Abstract

The negative–positive-uncoupled stiffness device (NPUSD) is a novel variable stiffness system recently developed by the authors, designed to efficiently and cost-effectively achieve multi-level seismic fortification in structures. This study aims to integrate the NPUSD with a viscous damper in parallel, forming an innovative negative–positive-uncoupled stiffness amplifying damper (NPUSAD). Additionally, it establishes the collapse capacity spectra for a degrading single-degree-of-freedom (SDOF) system equipped with the NPUSAD under three distinct seismic record sets. The study investigates the influence of both the SDOF structural parameters and the NPUSAD parameters on the collapse capacity spectra. The results indicate that the NPUSAD-SDOF system significantly enhances the collapse resistance of long-period structures, with improvements of 30%, 40%, and 50% under far-field non-impulsive, near-field non-impulsive, and near-field impulsive seismic record sets, respectively. Among the parameters of structural element, the ductility ratio, soften stiffness coefficient, and stability coefficient have a significant impact on the collapse capacity spectra. For the NPUSAD parameters, the transition displacement ratio has the greater influence, followed by the positive-to-negative stiffness ratio, while the connecting stiffness ratio has the least impact.

Similar content being viewed by others

Introduction

With the increasing understanding of earthquakes and structural seismic responses, the seismic fortification objectives for structures have evolved from a single fortification level to a multi-level performance-based design framework1,2,3. To satisfy the different performance demands under different seismic levels, existing studies have used a combination of different seismic mitigation and isolation technologies to play a dominant role at different levels respectively4, or used the weight coefficient method to convert multi-objective problems into a single-objective problem5. However, there are several shortcomings in the existing research: First, using different devices to achieve multi-level seismic mitigation will cost a lot; Second, the mutually restricted location of various seismic mitigation is still a problem in seismic mitigation with several kinds of dampers. Third, even though many novel dampers realize controlling responses under both moderate earthquakes and severe earthquakes, their collapse resistance abilities need to be further investigated. To sum up, the design and optimization of structures to meet the objectives of both seismic mitigation and collapse resistance under different seismic levels is an important but complex issue.

Using appropriate variable stiffness to achieve multi-level performance-based design is an efficient way. At present, in the research of multi-stage variable stiffness applied to structural seismic mitigation and isolation, the most popular one is the self-centering energy dissipation structure. The bilinear elastic self-centering system is paralleled with the metallic energy dissipation system to obtain a flag-type hysteretic curve, effectively reducing residual deformation of structure under strong earthquake6,7. Cao et al. proposed a multi-level SMA rubber-bearing isolation system by gradually stretching and activating different groups of SMA cables. The stiffness of the bearing is gradually improved, and a stepped-like hysteretic curve is obtained, which makes the bearing have good energy dissipation, self-centering and limiting excessive displacement capabilities8. However, the large positive stiffness of the self-centering system in the small displacement range will amplify the input of seismic force, leading to an increase in the peak acceleration response9. To address this issue, Gullu et al.10 proposed a Steel-SMA hybrid damper, which effectively mitigates the peak energy response while significantly reducing residual deformation.

The NSD (negative stiffness device) is a potential device that can not only improve the energy dissipation ability of structures under moderate earthquakes but also prevent the collapse of structures under extreme earthquakes. In the last decade, Nagarajaiah and other scholars proposed NSD11,12,13,14,15, and a series of studies have been conducted to improve the structural seismic isolation and mitigation performance by using the NSD to increase the additional damping ratio of structures. Besides, Ul Islam and Jangid16,17 demonstrated that negative stiffness and inerter devices (NSIDs) significantly enhance the seismic performance of base-isolated liquid storage tanks under both near-field and far-field excitations, and further established the H2 optimal control of NSIDs for base-isolated structures. Wang et al.18 first proposed a new seismic mitigation system by connecting NSD in paralleling with a viscous damper to amplify the damper’s stroke called negative stiffness amplifying damper (NSAD). The NSAD can achieve great seismic mitigation performance under small and moderate earthquakes. Wang et al.19 investigated the role of NSAD in improving the seismic mitigation effect of the yielding SDOF system to address the problem of limited damping dissipation due to insufficient stiffness of flexible supports in existing braced damping structures. The main structure was constructed using the Bouc–Wen model, and the effects of the key parameters such as flexible support stiffness, negative stiffness, and displacement threshold on the nonlinear response spectrum were analyzed. The displacement threshold is the critical displacement from the negative stiffness stage under small displacements to the positive stiffness stage under large displacements of NSD. It was found that if the displacement threshold was taken to be too large, i.e., positive stiffness was provided too late, it would cause significant residual deformation. Although viscous dampers were predominantly employed in most studies on NSADs, NSDs were also combined with other types of dampers, such as lead rubber bearings (LRBs) in parallel20, forming a negative stiffness isolation system. This system reduced the overall stiffness of the isolated structure, prolonged the structural period, achieved long-period isolation, and enhanced the energy dissipation capacity of the dampers. Similarly, it was anticipated that combining lead extrusion rod dampers21 with NSDs would also be applicable for structural vibration control. Furthermore, some researchers integrated NSDs with SMA self-centering devices22,23. The negative stiffness characteristics addressed the issue of amplified structural responses caused by the high initial stiffness of self-centering systems.

Recent studies have demonstrated the superior performance of NSAD in various applications. It has been found effective in bridge cables24, multi-story frame structures25,26 (utilizing multi-story placement of NSAD25 or introducing a rocking wall and a bottom NSAD26), and damped outrigger tall buildings. The theoretical analysis of damped outrigger-core tube structures with NSADs typically involves treating the influence of the outrigger and exterior columns as rotational springs, while the core wall is simplified using the Euler–Bernoulli beam27,28,29,30,31 or simplified using Timoshenko beam considering shear deformation effects32. There have been comprehensive studies of the damped outrigger structures with NSADs on the random seismic response analysis27,28,32, multi-objective optimization of seismic performance29, wind-induced vibration response control30, and integrated seismic and wind optimization31. In the application research, studies on seismic fragility analysis of braced-core-tube frame buildings33 and the seismic design of the 248-m-tall Lanzhou Global Harbor project in China34 have demonstrated that introducing NSAD in the outrigger effectively addresses the issue of limited additional damping ratio caused by insufficient stiffness of the exterior columns.

Since most of the existing NSD is implemented with a pre-compressed linear spring as the core component6,7,8, once the parameters related to the negative stiffness stage on the force–displacement curve have been optimized for the given seismic intensity level, the positive stiffness values at a large displacement range are also determined. This limitation causes the coupled positive stiffness stage to be underutilized for the strong seismic collapse performance objective. Nagarajaiah35,36 simplified the force–displacement curve of NSD with coupled negative–positive stiffness to an idealized piecewise linear force–displacement curve based on the principle of tangential stiffness equivalence, which is aimed to derive a closed solution of the response conveniently, instead of uncoupling and exploiting the positive stiffness properties. Adequate seismic collapse capacity of structures under strong earthquakes is an effective way to reduce casualties. It is noteworthy that the positive stiffness stage can serve the collapse resistance objective in the existing NSAD research. However, since the main objective in these researches is structural seismic mitigation by the negative stiffness characteristic, and the positive stiffness cannot be decoupled, the influence of positive stiffness parameters on the collapse resistance performance during an extreme earthquake has not been systematically studied. Recently, the authors have proposed a negative–positive-uncoupled stiffness mechanism that achieves independent variation of negative and positive stiffnesses, meeting the seismic mitigation and anti-collapse performance objectives under different levels of ground motion37.

In this paper, based on the novel negative–positive-uncoupled stiffness mechanism, this research develops the collapse capacity spectra of NPUSAD-SDOF system. “Mechanical model of NPUSAD-SDOF system” section establishes the mechanical model and the dynamic equation of the proposed NPUSAD-SDOF system. “Seismic collapse performance of degrading SDOF system with NPUSAD” section compares the seismic performance of NSAD-SDOF and NPUSAD-SDOF at different seismic levels and investigates the effect of key parameters of NPUSAD on the seismic collapse performance based on a NPUSAD-SDOF reference structure. “Incremental dynamic analysis of NPUSAD-SDOF system” section considers the record-to-record variability and establishes the collapse capacity spectra of the NPUSAD-SDOF reference structures with the fundamental period in the range of 0.1 s to 5 s under different record sets. Parametric analysis of the collapse capacity spectra and empirical formulas for the median spectra are presented in “Parametric analysis of seismic collapse capacity of NPUSAD-SDOF system” section. “Conclusion” section presents the concluding remarks.

Mechanical model of NPUSAD-SDOF system

Conventional NSDs provide coupled negative and positive stiffnesses. This section first derives the coupled relationship of the negative and positive stiffnesses of NSD, then illustrates the implementation mechanism for uncoupling the stiffnesses and establishes the dynamic equations for NPUSD (negative–positive-uncoupled stiffness device), NPUSAD (negative–positive-uncoupled stiffness amplifying damper) and NPUSAD-SDOF system.

Coupled relationship of negative and positive stiffnesses of conventional NSD

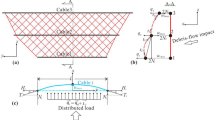

The working mechanism of the existing NSAD is shown in Fig. 1. Point A is connected with the fluid viscous damper (FVD), and the lever BC is hinged with the spring segment CD at point C with point B as the fulcrum. When point A deviates from the initial position, the lever BC makes the displacement of point C more amplified than that of point A. In the meantime, the preloaded spring CD releases the prestress to further promote the displacement of point A, amplifies the travel of the damper, and enlarges the hysteresis area of the FVD from the dotted line to the solid line. With the release of prestress to the process of spring tension, the force–displacement curve of point A gradually changes from negative stiffness to positive stiffness. The output force FNSD at point A can be obtained by taking the moment equilibrium equation at point B, and is described in Eq. (1).

When the spring is linearly elastic, the force–displacement relationship at point A is approximately a cubic function curve16, i.e., \(F_{{{\text{NSD}}}} \left( {x_{{\text{d}}} } \right) = ax_{{\text{d}}}^{{3}} + bx_{{\text{d}}}\) where \(b < 0\), \(a > 0\). The displacement corresponding to the maximum force in the negative stiffness stage can be obtained, that is, the displacement threshold \(x_{{\text{d,n}}} = \pm \sqrt { - {b \mathord{\left/ {\vphantom {b {\left( {3a} \right)}}} \right. \kern-0pt} {\left( {3a} \right)}}}\). The maximum displacement \(x_{{\text{d,p}}} = \pm \sqrt { - {b \mathord{\left/ {\vphantom {b a}} \right. \kern-0pt} a}}\) where the force is 0. Based on the simplified cubic model, two equivalent piecewise linear principles are proposed, as shown in Fig. 2: (1) keeping \(x_{{\text{d,n}}} , \, x_{{\text{d,p}}} , \, F_{{{\text{NSD}}}} \left( {x_{{\text{d,n}}} } \right)\) equal respectively (this method is called transition point equivalence principle), the relationship between negative and positive stiffnesses \(K_{{\text{p}}} = - \frac{{x_{{\text{d,n}}} }}{{x_{{\text{d,p}}} - x_{{\text{d,n}}} }}K_{{\text{n}}} = - 1.366K_{{\text{n}}}\); (2) keeping \(x_{{\text{d,n}}} , \, A_{{\text{n}}} , \, A_{{\text{p}}}\) equal respectively (this method is called areas equivalence principle), \(K_{{\text{p}}} = - \frac{{A_{{\text{n}}} }}{{A_{{\text{p}}} }}K_{{\text{n}}} = - 1.25K_{{\text{n}}}\) according to Eqs. (2) and (3). It can be seen that the relationship between the negative and positive stiffnesses is fixed. Therefore, the force–displacement of the conventional NSD exhibits negative–positive-coupled variable stiffness characteristics.

Negative–positive-uncoupled stiffness working mechanism

The essential reason for the coupling of negative and positive stiffnesses in conventional NSD is that the spring always provides linear elasticity. To resolve this issue, the authors have recently proposed to uncouple by replacing the preload linear spring with a preload multi-linear elastic spring while the other parts remain unchanged37, as shown in Fig. 3. The first and second rows in Fig. 3 correspond to a smaller or larger positive stiffness, respectively, than the coupled value. The implementation of the multi-linear spring can reference the existing researches about self-centering devices by gradually stretching and activating different groups of strings16 or adopt the composite disc springs with different number of overlapping pieces. The red spring in Fig. 3 indicates that it is participating in the work, and the white spring indicates that it is not participating or has quit the work. For simplicity, the uncoupling mechanism is illustrated with a bilinear spring as an example. The elastic force of the preload bilinear spring is shown in Eq. (4), where the elastic force is related to ks1, ks2, Δ1 and Δ2 in the small deformation stage, and related to ks2 and Δ2 in the large deformation stage. From Eq. (1) for the relationship between Fspring and FNSD, the variables influencing the different stages of the force–displacement curve of the device are the same as the preload spring, i.e., the first stage of the force–displacement curve of the device is related to ks1, ks2, Δ1 and Δ2, while the second stage relates to ks2 and Δ2 only, indicating that some of the parameters only affect a local stage. When the inflection point of the preload bilinear spring is reached, Δ = Δ1, and lCD = lBD-lBC + Δ1, the deformation of the device xd can be obtained by Eq. (5).

To illustrate the effectiveness of the mechanism more intuitively, Fig. 4 shows the influence of parameters of the force–displacement curve for the preload bilinear spring on the force–displacement curve for the NPUSD with lAB = 50 mm, lBC = 150 mm, lBD = 300 mm, α = 3, the values of ks1, ks2, Δ1 and Δ2 are given in the figures. When the preload bilinear spring degrades to a linear elastic spring (i.e., ks1 = ks2 or Δ1 = 0 in Fig. 4), the NPUSD becomes a traditional NSD. The dashed line in Fig. 4 represents the force–displacement curve of the NSD, which is approximately a cubic odd function, with positive and negative stiffnesses being coupled. However, it can be seen that the proportional relationship of the negative and positive stiffnesses of NPUSDs is adjustable, and the position of the stiffness transition is adjustable, both of which together demonstrate the effectiveness of the uncoupling mechanism. Furthermore, it is noteworthy that the more segments the curve of preload spring is taken, the closer the force–displacement curve of the NPUSD is to the simplified negative–positive bilinear model.

Equation of motion of NPUSAD-SDOF system

As shown in Fig. 5c, NPUSAD is composed of NPUSD in parallel with the additional viscous damping and then in series with the connecting spring. Considering the influence of strength and stiffness degradation and stiffness softening, the hysteresis model of the structural element adopts the peak-oriented IMK model38 which can be modeled by assigning IMKPeakOriented material to zero-length element in OpenSees39. P-Δ effect is considered by paralleling a negative stiffness spring40. The skeleton curve of the structural element is shown in Fig. 5a. The NPUSD adopts the bilinear elastic model for the sake of simplicity, as shown in Fig. 5b. When the structural element exhibits mild plastic behavior, the negative stiffness segment of the NPUSD plays a primary role. However, when the structural element experiences strength and stiffness degradation, the positive stiffness segment of the NPUSD comes into play, preventing overall system collapse.

NPUSAD

The dynamic equation of NPUSAD is shown in Eq. (6). The restoring force model of NPUSD adopts piecewise linear function, as shown in Eq. (7).

where x is the displacement of SDOF structure relative to the ground, xd is the deformation of NPUSD, xd,n is the transition displacement, Kn and Kp are the negative and positive stiffnesses of NPUSD respectively, Kb is the connecting stiffness, cd is the damping coefficient of additional linear viscous damping, FNPUSD and FNPUSAD are the forces of NPUSD and NPUSAD, respectively.

NPUSAD-SDOF system

The motion equation of degrading SDOF system with P-Δ effect under earthquake is as follows:

where m, c0 and Ke are the mass, inherent damping coefficient and elastic stiffness of SDOF, respectively, Fs is the nonlinear restoring force, θ is the stability coefficient considering the P-Δ effect20.

The main parameters of the peak-oriented IMK model include the strengthening coefficient (for the sake of simplification, αs = 0.02 in this study), ductility coefficient μ, softening coefficient αc, and material cyclic degradation parameters γs,c,a,k including four cyclic degradation modes of strength and stiffness, that is, basic strength deterioration γs, post-capping strength deterioration γc, accelerated reloading stiffness deterioration γa, and unloading stiffness deterioration γk. For simplification, the first three degradation parameters are assumed to take equal values and are denoted as γs,c,a. Also, to ensure the same degradation rate, γk = 2γs,c,a41.

The motion equation of the NPUSAD-SDOF system considering the P-Δ effect is controlled by

Define the following dimensionless parameters, including additional damping ratio ξd, connecting stiffness ratio αb, negative stiffness ratio αn, and positive stiffness ratio αp.

In previous studies on NSAD, a parameter determination method for the linear negative stiffness for seismic mitigation performance under small and medium earthquakes was given, where the optimal negative stiffness ratio αn and additional damping ratio ξd were determined from a given connecting stiffness ratio αb9, see Eqs. (11) and (12). Based on the idea of uncoupled multi-level hierarchical optimization, this paper mainly considers the effects of the connecting stiffness ratio αb, transition displacement coefficient μn and positive stiffness ratio αp of NPUSAD on seismic collapse resistance performance. This idea avoids at root the problem of competing performance objectives in multi-objective optimization at different seismic hazard levels, requires a small computational effort and has the prospect of easy engineering application.

In this paper, the transition displacement coefficient μn is reflected by the transition displacement ratio β1, defined as \(\beta_{1} = {{\left( {\mu_{{\text{n}}} - 1} \right)} \mathord{\left/ {\vphantom {{\left( {\mu_{{\text{n}}} - 1} \right)} {\left( {\mu - 1} \right)}}} \right. \kern-0pt} {\left( {\mu - 1} \right)}}\). β1 < 0 means that the transition displacement is less than the yield displacement of the structural element, β1 = 0 means that the transition displacement equals the yield displacement of the structural element, and β1 = 1 corresponds to the softening displacement xc. The positive stiffness ratio αp is reflected by the positive-to-negative stiffness ratio i.e., \(\beta_{2} = {{\alpha_{{\text{p}}} } \mathord{\left/ {\vphantom {{\alpha_{{\text{p}}} } {\alpha_{{\text{n}}} }}} \right. \kern-0pt} {\alpha_{{\text{n}}} }}\), β2 = 1 indicating that linear negative stiffness is always provided, and this case is referred to as LNSAD (linear negative stiffness amplifying damper) in this work.

Seismic collapse performance of degrading SDOF system with NPUSAD

To illustrate clearly the contributions of NPUSAD to the structural seismic performance at different seismic intensity levels, this section presents the force–displacement relationships for the components of a reference structure under different intensity levels and investigates the influence of the key NPUSAD parameters.

Ground motion and NPUSAD parameters

For the purpose of intuitively illustrating the mechanical behavior of each component in the SDOF system, a typical long- (or intermediate-) period seismic wave (Manji-184057 ground motion record, see Fig. 6) scaled to different intensity levels was employed as the excitation input. The uncertainty of ground motions will be addressed in Sects. 4 and 5. And univariate analysis was carried out based on the NPUSAD-SDOF reference structure to systematically study the effects of the three key parameters of NPUSAD (i.e., the transition displacement ratio β1, the positive-to-negative stiffness ratio β2, and the connecting stiffness ratio αb).

The nondimensional ground motion intensity is defined as Eq. (13), which is the ratio of the elastic seismic force demand of the structure to the yielding load capacity of the structure for a given intensity earthquake, with IM = 1 when the structure just reaches yield. The engineering demand parameter (EDP) is the ratio of the peak displacement to the yield displacement of the structural element, as shown in Eq. (14). The hysteresis curve is also normalized by the yield force and yield displacement of the structural element considering the P-Δ effect, as shown in Eqs. (15) and (16).

where Sa(T) is the 5% damped spectral acceleration at the fundamental period of the structure, and η is the ratio of yield force to gravity.

The structural element parameters of the reference structure: T = 3 s, μ = 4, αc = − 0.3, θ = 0.07, γs,c,a = 100 (γk = 200). The levels of the ground motion intensity and the default values and variation range of the three key parameters of NPUSAD are listed in Table 1. Seismic intensity IM is taken at five levels, covering different degrees of plastic development for elasticity, yielding until collapse state. The three key parameters of NPUSAD are the transition displacement ratio β1, the positive-to-negative stiffness ratio β2 and the connecting stiffness ratio αb. Specifically, the relationship between β1 and μn is \(\beta_{1} = {{\left( {\mu_{{\text{n}}} - 1} \right)} \mathord{\left/ {\vphantom {{\left( {\mu_{{\text{n}}} - 1} \right)} {\left( {\mu - 1} \right)}}} \right. \kern-0pt} {\left( {\mu - 1} \right)}}\). The smaller β1, the earlier the positive stiffness is provided. When β1 is taken as − 0.3, μn is 0.1, meaning that the positive stiffness starts to be provided when the structural element is still far from the yield point. When β1 is taken as 0.5, μn is 2.5, i.e. the transition displacement is 2.5 times the yield displacement of the structural element. The positive-to-negative stiffness ratio β2 is usually a negative number. If β2 is taken as 1, it always provides a linear negative stiffness, that is, LNSAD case. The β2 obtained from the two equivalence methods of the NSD with coupled negative–positive stiffness in “Coupled relationship of negative and positive stiffnesses of conventional NSD” section are − 1.366 and − 1.25 respectively, so the variation range of this parameter covers these two values to verify the need for uncoupling stiffnesses. Note that a larger αb indicates a stiffer connection segment with less deformation of itself; the corresponding optimal negative stiffness ratio and additional damping ratio determined by the seismic mitigation objective under small and medium earthquakes are shown in Table 2.

Seismic performance comparison of NPUSAD-SDOF and NSAD-SDOF

In order to visually illustrate the necessity of the negative–positive-uncoupled stiffness mechanism, assuming that linear negative stiffness and transition displacement threshold are equal, Fig. 7 gives a comparison of the responses of the NSAD-SDOF and NPUSAD-SDOF reference structure (T = 3 s, μ = 4, αc = − 0.3, θ = 0.07, γs,c,a = 100, β1 = 0.1, β2 = − 1, αb = 0.6) for different seismic intensities. The Manji-184057 record is adopted. It can be clearly seen from the hysteresis curves of the structural element that the displacement of the NSAD-SDOF system diverges and collapse occurs at large seismic intensity levels (IM = 9, 13), while the reference structure does not collapse. When the intensity is low, only the negative stiffness stage works, or the positive stiffness stage is very short, so the seismic response of the two systems is not very different.

Besides, it is noteworthy that the NPUSAD parameters for the NPUSAD-SDOF reference structure were not determined by optimization and that there is potential for better control of the seismic collapse resistance performance after optimization. On the premise of ensuring that the linear negative stiffness is determined by the seismic mitigation objective, the decoupling mechanism proposed in this work enables the device to provide the reasonable positive stiffness at a large displacement range that meet the requirements of the seismic collapse resistance objective. Therefore, in the subsequent comparison, this paper compares NPUSAD with LNSAD that only considers the seismic mitigation objective.

Influence of key parameters of NPUSAD on behaviors of components

To better visualize the working mechanism of variable stiffness at different stages, Figs. 8, 9 and 10 represent the force–displacement curves of the structural element, NPUSD and linear viscous damping under different seismic intensities.

Influence of transition displacement ratio β1

Figure 8 shows the influence of β1. At low seismic intensity IM = 0.5, NPUSAD with a small value of β1 (e.g., − 0.3) will provide positive stiffness when the structural element is still elastic, which results in the elastic response being greater than other NPUSAD cases.

At moderate seismic intensity level, IM = 2, if β1 is too small (e.g. β1 = − 0.3), the controlled system will yield but to a lesser extent than the uncontrolled system. It indicates that the positive stiffness should not be provided too early, so as not to affect the negative stiffness amplification damping effect under moderate ground motion intensity.

At large earthquake intensities, e.g., IM = 5, the controlled systems with different transition displacement ratios have both negative and positive stiffness stages engaged. Besides, NPUSAD promotes structural collapse when positive stiffness is provided too late, that is, the negative stiffness stage is too long causing the adverse effect of the weakened stiffness on the collapse capacity is not fully compensated by the damping amplification.

At IM = 9 and 13, both the uncontrolled system and the controlled systems that provided positive stiffness too late experienced displacement dispersion and collapse. But no collapse occurred for the other controlled structures.

Influence of positive-to-negative stiffness ratio β2

The positive-to-negative stiffness ratio β2 is varied from − 2.0 to 1.0 to investigate the influence of positive stiffness on the seismic collapse performance of NPUSAD. As shown in Fig. 9, only the negative stiffness stage is involved at lower seismic intensities (IM = 0.5, 2); thus the value of positive stiffness does not affect the force–displacement curves, i.e. the results for different values of β2 overlap.

When IM is taken as 5, the uncontrolled system has not yet collapsed, while the controlled structure, which has been providing linear negative stiffness, has collapsed, and the degree of plastic development of the structural element is not sufficient.

At excessive intensities (IM = 9 and 13), the uncontrolled system and the controlled system with β2 = 1.0 collapsed. In addition, the controlled system with insufficient positive stiffness (e.g., − 0.5) will collapse in the case of IM = 13. At the same time, from the structural element hysteresis curves of these two seismic intensity levels, it can be seen that the blue and green solid lines have larger envelope areas than the red solid line, indicating a higher degree of plastic development, especially at IM = 13, where the blue and green have entered the softening stage. The above shows that the positive stiffness is not the greater the better, and that the collapse capacity decreases beyond a specific value.

Influence of connecting stiffness ratio αb

The influence of αb can be analyzed from Fig. 10. The connecting stiffness ratio αb affects the negative stiffness ratio αn and the additional damping ratio ξd, but does not affect the transition displacement ratio β1 and positive-to-negative stiffness ratio β2. It can be seen that at low seismic intensity IM = 0.5, both structural elements of uncontrolled and controlled systems with different αb values do not yield, and NPUSDs are all in the negative stiffness stage, resulting in the response of controlled systems being much smaller than that of uncontrolled system, which verifies the effectiveness of negative stiffness for seismic mitigation under small earthquakes.

At moderate seismic intensity level, IM = 2, the uncontrolled system yields obviously, and the controlled system with a small connecting stiffness ratio (i.e., αb = 0.2) also yields slightly, and other controlled systems do not yield. The positive stiffness stage of NPUSD also appears at small connecting stiffness (i.e., αb = 0.2, 0.4) cases, while if αb is large enough, only the negative stiffness stage works. Due to the P-Δ effect (the stability coefficient θ = 0.07 and strengthening coefficient αs = 0.02, that is, θ-αs = 0.05), the post-yield stiffness of the structural element is negative.

At large earthquake intensities, e.g., IM = 5, the controlled systems begin to yield, and both negative and positive stiffness stages participate in the work, and the development of plastic deformations is obviously lower than that of the uncontrolled system. Meanwhile, the longer the positive stiffness stage of the NPUSD is observed at small connecting stiffness cases.

At excessive intensities, e.g., IM = 9 and 13, collapse occurs in the uncontrolled system and the controlled systems with too small connecting stiffness. In addition, different intensity levels show that with the increase of the connecting stiffness ratio, more energy is consumed. On the one hand, as shown in Table 2, with the increase of αb, the additional damping ratio becomes larger; on the other hand, because the connecting spring and the parallel unit of NPUSD and damping are connected in series, when the connecting spring is small, its own deformation is large, affecting the energy dissipation of the damper. Therefore, the larger αb is, the better the response control effect is, but considering the economic limit, it should not be too large.

Incremental dynamic analysis of NPUSAD-SDOF system

Seismic collapse fragility

In “Seismic performance comparison of NPUSAD-SDOF and NSAD-SDOF” section, the nonlinear time history analysis of different intensity levels of the Manji-184057 record was conducted to verify that the uncoupled properties of NPUSAD make it not only retain the excellent seismic mitigation effect of NSAD, but also can effectively improve the collapse capacity for strong seismic levels. In this section, the record-to-record variability is considered and the collapse fragility analysis method based on incremental dynamic analysis (IDA) is used to quantitatively compare the seismic collapse capacity of different SDOF systems and validate the effectiveness of the proposed mechanism.

The collapse criterion adopts a mixed criterion, where the collapse strength is determined by the smaller value of the collapse strength corresponding to the reduction of the tangent slope of the IDA curve to 20% of the initial slope and the achievement of the ultimate displacement of the SDOF skeleton curve (see Eq. (17)).

Sets of 44 far-field records (FF), 28 near-fault non-pulse records (NFNP) and 28 near-fault pulse-like records (NFP) recommended by ATC63 are adopted, the details can be found in FEMA P-69542.

The collapse capacity (CC) of the SDOF system is measured by the collapse strength level IMcollapse. The IMcollapse under different records is used as a statistical sample of the random variable CC, and the parameter estimation is carried out according to the log-normal distribution of Eq. (18) to obtain the collapse probability of the structure for a given IM in Eq. (19).

where βRTR is the logarithmic standard deviation of the random variable CC, reflecting the dispersion degree caused by record-to-record variability; Rc is the median value of the structural collapse capacity, that is, the 50% probability is not greater than Rc; Φ is the cumulative probability of the standard normal distribution.

Figure 11 shows the IDA curves for the three systems with T = 3 s under the ATC63-FF set, NFNP set and NFP set. Since the damping amplification mechanism of the negative stiffness stage serves to improve the seismic mitigation performance when the ground motion intensity is small, the IM corresponding to EDP = 1 for LNSAD-SDOF and NPUSAD-SDOF is significantly greater than 1, i.e. the yield strength of the two controlled systems is greater. However, as the intensity level increases, the IMcollapse of LNSAD-SDOF is even lower than that of uncontrolled SDOF. The reason is that the adverse effect of the weakened stiffness on the collapse capacity is not fully compensated by the damping amplification in the LNSAD-SDOF system. NPUSAD-SDOF has the highest collapse strength and is comparable in dispersion to uncontrolled SDOF. The counted and log-normal fitted collapse fragility curves obtained from the IDA analysis are given in Fig. 12.

Collapse capacity spectra

Inelastic displacement ratio spectra and collapse capacity spectra are often used to evaluate the seismic response of SDOF structures with various damping devices43,44.

To assess the collapse capacity more intuitively and quantitatively, and represent the acceleration-sensitive, velocity-sensitive and displacement-sensitive structures, the median collapse capacity spectra (Rc spectra) and the dispersion spectra (βRTR spectra) are given based on the results of parameter estimation based on a log-normal distribution, with T taking values from 0.1 to 5 s.

Figure 13 shows the Rc spectra of different systems subjected to different ground motion sets. It can be seen that the overall trend of the Rc spectra of NPUSAD-SDOF is similar to that of the uncontrolled SDOF, which gradually increases with the increase of the structural fundamental period, and basically remains unchanged after 4 s under the NFNP set and after 3 s under the NFP set; the Rc spectra of LNSAD-SDOF increases with the increase of the period in the acceleration sensitive region (structure period 0–0.5 s), and basically remains unchanged after the period greater than 0.5 s. In the acceleration-sensitive region (structural period 0–0.5 s), the Rc spectra of the NPUSAD-SDOF and uncontrolled SDOF are close to each other, with the former being slightly larger than that of LNSAD-SDOF. In the velocity-sensitive region (structural period 0.5–3.0 s), the difference between the spectra of the NPUSAD-SDOF and uncontrolled SDOF becomes larger with T; in the displacement-sensitive region (period 3.0–5.0 s) the difference basically does not change with T, and both show that the collapse capacity of near-field waves is greater than that of far-field waves in the long period range.

The values of the βRTR spectra are mainly distributed between 0.2 and 0.5, as shown in Fig. 13. The dispersion of LNSAD-SDOF is small, because the collapse occurs when the yield strength is slightly exceeded under different ground motions.

The δ-spectrum is then calculated from Eqs. (20) and (21), as shown in Fig. 14. There is a favorable increase in the collapse capacity by introducing NPUSAD. However, LNSAD is harmful to the collapse capacity although it is helpful for the seismic mitigation performance under small and medium earthquakes. It can be seen that although the dispersion of NPUSAD is somewhat greater, the different periods are all favorable effects and the longer the period, the more significant the improvement, with the median value being, for example, a 30% improvement for long periods under FF set, a 40% improvement under NFNP set and a 50% improvement under NFP set.

Parametric analysis of seismic collapse capacity of NPUSAD-SDOF system

In this section, the influence of the key parameters of the structural element and NPUSAD on the median and dispersion of the seismic collapse capacity is discussed. Besides, the empirical formulas for the median spectra of collapse capacity are obtained.

Parameters of structural element and NPUSAD

By changing the control parameters of the peak-oriented IMK hysteresis model, the structural hysteresis model with different hysteresis characteristics as shown in Fig. 15 can be obtained. The range of hysteresis parameters for collapse analysis refer to existing studies45,46,47,48: the change of the strengthening coefficient αs and internal damping ratio ξ0 is small, and for simplicity, 0.02 and 0.05 are taken respectively; the values of the ductility coefficient μ, the softening coefficient αc, the degradation coefficients γs,c,a and the stability coefficient θ are taken as three representative discrete values respectively. According to Eurocode 83 and ASCE 7–1049 codes, when the stability coefficient θ < 0.1, it has little influence on the ultimate ductility and strength capacity of the structure. The discrete values adopted are 0, 0.07, 0.14. Some scholars also use θ-αs as an indicator to measure the P-Δ effect24. The red solid line in Fig. 15 is the hysteresis curve of the reference model of the structural element (i.e., μ = 4, αc = − 0.3, θ = 0.07, γs,c,a = 100).

In addition, the key variables (i.e., β1, β2 and αb) of NPUSAD are considered and discrete values of each variable are determined in conjunction with the results of “Influence of key parameters of NPUSAD on behaviors components” section. The transition displacement ratio β1 = − 0.1, 0.1, and 0.3 denote positive stiffness provided early, provided at an intermediate level and provided late, respectively. The values of β2 = − 1.5, − 1.0, and − 0.5 correspond to the NPUSAD with large positive stiffness (greater than the negative stiffness), medium positive stiffness (equal to the negative stiffness), and small positive stiffness (less than the negative stiffness), respectively. The values of αb = 0.4, 0.6, and 0.8 denote small, medium and large connecting stiffness, respectively.

As mentioned before, the proposed NPUSAD-SDOF system considers the impact of seven key variables (i.e., μ, αc, θ, γ, β1, β2, αb) on the median spectra and dispersion spectra of seismic collapse capacity. The evaluated NPUSAD-SDOF systems with varying parameters are listed in Table 3.

Influence of parameters of structural element and NPUSAD on collapse capacity spectra

Influence of ductility ratio μ

The effect of μ on the Rc and βRTR spectra for different sets of ground motion is given in Fig. 16. It can be seen that increasing the ductility of the structure significantly improves the collapse capacity, while for the FF set and NFNP set, the dispersion due to record-to-record variability increases with increasing ductility. It indicates that high ductility structures are more sensitive to ground motion uncertainty and it is not advisable to rely on structural ductility to enhance seismic collapse capacity. In addition, for structures with T < 0.5 s, the effect of ductility on both the median spectra and the dispersion spectra is negligible.

Influence of soften stiffness αc

The effect of the soften stiffness is given in Fig. 17. The smaller value of αc indicates that the structure is more heavily softened and less able to resist collapse, especially for structures with long periods. For acceleration-sensitive structures (T < 0.5 s), the soften stiffness has no effect on either the median spectra or the dispersion spectra. Meanwhile, the effect of αc is nonlinear, that is, the change caused by αc from − 0.3 to − 0.1 is greater than the change from − 0.5 to − 0.3.

Influence of stability coefficient θ

The P-Δ effect is controlled by the stability coefficient θ. Figure 18 shows that the collapse capacity decreases linearly with increasing θ. The more significant the P-Δ effect the less discrete it is in the case of T < 2 s, while the more significant the P-Δ effect the more discrete it is in the case of T > 2 s.

Influence of cyclic deterioration γ

Figure 19 shows that under reciprocating loads, the degradation coefficient γ of strength capacity and stiffness has little effect. The smaller γ is, the more significant the degradation is, and the collapse capacity decreases slightly.

Influence of transition displacement ratio β1

As can be seen from Fig. 20, the smaller the transition displacement ratio, i.e., the earlier the positive stiffness is provided, the greater the collapse capacity of the structure at periods 0.1–5 s for both the FF set and NFNP set. For acceleration-sensitive structures, the later the positive stiffness is provided, the less discrete the collapse capacity is; for displacement-sensitive structures, the earlier the positive stiffness is provided, the less discrete it is. The median collapse capacity spectra are close for long-period structures with T > 4 s under NFP set when β1 taken as − 0.1 and 0.1, and the dispersion spectra are also close, indicating that the effect of β1 is nonlinear and that the collapse capacity does not keep increasing as β1 decreases.

Influence of positive-to-negative stiffness ratio β2

As can be seen from Fig. 21, the value of β2 ranges from − 0.5 to − 1.5, which means that the positive stiffness value becomes larger. For acceleration-sensitive structures (T < 0.6 s), increasing the value of positive stiffness has no significant effect on the collapse capacity; for medium to long period structures, increasing the value of positive stiffness increases the collapse capacity and does not affect the dispersion spectra. Furthermore, the effect of this parameter is also nonlinear, with the degree of increase in collapse capacity decreasing as the value of positive stiffness becomes larger.

Influence of connecting stiffness ratio αb

Figure 22 illustrates that the greater the connecting stiffness ratio, the stronger the seismic collapse capacity. And it varies linearly with the connecting stiffness ratio. The dispersion spectra are not affected much by connecting stiffness ratio αb.

Calculation formula of the Rc spectra

To obtain an explicit relationship between the collapse capacity and the key parameters, a series of nonlinear regressions are performed using 1stOpt software for the collapse capacity Rc spectra. Based on the results of the univariate analysis in “Parameters of structural element and NPUSAD” section, in terms of the parameters of the structural element, μ, αc and θ have a large effect on the collapse capacity, the stability coefficient θ has a linear effect on the Rc spectra and has little effect on the βRTR spectra, therefore, the value of θ is taken as 0.07. The degradation parameter γ has little effect, for simplicity, γs,c,a = 100, γk = 200. When constructing the empirical formula, the period T and ductility μ are used as variables and different values of αc are distinguished for separate regressions. Besides, the NPUSAD parameters are taken as the values of the parameters of the aforementioned reference structure, i.e., the transition displacement ratio β1 = 0.1, the positive-to-negative stiffness ratio β2 = − 1, and the connecting stiffness ratio αb = 0.6.

Note that unlike the univariate analysis in “Parameters of structural element and NPUSAD” section, the fitted regressions are conducted respectively according to different αc, and the model parameters are shown in Table 4. Using the Quick fit function and Universal Global Optimization algorithm of the 1stopt 6.0 (7D-Soft High Technology Inc.) software, the fitting formula of the median spectra can be obtained, as shown in Eq. (22), and the regression parameters are shown in Table 5, and results in excellent goodness of fit, R2 > 0.950. Also, the adjusted R2 is given, the adjusted R2 is different from the R2 in that it takes both the sample size and the number of independent variables in the regression into account, which makes the adjust R2 always smaller than the R2, and the value of the adjusted R2 does not get closer to 1 as the number of independent variables in the regression increases, avoiding the spurious improvement in the model fit by adding variables. A comparison of the fitted and true Rc spectra is shown in Fig. 23. It can be seen that the adjusted R2 is also around 0.95.

Conclusion

Based on the negative–positive-uncoupled stiffness mechanism, this research presents a series of studies on the collapse capacity of the proposed NPUSAD-SDOF system considering the record-to-record variability. The specific findings are as follows.

-

(1)

NPUSAD has an improved effect on the collapse capacity of SDOF systems in the period 0.1–5 s range, more significantly for long period structures, indicating that NPUSAD has an objective prospect to improve the collapse capacity of high-rise building structures.

-

(2)

Of the key parameters of NPUSAD, connecting stiffness ratio αb is a parameter shared by different levels and cannot be uncoupled, and inadequate αb has a more significant effect on collapse capacity than on seismic mitigation performance, hence αb should be determined by the collapse capacity objective. Larger values of αb are conducive to improving the collapse capacity, the degree of improvement is almost linear and the effect on the dispersion of the collapse capacity is negligible.

-

(3)

Transition displacement ratio β1 and positive-to-negative stiffness ratio β2 are the essential parameters reflecting the uncoupled negative–positive-variable stiffness characteristics. Within reasonable limits, the smaller the β1, the greater the collapse capacity and the smaller the dispersion in the medium to long period; larger values of positive stiffness have limited improvement in collapse capacity.

-

(4)

The fitted equations obtained from the nonlinear regressions of the Rc spectra of NPUSAD-SDOF have high R2 and adjusted R2 values and are well fitted.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author (Email: ffsun@tongji.edu.cn) or first author (Email: yue_liu@tongji.edu.cn) on reasonable request.

Abbreviations

- a, b :

-

Coefficients of NSD force–displacement curve approximated by cubic function curve

- A n, A p :

-

Areas enclosed by the negative or positive stiffness stages in the fourth quadrant of the NSD force displacement curve and the X-axis

- c 0, c d :

-

Inherent damping coefficient of SDOF and damping coefficient of additional linear viscous damping

- C C :

-

Collapse capacity

- E DP :

-

Engineering demand parameter

- F d0, F d :

-

Forces of inherent damping and additional linear viscous damping

- F NSD, F NPUSD, F NPUSAD :

-

Forces of NSD, NPUSD and NPUSAD

- F pre :

-

Pre-pressure of the preloaded spring in NSD and NPUSD

- F spring :

-

Elastic force of the preloaded spring in NSD and NPUSD

- F s :

-

Nonlinear restoring force of the structural element

- F y :

-

Yield displacement of the structural element

- I M :

-

Seismic intensity

- K b :

-

Stiffness of the connecting spring in NSAD and NPUSAD

- K e :

-

Initial elastic stiffness of the structural element

- K n, K p :

-

Linear negative and positive stiffnesses of NSD and NPUSD

- k s1, k s2 :

-

The first and the second stiffnesses of the preloaded spring

- l AB, l BC, l BD, l CD :

-

Length of the AB, BC, BD and CD segments

- m :

-

Mass of SDOF

- p 1, p 2, …, p 8 :

-

Regression coefficients of the Rc spectra

- R 2 :

-

Goodness of fit of the Rc spectra

- R c :

-

Median value of the structural collapse capacity considering the record-to-record variability

- S a :

-

Spectral acceleration

- T :

-

Fundamental period

- x :

-

Displacement of SDOF structure relative to the ground

- x y, x c, x u :

-

Yield, post-capping and residual deformations of the structural element

- x d :

-

Deformation of NPUSD

- x d,n, x d,p :

-

Displacement threshold and maximum displacement where the force is 0

- α :

-

Deformation amplification factor of the lever of NSD

- α b, α n, α p :

-

Connecting stiffness ratio, negative stiffness ratio, positive stiffness ratio of NPUSAD

- α s, α c :

-

Strengthening and softening coefficients of the structural element

- β RTR :

-

Logarithmic standard deviation of the random variable CC

- β 1, β 2 :

-

Transition displacement ratio, positive-to-negative stiffness ratio

- γ s, γ c, γ a, γ k :

-

Four cyclic degradation modes of strength and stiffness, that is, basic strength deterioration γs, post-capping strength deterioration γc, accelerated reloading stiffness deterioration γa, and unloading stiffness deterioration γk

- Δ:

-

Released deformation of the preloaded spring

- Δ1, Δ2 :

-

Released deformations of the first two stages of the preloaded spring

- δ R ,LNSAD , δ R ,NPUSAD :

-

Rate of change of collapse capacity caused by LNSAD and NPUSAD

- η :

-

Ratio of yield force to gravity

- θ :

-

Stability coefficient considering the P-Δ effect

- μ, μ collapse :

-

Ductility coefficient, ultimate displacement coefficient at collapse point of the SDOF skeleton curve

- μ n :

-

Transition displacement coefficient of NPUSD

- ξ d :

-

Additional damping ratio

- ω 0 :

-

Natural circular frequency

References

FEMA-356. Prestandard and Commentary for the Seismic Rehabilitation of Buildings. Report FEMA-356 (Federal Emergency Management Agency, 2000).

ASCE/SEI Standard 41-17. Seismic Evaluation and Retrofit of Existing Buildings (American Society of Civil Engineers, 2017).

CEN (European Committee for Standardisation). Eurocode 8: Design of Structures for Earthquake Capacity General Rules, Seismic Actions and Rules for Buildings EN1998-1:2004 (EN 1998-1, 2004).

Lee, C. H. et al. Numerical and experimental analysis of combined behavior of shear-type friction damper and non-uniform strip damper for multi-level seismic protection. Eng. Struct. 114, 75–92 (2016).

Panzera, I., Morelli, F. & Salvatore, W. Seismic multi-level optimization of dissipative re-centering systems. Earthq. Struct. 18, 129–145 (2020).

Liu, L., Zhao, J. X. & Li, S. Nonlinear displacement ratio for seismic design of self-centering buckling-restrained braced steel frame considering trilinear hysteresis behavior. Eng. Struct. 158, 199–222 (2018).

Liu, L., Liu, Y. & Zhu, X. J. Evaluation of nonlinear displacement of self-centering structures with metallic energy dissipaters by considering the early yield of the energy dissipating system. Soil Dyn. Earthq. Eng. 125, 1–18 (2019).

Cao, S. S. et al. Multi-level SMA/lead rubber bearing isolation system for seismic protection of bridges. Smart Mater. Struct. 29(5), 055045 (2020).

Tremblay, R., Lacerte, M. & Christopoulos, C. Seismic response of multistory buildings with self-centering energy dissipative steel braces. J. Struct. Eng. 134(1), 108–120 (2008).

Güllü, A., Danquah, J. O. & Dilibal, S. Characterization of energy dissipative cushions made of Ni-Ti shape memory alloy. Smart Mater. Struct. 31, 015018 (2022).

Sarlis, A. A. et al. Negative stiffness device for seismic protection of structures. J. Struct. Eng. 139(7), 1124–1133 (2013).

Pasala, D. T. R. et al. Simulated bilinear-elastic behavior in a SDOF elastic structure using negative stiffness device: Experimental and analytical study. J. Struct. Eng. 140(2), 04013049 (2014).

Sarlis, A. A. et al. Negative stiffness device for seismic protection of structures: shake table testing of a seismically isolated structure. J. Struct. Eng. 142(5), 04016005 (2016).

Attary, N. et al. Performance evaluation of negative stiffness devices for seismic response control of bridge structures via experimental shake table tests. J. Earthq. Eng. 19(2), 249–276 (2015).

Cimellaro, G. P., Domaneschi, M. & Warn, G. Three-dimensional base isolation using vertical negative stiffness devices. J. Earthq. Eng. 24(12), 2004–2032 (2020).

Islam, N. U. & Jangid, R. S. Negative stiffness and inerter-based dampers: Novel seismic response control approach for base isolated liquid storage tanks. Structures 60, 105860 (2024).

Islam, N. U. & Jangid, R. S. Closed form expressions for H2 optimal control of negative stiffness and inerter-based dampers for damped structures. Structures 50, 791–809 (2023).

Wang, M. et al. Seismic protection of SDOF systems with a negative stiffness amplifying damper. Eng. Struct. 190, 128–141 (2019).

Wang, M., Li, Y. W., Nagarajaiah, S. & Xiang, Y. Effectiveness and robustness of braced-damper systems with adaptive negative stiffness devices in yielding structures. Earthq. Eng. Struct. Dyn. 51(2), 1 (2022).

Yang, Q. R. et al. Study on seismic response of isolated structure based on damping negative stiffness device. J. Vib. Eng. 31(06), 920–929 (2018).

Soydan, C. et al. Experimental investigation of the effective parameters on the lead extrusion damper performance. Eng. Struct. 318, 118714 (2024).

Cao, S. S. et al. An SMA cable-based negative stiffness seismic isolator: development, experimental characterization, and numerical modeling. J. Intell. Mater. Syst. Struct. 33(14), 1819–1833 (2022).

Liu, M., Zhou, P. & Li, H. Novel self-centering negative stiffness damper based on combination of shape memory alloy and prepressed springs. J. Aerosp. Eng. 31(6), 04018100 (2018).

Chen, L. et al. Practical negative stiffness device with viscoelastic damper in parallel or series configuration for cable damping improvement. J. Sound Vib. 560, 117757 (2023).

Wang, M., Sun, F. F. & Nagarajaiah, S. Simplified optimal design of MDOF structures with negative stiffness amplifying dampers based on effective damping. Struct. Des. Tall Spl. Build. 28(15), e1664 (2019).

Li, Y. W., Xiang, Y. & Wang, M. Global optimization of locally installed adaptive negative stiffness amplifying damper in steel frames through rocking wall. J. Build. Eng. 60, 105196 (2022).

Wang, M., Nagarajaiah, S. & Sun, F. F. Dynamic characteristics and responses of damped outrigger tall buildings using negative stiffness. J. Struct. Eng. 146(12), 04020273 (2020).

Sun, F. F. et al. Dynamic characteristics and responses of tall building structures with double negative stiffness damped outriggers. Int. J. High-Rise Build. 10(3), 1–14 (2021).

Sun, F. F., Wang, M. & Nagarajaiah, S. Multi-objective optimal design and seismic performance of negative stiffness damped outrigger structures considering damping cost. Eng. Struct. 229, 111615 (2021).

Wang, M., Nagarajaiah, S. & Sun, F. F. A novel crosswind mitigation strategy for tall buildings using negative stiffness damped outrigger systems. Struct. Control Health Monit. 1, e2988 (2022).

Wang, M., Nagarajaiah, S. & Sun, F. F. Optimal design of supplemental negative stiffness damped outrigger system for high-rise buildings resisting multi-hazard of winds and earthquakes. J. Wind Eng. Ind. Aerodyn. 218, 104761 (2021).

Sun, F. F. et al. Random seismic response analysis on damping performance of multiple damped outrigger structures incorporating negative stiffness device. J. Build. Struct. 2024(5), 1 (2024).

Wang, M. et al. Fragility analysis and inelastic seismic performance of steel braced-core-tube frame outrigger tall buildings with passive adaptive negative stiffness damped outrigger. J. Build. Eng. 52, 104428 (2022).

Liu, G. R. et al. Structural design of negative stiffness damped outrigger in Lanzhou Global Harbor. Build. Struct. 53(1), 65–70 (2023).

Zou, K. & Nagarajaiah, S. Study of a piecewise linear dynamic system with negative and positive stiffness. Commun. Nonlinear Sci. Numer. Simul. 22(1–3), 1084–1101 (2015).

Nagarajaiah, S., Zou, K. & Herkal, S. Reduction of transmissibility and increase in efficacy of vibration isolation using negative stiffness device with enhanced damping. Struct. Control Health Monit. 1, e3081 (2022).

Liu, Y. et al. Development and experimental study of disc spring-based negative–positive-uncoupled stiffness devices for structural multi-level seismic fortification. J. Build. Eng. 95, 110231 (2024).

Ibarra, L. F. & Krawinkler, H. Global Collapse of Frame Structures Under Seismic Excitation (The John A. Blume Earthquake Engineering Research Center, Department of Civil and Environmental, 2005).

OpenSees. Open System for Earthquake Engineering Simulation (University of California, 2013).

Bernal, D. Amplification factors for inelastic dynamic p-Δ effects in earthquake analysis. Earthq. Eng. Struct. Dyn. 15(5), 635–651 (1987).

Ibarra, L. F., Medina, R. A. & Krawinkler, H. Hysteretic models that incorporate strength and stiffness deterioration. Earthq. Eng. Struct. Dyn. 34, 1489–1511 (2005).

FEMA P69. Quantification of Building Seismic Performance Factors (Federal Emergency Management Agency, 2009).

Zhu, R. et al. Seismic analysis and design of SDOF elastoplastic structures with self-centering viscous-hysteretic devices. J. Earthq. Eng. 1, 1–22 (2020).

Ji, D. F. et al. Inelastic displacement ratios for SDOF structures subjected to earthquake-tsunami loadings. J. Earthq. Eng. 26, 15 (2022).

Ibarra, L. & Krawinkler, H. Variance of collapse capacity of SDOF systems under earthquake excitations. Earthq. Eng. Struct. Dyn. 40(12), 1299–1314 (2011).

Norouzi, A. & Poursha, M. The collapse period of degrading SDOF systems considering a broad range of structural parameters. Soil Dyn. Earthq. Eng. 115, 730–741 (2018).

Shu, Z. et al. Development of seismic collapse capacity spectra for structures with deteriorating properties. Earthq. Struct. 12(3), 297–307 (2017).

Chenouda, M. & Ayoub, A. Inelastic displacement ratios of degrading systems. J. Struct. Eng. 134(6), 1030–1045 (2008).

ASCE/SEI. Minimum Design Loads for Buildings and Other Structures, ASCE 7–16 (American Society of Civil Engineers/Structural Engineering Institute, 2016).

Acknowledgements

This work was supported by the National Natural Science Foundation of China [Grant No. 52378531].

Author information

Authors and Affiliations

Contributions

Y. L.: Methodology, Formal analysis, Writing—original draft. F. S.: Funding acquisition, Supervision, Conceptualization, Methodology, Writing—reviewing and editing. D. X.: Supervision, Validation. J. Y.: Supervision, Validation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liu, Y., Sun, F., Xu, D. et al. Seismic collapse capacity analysis of degrading SDOF systems with uncoupled negative and positive stiffness mechanism. Sci Rep 15, 12107 (2025). https://doi.org/10.1038/s41598-025-91919-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-91919-8