Abstract

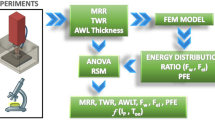

Titanium alloy (Ti-6Al-4V) is a difficult-to-machine material, known for its excellent physical and chemical properties. However, traditional machining methods incur high tool wear costs when processing this material. The near-dry electrical discharge milling (N-EDM) method, which removes excess material via electroerosion, mitigates the impact of titanium alloy’s hardness and strength, enabling effective material cutting. To enhance machining efficiency and surface quality, this study employs a simulation model of the inter-electrode flow field, combined with experimental data, to investigate the effect of milling thickness on key machining parameters and determine the optimal thickness. Subsequently, a four-factor, three-level (L27(43)) orthogonal experiment was designed, with current, duty cycle, gas pressure, and atomization rate as input parameters. Material removal rate (MRR), relative electrode wear ratio (REWR), width of cut (WOC), and roughness average (Ra) were selected as primary optimization indicators. Based on the orthogonal experiment results, analysis of variance (ANOVA) was conducted to examine the influence of the input parameters on the various process indicators and determine the optimal single-objective processing parameters. Using Grey Relational Analysis (GRA), the multi-objective optimal machining parameters were identified as: 2 A current, 40% duty cycle, 0.2 MPa gas pressure, and 20 ml/min atomization rate. These parameters significantly enhance both processing efficiency and surface quality.

Similar content being viewed by others

Introduction

Ti-6Al-4V is an \(\alpha+\beta\) titanium alloy known for its low density, excellent thermal stability, and superior corrosion resistance, making it widely applied in industries such as aerospace, biomedical, and automotive1,2. However, during machining, titanium alloys generate significant heat in the cutting zone due to their material properties, such as low thermal conductivity, high hardness, and high chemical reactivity. This leads to accelerated tool wear and failure, while the inability to effectively remove chips further destabilizes the machining process, potentially causing tool fracture. As a result, machining efficiency and precision are negatively affected3,4. Unconventional material removal methods like Electrical Discharge Machining (EDM) are essential, as they use discharge energy to remove metal from the workpiece5. Since there is no physical contact between the tool and the workpiece, no mechanical cutting forces are generated, thus eliminating constraints related to material strength and hardness. This enables non-contact machining of titanium alloys without inducing thermal deformation, among other advantages6,7.

With the development of EDM technology, researchers have sought to improve the low processing efficiency and other drawbacks of traditional EDM techniques, Wang et al.8 conducted comparative milling experiments on Ti-6Al-4V under three conditions: gas, liquid, and gas-liquid mixtures, finding that the quasi-dry EDM milling process showed improvements in both surface quality and machining efficiency compared to gas-only machining. Ramver Singh et al.9 evaluated the performance of three gas media: air, argon, and oxygen, Under the same parameters, replacing air or argon with oxygen can increase the MRR by approximately 19% and 51%, respectively, hile using argon instead of air and oxygen can reduce the Ra by approximately 17% and 34%, and the overcut width by nearly 17% and 34%, respectively.

Ganachari et al.10 created a thermoelectric model for the workpiece material using ANSYS Workbench, performing experiments and simulations on spring steel by adjusting current, gap voltage, cycle time, and pressure. Their research revealed that distilled water enhances the stability of the plasma channel in near-dry electrical discharge machining (NDEDM). Namboodiri et al.11 designed a finite element-based computational model to determine the MRR in the near-dry electrical discharge machining process using a glycerin-air mixture. Simulations were conducted under various processing conditions, revealing that the MRR increases with the rising volume ratio of glycerin in the glycerin-air mixture. Additionally, as the glycerin flow rate increases, the MRR also rises. Guo et al.12 investigated the effects of single-layer cutting thickness and electrode diameter on the flow field and machining performance in electrical discharge milling (ED-milling) through simulations and experiments. The three newly designed multi-hole electrodes improved the machining efficiency of ED-milling by 33%.

Many researchers have also attempted to explore the relationship between processing parameters and performance metrics using parameter optimization methods. Ashish Goyal et al.13 utilized fuzzy logic and the Adaptive Neuro-Fuzzy Inference System (ANFIS) model to establish optimal processing conditions, achieving accurate predictions of machining performance based on Ra and roundness. Vora, Shah Y et al.14 applied grey relational analysis to optimize process parameters for quasi-dry EDM cutting with multiple objective responses, validating the results through experimental data, which showed simultaneous improvements in MRR, surface roughness (SR), and recast layer thickness (RLT). Chakraborty et al.15 conducted a comparative study between grey relation analysis (GRA) and grey relation analysis coupled with principal component analysis (GRA-PCA), finding that the recognition ability of GRA-PCA was 23.04% higher than that of GRA. Subsequently, they used a combination of GRA and GRA-PCA to analyze and optimize the process parameters, ultimately identifying the optimal process parameters for powder-mixed wire EDM of Ti-6Al-4V alloy16. GRA is used to address the conflicts between multiple objectives commonly encountered in multi-objective optimization. It helps identify a relatively balanced optimal solution that provides a good compromise between competing objectives17. This means that the optimal process parameter set obtained through GRA may not represent the best value for each individual objective, but rather reflects a balanced and optimal solution across all objectives18.

From the above research methods, it is evident that GRA can optimize multiple responses simultaneously to obtain the best machining parameters, while fluid simulations provide key information regarding fluid flow, pressure, and velocity distribution. This study focuses on titanium alloy Ti-6Al-4V to explore the machining performance of N-EDM. First, single-factor experiments were conducted on each layer’s cutting thickness, and a simulation model was established for fluid simulation of the atomization medium in N-EDM. Subsequently, orthogonal experiments were utilized to investigate the primary and secondary effects of N-EDM processing parameters on MRR, REWR, WOC, and Ra. GRA was employed for multi-objective optimization to derive the optimal combination of machining parameters, followed by experimental validation.

Materials and methods

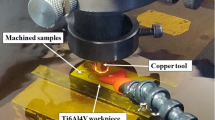

The experiments were conducted using a Beijing Ninghua Technology Co., Ltd. NH25F-type electrical discharge machine equipped with a self-developed rotating device, as shown in Fig. 1. Titanium alloy Ti-6Al-4V was machined using N-EDM, which primarily utilizes inter-electrode discharge energy for material removal. During the machining process, a mist medium, created by the combination of compressed air and water, was introduced into the machining area through multi-channel electrodes. This medium serves to cool both the workpiece and electrode while removing the debris generated during the discharge process from the machining zone19.

The tool electrode is a multi-channel copper electrode with a diameter of 3 mm, and the workpiece is made of Ti-6Al-4V material with a thickness of 30 × 20 × 5 mm. The milled sample is a slot with dimensions of 16 mm in length, 3 mm in width, and 0.6 mm in depth. This study examines the influence of each layer’s milling thickness on N-EDM of titanium alloy, employing a layer-by-layer reciprocating milling approach. The machining parameters used in the experiment are listed in Table 1. For N-EDM, the medium consists of a combination of air and water, which are introduced into the atomizer under high pressure to form a mist. The machining performance is assessed using indicators such as MRR, REWR, Ra, and WOC. The machined surface roughness Ra was measured by using a TR200 surface roughness tester. To reduce the error, three locations were selected on each sample machined surface for measurement. WOC is defined as the difference between the removed width of the machined slot and diameter of the electrode20. The MRR and REWR were calculated using Eqs. (1) and (2), respectively.

In Eqs. (1) and (2): \({\text{m}}_{\text{t}}\) and \({\text{m}}_{\text{d}}\) are respectively the mass of the workpiece that is etched (g) and the mass of the electrode that is lost during the machining process (g). \({{\uprho}}_{\text{t}}\) and \({{\uprho}}_{\text{d}}\) are the density of the Ti-6Al-4V workpiece (g/mm3) and the electrode (g/mm3) respectively. t denotes the processing time (min).

Results and discussion

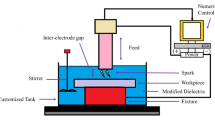

A 3D solid model of the inter-electrode flow field during single-layer machining was developed in SolidWorks based on the multi-channel electrode and the actual discharge gap, as shown in Fig. 2. The medium enters through the electrode channel, with the outlet divided into three distinct regions. The actual thickness of each milling layer is the sum of the height of the discharge gap at the electrode sidewall and the discharge gap at the electrode bottom. Different milling layer thicknesses are distinguished by varying the height of the discharge gap between the workpiece and the electrode sidewall at Outlet 2. Mesh division is conducted separately for the three-dimensional models of different milling thicknesses, with a minimum mesh size of 0.005 mm. The flow field between the electrode and the workpiece is simulated using the fluid simulation software ANSYS Fluent. The simulated medium is water vapor, with a density of 0.589 and a kinematic viscosity of 1.5 × 10, while the discharge gap between the electrode and the workpiece is 0.01 mm. The boundary condition for the inlet pressure is 0.2 MPa, while the outlet environmental pressure is 0.1 MPa, with the remaining surfaces in the computational domain defined as Wall. A viscous fluid flow model is selected based on the Reynolds number (Re). The flow velocity of the medium is approximately 20 m/s, derived from the inlet pressure and the electrode inner diameter. The calculated Re for the porous electrode is 2460, which is greater than 2000, indicating turbulent flow. Therefore, a turbulent flow model is chosen for the simulation analysis21,22.

Figure 3 presents the pressure contour maps of the simulation models at different milling thicknesses, along with the cross-sectional view at the bottom. It was observed that as the milling thickness increased, the maximum pressure also increased. The rise in the height of the discharge gap at the electrode sidewall, coupled with restricted flow and difficulties in discharging the medium within the machining gap, led to a gradual accumulation of pressure, which resulted in increased pressure peaks in certain regions. An appropriate flow field pressure can facilitate the diffusion of heat within the discharge gap and the expulsion of removed material, maintaining cleanliness in the machining gap and preventing short circuits or abnormal discharges, thereby enhancing discharge stability and material removal efficiency23,24.

In this single-factor experiment, while the milling depth remained constant, the variation in milling thickness resulted in different total travel distances (i.e., the length of the tool path), influencing both the number of layers and the number of tool passes during the machining process, as illustrated in Fig. 4. The overall MRR during processing at different layer counts was analyzed, and the MRR for processing a single layer of material was calculated, as shown in Fig. 5. It was observed that as the milling thickness increased, the MRR for a single layer also increased, which is consistent with the results of the inter-electrode fluid simulation for single-layer processing. However, in practical machining, an increase in milling thickness also leads to an increased volume of material removal, which impairs the cooling effect. This results in heat accumulation within the discharge gap, a rise in temperature, and a slowdown in the re-solidification of the material, thereby hindering further material removal25. Furthermore, as observed in Fig. 3, when the milling thickness was set to 2 mm, there was a significant change in pressure within the discharge gap. The increase in the height of the discharge gap between the electrode and the workpiece led to a noticeable increase in the coverage area of high-pressure regions within the discharge gap, which could affect discharge stability and frequency26. Moreover, if the pressure is too high, poor flow of the medium can hinder inter-electrode cooling and chip removal efficiency, compromising the cleanliness of the discharge gap and the stability of the spark discharge, thereby affecting machining efficiency.

Experiments were conducted using the N-EDM parameters listed in Table 1. Figure 6 illustrates the impact of milling thickness on the process indicators. As seen in Fig. 6, when the milling thickness is less than 0.15, the MRR is directly proportional to the milling thickness; however, when it exceeds 0.15, the relationship becomes inversely proportional. The N-EDM process uses the energy generated by spark discharge to erode the workpiece. A moderate increase in the thickness of each milling layer helps better concentrate the discharge energy in the machining area, increasing the volume of material involved in the discharge reaction per unit area. The gasification and melting processes become more complete, the atomized medium effectively cools and removes the molten material, maintaining cleanliness in the gap, thereby maximizing the material removal rate. However, if the milling layer is too thick, the discharge heat will spread rapidly across the machining area, and the amount of molten and vaporized material will exceed the slag removal capacity of the atomized medium. As a result, some of the molten material cannot be expelled in time and reattaches to the processing surface. The accumulation of material hinders the formation of subsequent discharge channels, further reducing machining efficiency.

Figure 7 shows that as the milling thickness increases, the REWR gradually decreases. This is because a greater milling thickness results in an increased amount of material removed during the discharge process. This implies that the energy from each discharge is utilized more effectively for material removal, rather than being wasted on multiple shallow discharges. Fewer discharge occurrences and shorter discharge durations can significantly enhance discharge machining efficiency while reducing electrode wear27. Figure 8 reveals that the corner radius of the electrode tip gradually decreases after processing, indicating a corresponding reduction in REWR. The energy spectrum shows that the copper content on the electrode surface gradually increases, while shorter processing times correlate with a reduction in the thickness and area of the oxide layer and molten workpiece material on the electrode surface, resulting in higher copper content.

Figure 9 and Figure 10 reveal that as the milling thickness increases, the Ra gradually decreases, showing a slight overall downward trend. This is primarily due to the fact that a larger milling thickness facilitates better dispersion of discharge energy, which helps mitigate thermal accumulation and reduce thermal losses, thus improving the overall effectiveness of the discharge process. Moreover, variations in milling thickness have little impact on the discharge state at the electrode’s bottom. Although an increase in milling thickness may increase the likelihood of spark discharge occurring on the electrode sidewall, this effect has minimal influence on the discharge quality at the bottom of the electrode28.

Figure 11 illustrates the impact of milling thickness on the WOC. Figure 12 shows the entry morphology and cross-sectional view of the workpiece after machining at different milling thicknesses. Measurements indicate that as the milling thickness increases, the vertical corner radius decreases, resulting in improved shaping accuracy of the workpiece entry. During the N-EDM machining process, WOC is closely related to the REWR; a smaller REWR correlates with better preservation of the electrode shape and a smaller vertical corner radius, leading to improved machining quality. With a smaller milling thickness, the discharge energy is spread across a thinner material layer, leading to insufficient energy concentration and causing lateral diffusion of the spark discharge. In contrast, increasing the milling thickness concentrates the discharge energy in the thicker material layer at the electrode’s front, thereby reducing lateral material removal and, as a result, lowering the WOC29.

To investigate the order of influence of processing parameters on MRR, REWR, WOC, and Ra, traditional experimental design methods require extensive experimentation under selected process variables and levels. These challenges can be addressed by implementing orthogonal experiments30. This study designs a four-factor, three-level (L27 (43)) orthogonal experiment, with a milling thickness of 1 mm and a depth of 6 mm. The factor level table is presented in Table 2, with other parameters remaining consistent with those in the single-factor milling thickness experiment. The orthogonal experiment results are presented in Table 3.

The variance analysis of MRR and Ra is presented in Table 4. From Table 4, it is clear that the current significantly influences both MRR and Ra. In N-EDM, material is removed from the workpiece solely through spark discharge, with the current being the primary source of machining energy. The main effect plot shows that both MRR and Ra are directly proportional to the current magnitude, which determines the energy of the spark discharge. A higher discharge energy leads to a greater force exerted by the spark on the material surface, generating larger molten droplets and cavities, which results in higher material removal rates and surface roughness. Additionally, the atomization rate significantly affects REWR and WOC, as an increase in atomization improves cooling efficiency. In EDM, a discharge channel forms between the electrode and the workpiece, and the high temperatures generated during discharge can affect both the electrode and the workpiece thermally. Effective cooling helps regulate the discharge channel temperature, ensuring stable spark discharge and reducing WOC and REWR31.

The main effect plot of MRR shown in Fig. 13 clearly illustrates that an increase in current leads to a corresponding increase in MRR, with current having the most significant impact on MRR, followed by duty cycle and gas pressure, while atomization amount has minimal effect. This is because changes in current and duty cycle directly influence the energy source during processing, whereas variations in atomization primarily affect inter-electrode temperature and chip removal32. Based on the main effect plot, it can be concluded that MRR is maximized when the current is set to 6 A, the duty cycle is 60%, the gas pressure is 0.4 MPa, and the atomization amount is 15 ml/min.

The main effect plot of REWR in Fig. 14 demonstrates that electrode wear increases with rising current, while the influence of duty cycle is relatively minor. This indicates that as current increases, discharge energy also increases, resulting in greater erosion of the electrode by the spark discharge and, consequently, the largest change in REWR. An increase in duty cycle extends the discharge duration, leading to a continuous rise in electrode temperature. At elevated temperatures, the electrode material is more susceptible to melting and evaporation, thereby accelerating electrode wear. Furthermore, higher gas pressure results in atomization media carrying more energy, which enhances the erosion effect on the electrode surface and accelerates material wear. The main effect plot indicates that REWR is minimized when the current is 4 A, the duty cycle is 50%, the gas pressure is 0.2 MPa, and the atomization rate is 20 ml/min.

From the main effect plot of WOC in Fig. 15, it can be observed that increases in both current and duty cycle lead to greater discharge energy. When both current and duty cycle are low, the discharge energy is insufficient to completely melt and evaporate the titanium alloy in the processing area, resulting in relatively small WOC. As current and duty cycle increase, discharge energy intensifies, potentially exceeding the melting and vaporization points of the titanium alloy, leading to substantial melting and evaporation of the material. This results in significant thermal expansion and splashing, which increases WOC. As the atomization rate increases, WOC initially rises and then decreases. When the atomization rate reaches a certain threshold, a substantial cooling effect occurs, leading to energy dissipation and excessively low temperatures in the processing area, thereby reducing WOC. The main effect plot shows that WOC is minimized when the current is 2 A, the duty cycle is 40%, the gas pressure is 0.2 MPa, and the atomization rate is 20 ml/min.

From the main effect plot of Ra in Fig. 16, It is clear that surface roughness increases with higher current, which has the most significant impact, while the effects of duty cycle, gas pressure, and atomization amount on roughness are relatively minor. The magnitude of the current is the primary determinant of the energy source. Fluctuations in current can lead to uneven distribution of discharge energy within the processing area, creating regions with either excessive or insufficient energy concentration, thereby increasing Ra33. The main effect plot indicates that Ra is minimized when the current is 2 A, the duty cycle is 40%, the gas pressure is 0.2 MPa, and the atomization amount is 10 ml/min.

The results of variance analysis and the main effect plot indicate that different parameters have varying degrees of impact on the processing outcomes. To find the optimal combination of MRR, REWR, WOC, and Ra, GRA is employed for multi-objective optimization of the process parameters in mixed gas atomization discharge machining of titanium alloys34. GRA is a multi-factor analysis method based on grey system theory, used to evaluate the degree of association and significance among factors. The complex interrelationships among multiple responses can be solved using GRA35. The steps for GRA are as follows: dimensional normalization of the process indicators, calculation of the grey relational coefficients, and computation of the grey relational values36. The computed relational values for each set of experiments are shown in Table 5.

The grey relational analysis of MRR, REWR, WOC, and Ra is shown in Table 6. From In Table 6, it can be observed that the grey relational degree reaches its highest value when the current is set at 2 A, the duty cycle is 40%, the gas pressure is 0.2 MPa, and the atomization amount is 20 ml/min. This set of parameters was chosen for experimental validation, with results presented in Table 7, and the validated workpiece illustrated in Fig. 17. The results of the optimized parameters in Table 7 indicate that the computed grey relational value of the optimal parameters is 0.752, which is greater than the maximum grey relational value in Table 5, achieving the desired experimental objectives.

Conclusion

This study conducted experimental research and parameter optimization on N-EDM of titanium alloys, with the following findings:

-

1.

The thickness of each milling layer has varying degrees of influence on the process indicators of N-EDM. The results from the single-factor experiments indicate that an increase in milling layer thickness leads to a 31.8% increase in MRR, a 70% reduction in REWR, approximately a 30.4% decrease in WOC, and about an 18.5% reduction in Ra. The results demonstrate that a moderate increase in milling layer thickness can enhance machining efficiency, reduce REWR, and decrease surface roughness.

-

2.

The results of fluid simulation tests indicate that as the milling thickness increases, the pressure within the discharge gap also rises, primarily due to the restricted flow of the atomized medium and the increased discharge gap height along the electrode side wall. While thicker milling layers enhance the MRR, they simultaneously reduce the cooling efficiency, leading to heat accumulation and a slower resolidification rate of the material. Additionally, it is evident that the milling thickness of each layer significantly influences discharge stability, frequency, and chip removal efficiency.

-

3.

By designing orthogonal experiments and conducting variance analysis, the effects of the machining parameters were evaluated. The results indicate that the current has the most significant impact on the process indicators, followed by the duty cycle. The analysis of the main effect plot reveals that an increase in current significantly boosts both MRR and Ra, but also leads to an increase in REWR and WOC. An increase in atomization amount contributes to the improvement of REWR and WOC, while a moderate increase in duty cycle can reduce REWR.

-

4.

Grey Relational Analysis was employed to analyze and calculate MRR, REWR, WOC, and Ra. Through optimal fitting and approximation, a set of optimal parameter combinations was obtained: a current of 2 A, a duty cycle of 40%, a gas pressure of 0.2 MPa, and an atomization amount of 20 ml/min, which were selected for validation.

Data availability

All data generated or analysed during this study are included in this published article.

References

Williams, J. C. & Boyer, R. R. Opportunities and issues in the application of titanium alloys for aerospace components. Metals https://doi.org/10.3390/met10060705 (2020).

Thangaraj, M. et al. Enhancing the surface quality of Micro titanium alloy specimen in WEDM process by adopting TGRA-Based optimization. Materials 131440. https://doi.org/10.3390/ma13061440 (2020).

Ahmed, N., Ishfaq, K., Moiduddin, K., Ali, R. & Al-Shammary, N. Machinability of titanium alloy through electric discharge machining. Mater. Manuf. Proc. 34 (1), 93–102. https://doi.org/10.1080/10426914.2018.1532092 (2019).

Liu, S., Thangaraj, M., Moiduddin, K. & Al-Ahmari, A. M. Influence of adaptive gap control mechanism and tool electrodes on machining titanium (Ti-6Al-4V) alloy in EDM process. Materials 15, 513. https://doi.org/10.3390/ma15020513 (2022).

Unnikrishna, P. R. et al. Effects of machining parameters on enhancing Alpha-Beta Titanium alloy using Taguchi-grey relational analysis for aerospace applications. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 237, 118–127 (2022).

Mullya, S. A., Karthikeyan, G. & Ganachari, V. S. Electric discharge milling: A state-of-the-art review. J. Braz. Soc. Mech. Sci. 43 (9), 424. https://doi.org/10.1007/s40430-021-03146-7 (2021).

Min Ji, T., Muthuramalingam, D., Saravanakumar, P. K. O., Nikolaos, E. & Karkalos, Zhang, W. Predicting depth of cut in vibration-assisted EDM cutting on titanium alloy using adaptive neuro fuzzy inference system. Measurement 219, 113245. https://doi.org/10.1016/j.measurement.2023.113245 (2023).

Wang, X. & Shen, Y. High-speed EDM milling with in-gas and outside-liquid electrode Flushing techniques. Int. J. Adv. Manuf. Technol. 104 (5–8), 3191–3198. https://doi.org/10.1007/s00170-019-04242-8 (2019).

Singh, R., Tiwari, T., Dvivedi, A. & Kumar, P. Assessing the performance of air, argon, and oxygen as dielectric mediums during dry-micro-EDM of Ti-6Al-4V alloy: A comparative study. Mater. Manuf. Proc. 38(7), 859–877 https://doi.org/10.1080/10426914.2022.2149782 (2023).

Ganachari, V. et al. Simulation and experimental investigation of performance characteristics of dry and near dry EDM process. Adv. Mater. Process. 8 (3), 3013–3028. https://doi.org/10.1080/2374068X.2021.1945296 (2022).

Jishnu Namboodiri, V. N., Pazhamannil, R. V. & Govindan, P. Finite element based numerical modelling of Near-Dry EDM with glycerin-air dielectric mixture. IOP Conf. Ser. Mater. Sci. Eng. 1248(1), 012019 https://doi.org/10.1088/1757-899X/1248/1/012019 (2022).

Guo, C., Sun, S., Di, S. & Wei, D. Experimental and simulation study of the ED-milling flow field to improve its machining performance. Int. J. Adv. Manuf. Technol. 113 (9), 2513–2522. https://doi.org/10.1007/s00170-021-06804-1 (2021).

Goyal, A., Sharma, D., Bhowmick, A. & Pathak, V. K. Experimental investigation for minimizing circularity and surface roughness under nano graphene mixed dielectric EDM exercising fuzzy-ANFIS approach. IJIDeM 16 (3), 135–1154. https://doi.org/10.1007/s12008-021-00826-5 (2022).

Vora, J., Shah, Y., Khanna, S. & Chaudhari, R. Effect of Near-Dry WEDM process variables through Taguchi-Based-GRA approach on performance measures of nitinol. J. Manuf. Mater. Process. 6 (6), 131. https://doi.org/10.3390/jmmp6060131 (2022).

Chakraborty, S., Mitra, S. & Bose, D. Optimisation of machining performance in PMWEDM of titanium alloy using the hybrid technique (GRA-PCA). Adv. Mater. Process. Technol. 8 (2), 1467–1480. https://doi.org/10.1080/2374068X.2020.1860500 (2020).

Chakraborty, S., Mitra, S. & Bose, D. An investigation on dimensional accuracy and surface topography in powder mixed WEDM using RSM and GRA-PCA. Mater. Today Proc. 44, 1524–1530. https://doi.org/10.1016/j.matpr.2020.11.734 (2021).

Kumar, D. & Mondal, S. Process parameters optimization of AISI M2 steel in EDM using Taguchi based TOPSIS and GRA. Mater. Today Proc. 2477-84 https://doi.org/10.1016/j.matpr.2020.02.527 (2020).

Payal, H., Maheshwari, S. & Bharti, P. S. Parametric optimization of EDM process for inconel 825 using GRA and PCA approach. JIOS 40 (2), 291–307. https://doi.org/10.1080/02522667.2019.1578090 (2019).

Tang, L. & Du, Y. T. Experimental study on green electrical discharge machining in tap water of Ti-6Al-4V and parameters optimization. Int. J. Adv. Manuf. Technol. 70 (1–4), 469–475. https://doi.org/10.1007/s00170-013-5274-5 (2013).

Shen, Y. et al. High-speed near dry electrical discharge machining. J. Mater. 233, 9–18. https://doi.org/10.1016/j.jmatprotec.2016.02.008 (2016).

Najati Ilkhchi, R., Shabgard, M. & Kabirinia, F. Numerical studying and experimental investigation: Effect of Reynolds number on performance measures of EDM with high speed Flushing. J. Manuf. Process. 48, 228–235. https://doi.org/10.1016/j.jmapro.2019.10.035 (2019).

Mullya, S., Karthikeyan, G. & Ganachari, V. Simulation of flow-field and debris temperature analysis in micro-electrical discharge milling using slotted tools. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 236(9), 1169–1180 https://doi.org/10.1177/09544054211061934 (2022).

Jiang, Y., Kong, L., Ping, X., Zhang, Y. & Zhao, W. Utilizing a porous-electrode for the Flushing fluid in electrical discharge machining. J. Manuf. Process. 62, 248–256. https://doi.org/10.1016/j.jmapro.2020.12.012 (2021).

Das, S., Paul, S. & Doloi, B. Assessment of the impacts of bio-dielectrics on the textural features and recast-layers of EDM-surfaces. Mater. Manuf. Proc. 36 (2), 245–255. https://doi.org/10.1080/10426914.2020.1832678 (2021).

Oezkaya, E., Beer, N. & Biermann, D. Experimental studies and CFD simulation of the internal cooling conditions when drilling inconel 718. Int. J. Mach. Tool. Manuf. 108, 52–65. https://doi.org/10.1016/j.ijmachtools.2016.06.003 (2016).

Fujiki, M., Ni, J. & Shih, A. J. Investigation of the effects of electrode orientation and fluid flow rate in near-dry EDM milling. Int. J. Mach. Tool. Manuf. 49 (10), 749–758. https://doi.org/10.1016/j.ijmachtools.2009.05.003 (2009).

Boopathi, S. An extensive review on sustainable developments of dry and near-dry electrical discharge machining processes. J. Manuf. Sci. Eng. 144, 1–37. https://doi.org/10.1115/1.4052527 (2021).

Dhakar, K., Chaudhary, K., Dvivedi, A. & Bembalge, O. An environment-friendly and sustainable machining method: Near-dry EDM. Mater. Manuf. Proc. 34 (12), 1307–1315. https://doi.org/10.1080/10426914.2019.1643471 (2019).

Yadav, V. K., Singh, R., Kumar, P. & Dvivedi, A. Investigating the performance of the rotary tool Near-Dry electrical discharge machining process through debris analysis. J. Mater. Eng. Perform. 31 (10), 8405–8417. https://doi.org/10.1007/s11665-022-06811-7 (2022).

Verma, M. & Shrivastava, R. Multi objective optimization of Near-Dry EDM using MOORA-PCA based Taguchi optimization method. IJTSRD 2534–2539. https://doi.org/10.31142/ijtsrd15647 (2018).

Dhakar, K. & Dvivedi, A. Influence of glycerin-air dielectric medium on near-dry EDM of titanium alloy. IJASMM 1 (3/4), 328. https://doi.org/10.1504/IJASMM.2017.089928 (2017).

Kong, L. et al. Experimental investigations into the performance of die-sinking mixed-gas atomization discharge ablation process on titanium alloy. Sci. Rep. 122399. https://doi.org/10.1038/s41598-022-06457-4 (2022).

Kong, L. et al. Machining characteristics and optimization of TC4 alloy by mixed gas atomization discharge ablation milling (MA-DAM). J. Manuf. Process. 133, 11–24 (2025).

Gugulothu, B., Rao, G. K. M. & Bezabih, M. Grey relational analysis for multi-response optimization of process parameters in green electrical discharge machining of Ti-6Al-4V alloy. Mater. Today Proc. 46, 89–98. https://doi.org/10.1016/j.matpr.2020.06.135 (2021).

Huang, C. H., Yang, A. B. & Hsu, C. Y. The optimization of micro EDM milling of Ti-6Al-4V using a grey Taguchi method and its improvement by electrode coating. Int. J. Adv. Manuf. Technol. 96 (9), 3851–3859. https://doi.org/10.1007/s00170-018-1841-0 (2018).

Chen, N., Kong, L., Lei, W. & Qiu, R. Experimental study on EDM of CFRP based on graphene aqueous solution. Mater. Manuf. Proc. 38 (9), 1180–1189. https://doi.org/10.1080/10426914.2023.2165674 (2023).

Funding

This work was supported by National Natural Science Foundation of China (Grant No. 52205470). Changzhou Leading Innovative Talent Introduction and Cultivation Project (CQ20220103, CQ20210093). The Natural Science Foundation of the Jiangsu Higher Education Institutions of China (Grant No. 22KJB460021, 23KJA460006). College Students’ Innovation and Entrepreneurship Training Program (202411463002Z). Jiangsu University of Technology Sino Wu Youth Innovation Talent Program. Changzhou Science and Technology Support Plan (Social Development): CE20235051.

Author information

Authors and Affiliations

Contributions

S, K is primarily responsible for the structure, methodology, and formulation of the entire paper, as well as solving the investigation and data compilation of the manuscript. X, Z. is mainly responsible for experimental exploration, result analysis, and manuscript writing.L, K. is mainly responsible for the economic support of the experimental portion of the manuscript.Y, L. and Y, H. is primarily responsible for experimental site support.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kang, S., Zhuo, X., Kong, L. et al. Machining characteristics and process parameter optimization of Near-dry electrical discharge milling of titanium alloy. Sci Rep 15, 8139 (2025). https://doi.org/10.1038/s41598-025-92830-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-92830-y

Keywords

This article is cited by

-

Shaping superalloys with sparks: Electric discharge machining for next-generation manufacturing

Journal of the Brazilian Society of Mechanical Sciences and Engineering (2026)

-

An inclusive parametric study for performance improvement in WEDM process of pure titanium using Naive Bayes classifier

Scientific Reports (2025)

-

Performance evaluation and multi-objective optimization of EDM parameters for Ti6Al4V using different tool electrodes

Scientific Reports (2025)

-

Process optimization in micro electrical discharge machining of carbon kevlar hybrid composite using TOPSIS

Scientific Reports (2025)

-

Performance optimization of upward sinking electrical discharge machining based on multi-factor coupling analysis

The International Journal of Advanced Manufacturing Technology (2025)