Abstract

Deep mining rock masses often contain numerous fractures and significant water content, making them highly susceptible to instability and failure under external disturbances such as mining and blasting. This study investigates the effects of water content and fracture angle on the creep behavior and crack evolution of sandstone. Uniaxial compression and creep disturbance experiments were conducted on sandstone samples with varying fracture angles (0°, 30°, 45°, 60°, and 90°) and water contents (0%, 50%, 100%), with DIC-2D technology employed to monitor failure modes and crack propagation. Results show that fracture angle significantly influences the compressive strength, which decreases with increasing angle, and transitions failure modes from tension-dominated to shear-dominated. Higher water content prolongs creep failure time, particularly for fully saturated samples with 45° and 30° fractures, which did not fail during testing. DIC analysis reveals that 45° fractures exhibit the highest shear stress concentration, leading to localized crack propagation and coalescence. However, high water content accelerates crack growth, causing rapid failure. These findings provide insights into the complex creep behavior of sandstone under combined fracture and water conditions, offering guidance for improving the stability of deep engineering projects.

Similar content being viewed by others

Introduction

As mineral resources gradually deplete, the demand for deep mining operations is increasing, making the stability of fractured rock an increasingly critical issue1. The conditions of deep underground rock masses are complex and variable, with many of them subjected to both static loads and external disturbances. As the depth of the rock mass increases, the pressure it experiences also gradually increases. Particularly in deep tunnels, rock masses often contain fractures and water and are already under high-stress conditions before excavation. Under external disturbances such as excavation and blasting, local instability is likely to occur, which can subsequently lead to overall instability and failure of the tunnel2,3,4.

The series of failures caused by disturbances to underground rock masses during construction operations fall under the category of rock subjected to dynamic disturbances under high stress (creep conditions). Currently, research on the creep behavior of ordinary rock masses is extensive. Since the early work of Griggs (1939)5conducted creep studies on rocks and concluded that when the constant stress reaches a certain proportion of the short-term failure strength, the rock will deform over time. Since then, extensive research has been conducted on the creep behavior of conventional rocks. There are two main methods of applying creep stress: the first is staged loading, where the stress gradually increases to the maximum creep stress after several loading cycles6,7,8,9. The second method involves initially loading the rock at a constant rate until the creep stress is reached and then maintaining that stress level10,11. In conventional creep experiments, only creep stress is applied; however, under real operational conditions, it is not ideal to consider only a single creep stress. There are other disturbances, such as blasting and earthquakes, and underground rock masses often experience the combined effects of multiple disturbances in complex stress environments. These disturbances significantly affect the mechanical behavior of rock masses, making an in-depth study of the creep characteristics of rock under dynamic disturbances crucial for engineering safety assessment and design, both theoretically and practically12,13,14.

Current research on rock creep under dynamic disturbances includes the effects of dynamic disturbances on the creep rate15,16, the influence of dynamic disturbances on creep failure modes17,18, the coupling effects of dynamic disturbances and stress paths19,20, the impact of seismic disturbances on rock creep21, and the influence of the dynamic disturbance frequency22,23. Most of the research has focused on how disturbances alter creep behavior. Additionally, considering the condition of the rock itself is important. Rocks in nature are not always intact or dry; they often contain water and fractures. Changes in water content can significantly affect the mechanical properties of rocks, especially under dynamic loading conditions, where increased water content reduces compressive strength and accelerates creep deformation24,25,26,27. Moreover, fractures in rock serve as natural weak planes that significantly impact the mechanical behavior and deformation patterns of rock. The presence of fractures not only reduces the overall strength of rock but also provides pathways for water infiltration and accelerated creep deformation28,29,30. Comparative analysis reveals that the effects of water content and fractures on rock creep performance exhibit different mechanisms and modes under varying loading conditions, with their combined influence being particularly significant for creep behavior. However, research on the creep disturbance of rock under such complex conditions is still insufficient, and the failure mechanism and crack growth patterns remain unclear. Therefore, further research on the coupling effects of water content and fractures on the creep characteristics of rock under dynamic disturbances, as well as their failure mechanisms and crack evolution processes, is of great scientific significance and engineering value for accurately predicting the long-term stability of rock masses and assessing catastrophic risks in underground engineering. This work aims to reveal the effects of water content and fracture angle on the creep behavior of sandstone through experimental and microlevel analyses.

The main work conducted includes (1) analysing the influence of different fracture angles and water contents on sandstone creep failure on the basis of uniaxial compression test results, revealing the crack evolution pattern under the combined effects of water and fractures; (2) using DIC technology to monitor and analyse the strain field changes in samples with different fracture angles, determining the influence of the fracture angle on the shear stress distribution and crack propagation; (3) studying the effect of the water content on the creep failure time and plastic deformation, particularly because the creep duration significantly decreases under high water contents; and (4) exploring the failure modes of sandstone with different fracture angles and water contents by analysing the creep stress and crack growth processes.

Materials and methodology

Sample materials

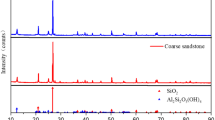

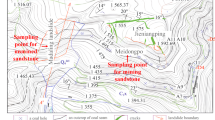

The material used throughout this study was sandstone from Jining city, Shandong Province, and its physical properties are shown in the table below. The longitudinal wave velocity of the sandstone samples ranged between 2660 and 3000 m/s. The samples were precisely ground with a tolerance of ± 0.02 mm and fabricated into cylindrical samples with an axial length of 100 mm and a lateral width of 50 mm. The top and bottom surfaces were polished to ensure a flatness of 0.01 mm. A water jet was used to artificially create a fracture in the center of the rock sample, which measured 10 mm in length and 1.5 mm in width, to simulate rock joints. The angle between the fracture and the horizontal axis (α) was set to 0°, 30°, 45°, 60°, or 90°(Fig. 1). The initial physical properties of the sandstone were determined by calculating the average sample parameters: a porosity of 14.31%, a dry density of 2.34 g/cm³, a saturated density of 2.43 g/cm³, and a longitudinal wave velocity of 2738 m/s.

Experimental equipment

(1) Electric blast drying oven: The temperature ranged from 25 °C to 105 °C, with a constant temperature setting of up to 12 h.

(2) RMT-301 mechanical testing system(Fig. 2(a)): This system is used for uniaxial compression tests, including a data acquisition system and stress loading system, with a maximum hydraulic pressure of 1500 kN. The system features high rigidity to minimize errors and supports both the stress control and displacement control modes. The vertical pressure sensors and horizontal displacement sensors were used to simultaneously record the axial and radial strains of the sample.

(3) RBRD-5050 Creep Disturbance Testing Machine(Fig. 2(b)): Comprising a constant stress loading system, a disturbance loading system, and a data acquisition system. The constant stress system provides a maximum pressure of 5000 kN. The disturbance loading system delivers disturbances through a drop hammer, with a hammer weight of 5.0 kg, a steel rod diameter of 20 mm, and a length of 2000 mm.

(4) DIC system: This system consists of a CCD camera, lighting, and a control system.The DIC system used has a spatial resolution of 2592 × 1944, and the strain field data were analyzed using VIC-2D software(URL:www.CorrelatedSolutions.com;

The software version is VIC-2d-v6).

.

Experimental methods

To determine the failure characteristics of sandstone under different water contents and fracture angles under uniaxial pressure, the experimental procedure was designed as follows(As shown in Fig. 3):

-

1.

Drying and saturation: All the samples were weighed to determine their saturated mass and then dried in an oven until a constant weight was reached. The drying temperature was set to 105 °C for 12 h. After drying, the samples were left to cool at room temperature.

-

2.

Water content control: The water content was controlled via a natural soaking method, ensuring that the mass change within 24 h was less than 0.01%, indicating that the sample was saturated. The samples were prepared with three different water content levels: 0% (denoted as D), 50% (denoted as M), and 100% (denoted as S). All the samples were wrapped with plastic film to prevent evaporation or additional water absorption.

-

3.

Uniaxial compression test: Specimens with different fracture angles and water contents were installed in the RMT-301 Concrete and Rock Mechanics Testing System for uniaxial compression tests. Each combination was tested three times, resulting in a total of 15 groups. The displacement control mode was used, with a loading rate of 0.05 mm/min.

-

4.

Creep Disturbance Test: Specimens with different fracture angles and water contents were loaded into the RBRD-5050 Rock Creep Disturbance Testing Machine for creep disturbance testing, with one specimen per group, for a total of 15 groups. The hammer drop height was set to 40 cm. A constant stress of 5 MPa/min was applied until the predetermined stress was reached, which was then maintained for 38 h or until failure occurred. To prevent changes in water content, a waterproof coating was applied to the surface of each sample to ensure negligible changes over 38 h. The samples were painted with a white base and sprayed with speckle patterns for DIC (digital image correlation) analysis. Images were taken every 5 s during the first hour before and after disturbance and every 20 min for the remainder of the time, with the data analysed via VIC-2D software.

The selection of the creep stress in the experiment is crucial. As shown in Fig. 4, point C represents the stress level at which the main axial crack begins to grow, whereas point D represents the maximum volumetric strain, indicating the transition from compaction-dominated deformation to expansion-dominated deformation. According to Meredith (1997), the creep stress should be greater than the stress level at point C but lower than the stress level that would cause failure within a few minutes. Considering the possibility of water evaporation during the creep process, even with protective measures, which could lead to changes in water content and errors in the experimental results, the creep stress in this study was set at 75% of the uniaxial compressive strength to ensure the validity of the results and meet the requirements for creep stress.

Experimental results

Creep failure time

The failure times of the creep impact experiments are summarized in the table below.

As shown in Fig. 5, water content significantly influences the creep behavior of sandstone. In dry samples (0% water content), failure times are relatively dispersed, whereas samples with 50% water content exhibit more consistent failure times, generally exceeding 38 h. In contrast, fully saturated samples (100% water content) show a polarized distribution, with some failure times exceeding 38 h and others being markedly shorter.

Specifically, under dry conditions, samples with 0° and 30° fractures demonstrate higher creep resistance under uniaxial creep-impact loading. In contrast, samples with 90° fractures are most prone to failure. When water content increases to 50%, samples with 30° and 45° fractures show enhanced creep resistance, while those with 0° and 90° fractures exhibit reduced failure times. At 100% water content, creep resistance further improves for 30° and 45° fractures but decreases significantly for 0° fractures. Across all conditions, samples with 90° fractures consistently display the shortest creep durations, which decline further as water content increases. Notably, the failure time of samples with 60° fractures, approximately 12 h, is minimally affected by water content.

In summary, the combined effects of water content and fracture angle play a crucial role in determining the creep behavior of sandstone. Higher water content amplifies the influence of fracture orientation. For instance, the failure time of samples with 90° fractures decreases from 5.7 h under dry conditions to less than 1 h under saturated conditions. Conversely, the shortest failure times for samples with 45° fractures under dry conditions highlight the interplay between water content and fracture angle in shaping creep behavior.

Specimen results

In this experiment, rock samples with different fracture angles and water contents exhibited four possible outcomes: failure did not occur before impact disturbance, failure occurred due to impact disturbance, impact disturbance accelerated creep failure, and no failure occurred.

Specimens not subjected to impact disturbance

Among the four experimental outcomes, two samples remained intact for two hours after the third impact.

As shown in Fig. 6(a), the strain changes caused by the three impacts decreased progressively. The first impact reduced the stress by 1.324 MPa, the second by 0.693 MPa, and the third by 0.311 MPa, indicating that the sample becomes denser as the creep process progresses, diminishing the effects of subsequent impacts. After each impact, stress dropped abruptly before gradually returning to the creep stress level. A similar trend is observed in Fig. 6(b), where the first, second, and third impacts reduced stress by 2.18 MPa, 1.05 MPa, and 0.84 MPa, respectively. This behavior aligns with the results for the sample with a fracture angle (α) of 30°. However, after the second impact, the stress gradually increased, while following the third impact, it returned to the pre-second-impact level of 62.38 MPa.

The gradual stress increase after the second impact can be attributed to microcrack formation within the sample. During the subsequent creep process, these microcracks caused a slight volume reduction, increasing hydraulic pressure and, consequently, stress. The lateral strain behavior of the sample with α = 45° further supports this observation. Four segments of lateral strain increments under creep stress were selected, each separated by an impact disturbance, yielding time-strain curves shown in Fig. 7. These curves reveal that the lateral strain increment decreased after each impact, particularly following the second impact, where the decrease was substantial, and the fitted curve approached a horizontal line. After the third impact, the lateral strain curve was nearly linear, demonstrating that the combined effects of creep and repeated impacts caused the sample to become denser.

This behavior highlights the role of water in enhancing the creep resistance of rock. Water dissolves internal structures, strengthening internal bonding and contributing to the observed densification during the creep process.

Specimens failed under impact disturbance

Table 1 summarizes the failure times during the creep impact tests. Under the combined effects of creep loading and dynamic disturbances, the failure of rock samples can be classified into two modes: accelerated creep failure and dynamic disturbance failure. Accelerated creep failure generally occurs within 12 h after impact, indicating that dynamic disturbances significantly accelerate the creep failure process. A total of five samples experienced this failure mode, and their initial behavior was similar to that shown in Fig. 6, so it is not discussed in detail here. During the final impact leading to failure, the failure modes can be further classified into sudden failure and stepwise failure. Dynamic disturbance failure, on the other hand, is characterized by the failure of a sample rapidly and consistently shortly after impact.

As shown in Fig. 8(a), the stress exhibited a stepwise decrease following a period of impact. The first step resulted in a stress reduction of 0.148 MPa, followed by a partial recovery that did not reach the pre-step level. The second step showed a larger decrease of 0.85 MPa, and during the subsequent stress recovery, a third step occurred, ultimately leading to specimen failure. In contrast, Fig. 8(b) illustrates a sudden failure mode, where failure occurred abruptly without apparent stress indicators.

Figure 9 presents the outcomes of impact-induced failure. After experiencing impact disturbances, the sample’s compressive stress initially decreased, followed by sudden failure as the stress returned to the creep stress level. These findings highlight that the expansion of microcracks during the creep process is the primary driver of failure. As microcracks form, the sample undergoes volumetric and axial collapse under creep stress, reflected in the decreasing creep stress. Impact disturbances accelerate crack growth, and as the creep stress increases and triggers crack coalescence, the sample ultimately fails.

Specimens failed before impact disturbance

Before impact disturbances, failure of the samples occurred in two scenarios. The first scenario is similar to that of the samples with 90° fractures, which, under fully saturated or partially saturated conditions, could not maintain a stable creep state after being subjected to creep stress (see Fig. 10). The sample failed in a relatively short period of time, with significant crack propagation occurring internally after creep stress was applied, causing the stress curve to deviate from a linear trend, leading to failure after 0.06 h.

The second scenario involves failure after a constant creep state is maintained for some time. The failure modes include stepwise failure and sudden failure, which are similar to the failure results observed some time after impact (see Fig. 8).

These experimental results indicate that rock failure behavior is closely related to the fracture angle and water content. Impact disturbances can lead to direct failure, accelerated creep, or maintenance of rock integrity under different conditions. Different combinations of fractures and water contents result in various failure modes under stress, further verifying the complex coupling effect between water and fractures in rock mechanical behavior. By observing the failure modes of the samples, we can clearly identify differences in the creep resistance of the samples under different combinations of water content and fracture angle. Specifically, the samples that failed before impact presented the weakest creep resistance, whereas those that failed after impact presented moderate resistance. In contrast, the samples that did not fail exhibited the strongest creep resistance. These findings are significant for predicting rock stability under complex stress conditions and contribute to a better assessment of rock safety and reliability in geological engineering and underground space development.

Strain characteristics

Volumetric strain‒time curve

Figure 11 presents the volumetric strain‒time curves for samples with various fracture angles and water contents. The curves illustrate a transition in volumetric strain from a compressive state in dry samples (below the zero line) to an expansive state in saturated samples (above the zero line) as water content increases during the creep process.

Comparing samples with different fracture angles but identical water content reveals variations in the rate and extent of volumetric strain during the initial loading phase. Among the saturated samples, those with 0° fractures exhibited the slowest strain rate, followed by those with 30° fractures, while other fracture angles showed similar rates of change. In the dry group, samples with 0° fractures experienced less deformation during initial loading, likely due to the fracture orientation influencing stress distribution and deformation resistance. Notably, a critical fracture angle of 45° was observed in the initial deformation phase across all cases, where volumetric strain peaked. This indicates that at 45°, the interaction between fractures and principal stress direction minimizes the system’s ability to resist deformation, leading to maximum volumetric deformation. Samples with a 45° fracture angle also displayed the longest creep duration, whereas those with 90° fractures exhibited the shortest failure times. Other fracture angles showed less pronounced effects, suggesting that the influence of fracture orientation on rock brittleness is complex and shaped by multiple interacting factors.

When comparing samples with varying water contents but identical fracture angles, all exhibited compressive volumetric strain during the initial loading phase. As pressure increased and time progressed, the compressive strain decreased, and the volume expanded, consistent with uniaxial compression test results. An exception was observed in dry samples with 0° fractures, which initially expanded during compression, unlike other dry samples that first contracted before entering long-term creep. Fully and partially saturated samples exhibited the fastest volumetric change rates, whereas dry samples changed more slowly, indicating that higher water content accelerates volume change during compression and enhances rock plasticity while reducing brittleness.

In the creep phase, the volumetric compression of all samples gradually decreased. Dry samples exhibited a “right-angle” transition from initial loading to creep, while saturated samples displayed a “U” shape. This may result from mineral dissolution in saturated conditions, which increases rock elasticity. These findings highlight that under identical fracture angles, differences in water content significantly affect the rate and extent of volumetric strain changes, underscoring the critical role of water in altering rock deformation behavior.

Axial strain‒time curve

The axial strain‒time curves are presented in Figs. 12, 13 and 14, illustrating the significant effects of water content and fracture angle on the strain behavior of rock. These factors exhibit a coupling effect, where their combined influence intensifies deformation. Under high water content conditions, larger fracture angles result in greater compression and higher strain rates, with the effect being most pronounced in samples with a 90° fracture angle. As water content increases, the strain magnitude and initial loading strain rate of samples consistently rise with increasing fracture angles.

In the dry state (Fig. 12), the sample with a 45° fracture angle exhibited the highest strain rate, whereas the sample with a 0° fracture angle showed the lowest rate of strain change. At 50% water content (Fig. 13), the sample with a 90° fracture angle demonstrated the fastest strain rate during the initial loading phase, with a maximum compression of 51.32 × 10−4. At 100% water content (Fig. 14), compression was strongly correlated with fracture angle; larger angles resulted in greater compression. For fracture angles below 60°, the compression rate increased with angle, while the compression rate for the 90° fracture angle slightly exceeded that of the 60° angle, though the difference was minimal.

Under all water content conditions, samples with a 0° fracture consistently exhibited the lowest compression rate and degree. The water content significantly influenced axial strain behavior, with its effects varying considerably across different fracture angles. In the dry state, samples with a 45° fracture angle had the highest strain rate. However, under high water content conditions, samples with a 90° fracture angle exhibited both the highest compression degree and rate. This demonstrates a coupling effect between water content and fracture angle on the deformation behavior of rock under stress, with 90° fracture angle samples being particularly prone to substantial compression under saturated conditions.

Adjusting fracture orientation to 45° in slope stability design enhances creep resistance and delays instability. In tunnel support design, 45° fracture mechanics inform support layout, optimize load distribution, and mitigate crack propagation risks.

Types of crack growth

Chen et al.31 categorized crack types in sandstone samples containing a single flaw into nine types on the basis of an analysis of the final failure mode. Zhang et al.32 further analysed one of these tensile crack types as a combination of shear failure and tensile failure.

In this study, an imaging system was used to monitor the crack propagation throughout the entire experiment. Based on experimental observations and mechanistic analysis, crack types were broadly classified into 10 categories, as shown in Fig. 15. Tensile cracks were divided into four modes (Modes I-IV) according to their initiation points and propagation directions. Other types include mixed tensile‒shear cracks (Mode V), lateral cracks (Mode VI), shear cracks initiating at flaw tips (Mode VII), far-field cracks initiating away from flaw tips (Mode VIII), surface spalling (Mode IX), and mixed tensile-lateral cracks (Mode X).

To investigate the rock failure mechanism, the cracking sequences of sandstone specimens with flaws are illustrated in Figs. 16 and 17, and 18. The notations T, S, Ss, Lc, and F represent tensile cracks, shear cracks, surface spalling, lateral cracks, and far-field cracks, respectively, with subscript numbers denoting their formation sequence. Crack initiation and failure modes are closely linked to the fracture angle (see Table 2), and the cracking mechanisms vary significantly with changes in water content.

Tensile wing cracks (Types I, II, and III) typically form at the flaw tips due to stress concentration under tensile stress. Crack IV, unique to specimens with α = 0°, initiates at a distance from the flaw tips, unlike other tensile stress-induced cracks. Crack V, also exclusive to 0° fractures, forms initially under shear stress before transitioning to tensile failure. Crack VI, a secondary crack branching from Cracks I and II at low angles, coalesces with them to form Crack X. At higher fracture angles, Crack VI may also originate at the flaw tips. Crack VII is primarily observed in high-angle specimens, where increasing fracture angles promote the development of shear stress. Crack VIII occurs infrequently and has a minimal effect, highlighting the dominant role of fracture orientation in crack initiation and propagation.

Surface spalling cracks (Crack IX) were observed in most flawed specimens, caused by material fragmentation. The extent of these cracks showed a slight decrease as water content increased, indicating that water influences the cracking patterns and associated failure mechanisms.

The results reveal significant differences in the failure mechanisms of rock samples under varying water content and fracture angle conditions. At small fracture angles, failure is primarily driven by tensile cracks. As the fracture angle increases, shear cracks become more prevalent until, at a fracture angle of 90°, tensile action once again dominates the failure process. Most cracks initiate at flaw tips, and surface fractures play a critical role in determining the locations of crack growth. Surface spalling cracks are commonly observed along the propagation paths of other cracks, indicating that the expansion of different crack types can contribute to surface spalling.

Water content also has a pronounced effect on crack morphology, particularly in samples with a 0° fracture angle. With increasing water content, the failure mode transitions from being dominated by Crack IV to being dominated by Crack II, indicating that water influences the crack growth mechanism even when the crack type remains tensile. These findings suggest that prefabricated flaws in rock are the primary factor shaping crack patterns, while water content acts as a secondary factor, modifying the specific morphology of cracks within the same type.

Crack growth process

Crack growth process under different fracture angles

In the impact-creep tests, samples with varying fracture angles exhibited different types of cracks, classified based on their initiation points and propagation directions. Since the evolution of high-strain zones closely aligns with crack propagation characteristics, analyzing the strain field provides valuable insights into crack growth and the types of cracks formed under impact-creep conditions with different fracture angles.

Direct observation of crack growth is inherently limited; however, digital image correlation (DIC) technology enables more precise identification of crack initiation and propagation. Experimental images revealed that in samples with a fracture angle of 90° and water contents of 50% and 100%, the failure process occurred too rapidly to capture meaningful changes in the strain field. To examine the effects of fracture angle on crack growth, detailed analysis was conducted on dry samples with fracture angles of 0°, 30°, 45°, 60°, and 90°. This analysis highlighted differences in crack types among the samples and provided critical insights into the initiation, propagation, and coalescence of cracks under impact-creep conditions. These findings not only enhance understanding of crack behavior but also offer a foundation for predicting rock failure modes under complex stress conditions. Notably, analysis of the shear stress field allowed clear visualization of crack growth in the samples.

As shown in Fig. 19, strain field changes were concentrated around the flaw before spreading outward. In the sample with a 0° fracture angle, as strain rapidly increased, the crack grew vertically upward, perpendicular to the flaw orientation, ultimately causing sample failure. Interestingly, crack growth did not initiate at the two ends of the flaw.

Under conventional conditions, stress concentration typically occurs at flaw tips, leading to crack propagation from these points. However, in this impact-creep test, the crack in the 0° fracture sample grew vertically from the middle of the flaw, bypassing the flaw tips. This atypical crack growth path suggests that impact disturbances uniquely influence the strain field, altering the typical stress distribution and resulting in unconventional crack propagation behavior.To effectively illustrate the variations in strain fields for each fracture angle, distinct legend value ranges were applied. This approach enables a clear visual comparison of the strain field characteristics in rocks with fractures at various angles by highlighting differences in strain magnitudes33,34.

For the sample with a fracture angle of α = 30°, cracks initiated from both ends of the fracture and extended perpendicular to its orientation. As these cracks propagated, secondary cracks formed around the fracture, eventually coalescing into a large inclined crack that led to sample failure. In the sample with α = 45°, cracks propagated along the fracture direction, while a smaller crack extended perpendicularly from a discontinuity in the upper right corner. The eventual connectivity of these three cracks resulted in failure.

Samples with fracture angles of α = 60° and α = 90° exhibited similar failure modes. The strain field showed that strain concentration was primarily confined to one side of the sample, culminating in failure through splitting. Although no visible surface cracks were observed during the experiments, the principal strain field revealed pronounced strain concentrations that eventually caused sudden and intense failure. This indicates that in samples with 60° and 90° fractures, the fractures accelerated the formation of internal cracks, thereby increasing the likelihood of creep failure.

From a numerical analysis perspective, the sample with α = 45° exhibited the highest strain values. However, no significant growth of fine cracks or strain anomalies was observed, suggesting a strong strain concentration effect under uniaxial compressive force. The extended creep duration of the 45° fracture samples indicates that failure during the impact-creep process primarily results from the gradual growth of numerous fine cracks. Stress concentration within the rock appears to delay failure, thereby prolonging the creep process.

Crack growth process under different water contents

The above analysis revealed that water causes changes in the type of crack growth, and it significantly affects the crack growth process. The photographic records obtained through the camera indicate that, compared with saturated samples, dry samples require more time from crack initiation to specimen failure.

As shown in Fig. 20, the water content has a significant effect on the failure time of fractured samples. For the samples with fracture angles of 0°, 60°, and 90°, the time from crack initiation to sample failure decreases significantly as the water content increases. When the water content reaches 100%, the time from crack initiation to failure is less than 5 s. For the samples with fracture angles of 30° and 45°, the time from crack initiation to failure also decreases as the water content increases under dry and partially saturated conditions. However, when the water content reached 100%, no failure occurred in the fractured samples. Under creep-impact conditions, crack growth and connectivity in rock were observed. In dry samples, cracks evolved gradually, indicating that the rock retained some strength after crack growth. In contrast, in the saturated samples, except for those that did not fail, all the samples failed rapidly after cracks appeared, suggesting that the formation of cracks led to a sharp decrease in rock strength. This finding indicates that the presence of water significantly accelerates crack growth and reduces the overall strength of rock.

Discussion

1. The stress concentration effect for a 45° fracture can be explained using fracture mechanics theory. In this scenario, the corresponding stress intensity factor is calculated as follows:

σ: Applied stress (MPa).

a: Half of the crack length (m).

β: Fracture angle (the angle between the fracture plane and loading direction, °).

When the fracture angle is 45°, the Mode I and Mode II stress intensity factors (KI = KII) are equal, resulting in a dynamic equilibrium between tensile and shear stresses at the crack tip. At this configuration, stress concentration is localized at the crack tip, while the overall stress distribution is relatively uniform. This enhances the load-bearing capacity of the structure, allowing the specimen to maintain stability under sustained loading for a longer duration, delaying macroscopic deformation.(Regarding this point, it is clearly evident in the DIC images(Fig. 19).)

The geometric characteristics of the 45° fracture angle impose significant constraints on crack slip while redistributing external stress. Compared to vertical (0°) or parallel (90°) fractures, the inclined loading mechanism of the 45° fracture angle is more conducive to structural stability, exhibiting superior creep resistance. Shear stress concentration enhances frictional resistance between crack surfaces, effectively inhibiting crack slip and delaying creep deformation. The balance between shear and tensile stresses inhibits rapid crack propagation, allowing localized deformation to remain stable over an extended period. Moreover, reduced macroscopic strain concentration fundamentally delays the progression of creep failure.

In engineering practice, the stress distribution associated with a 45° fracture angle has substantial implications. In slope stability analysis, underground excavation, and tunnel support design, optimizing fracture orientations or adjusting loading directions can enhance deformation resistance and delay creep failure. This study provides theoretical support for evaluating the long-term performance of fractured rock masses and offers insights for predicting and controlling crack propagation, providing significant engineering value.

2. Analysis of Mixed Tensile-Lateral Crack (Mode X) Growth

In fracture mechanics, cracks under tensile stress typically deviate from the principal stress direction and propagate at an angle of 70.5°, theoretically derived from the equilibrium of stress intensity factors (Mode I and Mode II). In regions of high stress concentration, crack propagation at 70.5° maximizes energy release, a characteristic feature of mixed-mode tensile-shear fracture.The stress intensity factor formula, however, neglects crack width. In this study, the crack initially displayed tensile growth due to its width. As propagation continued and the width effect diminished, the crack transitioned to lateral growth, aligning with the theoretical 70.5°angle(Fig. 21).Compared to the “tensile-shear mixed crack” model proposed by Zhang et al. (2022), Mode X demonstrates greater crack propagation capacity and faster failure rates under complex stress fields and high water content conditions. This study enriches existing crack growth theories and provides a new framework for assessing rock stability in complex stress environments.

3. Experiments indicate that at the initial stage of crack formation, a dynamic balance between tensile stress (Mode I) and shear stress (Mode II) at a 45° crack angle inhibits rapid crack propagation. Regarding crack propagation paths, DIC images reveal significant differences under varying crack angles and water content conditions. Cracks at a 90° angle exhibit mixed tensile-shear propagation, 45° cracks are predominantly influenced by shear stress, while 0° cracks primarily display tensile failure.

Based on experimental results and fracture mechanics theory, we infer the following mechanisms for the formation and development of sandstone cracks:

(1). Relationship Between Stress Concentration and Crack Angle: Stress concentration at the crack tip is the primary driving force for crack formation, and the crack angle significantly influences the propagation path and rate of the cracks.

(2). Role of Water: Water accelerates crack propagation and penetration by reducing friction and enhancing lubrication effects.

(3). Synergistic Effect of Microcracks: During the creep process, the synergistic interaction among microcracks leads to accelerated crack propagation, particularly under conditions of high water content and large crack angles.

4. Aligning the excavation design and orientation with 45° fracture trends can effectively reduce local creep instability and minimize required reinforcement measures.For areas with 45° fractures, lighter or standard support measures may suffice. In contrast, high-strength or dense support should be allocated to fractures at angles posing higher risk, thus ensuring a more efficient use of resources.

Conclusions

This study investigated the effects of water content and fracture angle on the creep behavior of sandstone during creep-impact tests using uniaxial compression tests, creep-disturbance experiments, and DIC system analysis. The main findings are as follows:

1.Water Content and Fracture Angle Effects

Water content and fracture angle significantly influenced the creep behavior of sandstone. Higher water content prolonged creep duration and increased the damage threshold for 45° and 30° fractures but accelerated failure and reduced the damage threshold for 0°, 60°, and 90° fractures. These results highlight the complex interaction between water and fractures, where brittleness increases in high-defect samples, and toughness improves in low-defect samples.

2.Crack Growth Mechanisms

Prefabricated fractures were identified as the dominant factor affecting crack growth mechanisms, while water content influenced crack morphology and propagation patterns.

3.DIC Observations

DIC analysis revealed that water content and fracture angle significantly affected stress distribution and crack propagation behavior. Water altered the crack propagation rate and direction, while fracture angles determined stress localization and permeability effects.

4.Volumetric Strain Transition

Water content caused volumetric strain to transition from compression under dry conditions to expansion under saturated conditions. A coupling effect between water and fracture angle was observed, with 90° fractures under high water content conditions showing the highest compressive strain.

5.Proposed Mixed Fracture Mode (Mode X)

A new mixed tensile-lateral crack type (Mode X) was identified, enriching the understanding of rock fracture mechanisms under complex stress fields. This finding provides valuable insights for predicting rock failure and improving stability in engineering applications.

Data availability

The data used and analyzed during this study are available from the corresponding author upon reasonable request.

References

Xibing, L. I. & Fengqiang, G. Research progress and prospect of deep mining rock mechanics based on coupled static-dynamic loading testing. J. China Coal Soc. 46, 846–866. https://doi.org/10.13225/j.cnki.jccs.YT21.0176 (2021).

Yu, Y. et al. Experimental study of the creep disturbance effect and acoustic emission characteristics of mudstone with different moisture contents. Shock Vib. 2021 https://doi.org/10.1155/2021/7941242 (2021).

Ma, S. et al. Surface multi-hazard effect of underground coal mining. Landslides 20, 39–52. https://doi.org/10.1007/s10346-022-01961-0 (2023).

Zhou, X., Pan, X. & Berto, F. A state-of‐the‐art review on creep damage mechanics of rocks, fatigue fract. Eng. Mater. Struct. 45, 627–652. https://doi.org/10.1111/ffe.13625 (2022).

Griggs, D. Creep of rocks. J. Geol. 47 (3), 225–251 (1939).

Qiao, L., Wang, Z., Liu, J. & Li, W. Internal state variable creep constitutive model for the rock creep behavior. Bull. Eng. Geol. Environ. 81 https://doi.org/10.1007/s10064-022-02921-7 (2022).

Yang, W. et al. Loading history effect on creep deformation of rock. Energies 11, 1462. https://doi.org/10.3390/en11061462 (2018).

Wu, F., Chen, J. & Zou, Q. A nonlinear creep damage model for salt rock. Int. J. Damage Mech. 28, 758–771. https://doi.org/10.1177/1056789518792649 (2019).

Hu, S. et al. Creep properties and energy evolution characteristics of weakly cemented rock under step loading, International journal of rock mechanics and mining sciences (Oxford, England : 170 (2023) 105428, (1997). https://doi.org/10.1016/j.ijrmms.2023.105428

Zhu, W., Li, S., Li, S. & Niu, L. Influence of dynamic disturbance on the creep of sandstone: an experimental study, rock mech. Rock. Eng. 52, 1023–1039. https://doi.org/10.1007/s00603-018-1642-7 (2019).

Li, X., Wu, D. & Wu, M. Creep characteristics and fractional rheological model of granite under temperature and disturbance load coupling. Mech. Time-Depend Mater. 28, 81–98. https://doi.org/10.1007/s11043-023-09618-8 (2024).

Li, W. et al. Blasting damage mechanism and excavation stability of surrounding rock of shallow-buried metro station. Phys. Fluids. 36 https://doi.org/10.1063/5.0206732 (2024).

Yang, Z., Zhu, W., Guan, K., Yan, B. & Jia, H. Influence of dynamic disturbance on rock creep from time, space and energy aspects. Geomatics Nat. Hazards Risk. 13, 1065–1086. https://doi.org/10.1080/19475705.2022.2064775 (2022).

He, M. et al. Numerical simulation of rock bursts triggered by blasting disturbance for deep-buried tunnels in jointed rock masses. Comput. Geotech. 161, 105609. https://doi.org/10.1016/j.compgeo.2023.105609 (2023).

Sun, Q., Li, B., Tian, S., Cai, C. & Xia, Y. Creep properties of geopolymer cemented coal gangue-fly Ash backfill under dynamic disturbance. Constr. Building Mater. 191, 644–654. https://doi.org/10.1016/j.conbuildmat.2018.10.055 (2018).

Yu, M., Wei, C. & Niu, L. The coupled effect of loading rate and grain size on tensile strength of sandstones under dynamic disturbance. Shock Vib. 2017, 1–13. https://doi.org/10.1155/2017/6989043 (2017).

He, B., Wang, L., Feng, X. & Zhen, R. Failure modes of jointed granite subjected to weak dynamic disturbance under true-triaxial compression, rock mech. Rock. Eng. 56, 7939–7957. https://doi.org/10.1007/s00603-023-03507-9 (2023).

Chun, W., Luping, C., Cheng, W., Zhuqiang, X. & Shiming, W. Dynamic mechanical characteristics and failure mode of serpentine under a three-dimensional high static load and frequent dynamic disturbance. PLoS One. 2019 https://doi.org/10.1371/journal.pone.0222684 (2019).

Wang, Y., Cao, Z., Mao, T., Li, P. & Cai, M. Investigation of fatigue failure and energy characteristics of rock exposed to complicated stress disturbance paths: Cyclic stress amplitude effect, fatigue fract. Eng. Mater. Struct. 46, 2697–2713. https://doi.org/10.1111/ffe.14026 (2023).

Gao, Y. et al. The acoustic emission behavior and its fractal characteristics of the sandstone under the disturbance stress paths, rock mech. Rock. Eng. 56, 5487–5511. https://doi.org/10.1007/s00603-023-03342-y (2023).

Hu, L., Li, Y., Liang, X., Tang, C. A. & Yan, L. Rock damage and energy balance of strainbursts induced by low frequency seismic disturbance at high static stress, rock mech. Rock. Eng. 53, 4857–4872. https://doi.org/10.1007/s00603-020-02197-x (2020).

Wu, W., Gong, F., Jiang, Q. & He, L. Fracture toughness weakening effect of high static pre-loaded Cstbd granite subjected to low frequency dynamic disturbance during the rock fracture. Eng. Fract. Mech. 269, 108566. https://doi.org/10.1016/j.engfracmech.2022.108566 (2022).

Gong, F., Wu, W. & Zhang, L. Brazilian disc test study on tensile strength-weakening effect of high pre-loaded red sandstone under dynamic disturbance. J. Cent. South. Univ. 27, 2899–2913. https://doi.org/10.1007/s11771-020-4517-5 (2020).

Caselle, C., Baud, P., Kushnir, A. R. L., Reuschlé, T. & Bonetto, S. M. R. Influence of water on deformation and failure of gypsum rock. J. Struct. Geol. 163, 104722. https://doi.org/10.1016/j.jsg.2022.104722 (2022).

Zhongliang, Z., Wukui, D., Jianjun, Y., Mi, Z. & Ziwei, L. Creep mechanical tests and shear rheological model of the anchorage rock mass under water–rock coupling. PLoS One. 18, e284569. https://doi.org/10.1371/journal.pone.0284569 (2023).

Li, J. et al. Effect of water on the rock strength and creep behavior of green mudstone, Geomech. Geophys. Geo-Energy Geo-Resour. 9 https://doi.org/10.1007/s40948-023-00638-9 (2023).

Urai, J. L., Spiers, C. J., Zwart, H. J. & Lister, G. S. Weakening of rock salt by water during long-term creep. Nature 324, 554–557. https://doi.org/10.1038/324554a0 (1986).

Yang, S. & Hu, B. Creep and permeability evolution behavior of red sandstone containing a single fissure under a confining pressure of 30 Mpa. Sci. Rep. 10 https://doi.org/10.1038/s41598-020-58595-2 (2020).

Li, Y. & Huang, D. Damage properties and rheological model of spatial-rotation fissured red sandstone subjected to freeze–thaw and loading, rock mech. Rock. Eng. https://doi.org/10.1007/s00603-024-04057-4 (2024).

Wang, B. et al. Study on the creep properties and fracture behavior of three different rock types with a single preexisting fissure. Bull. Eng. Geol. Environ. 82 https://doi.org/10.1007/s10064-023-03283-4 (2023).

Chen, J., Ye, Y., Pu, Y., Xu, W. & Mengli, D. Experimental study on uniaxial compression failure modes and acoustic emission characteristics of fissured sandstone under water saturation. Theor. Appl. Fract. Mech. 119, 103359. https://doi.org/10.1016/j.tafmec.2022.103359 (2022).

Zhang, G. et al. Micro- and macrocracking behaviors in granite and molded gypsum containing a single flaw. Constr. Build. Mater. 292, 123452. https://doi.org/10.1016/j.conbuildmat.2021.123452 (2021).

Cheng, J. et al. Uniaxial experimental study of the acoustic emission and deformation behavior of composite rock based on 3d digital image correlation (dic). Acta Mech. Sin. 33, 999–1021. https://doi.org/10.1007/s10409-017-0706-3 (2017).

Tan, L., Zhou, Z., Cai, X. & Rui, Y. Analysis of mechanical behaviour and fracture interaction of multi-hole rock mass with dic measurement. Measurement 191, 110794. https://doi.org/10.1016/j.measurement.2022.110794 (2022).

Acknowledgements

The authors acknowledge support from the Guizhou Provincial Basic Research Program (Natural Science) (No. QianKeHeJiChu-ZK[2024]YiBan094, the Science and Technology Support Plan of Guizhou Province ([2020]4Y046) and Guizhou Provincial Education Department (Guizhou Education Union YJSCJH (2020) 018).

Author information

Authors and Affiliations

Contributions

Guixing yuan contributed to manuscript writing, experimental design, conducting experiments, data analysis, and theoretical analysis. Jianhua Deng provided funding support, while Anli Wang was involved in project supervision.All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yuan, G., Deng, J. & Wang, A. The effects of water content and fracture angle on rock creep and crack behavior under impact conditions. Sci Rep 15, 7721 (2025). https://doi.org/10.1038/s41598-025-92163-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-92163-w