Abstract

As the proportion of building energy consumption gradually increases, adding insulation materials to the existing building envelope has become an important method to improve building thermal performance. Currently, most research on the optimum thickness of insulation layers is calculated from the perspective of heat transfer. However, in humid and hot areas, the influence of humidity and solar radiation should not be ignored. Therefore, this study used the coupled heat and moisture transfer model to calculate the yearly cooling and heating transmission loads. Three kinds of materials: expanded polystyrene, polyurethane and extruded polystyrene were compared in thickness ranging from 10 to 90 mm. The P1-P2 economic model consisting of lifecycle energy P1 and lifecycle expenditure ratio P2 was used to calculate the optimum thickness, payback periods and energy savings. The results show that, the optimum thicknesses for expanded polystyrene, polyurethane, and extruded polystyrene are 66.8 to 74.5 mm, 38.3 to 40.2 mm, and 46.3 to 49.5 mm, respectively. The required payback periods are 5.57 to 5.72 years, 6.86 to 7.47 years, and 6.32 to 6.74 years, respectively. Expanded polystyrene is the most economical thermal insulation materials because of its lowest lifecycle total cost, the shortest payback period and the most energy savings. This study is helpful for obtaining more accurate optimum thickness of insulation layer in hot and humid areas, and guiding the renovation of existing buildings.

Similar content being viewed by others

Introduction

Background information

Currently, energy consumption and carbon emissions are experiencing rapid growth globally1, which has a profound impact on the global climate and ecological environment, and therefore all countries have made energy conservation and carbon reduction an important task. The Chinese government has also proposed the goals of achieving carbon peak by 2030 and carbon neutrality by 20502.

The construction industry and its related sectors play a crucial role in energy consumption and carbon emissions. According to statistics, in 2021, the energy consumption and carbon emissions of the construction industry and related industries accounted for as much as 36% of the global total energy consumption and carbon emissions3. Despite the continuous advancement of technologies related to building thermal management and increasingly strict building regulations, the situation has not improved, and the proportion of building energy consumption continues to increase and is gradually breaking through 40%4. This highlights the dominant position of the construction industry in global carbon emissions and emphasizes the urgency of promoting the reduction of building energy consumption.

Building envelope

Optimization of building envelope structure and materials

Given that people typically spend around 90% of their time indoors, over half of building energy consumption is consumed by heating, ventilation and air-conditioning (HVAC) systems5,6. A significant portion of the energy consumption in HVAC systems is dissipated by the building envelopes7,8. According to statistics, the energy consumption of building envelope accounts for approximately 20 to 25% of the total energy consumption of buildings worldwide9,10. In China, this proportion is even higher, reaching 57 to 77%11. Especially for exterior walls, the heat transfer loss accounts for 35 to 49% of the total heat consumption of buildings12,13, making them a key focus of attention in building energy-saving design and existing building renovation projects14. Therefore, many scholars are optimizing the structure and materials of building envelope to reduce building energy consumption and improve building thermal management.

Erdem Cuce et al.15 developed a new type of insulation plaster for building insulation to reduce the heat transfer coefficient of building envelope. The results showed that compared with conventional briquettes, the overall heat transfer coefficient of 2–2 novel insulation plaster was reduced by about 47.9%, which can effectively avoid high thermal energy loss of buildings. Pinar Mert Cuce et al.16 proposed a bamboo fiber-reinforced briquette to address the issue of high heat transfer coefficients in conventional briquettes. The results showed that the addition of bamboo fibers can significantly enhance thermal performance of building envelope. By adding 2%, 4%, and 6% bamboo, the heat transfer coefficients of briquettes were 4.698 W/m2·K, 3.94 W/m2·K, and 2.77 W/m2·K, respectively.

In addition to the development of new insulation materials for building envelope, many scholars are also concerned about energy-saving renovations of existing buildings17. The demand for energy-saving renovation of existing buildings is huge and shows a continuous growth trend. For example, the European Union revised the Energy Performance of Buildings Directive (EPBD) in 202418,19, setting more ambitious energy efficiency standards for all new and existing buildings in the EU, encouraging building owners to carry out energy-saving renovation of buildings, in order to reduce greenhouse gas emissions in the EU building industry by at least 60% compared to 2015 by 2030, and achieve zero emissions for all existing buildings in the EU by 2050. The Chinese government has also introduced a series of policies to promote energy-saving renovations of existing buildings. For example, the ‘14th Five Year Plan for Building Energy Efficiency and Green Building Development’ proposes to complete energy-saving renovations of over 350 million square meters of existing buildings by 202520.

Currently, in engineering, the most common way to achieve energy-saving renovation of existing building envelope is to install thermal insulation materials on the exterior walls. Saboor Shaik et al.21 studied six different types of insulation materials and inserted each type of insulation material into the porous brick cavity. The thermal and economic performance of the filled porous bricks was evaluated in New Delhi and Bikaner, India. The results indicated that under hot and dry climate conditions, rock wool porous brick walls had lower non-stable transmittance, greater air conditioning cost savings, appropriate investment payback period, and more annual carbon emission reduction. Saboor Shaik et al.22 also found that in hot, arid, and composite climate zones, installing a thermal insulation layer on the outside of the coal wall can save the most air conditioning costs, at 0.89 USD/m2 and 0.90 USD/m2, respectively. They also achieved the highest carbon reduction.

Optimum thickness of thermal insulation layer

Although installing thermal insulation layers on the exterior walls of buildings has been widely proven to be an effective way to improve building energy efficiency23, increasing the thickness of the insulation layer without restrictions will obviously lead to an increase in costs, which in turn will affect the thermal economy of building envelope renovation projects. As pointed out by Pinar Mert Cuce et al.24, although building envelope improved with insulation materials have high thermal resistance, there are still some challenges, especially cost issues. Therefore, when considering the thermal insulation performance and economic cost of insulation materials, there must be an optimum thickness of insulation layer suitable for the local outdoor climate conditions and indoor conditions over the lifetime of buildings25,26.

For example, Erdem Cuce et al.27 renovated a traditional house built in the 1930s in the UK, and the results showed that using insulation materials and optimal thickness to achieve cost-effective energy-saving strategies was of great significance. Huang et al.28 established an energy-saving renovation thermal performance optimization model for an existing residential building in Beijing, and obtained the optimum thickness of the insulation layer for the basement ceiling, exterior walls, and floor slabs. The results showed that the optimized model determined a savings rate of insulation materials between 0.53% and 73.59%. When the energy-saving rate of the building envelope changed from 0.65 to 0.85, the savings rate of insulation investment was between 0.21% and 64.93%. Konstantin Verichev et al.29 calculated the optimum thickness of EPS insulation material for the exterior walls of a typical building in Andalusia, Spain, using heating degree days (HDD), cooling degree days (CDD), and ASHRAE methods under Mediterranean and Semi-Arid climate conditions. The results indicated that the optimum thickness of EPS insulation material under local climate was between 0.027 m and 0.054 m. Yuan et al.30 conducted building heating load calculations and total cost economic analysis on the optimum thickness of external thermal insulation (ETI) layers in six cities in Japan from high to low latitudes. The results indicated that the optimum thickness for ETI layers of building envelope in Sapporo, Tokyo, Nagoya, Osaka, Fukuoka, and Naha was 100 mm, 70 mm, 60 mm, 60 mm, 50 mm, and 10 mm, respectively. Huang et al.31 analyzed the thermal insulation performance and economy of the aerogel ETI system in the subtropical humid climate zone of China, and established a lifecycle total cost (LCT) model to calculate its optimum thickness and energy saving percentage. The results showed that the optimum thickness of aerogel was 3.7 mm. When the thickness of aerogel reached the optimum value, the annual cooling and heating loads of hollow shale brick buildings were reduced by 7.5% and 18.2% respectively. Bilal Cemek32 used HDD and CDD method and steady-state heat transfer model to calculate the optimum thickness of insulation layers of poultry buildings with constant temperature and relative humidity indoors in four climatic areas in Turkey. The results showed that, in Turkey, the insulation cost was generally higher in colder regions than warmer regions, but the payback period for insulation was generally shorter. Merve Köse Özturan et al.33 calculated the optimum thickness and payback period of the combination of three thermal insulation materials (XPS, EPS and rock wool) under the climate conditions in Erzincan, Turkey. The results showed that the pumice/XPS combination achieved the lowest optimum thickness, which was 0.037 m in the north, 0.025 m in the east and west, and 0.02 m in the south. The calculated payback period for all combinations was 0.9 to 4 years.

The above studies on optimum thickness are based on heat transfer models, ignoring the influence of moisture transfer, and most of them use CDD and HDD methods. Calculating transmission load solely from the perspective of heat transfer in building walls can sometimes lead to inaccurate results, especially in humid areas34. In humid climates, the transfer of gaseous or liquid water cannot be ignored in the field of computational heat transfer35. Mendes’s36 research showed that neglecting the effect of moisture transfer may underestimate the annual integrated heat flux up to 59%. R.M.Barbosa’s37 study showed that ignoring the effect of moisture transfer process inside the envelope may underestimate the cooling load of buildings by 4%.

The hot summer and warm winter (HSWW) zone in South China is a typically hot and humid area. The relative humidity is very high throughout the entire year. Under these climatic conditions, hot and humid air infiltration leads to moisture transfer and condensation at the surface or inside building envelopes, which has a significant influence on the heat transfer process.

Therefore, it is crucial to calculate the process of moisture transfer in order to obtain a more accurate and realistic transmission loads entering the room through the building envelope.

Purpose of this study

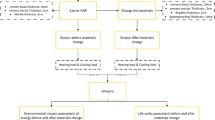

In most existing researches on the optimum thickness of thermal insulation layers for building envelope, moisture transfer has been neglected. In order to improve the accuracy of the optimum thickness of thermal insulation layers in the HSWW zone in China, a coupled heat and moisture transfer model of a one-dimensional wall with temperature and relative humidity as the driving potential was used.

The effect of the moisture transfer and solar radiation on the heat transfer process was considered to calculate the cooling and heating transmission load of three kinds of ETI walls. Then, the insulation thickness was optimized by using a lifecycle total cost analysis with the P1-P2 economic model. The optimum thicknesses and payback periods of three kinds of insulation materials for the ETI walls under Guangzhou climate condition were obtained.

This study aims to improve the optimum thickness of the insulation layer for the building envelope, guide the renovation of existing buildings and the installation of insulation layers for new buildings, and contribute to reducing building energy consumption and improving the thermal economy of exterior walls.

Heat and moisture transfer model and economic analysis model

Heat and moisture transfer model

Heat transfer and moisture transfer are highly complex processes38,39. The coupled heat and moisture transfer model, which was previously proposed40 and validated for accuracy34, was applied in this paper. In the simulation process of dynamic heat and moisture transfer, additional conditions included the initial temperature and humidity distribution inside the wall, as well as the boundary conditions on both sides of the wall. The outdoor and indoor environments were considered as heat sources for the walls, and the influence of solar radiation on walls with different orientations has also been taken into account in this model. The main contents of the model are as follows:

Moisture transfer equation

According to the law of conservation of mass, the moisture transfer equation inside walls can be expressed as follows without considering other source terms.

u is the balanced moisture content of the material, which can be determined by the isothermal absorption and desorption curve of the material.

According to the moisture absorption curve of the material, the balanced moisture content of the material is \(u = f\left( \varphi \right)\), and the following relation can be obtained.

According to Fick’s law and Darcy’s law, the relationship between the diffusion flux of water vapour and liquid water can be obtained as follows:

The gradient of the partial pressure of water vapour can be transformed as follows:

Among the partial pressures, the partial pressure of saturated vapour is a uniform function of temperature:

According to the Kelvin relation41, the capillary pressure Pl of liquid water can be obtained as follows:

According to Eqs. (4), (7), Eq. (8) can be obtained as follows:

According to Eqs. (1), (5), (6), (7), (8), the moisture transfer equation of the wall can be obtained as follows:

Heat transfer equation

According to the energy conservation law and Fourier’s law, the following heat transfer equation can be obtained.

During heat and moisture transfer in the wall, the heat source is mainly the phase change heat of water.

According to Eqs. (3), (5), (6), (10), (11),

Coupled heat and moisture transfer equation

According to Eqs. (9), (12), the heat transfer and moisture transfer inside the wall are coupled to each other. In conjunction with these two equations, the coupled heat and moisture transfer equation can be obtained.

In the above equation, the coefficients are expressed as follows:

Moisture parameters

The empirical formula for the partial pressure Pv,s of saturated water vapour is as follows42:

The formula for calculating the gasification latent heat of water vapour is as follows43:

According to the BET equation44, u can be calculated.

a, b and c are materials coefficients whose values are listed in Table 1.

The balanced moisture content of materials u reflects the moisture capacity of those materials. Physically, this moisture content refers to the quality of water and water vapour contained in a material of unit mass. Dv embodies the rate of diffusion of water vapour in a wall. According to45,46,47,48, Dv can be calculated as follows:

d, e, and f are materials coefficients whose values are listed in Table 2.

P1-P2 economic model

The P1-P2 economic model is widely used to evaluate the economy of thermal insulation materials40,49. P1 is the life cycle energy and P2 is the life cycle expenditure ratio. P1 is determined by the discount factoring PWF, and the formula of P1 is:

where Ne is the life cycle, in this paper, it refers to the service life of the insulation materials. i is the rate of inflation. d is the rate of market discount.

The formula of P2 is:

where Ms is the ratio of additional investment to initial investment. D is the ratio of advance payment to initial investment. RV is the ratio of initial selling price to initial investment. NL is the loan term. Nmin is the mortgage year.

The lifecycle total cost (LCT) consists of two parts: energy cost and insulation cost. The formula of LCT is:

where Ce is the price of the electricity ($/kWh). Cin is the price of insulation materials ($/m3). Rv is the ratio of initial selling price to initial investment. xins is the thickness of insulation materials (m). Eh is the annual energy consumption of heating systems of per unit area of external walls (kWh/m2). Ec is the annual energy consumption of cooling systems of per unit area of external walls (kWh/m2).

The annual heating and cooling load (Qc, Qh) caused by the heat transfer of envelope is calculated by the coupled heat and moisture transfer model in this paper. The energy consumption of heating and cooling is calculated hourly. The formula of Eh and Ec is:

where Qh is the annual heating load of per unit area envelope (kWh/m2). Qc is the annual cooling load of per unit area envelope (kWh/m2). \(\eta\) is the efficiency of heating systems. EER is the energy efficiency ratio of cooling systems.

The formula of payback period (Np) is

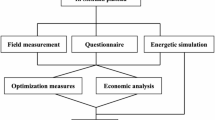

Methodology

Outdoor and indoor boundary conditions

Climatic divisions for building design divide China into the following five zones: severe cold zone, cold zone, HSCW zone, HSWW zone, and mild zone50. The HSWW zone is located in the south of China, where many important and large cities are located, such as Guangzhou, Hong Kong, Macao, Shenzhen and Xiamen. In this paper, Guangzhou was taken as the representative city of the HSWW zone, and the typical meteorological year parameters in Guangzhou were taken as the outdoor boundary conditions.

Guangzhou is the capital of Guangdong Province. Guangzhou is geographically located between 22°26ʹN and 23°56ʹN latitude and 112°57ʹE and 114°3ʹE longitude. The geographical coordinates of the city centre are 23°06ʹ32ʹʹN latitude and 113°15ʹ53ʹʹE longitude. The average elevation is 6.6 m, and the city covers a land area of approximately 7434.4 km2. Guangzhou is in the humid climate area in the north of the subtropical monsoon climate zone. According to the Chinese climatic divisions for building design, Guangzhou typically belongs to the HSWW zone. The city’s annual mean temperature is 22.2 °C, the mean temperature of the hottest month of the year is 28.81 °C, and the mean temperature of the coldest month is 13.89 °C. The yearly average relative humidity and recorded rainfall are 76% and 1727.8 mm, respectively.

Meteorological data for a typical meteorological year in Guangzhou, including temperature, relative humidity and solar radiation, are shown in Fig. 1, which are used as the outdoor boundary conditions. A wall has four orientations; thus, the hourly value of solar radiation is converted to magnitudes along four directions. Figure 1b shows the daily total solar radiation in Guangzhou.

For many occasions, indoor environments with constant temperature and relative humidity must be maintained, such as in a laboratory, precision instrument production workshop, hospital ward and museum. In this paper, constant temperature and relative humidity were adopted as indoor boundary conditions. The indoor environment is controlled accurately by the heating and cooling systems to maintain the constant temperature and humidity in a unit time of 1 h. Taking museums as an example, in order to ensure the environmental requirements of exhibiting cultural relics, the best setting temperature and humidity is 22 °C, 55% in China40,51.

ETI wall model

The thermal insulation materials used for numerical simulation in this study are EPS, PU, and XPS, which are also the most commonly used materials in construction projects in Guangzhou52. The wall model adopts the most commonly used ETI wall in Guangzhou. The base materials are clay bricks. Cement mortar is used on both sides of the wall. The layout and thickness of each layer of ETI wall used in this study are shown in Fig. 2.

The thicknesses of the base layer and cement mortar are 240 mm and 10 mm, respectively. Due to simulating the heat and moisture transfer of the walls for a whole year, the simulation time step is set to 200 s and the spatial step is set to 1 mm. To simplify the calculation process, it is assumed that the interface of different materials is thin such that there is no contact thermal resistance or moisture resistance. The slight expansion or contraction of the wall caused by temperature and humidity changes is also ignored. The thickness of the insulation layer is from 10 to 90 mm, a total of 56 simulations are carried out under climatic conditions in Guangzhou. The south and north wall is used as the representative orientations.

The relevant parameters involved in the calculation of the P1-P2 economic model53,54 are shown in Table 3.

Results and analysis

Energy consumption

In the outdoor climate of Guangzhou, the annual heat and moisture transfer simulation of ETI walls with three different insulation materials and insulation layer thicknesses ranging from 10 to 90 mm was conducted. The hourly heat transfer per unit area for the whole year was obtained, and the annual heat transfer quantity was calculated. The results are shown in Table 4.

Qout: Heat transfer from indoor to the inner surface of the wall, Qin: Heat transfer from the inner surface of the wall to indoor.

Convert the data of Table 3 into the total energy consumption of cooling and heating system with Eqs. (26), (27), and the results are shown in Fig. 3. As shown in Fig. 3, both for south and north walls, under the condition of certain thickness of insulation layer, the energy consumption of EPS insulation wall is the largest, followed by XPS and PU is the smallest.

With the increasing thickness of insulation layer, the energy consumption per unit area of cooling and heating system caused by heat transfer of the envelope is decreasing. At the same time, as the thickness of the insulation layer increases, the rate of energy consumption reduction decreases. From this trend, it can be seen that as the thickness of the insulation layer increases, the energy consumption of cooling and heating systems per unit area tends to be stable gradually. Therefore, when the insulation layer is increased to a certain thickness, continuing to increase the insulation layer thickness does not have a high energy consumption benefit, but it will increase the cost of the insulation layer, occupy more space, and increase the difficulty of the project. Therefore, a balance needs to be struck between reducing energy consumption and increasing insulation material costs, so there must be an optimum thickness of insulation materials suitable for the climatic conditions in HSWW zone, which can achieve the lowest investment cost.

Optimum thickness

Figures 4, 5, 6 are the life cycle total cost (LCT) per unit area of EPS, PU and XPS insulation walls, respectively. LCT is composed of two parts: energy cost and insulation cost.

As shown in Figs. 4, 5, 6, as described in Sect “Energy consumption”, as the thickness of the insulation layer increases, the energy cost gradually decreases, while the insulation cost increases linearly. Based on the comprehensive energy cost and insulation cost, the LCT of each insulation wall shows a trend of decreasing first and then increasing. Therefore, LCT has a lowest point, which corresponds to the thickness of thermal insulation materials is the optimum thickness.

According to the boundary conditions in Sect “Methodology”, the optimum thickness in this study is applicable to the thermal insulation materials in HSWW zone under constant temperature and humidity conditions. When the thickness of the insulation material is less than or greater than this optimum thickness, LCT will increase accordingly. After calculation, the optimum thickness for EPS, PU and XPS insulation south walls are 74.5 mm, 40.2 mm and 49.5 mm respectively. The optimum thickness of EPS, PU and XPS insulation north walls are 66.8 mm, 38.3 mm and 46.3 mm respectively. When the insulation thickness is set as the calculated optimum thickness, the LCT of EPS is the lowest, followed by XPS and PU is the highest. These conclusions are summarized in Table 5. It is obvious that the optimum thickness of the north wall is thinner than that of the south wall. This indicates that due to the difference in orientation of solar radiation, the south wall receives higher levels of solar radiation than the north wall, therefore the insulation layer thickness requirement for the south wall is higher than that for the north wall.

Payback period

According to P1-P2 model, the payback period of three kinds of thermal insulation materials can be calculated. As can be seen from Fig. 7, under the same thickness, PU has the longest payback period, XPS followed by EPS. In addition, the investment payback period of the three insulation materials increases linearly with the increase of the thickness.

The investment payback periods of EPS, PU and XPS insulation south walls are 5.57, 6.86 and 6.32 years respectively and the north walls are 5.72, 7.47 and 6.74 years respectively after the optimum thickness of the three insulation materials is determined. As shown in Table 6, these data are all in the life span of insulation materials, of which EPS has the shortest payback period for both south and north walls. Therefore, the optimum thickness calculated in this paper can be applied to the project of the actual building envelope in HSWW zone, which will have good economic benefits.

As can be seen from Fig. 8, when the thickness of the insulation material takes the optimum thickness, the energy savings are the highest compared with the wall without thermal insulation. When the thickness is not equal to the optimum thickness, the energy savings will decline.

When the optimum thickness is used for the three materials, the energy savings and carbon emission reduction achieved compared to without insulation layer are shown in Table 7. Due to the fact that the majority of cooling and heating methods in Guangzhou are air source heat pumps, and the electricity produced in China is mainly from coal-fired power plants, the calculation of carbon emission reduction is based on the CO2 emissions generated per unit mass of standard coal. According to Table 7, whether it is the south wall or the north wall, the use of EPS can achieve the highest energy-saving effect and carbon emission reduction, while PU has the lowest energy-saving effect and carbon reduction. From the perspective of investment payback period, whether it is the south wall or the north wall, EPS has the shortest payback period, while PU has the longest payback period. This conclusion corresponds to the market prices of EPS and PU.

Limitations of this study

Due to space limitations, this study only uses climate parameters from Guangzhou as outdoor boundary conditions, and indoor boundary conditions are constant temperature and humidity conditions. The transmission load of building envelope is affected by changes in indoor and outdoor boundary conditions, which is more significant under the boundary conditions of the third kind. Therefore, in future research, the research method proposed in this study can be extended to other climate zones, and more different indoor conditions can be considered for indoor boundary conditions. However, for buildings in Guangzhou that require indoor constant temperature and humidity, such as museums, precision instrument manufacturing workshops, pharmaceutical workshops, etc., the results of this paper can be considered reliable.

In terms of the external envelope of buildings, the roof and floor are also important external envelopes. There are significant differences in the shape and material of roofs in Guangzhou architecture. In future research, insulation studies can be considered for different forms of roofs. However, for the middle floors, the results of this paper can be considered reliable.

Conclusions

In order to obtain the more accurate optimum thickness of the insulation layer, the coupled heat and moisture transfer model considering the effect of the moisture transfer and solar radiation was used to calculate the heating and cooling load. Then, the optimum thicknesses, required payback periods and lifecycle total costs of the ETI walls using different insulation materials were determined by P1-P2 economic model. The conclusions reached in this study are as follows:

-

(1)

With the increase of wall insulation material thickness, the energy consumption caused by the envelope is lower, and gradually tends to be stable. Therefore, it is meaningless to increase the thickness of insulation material without restriction.

-

(2)

The optimum thicknesses for EPS, PU, and XPS are 66.8 to 74.5 mm, 38.3 to 40.2 mm, and 46.3 to 49.5 mm, respectively. The required payback periods are 5.57 to 5.72 years, 6.86 to 7.47 years, and 6.32 to 6.74 years, respectively. The lifecycle total cost of insulation walls using EPS as insulation material is the lowest, and the energy saving of insulation walls using EPS as insulation material is the highest when the optimum thickness is adopted. It indicates that EPS is the most economical.

-

(3)

When designing the parameters related to the building envelope, full consideration should be given to the local climate and indoor conditions during the use of the buildings. This study is helpful for obtaining more accurate optimum thickness of insulation layers in hot and humid areas, and guiding the renovation of existing buildings.

-

(4)

Due to space limitations, this study selected Guangzhou as a representative city and used constant temperature and humidity indoor conditions. In the future research, it is recommended to consider more other climate zones and simulating different indoor conditions.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

Abbreviations

- HSWW:

-

Hot summer and warm winter

- EPS:

-

Expanded polystyrene

- HSCW:

-

Hot summer and cold winter

- ETI:

-

External thermal insulation

- P1 :

-

Lifecycle energy

- P2 :

-

Lifecycle expenditure ratio

- ρ :

-

Density of materials (kg·m-3)

- u :

-

Balanced moisture content of materials (kg·kg-1)

- ξ :

-

Slope of the moisture absorption and liberation curve of materials

- φ :

-

Relative humidity (%)

- P l :

-

Capillary pressure of liquid water (Pa)

- λ :

-

Thermal conductivity of materials (W·m-1·K-1)

- c :

-

Specific heat capacity of materials (J·kg-1·K-1)

- s :

-

Heat source term (J·m-2·s-1)

- L :

-

Latent heat of water vapour (J·kg-1)

- i :

-

Rate of inflation

- LCT :

-

Lifecycle total cost

- \(\eta\) :

-

Efficiency of heating systems

- EER :

-

Energy efficiency ratio of cooling systems

- C in :

-

Price of insulation materials ($/m3)

- R v :

-

Ratio of initial selling price to initial investment

- N L :

-

Loan term

- N min :

-

Mortgage year

- N p :

-

Payback period

- PU:

-

Polyurethane

- XPS:

-

Extruded polystyrene

- HVAC:

-

Heating, ventilation and air-conditioning

- ITI:

-

Internal thermal insulation

- LCT:

-

Lifecycle total cost

- N e :

-

Lifecycle

- J v :

-

Diffusion flux of water vapour (kg·m-2·s-1)

- J l :

-

Diffusion flux of liquid water (kg·m-2·s-1)

- D v :

-

Penetration coefficient of water vapour (kg·Pa-1·m-1·s-1)

- D l :

-

Penetration coefficient of liquid water (kg·Pa-1·m-1·s-1)

- P v,s :

-

Partial pressure of saturated vapour (Pa)

- R v :

-

Gas constant of water vapour (J·kg-1·K-1)

- h :

-

Heat transfer coefficient of wall surface (W·m-2·K-1)

- h m :

-

Mass transfer coefficient of water vapour (m·s-1)

- x ins :

-

Thickness of insulation materials (m)

- E h :

-

Energy consumption of heating systems of per unit area (kWh/m2)

- E c :

-

Energy consumption of cooling systems of per unit area (kWh/m2)

- Q h :

-

Annual heating load of per unit area envelope (kWh/m2)

- Q c :

-

Annual cooling load of per unit area envelope (kWh/m2)

- C e :

-

Price of the electricity ($/kWh)

- d :

-

Rate of market discount

- M s :

-

Ratio of additional investment to initial investment

- D :

-

Ratio of advance payment to initial investment

- R V :

-

Ratio of initial selling price to initial investment

References

Bendaikha, W., Ghriss, O., Larbi, S., Bouabidi, A. & Cuce, E. Micro-scale fuel cell cogeneration system response combined with heat pump consumption in arid zones. Energy 305, 132107 (2024).

Chengcheng, Xu. & Shao, S. Performances investigations on thermal characteristics of a novel direct-condensation convective-radiant heating panel: An experimental and numerical study. Appl. Therm. Eng. 244, 122705 (2024).

Ma, X., Ghosh, A., Cuce, E. & Saboor, S. Building integrated photovoltaic-thermal systems (BIPVT) and spectral splitting technology: A critical review. Next Sustain. 4, 100056 (2024).

Christopher, S. et al. Renewable energy potential towards attainment of net-zero energy buildings status—A critical review. J. Clean. Prod. 405, 136942 (2023).

Ma, Y. X. & Yeung, L. K. BEForeGAN: An image-based deep generative approach for day-ahead forecasting of building HVAC energy consumption. Appl. Energy 376, 124196 (2024).

Chengcheng, Xu. et al. Thermal comfort and thermal adaptive behaviours in traditional dwellings: A case study in Nanjing, China. Build. Environ. 142, 153–170 (2018).

Kontoleon, K. J. et al. The impact of thermal insulation on the vulnerability of hollow masonry walls under elevated temperatures. Energy Build. 298, 113522 (2023).

Gobinath, P., Crawford, R. H., Traverso, M. & Rismanchi, B. Life cycle energy and greenhouse gas emissions of a traditional and a smart HVAC control system for Australian office buildings. J. Build. Eng. 82, 108295 (2024).

Delač, B., Pavković, B., Lenić, K. & Mađerić, D. Integrated optimization of the building envelope and the HVAC system in nZEB refurbishment. Appl. Therm. Eng. 211, 118442 (2022).

Ali, N. A., Sadek, S. & Abdin, A. A review on innovative nanomaterials for enhancing energy performance of the building envelope. Curr. Nanomater. 9(4), 287–302 (2024).

Zhang, Z. et al. Demand response strategies for air-conditioning systems based on direct load control: Considering envelope structures. Appl. Therm. Eng. 256, 124026 (2024).

Zhang, Z., Neng, Z., Hou, Y., Considine, B. & Nabola, A. M. Thermal performance of a wooden pipe-embedded building envelope using a low-grade heat source in extreme cold climate conditions. J. Build. Eng. 93, 109713 (2024).

Cao, L., Li, T. & Wang, F. Heat insulation and thermal insulation method of passive low energy consumption residential building exterior envelope structure based on BIM. Results Eng. 23, 102734 (2024).

Alvur, E., Anaç, M., Cuce, P. M. & Cuce, E. The potential and challenges of Bim in enhancing energy efficiency in existing buildings: A comprehensive review. Sustain. Clean Build. 1(1), 42–65 (2024).

Cuce, E. et al. Experimental performance assessment of a novel insulation plaster as an energy-efficient retrofit solution for external walls: A key building material towards low/zero carbon buildings. Case Stud. Thermal Eng. 49, 103350 (2023).

Cuce, P. M. et al. Unlocking energy efficiency: Experimental investigation of bamboo fibre reinforced briquettes as sustainable solution with enhanced thermal resistance. Case Stud. Thermal Eng. 60, 104680 (2024).

Cao, H. et al. Research on the evaluation of the renovation effect of existing energy-inefficient residential buildings in a severe cold region of China. Energy Build. 312, 114184 (2024).

di Filippo, R. & Maracchini, G. A probabilistic framework for stranding risk assessment and EPBD IV scenario analysis for the Italian building stock. J. Build. Eng. 96, 110448 (2024).

Garzia, F. et al. Assessment of the potential correlation between smart readiness indicator and energy performance in a dataset of buildings in South Tyrol. Energy Build. 321, 114623 (2024).

Liu, Z. et al. Incentive initiatives on energy-efficient renovation of existing buildings towards carbon–neutral blueprints in China: Advancements, challenges and prospects. Energy Build. 296, 113343 (2023).

Shaik, S. et al. Air-conditioning cost savings, CO2 emission benefits and return on investment by using waste in porotherm bricks in hot-arid and warm-temperate climates. Energy Build. 286, 112955 (2023).

Shaik, S. et al. Innovate, insulate, integrate: Embracing circular economy in innovative insulations for reduced air conditioning expenses and carbon mitigation in fly ash brick buildings. Energy Build. 322, 114694 (2024).

Cuce, E. & Cuce, P. M. The impact of internal aerogel retrofitting on the thermal bridges of residential buildings: An experimental and statistical research. Energy Build. 116, 449–454 (2016).

Cuce, P. M., Cuce, E. & Alvur, E. Internal or external thermal superinsulation towards low/zero carbon buildings? A critical report. J. Eng. Sci. 9(3), 435–442 (2023).

Bojic, M., Yik, F. & Sat, P. Influence of thermal insulation position in building envelope on the space cooling of high-rise residential buildings in Hong Kong. Energy Build. 33, 569–581 (2001).

Ozel, M. Cost analysis for optimum thickness and environment impacts of different insulation materials. Energy Build. 49, 552–559 (2012).

Cuce, E., Cuce, P. M., Wood, C., Gillott, M. & Riffat, S. Experimental investigation of internal aerogel insulation towards low/zero carbon buildings: A comprehensive thermal analysis for a UK building. Sustain. Clean Build. 1(1), 1–22 (2024).

Huang, J., Wang, S., Teng, F. & Feng, W. Thermal performance optimization of envelope in the energy-saving renovation of existing residential buildings. Energy Build. 247, 111103 (2021).

Verichev, K., Serrano-Jiménez, A., Carpio, M., Barrios-Padura, Á. & Díaz-López, C. Influence of degree days calculation methods on the optimum thermal insulation thickness in life-cycle cost analysis for building envelopes in Mediterranean and semi-arid climates. J. Build. Eng. 79, 107783 (2023).

Yuan, J., Farnham, C., Emura, K. & Alam, M. A. Proposal for optimum combination of reflectivity and insulation thickness of building exterior walls for annual thermal load in Japan. Build. Environ. 103, 228–237 (2016).

Huang, H. et al. Optimum insulation thicknesses and energy conservation of building thermal insulation materials in Chinese zone of humid subtropical climate. Sustain. Cities Soc. 52, 101840 (2020).

Küçüktopcu, E. & Cemek, B. A study on environmental impact of insulation thickness of poultry building walls. Energy 150, 583–590 (2018).

Ozturan, M. K. & Seyhan, A. K. Determination of optimum insulation thickness of building walls according to four main directions by accounting for solar radiation: A case study of Erzincan, Türkiye. Energy Build. 304, 113871 (2024).

Chengcheng, Xu., Li, S. & Zou, K. Study of heat and moisture transfer in internal and external wall insulation configurations. J. Build. Eng. 24, 100724 (2019).

Qin, S. et al. Effect of wall wettability coupled nanostructure on fluid molecular ordering near wall and flow heat transfer in asymmetric nanochannels. Int. Commun. Heat Mass Transfer 159, 108070 (2024).

Mendes, N., Winkelmann, F. C., Lamberts, R. & Philippi, P. C. Moisture effects on conduction loads. Energy Build. 35, 631–644 (2003).

Barbosa, R. M. & Mendes, N. Combined simulation of central HVAC systems with a whole-building hygrothermal model. Energy Build. 40, 276–288 (2008).

Zhou, J., Zhang, G., Lin, Y. & Li, Y. Coupling of thermal mass and natural ventilation in buildings. Energy Build. 40, 979–986 (2008).

Gao, W. Z. et al. Experimental investigation on the heat and mass transfer between air and liquid desiccant in a cross-flow dehumidifier. Renew. Energy 37, 117–123 (2012).

Chengcheng, Xu. & Li, S. Analysis on optimum insulation thickness of external thermal insulation walls in Nanjing zone. J. Southeast Univ. Nat. Sci. Ed. 49(3), 558–564 (2019).

Künzel, H. M. Simultaneous Heat and Moisture Transport in Building Components: One-and-Two-Dimensional Calculation Using Simple Parameters (Irb Verlag, 1995).

Mendes, N., Philippi, P. C. & Lamberts, R. A new mathematical method to solve highly coupled equations of heat and mass transfer in porous media. Int. J. Heat Mass Transfer 45(3), 509–518 (2002).

Rongyi, Z. et al. Air Conditioning 4th edn. (China Construction Industry Press, 2009).

Richards, R. F., Burch, D. M. & Thomas, W. C. Water vapor sorption measurements of common building materials. ASHRAE Trans. 98, 475 (2014).

Fanney, A. H. et al. Measurements of moisture diffusion in building materials. ASHRAE Trans. 97(2), 99–113 (1991).

Kuishan, Li. et al. Experimental study on water vapor permeability coefficient of building materials. J. Build. Mater. 12(3), 288–291 (2009).

Hagentoft CE. HAMSTAD-Final report: Methodology of HAM-modeling, Report R-02:8. Gothenburg: Department of Building Physics. Chalmers University of Technology, 5–51. (2002).

Hagentoft, C. E. et al. Assessment method of numerical prediction models for combined heat, air and moisture transfer in building components: Benchmarks for one-dimensional cases. J. Build. Phys. 27(4), 327–352 (2003).

Ashouri, M. et al. Optimum insulation thickness determination of a building wall using exergetic life cycle assessment. Appl. Therm. Eng. 106, 307–315 (2016).

GB 50178. Standard of Climate Regionalization for Architecture, Chinese Plan Publication House, Beijing, China. (1993). [In Chinese]

Wang, Y. et al. Design and optimization of special environmental temperature field control system for Ruins Museum. J. Xi’an Jiaotong Univ. 50(7), 131–139 (2016) ([In Chinese]).

DBJ15-51-2020, Design Standard for Energy Efficiency of Public Buildings in Guangdong province, Guangdong Provincial Department of Housing and Urban Rural Development, Guangzhou. (2020). [In Chinese]

JGJ134-2010, Energy saving design standard for dwellings in hot summer/cold winter area, Ministry of housing and urban rural development of the People’s Republic of China. China Architecture & Building Press, Beijing. (2010). [In Chinese]

Mahlia, T. M. I., Taufiq, B. N. & Masjuki, H. H. Correlation between thermal conductivity and the thickness of selected insulation materials for building wall. Energy Build. 39, 182–187 (2007).

Acknowledgements

This study was supported by the Nanxun Scholars Program for Young Scholars of ZJWEU (RC2022021082) and “Pioneer” and “Leading Goose” R&D Program of Zhejiang Province (2025C02239). This study was also funded by the Student Innovation and Entrepreneurship Training Program (approved in 2023) at Zhejiang University of Water Resources and Electric Power.

Author information

Authors and Affiliations

Contributions

Chengcheng Xu: Investigation, Supervision, Data Curation, Validation, Writing—Original Draft, Supervision, Funding acquisition. Suola Shao: Project administration, Supervision, Conceptualization, Investigation, Data Curation, Software, Validation, Writing—Original Draft, Resources, Formal analysis, Methodology. Wenjian Wei: Supervision, Data Curation, Validation. Nan Li, Yanluan Qin: Data Curation, Validation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Xu, C., Shao, S., Wei, W. et al. A study on optimum insulation thickness of building walls in hot summer and warm winter zone in China. Sci Rep 15, 10307 (2025). https://doi.org/10.1038/s41598-025-93945-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-93945-y