Abstract

To study the water absorption characteristics of corn, rice, and wheat straw after thermal pretreatment (120 ~ 200 °C). This work introduces an internal particle diffusion model for the moisture adsorption mechanism and measures the water contact angle to assess hydrophobicity, establishing a linear relationship between the water absorption kinetic parameters and temperature. The results show that when the temperature rises to 200 °C, the hygroscopicity reduction extent of corn straw, rice straw and wheat straw are 58.45%, 28.32% and 12.12%, respectively, significant increase in hydrophobicity. The three-stage internal particle diffusion equation can effectively describe the adsorption process of straw to moisture. At 70% humidity, the diffusion rate constant decreased and the boundary layer thickness increased. The ASABE equation can accurately predict the moisture content of corn straw; the water absorption process of rice and wheat straw conforms to the Peleg equation, which is significant for the subsequent large-scale high-quality utilization of straw.

Similar content being viewed by others

Introduction

Biomass naturally possesses a certain degree of water absorption in nature. Moisture, as a very important aspect of the physical and chemical properties of biomass, can be absorbed onto the cell wall and bond with hydroxyl hydrogen bonds in the cell wall components1, significantly impacting subsequent thermochemical utilization2. During the pyrolysis process, the presence of moisture helps increase the yield of charcoal and has both inhibitory and promoting effects on the yield of tar, mainly depending on the pyrolysis temperature and ash content3. During biomass gasification, a small amount of moisture can enhance hydrogen yield through steam reforming reactions4,5, thereby promoting the gasification reaction6. Excessive moisture can lead to increased heat absorption during the gasification reaction, raising the operating costs of the gasification reactor7, and can cause ignition difficulties during biomass direct combustion power generation, leading to subsequent corrosion issues on the heated surfaces8. Biomass inevitably gets exposed to the surrounding environment and comes into contact with moisture during storage and transportation. Its adsorption state of moisture primarily involves: first, water molecules contact the biomass surface, and the difference in moisture between the biomass and the surrounding environment causes moisture to diffuse and be adsorbed onto the biomass surface; second, water molecules diffuse within the pore structure of the biomass and are adsorbed onto the pore surfaces; finally, soluble substances in the biomass provide adsorption sites for water molecules, leading to certain chemical reactions with the water molecules9.

The equilibrium moisture content of biomass affects its transportation, storage, feeding treatment, and overall economic viability, while external conditions have a significant impact on its equilibrium moisture content. Analyzing the relationship between the two helps in designing thermochemical conversion systems and can provide references for the collection and storage of different types of biomass10. Many studies have been conducted by scholars both domestically and internationally on the relationship between equilibrium moisture content and water absorption kinetics11,12,13. Currently, over 270 models have been established to describe the water absorption properties of biomass, which can generally be categorized into three types: theoretical models, semi-empirical models, and empirical models14. Theoretical models are mainly based on theories related to monomolecular/multimolecular water and capillary water adsorption forming water films15, where the physical parameters in these models have specific physical meanings, while the parameters in empirical models are unrelated to the properties of the biomass. Different solid products obtained from thermal pretreatment of different biomasses exhibit varying water absorption characteristics. The water absorption characteristics of biomass are a prerequisite for determining its water absorption capacity. Currently, there is considerable research on the water absorption characteristics of different biomasses, mainly focusing on the modeling of equilibrium moisture content, but there is less research on the mechanisms of the adsorption process16,17. Chen et al.18 studied the water absorption process of tobacco stalk charcoal and found that it rapidly absorbs water initially, then gradually reaches a relatively stable state after a slow absorption phase, with the amount of water absorbed increasing with humidity. Lin et al.13 investigated the water absorption process and mechanisms of six different agricultural biomasses under various temperatures and humidity levels, finding that the water absorption process mainly consists of two stages: an initial rapid absorption phase and a later slow absorption phase; pseudo-second-order reaction kinetics better describe the water absorption process of biomass compared to pseudo-first-order kinetics. He et al.19 studied the water absorption process of poplar under different humidity and temperature conditions, discovering that higher environmental temperatures increase the absorption rate, and higher humidity facilitates the absorption process, resulting in greater water absorption by poplar.

The moisture content of biomass directly affects the fungal corrosion loss rate during long-term storage20, while hydrophobic biomass has lower water re-absorption, helping to reduce transportation costs21,22. Straw, due to its high hemicellulose content, is hydrophilic, making it prone to re-absorbing moisture even after pre-drying, and its high moisture content and water absorption capacity have always been one of the biggest drawbacks of straw as fuel23,24. Different types of straw exhibit different water absorption processes, and the influencing factors of these processes are unclear with limited mechanistic research. Therefore, this study aims to control the moisture content of straw through thermal pretreatment to avoid re-absorption during storage25, establish an internal particle diffusion model for an in-depth analysis of the straw water absorption process26, and explore the adsorption mechanism of straw for moisture, providing a theoretical basis for the water absorption process of straw. The Peleg and ASABE water absorption kinetic equations are selected to describe the hydrophobic properties of straw after thermal pretreatment and to establish the relationship between water absorption kinetic parameters and temperature27,28, elucidating the impact of temperature on the hydrophobicity of straw, which is significant for the subsequent large-scale high-quality utilization of straw.

Materials and methods

Experimental materials

This study selected corn straw, rice straw, and wheat straw as raw materials, the crop straw samples were washed with distilled water 3 ~ 4 times to remove the dust particles. The washed samples were placed in oven at 105 °C for overnight to remove the moisture content, and then placing them in a grinder to be crushed into a powder with a particle size of less than 0.5 mm.

Thermal pretreatment

Place 10.00 g of straw powder in a sapphire crucible measuring 100 mm in length, 30 mm in width, and 20 mm in height. The sapphire crucible is pushed into the middle heating zone of the furnace and nitrogen gas is introduced. A program is set so that the tube furnace (OTF-1200X, China Kejing) heats from 30 °C to the target temperatures (120, 140, 160, 180, and 200 °C) at a rate of 5 °C/min and maintains the temperature for 1 h. After natural cooling to room temperature, the straw powder is placed in a sealed bag and stored in a desiccator for subsequent experiments and analyses.

Determination of water absorption

Spread approximately 1.00 g of the pretreated straw powder in a flat weighing bottle measuring 40 mm × 25 mm. Use a constant temperature and humidity box (HWS-50, China Shangcheng Instrument) to simulate a natural air environment, setting the temperature to 30 °C and humidity to 70% for stability. Weigh the sample every 2 h, 4 h, 6 h, 10 h, 18 h, 24 h, and 48 h. Generally, when the water absorption experiment lasts for 48 h and the mass change is less than 1%, it can be considered that the water absorption process of the biomass is complete, at which point the moisture content of the biomass is approximately the equilibrium moisture content.

The equilibrium moisture content (EMC) is used to evaluate the hydrophobic performance of the biomass29, and its calculation method is as follows equation (Eq. (1)).

In the equation, ηEMC is the equilibrium moisture content of the straw, %; mf is the mass of the straw after water absorption, g; md is the mass of the straw after drying, g.

The hygroscopicity reduction extent (HRE) is used to evaluate the degree of change in the water absorption of the biomass30,31, with a larger value indicating a greater reduction in water absorption; a smaller value indicates a smaller reduction. Its calculation method is as follows equation (Eq. 2).

In the equation, λHRE is the hygroscopicity reduction extent, %; ηEMC is the equilibrium moisture content of the pretreated straw, %; ηEMC, rb is the equilibrium moisture content of the untreated straw, %.

Calculation of internal particle diffusion model

The internal particle diffusion model reflects the behavior of the adsorbate diffusion within the adsorbent particles32, and its calculation method is as follows equation (Eq. 3).

In the equation, kid is the internal particle diffusion rate constant, mg/g h1/2; I is the thickness of the adsorbent boundary layer, mg/g, with a larger value indicating a greater influence of the boundary layer on the water absorption process.

Determination of water contact angle

The contact angle of the straw is measured using a standard contact angle measuring instrument (DSA25, Germany Kruss). A pressure of 10 MPa is applied to form a disc of straw powder with a diameter of 13.5 mm, and 5 µL of water is dropped onto the center of the disc. The instrument’s reference line is adjusted, and the angle between the water droplet and the disc contact surface is observed33. It takes 1 ~ 3 s to capture images of the water droplets.

Establishment of water absorption kinetic equation

Peleg equation

According to the Peleg equation, the calculation of the water absorption kinetics of straw is as follows equation (Eq. 4) 34.

In the equation, t is the water absorption time of the straw, h; Mt is the moisture content of the straw at time t, %; M0 is the initial moisture content of the straw, %; K1 and K2 are the water absorption kinetic parameters, obtained from the slope and intercept of the equation, where 1/t is the independent variable and 1/(M–M0) is the dependent variable.

To determine the correlation of active water absorption of straw with the Peleg equatios 35,36, relative error analysis is conducted using the following equation (Eq. 5).

In this equation, Mexp is the experimentally determined moisture content of the straw; Mpro is the predicted value from the Peleg equation. When E < 10%, it can be considered that the established Peleg equation has a good fit.

ASABE equation

According to the ASABE equation, the calculation of the water absorption kinetics of straw is as follows equation (Eq. (6))37.

By transforming the equation,

In this equation, ηEMC is the equilibrium moisture content of the straw, %; Mt is the moisture content of the straw at time t, %; M0 is the initial moisture content of the straw, %; t is the water absorption time of the straw, h; k is the water absorption kinetic parameter, obtained from the slope of the equation, where t is the independent variable and ln[1/(ηEMC–Mt)] is the dependent variable.

Results and discussion

Effects of thermal pretreatment on straw water absorption characteristics and diffusion mechanism

The coefficients of equilibrium moisture content (ηEMC) and hygroscopicity reduction extent (λHRE) of corn, rice, and wheat straw after thermal pretreatment are shown in Table 1. It can be seen from the table that when the temperature rises to 200 °C, the equilibrium moisture content of corn straw decreases from 16.23 to 6.78%, a reduction of 9.45%, hygroscopicity reduction extent of 58.45%; the equilibrium moisture content of rice straw decreases from 11.75 to 8.42%, a reduction of 3.33%, hygroscopicity reduction extent of 28.32%; the equilibrium moisture content of wheat straw decreases from 12.12 to 10.65%, a reduction of 1.47%, hygroscopicity reduction extent of 12.12%. The equilibrium moisture content of solid products significantly decreases, indicating that thermal pretreatment notably suppresses the water absorption capacity of straw, attributed to the degradation of hemicellulose and cellulose contained in the straw (see supplementary Tab. S1 online), forming lightweight volatiles (monosaccharides, polysaccharide fractions, and dehydrogenated sugars), which then degrade to form CO and CO2, leading to damage to part of the cellular structure, with pore structures breaking into smaller fragments of various sizes (see supplementary Fig. S1 online), hindering water molecules from entering the interior38. After thermal pretreatment, hemicellulose in the straw has not completely disappeared; the degradation of hemicellulose and cellulose, along with further cross-linking of lignin, makes the solid products more hydrophobic. The strength of water absorption capacity depends on the amounts of hemicellulose, cellulose, and lignin present39, with hemicellulose having the strongest water absorption capacity and lignin the weakest40. The non-crystalline regions of hemicellulose and cellulose contain a large number of hydroxyl functional groups, which are typical polar groups that can form hydrogen bonds with water. Thermal pretreatment reduces the hydrogen and a large amount of oxygen content in the straw and removes a significant number of hydroxyl functional groups that easily combine with water molecules, leading to the decomposition of hydroxyl compounds and a corresponding reduction in binding sites30,41, resulting in a significant decrease in the water that can be adsorbed by the solid products. Meanwhile, the carboxyl content in hemicellulose is relatively high, and carboxyl groups are also hydrophilic, giving the straw a higher water absorption capacity. Lignin is the most stable, with a low content of polar groups; the higher the lignin content, the weaker the water absorption capacity. Therefore, thermal pretreatment can effectively degrade hemicellulose in the straw to achieve a reduction in equilibrium moisture content, thereby enhancing its hydrophobicity, making the straw unaffected by seasonal changes, allowing for stable storage, which not only reduces the risk of deterioration but also helps save transportation and storage costs, improving economic benefits.

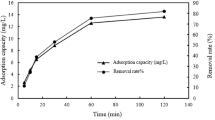

The fitting of the internal particle diffusion model for corn, rice, and wheat straw at 70% humidity is shown in Fig. 1. From the figure, it can be seen that the water absorption process and rate changes are nonlinear, indicating that the water absorption behavior is controlled by multiple processes42. The parameters of the three-stage internal particle diffusion model are shown in Table 1. It can be seen from the table that the three-stage internal particle diffusion equation can better describe the water absorption process of straw43, with a high fitting correlation coefficient. In the initial rapid water absorption process, water molecules are adsorbed onto the surface of the straw and quickly diffuse within the pore structure of the straw, exhibiting a high diffusion rate, while water molecules also diffuse between different particles. As the adsorption process continues, a large number of water molecules are adsorbed on the pore surface of the straw, and water continuously seeps into the interior, with a relatively slower diffusion rate; eventually, during the diffusion process of water within the straw’s internal structure, chemical adsorption occurs with the soluble substances in the straw44, lasting for a longer duration until a relatively stable state is reached. The water absorption process of straw is primarily characterized by single molecular layer adsorption in the early stage, with a high diffusion rate and a thin boundary layer; as the adsorption process progresses, multilayer adsorption occurs based on single molecular adsorption45, resulting in a slower diffusion rate and an increased boundary layer thickness; ultimately, the moisture content of the straw approaches that of the surrounding environment, with the rates of release and absorption of water molecules being the same, reaching a stable state. The diffusion rate constants and boundary layer thickness changes of rice and wheat straw are similar, while after thermal pretreatment, the diffusion rate constant of corn straw first decreases and then increases, with the highest value in the first stage, attributed to the physicochemical properties and structural composition of corn straw, which gives it a higher water absorption capacity; in the third stage, the fitting correlation coefficient of corn straw is lower, and the three-stage internal particle diffusion equation cannot accurately describe its water absorption process. As the temperature rises, the thickness of the first segment of the boundary layer for corn, rice, and wheat straw first increases and then decreases, while the thickness of the second and third segments shows a downward trend, reaching a minimum at 200 °C, indicating that at higher temperature conditions, less moisture is adsorbed on the surface of the straw, and the adsorption force of the straw for moisture weakens after pretreatment, enhancing its hydrophobicity. The water absorption processes of corn, rice, and wheat straw show slight differences in the first stage compared to the second and third stages, but exhibit the same trend in relative equilibrium state. In the first stage, the diffusion rate constant of the straw decreases with increasing temperature, while in the second and third stages, there is no significant pattern of change, reaching the lowest value at 200 °C, attributed to the better stability of the moisture diffusion process within the straw at higher temperatures.

Figure 2a shows the variation of moisture content in corn straw after thermal pretreatment over time. It can be seen from the figure that within a short period after water absorption begins, corn straw rapidly absorbs water, and the moisture content increases quickly. During this stage, moisture is transferred from the surrounding environment to the surface of the corn straw and then diffuses inward through the gas film on the straw’s surface, with the mechanism varying due to the structural characteristics of the straw. When the water absorption time reaches 4 h, influenced by environmental temperature, humidity, air flow rate, exposed surface area, and pressure, the moisture content of corn straw reaches a dynamic balance of adsorption and desorption, tending toward saturation. The water absorption rate of corn straw decreases with increasing temperature, and the moisture content reduces due to the weakened interaction and van der Waals forces between the straw and water molecules, disrupting the formation of hydrogen bonds46. When the temperature rises to 180 °C, the equilibrium moisture content of corn straw decreases from 16.23 to 8.73%, a reduction of 7.5%, attributed to the decomposition of a large number of functional groups and the collapse of pore structures (see supplementary Fig. S1 online), leading to a significant reduction in polar, water-absorbing oxygen-containing functional groups (O-H, C = O, C-O, etc.) and a weakening of physical adsorption, thus significantly lowering the equilibrium moisture content of the straw47. When the temperature rises to 140 °C, the reduction coefficient of water absorption capacity of corn straw is -11.49%, indicating an increase in water absorption compared to the original sample, suggesting that the equilibrium moisture content of corn straw does not continuously decrease with increasing temperature. Research by Medic et al.48 found that when the temperature rises to 300 °C, the equilibrium moisture content of corn straw increases compared to 250 °C, drawing similar conclusions. The increase in moisture content is attributed to the degradation of hemicellulose and cellulose (see supplementary Tab. S1 online), which disrupts the bonding between hemicellulose, cellulose, and lignin, leading to depolymerization of the fiber structure and splitting of the middle lamella49, thus opening pathways for moisture to enter the interior of the corn straw, resulting in a certain degree of increased water absorption. The water absorption capacity of the straw is influenced not only by the chemical adsorption of oxygen-containing functional groups but also by physical adsorption.

Figure 2 (b) shows the variation of moisture content in rice straw after thermal pretreatment over time. It can be seen that when the temperature rises to 200 °C, the water absorption time is 2 h, and the instantaneous moisture content decreases from 10.36% (RS-140) to 5.67%, a reduction of 4.69%, reaching over 67.37% of the equilibrium moisture content (8.42%). This stage mainly involves bulk water absorption and capillary water absorption through physical adsorption in the internal voids of the straw, with a relatively fast absorption rate. After 6 h of rapid water absorption, rice straw enters a slow water absorption phase, where chemical adsorption occurs primarily through the formation of hydrogen bonds between oxygen in the functional groups on the straw surface and hydrogen in water molecules, controlled by monolayer and multilayer adsorption simultaneously50, the water absorption rate slows down. After thermal pretreatment, the hydrophilic oxygen-containing functional groups on the surface of rice straw are removed, and hydroxyl groups are destroyed through dehydration, hindering the formation of hydrogen bonds51, thus improving the hydrophobicity of rice straw. Meanwhile, the tar formed during the thermal pretreatment condenses in the pores of the rice straw, preventing moist air and avoiding the condensation of water vapor, leading to a reduction in the saturated moisture content of the solid products1.

Figure 2c shows the variation of moisture content in wheat straw after thermal pretreatment over time. It can be seen that when the temperature rises to 200 °C, the water absorption time is 2 h, and the instantaneous moisture content decreases from the original 10.90–7.35%, a reduction of 3.55%, reaching over 69.01% of the equilibrium moisture content (10.65%). This stage primarily involves water absorption through the pores of the straw from the external environment, with a fast absorption rate. After 6 h of rapid water absorption, wheat straw enters a slow absorption phase, where the absorption rate tends to stabilize over time, and the adsorption gradually reaches saturation, mainly involving water absorption on the surface of the cell wall, which is similar to the water absorption process of coal52. The content of hemicellulose in wheat straw is an important factor affecting its equilibrium moisture content. After thermal pretreatment, the hemicellulose content in wheat straw decreases, and the hydrophilic groups are decomposed, resulting in reduced water absorption. The lower the equilibrium moisture content, the higher the hydrophobicity, and the better the combustion performance of wheat straw, which is beneficial for the high-quality utilization and storage of straw.

From Fig. 2, it can also be seen that at a water absorption time of 4 h, the moisture content of corn straw can reach 85.13% (CS-200) to 92.64% (CS) of the equilibrium moisture content; at a water absorption time of 6 h, the moisture content of rice straw can reach 85.75% (RS-200) to 95.49% (RS) of the equilibrium moisture content; and at a water absorption time of 6 h, the moisture content of wheat straw can reach 88.83% (WS-200) to 94.55% (WS) of the equilibrium moisture content. The water absorption characteristics of rice and wheat straw are quite similar, with weaker anisotropic features. As the temperature increases, the time required for corn, rice, and wheat straw to approach saturation in water absorption varies, with decreasing absorption rates and moisture content, making the straw more hydrophobic. This is attributed to the different physical properties and chemical compositions of the straw, as well as the macroscopic physical structure of the surface53, with differences in pore structure and pore size distribution (see supplementary Fig. S1 online), as well as the types and quantities of functional groups on the carbon skeleton of the straw54.

Effects of thermal pretreatment on straw water contact angle

The transient distribution of water contact angles for corn straw after thermal pretreatment is shown in Fig. 3a. According to the Young’s equation, when the surface of thermal treated material comes into contact with moisture, a Young-Laplace arc is formed. The contact angle is the angle between the tangent line formed by the arc at the solid-liquid-gas three-phase contact point and the contact point connection line, which can evaluate the hygroscopicity and adhesion behavior of the material. The size of the contact angle directly affects the hydrophilicity and hydrophobicity, thus influencing its performance during the thermal treatment process. From the figure, it can be seen that the water contact angles of CS, CS-120, CS-140, and CS-160 are all less than 90°, indicating significant absorption of water droplets and demonstrating the hygroscopicity of corn straw. The initial contact angle of untreated corn straw is 46.2°, which changes to 0° in about 3 s, indicating high hydrophilicity. When the temperature rises to 200 °C, the water contact angle of corn straw increases to 110.5°, greater than 90°, and approaches 0° after 20 s, indicating a significant increase in hydrophobicity55, attributed to the degradation of hemicellulose and cellulose (see supplementary Tab. S1 online), destruction of the surface protective layer, and collapse of the pore structure (see supplementary Fig. S1 online), which hinders the entry of moisture and increases the interfacial tension between corn straw and water. In corn straw cells, hemicellulose and cellulose are wrapped by lignin and surface protectants, forming a rigid structure. Considering that hemicellulose, cellulose, and lignin have higher hydrophilicity than surface protectants, thermal pretreatment can not only release hemicellulose, cellulose, and lignin from the corn straw protectants but also reduce the crystallinity of corn straw, damaging its dense structure and thus reducing its accessibility to water molecules. Although thermal pretreatment cannot completely degrade hemicellulose, it weakens the interactions between hemicellulose and cellulose, making it easier for them to undergo thermochemical conversion.

The transient distribution of water contact angles for rice straw after thermal pretreatment is shown in Fig. 3b. From the figure, it can be seen that the water contact angles of RS and RS-120 are 87.7° and 85.0°, respectively, both less than 90°, indicating that their hydrophilicity is greater than their hydrophobicity; when the temperature is greater than or equal to 140 °C, the water contact angle of rice straw is between 90.3° and 120.8°, all greater than 90°, indicating good hydrophobicity56. Therefore, thermal pretreatment can effectively reduce the hydrophilicity of rice straw.

The transient distribution of water contact angles for wheat straw after thermal pretreatment is shown in Fig. 3c. From the figure, it can be seen that the water contact angle of WS-120 is less than 90°, indicating that its hydrophilicity is greater than its hydrophobicity; when the temperature is greater than or equal to 140 °C, the water contact angle of wheat straw is between 104.3° and 115.3°, all greater than 90°, indicating good hydrophobicity of the wheat straw surface. Overall, wheat straw exhibits good hydrophobicity after thermal pretreatment.

From Fig. 3, it can also be observed that when the temperature range is between 160 °C and 200 °C, the water contact angles of corn, rice, and wheat straw are all greater than 90°, demonstrating good hydrophobic properties. The hydrophobicity of different types of straw increases in the following order: corn straw, rice straw, and wheat straw, which is related to their chemical composition and morphological structure. As the temperature increases, the water contact angles of the straw particles show an upward trend, and water droplets can be clearly observed adhering to the surface of the straw, forming regular small spheres, with slow penetration of water molecules and an increase in interfacial tension. At lower temperatures, water droplets on straw particles penetrate their interiors in a short time, which is related to the roughness of the straw surface; the fewer the gaps, the easier it is for water droplets to adhere to the straw surface, slowing the diffusion rate of water droplets into the straw particles, thereby reducing the mass transfer capability between the straw particles and the water droplets, improving the water absorption characteristics of the straw.

The initial contact angle value largely depends on the type of straw. It should be noted that these conclusions pertain to this specific situation, and the effects of different treatment parameters may vary, which is related to the chemical composition and morphological structure (see supplementary Tab. S1 and Fig. S1 online). On the one hand, the roughness of the material’s surface affects the size of the contact angle, the surface of thermally treated straw is rougher with increased porosity caused by the decomposition of hemicellulose57, the wall thickness between the vascular cells decreases, making it more difficult for water droplets to penetrate. Surface porosity of material mainly depends on the open pores, while the bulk porosity also depends on the closed pores, which are not connected with each other57. On the other hand, the size of the contact angle is also related to the surface energy of the material. The lower the surface energy, the more difficult it is for the material to be wetted by water. There are differences in the wettability of different straws, possibly due to the thermal treatment producing more tar, and the condensation of tar vapor on the pore surfaces leading to increased hydrophobicity. The water contact angle of the straw increases with the rise in thermal treatment temperature, and the rate at which water droplets penetrate into the straw decreases. The rate of water adsorption and effective water diffusion in straw is mainly related to the shape of its pores and the number and size of the pores. According to Peirce’s two-stage absorption theory, direct water adsorption primarily depends on the polar groups present in the straw, while indirect water adsorption mainly depends on the relative humidity and size of the straw surface, pores, and amorphous regions.

Korshunov et al.57 found that the hydrophobicity of biofuel increases with the temperature and holding time, and the dispersive component of surface free energy rises, while a polar component decreases in the thermal treatment process. The total surface energy is a sum of the dispersive and the polar components, some increase in dispersive components and the reduction of polar components are observed for torrefied poplar in comparison with the raw materials. It is also shown that the dispersive component of the surface free energy slightly increases after thermal treatment, while the polar component decreases strongly. This is caused by a decrease in the polar groups (− OH) and (− COOH) in the thermal treatment process. The increase in the temperature led to a significant decrease in the share of the polar component in the surface free energy. Therefore, this further proves that the increase in the water contact angle of the straw after thermal treatment, leading to an increase in hydrophobicity. In summary, the water contact angle is an important parameter, and thermal treatment significantly regulates the hygroscopicity and adhesion behavior, which is conducive to the subsequent large-scale transportation and storage of biomass fuels. By accurately measuring and controlling the contact angle, it is possible to optimize the thermal treatment process and improve the product quality for the research of the interaction of material with the biological environment.

Effects of thermal pretreatment on straw water absorption kinetics

The relationship between the Peleg dynamic parameters (K1) and (K2) and temperature (T) is shown in Fig. 4. By substituting K1 and K2 into the Peleg equation, specific water absorption kinetic equations are obtained, which are used to calculate the moisture content of straw at different temperatures (approximate values)58. The experimental data are generally consistent with the predicted data. After thermal pretreatment, the Peleg dynamic parameters and fitting equations for corn, rice, and wheat straw are shown in Table 2. It can be seen from the table that when the temperature rises to 200 °C, compared to CS-120, the Peleg dynamic parameter (K1) for corn straw increases from 4.59 to 11.50, and (K2) increases from 7.36 to 19.30; for rice straw, (K1) increases from 6.62 to 39.40, and (K2) increases from 9.67 to 18.02; for wheat straw, (K1) increases from 5.23 to 30.13, and (K2) increases from 10.60 to 14.78. The dynamic parameters (K1) and (K2) for corn, rice, and wheat straw all show an increasing trend, indicating that at the same water absorption time, the higher the temperature, the slower the water absorption rate, and the longer it takes for the straw to reach adsorption-desorption dynamic equilibrium, resulting in a lower equilibrium moisture content. The correlation coefficients (R2) between the Peleg equation and corn, rice, and wheat straw are all above 0.99, indicating that the experimental data fit the Peleg equation well. The theoretical moisture content of corn straw calculated from the fitted Peleg equation has a relative error greater than 10% compared to the actual test value, indicating that the water absorption characteristics of corn straw are not well correlated with the Peleg equation; whereas the theoretical moisture content of rice and wheat straw has a relative error of less than 10% compared to the actual test value, indicating a better correlation with the Peleg equation. Therefore, the Peleg equation can be used to describe the relationship between the moisture content of rice and wheat straw and temperature and water absorption time during the constant temperature and humidity water absorption process.

The relationship between the ASABE dynamic parameter (k) and temperature (T) is shown in Fig. 5. By substituting (k) into the ASABE equation, specific water absorption kinetic equations are obtained, which can be used to approximately calculate the moisture content of straw at different temperatures. After thermal pretreatment, the ASABE dynamic parameters and fitting equations for corn, rice, and wheat straw are shown in Table 2. It can be seen from the table that after thermal pretreatment, the ASABE dynamic parameter (k) for corn straw decreases to varying degrees. Generally speaking, the larger the (k) value, the better the hydrophilicity and the poorer the hydrophobicity. When the temperature rises to 200 °C, the (k) value for corn straw decreases from 0.1080 to 0.0516, indicating reduced hydrophilicity and increased hydrophobicity. After thermal pretreatment, the ASABE dynamic parameter (k) for rice straw increases to varying degrees, with the (k) value increasing from 0.0403 to 0.1156 at 200 °C. Similarly, the ASABE dynamic parameter (k) for wheat straw also increases to varying degrees, with the (k) value increasing from 0.0543 to 0.0968 at 200 °C. The correlation coefficient (R2) between the water absorption kinetics of corn straw and the ASABE equation is above 0.94, indicating that the experimental data fit the ASABE equation well; whereas the correlation coefficients (R2) for the water absorption kinetics of rice and wheat straw are below 0.90, indicating that the experimental data do not fit the ASABE equation well. Therefore, the water absorption kinetics of corn straw after thermal pretreatment can be described using the ASABE equation, thus determining the effect of temperature on the water absorption characteristics.

Conclusions

-

a.

When the temperature rises to 200 °C, the hygroscopicity reduction extent of corn straw, rice straw and wheat straw are 58.45%, 28.32% and 12.12%, respectively, the water absorption of solid products significantly decreases. The three-stage internal particle diffusion equation can well describe the adsorption process of straw to moisture, the diffusion rate parameter (kid) of straw decreases, while the boundary layer thickness (I) increases. Throughout the water absorption process, the physicochemical properties of straw have a certain impact on its water absorption characteristics, with physical and chemical adsorption working together to influence its water absorption properties. Therefore, thermal pretreatment allows this seasonal biomass to be stored for a long time, which helps save transportation and storage costs.

-

b.

After thermal pretreatment, the correlation coefficient of corn straw with the ASABE equation is above 0.94, indicating a good fit and confirming the impact of temperature on the water absorption characteristics of corn straw, establishing the relationship between the water absorption kinetic parameter and temperature. The theoretical moisture content of rice and wheat straw calculated from the Peleg equation after thermal pretreatment has a relative error of less than 10% compared to the actual test values. The Peleg equation can be used to describe the relationship between the moisture content of rice and wheat straw and temperature and water absorption time during constant temperature and humidity water absorption. The water contact angle and water absorption kinetics can intuitively quantify the hydrophobic properties of straw, providing a basis for elucidating the scientific connotation of traditional experience in straw water absorption characteristics.

-

c.

Thermal treatment has a significant impact on the moisture absorption of crop straws. Combining scanning electron microscope and water contact angle, thermal treatment can effectively degrade the hemicellulose in straw, increasing the relative content of cellulose and lignin, resulting in a rougher surface and the formation of a porous structure, which inhibits the penetration of water molecules and significantly enhances hydrophobicity. At the same time, based on the diffusion mechanism of water molecules in cotton fibers, there are significant differences in the moisture adsorption rate and effective moisture diffusion rate of different straws under the same thermal treatment conditions. In addition, compared to carbonization processes, the advantages of lower temperature thermal treatment include time-saving, energy efficiency, and low cost, paving an effective and promising path for the transportation and production of large-scale alcohol fuels.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Chen, W. H., Peng, J. & Bi, X. T. A state-of-the-art review of biomass torrefaction, densification and applications. Renew. Sustain. Energy Rev. 44, 847–866. https://doi.org/10.1016/j.rser.2014.12.039 (2015).

Pelaez-Samaniego, M. R. et al. Aqueous byproducts from biomass wet thermochemical processing: valorization into fuels, chemicals, fertilizers, and biomaterials. Energy. Conv. Manag. 307 https://doi.org/10.1016/j.enconman.2024.118360 (2024).

Gray, M. R. Z. The effects of moisture and ash content on the pyrolysis of a wood derived material. https://resolver.caltech.edu/CaltechETD:etd-11152005-102832 (1984).

Cerone, N. et al. Production of hydrogen-rich Syngas from biomass gasification by double step steam catalytic Tar reforming. Int. J. Hydrog. Energy. https://doi.org/10.1016/j.ijhydene.2024.07.290 (2024).

Kuttin, K. W. et al. Cfd modelling of hydrothermal carbonized biomass pellets gasification: synergistic effects of pellets size and moisture content on gasification efficiency. Int. J. Hydrog. Energy. 84, 420–434. https://doi.org/10.1016/j.ijhydene.2024.07.205 (2024).

Barontini, F., Biagini, E. & Tognotti, L. Influence of torrefaction on biomass devolatilization. Acs Omega. 6, 20264–20278. https://doi.org/10.1021/acsomega.1c02141 (2021).

Haidar, H. M. et al. Modeling of a heat-integrated biomass downdraft gasifier: influence of feed moisture and air flow. Biomass Bioenerg. 187 https://doi.org/10.1016/j.biombioe.2024.107282 (2024).

Glushkov, D. O., Nyashina, G. S., Anand, R. & Strizhak, P. A. Composition of gas produced from the direct combustion and pyrolysis of biomass. Process Saf. Environ. Prot. 156, 43–56. https://doi.org/10.1016/j.psep.2021.09.039 (2021).

Ho, Y. S. & McKay, G. The kinetics of sorption of basic dyes from aqueous solution by sphagnum moss peat. Canadlan J. Chem. Eng. 76, 822–827. https://doi.org/10.1002/cjce.5450760419 (1998).

Singh, R. N. Equilibrium moisture content of biomass briquettes. Biomass Bioenerg. 26, 251–253. https://doi.org/10.1016/S0961-9534(03)00082-5 (2004).

Wang, M. & Lu, Z. Study on the hygroscopic performances of Poplar wood fiber biomass brick. Int. Commun. Heat Mass Transfer. 135, 106063. https://doi.org/10.1016/j.icheatmasstransfer.2022.106063 (2022).

Zhang, X., Zillig, W., Künzel, H. M., Zhang, X. & Mitterer, C. Evaluation of moisture sorption models and modified mualem model for prediction of desorption isotherm for wood materials. Build. Environ. 92, 387–395. https://doi.org/10.1016/j.buildenv.2015.05.021 (2015).

Lin, G. et al. The moisture sorption characteristics and modelling of agricultural biomass. Biosyst. Eng. 150, 191–200. https://doi.org/10.1016/j.biosystemseng.2016.08.006 (2016).

Khatun, P., Karmakar, A. & Chakraborty, I. Microwave-vacuum drying: modeling validation of drying and rehydration kinetics, moisture diffusivity and physicochemical properties of dried Dragon fruit slices. Food Humanity. 2, 100292. https://doi.org/10.1016/j.foohum.2024.100292 (2024).

Zhu, T. et al. Drying kinetics of soy protein isolate-corn starch film during Preparation and its moisture adsorption characteristics during storage. Grain Oil Sci. Technol. 6, 120–126. https://doi.org/10.1016/j.gaost.2023.08.002 (2023).

Arabhosseini, A., Huisman, W. & Müller, J. Modeling of the equilibrium moisture content (emc) of miscanthus (miscanthus×giganteus). Biomass Bioenerg. 34, 411–416. https://doi.org/10.1016/j.biombioe.2009.12.004 (2010).

Yu, M., Igathinathane, C., Hendrickson, J. & Sanderson, M. Moisture sorption kinetics of Switchgrass, big Bluestem, and bromegrass biomass. Trans. ASABE. 57, 1219–1230. https://doi.org/10.13031/trans.57.10130 (2014).

Chen, H. et al. Physicochemical properties and hygroscopicity of tobacco stem Biochar pyrolyzed at different temperatures. J. Renew. Sustain. Energy. 8 https://doi.org/10.1063/1.4942784 (2016).

He, X. et al. Moisture sorption isotherms and drying characteristics of Aspen (populus tremuloides). Biomass Bioenerg. 57, 161–167. https://doi.org/10.1016/j.biombioe.2013.07.007 (2013).

Lekounougou, S. & Kocaefe, D. Comparative study on the durability of heat-treated white Birch (betula papyrifera) subjected to the attack of brown and white rot fungi. Wood Mater. Sci. Eng. 7, 101–106. https://doi.org/10.1080/17480272.2012.663407 (2012).

Bhutto, A. W. et al. Insight into progress in pre-treatment of lignocellulosic biomass. Energy 122, 724–745. https://doi.org/10.1016/j.energy.2017.01.005 (2017).

Zhang, Y. et al. Upgrading of biomass pellets by torrefaction and its influence on the hydrophobicity, mechanical property, and fuel quality. Biomass Convers. Biorefinery. 12, 2061–2070. https://doi.org/10.1007/s13399-020-00666-5 (2022).

Poornima, S. et al. Biofuel and biochemical production through biomass transformation using advanced thermochemical and biochemical processes – a review. Fuel 372, 132204. https://doi.org/10.1016/j.fuel.2024.132204 (2024).

Morris, J. D., Daood, S. S., Chilton, S. & Nimmo, W. Mechanisms and mitigation of agglomeration during fluidized bed combustion of biomass: A review. Fuel 230, 452–473. https://doi.org/10.1016/j.fuel.2018.04.098 (2018).

Singh, R., Sarkar, A. & Chakraborty, J. P. Effect of torrefaction on the physicochemical properties of pigeon pea stalk (cajanus cajan) and Estimation of kinetic parameters. Renew. Energy. 138, 805–819. https://doi.org/10.1016/j.renene.2019.02.022 (2019).

Wu, F. C., Tseng, R. L. & Juang, R. S. Initial behavior of intraparticle diffusion model used in the description of adsorption kinetics. Chem. Eng. J. 153, 1–8. https://doi.org/10.1016/j.cej.2009.04.042 (2009).

Peleg, M. Empirical models of sigmoid and non-sigmoid hydration and moisture sorption curves. Food Eng. Rev. 15, 15–23. https://doi.org/10.1007/s12393-022-09328-w (2023).

Iqbal, T. et al. Biomass conservation using an optimised drying process for energy sorghum Bagasse. Renew. Energy Focus. 19–20, 1–7. https://doi.org/10.1016/j.ref.2017.03.005 (2017).

Kaewtrakulchai, N. et al. Hydrophobicity and performance analysis of beverage and agricultural waste torrefaction for high-grade bio-circular solid fuel. Carbon Resour. Convers. 100243 https://doi.org/10.1016/j.crcon.2024.100243 (2024).

Chen, W. H. et al. Hygroscopic transformation of Woody biomass torrefaction for carbon storage. Appl. Energy. 231, 768–776. https://doi.org/10.1016/j.apenergy.2018.09.135 (2018).

Zhang, C., Chen, W. H., Zhang, Y. & Ho, S. H. Influence of microorganisms on the variation of Raw and oxidatively torrefied microalgal biomass properties. Energy 276 https://doi.org/10.1016/j.energy.2023.127612 (2023).

Li, L., Liu, S. & Zhu, T. Application of activated carbon derived from scrap tires for adsorption of Rhodamine B. J. Environ. Sci. 8 https://doi.org/10.1016/S1001-0742(09)60250-3 (2010).

Wongrerkdee, S. & Pimpang, P. Ultraviolet-shielding and water resistance properties of graphene quantum Dots/ Polyvinyl alcohol composite-based film. (2020). https://doi.org/10.14456/jmmm.2020.56.

Peleg, M. An empirical model for the description of moisture sorption curves. J. Food Sci. 53. https://doi.org/10.1111/j.1365-2621.1988.tb13565.x (1988).

Uriarte-Aceves, P. M., Rangel-Peraza, J. G. & Sopade, P. A. Kinetics of water absorption and relation with physical, chemical, and wet-milling properties of commercial yellow maize (zea Mays l.) hybrids. J. Food Process. Preserv. 44 https://doi.org/10.1111/jfpp.14509 (2020).

Uriarte-Aceves, P. M. & Sopade, P. A. Hydration kinetics of commercial white maize (zea Mays l.) hybrids, and associations with grain intrinsic and wet-milling properties. J. Cereal Sci. 101, 103279. https://doi.org/10.1016/j.jcs.2021.103279 (2021).

Tan, M. et al. Pelletization of camellia Oleifera Abel. Shell after storage: energy consumption and pellet properties. Fuel Process. Technol. 201, 106337. https://doi.org/10.1016/j.fuproc.2020.106337 (2020).

Mei, Y. et al. Torrefaction of different parts from a corn stalk and its effect on the characterization of products. Ind. Crops Prod. 92, 26–33. https://doi.org/10.1016/j.indcrop.2016.07.021 (2016).

Giang, D. K. et al. Effect of torrefied biomass on hydrophobicity and mechanical properties of polylactic acid composite. Int. J. Biol. Macromol. 215, 36–44. https://doi.org/10.1016/j.ijbiomac.2022.06.084 (2022).

Adeleke, A. A. et al. A comprehensive review on the similarity and disparity of torrefied biomass and coal properties. Renew. Sustain. Energy Rev. 199, 114502. https://doi.org/10.1016/j.rser.2024.114502 (2024).

Alamgir Ahmad, K., Ahmad, E., Al Mesfer, M. K. & Nigam, K. D. P. Bio-coal and bio-coke production from agro residues. Chem. Eng. J. 473, 145340. https://doi.org/10.1016/j.cej.2023.145340 (2023).

Zhang, G. et al. Early hydration characteristics and kinetics model of cement pastes containing internal curing materials with different absorption behaviors. Constr. Building Materlals. 383 https://doi.org/10.1016/j.conbuildmat.2023.131412 (2023).

Dharmarathna, S. P. & Priyantha, N. Investigation of boundary layer effect of intra-particle diffusion on methylene blue adsorption on activated carbon. Energy Nexus. 14, 100294. https://doi.org/10.1016/j.nexus.2024.100294 (2024).

Sheng, X. et al. Moisture absorption and chemical properties of walnut peptide by gelatin embedding and zinc chelation. LWT 116945 https://doi.org/10.1016/j.lwt.2024.116945 (2024).

Kang, X., Shen, J., Gui, Y. & Ma, X. Unveiling the dynamic behavior of water molecules and subsequent kaolinite microstructure change during wetting: A large-scale molecular dynamics investigation. Comput. Geotech. 175, 106705. https://doi.org/10.1016/j.compgeo.2024.106705 (2024).

Wen, J. L., Sun, S. L., Yuan, T. Q., Xu, F. & Sun, R. C. Understanding the chemical and structural transformations of lignin macromolecule during torrefaction. Appl. Energy. 121, 1–9. https://doi.org/10.1016/j.apenergy.2014.02.001 (2014).

Chen, Y., Yang, H., Zhu, B., Hao, H. & Chen, H. Torrefaction of agriculture straw and its effect on material and energy characteristics. Trans. Chin. Soc. Agricultural Mach. 43, 75–82. https://doi.org/10.6041/j.issn.1000-1298.2012.04.016 (2012).

Medic, D., Darr, M., Shah, A. & Rahn, S. Effect of torrefaction on water vapor adsorption properties and resistance to microbial degradation of corn Stover. Energy Fuels. 26, 2386–2393. https://doi.org/10.1021/ef3000449 (2012).

Tumuluru, J. S., Ghiasi, B., Soelberg, N. R. & Sokhansanj, S. Biomass torrefaction process, product properties, reactor types, and moving bed reactor design concepts. Front. Energy Res. 9 https://doi.org/10.3389/fenrg.2021.728140 (2021).

Liu, M. et al. Influence of torrefaction, hydrothermal carbonization and degradative solvent extraction pretreatments on moisture absorption and self-ignition characteristics of biomass. Fuel 282, 118843. https://doi.org/10.1016/j.fuel.2020.118843 (2020).

Chen, D. et al. Investigation of biomass torrefaction based on three major components: hemicellulose, cellulose, and lignin. Energy. Conv. Manag. 169, 228–237. https://doi.org/10.1016/j.enconman.2018.05.063 (2018).

Kanwal, S., Chaudhry, N., Munir, S. & Sana, H. Effect of torrefaction conditions on the physicochemical characterization of agricultural waste (sugarcane bagasse). Waste Manage. 88, 280–290. https://doi.org/10.1016/j.wasman.2019.03.053 (2019).

Silakul, T. & Jindal, V. K. Equilibrium moisture content isotherms of Mungbean. Int. J. Food Prop. 5, 25–35. https://doi.org/10.1081/JFP-120015591 (2002).

Smith, H. Transport phenomena. Encycl. Appl. Phys. https://doi.org/10.1002/3527600434.eap538 (2003).

Law, K. Y. Definitions for hydrophilicity, hydrophobicity, and superhydrophobicity: getting the basics right. J. Phys. Chem. Lett. https://doi.org/10.1021/jz402762h (2014).

Strandberg, M. et al. Effects of temperature and residence time on continuous torrefaction of Spruce wood. Fuel Process. Technol. 134, 387–398. https://doi.org/10.1016/j.fuproc.2015.02.021 (2015).

Korshunov, A. et al. Hygroscopic property of biofuel obtained by torrefaction of wood in a quiescent layer of bentonite. Fuel 282, 118766. https://doi.org/10.1016/j.fuel.2020.118766 (2020).

Uriarte-Aceves, P. M. & Sopade, P. A. Water absorption kinetics of blue maize (zea Mays l.) and influence on wet-milling properties. J. Cereal Sci. 114 https://doi.org/10.1016/j.jcs.2023.103764 (2023).

Acknowledgements

This work was supported by the National Key Research and Development Program of China (No. 2022YFB4201901) and Guangdong Provincial Key Laboratory of New and Renewable Energy Research and Development (No. E439kf0501). The authors also want to express their gratitude to the Analytical and Testing Center of Changzhou University for providing the experimental equipment for measurements.

Author information

Authors and Affiliations

Contributions

L. S. : Conceptualization, Formal analysis, Data curation, Writing – original draft. Y. L. : Investigation, Validation. T. L. : Resources, Project guidance, Methodology. Y. Y. : Project administration, Funding acquisition, Supervision, Writing – review & editing. Y. S. : Software, Investigation. M. Y. : Software. Y. W. : Investigation. H. Z. : Investigation, Visualization.All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Song, L., Li, Y., Lei, T. et al. Research on the water absorption diffusion model and kinetics of pretreated straw. Sci Rep 15, 9927 (2025). https://doi.org/10.1038/s41598-025-94157-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-94157-0