting with a 7th-degree polynomial. The resulting trajectory is smoother, as shown in the Fig. 10. After densifying the grid points M, the optimal velocity can be obtained by eliminating redundant constraints.

The process diagram of the trajectory planning method of optimal time based on reachability quadratic analysis is shown below in Table 2:

Feasibility verification of the algorithm

Taking the experiment of fitting a 7th-degree polynomial with non-uniformly distributed discretized points as an example, we select 6 non-uniform discrete points q = [16.1,16.5,16.8,20.1,20.5,20.8] and time parameters t1 = [0,1,2,3,4,5] for the initial fitting, as shown in the figure.

Given a maximum acceleration constraint of 3 mm/s2 and a maximum velocity constraint of 1 mm/s, we use TOPP-RA to perform coarse planning on the polynomial coefficients, obtaining grid point times t2 = [0 1.64 2.83 5.04 6.23 7.86]. These times are then used as the time parameters for a second 7th-degree polynomial fitting, resulting in Fig. 8. As can be seen in Fig. 10a, the curve after quadratic fitting is noticeably smoother, better conforming to the time-optimal characteristics. In Fig. 10b, the velocity planning in TOPP-RQA is smoother compared to TOPP-RA.

Experiment of TOPP-RQA and grid point sparse method for laying of hyperboloid fibers in 6-RUS mechanism

To validate the feasibility of the algorithm, we use Vrep/MATLAB to simulate the experiment, as illustrated in Fig. 11. we utilize a hyperboloid as the laying surface and use the two representative paths depicted in Fig. 4 as the laying paths. The time-optimal trajectory planning is performed using a 6-degree-of-freedom parallel mechanism with RUS joints. The effects of sparse point strategies and quadratic polynomial optimization on TOPP are analyzed.

First, we sparse the discrete points of Path1 and Path2 in Fig. 4. The original discrete points before sparse are shown in Fig. 12a, where Path1 is discrete to 100 points and Path2 is discrete to 97 points. After the sparsity algorithm, the sparsity paths are shown in Fig. 12b, where Path1 is reduced to 38 points and Path2 is reduced to 36 points. Then, the inverse kinematics of the sparse points are solved using a 6-degree-of-freedom parallel mechanism with RUS joints to perform time-optimal velocity planning on the joints, given a maximum velocity constraint of 150 deg/s and a maximum acceleration constraint of 100 deg/s2.

The velocity planning results for Path1 are shown in Fig. 13. In Fig. 13a, the trajectory duration is 2.05 s using the unimproved algorithm. In Fig. 13b, the trajectory duration is reduced to 1.83 s by applying the sparse point algorithm proposed in this paper. In Fig. 13c, the trajectory duration further decreases to 1.66 s by using the TOPP-RQA algorithm. In Fig. 13d, both optimization methods proposed in this paper are applied, resulting in a trajectory duration of 1.55 s.

The velocity planning results for Path2 are shown in Fig. 14. In Fig. 14a, the trajectory duration is 2.29 s using the unimproved algorithm. In Fig. 14b, the trajectory duration is reduced to 1.80 s by applying the sparse point algorithm proposed in this paper. In Fig. 14c, the trajectory duration increases slightly to 1.85 s when using the TOPP-RQA algorithm. In Fig. 14d, when both optimization methods proposed in this paper are applied, the trajectory duration is further reduced to 1.76 s.

This demonstrates that both methods proposed in this paper can achieve trajectory optimization, and better optimization results are achieved when both methods are used together.

Conclusion

This paper focuses on improving the solving effectiveness of Time-Optimal Path Parameterization (TOPP). The effectiveness of TOPP is mainly influenced by the path parameters. Dense path discretization points and unreasonable time parameters can lead to sub-optimal path parameters. Based on this, the paper proposes two directions for optimizing the path parameters.

Firstly, a sparse point strategy is proposed. Firstly, considering the complexity of the surface laying scene for fiber deployment, a trajectory error calculation method based on third-order circular cone helix approximation is introduced to describe the trajectory accuracy, ensuring the accuracy of the sparse point strategy. Then, a sparse point coefficient strategy is proposed with the constraint of maximum trajectory error and maximum normal offset, which prevents excessive constraints of path points and avoids speed jitter and discontinuity in fiber deployment. Finally, redundant constraints are removed, and the path discretization points that meet the process characteristics are retained.

Secondly, a time-optimal path parameter optimization method based on dual search (TOPP-RQA) is proposed. The sparsified discretization points are fitted and input together with the constraints of a 6-degree-of-freedom parallel mechanism with RUS joints into a quadratic linear programming solver. A coarse search is performed to obtain more reasonable time parameters influenced by the density of discretization points. These parameters are then used for quadratic trajectory fitting to obtain a smoother and more time-optimal trajectory. The polynomial coefficient matrix is re-input into the quadratic linear programming solver to solve for the time-optimal velocity.

Compared with traditional TOPP methods, the algorithm in this paper removes redundant data and makes the laying trajectory smoother, greatly improving the deployment speed.

Data availability

The datasets generated and analysed during the current study are not publicly available due confidentiality of the study but are available from the corresponding author on reasonable request.

References

Forcellese, A., Mancia, T., Russo, A. C., Simoncini, M. & Vita, A. Robotic automated fiber placement of carbon fiber towpregs. Mater. Manuf. Processes 37, 539–547 (2022).

Cheng, L., Zhang, L., Zheng, C. & Li, J. Research on the method of improving the laying accuracy of automated fiber placement. Int. J. Adv. Manuf. Technol. 125, 4883–4897 (2023).

Pei, J. Z. & Wang, X. P. Ply orientation-driven path planning with multi reference paths for robotic fiber placement on mesh surface. Key Eng. Mater. 748, 45–50 (2017).

Debout, P., Chanal, H. & Duc, E. Tool path smoothing of a redundant machine: Application to automated fiber placement. Comput. Aided Des. 43, 122–132 (2011).

Lukaszewicz, D.H.-J.A., Ward, C. & Potter, K. D. The engineering aspects of automated prepreg layup: History, present and future. Compos. B Eng. 43, 997–1009 (2012).

Zhao, Y., Yu, H., Zhang, J., Yang, J. & Zhao, T. Kinematics, dynamics and control of a stabilized platform with a 6-rus parallel mechanism. Int. J. Robot. Automat. 32, 283–290 (2017).

Rao, S., Umer, R., Thomas, J. & Cantwell, W. J. Investigation of peel resistance during the fibre placement process. J. Reinf. Plast. Compos. 35, 275–286 (2016).

Cheng, J., Zhao, D., Chen, H., Zhang, Y. & Wang, Y. Effect of the attitude fine-adjustment of compaction roller on automated fiber placement defects and trajectory. J. Reinf. Plast. Compos. 38, 539–555 (2019).

Martinec, T., Mlýnek, J. & Petrů, M. Calculation of the robot trajectory for the optimum directional orientation of fibre placement in the manufacture of composite profile frames. Robot. Comput.-Integrat. Manuf. https://doi.org/10.1016/j.rcim.2015.02.004 (2015).

Li, L., Wang, X., Xu, D. & Tan, M. An accurate path planning algorithm based on triangular meshes in robotic fibre placement. Int. J. Robot. Automat. https://doi.org/10.2316/Journal.206.2017.1.206-4673 (2017).

He, R., Qu, W. & Ke, Y. An improved path discretization method for automated fiber placement. J. Reinf. Plast. Compos. 39, 545–559 (2020).

Bobrow, J. E., Dubowsky, S. & Gibson, J. S. Time-optimal control of robotic manipulators along specified paths. Int. J. Robot. Res. https://doi.org/10.1177/027836498500400301 (1985).

Kang, S. & McKay, N. Selection of near-minimum time geometric paths for robotic manipulators. IEEE Trans. Automat. Contr. 31, 501–511 (1986).

Kunz, T. & Stilman, M. Time-optimal trajectory generation for path following with bounded acceleration and velocity. Robot.: Sci. Syst. https://doi.org/10.7551/mitpress/9816.001.0001 (2013).

Pham, Q.-C. A general, fast, and robust implementation of the time-optimal path parameterization algorithm. IEEE Trans. Rob. https://doi.org/10.1109/tro.2014.2351113 (2014).

Verscheure, D., Demeulenaere, B., Swevers, J., De Schutter, J. & Diehl, M. Time-optimal path tracking for robots: A convex optimization approach. IEEE Trans. Autom. Control https://doi.org/10.1109/tac.2009.2028959 (2009).

Hauser, K. Fast interpolation and time-optimization with contact. Int. J. Robot. Res. https://doi.org/10.1177/0278364914527855 (2014).

Pham, H. & Pham, Q.-C. A new approach to time-optimal path parameterization based on reachability analysis. IEEE Trans. Rob. https://doi.org/10.1109/tro.2018.2819195 (2018).

Pham, H. & Pham, Q.-C. Critically fast pick-and-place with suction cups. arXiv: Robotics, arXiv: Robotics (2018).

Du, X., Huang, J., Zhu, L.-M. & Ding, H. Third-order chord error estimation for freeform contour in computer-aided manufacturing and computer numerical control systems. Proceed. Institut. Mech. Eng, Part B: J. Eng. Manuf. 233, 863–874 (2019).

Author information

Authors and Affiliations

Contributions

Guangyu Dong (First Author): Conceptualization, Methodology, Software, Investigation, Formal Analysis, Writing—Original Draft; Wenpeng Li : Conceptualization, Funding Acquisition, Resources, Supervision, Writing—Review & Editing; Yuhong Du(Corresponding Author): Data Curation, Writing—Original Draft; Leicheng Yang : Resources, Funding Acquisition, Writing—Review & Editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Dong, G., Li, W., Du, Y. et al. Time-optimal path parameterization planning for automatic fiber placement based on reachability quadratic analysis. Sci Rep 15, 11224 (2025). https://doi.org/10.1038/s41598-025-91718-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-91718-1