Abstract

The importance of support system dynamic fidelity in capturing turbine rotor performance in unbalance response and critical speed is considered. Lobal optimization methods based on multi-scale quantum harmonic oscillator algorithm and genetic algorithm are used, and the extent to which the non-dominated solution of objective function interactions is appropriately captured by the different algorithm models is explored. The support system models are deployed within a multi-objective optimization framework. This framework pairs a rotor finite element model with parameters to guide the search for an optimal geometry over harmonic response modes. We demonstrate the use of the quantum harmonic oscillator algorithms and hybrid genetic algorithm to capture the behavior of the high-fidelity model over the design space with reduced computational needs. Results of the optimization show quantum harmonic oscillator perturbation to be a dominant factor, with different design implications for convergence speed and repetition retention. Control parameters and convergence scale were also critical. Importantly, a number of design candidates were encountered during the optimization that performed very closely to the non-dominant frontiers, highlighting the conflicting objective functions and multi-modal nature of the problem.

Similar content being viewed by others

Introduction

Reliability combined with the high thermal efficiencies related advantages has led to an increasing attention to supercritical carbon dioxide (SCO2) energy conversion system1. High-temperature supercritical carbon dioxide (> 500 °C and > 7.38 MPa) is considered to be the circulating medium for more efficient next-generation energy conversion systems. Therefore, elevated temperature turbines may still remain a pivotal component within future SCO2 power cycles. On the other hand, in the drive towards compact physical footprint, and to surmount challenges of the rotor dynamics related to high speed, attention has turned to the small scale of thermodynamic turbine2. As the working speeds (300 kW, 50,000 rpm) and inlet temperature of the small SCO2 turbines are often extreme, a strict optimization design of the shaft bearing system is required. The integrated optimization for multiple physics including thermomechanics, rotor-bearing dynamics. Researches on these optimization algorithms for bearing-rotor system applications are neither unique nor trivial as they have applications in the rotating machinery within turbine engines and synchronous motors. The development of contemporary designs of bearing-rotor systems depends on the amelioration of methods of simulation and design as well as algorithms of optimization. Combined with Finite element analysis (FEA), it allows the time-consuming repetitive work of optimization of prototypes to be avoided3.

Reasonable rotor dynamics design is crucial for high-speed rotating machinery to meet stability and reliability requirements4. There are many factors that affect the dynamic characteristics of rotating machinery, such as the geometric shape of the rotor system, the mass and force coefficient of the support system, the stiffness and mass distribution of rotating components, and the fluid excitation of the turbine and cooling system. In order to improve the efficiency and reliability of the system, appropriate parameters must be selected to make the system more stable. Due to the involvement of multiple geometric and physical variables, the design process of rotating machinery is complex and time-consuming. The optimization design method can be applied to the rotor dynamics design of rotating machinery to meet the increasing demand for rotor speed and lightweight design, while adjusting the natural frequency to avoid resonance near operating conditions, thereby improving the stability margin of the rotor system and significantly shortening the design cycle, ultimately achieving significant economic benefits. The optimization problem of rotor systems in engineering can be divided into three main aspects: (1) parameter optimization, such as the mass, stiffness, and damping of supporting components, and the axial position of concentrated mass; (2) Shape optimization, such as the cross-sectional shape of the shaft and the shape of the turbine blades; (3) Topology optimization, such as rotor winding and material porosity of permanent magnet synchronous motors5.

Optimization techniques can be divided into local optimization and global optimization. Local optimization methods, such as Gradient descent, can only search a continuous finite part of the design space. Global optimization methods are pseudo-stochastic methods that consider the entire design space and have the advantage of operating in a discontinuous design space. Mahdiyeh et al.6 proposed an efficient hybrid optimization method based on adaptive rat population optimization (ARSO) and pattern search (PS) for efficient and consistent extraction of photovoltaic (PV) models parameters. This method balances the global search capability of ARSO and the local search capability of PS. Mokhtar et al.7,8 has improved the swarm evolutionary optimization algorithm based on the salp swarm algorithm and tunicate swarm optimization, enhancing the exploration potential of the optimization while also preventing premature convergence.

Optimization algorithms combined with simulation techniques such as finite element analysis can avoid time-consuming repetitive work such as prototyping and numerical calculation. The main challenge of design optimization for rotor dynamics problems is that high order modes, conflicting objective functions, and complex rotor dynamics models limit the effectiveness of some traditional optimization methods, and add complex modeling processes and significant computational costs to the optimization work. Damping vibration reduction is usually considered a robust solution for rotor system vibration control, but it requires adjusting technical parameters to adapt to different operating speed ranges9. Compact advanced rotating machinery typically requires the use of a wide range of rotor speeds to achieve the desired power level10,11. In the problem of coupling these complex factors, the robustness and efficiency of optimization methods become particularly important.

Genetic algorithm (GA), as a global optimization method, is an evolutionary intelligence algorithm based on natural selection and genetics. The basic genetic algorithm includes three operators: genetic, crossover and mutation12. Similar to the principle of biological genetics, in the process of reproduction, a single chromosome in the population is selectively replicated according to its objective function value and transmitted to the next generation population. Crossover refers to the random exchange of genes between parent chromosomes. Mutation refers to the random mutation of genes in chromosomes to prevent genetic algorithms from getting stuck in local optima. The genetic algorithms commonly used at present are various improved algorithms based on the genetic algorithm with complete structure and theory proposed by Holland in 197513.

On the premise that the rotor critical speed feasible region is constrained, Jia14 and Zheng et al.15 used the non-dominated sorting genetic algorithm II (NSGA-II) to minimize the transient response of the bearing node force and the disk amplitude of the power turbine rotor system and the aero-engine rotor system, respectively. The optimization design variable is the installation position of the turbine. The optimization work is based on the finite element software ANSYS and the commercial optimization software ISIGHT. Zhou et al.16 adopted the single objective genetic algorithm to optimize the seal clearance, seal length and seal radius of the oil-film bearing-hermetic-rotor system, thereby improving the minimum instability speed of the rotor. Mittelstedt et al. combined genetic algorithm with sequential quadratic programming algorithm and proposed a hybrid multi-objective optimization strategy. A multi-objective optimization design was carried out for the energy storage, production cost, and production efficiency of fiber-reinforced polymer composite flywheel rotors under the constraints of strength, strain, and Tsai Wu failure criteria17 Chen et al.18 optimized the assembly process that affects the dynamic imbalance of multi-stage rotors and proposed a new dynamic imbalance optimization assembly benchmark model. They used genetic algorithms to achieve error propagation optimization of multi-stage rotor assembly. Adeyemi et al.19 applied differential evolution (DE) and genetic algorithm respectively to the dynamic balance optimization design of flexible rotors. Several tests show that genetic algorithm is slightly better than differential evolution algorithm in optimizing speed and amplitude suppression.

The passive vibration control of the rotating subsystem can be achieved by using viscoelastic dynamic vibration absorber. Eduardo et al.9 used a hybrid optimization method of genetic algorithm and Nealder Mead to optimize and study the structural parameters and arrangement of multi degree of freedom viscoelastic dynamic neutralizers (VDN) in the shaft system, and compared and analyzed the dynamic characteristics of the bearing rotor system with multi degree of freedom viscoelastic support (VES). The results indicate that compared to VDN, VES endows rotating mechanical systems with more flexibility and damping, thus enabling more effective vibration control. On the other hand, VDN is a structurally simpler auxiliary vibration attenuation device. When the support system of rotating machinery cannot be replaced, multi degree of freedom VDN is a feasible alternative solution. Squeeze film damper (SFD) plays an important role in improving the dynamic stability of rotors. In order to optimize the force transmission between the rotor and the bearing, Choluk et al.20 used genetic algorithm to optimize the design of a dual rotor system with SFD, effectively suppressing the vibration amplitude of the rotor and improving the stability of the system. Minor changes in the rotor structure can have a significant impact on the mechanical power of the electric motor. The current common optimization strategy is to constrain parameters such as electromagnetic torque, back electromotive force, and saturation flux density in the magnetic yoke, and then optimize the geometric and topological structure of the rotor, which may result in significant improvements in electromechanical performance21. Mendaci et al.22 used NSGA-II to perform multi-objective optimization on the quality and power loss of radial surface permanent magnet synchronous motors. Nenad et al.23 applied the gradient based Method of Moving Asymptotes (MMA) to the topology optimization design of the rotor air gap in a built-in permanent magnet motor, which improved the torque of the motor under the dynamic constraints of cogging effect and ripple torque.

Mehmet et al.24 developed an improved particle swarm optimization algorithm for optimizing parameters such as equivalent circuit resistance, rotor slot, and air gap of induction motor rotors. The optimization results were compared and analyzed with those obtained from traditional particle swarm optimization, genetic algorithm, and experimental data. Bilquis et al.21 used genetic algorithm to optimize the topology structure of the salient pole motor rotor, improving the magnetic flux density in the stator yoke and air gap while significantly reducing the 5th harmonic component in the motor model.

Considering the high-temperature and high-speed operating characteristics of advanced SCO2 turbines, the attenuation of harmonic response amplitude, adjustment of critical frequency, and temperature control have become important issues in the development process of this shaft system. Intelligent algorithms can effectively drive personalized design of parameters and boundary conditions, ensuring that the final design strategy meets a set of specified performance indicators. Although some researches use natural heuristic algorithms to try to solve the parameter and topology optimization problems of rotor systems, such swarm intelligence algorithms (usually non-deterministic algorithms) are greatly affected by subjective factors, which makes the parameter research very tedious25,26. In addition, the Pareto frontier of high-dimensional multi-objective optimization is difficult to capture, especially in the optimization design with multiple conflicting objective functions, so it is necessary to conduct in-depth research and comprehensive evaluation on the convergence speed and repeatability of the optimization algorithm.

The SCO2 turbine machines exchange energy through supercritical carbon dioxide. Their impellers have the features of high-temperature and -speed to enhance energy conversion efficiency, but the rotor needs to be cooled to be compatible with bearings and seals. The paper introduces a pivotal parameter optimization of a concentrating solar SCO2 turbine rotor and seeks to control the harmonic response amplitude while preserving the distance between the critical speed and the working speed. The optimization considers several parameters including bearing span, stiffness, effective mass and damping of the bearing hub, and gas film stiffness coefficients of the cooler. lobal optimization methods based on multi-scale quantum harmonic oscillator algorithm and genetic algorithm are used, and the extent to which the non-dominated solution of objective function interactions is appropriately captured by the different algorithm models is explored. The optimization is based on the design of the parameters, and three different objective functions are proposed to build a universal model, which can be further used to simulate the optimization of the bearing rotor system. An optimization algorithm was constructed based on the wave function in quantum mechanics and genetic algorithm. During the sampling process, both the quantum tunneling effect and the uncertainty principle were taken into account. It has a complete mathematical model and good convergence. Each particle is updated independently in an iterative manner, which gives it a natural advantage in parallel computing. Due to this, the algorithm can achieve multi-scale convergence and has a relatively fast convergence speed when optimizing complex multi-objective problems.

Shafting dynamics model and objective functions

Shafting dynamics model

The shaft structure of the supercritical carbon dioxide turbine is shown in Fig. 1, and the rotor system was modeled using finite element method. The generalized coordinates of the elastic shaft section unit of the turbine are composed of the unit centerline coordinates \(x_{i}\) and \(y_{i}\), as well as the shaft section rotation angles \(a_{i}^{x}\) and \(a_{i}^{y}\). The projection of generalized coordinates in the Cartesian coordinate system is shown in Fig. 2. The kinetic energy of any micro-element with finite length Δz in the elastic shaft section is

where, \(m_{e}\), \(\eta_{p}\) and \(\eta_{d}\) represent the mass per unit length, the polar moment of inertia and the diameter moment of inertia of the axial segment element respectively. ω is the rotational angular speed of the axis. \(\dot{x}_{i}\)、\(\dot{y}_{i}\)、\(\dot{a}_{i}^{x}\) and \(\dot{a}_{i}^{y}\) represent the first derivative of displacement and deflection angle, respectively.

The elastic potential energy of the microelement is

where, \(x^{\prime\prime}\) and \(y^{\prime\prime}\) represent the second derivative of the microelement displacement. The concrete expressions of the kinetic energy equation and the potential energy equation are substituted into the beam element function and Lagrange equation, the finite element motion differential equations of the elastic shaft segment element can be obtained:

where, \({\dot{\mathbf{q}}}_{ix}^{{}}\), \({\dot{\mathbf{q}}}_{iy}^{{}}\), \({\mathbf{\ddot{q}}}_{ix}^{{}}\) and \({\mathbf{\ddot{q}}}_{iy}^{{}}\) are the first and second derivatives of the generalized displacement vector of the axial segment element with respect to time, respectively.

The turbine impeller is equivalent to eccentric mass disc, which is consolidated on the shaft cantilever. The attitude angle of the disk is described by Cardan angle, as shown in Fig. 3, Then the kinetic energy of the disk is

where, \(\omega_{a}\), \(\omega_{b}\) and \(\omega_{c}\) are the angular velocities of the disk. The \(\dot{\alpha }\), \(\dot{\beta }\) and \(\dot{\gamma }\) are the first derivatives of the disk attitude angle with respect to time. The \(m_{d}\), \(H_{d}^{d}\) and \(H_{p}^{d}\) are the equivalent mass, the equivalent polar moment of inertia and the equivalent diameter moment of inertia of the impeller, respectively. The \(\dot{x}_{id}\) and \(\dot{y}_{id}\) are the first derivative of the disk displacement with respect to time.

The generalized displacement vector of the disk is \({\mathbf{q}}_{ix}^{d} = \left[ {x_{id} ,a_{id}^{y} } \right]\) and \({\mathbf{q}}_{iy}^{d} = \left[ {y_{id} , - a_{id}^{x} } \right]\). where \(a_{id}^{y} = \beta\), \(\alpha_{id}^{x} = \alpha\). Substitute the kinetic energy equation and generalized vector into the Lagrange equation to obtain the system of differential equations for disk motion:

where, \({\mathbf{F}}_{ix}^{d} \left( t \right)\) and \({\mathbf{F}}_{iy}^{d} \left( t \right)\) are generalized force vectors.

The inertia matrix of the bearing and support system is \({\mathbf{M}}_{{}}^{hb}\)\(=\)[\({\mathbf{M}}_{XX}^{hb}\),\({\mathbf{M}}_{XY}^{hb}\);\({\mathbf{M}}_{YX}^{hb}\),\({\mathbf{M}}_{YY}^{hb}\)]. The gyroscope matrix is \({\mathbf{G}}_{{}}^{hb}\)\(=\)[\({\mathbf{G}}_{YX}^{hb}\),\({\mathbf{G}}_{YY}^{hb}\);\(- {\mathbf{G}}_{XX}^{hb}\),\({\mathbf{G}}_{XY}^{hb}\)]. The damping matrix is \({\mathbf{C}}_{{}}^{hb}\)\(=\)[\({\mathbf{C}}_{XX}^{hb}\),\({\mathbf{C}}_{XY}^{hb}\);\({\mathbf{C}}_{YX}^{hb}\),\({\mathbf{C}}_{YY}^{hb}\)]. The stiffness matrix is \({\mathbf{K}}_{{}}^{hb}\)\(=\)[\({\mathbf{K}}_{XX}^{hb}\),\({\mathbf{K}}_{XY}^{hb}\);\({\mathbf{K}}_{YX}^{hb}\),\({\mathbf{K}}_{YY}^{hb}\)]. The above matrices are all 2 (N + \(N_{b}\)) dimensional cell arrays, where \(N_{b}\) represents the number of bearings. When considering the stiffness and damping of the bearing and its supporting system, it is necessary to extend the finite element model. The extended rotor system model is often used for linear dynamics calculation. Considering the flexibility of the bearing support system, the inertia matrix is extended to

The gyroscope or damping matrix is extended to

The stiffness matrix is extended to

where, \({\mathbf{Z}}_{e}\) is a \(2N \times 2N_{b}\)-dimensional matrix with zero element; \({\mathbf{O}}_{e}\) is a \(2N_{b} \times 2\left( {N + N_{b} } \right)\)-dimensional matrix with zero elements. The extended inertia matrix of the rotor system is \({\mathbf{M}}_{{}}^{E}\)\(=\)[\({\mathbf{M}}_{XX}^{E}\),\({\mathbf{M}}_{XY}^{E}\);\({\mathbf{M}}_{YX}^{E}\),\({\mathbf{M}}_{YY}^{E}\)], the extended gyro or damping matrix is \({\mathbf{G}}^{E}\)\(=\)[\({\mathbf{G}}_{YX}^{E}\),\({\mathbf{G}}_{YY}^{E}\);\(- {\mathbf{G}}_{XX}^{E}\),\({\mathbf{G}}_{XY}^{E}\)] and the extended stiffness matrix is \({\mathbf{K}}_{{}}^{E}\)\(=\)[\({\mathbf{K}}_{YX}^{E}\),\({\mathbf{K}}_{YY}^{E}\);\(- {\mathbf{K}}_{XX}^{E}\),\({\mathbf{K}}_{XY}^{E}\)]. In the process of shafting optimization algorithm and shafting stability analysis, tilting tile bearing with cross stiffness and damping coefficient and angular contact ball bearing rotor system without cross stiffness and damping coefficient are considered. The stiffness coefficient of angular contact ball bearing is \(2.02 \times 10^{8}\). The stiffness and damping of tilting pad bearing can be calculated numerically by COMBI214 element in ANSYS software and references27,28.

Objective functions

The first objective function is defined by the maximum resonance amplitude of the cantilever disc. It is expressed as

where, A = \(\sqrt {X^{2} + Y^{2} }\). The second objective function is defined by the partial derivatives of the unbalanced response function with respect to frequency, which is expected to represent the flatness of the operating frequency region if the sweep interval is sufficiently small.

In the actual numerical calculation, the second one can be written as a difference form:

where, \(A_{n + 1}\) and \(A_{n - 1}\) respectively represent the amplitude of the harmonic response at the rotational speed adjacent to the working frequency, which can also be obtained from the state vector of the disc. Applying this transformation to the objective function can increase the discrepancy between the operating speed point and the critical speeds. The absolute value of the difference between the rotor working frequency and the nearest critical frequency is

Then the third objective function is defined as

The formulation is employed for the evaluation of the global stiffness of a rotor system. As the stiffness of the system increases, the critical speed ratio increases, and vice versa. In some ranges of support stiffness, the variation of modal frequency is also drastic, while in other ranges it is relatively gentle. These factors must be considered during optimization, so that the modal frequency of each order can be actively adjusted to a reasonable position by adjusting the rotor body or supporting parameters. The purpose of this effort is also to include further modal frequency information in objective functions. In the current problem, the optimal solutions would be the ones while all three objective functions reach their minimum.

As shown in Fig. 1, many parameters may affect the harmonic response performance of a SCO2 turbine rotor, including (1) hub stiffness \(k_{hub}\), (2) hub damping \(c_{hub}\), (3) hub mass \(m_{hub}\), (4) support span b, and (5) cooling unit gas film stiffness \(k_{g}\).They make up the particles in the design space, denoted as

The initial design of turbine shafting is carried out, and the base-line design particle based on experience is defined as

where, \(k_{oil}^{w}\) = \(7 \times 10^{8} N/m\) and \(c_{oil}^{w}\) = \(2 \times 10^{5} N \cdot s/m\) are the stiffness and damping coefficient of the four-pad tilting pad bearing at working speed (50 krpm), respectively. The \(m_{s}\) is the mass of the rotor shaft.

Optimization algorithm and design calculation

The performance of swarm intelligence algorithms (non-deterministic algorithms) inspired by nature, such as particle swarm optimization, is affected by subjective factors, and the parameter setting of the algorithm is crucial to its effectiveness, which makes the optimization research extremely tedious and difficult to capture the Pareto frontier of high-dimensional and multi-objective problems29. Based on the multi-objective multi-scale quantum harmonic oscillator algorithm (IM2HOA), a multi-objective multi-scale quantum harmonic oscillator genetic algorithm (HMGA) was designed, and the advantages and convergence characteristics of the coupling algorithms in multi-objective optimization problems were discussed.

Multi objective and multi-scale quantum harmonic oscillator algorithm

Wang Peng et al.30 proposed the basic framework of multi-scale quantum harmonic oscillator algorithm. The main feature of this intelligent algorithm is that only one parameter (scale) needs to be determined by the decision maker, and multi-scale convergence can be realized. In the case of single objective optimization, MQHOA completes the update of each element scale by solving the standard deviation of particle swarm. Aiming at multi-objective function optimization model, this paper firstly uses fast non-dominated sorting algorithm (FNS) to improve MQHOA. Secondly, the concept of energy level scale vector is proposed and defined as the standard deviation of particle swarm objective function value, so as to solve the convergence problem of multi-objective optimization solution. The operation procedure of the multi-objective and -scale quantum harmonic oscillator algorithm (mMQHOA) is evident in the description proposed above. The pseudo-code of mMQHOA is shown in Table 1, and its evolutionary algebra depends on the convergence accuracy of the dimensionality of the optimization problem and the pre-specified standard deviation, as well as the complexity of the model and the objective function. Based on the multi-objective optimization model of rotor system, the basic structure of the algorithm is as follows:

-

(1)

Initialize. In the initial stage of the optimization process, a set of random particles \({\mathbf{x}}_{i}\) is generated in the design space to form a particle swarm X, and the convergence accuracy vector (Ac) of the standard deviation is specified. The initial scale is determined by the maximum and minimum values of particle elements in the design space, denoted as

$${{\varvec{\upsigma}}}_{s} = {\mathbf{x}}_{{}}^{{{\text{max}}}} - {\mathbf{x}}_{{}}^{{{\text{min}}}}$$(25)Secondly, the fitness of the particle swarm is evaluated using the objective function, and the objective function matrix (\({\mathbf{F}}\left( {\mathbf{X}} \right)\)) is obtained.

-

(2)

Energy level stability and energy level scale. Different from the standard MQHOA, before the start of each iteration, the improved algorithm needs to calculate the standard deviation of the current particle and the standard deviation of its objective function value, denoted as \({{\varvec{\upsigma}}}_{k}\) and \({{\varvec{\upkappa}}}_{k}\). After the operation is completed, the algorithm program continues to generate a new set of particle swarm \({\mathbf{X}}^{N}\) for all k particles. The sampling of all particles is randomly realized by Gaussian distribution \({\mathbf{x}}_{i}^{N} \sim N\left( {{\mathbf{x}}_{i} ,{{\varvec{\upsigma}}}_{s}^{2} } \right)\), which corresponds to the wave function in quantum mechanics and serves as a constraint on the evolution process of particles. The objective function values of the new particle swarm and the current particle are then non-dominated sorted by running the FNS program to obtain the local optimal solution, so as to realize the independent evolution of individual particles.

With reference to the suggestion of Peng et al.30, before lowering the Energy of quantum harmonic oscillator (EQHO) and scaling down, an energy level metastable state is applied. In the current iteration process, the energy level metastable state is defined as the absolute value of the standard deviation \({{\varvec{\upsigma}}}_{s}\) before evolution minus the standard deviation \({{\varvec{\upsigma}}}_{s}\) after evolution

$${\Delta }{{\varvec{\upsigma}}}_{k} = {\text{abs}}\left( {{{\varvec{\upsigma}}}_{k} - {{\varvec{\upsigma}}}_{k}^{N} } \right)$$(26)and the standard deviation \({{\varvec{\upkappa}}}_{k}^{N}\) of the objective function after evolution. Due to the independent evolution of each particle, it is impossible to determine whether the optimal value is local or global. Therefore, optimization will continue to run until the energy level stabilizes(\(\Delta {{\varvec{\upsigma}}}_{k} > {{\varvec{\upsigma}}}_{s}\),\({{\varvec{\upkappa}}}_{k}^{N} > {{\varvec{\upkappa}}}_{s}\)).This strategy seeks a stable state of the objective function while balancing sampling diversity and local exploration.

-

(3)

The energy level (EQHO) converges and decreases. After the completion of particle evolution, the order of each particle is specified in a non-dominated sorting form, that is, the particle swarm is classified into levels based on the dominant inertia of the objective function. The fast non-dominated sorting algorithm is used to sort each particle according to the objective function vector, and the particle \({\mathbf{x}}^{w}\) with the worst energy level is obtained. Replacing \({\mathbf{x}}^{w}\) with the average \({\overline{\mathbf{x}}}\) of all particles in the current iteration step reduces the energy level of the system, while also helping to maintain the diversity of particle swarm individuals. In each iteration step, continuous implementation for particle swarm optimizer will level to reduce the process, until the \({{\varvec{\upsigma}}}_{k} < {{\varvec{\upsigma}}}_{s}\) and \({{\varvec{\upkappa}}}_{k} < {{\varvec{\upkappa}}}_{s}\), argues that convergence to the current level.

-

(4)

Multi-scale convergence process. The fineness of the search depends on the standard deviation of the particle population and the standard deviation of the objective function, which also serves as the convergence criterion or convergence scale. Similar to standard MQHOA, optimization is done to progressively approximate the search accuracy \({\mathbf{A}}_{c}\) by progressively halving the scale value (\({{\varvec{\upsigma}}}_{s} = 0.5{{\varvec{\upsigma}}}_{s}\),\({{\varvec{\upkappa}}}_{s} = 0.5{{\varvec{\upkappa}}}_{s}\)). The scaling down process means that the algorithm is gradually reducing the reasonable search area, while ensuring the independence of local exploration for each particle until \({{\varvec{\upsigma}}}_{k} \le {\mathbf{A}}_{\sigma }\) and \({{\varvec{\upkappa}}}_{k} \le {\mathbf{A}}_{\kappa }\), then the optimization is considered to converge to the current scale.

In order to improve the evolution of particles, an information exchange operator was introduced in the convergence and descent steps of mMQHOA’s energy level (EQHO):

Finally, A multi-objective multi-scale quantum harmonic oscillator algorithm (IM2HOA) based on social behavior is obtained. Where, \({\mathbf{x}}_{opt}^{t}\) and \({\mathbf{x}}_{m}^{t}\) are global non-dominant particles and the average values of all particles in the current iteration step respectively; The \(R_{o}\) is a random number between 0.2 and 0.6. The improved algorithm enables each particle to exchange information with each other and with the current non-dominant particle in order to balance the local fine search (multi-scale Gaussian perturbation) of the particle swarm with the global extended exploration.

Improvement of IM2HOA

Compared with swarm intelligence algorithm, multi-scale quantum harmonic oscillator algorithm is constrained by harmonic oscillator potential and has a complete theoretical foundation. The physical model determines the multi-scale and convergence characteristics of the algorithm, so it can provide a strong mathematical foundation for the classical particle swarm algorithm and genetic algorithm. In this section, a multi-scale convergence hybrid genetic algorithm (HMGA) is proposed by coupling the improved social behavior-based multi-objective multi-scale quantum harmonic oscillator algorithm (IM2HOA) and parallel selection multi-objective genetic algorithm (mGA). The performance parameters that affect the algorithm are studied in detail.

Genetic algorithm (GA) is a classic swarm intelligence optimization algorithm developed based on the principles of natural selection and biological genetics. It has the characteristics of information organization and sharing, adaptability and uncertainty, as well as the advantage of running in discontinuous design spaces. The basic structure of multi-objective genetic algorithm includes encoding, non-dominated sorting, selection, genetics, crossover, and mutation, etc. Its basic framework is shown in Fig. 4. The mapping of group particles from physical parameters to numerical genes is called encoding. Selection and genetics refer to the process of gene replication in a population of particles based on the non-dominated ranking of their objective function values with a certain probability. Crossover refers to the gene exchange between parental particles at a certain probability (crossover rate), reflecting the idea of information exchange. Mutation corresponds to the concept of gene mutation in biological evolution theory, in order to avoid particle swarm getting trapped in local optimal regions.

In order to achieve multi-scale and fast convergence of high-dimensional multi-objective nonlinear optimization problems, the basic structure of the hybrid algorithm HMGA was proposed based on the parallel selection multi-objective genetic algorithm (mGA) framework and IM2QHOA, and the parameters were deeply studied. In order to achieve multi-scale fast convergence of high-dimensional multi-objective nonlinear optimization problems, the basic structure of hybrid algorithm HMGA is proposed based on parallel selection multi-objective Genetic algorithm (mGA) framework and IM2QHOA.

In mGA, randomly generated particle populations are divided into three sub-particle populations corresponding to three objective functions. In each subpopulation, the fitness of each particle is evaluated according to all the objective function values, and the fitness is mapped to the selection probability and the surviving particle individuals are selected accordingly in the subpopulation. Then, all the surviving particles are formed into a complete parent particle population, preparing for the next step of hybridization and mutation. In the current study, the probabilities of genetic selection, discrete recombination, and variation for the hybrid genetic algorithm are 0.9, 0.7, and \(1/N_{p}\), respectively, where \(N_{p}\) is the number of particles in the sample.

The next step in the construction of the hybrid algorithm is to apply IM2QHOA to each individual particle in the progeny particle swarm. As mentioned above, IM2QHOA is a natural search algorithm that simulates the probabilistic behavior of wave functions in quantum harmonic oscillators. The probability distribution of the ground state wave function is the probability distribution of the optimal solution of the objective function. The whole optimization process is to simulate the multi-level step transition of the quantum harmonic wave function from high energy to ground state by using particles with specific standard deviation and coordinates. Hybrid genetic algorithm uses this operation process to achieve multi-scale convergence.

After crossing and mutating, the iterative process moves from a “rough” global search phase to a “fine” exploration phase of individual parts based on the particle’s current location. A perturbation operator called PERTUR (similar to MUTATION in a genetic algorithm) will call IM2QHOA to act directly on the swarm of particles evolved from the mGA algorithm, which reflects the fine search of particles at different energy levels. In PERTUR operation, multi-scale sampling is achieved by applying Gaussian distribution theory directly to a single particle in a genetic algorithm.

However, perturbing particles increase the robustness and convergence of the algorithm, while the search time and computation amount of the algorithm may also increase. Therefore, in the perturbation process, the influence of sample quantity Rm of each individual generated by Gaussian distribution on the optimization performance is deeply studied.

To determine the accuracy of convergence, the scale function is expressed as

where, \({{\varvec{\upsigma}}}_{k}\) is the standard deviation vector of the current particle swarm, and \({{\varvec{\upkappa}}}_{k}\) is the standard deviation vector of its objective function value. If the standard deviations of all dimensions of the objective function and particle population are smaller than the current scale, the optimization converges at the current energy level. The standard deviation of each dimension of the particle and each dimension of the objective function are called the scale (\({{\varvec{\upsigma}}}_{k}\)) and the energy level (\({{\varvec{\upkappa}}}_{k}\)), respectively. The process of energy level transition and scale reduction of group members is independent.

The special operator that provides scale and energy level evaluation for the algorithm is still the fast non-dominated sorting algorithm, which can determine the current optimal and worst particles (\({\mathbf{x}}_{o}\) and \({\mathbf{x}}_{w}\)) by comparing the value of the objective function, and replace the worst particle o with the current optimal particle x, that is, reduce the energy level of the particle swarm. The particles are approximately bound in a set of continuously aggregated normal distributions during iteration, and the final scale of convergence is the standard deviation, where the expected value of each normal distribution corresponds to the coordinates of each dimension of the particle.

Optimization examples and results discussion

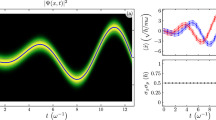

The effect of the perturbed particle parameter \(R_{m}\) on the performance of hybrid genetic algorithm HMGA is studied. The sample number of randomly initialized particle swarm is 16. Figure 5 shows the harmonic response curves corresponding to the reference particle Bas x and the optimized particle Opt x model. As shown in the figure, all optimization test instances (\(R_{m} = 2\), \(R_{m} = 5\), and \(R_{m} = 10\)) produced a similar set of Feasible designs. Compared with the reference design, the resonant frequency and maximum amplitude corresponding to the feasible particles are reduced by an average of approximately 89.5% and 25.9%, respectively. As expected, the resonance amplitude value of the harmonic response is effectively attenuated, and the bandwidth (Bw) between the critical frequency and the operating frequency is increased. However, with \(R_{m} = 2\) and \(R_{m} = 5\) occurred on the corresponding optimization example of the solution of failure.

In order to ensure that the number of evolutions of the particles remains consistent in each test, the total number of evolutions of the particle swarm is calculated as

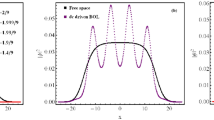

where, \(N_{s}\) is the number of iteration steps. Figures 6, 7 and 8 show the scatterplot of the convergence process of the objective function when the perturb particle parameters \(R_{m} = 1\), \(R_{m} = 5\), \(R_{m} = 10\) and \(R_{m} = 18\), respectively. It can be seen from the figures that different degrees of oscillation occur in the iterative process of the objective function under all perturbation parameters, which reflects the complexity of the model and the conflicting constraint space between the objective functions. However, with the increase of \(R_{m}\), the number of oscillation points and amplitude of the objective function decrease obviously, when \(R_{m} = 18\), all the objective functions converge quickly to the Pareto frontier.

The above data combined with the probability of feasible particle occurrence shown in Fig. 5 indicates that the multi-scale multi-objective quantum harmonic oscillator algorithm significantly enhances the optimization performance of the parallel selection non dominated multi-objective genetic algorithm. From Fig. 8, it can be seen that although the convergence performance of the algorithm is much better when \(R_{m} = 5\) and \(R_{m} = 10\) than when \(R_{m} = 1\), the overall number of evolution times (\(N_{s} \left( {R_{m} + {1}} \right)\)) of the particle swarm also increases correspondingly during the iterative convergence process of the former. The increase of perturbation particles \(R_{m}\) means that the second-order finite element differential equations of the rotor system must be solved more frequently. However, as the perturbation parameter values continued to increase to \(R_{m} = 18\), the overall evolution of the particle swarm significantly decreased, even lower than the hybrid genetic algorithm HMGA with \(R_{m} = 1\), the chaotic interval multi-objective particle swarm algorithm CIMPSOA30, and the social behavior based multi-objective multi-scale quantum harmonic oscillator algorithm IM2QHOA. The above facts indicate that in the optimization process of high-dimensional and multi-objective problems using HMGA, appropriately increasing the number of perturbation particles (\(R_{m}\)) in IM2QHOA is beneficial for improving the optimization performance of the algorithm and reducing the overall evolution of the particle swarm.

Conclusion

-

(1)

Table 2 compares and summarizes the control parameter composition and convergence performance of the proposed optimization algorithm. The control parameter of mMQHOA based on multi-scale quantum harmonic oscillator algorithm is the convergence accuracy vector \({\mathbf{A}}_{c}\), which essentially belongs to the convergence scale of the algorithm determined by the decision maker, defined by the particle swarm and the standard deviation of the objective function. Therefore, in the iterative process of optimizing the program, the parameters for controlling particle updates are determined by the algorithm itself, without the need for pre-defined or adaptive control of other optimization algorithms. This is also one of the most important qualities of intelligent algorithms. Due to the fact that the algorithm is constructed based on the wave function in quantum mechanics, it takes into account both quantum tunneling effect and uncertainty principle during the sampling process, and has a complete mathematical model with good convergence. Each particle iteratively updates independently, thus possessing a natural advantage in parallel computing. However, precisely because of this, although the algorithm can achieve multi-scale convergence, its convergence speed is slow when optimizing complex multi-objective problems.

Table 2 Characteristics comparative analysis of the performance and the control parameters of improved optimization algorithms. -

(2)

IM2QHOA is proposed by introducing the information interaction algorithm between particles on the basis of mMQHOA. Based on the social behavior thought in particle swarm optimization (swarm intelligence algorithm), the internal information sharing mechanism of particle swarm is realized. While ensuring that the control parameters are constant and multi-scale convergence, the convergence speed of the algorithm is significantly increased.

-

(3)

HMGA is a swarm intelligence algorithm constructed by coupling multi-population parallel selection non-dominated genetic algorithm mGA with IM2QHOA, which retains the basic framework and adaptive advantages of genetic algorithm. The basic control parameters of HMGA include the convergence accuracy \({\mathbf{A}}_{c}\) of IM2QHOA, the genetic selection rate \(g_{s}\), the discrete recombination rate \(d_{r}\), the mutation rate \(v_{r}\) and the perturbation particle number \(R_{m}\) of coupled IM2QHOA. The genetic algorithm is essentially an uncertain algorithm. In multiple tests of multi-objective optimization problems for SCO2 turbine rotor systems, it has been found that the success rate of HMGA in finding feasible solutions is directly related to the parameter \(R_{m}\). In a certain range of iteration steps, the greater the value of \(R_{m}\), the higher the success rate. On the other hand, with the increase of the number of perturbation particles \(R_{m}\), the total number of generations that all particles need to evolve in the HMGA convergence process increases first and then decreases significantly.

Data availability

All relevant data are within the paper.

Abbreviations

- \(x_{i} ,y_{i}\) :

-

Unit center coordinates

- \(a_{i}^{x} ,a_{i}^{y}\) :

-

Shaft section rotation angle

- Δz:

-

Haft element length

- \(m_{e}\) :

-

Shaft element mass

- \(\eta_{p}\) :

-

Polar moment of inertia

- \(\eta_{d}\) :

-

Diameter moment of inertia

- \(\omega\) :

-

Rotational angular speed

- \(\dot{x}_{i} ,\dot{y}_{i}\) :

-

Derivative of displacement

- \(\dot{a}_{i}^{x} ,\dot{a}_{i}^{y}\) :

-

Derivative of deflection angle

- \({\Delta }E_{p}\) :

-

Elastic potential energy

- \(H_{p}^{d}\) :

-

Impeller’s diameter moment of inertia

- \({\mathbf{G}}_{{}}^{hb}\) :

-

Support system gyroscope matrix

- \(A_{n}\) :

-

Amplitude of the harmonic response

- \(b\) :

-

Support span

- \(k_{hub}^{{}}\) :

-

Stiffness of support system

- \(k_{gx} ,k_{gy}\) :

-

Cooling system stiffness

- \(k_{oil}^{w} ,c_{oil}^{w}\) :

-

Stiffness and damping of plain bearing

- \({\mathbf{X}}\) :

-

Particle swarm

- \({{\varvec{\upsigma}}}_{k} ,{{\varvec{\upsigma}}}_{s}\) :

-

Evolutionary scale

- \({\mathbf{x}}_{opt}^{t}\) :

-

Global non-dominant particles

- \(N_{p}\) :

-

Number of particles

- \(R_{m}\) :

-

Perturbed particle parameter

- \(d_{r}\) :

-

Discrete recombination rate

- \(v_{r}\) :

-

Mutation rate

- \(w_{v}\) :

-

Speed inertia weight

- \(x^{\prime\prime},y^{\prime\prime}\) :

-

Second derivative of displacement

- \({\mathbf{M}}_{s}\) :

-

Shaft element inertia matrix

- \({\mathbf{G}}_{s}\) :

-

Shaft element damping matrix

- \({\mathbf{K}}_{s}\) :

-

Shaft element stiffness matrix

- \({\mathbf{q}}_{iy} ,{\mathbf{q}}_{ix}\) :

-

Generalized displacement vector

- \({\mathbf{F}}_{iy} ,{\mathbf{F}}_{iy}\) :

-

Generalized force

- \(\dot{\alpha },\dot{\beta },\dot{\gamma }\) :

-

Derivatives of disk attitude angle

- \(\dot{x}_{id} ,\dot{y}_{id}\) :

-

Derivative of disk displacement

- \(m_{d}\) :

-

Disc mass

- \(H_{d}^{d}\) :

-

Impeller’s polar moment of inertia

- \({\mathbf{M}}_{{}}^{hb}\) :

-

Support system inertia matrix

- \({\mathbf{K}}_{{}}^{hb}\) :

-

Support system stiffness matrix

- \({\mathbf{Z}}_{e} ,{\mathbf{O}}_{e}\) :

-

Zero element matrix

- \(m_{hub}^{{}}\) :

-

Vibration quality of support system

- \(c_{hub}^{{}}\) :

-

Support system damping

- \(\Delta n\) :

-

Frequency bandwidth

- \({\mathbf{A}}_{c}\) :

-

Scale convergence accuracy

- \({{\varvec{\upkappa}}}_{k} ,{{\varvec{\upkappa}}}_{s}\) :

-

Energy level scale

- \(R_{o}\) :

-

Random number

- \({\mathbf{x}}_{m}^{t}\) :

-

Average values of all particles

- \({\mathbf{x}}_{o} ,{\mathbf{x}}_{w}\) :

-

Current optimal and worst particles

- \(N_{s}\) :

-

Number of iteration steps

- \(g_{s}\) :

-

Genetic selection rate

- \(c_{1}\) :

-

Cognition factor

- \(c_{2}\) :

-

Social factors

References

Ehsan, M. M., Guan, Z. Q., Gurgenci, H. & Klimenko, A. Feasibility of dry cooling in supercritical CO2 power cycle in concentrated solar power application: Review and a case study. Renew. Sustain. Energy Rev. 132. https://doi.org/10.1016/j.rser.2020.110055 (2020).

Rzadkowski, R. et al. Design and investigation of a partial admission radial 2.5-kW organic Rankine cycle micro-turbine. Int. J. Energy Res. 44, 11029–11043. https://doi.org/10.1002/er.5670 (2020).

Jun, L. et al. Multi-objective optimization of a small scale SCO2 turbine rotor system with a shaft cooler. Mech. Ind. 23 (2022).

Huang, Z. Y. & Le, Y. Rotordynamics modelling and analysis of high-speed permanent magnet electrical machine rotors. IET Electr. Power Appl. 12, 1104–1109. https://doi.org/10.1049/iet-epa.2017.0739 (2018).

Boccini, E. et al. ASME Turbine Technical Conference and Exposition (Turbo Expo) (2017).

Eslami, M., Akbari, E., Sadr, S. T. S. & Ibrahim, B. F. A novel hybrid algorithm based on rat swarm optimization and pattern search for parameter extraction of solar photovoltaic models. Energy Sci. Eng. 10, 2689–2713. https://doi.org/10.1002/ese3.1160 (2022).

Yaghoubi, M. et al. Modified Salp swarm optimization for parameter estimation of solar PV models. IEEE Access 10, 110181–110194. https://doi.org/10.1109/access.2022.3213746 (2022).

Arandian, B. et al. An effective optimization algorithm for parameters identification of photovoltaic models. IEEE Access 10, 34069–34084. https://doi.org/10.1109/access.2022.3161467 (2022).

Ribeiro, E. A. & Bavastri, C. A. Optimal design of multi-DOF viscoelastic dynamic neutralizers for passive vibration control in rotordynamics. J. Braz. Soc. Mech. Sci. Eng. 42. https://doi.org/10.1007/s40430-020-02706-7 (2020).

Clementoni, E. M., Cox, T. L. & ASME. In ASME Turbo Expo: Turbomachinery Technical Conference and Exposition (2018).

Turchi, C. S. et al. Fundamentals and Applications of Supercritical Carbon Dioxide (SCO2) Based Power Cycles (Woodhead Publishing, 2017).

Minle, W., Xiaoguang, G. & Yangtao, F. Advanced Genetic Algorithm and Its Engineering Applications (Northwestern Polytechnical University Press, 2019).

Chun’an, L. et al. Dynamic Multi-objective Optimization Evolutionary Algorithm and Its Application (Science Press, 2011).

Jia, S. X., Zheng, L. X., Huang, J. J. & Qing, M. Dynamic characteristics analysis and optimization design of a simulated power turbine rotor based on finite element method. Int. J. Turbo Jet-Engines 37, 31–39. https://doi.org/10.1515/tjj-2017-0006 (2020).

Huang, J. J., Zheng, L. X., Mechefske, C. K. & Han, B. B. optimization design and experimental study of a two-disk rotor system based on multi-island genetic algorithm. Int. J. Turbo Jet-Engines 36, 1–8. https://doi.org/10.1515/tjj-2017-0010 (2019).

Zhou, W. J., Wei, X. S., Zhai, L. L., Wei, X. Z. & Wang, L. Q. Nonlinear characteristics and stability optimization of rotor-seal-bearing system. J. Vibroeng. 16, 818–831 (2014).

Mittelstedt, M., Hansen, C. & Mertiny, P. Design and multi-objective optimization of fiber-reinforced polymer composite flywheel rotors. Appl. Sci. 8. https://doi.org/10.3390/app8081256 (2018).

Chen, Y., Cui, J. W. & Sun, X. An unbalance optimization method for a multi-stage rotor based on an assembly error propagation model. Appl. Sci. 11. https://doi.org/10.3390/app11020887 (2021).

Oke, W. A., Abido, M. A. & Asafa, T. B. Balancing of flexible rotors based on evolutionary algorithms. Mech. Ind. 16. https://doi.org/10.1051/meca/2015013 (2015).

Choluk, R. et al. optimization design analysis of the eccentric rotor system with SFD. J. Vib. Eng. Technol. 10, 751–765. https://doi.org/10.1007/s42417-021-00406-7 (2022).

Mohamodhosen, B., Tounzi, A. & Gillon, F. Rotor head shape optimization in a salient pole synchronous machine. Int. J. Appl. Electromagnet. Mech. 64, S3–S13. https://doi.org/10.3233/jae-209501 (2020).

Mendaci, S., Allag, H. & Mekideche, M. R. Multi-objective optimal design of surface-mounted permanent magnet motor using NSGA-II. Appl. Comput. Electromagn. Soc. J. 30, 519–526 (2015).

Hermann, A. N. A., Mijatovic, N., Henriksen, M. L. & IEEE. 22nd IEEE International Conference on Electrical Machines (ICEM) 2119–2125 (2016).

Celebi, M. & Toren, M. Heuristic algorithm-based estimation of rotor resistance of an induction machine by slot parameters with experimental verification. Turk. J. Electr. Eng. Comput. Sci. 25, 3553–3568. https://doi.org/10.3906/elk-1511-232 (2017).

Neupane, A. & Goodrich, M. A. Resilient swarm behaviors via online evolution and behavior fusion. Swarm Intell. 1–32 (2024).

Diehl, G. & Adams, J. A. The viability of domain constrained coalition formation for robotic collectives. Swarm Intell. 1–42 (2024).

Phan, H. D., Ellis, K., Barca, J. C. & Dorin, A. A survey of dynamic parameter setting methods for nature-inspired swarm intelligence algorithms. Neural Comput. Appl. 32, 567–588. https://doi.org/10.1007/s00521-019-04229-2 (2020).

Lie, Y. Fundamentals of Bearing Rotor System Dynamics (Xi’an Jiaotong University Press, 2016).

Peng, W., Yan, H., Bo, L. & Qianhe, X. Multi-scale Quantum Harmonic Oscillator Optimization Algorithm (Posts and Telecom Press, 2016).

Jun, L., Gurgenci, H. & Zhiqiang, G. Optimal design to control rotor shaft vibrations and thermal management on a supercritical CO2 microturbine. Mech. Ind. 22 (2021).

Acknowledgements

This work is supported by the National Natural Science Foundation, China (No.51475150), the Hubei Provincial KeyResearch and Development Program, China(No. 2021BAA056) and the Doctoral Scientific Research Foundation of Hubei University of Automotive Technology (No. XJ2024001203).

Author information

Authors and Affiliations

Contributions

Jun Li wrote the main manuscript text. Hal Gurgenci and Zhiqiang Guan provide research ideas. Jiaxin Wang, Junwen Chen and Zhenyu Huang prepared figure. Chen Wang funding for the research.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, J., Gurgenci, H., Guan, Z. et al. Multi objective optimization algorithm for hybrid quantum harmonic oscillator and its application in rotor system optimization. Sci Rep 15, 7534 (2025). https://doi.org/10.1038/s41598-025-92070-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-92070-0

Keywords

This article is cited by

-

An Iterative Approach to Solve the Viscous Damper Temperature and the Torsional Vibration Amplitude of a Diesel Engine

Journal of Vibration Engineering & Technologies (2025)