Abstract

Microstructural damage is an important cause of macrofracture in fissured rocks. To investigate the microscopic fracture mechanism of fissured rocks, a fissured rock model was established using the CZM-FDEM method. The model considers the mechanical behaviour of cohesive elements between particles within the rock and the propagation of cracks through the damage of cohesive elements. In the damage evolution stage of the cohesive element ontological relationship, the damage variable D is introduced to describe the damage degree of the unit stiffness, which in turn characterises the microscopic damage features of the model. The results show that the stress–strain curve morphology and strength characteristics of the numerical model are in high agreement with the indoor test results, and the model exhibits significant advantages in crack extension, which verifies the applicability of the method in rock fracture simulation. The microscopic damage field exhibits X-shaped conjugate fracture characteristics, and the crack inclination leads to differences in fracture paths by changing the stress field distribution at the crack tip. The number of cohesive element fractures on the microscopic scale shows a high correlation with the macroscopic strength, and the cleavage inclination angle directly affects the load carrying capacity of the structure by regulating the fracture element rate.

Similar content being viewed by others

Introduction

As a widespread non-homogeneous engineering material, the internal defects (e.g., joints and fissures) of rock can significantly affect engineering stability. In scenarios such as tunneling, mining, and dam construction, strength deterioration effects and damage mode shifts due to fracture networks have become key triggers of rock instability.

The crack initiation behavior of fractured rocks under external forces has long been the focus of scholars’ research1,2,3,4,5,6,7. Through monitoring means such as acoustic emission8,9,10,11,12,13,14, high-speed photography15,16,17,18,19,20, DIC21,22,23,24,25 and CT26,27,28,29,30, scholars have established the linkage between the geometric parameters of the fracture and the macroscopic mechanical response characteristics under static and dynamic loading conditions31,32,33,34,35,36,37. However, there are dual limitations in the existing studies: (1) the regular statistics based on the apparent mechanical parameters are difficult to reveal the cross-scale mechanism of microcrack nucleation-expansion; (2) although the CT scanning technique has the advantage of detecting the internal damage in rocks, the microscopic characterization of the damage evolution process is still difficult to be truly and widely applied in real engineering due to the limitations of the cost and the size of the specimen38.

To overcome the limitations of experimental studies, numerical simulation has become an important tool to study the discontinuous fracture behavior of fractured rock bodies. The current commonly used numerical simulation methods can be divided into two categories: continuous and discontinuous methods39,40,41. The main continuum methods are finite element method (FEM), finite difference method (FDM), boundary element method (BEM), scaled boundary finite element method (SBFEM), extended finite element method (XFEM), near-field dynamics method42,43,44,45, and phase field method46,47,48,49. The main discontinuity methods are discrete element method (DEM), discontinuous deformation analysis (DDA) and bonded particle method (BPM).

Among the crack extension simulation methods, the FEM has been applied to simulate crack initiation and extension by virtue of its advantages in dealing with problems in continuous media50,51. The XFEM52,53 and the RFPA54, which were developed based on this, have also been widely used as extensions of the FEM for the study of macroscopic fracture in rock bodies. However, these FEM methods suffer from mesh dependence and have limitations in simulating nonlinear behaviors such as crack initiation, extension and penetration, making it difficult to effectively describe discontinuous fracture behaviors55. Similarly, the FDM cannot effectively deal with the transition from continuous to discontinuous, especially in the simulation of the post-peak phase of rock fracture.

To make up for the shortcomings of continuous methods, scholars have proposed discontinuous techniques represented by the DEM56,57,58,59, DDA60 and BPM61. This technique describes the discontinuous damage process of fractured rock bodies by simulating inter-particle interactions56,57,58, and is able to simulate rock crack extension and penetration, obtaining results similar to those of indoor experiments. However, the high dependence of the discontinuity technique on the particles and the linear damage envelope leads to a huge amount of model calculations, which makes it difficult to be widely used in large-scale engineering.

To solve the above problems, the finite discrete element method (FDEM) was developed62,63,64, which has gradually developed into an important numerical simulation method for the mechanical study of fractured rock bodies. FDEM combines the continuous deformation analytical capability of FEM with the advantages of discontinuous fracture characterization of DEM63,65,66,67,68,69,70, and is capable of simulating the whole process from continuous to discontinuous fracture. Munjiza71 took the lead in the application of FDEM to simulate the damage process of fractured rock bodies. FDEM was applied to the simulation of the damage process of fractured rock bodies, and successfully revealed its transition mechanism from continuous deformation to discontinuous fracture. Currently, FDEM has made significant progress in rock fracture simulation72,73,74,75,76,77, especially in the simulation of crack initiation, extension and penetration processes, showing excellent computational efficiency and accuracy. However, most of the existing studies focus on the macroscopic fracture characteristics, and the microscopic interpretation of the internal damage evolution mechanism of fractured rock bodies is still insufficient.

In summary, this paper is based on the coupled cohesive zone model and finite discrete element method (CZM-FDEM) to study the microscopic fracture mechanism of fractured rocks under uniaxial compression conditions. The damage degree of unit stiffness is described by the method of introducing the damage variable D in the damage evolution stage of the bonded unit ontological relationship, which in turn characterises the micro-fracture mechanism. This study not only contributes to an in-depth understanding of the microscopic fracture mechanism of fractured rocks, but also provides theoretical support for rock stability assessment in practical engineering.

Numerical simulation methods

The cohesive zone model is widely used to simulate the mechanical behaviour of material joints because of its compliance with classical fracture mechanics theory. The basic principle lies in the fact that the mechanical behaviour of material interfaces is simulated using a separate principal structure and can be combined with several principal structures (e.g. softening, hardening principal structures, etc.). This makes the calculation results look closer to the real state of the fracture. It is therefore extremely suitable for modelling the propagation of cracks between two contact surfaces.

Cohesive zone model theory

The cohesive zone model (CZM) theory treats the crack as two parts. One part is the two free surfaces that are completely separated. The other part is the cohesive zone. Cohesive zone crack tip part of the microscopic level of cohesive force, resulting in the material does not immediately after cracking complete disconnection.

Figure 1 is a schematic representation of the cohesive zone. During discontinuous fracture of a material at an interface, there exists a crack opening displacement \(\delta\) in the cohesive force zone that is less than a critical value \({\delta }_{m}^{f}\). The cohesive force \(t\) acting on the crack surface is defined as a function of the crack opening displacement \(\delta\), and the relationship between \(t\) and \(\delta\) is referred to as the Traction Separate Law. When the cohesive zone starts to load, the cohesive force \(t\) gradually increases with the crack tension displacement \(\delta\). When the crack opening displacement reaches \({\delta }_{m}^{o}\), it means that the material starts to show damage. Subsequently the cohesive force starts to decrease to zero as the crack opening displacement increases. The fracture energy reaches the critical fracture energy \({G}_{IC}\) (the area included in the \(t-\delta\) curve). Currently, the cohesive force unit is completely disconnected and develops forward, and the structure produces cracks.

Principles of implementation of cohesive elements in FEM

The dynamic propagation process of cracks is investigated by using cohesive elements as part of finite elements. The introduction of cohesive elements allows crack propagation to proceed spontaneously. The dynamic finite element formulation incorporating the cohesive element can be derived by the principle of virtual work in the two-dimensional state:

In the formula, \(\Omega\) denotes the area, \(\sigma\) denotes the Cauchy stress tensor, \(\rho\) is the material density, \(\ddot{u}\) denotes the differentiation with respect to time, \(u\) is the displacement vector, \(\Gamma\) is the boundary line of the area, \(T\) is the traction force acting on the boundary, and \(n\) is the external normal. Applying the partition integral formula and the dispersion theorem to Eq. (1) without considering the viscous surface leads to:

In the formula, \(E\) denotes the Green’s strain tensor, and \({\Gamma }_{ext}\) is the boundary line of the region where the external traction force \({T}_{ext}\) acts. If a cohesive surface is considered, the partition integral formula is applied to Eq. (1). Since the cohesive element traction–separation does the work, Eq. (2) is expressed as:

In the formula, \({\Gamma }_{coh}\) denotes the cohesive element surface, \({T}_{coh}\) denotes the traction force acting on the cohesive element, and \(\Delta u\) is denoted as the displacement. Equations (1–3) are generally used to describe the current configuration. However, when deformation occurs, Eqs. (1–3) needs to be converted to the reference configuration. Under finite deformation conditions, the displacement vector \(u\) can be expressed as:

where \(X\) is the material coordinates of the reference configuration at the initial moment, and \(x\) denotes the spatial coordinates of the current configuration. Equations (5–6) is the definition of the deformation gradient tensor \(F\) and strain tensor \(E\):

where \(I\) denotes the fourth order unit tensor. Combining Eqs. (1–3), the following equations can be derived:

The relationship between the first \(PK\) stress tensor \(P\) and the Cauchy stress tensor \(\sigma\) can be expressed in Eq:

On the boundary, \(T=Pn\). Equation (10) shows the result of applying the partition integral formula and the dispersion theorem to Eq. (7) without considering the cohesive element surfaces:

Equation (10) in the case of considering the cohesive element surface can be rewritten as:

Equation (12) is the expression for the second \(PK\) stress tensor \(S\). Equation (13) is the expression after substituting the stress tensor \(S\) into Eq. (11):

Equations (14–16) are the updated formulas for the displacement, velocity and acceleration of the nodes at time steps N to N + 1 in the explicit analysis:

In the equation, \(\Delta t\) is the unit time, \(M\) is the mass matrix, \(F\) is the external force vector, \({R}_{int}\) is the global internal force vector and \({R}_{coh}\) is the cohesive force vector. The above equations are applicable to both homogeneous and non-homogeneous materials.

Cohesive zone model

Currently scholars have proposed many cohesive zone models for different situations. Such as Bilinear Cohesive Zone Model78,79,80,81, Trapezoidal Cohesive Zone Model82 and Exponential Cohesive Zone Model83,84,85,86. Among them, the bilinear cohesive zone model is widely used to describe the mechanical behaviour of cohesive elements because of its simplicity and good simulation effect.

The ontological relationship of the bilinear cohesive zone model is defined by three stages: traction–separation, damage initiation, and damage evolution. When the cohesive zone model reaches the damage criterion under the action of external force, it will be removed from the model and a fracture surface will be formed at this interface. Figure 2 shows the schematic diagram of the bilinear cohesive zone model.

The derivation of the relevant parameters in the figure is shown in Eqs. (17–19):

In the formula, \({t}_{n}^{0}\) is the damage onset stress, \({\delta }_{m}^{0}\) is the damage onset displacement, \({\delta }_{m}^{f}\) is the damage failure displacement, \({G}_{IC}\) is the normal fracture energy, \(K\) is the stiffness of the cohesive unit, \({E}_{n}\) is the modulus of the cohesive element, \({T}_{0}\) is the intrinsic thickness of the cohesive element.

Equation (20) is the ontological relationship for the traction-detachment phase of the cohesive element and corresponds to the OA segment in Fig. 2:

In the formula, \(\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle\thicksim}$}}{t}\) is the traction stress vector of the cohesive element, \({t}_{n}\) is the normal stress component, \({t}_{s}\) and \({t}_{t}\) are the tangential stress components in two directions, respectively, \(\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle\thicksim}$}}{E}\) is the elasticity matrix of the cohesive element, and \(\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle\thicksim}$}}{\varepsilon }\) is the strain vector of the cohesive element. When the intrinsic thickness \({T}_{0}\) of the cohesive element is 1, the nominal strain in each direction of the cohesive element is numerically equal to the relative displacement of the upper and lower surfaces in each direction. Equation (5) shows the relationship between nominal strain and relative displacement:

where \({\delta }_{n}\), \({\delta }_{s}\) , \({\delta }_{t}\) are the displacements in the normal direction and the other two directions, respectively. For isotropic materials, the elastic principal structure of the traction separation stage is shown in Eq. (22):

Damage initiation refers to the occurrence of damage initiation in a element when the stresses and strains reach the damage initiation criteria of the element. Some common damage initiation criteria are Maximum Nominal Stress Criterion (MAXS), Maximum Nominal Strain Criterion (MAXE), Quadratic Nominal Stress Criterion (QUADS), and Quadratic Nominal Strain Criterion (QUADE). In this paper, the MAXS criterion is used to describe the damage behaviour of cohesive elements, the principle of which is shown in Eq. (23):

The formula indicates that the damage starts when the ratio of the maximum nominal stress reaches 1, which corresponds to the place MAXSCRT = 1 and SDEG = 0 in Fig. 2.

The damage evolution stage of the cohesive element corresponds to segment AB in Fig. 2, which enters the damage evolution stage when the stress state satisfies the MAXS criterion. In this stage, the damage variable D is introduced to describe the degree of damage to the stiffness of the cohesive element, and in the damage evolution stage, the damage variable D is monotonically increased from 0 to 1. When the damage variable D is 1, the cohesive element is damaged. There are two ways to define the cohesive damage evolution stage, namely effective displacement-based damage evolution, which requires specifying the maximum effective displacement \({\delta }_{m}^{f}\) of the material at the time of fracture, and energy-based damage evolution, which requires specifying the fracture energy \({G}_{IC}\) of the material at the time of fracture.In terms of the curve form, the effective displacement-based damage evolution stage is classified into linear and exponential types. Figure 3 shows a schematic diagram of the two modes.

For the linear damage evolution stage, the damage variable D can be expressed as:

For the exponential damage evolution phase, the damage variable D can be expressed as:

In the formula, \(\alpha\) is a dimensionless parameter. From the point of view of applicability and ease of calculation, the linear damage evolution based on effective displacement is chosen to describe the damage process of the cohesive element in this paper.

Geometrical model and material structural parameters

Numerical modelling was carried out by conducting indoor uniaxial compression tests for the working conditions in Table 1 and obtaining the corresponding material parameters. It is worth mentioning that the indoor test data for the fissured rocks in this study were obtained from Zhang and Zou et al.87.

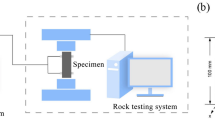

ABAQUS finite element software was used to establish a test model of the fractured rock body to verify the effectiveness of the CZM-FDEM model in analysing the microfracture test of the fractured rock body. As shown in Fig. 4, the numerical model is a planar model, consisting of solid and cohesive zone models. The height of the model is 100 mm, the width is 50 mm, and a prefabricated fracture with a width of 0.4 mm and a length of 20 mm is left in the middle. In order to ensure the calculation accuracy and cracking effect, the discrete unit size at the edge of the model is set to 0.5 mm, the unit size at the tip of the crack is 0.2 mm, and the unit size at the edge of the fissure is 0.4 mm.Based on the results of the indoor test, the explicit kinetic analysis model is used, and the analysis step is set to be 0.001 s, and the sampling rate to be 0.000005 s/time. A load of 1 mm was applied in the axial direction of the model, and a ‘tie’ set was established at the upper end of the model to extract the displacement-load data. The material parameters are shown in Table 2.

Numerical simulation of uniaxial compression tests on fractured rocks

Mechanical characterisation of cohesive element-based damage simulation

Model reliability verification

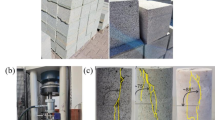

To verify whether the CZM-FDEM method can truly reflect the mechanical properties of the fractured rock mass under uniaxial compression, the test results of condition A-0 in the indoor test are selected in this paper for comparison with the corresponding simulation results. It is worth mentioning that the numerical simulation results in this paper are supported by the indoor research results in this topic87. The physical and mechanical parameters of the indoor test specimens are consistent with those of the matrix in Table 2, with a specimen size of 100 × 50 × 20 mm and a loading rate of 0.01 mm/s.

Figure 5 shows the comparison of the stress–strain curves for condition A-0 indoor test and numerical simulation cases. As can be seen from the figure, the stress–strain curves derived from the numerical simulation and indoor test have a high degree of overlap in curve shape, peak stress and peak strain characteristics, which verifies the validity of the numerical simulation model. However, it is worth noting that the stress–strain curves of the numerical model did not show the phenomenon of stress decrease. This is because the established numerical model is an elastic model, and the damage of the cohesive unit in the model is deleted after exceeding the threshold value to form a macroscopic crack, so the phenomenon of a sudden drop in stress in the indoor test did not occur.

Strength deformation characteristics

Figure 6 shows the stress–strain relationship curves and strength characteristics of the fracture model for each working condition. From Fig. 6, the stress–strain curves of the fracture model are generally similar in morphological characteristics, and the three stages of pore compaction, linear elastic deformation and plastic deformation are intercepted and analysed in this section. The conditions in the pore compacting stage are generally similar, but each condition shows different characteristics in the latter two stages due to the influence of the angle of the prefabricated slit. The modulus of elasticity, peak stress and peak strain of the modelled stress–strain curves for each condition have significant differences with the increase of axial strain before reaching the peak stress.

Stress–strain relationship curves: (a) Numerical simulation; (b) Indoor test87.

Figure 7 shows the comparison of strength characteristics between numerical simulation and indoor test results. With the increase of the prefabricated fracture angle α, the strength characteristics of both numerical simulation and indoor test results show the same pattern of change, showing the classical ‘V’ shape. The inflection point appears at α = 75°. The numerical simulation results are in high agreement with the indoor test results in terms of stress–strain curve shape and strength characteristics. This shows that the CZM-FDEM can be flexibly applied to the fracture simulation analysis of rocks.

Fracture simulation based on cohesive element damage

In this study, the extent of damage to the stiffness of the cohesive element under uniaxial compression conditions is described by introducing the damage variable D in the damage evolution stage. Figure 8 shows a schematic diagram of cohesive element damage. In the damage evolution stage, the damage variable D is monotonically increased from 0 to 1. When the damage variable D is 1, the cohesive element undergoes damage and crack propagation starts. When the total number of cohesive zone elements undergoing damage reaches the quantity threshold, the model undergoes damage. Based on this, the effect of uniaxial compression condition crack angle on the internal damage of the crack model is explored by processing and analysing the data of damage elements. The number of cohesive elements for which the damage variable D exceeded 0.9 during the test was extracted. Figure 9 shows the variation of axial stress and the number of cohesive element fractures with axial strain for the fissure model.

At the initial stage of applying axial load (Stage I), the stress–strain curve of the model is in the stage of pore compaction and elastic deformation. At this time, the damage variable D of the cohesive element is less than 0.9, the number of fracture elements is basically 0, and the slope of the curve of the total number of fracture elements is also 0.

In the middle of the applied axial load (Stage II), the stress–strain curve of the model is in the early stage of the plastic deformation phase. At this time, some regions of stress concentration appeared inside the model, mainly concentrated in the tips of the prefabricated cracks. And the slope of the curve of the total number of ruptured units gradually increases along with the generation of nascent cracks and the destruction of a small number of cohesive elements.

At the later stage of the applied axial load (Stage III), the stress–strain curve of the model is in the unstable development stage of cracking. At this time, a large number of cohesive units within the model break and form macroscopic cracks. The slope of the curve of the number of ruptured units versus the total number of ruptured units within the model surges until the model reaches the peak stress where damage occurs. The peak point of the number of fracture elements is mainly concentrated in the peak strain condition.

Micro destructive characterisation

Characteristics of crack evolution

Figure 10 shows the 10 crack types under compression conditions summarised by scholars to describe the crack types and propagation behaviour12,19,20.

Subplots (1) (2) (3) in Fig. 11 show the damage pattern, SDEG and stress cloud for the fracture model, respectively. The main types of cracks generated in the cracked specimens under uniaxial compression conditions in the indoor tests were: tensile wing cracks T1,2, tensile cracks T3 originating at the crack tip or at some distance from the tip, counter-tensile cracks T4, tensile wing cracks T5 and tensile cracks T6, shear cracks S2 originating at the crack tip, and far-field cracks F away from the cracked region.

When α = 0°, the initial damage of the cracked specimen is small, and the far-field crack F generated along the perimeter of the specimen is the main form of crack initiation. Far-field crack propagation through is the main reason to make it lose its load carrying capacity. The stress distribution in the model stress cloud diagram is more uniform. From the SDEG cloud diagram, there is no crack initiation at the tip of the prefabricated crack, which is the same as the actual test.

When α is 15° and 30°, the main crack initiation types of the specimen are tension cracks T1 and T3 propagated along the axial direction, but the main damage mode is shear damage caused by the propagation of shear cracks S2 and S3.

When α is 45°, the main damage mode of the specimen is a mixed tension-shear damage caused by the joint action of tensile cracks T1 and shear cracks S1.

When α > 45°, under the action of loading, the nascent cracks start from the tip of the prefabricated cracks, forming wing tension cracks T1 and T2, sometimes accompanied by reverse tension cracks T4 and secondary far-field cracks F. With the increase of α, the middle part of the cracks will also sprout tension cracks T6, and the main damage mode of the specimen is the tensile damage due to the propagation of tension cracks through the specimen.

When α = 15°–90°, the stress is mainly concentrated at the tip of the crack in the stress map. Different stress distributions are exhibited with the emergence and propagation of the nascent cracks. It can be found in the corresponding SDEG cloud diagrams for the working conditions that when α is 15°, 30°, the main cause of damage to the model is shear damage due to the development of shear cracks and reverse shear cracks. When α is 45°, 60°, 75° and 90°, the de novo cracks change from shear cracks to tensile cracks as the prefabricated crack angle increases. And the crack propagation evolution is often accompanied by the generation of far-field cracks, and the joint development leads to the mixed tensile-shear damage of the model.

Micro fracture characteristics

Figure 12 shows the spatial distribution of the failed cohesive elements during the crack evolution of each condition model. From the figure, the cleavage model undergoes classical X-type conjugate-like fracture under uniaxial compression conditions, and the microscopic fracture characteristics also show different states with the increase of cleavage inclination angle. When α = 0°, the stress concentration phenomenon is not obvious, and the spatial distribution of the failed cohesive elements is more uniform; when α is 15° and 30°, the closure process of the fissure under axial load is more difficult, resulting in the obvious cohesive element failure phenomenon at the end of the fissure, and the number of failed cohesive elements appearing in the reverse shear fracture zone is higher; when α is 45°, the number of failed cohesive elements on the forward developed and reverse developed When α is 45°, the number of failed cohesive elements in the forward-developed and reverse-developed fracture zones is similar, which is in line with the characteristics of mixed tensile-shear damage; when α > 45°, the failed cohesive elements mainly appear in the forward-developed fracture zones.

Fracture inclination is a key parameter regulating the rock fracture mode, which directly affects the distribution of stress field at the crack tip by influencing the ratio of positive stress to shear stress, leading to the gradual transition of microscopic features from shear to mixed tension-shear damage.

Discussions

Discussion of the fracture damage mechanism of the model

Fracture configuration is a key factor influencing the mechanical properties and damage mechanisms of rocks. These effects mainly originate from the alteration of the internal stress distribution state of the rock by the cleavage.

On the one hand, the fracture angle determines the stress state of the fracture tip when subjected to external forces, which is shown in Figs. 11 and 13. Fissures with different angles form different structural features inside the rock, which directly affects the stress concentration and distribution pattern at the crack tip. The propagation path of the cracks and the damage mode of the rock change significantly when the angle of the cleavage varies. This further affects the strength and deformation properties of the rock. For example, the equivalent stress (Mises) at the tip of the modelled fissure is maximum when the fissure inclination angle is 75°. As a result, the damage variable D of the cohesive elements is more likely to reach 1, leading to the destruction and deletion of the cohesive elements. At this point, the cracks are more likely to propagate along these weak surfaces, which ultimately leads to the destruction of the rock and a significant reduction in compressive strength. In addition, the peak strength of the rock shows a pattern of decreasing and then increasing as the fracture angle increases. This indicates that the strength characteristics of the rock have a high sensitivity to changes in the cleavage angle.

On the other hand, the evolution of the macroscopic mechanical characteristics and the fracture behaviour is correlated with the damage of the microstructure. Figure 14 shows the profiles of cohesive zone model fracture rate for different cleavage models under the same strain condition. The prefabricated fissure angle significantly affects the damage of the microstructure, resulting in the difference of the cohesive element fracture rate curves under different working conditions. The total number of fractured elements under coaxial strain conditions increases and then decreases with the increase of the cleft inclination angle α, specifically 75° > 90° > 60° > 45° > 30° > 15° > 0°, which shows a similar pattern of change as that of the peak stress. This indicates that the cleavage angle affects the difficulty of microstructural damage by influencing the degree of stress concentration at the cleavage tip, which in turn affects the difficulty of microstructural damage. In contrast, the unit damage threshold within the fissure model determines the compressive strength of the model.

Evaluation of numerical modelling methods

The core idea of the CZM-FDEM method is to characterize the macroscopic fracture behavior through microscopic damage. In this respect it is similar to the use of representative volume element (RVE) to characterize particle damage in the literature88,89. Both are designed to characterize the behavior of a macroscopic scale object by taking the microscopic properties of the substance into account in the modeling as well.

By coupling FEM and DEM and embedding CZM, the CZM-FDEM method is able to achieve efficient simulation of crack dynamic expansion and accurate characterization of multi-scale mechanical behavior. Compared with the limitations of traditional FEM, which is difficult to directly simulate discontinuous cracks, and DEM, which is computationally inefficient55,56,57,58,90. The method shows significant advantages in scenarios such as damage prediction of perimeter rock in deep-buried tunnels, fracture network reconstruction for hydraulic fracturing of shale gas, and early warning of progressive damage on slopes91,92. However, the CZM-FDEM method still has multiple limitations in practical applications, which are summarized in:

-

(1)

Due to the sensitivity of the CZM-FDEM method to meshing, the crack extension direction may deviate from the actual physical path, which will directly affect the engineering structural stability assessment. For example, in tunnel excavation simulation, the grid dependency may lead to the predicted crack extension direction not matching the actual surrounding rock damage pattern, thus underestimating the risk of local instability. Secondly, in complex geometric models (e.g., jointed rock mass or pore-containing structures), twisted cells can trigger distortions in the stress field, leading to convergence problems in the computational model.

-

(2)

The CZM-FDEM method requires precise input of interface parameters, but experimental acquisition of these parameters is costly and computationally cumbersome. In the absence of reliable experimental data, the model prediction results may deviate from reality. Second, the CZM-FDEM method usually assumes that the parameters are constants, whereas temperature and humidity variations and chemical corrosion effects significantly change the interfacial behavior in actual engineering. This neglect can lead to underestimation of the performance degradation of engineered structures.

Conclusions

In this study, the CZM- FDEM method was used to simulate the microfracture mechanism of fractured rocks containing fractures with different inclinations under uniaxial compression conditions. The established numerical model enables the propagation of cracks through the damage of bonded elements. And the damage degree of bonded unit stiffness is described by introducing the damage variable D in the damage evolution stage of the bonded unit ontological relationship. Finally, the effect of uniaxial compression condition crack angle on the internal damage of the fissure model is explored by processing and analysing the data on the number of damage elements. More cross-scale insights into the effect of microscopic damage on the macroscopic mechanical behaviour of fractured rocks are provided. The main conclusions are summarised below:

-

(1)

With the increase of fracture inclination angle, the strength characteristics of the numerical model show the classical ‘V’ pattern of change, which is consistent with the indoor test. The strength characteristics and stress–strain curves are in high agreement with the indoor test results. This shows that the CZM- FDEM method can be flexibly applied to the fracture simulation analysis of rocks.

-

(2)

Under the compression test, the damage mode of the model changes from shear damage to mixed tensile-shear damage as the crack inclination angle increases. The established numerical model can well simulate the propagation process of cracks in a short computation time, which is difficult to achieve in separate FEM or DEM methods.

-

(3)

By extracting the spatial location information of the failed cohesive elements, it is found that the fracture model generally shows X-type cohesive-like fracture. The crack inclination angle leads to differences in microscopic fracture characteristics by affecting the distribution of the stress field at the crack tip.

-

(4)

Microscopic fracture analyses show that crack formation and development are accompanied by a sharp increase in the number of fractured cohesive elements. The crack inclination angle determines the stress state of the crack tip under external force, which directly affects the difficulty of bond unit damage in the microstructure, and ultimately causes the difference in the number of fracture elements. Under the same strain, the model fracture unit rate shows a negative correlation with the strength, and the crack inclination angle affects the damage threshold of the model, which in turn affects the strength characteristics.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Brace, W. & Bombolakis, E. A note on brittle crack growth in compression. J. Geophy Res. 68, 3709–3713 (1963).

Bobet, A. The initiation of secondary cracks in compression. Eng. fract. mech. 66, 187–219 (2000).

Sagong, M. & Bobet, A. Coalescence of multiple flaws in a rock-model material in uniaxial compression. Int. J. Rock Mech. Min sci. 39, 229–241 (2002).

Haeri, H., Shahriar, K., Marji, M. F. & Moarefvand, P. On the strength and crack propagation process of the pre-cracked rock-like specimens under uniaxial compression. Strength. Mater. 46, 140–152 (2014).

Haeri, H. Crack analysis of pre-cracked brittle specimens under biaxial compression. J. Min Sci. 51, 1091–1100 (2015).

Shimbo, T., Shinzo, C., Uchii, U., Itto, R. & Fukumoto, Y. Effect of water contents and initial crack lengths on mechanical properties and failure modes of pre-cracked compacted clay under uniaxial compression. Eng. Geol. 301, 106593 (2022).

Tian, X.-Y. et al. Study on energy evolution and fractal characteristics of sandstone with different fracture dip angles under uniaxial compression. Sci. Rep. 14, 10464 (2024).

Ghasemi, S., Khamehchiyan, M., Taheri, A., Nikudel, M. R. & Zalooli, A. Crack evolution in damage stress thresholds in different minerals of granite rock. Rock Mech. Rock Eng. 53, 1163–1178 (2020).

Moradian, Z., Ballivy, G., Rivard, P., Gravel, C. & Rousseau, B. Evaluating damage during shear tests of rock joints using acoustic emissions. Int. J. rock mech. min sci. 47, 590–598 (2010).

Labuz, J. F., Cattaneo, S. & Chen, L.-H. Acoustic emission at failure in quasi-brittle materials. Constr. build. Mater. 15, 225–233 (2001).

Wang, C., Chang, X. & Liu, Y. Experimental study on fracture patterns and crack propagation of sandstone based on acoustic emission. Adv. Civ. Eng. 2021, 8847158 (2021).

Yang, S.-Q. & Jing, H.-W. Strength failure and crack coalescence behavior of brittle sandstone samples containing a single fissure under uniaxial compression. Int. J. Fracture. 168, 227–250 (2011).

Li, K., Zhao, Z., Ma, D., Liu, C. & Zhang, J. Acoustic emission and mechanical characteristics of rock-like material containing single crack under uniaxial compression. Arab. J. Sci Eng. 47(4), 4749–4761 (2022).

Wang, Y., Deng, H., Deng, Y., Chen, K. & He, J. Study on crack dynamic evolution and damage-fracture mechanism of rock with pre-existing cracks based on acoustic emission location. J. Petrol Sci. Eng. 201, 108420 (2021).

Yang, S., Yang, D., Jing, H., Li, Y. & Wang, S. An experimental study of the fracture coalescence behaviour of brittle sandstone specimens containing three fissures. Rock Mech. Rock Eng. 45, 563–582 (2012).

Yang, S.-Q., Liu, X.-R. & Jing, H.-W. Experimental investigation on fracture coalescence behavior of red sandstone containing two unparallel fissures under uniaxial compression. Int. J. Rock Mech. Min sci. 63, 82–92 (2013).

Cao, P., Liu, T., Pu, C. & Lin, H. Crack propagation and coalescence of brittle rock-like specimens with pre-existing cracks in compression. Eng. geol. 187, 113–121 (2015).

Zhou, X., Cheng, H. & Feng, Y. An experimental study of crack coalescence behaviour in rock-like materials containing multiple flaws under uniaxial compression. Rock Mech. Rock Eng. 47, 1961–1986 (2014).

Wong, L. & Einstein, H. Crack coalescence in molded gypsum and Carrara marble: part 1. Macroscopic observations and interpretation. Rock Mech. Rock Eng. 42, 475–511 (2009).

Wong, L. & Einstein, H. Crack coalescence in molded gypsum and Carrara marble: part 2—microscopic observations and interpretation. Rock Mech. Rock Eng. 42, 513–545 (2009).

Wu, X. et al. Strength characteristics and failure mechanism of granite with cross cracks at different angles based on dic method. Adv. Mater Sci Eng. 2022, 9144673 (2022).

Wang, H., Gao, Y. & Zhou, Y. Experimental and numerical studies of brittle rock-like specimens with unfilled cross fissures under uniaxial compression. Theor. Appl Fract Mech. 117, 103167 (2022).

Nguyen, T. L., Hall, S. A., Vacher, P. & Viggiani, G. Fracture mechanisms in soft rock: Identification and quantification of evolving displacement discontinuities by extended digital image correlation. Tectonophysics. 503, 117–128 (2011).

Peng, Y. et al. Study on crack propagation and coalescence in fractured limestone based on 3d-dic technology. Energies 15, 2007 (2022).

Lotidis, M. A., Nomikos, P. P. & Sofianos, A. I. Laboratory study of the fracturing process in marble and plaster hollow plates subjected to uniaxial compression by combined acoustic emission and digital image correlation techniques. Rock Mech. Rock Eng. 53, 1953–1971 (2020).

Song, R., Wu, M., Wang, Y., Liu, J. & Yang, C. In-situ X-CT scanning and numerical modeling on the mechanical behavior of the 3D printing rock. Powder Technol. 416, 118240 (2023).

Qin, H., Cao, S. & Yilmaz, E. Mechanical, energy evolution, damage and microstructural behavior of cemented tailings-rock fill considering rock content and size effects. Constr. Build. Mater. 411, 134449 (2024).

Gao, B., Cao, S. & Yilmaz, E. Effect of content and length of polypropylene fibers on strength and microstructure of cementitious tailings-waste rock fill. Minerals. 13, 142 (2023).

Huang, Z., Cao, S. & Yilmaz, E. Microstructure and mechanical behavior of cemented gold/tungsten mine tailings-crushed rock backfill: Effects of rock gradation and content. J. Environ Manage. 339, 117897 (2023).

Wang, A. A., Cao, S. & Yilmaz, E. Quantitative analysis of pore characteristics of nanocellulose reinforced cementitious tailings fills using 3D reconstruction of CT images. J. Mater Res. Technol. 26, 1428–1444 (2023).

Feng, G. et al. Tensile mechanical properties and fracture evolution characteristics of sandstone containing parallel pre-cracks under dynamic loading. Theor. Appl Fract Mech. 125, 103849 (2023).

Zhou, X.-P. & Gu, S.-Y. Dynamic mechanical properties and cracking behaviours of persistent fractured granite under impact loading with various loading rates. Theor. Appl Fract Mech. 118, 103281 (2022).

You, W., Dai, F., Liu, Y. & Li, Y. Dynamic mechanical responses and failure characteristics of fractured rocks with hydrostatic confining pressures: An experimental study. Theor. Appl Fract Mech. 122, 103570 (2022).

You, W., Dai, F. & Liu, Y. Experimental and numerical investigation on the mechanical responses and cracking mechanism of 3D confined single-flawed rocks under dynamic loading. J. Rock Mech. Geotech. 14, 477–493 (2022).

Jun, X., Luo, S. & Xiao, X. Review of the experimental studies of the cracking behaviors of fractured rocks under compression. Geohazard Mechan. 2(2), 59–82. https://doi.org/10.1016/j.ghm.2024.02.002 (2024).

Wang, A. A., Cao, S. & Yilmaz, E. Effect of height to diameter ratio on dynamic characteristics of cemented tailings backfills with fiber reinforcement through impact loading. Constr. Build. Mater. 322, 126448 (2022).

Wang, A. A., Cao, S. & Yilmaz, E. Influence of types and contents of nano cellulose materials as reinforcement on stability performance of cementitious tailings backfill. Constr. Build. Mater. 344, 128179 (2022).

Liang, D., Zhang, N., Liu, H., Fukuda, D. & Rong, H. Hybrid finite-discrete element simulator based on GPGPU-parallelized computation for modelling crack initiation and coalescence in sandy mudstone with prefabricated cross-flaws under uniaxial compression. Eng. Fract. Mech. 247, 107658 (2021).

Lei, Q., Latham, J.-P. & Tsang, C.-F. The use of discrete fracture networks for modelling coupled geomechanical and hydrological behaviour of fractured rocks. Comput. Geotech. 85, 151–176 (2017).

Lisjak, A. & Grasselli, G. A review of discrete modeling techniques for fracturing processes in discontinuous rock masses. J. Rock Mech. Geotech. 6, 301–314 (2014).

Mohammadnejad, M., Liu, H., Chan, A., Dehkhoda, S. & Fukuda, D. An overview on advances in computational fracture mechanics of rock. Geosystem. Eng. 24, 206–229 (2021).

Ha, Y. D., Lee, J. & Hong, J.-W. Fracturing patterns of rock-like materials in compression captured with peridynamics. Eng. Fract. Mech. 144, 176–193 (2015).

Wang, Y., Zhou, X. & Xu, X. Numerical simulation of propagation and coalescence of flaws in rock materials under compressive loads using the extended non-ordinary state-based peridynamics. Eng. Fract. Mech. 163, 248–273 (2016).

Lee, J., Ha, Y. D. & Hong, J.-W. Crack coalescence morphology in rock-like material under compression. Int. J. Fracture. 203, 211–236 (2017).

Wang, Y., Zhou, X. & Shou, Y. The modeling of crack propagation and coalescence in rocks under uniaxial compression using the novel conjugated bond-based peridynamics. Int. J. Mech. Sci. 128, 614–643 (2017).

Wu, J.-Y. A unified phase-field theory for the mechanics of damage and quasi-brittle failure. J. Mech. Phys. Solids. 103, 72–99 (2017).

Zhang, X., Vignes, C., Sloan, S. W. & Sheng, D. Numerical evaluation of the phase-field model for brittle fracture with emphasis on the length scale. Comput. Mech. 59, 737–752 (2017).

Ambati, M., Gerasimov, T. & De Lorenzis, L. A review on phase-field models of brittle fracture and a new fast hybrid formulation. Comput. Mech. 55, 383–405 (2015).

Borden, M. J., Hughes, T. J., Landis, C. M. & Verhoosel, C. V. A higher-order phase-field model for brittle fracture: Formulation and analysis within the isogeometric analysis framework. Comput. Method. Appl M. 273, 100–118 (2014).

Tang, C. & Kou, S. Crack propagation and coalescence in brittle materials under compression. Eng. Fract. Mech. 61, 311–324 (1998).

Tang, C., Lin, P., Wong, R. & Chau, K. T. Analysis of crack coalescence in rock-like materials containing three flaws—Part II: Numerical approach. Int. J. Rock Mech. Min Sci. 38, 925–939 (2001).

Mohammadi, S. Extended finite element method: for fracture analysis of structures (Wiley, 2008). https://doi.org/10.1002/9780470697795.

Zhou, Y. et al. Numerical simulation of fracture propagation in freezing rocks using the extended finite element method (XFEM). Int. J. Rock Mech. Min Sci. 148, 104963 (2021).

Tang, C., Yang, W., Fu, Y. & Xu, X. A new approach to numerical method of modelling geological processes and rock engineering problems—continuum to discontinuum and linearity to nonlinearity. Eng. Geol. 49, 207–214 (1998).

Euser, B. et al. Simulation of fracture coalescence in granite via the combined finite–discrete element method. Rock Mech. Rock Eng. 52, 3213–3227 (2019).

Ye, Y., Zeng, Y., Cheng, S., Chen, X. & Sun, H. Three-dimensional DEM simulation of the nonlinear crack closure behaviour of rocks. Int. J. Numer Meth. Eng. 46, 1956–1971 (2022).

Mayer, J. & Stead, D. Exploration into the causes of uncertainty in UDEC grain boundary models. Comput. Geotech. 82, 110–123 (2017).

Bobillier, G. et al. Micro-mechanical insights into the dynamics of crack propagation in snow fracture experiments. Sci. Rep. 11, 11711 (2021).

Ferguen, N., Mebdoua-Lahmar, Y., Lahmar, H., Leclerc, W. & DEM Guessasma, M. model for simulation of crack propagation in plasma-sprayed alumina coatings. Surf. Coat Tech. 371, 287–297 (2019).

Ben, Y., Wang, Y. & Shi, G. in Proceedings of the 11th International Conference on Analysis of Discontinuous Deformation (ICADD’13). 169–175.

Potyondy, D. O. & Cundall, P. A. A bonded-particle model for rock. Int. J. Rock mech. Min sci. 41, 1329–1364 (2004).

Boaga, J. The use of FDEM in hydrogeophysics: A review. J. Appl. Geophys. 139, 36–46 (2017).

Munjiza, A., Owen, D. & Bicanic, N. A combined finite-discrete element method in transient dynamics of fracturing solids. Eng computation. 12, 145–174 (1995).

Munjiza, A. A. The combined finite-discrete element method (John Wiley & Sons, 2004).

Nitka, M., Combe, G., Dascalu, C. & Desrues, J. Two-scale modeling of granular materials: a DEM-FEM approach. Granul Matter. 13, 277–281 (2011).

Morris, J. P., Rubin, M., Block, G. & Bonner, M. Simulations of fracture and fragmentation of geologic materials using combined FEM/DEM analysis. Int. J. Impact Eng. 33, 463–473 (2006).

Ma, G., Zhou, W., Regueiro, R. A., Wang, Q. & Chang, X. Modeling the fragmentation of rock grains using computed tomography and combined FDEM. Powder Technol. 308, 388–397 (2017).

Mahabadi, O. K., Lisjak, A., Munjiza, A. & Grasselli, G. Y-Geo: new combined finite-discrete element numerical code for geomechanical applications. Int. J. Geomech. 12, 676–688 (2012).

Andrade, J. E., Avila, C., Hall, S. A., Lenoir, N. & Viggiani, G. Multiscale modeling and characterization of granular matter: from grain kinematics to continuum mechanics. J. Mech. Phys. Solids. 59, 237–250 (2011).

Xie, H. & Feng, J. Implementation of numerical mesostructure concrete material models: A dot matrix method. Materials 12, 3835 (2019).

Munjiza, A. & Andrews, K. Penalty function method for combined finite–discrete element systems comprising large number of separate bodies. Int. J. Numer Meth. Eng. 49, 1377–1396 (2000).

Lisjak, A. et al. A 2D, fully-coupled, hydro-mechanical, FDEM formulation for modelling fracturing processes in discontinuous, porous rock masses. Comput. Geotech. 81, 1–18 (2017).

Lisjak, A. et al. Acceleration of a 2D/3D finite-discrete element code for geomechanical simulations using General Purpose GPU computing. Comput. Geotech. 100, 84–96 (2018).

Thakur, M. M. & Penumadu, D. Triaxial compression in sands using FDEM and micro-X-ray computed tomography. Comput. Geotech. 124, 103638 (2020).

Han, W. et al. Numerical investigation on the shear behavior of rock-like materials containing fissure-holes with FEM-CZM method. Comput. Geotech. 125, 103670 (2020).

Zhang, S. et al. Mode I fracture behavior of heterogeneous granite: Insights from grain-based FDEM modelling. Eng. Fract. Mech. 284, 109267 (2023).

Wu, D., Li, H., Fukuda, D. & Liu, H. Development of a finite-discrete element method with finite-strain elasto-plasticity and cohesive zone models for simulating the dynamic fracture of rocks. Comput. Geotech. 156, 105271 (2023).

Mi, Y., Crisfield, M. A., Davies, G. & Hellweg, H. Progressive delamination using interface elements. J. compos mater. 32, 1246–1272 (1998).

Geubelle, P. H. & Baylor, J. S. Impact-induced delamination of composites: A 2D simulation. Compos Part B Eng. 29, 589–602 (1998).

Alfano, G. & Crisfield, M. Finite element interface models for the delamination analysis of laminated composites: Mechanical and computational issues. Int. J. Numer Meth. Eng. 50, 1701–1736 (2001).

Jiang, W. G., Hallett, S. R., Green, B. G. & Wisnom, M. R. A concise interface constitutive law for analysis of delamination and splitting in composite materials and its application to scaled notched tensile specimens. Int. J. Numer Meth. Eng. 69, 1982–1995 (2007).

Tvergaard, V. & Hutchinson, J. W. The influence of plasticity on mixed mode interface toughness. J. Mech. Phys. Solids. 41, 1119–1135 (1993).

Needleman, A. A continuum model for void nucleation by inclusion debonding. J. Appl Mech. 54, 525 (1987).

Xu, X.-P. & Needleman, A. Numerical simulations of fast crack growth in brittle solids. J. Mech. Phys. Solids. 42, 1397–1434 (1994).

Ortiz, M. & Pandolfi, A. Finite-deformation irreversible cohesive elements for three-dimensional crack-propagation analysis. Int. J. Numer Meth. Eng. 44, 1267–1282 (1999).

Liu, P., Gu, Z., Peng, X. & Zheng, J. Finite element analysis of the influence of cohesive law parameters on the multiple delamination behaviors of composites under compression. Compos. Struct. 131, 975–986 (2015).

Zhang, J. Y., Zou, Q. J. & Guan, H. D. Fracture characterization of fractured rock bodies based on acoustic and optical characteristics. Front. Earth Sci. 12, 2296–6463 (2024).

Wang, Y., Nie, J.-Y., Zhao, S. & Wang, H. A coupled FEM-DEM study on mechanical behaviors of granular soils considering particle breakage. Comput. Geotech. 160, 105529 (2023).

Yu, J.-C., Wang, J.-T., Pan, J.-W., Guo, N. & Zhang, C.-H. A dynamic FEM-DEM multiscale modeling approach for concrete structures. Eng. Fract. Mech. 278, 109031 (2023).

Liu, H., Kang, Y. & Lin, P. Hybrid finite–discrete element modeling of geomaterials fracture and fragment muck-piling. Int. J. Geotech Eng. 9, 115–131 (2015).

Du, C. L. et al. A new type of rockbolt model in 3D FDEM and its application to tunnel excavation. Tunn. Undergr Sp Tech. 155, 106210 (2025).

Liu, Z. H., Ngai, L. & Wong, Y. A new thermomechanical coupled FDEM model for geomaterials considering continuum-discontinuum transitions. J. Rock Mech. Geotech. 16, 4654–4668 (2024).

Acknowledgements

This study was supported by the National Key Research and Development Program of China under the 14th Five-Year Plan (2023YFC3012200).

Author information

Authors and Affiliations

Contributions

Q. Z.: Writing—original draft, Methodology, Investigation, Formal analysis, Conceptualization. H. L.: Supervision, Validation, Methodology, Funding acquisition. Y. Z.: Visualization, Software, Investigation, Data curation. X. Z.: Investigation, Data curation. L. W.: Investigation, Formal analysis, Data curation. J. Z.: Investigation, Data curation.

Corresponding authors

Ethics declarations

Competing interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zou, Q., Li, H., Zheng, Y. et al. Simulation of microscopic fracture characteristics of fractured rock based on CZM-FDEM method. Sci Rep 15, 10451 (2025). https://doi.org/10.1038/s41598-025-94232-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-94232-6

Keywords

This article is cited by

-

Experimental Study and Numerical Analysis of Rock Dynamic Failure Based on Corner Correlation Method

Experimental Techniques (2026)