Abstract

This study explores the potential of RCA combined with nano silica and chemically activated fly ash to produce sustainable and high strength concrete. The research addresses the challenges posed by RCA’s inferior mechanical and durability properties by incorporating SCM. A comprehensive experimental program includes 420 and 240 samples for compressive strength and acid resistance. Machine learning algorithms such as Decision Trees, Random Forest, XG-Boost, and Ada Boost are used to predict RCA concrete performance metrics, with XG-Boost achieve the highest predictive accuracy (R2 = 0.995) for compressive strength while random forest performance is better for acid resistance (R2 = 0.909). The findings demonstrate substantial improvement in mechanical performance and durability, under scoring the effectiveness of SCMs in optimizing RCA- based concrete. The integration of machine learning provides a robust framework for performance predictions, contributing to the advancement of sustainable and resilient construction materials.

Similar content being viewed by others

Introduction

The growing environmental deterioration resulting from conventional construction practices has created significant pressure on material consumption in the construction sector. As a result, the drive for innovation and development of quality and sustainable concrete mixes has taken shape, made possible through the integration of RCA into high strength concrete1,2,3. RCA offers a dual advantage: cutting down the amount of waste that is generated in building construction to preserve our limited natural resources4,5,6. Nevertheless, the application of RCA assumes significant benefits in environmental concern, but it gives rise to many disadvantages such as reducing mechanical properties, porosity of the concrete than natural aggregates which in return affect the overall concrete structure and durability7,8. To overcome these difficulties, researchers have studied the utilization of supplementary cementitious materials like fly ash and nano silica in combination with chemical activation to improve the performance of RCA concrete9,10,11.

Concrete containing fly ash has attracted a great deal of attention in recent years because of the contribution of fly ash as a pozzolanic material with a prospect of enhancing the sustained concrete strength and durability12,13. However, this has been deemed to be a major drawback of fly ash since the pozzolanic reaction proceeds at a slow pace in the early stages, benefiting strength gain. This delayed reaction limits the application of fly ash concrete in areas where early strength gain is pertinent. Some of the current research has shown that chemical activation, especially by using sodium sulfate (Na₂SO₄), can increase the reactivity of fly ash and therefore accelerate the rate of early gain in strength. According to the research, sodium sulfate enhances the dissolution of fly ash particles and enhances the creation of additional C-S-H phases in the hydrated cementitious system14,15,16.

The combination of nano-silica with fly ash has also indicated a possibility in overcoming the problem of the low early strength of fly ash concrete. As with fly ash, nano-silica also enhances the pozzolanic reactivity of mineral admixture through its very small particle size and large surface area that provides a nucleus for the creation of C-S-H and the promotion of early-age concrete strength17. Use of nano-silica in high strength concrete movements not only increases strength but also an enhanced micro-structure and assembly which improves durability characteristics like permeability and chloride ion resistance18. In addition, while incorporating fly ash and nano-silica makes high-strength concrete better, RCA as an ingredient in concrete has some difficulties. RCA generally has higher porosity and lower mechanical strength than natural aggregates because of the adhered mortar on the aggregate surface as indicated by19. This is mainly due to the fact that RCA exhibit high porosity and therefore presents itself as good absorber of water this unfavorably affects workability and compressive strength of concrete. However, the literature has revealed that some of these impacts can be minimized by using SCMs like fly ash and nano-silica to enhance the binding matrix and the permeability of RCA concrete20,21,22.

The work has also highlighted the possibility of achieving complete substitution of natural aggregates by RCA in high-strength concrete, albeit with variable outcomes. Although RCA can be applied in high-strength concrete, it is evident that the mechanical properties and durability of such concrete are affected due to poor quality RCA as compared to NA. But it has been illustrated that by incorporating the fly ash, nano-silica, and chemical activators like Na₂SO₄, major problems of these high strength concrete can be overcome; mechanically as well as durability wise RCA based high strength concrete are much better19,21,22,23.

In conclusion, the application of RCA in high strength concrete is effective from an environmental point of view, however, some concern can be raised in terms of mechanical properties and durability aspects. Fly ash incorporating SCMs such as nano silica along with chemical activation through Na₂SO₄ can potentially serve as an effective strategy to meet the mentioned challenges. When the fly ash is activated by Na₂SO₄ solution, it can lead to enhance the early-age strength of the concrete particularly, while the incorporation of the nano-silica helps in improving not only the mechanical characteristics but also the durability factor of the concrete. The use of these materials in RCA-based high-strength concrete could help develop sustainable, high-performance concrete for structural applications.

Nevertheless, the performance of RCA-based concrete particularly in terms of compressive strength and durability remains difficult to predict due to the complicated relationship that exists between the macro and micro properties of concrete and the prevailing environmental factors. To overcome this, we have used sophisticated artificial intelligence tools such as decision trees, XGBoost random forest, and ADA boost regression analysis for the prediction of conditions such as compressive strength and acid resistance of concrete. The proposed ML models have displayed robust performances through the identification of patterns within larger datasets for accurate prediction compared to conventional regression models24,25,26,27. Decision tree algorithms are easy to interpret and as such, when it comes to concrete performance the decision rules are easy to grasp hence providing a clear way of showing pre-determinants of performance. On the other hand, gradient boosting framework called XGBoost boasts high predictive power and practicality to solve several intricate data related issues frequently met in concrete research28. Random forests, an extension of the decision tree learning, apply decision trees in parallel to enforce low variance by combining multiple trees or decision trees to minimize overfitting29. Finally, AdaBoost regression is centered on adjusting the model to highlight specific situations that are challenging to forecast, enhancing the model’s general resilience30. Applying these machine learning methods makes it possible to analyze the degree of dependencies of compressive strength and durability on different factors, including the proportions of fly ash, nano-silica, and RCA. This systematic approach not only aids in identifying the optimal mix design but also enhances model reliability, thereby improving decision making in the design of high strength concrete. Despite advancements, limited research exists on the combining use of chemically activated fly ash and nano silica in RCA based concrete, particularly with Na2SO4 activation. RCA has affected the mechanical and durability properties of concrete, presenting significant challenges to its effective utilization in high strength concrete. The incorporation of SCMs such as nano silica and fly ash (chemically activated) provides a promising solution to these issues. In addition, the use of machine learning algorithms to predict compressive strength and durability enhances the understanding of the interaction between concrete constituents. This combined approach holds significant potential for the development of durable, high performance concrete suitable for diverse structural applications.

Materials

Binders

In this research, Type-1 OPC were used in the preparation of all mixes which meet the specifications of ASTM C-150. It is available as Maple leaf brand in Pakistan which 53 grade. Fly ash and nano silica is obtained from Sika Pakistan. However fly ash is activated through Na₂SO₄. The chemical properties of Cement, fly ash and Nano silica are presented in Table 1 while the physical properties of cement, fly ash and nano silica are shown in Table 2.

Aggregates

Locally available fine aggregates and coarse aggregates were used in this study. The fineness modulus of sand is 2.9. The size of coarse aggregates ranges from 9 mm to 12 mm. The recycled is produced by breaking down manually the laboratory high strength concrete waste. The properties of aggregates are shown in Table 3.

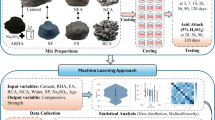

Methodology

This study focusses on developing models to predict the compressive Properties and durability properties of AFA/NS-based high strength RCA concrete using machine learning algorithms. Figure 1 shows the flowchart of this study. Google Colab, a python language platform, was used to run the models. ML (machine learning) algorithms like Tree-based algorithm (Decision Tree and Random Forest) and Boosting algorithm (XG Boost and Ada Boost) were determined in this study. These models use linear equations to figure out how the input parameters relate to the desired properties31,32.

The data utilized for the development of models was divided into two groups: the training set used for training the model and a testing set to evaluate their performance. The data set was split into 80:20 for training and testing purposes. To address the variability in the initial ranges and units of the data, the input features were standardized to follow a normal distribution. This was achieved using the standard scaler function from scikit learn, which centers the mean at zero and sets the standards deviation to one. Standardization ensured consistent feature scaling, enhancing model convergence during training.

Boosting techniques

Boosting techniques, also known as ensemble methods. These techniques integrate to predict various basic models to improve robustness and overall precision33,34,35. XG-Boost is an efficient gradient boosting algorithm known for its speed, scalability and robustness. It uses second order gradient information, L1 and L2 regularization and tree pruning to enhance efficiency and reduce overfitting. With parallel processing, it handles large datasets effectively, manages missing data and identifies optimal split points using a weighted quantile sketch algorithm36.

AdaBoost, or Adaptive Boosting, is a specific approach of ensemble learning that utilizes weak predictors, such as decision trees, and creates a powerful model. This approach pays more attention to misclassified samples in each iteration and incorporates the more accurate learners in the final solution. Despite its applicability in dealing with large data sets and enhancing the performance of weak learners, AdaBoost is prone to overfitting and hence the input data must be preprocessed to remove noise and outliers and the parameters properly tuned. AdaBoost is particularly used in classification problems owing to its flexibility and effectiveness37. Figure 2 shows the functional framework of Boosting techniques.

Tree regression

The decision tree algorithm is an effective and basic technique for classification, utilizing a tree-like framework to categorize different data points into several classes based on defined criteria. To improve the accuracy of predictions, Random Forest combines numerous trees, making it an enhanced form of decision tree algorithms38,39,40,41. It recursively splits data based on features values to maximize information gain or minimize Gini impurity. Predictions are made at the leaf nodes using the majority class or average target value. Its ease of use makes it popular across various domains39,42.

A random forest system weaves together multiple decision trees constructed from randomly sampled features to address data problems and improve predictions. A Decision Tree stands alone as an easily understood algorithm but tends to distort results when applied to difficult datasets. Random Forest better predicts data and prevents overfitting but has less interpretability than single decision trees39,40. Figure 3 shows the functional framework of Tree based algorithms.

Table 4 outlines the key parameters used to implement different models for predicting the compressive strength and acid resistance of RCA based high strength concrete. For enable techniques 100 estimators were utilized to balance computational efficiency and accuracy, with XG Boost and ADA Boost using a learning rate of 0.1 for alterative optimization. Max depth was set to 10 for decision tree and random forest, and 6 for XG Boost, ensuring model complexity without overfitting. The minimum data in leaves was set to 20 for Decision tree, Random Forest and XG Boost, while Ada Boost relies on its boosting framework without directly using this parameter. XG Boost incorporates both L1 and L2 regularization (0.1 each) to improve generalization and employed a subsample rate of 0.8 for additional robustness. A consistent random state value of 42 was applied across all models to ensure reproducibility and result consistency. These parameters choice optimized the model’s predictive accuracy and reliability for the study.

Experimental program and mix proportion

A total of 420 samples were cast and tested for compressive strength in accordance with ASTM C39/C39M standard with the findings based on the average of 3 specimen per mix (140 readings) while for acid attack 240 samples were cast and tested by ASTM C1898 standard with average reading of 80. The size of the cylinder is 100 mm x 200 mm. The curing days in water for compressive strength are 3,7,14,28,56,90 and 120 days. For acid attack the samples are cured in water for 7 days, to evaluate the effect of acid the samples are placed in 5% H2SO4 solution for a period of 1,2,3,4 months. The mix proportion of mixes are displayed in Table 5.

Statistical parameters

R2 (coefficient of determination)

The degree addresses the amount of variation of the target variable that may be predicting from input features characterized by R2 coefficient, also called the coefficient of determination. This value varies between 0 and 1, where the value of 1 (or 100%) proves how well the constructed model reflects the actual scenarios.

Where: \(\:{y}_{i}\) show the experimental finding of the variable (compressive strength). \(\:{\widehat{y}}_{i}\) show the predicted findings. ’n’ shows the data points.

Mean square error

The Mean Squared Error or MSE calculates mean of the square of the deviations between the predicted variable values to the actual values. It is used to judge the general performance of the model as the lower the MSE, the better the model.

Root mean squared error

RSME is estimated from the square root of the mean squared error. It determines the mean magnitude of predicted errors and is stated in the variable’s units.

Mean absolute error

A measure of the mean magnitude of predicted errors, Mean Absolute Error (MAE) is determined in similar units as the desired variable, just like Root Mean Square Error (RMSE). This statistic is useful for understanding the absolute error, regardless of the direction the predicted errors are taking. The model’s performance is good when the MAE value is lower.

Mean absolute percentage error

MAPE determines the proportion of variance between the actual and predicted values. It is especially beneficial for understanding the model’s precision while addressing different data scales.

Results and discussion

Compressive strength

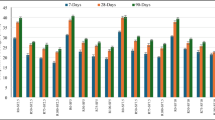

The study results show variable effects on compressive strength as a function of five groups, varying the combinations of RCA content and fly ash activation. Inactivated Fly Ash (Group 1): The baseline group where the inactivated fly ash with 0% RCA replacement is taken. In this group, compressive strength increased gradually from 16.8 MPa in 3 days to 60.35 MPa at 120 days, the highest recorded in the group was RCA0-F 45 (60.35 MPa). Unlike activated fly ash, only a limited pozzolanic reaction was observed in inactivated fly ash. Less efficient hydration and pozzolanic reaction are evidenced by a slower strength gain and a lower ultimate strength, as well as a less dense microstructure. Activated Fly Ash (Group 2): The result of Compressive strength were improved in all curing durations because of fly ash chemical activation. RCA0-F45-A reached 68.64 MPa at 120 days, which is much greater than its non-activated counterpart. The activation process increased fly ash reactivity and promoted formation of additional CSH gel and a denser matrix. That resulted in a stronger bond between the aggregates and the cement paste43,44,45. They show that effective activated fly ash promotes both early and long-term performance in terms of its fast strength development and higher ultimate strength. Activated Fly Ash + 50% RCA (Group 3): It show a moderate reduction in compressive strength compared to those of Group 2. The compressive strength of mix RCA50-F45-A 57.13 MPa at 120 days which was less than that of RCA0-F45-A (68.64 MPa). Such reduction was also owing to the presence of RCA (higher porosity; weaker interfacial transition zones (ITZs))46. However, despite weaknesses of RCA correlated to the lower strengths, the activated fly ash was still important in improving strength through its action of filling micro pores and refining the ITZs47,48. Results show that the performance of a 50% RCA replacement with activated fly ash is satisfactory for compressive strength making it a sustainable performance. Activated Fly Ash + 75% RCA (Group 4): Further reduction of compressive strength was observed with 75% RCA replacement, suggesting that the inherent weaknesses of RCA are dominating. For instance, compressive strength of 51.24 MPa was achieved for RCA75-F45-A after 120 days, which is well below the compressive strength of 50% RCA mixes. The additional RCA content improved overall porosity and degraded ITZ, but did not attain the full benefits of activated fly ash. Even in cases where strength was reduced, the trend of increasing strength with time was consistent, representing that activated fly ash continued to promote hydration, pozzolanic reactions, even at higher RCA levels. However, this group shows that the mechanical performance of the concrete is lowered with enhanced RCA content, yet the addition of activated fly ash to the concrete prevents a reduction of concrete durability and long-term strength, though to a narrower extent. Activated Fly Ash + 100% RCA (Group 5): This constitutes the most sustainable mix with 100% RCA replacement and activated fly ash. The quality of RCA100-F45-A was the lowest, with 42.67 MPa at 120 days, which was the lowest among the studied groups. Complete substitution of natural aggregate by RCA resulted in increased porosity, weaker bond, and more severe ITZ problems. Activated fly ash increased the matrix’s density, but the high porosity of RCA hindered overall effectiveness of RCA. Results show the difficulty in completely using 100% RCA in high strength applications, even with the presence of activated fly ash. This mix, however, still offers a sustainable solution with acceptable performance for non-structural uses where lower strength requirements are permitted. Furthermore, the descriptive statistics of compressive strength are shown in Table 6 while the performance indicator for different models are shown in Table 7.

Tree-based models

This part of the study explores the findings of Tree-based models, such as Random Forest regression and Decision Tree regression, emphasizing their significance, robustness, and justifications for improved accuracy. It is observed in Fig. 4 that the correlation of Random Forest and Decision Trees shows better results in predicting the compressive strength of FA/NS-based high-strength RCA concrete. The value of R2 is high for the random forest, which is 0.9922, while for the decision tree, it is 0.9547. It has been observed in previous studies that statistical parameters give accurate results after the prediction (R2 greater than 0.90) of compressive strength using decision tree and random forest regression49,50,51. The improved precision of the RF regression model is due to its ensemble characteristics, which use bagging selection of features and combine various tree of decision. This ensemble method reduces overfitting and improves generalization and enhances predictive robustness.

Boosting models

Figure 4 shows the correlation of boosting (ensemble) regression. It is revealed that the XG boost regression gives the best result (R2 = 0.99) than that of using Ada boost regression for the prediction of compressive strength. This shows the accuracy between the actual findings and targeted findings. The precision of the results is due to the gradient boost methodology, regularization, and feature significance, employing L1 and L2 regularization techniques, along with tree pruning, which mitigates model complexity and noise capture, thereby collectively improving model accuracy. Additionally, it is reported in previous research that the value of R2 using XG Boost is 0.950, which further supports the results of this study49.

In summary, machine learning demonstrates high predictive accuracy for compressive strength, with XG Boost achieving the highest R2 value of 0.995, indicating an almost perfect relation between predicted and actual values. This suggests that XG Boost effectively captured the complex relationship between compressive strength and concrete mix parameters. Random forest followed closely with R2 = 0.992, confirming the robustness of ensembled based models in handling variability in material properties. The mean square error and root mean square error values were lowest for XG Boost (MSE = 0.786, RSME = 0.887 MPa), which indicate minimal prediction errors and a high degree of reliability. Furthermore, Ada Boost exhibits slightly lower performance with R2 value of 0.974, and higher RMSE values suggesting these model overfitted in certain cases. The results confirm that XG Boost and Random Forest are the most suitable models for predicting compressive strength in RCA based high strength concrete, offering a reliable alternative to traditional regression techniques.

Acid attack

The acid exposure data in relation to five groups revealed different patterns of compressive strength loss over time, as well as different levels of resistance. Concrete with inactivated fly ash in Group 1 displayed the highest susceptibility to acid attack; average strength losses of 5.74%, 10.45% and 16.72% at 1 month, 2 months, and 3 months respectively. The progressive loss, up to 22.48% at the 4th month indicates that inactivated fly ash offers not much protection against acidic conditions and the degradation proceeds toward time. In contrast, Group 2, with activated fly ash, exhibited better resistance, as evident from the lower average strength losses: 4.57% at 1 month,8.23% at 2 months, 15.21% at 3 months. Along with improved pozzolanic reactivity, increased densification of the microstructures and subsequent acid penetration were restricted by strength losses that stabilized at 17.34% over four months. The enhanced performance is further evidence of activated fly ash’s contribution to higher resistance to acid, especially in the longer exposure. Activated fly ash with 50% RCA in Group 3 had moderate strength loss: corresponding to 5.40% strength loss at 1 month, 9.43% loss at 2 months, 18.52% at 3 months, reaching 20.56% at 4 months. Porosity of specimens of Group 3, resulted from the partial replacement of natural aggregates with RCA material, was higher than specimens of Group 2, thereby improving their vulnerability. Nevertheless, activated fly ash worked better in inactivated mixes. In Group 4, with 75% RCA, the average strength losses were higher: 5.79% reduction in 1 month, 10.43% at 2 months and 21.29% at 3 months, ending at 24.71% at 4 months. Even in the case of activated fly ash, the increased RCA content weakened the microstructure even more, which made it more inclined to acid attack. Results show that activated fly ash improves acid resistance, but too high RCA reduces resistance to an unacceptable level. Averages of 6.70%, 12.01%, and 25.46% (up to 30.57%) at 1, 2, and 3 months respectively were observed for Group 5, which consisted of 100% RCA with activated fly ash. The replacement of natural aggregates with RCA resulted in a highly porous matrix that provided more acid penetration and greater loss of strength, even in the presence of activated fly ash. This finding indicates that fly ash induction improves durability, but to a lesser extent if the RCA dosage is increased. Overall, the findings indicate that activated fly ash increases acid resistance of all groups and performs best in mixes with no RCA (Group 2). However, as RCA content rises, strength loss is higher and the porosity and bond strength of RCA are poorer than conventional cement, meaning that strength loss is increase as RCA content increases. Furthermore, the descriptive statistics of acid attack are shown in Table 8 while the performance indicators for different models are shown in Table 9.

Tree-based models

The correlation of ensemble regression is displayed in Fig. 5. The random forest shows the best performance with R2 value of 0.9148 than that of decision tree regression (0.9098). The difference between the values is attributed to ensemble techniques which improve generalization and decrease overfitting while decision tree overfit in a certain area. Random forest combines the predicting values from various trees where it adds uncertainty by bagging and random feature selection. This leads to the capturing of complex patterns in the data as well as leading to the production of a more stable model. Previous researchers have worked on the prediction of loss in compressive strength (CS) of the materials exposed to acid attacks using machine learning techniques such as decision trees and random forests. A study by Wang et al.52 employed the decision trees and Random Forests models to evaluate the CS loss after the acid attack on ESP (eggshell powder) modified mortar. The models achieved high predictive accuracy. For Random Forest, the value of R2 was 0.95. Alfaiad et al.,53 examined recycled glass powder (RGP)-based mortar exposed to acid solutions, Random Forest model was used for CS loss assessment. The value of R2 is 0.96 signifying that the values predicted by the model had a good fit with the observed data.

Boosting models

It is observed in Fig. 5 that XG boost regression give best result than that of Ada boost. The value of R2 is 0.9592 and 0.8741 respectively. XG Boost performs better than AdaBoost regression. It is influenced by the gradient boosting that is used in its algorithm to iteratively minimize the errors through gradient descent and is therefore able to capture nonlinear relationships in the data. XG Boost also comes with other advanced methods known as regularization (L1 and L2) to enhance generalization and avoid overfitting. Similar finding reveals that XG boosts better findings than that of other regression models54,55,56,57.

In summary, the machine learning models for acid resistance demonstrated moderate to high accuracy, with Random Forest revealing the best R2 values (0.909), indicating that it effectively captured the underlying pattern of strength reduction in acid exposed samples. XG Boost followed with a R2 of 0.959, demonstrating its ability to predict resistance with high precision. The MSE and RMSE for XG Boost (2.03 and 1.42) were the lowest, proved to be the lowest, suggesting that it provided the most reliable prediction for compressive loss under acidic conditions. Furthermore, Ada Boost has the lowest R2 (0.874) and the highest RMSE (2.23), suggesting that it struggled to generalize as effectively as other ensemble methods. The superior performance of Random Forest and XG Boost can be attributed to their ability to model nonlinear interaction and reduce overfitting, making them more suitable for predicting acid attack resistance. The results highlight the importance of using ensemble learning techniques in forecasting acid resistance of RCA based concrete, providing insights into optimizing mix design for enhanced acid resistance.

Comparison of ML algorithms

The comparison of experimental CS and predicted CS using Decision tree, Random Forest, XG boost, and Ada boost regression are shown in Fig. 6. The graph demonstrates the results of four machine learning algorithms in terms of predicted CS values against the experimental values based on 28 data points of the graph. In comparison to other regressions, XG boost, and Random Forest give nearly correct results in terms of experimental results and are the best in terms of capturing the underlying trends in the patterns. This is attributed to the using multiple learning algorithms to come up with an ensemble, give more accurate and consistent estimates of the compressive strength compared to the other models and are therefore the most accurate models for this dataset58,59,60. On the other hand, Decision Tree and AdaBoost are more variable though there are slight overfitting or underestimation at some points.

The reduction in CS: predicted by four machine learning models (Decision Tree, Random Forest, XG boost, and AdaBoost) compared to the experiment reduction in CS for 16 data points are displayed in Fig. 7. The comparison of the models showed that XG boost, and Random Forest have predictions that correlate well with the experimental data most of the points; therefore, the models have a high potential in approximating the material’s behavior. Decision Tree and AdaBoost have higher variance and at some times, are more off the experimental values notably at point 9, 12, and 14. This demonstrates that XG Boost random forest are more accurate and reliable models for evaluating compressive strength loss after an attack by acid.

Conclusion

-

The use of Nano Silica and chemically activated fly ash significantly improved the compressive strength of RCA based high strength concrete, by promoting pozzolanic reaction, addressing the inherent weaknesses of RCA.

-

Concrete mixes with activated fly ash exhibits superior resistance to acid exposure, reducing porosity and improving the long-term durability of the RCA based concrete in harmful environment.

-

The study revealed that up to 50% RCA replacement maintain acceptable strength and durability, while 100% RCA replacement results in significant strength loss, highlighting the need for a balanced mix design integrating SCMs for sustainable high-performance concrete.

-

Among all the machine learning models tested, XG Boost show the highest predictive accuracy for compressive strength (R2 = 0.995) while Random Forest performance is best for acid resistance (R2 = 0.909), demonstrating the potential of AI driven approaches for optimizing RCA concrete mix design.

-

The successful integration of Machine learning models and SCMs in RCA based concrete provides a sustainable pathway for reducing cement dependency, minimizing construction waste, and enhancing the resilience of ecofriendly high strength concrete in real world applications.

Data availability

The data are available from the corresponding author upon request.

References

Chen, L. et al. Conversion of waste into sustainable construction materials: A review of recent developments and prospects. Mater. Today Sustain. 100930. https://doi.org/10.1016/j.mtsust.2024.100930 (2024).

Althoey, F., Ansari, W. S., Sufian, M. & Deifalla, A. F. Advancements in low-carbon concrete as a construction material for the sustainable built environment. Dev. Built. Environ. 16 https://doi.org/10.1016/j.dibe.2023.100284 (2023).

Barbhuiya, S., Kanavaris, F., Das, B. B. & Idrees, M. Decarbonising cement and concrete production: strategies, challenges and pathways for sustainable development. J. Building Eng. https://doi.org/10.1016/j.jobe.2024.108861 (2024). 108861.

Zengfeng, Z. H. A. O. et al. Use of recycled concrete aggregates from precast block for the production of new Building blocks: an industrial scale study. Resour. Conserv. Recycl. 157, 104786. https://doi.org/10.1016/j.resconrec.2020.104786 (2020).

Safiuddin, M., Alengaram, U. J., Rahman, M. M., Salam, M. A. & Jumaat, M. Z. Use of recycled concrete aggregate in concrete: a review. J. Civil Eng. Manage. 19 (6), 796–810. https://doi.org/10.3846/13923730.2013.799093 (2013).

Zheng, Y., Zhang, Y. & Zhang, P. Methods for improving the durability of recycled aggregate concrete: A review. J. Mater. Res. Technol. 15, 6367–6386. https://doi.org/10.1016/j.jmrt.2021.11.085 (2021).

Fanijo, E. O., Kolawole, J. T., Babafemi, A. J. & Liu, J. A comprehensive review on the use of recycled concrete aggregate for pavement construction: properties, performance, and sustainability. Clean. Mater. 9, 100199. https://doi.org/10.1016/j.clema.2023.100199 (2023).

Ismail, S. & Ramli, M. Engineering properties of treated recycled concrete aggregate (RCA) for structural applications. Constr. Build. Mater. 44, 464–476. https://doi.org/10.1016/j.conbuildmat.2013.03.014 (2013).

Li, G. et al. Fly Ash application as supplementary cementitious material: A review. Materials 15 (7), 2664. https://doi.org/10.3390/ma15072664 (2022).

Mukharjee, B. B. & Barai, S. V. Influence of incorporation of nano-silica and recycled aggregates on compressive strength and microstructure of concrete. Constr. Build. Mater. 71, 570–578. https://doi.org/10.1016/j.conbuildmat.2014.08.040 (2014).

Villagrán-Zaccardi, Y. A. et al. Complete re-utilization of waste concretes–Valorisation pathways and research needs. Resour. Conserv. Recycl. 177, 105955. https://doi.org/10.1016/j.resconrec.2021.105955 (2022).

Mohsen, M. O. et al. Fly Ash and natural Pozzolana impacts on sustainable concrete permeability and mechanical properties. Buildings 13 (8), 1927. https://doi.org/10.3390/buildings13081927 (2023).

Gaikwad, P. & Sathe, S. Effect of fly Ash on compressive strength, carbonation and corrosion resistance of reinforced concrete: a systematic review. World J. Eng. 22 (1), 40–60. https://doi.org/10.1108/WJE-07-2023-0240/FULL/HTML (2025).

Golewski, G. L. The role of pozzolanic activity of siliceous fly Ash in the formation of the structure of sustainable cementitious composites. Sustainable Chem. 3 (4), 520–534. https://doi.org/10.3390/suschem3040032 (2022).

Ruan, S. & Unluer, C. Influence of supplementary cementitious materials on the performance and environmental impacts of reactive Magnesia cement concrete. J. Clean. Prod. 159, 62–73. https://doi.org/10.1016/j.jclepro.2017.05.044 (2017).

Lodeiro, I. G., Fernández-Jiménez, A., Palomo, A. & Macphee, D. E. Effect on fresh CSH gels of the simultaneous addition of alkali and aluminium. Cem. Concr. Res. 40 (1), 27–32. https://doi.org/10.1016/j.cemconres.2009.08.004 (2010).

Senff, L., Labrincha, J. A., Ferreira, V. M., Hotza, D. & Repette, W. L. Effect of nano-silica on rheology and fresh properties of cement pastes and mortars. Constr. Build. Mater. 23 (7), 2487–2491. https://doi.org/10.1016/j.conbuildmat.2009.02.005 (2009).

Saraswathy, V., Karthick, S. & Kwon, S. J. Durability enhancement in nano-silica admixed reinforced mortar. J. Korean Recycled Constr. Resour. Inst. 2 (4), 297–306. https://doi.org/10.14190/JRCR.2014.2.4.297 (2014).

Kou, S. C., Poon, C. S. & Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 33 (8), 788–795. https://doi.org/10.1016/j.cemconcomp.2011.05.009 (2011).

Roychand, R., De Silva, S. & Setunge, S. Nanosilica modified high-volume fly Ash and slag cement composite: environmentally friendly alternative to OPC. J. Mater. Civ. Eng. 30 (4), 04018043. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002220 (2018).

Silva, L. F. et al. Geochemistry and mineralogy of coal-fired Circulating fluidized bed combustion fly ashes. Coal Combust. Gasif. Prod. 6 (2), 16–28 (2014).

Limbachiya, M. C., Leelawat, T. & Dhir, R. K. Use of recycled concrete aggregate in high-strength concrete. Mater. Struct. 33, 574–580. https://doi.org/10.1007/BF02480538 (2000).

Singh, R., Nayak, D., Pandey, A., Kumar, R. & Kumar, V. Effects of recycled fine aggregates on properties of concrete containing natural or recycled coarse aggregates: A comparative study. J. Building Eng. 45, 103442. https://doi.org/10.1016/j.jobe.2021.103442 (2022).

Tien, P. W., Wei, S., Darkwa, J., Wood, C. & Calautit, J. K. Machine learning and deep learning methods for enhancing Building energy efficiency and indoor environmental quality–a review. Energy AI. 10, 100198. https://doi.org/10.1016/j.egyai.2022.100198 (2022).

Sarker, I. H. Machine learning: algorithms, real-world applications and research directions. SN Comput. Sci. 2 (3), 160. https://doi.org/10.1007/S42979-021-00592-X (2021).

Shin, S. et al. Machine learning vs. conventional statistical models for predicting heart failure readmission and mortality. ESC Heart Fail. 8, 106–115. https://doi.org/10.1002/EHF2.13073 (2021).

Long, F., Wang, L., Cai, W., Lesnik, K. & Liu, H. Predicting the performance of anaerobic digestion using machine learning algorithms and genomic data. Water Res. 199, 117182. https://doi.org/10.1016/j.watres.2021.117182 (2021).

Chen, T. & Guestrin, C. Xgboost: A scalable tree boosting system. In Proc. of the 22nd ACM Sigkdd International Conference on Knowledge Discovery and Data Mining, 785-794. https://doi.org/10.1145/2939672.2939785 (2016).

Breiman, L. Random forests. Mach. Learn. 45, 5–32 (2001). https://link.springer.com/article/10.1023/a:1010933404324

Freund, Y. & Schapire, R. E. A decision-theoretic generalization of on-line learning and an application to boosting. J. Comput. Syst. Sci. 55 (1), 119–139 (1997).

Yuvaraj, K., Ramesh, S. & Velumani, M. Predicting the mechanical strength of coal pond Ash based geopolymer concrete using linear regression method. Mater. Today Proc. https://doi.org/10.1016/J.MATPR.2023.04.514 (2023).

Rajakarunakaran, S. A. et al. Prediction of strength and analysis in self-compacting concrete using machine learning based regression techniques. https://doi.org/10.1016/J.ADVENGSOFT.2022.103267

Mahajan, P., Uddin, S., Hajati, F. & Moni, M. A. Ensemble learning for disease prediction: A review. In Healthcare, 11(12), 1808. https://doi.org/10.3390/healthcare11121808 (2023).

Che, D., Liu, Q., Rasheed, K. & Tao, X. Decision tree and ensemble learning algorithms with their applications in bioinformatics. Softw. Tools Algorithms Biol. Syst. 191-199 https://doi.org/10.1007/978-1-4419-7046-6_19 (2011).

Mienye, I. D. & Sun, Y. A survey of ensemble learning: concepts, algorithms, applications, and prospects. Ieee Access. 10, 99129–99149 (2022).

Yan, H. et al. Investment Estimation of prefabricated concrete buildings based on XGBoost machine learning algorithm. Adv. Eng. Inform. 54, 101789 (2022).

DeRousseau, M. A., Laftchiev, E., Kasprzyk, J. R., Rajagopalan, B., Srubar, I. I. I. & W. V A comparison of machine learning methods for predicting the compressive strength of field-placed concrete. Constr. Build. Mater. 228, 116661. https://doi.org/10.1016/j.conbuildmat.2019.08.042 (2019).

Huang, J., Sabri, M. M. S., Ulrikh, D. V., Ahmad, M. & Alsaffar, K. A. M. Predicting the compressive strength of the cement-fly ash–slag ternary concrete using the firefly algorithm (fa) and random forest (rf) hybrid machine-learning method. Materials 15 (12), 4193. https://doi.org/10.3390/MA15124193 (2022).

Li, H., Lin, J., Lei, X. & Wei, T. Compressive strength prediction of basalt fiber reinforced concrete via random forest algorithm. Mater. Today Commun. 30, 103117. https://doi.org/10.1016/J.MTCOMM.2021.103117 (2022).

Ammari, B. L. et al. Linear model decision trees as surrogates in optimization of engineering applications. Comput. Chem. Eng. 178, 108347. https://doi.org/10.1016/j.compchemeng.2023.108347 (2023).

Zhang, J., Ma, G., Huang, Y., sun, J. & Aslani, F. Nener, modelling uniaxial compressive strength of lightweight self-compacting concrete using random forest regression. Constr. Build. Mater. 210, 713–719. https://doi.org/10.1016/J.CONBUILDMAT.2019.03.189 (2019).

Feng, J. et al. Efficient creep prediction of recycled aggregate concrete via machine learning algorithms. Constr. Build. Mater. 360, 129497. https://doi.org/10.1016/j.conbuildmat.2022.129497 (2022).

Wang, L., Guo, F., Lin, Y., Yang, H. & Tang, S. W. Comparison between the effects of phosphorous slag and fly Ash on the CSH structure, long-term hydration heat and volume deformation of cement-based materials. Constr. Build. Mater. 250, 118807. https://doi.org/10.1016/j.conbuildmat.2020.118807 (2020).

Liu, S. et al. Early mechanical strength, hydration mechanism and leaching behavior of alkali-activated slag/fly Ash paste filling materials. J. Building Eng. 84, 108481. https://doi.org/10.1016/j.jobe.2024.108481 (2024).

Pan, Z., Tao, Z., Cao, Y. F., Wuhrer, R. & Murphy, T. Compressive strength and microstructure of alkali-activated fly ash/slag binders at high temperature. Cem. Concr. Compos. 86, 9–18. https://doi.org/10.1016/j.cemconcomp.2017.09.011 (2018).

Liu, Y., Ren, P., Garcia-Troncoso, N., Mo, K. H. & Ling, T. C. Roles of enhanced ITZ in improving the mechanical properties of concrete prepared with different types of recycled aggregates. J. Building Eng. 60, 105197. https://doi.org/10.1016/j.jobe.2022.105197 (2022).

Wang, R., Yu, N. & Li, Y. Methods for improving the microstructure of recycled concrete aggregate: A review. Constr. Build. Mater. 242, 118164. https://doi.org/10.1016/j.conbuildmat.2020.118164 (2020).

Makul, N. et al. Use of recycled concrete aggregates in production of green cement-based concrete composites: A review. Crystals 11 (3), 232 (2021).

Paudel, S., Pudasaini, A., Shrestha, R. K. & Kharel, E. Compressive strength of concrete material using machine learning techniques. Clean. Eng. Technol. 15, 100661. https://doi.org/10.1016/J.CLET.2023.100661 (2023).

Rajender, A. & Samanta, A. K. Compressive strength prediction of metakaolin based high-performance concrete with machine learning. Mater. Today Proc. https://doi.org/10.1016/J.MATPR.2023.03.522 (2023).

Huang, J., Sabri, M. M. S., Ulrikh, D. V., Ahmad, M. & Alsaffar, K. A. M. Predicting the compressive strength of the cement-fly ash–slag ternary concrete using the firefly algorithm (fa) and random forest (rf) hybrid machine-learning method. Materials 15(12), 4193. https://doi.org/10.3390/MA15124193 (2022).

Zhu, F., Wu, X., Lu, Y., & Huang, J. Strength reduction due to acid attack in cement mortar containing waste eggshell and glass: A machine learning-based modeling study. Buildings 14(1), 225.https://doi.org/10.3390/buildings14010225 (2022).

Alfaiad, M. A. et al. N Evaluating the compressive strength of glass powder-based cement mortar subjected to the acidic environment using testing and modeling approaches. PLos One 18(4), e0284761. https://doi.org/10.1371/JOURNAL.PONE.0284761 (2023).

Zhang, J., Wang, R., Lu, Y., & Huang, J. Prediction of compressive strength of geopolymer concrete landscape design: Application of the novel hybrid RF–GWO–XGBoost algorithm. Buildings 14(3), 591. https://doi.org/10.3390/buildings14030591 (2024).

Verma, M. Prediction of compressive strength of geopolymer concrete using random forest machine and deep learning. Asian J. Civil Eng. 24, 2659–2668. https://doi.org/10.1007/S42107-023-00670-W (2023).

Nguyen, M. H., Mai, H. V. T., Trinh, S. H. & Ly, H. B. A comparative assessment of tree-based predictive models to estimate geopolymer concrete compressive strength. Neural Comput. Appl. 35, 6569–6588. https://doi.org/10.1007/S00521-022-08042-2 (2023).

Al-Taai, S. R. et al. XGBoost prediction model optimized with bayesian for the compressive strength of eco-friendly concrete containing ground granulated blast furnace slag and recycled coarse aggregate. Appl. Sci. 13 (15), 8889. https://doi.org/10.3390/app13158889 (2023).

Ozcan, G., Kocak, B., Gulbandilar, E. & Kocak, Y. Efficient machine learning models for Estimation of compressive strengths of zeolite and diatomite substituting concrete in sodium chloride solution. Arab. J. Sci. Eng. 49 (10), 14241–14256. https://doi.org/10.1007/s13369-024-09042-1 (2024).

Inqiad, W. B. et al. Comparative analysis of various machine learning algorithms to predict 28-day compressive strength of Self-compacting concrete. Heliyon 9 (11). https://doi.org/10.1016/j.heliyon.2023.e22036 (2023).

Pal, A., Ahmed, K. S., Hossain, F. Z. & Alam, M. S. Machine learning models for predicting compressive strength of fiber-reinforced concrete containing waste rubber and recycled aggregate. J. Clean. Prod. 423, 138673. https://doi.org/10.1016/j.jclepro.2023.138673 (2023).

Acknowledgements

The authors extend their appreciation to the Deanship of Research and Graduate Studies at King Khalid University for funding this work through Large Research Project under grant number RGP2/105/46.

Author information

Authors and Affiliations

Contributions

1. Muhammad Adil Khan data curation, Analysis validation resources, 2. Muhammad Shoaib Ashraf Supervision Review and Editing, 3.Kennedy C. Onyelowe Supervision Investigation Funding Review and Editing, 4. Khawaja Adeel Tariq Resources Software Revision, 5.Mohd Ahmed Supervision Investigation. 6. Tariq Ali conceptualization Analysis validation 7. Muhammad Zeeshan Qureshi Writing orignal paper Software.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

All authors approve that the research was performed under all the ethical norms.

Consent to publish

All authors consent to publishing this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Annexure-A (compressive strength results)

Mix ID | Cement (kg/m3) | Nano silica (kg/m3) | Fly ash (kg/m3) | Na2SO4 (kg/m3) | NCA (kg/m3) | RCA (kg/m3) | Sand (kg/m3) | Water (kg/m3) | SP (kg/m3) | Compressive strength (MPa) |

|---|---|---|---|---|---|---|---|---|---|---|

RCA0-F0 | 550 | 8.25 | 0 | 0 | 900 | 0 | 800 | 180 | 12 | 16.8 |

RCA0-F15 | 467.5 | 8.25 | 82.5 | 0 | 900 | 0 | 800 | 180 | 12 | 17.8 |

RCA0-F30 | 385 | 8.25 | 165 | 0 | 900 | 0 | 800 | 180 | 12 | 18.45 |

RCA0-F45 | 302.5 | 8.25 | 247.5 | 0 | 900 | 0 | 800 | 180 | 12 | 19.31 |

RCA0-F0 | 550 | 8.25 | 0 | 0 | 900 | 0 | 800 | 180 | 12 | 33.52 |

RCA0-F15 | 467.5 | 8.25 | 82.5 | 0 | 900 | 0 | 800 | 180 | 12 | 35.74 |

RCA0-F30 | 385 | 8.25 | 165 | 0 | 900 | 0 | 800 | 180 | 12 | 37.43 |

RCA0-F45 | 302.5 | 8.25 | 247.5 | 0 | 900 | 0 | 800 | 180 | 12 | 36.3 |

RCA0-F0 | 550 | 8.25 | 0 | 0 | 900 | 0 | 800 | 180 | 12 | 44.32 |

RCA0-F15 | 467.5 | 8.25 | 82.5 | 0 | 900 | 0 | 800 | 180 | 12 | 45.23 |

RCA0-F30 | 385 | 8.25 | 165 | 0 | 900 | 0 | 800 | 180 | 12 | 46.18 |

RCA0-F45 | 302.5 | 8.25 | 247.5 | 0 | 900 | 0 | 800 | 180 | 12 | 45.56 |

RCA0-F0 | 550 | 8.25 | 0 | 0 | 900 | 0 | 800 | 180 | 12 | 52.36 |

RCA0-F15 | 467.5 | 8.25 | 82.5 | 0 | 900 | 0 | 800 | 180 | 12 | 53.81 |

RCA0-F30 | 385 | 8.25 | 165 | 0 | 900 | 0 | 800 | 180 | 12 | 55.74 |

RCA0-F45 | 302.5 | 8.25 | 247.5 | 0 | 900 | 0 | 800 | 180 | 12 | 55.71 |

RCA0-F0 | 550 | 8.25 | 0 | 0 | 900 | 0 | 800 | 180 | 12 | 56.34 |

RCA0-F15 | 467.5 | 8.25 | 82.5 | 0 | 900 | 0 | 800 | 180 | 12 | 57.21 |

RCA0-F30 | 385 | 8.25 | 165 | 0 | 900 | 0 | 800 | 180 | 12 | 58.56 |

RCA0-F45 | 302.5 | 8.25 | 247.5 | 0 | 900 | 0 | 800 | 180 | 12 | 58.92 |

RCA0-F0 | 550 | 8.25 | 0 | 0 | 900 | 0 | 800 | 180 | 12 | 57.87 |

RCA0-F15 | 467.5 | 8.25 | 82.5 | 0 | 900 | 0 | 800 | 180 | 12 | 57.98 |

RCA0-F30 | 385 | 8.25 | 165 | 0 | 900 | 0 | 800 | 180 | 12 | 58.67 |

RCA0-F45 | 302.5 | 8.25 | 247.5 | 0 | 900 | 0 | 800 | 180 | 12 | 59.23 |

RCA0-F0 | 550 | 8.25 | 0 | 0 | 900 | 0 | 800 | 180 | 12 | 58.67 |

RCA0-F15 | 467.5 | 8.25 | 82.5 | 0 | 900 | 0 | 800 | 180 | 12 | 59.34 |

RCA0-F30 | 385 | 8.25 | 165 | 0 | 900 | 0 | 800 | 180 | 12 | 59.76 |

RCA0-F45 | 302.5 | 8.25 | 247.5 | 0 | 900 | 0 | 800 | 180 | 12 | 60.35 |

RCA0-F0-A | 550 | 8.25 | 0 | 11 | 900 | 0 | 800 | 180 | 12 | 16.8 |

RCA0-F15-A | 467.5 | 8.25 | 82.5 | 11 | 900 | 0 | 800 | 180 | 12 | 19.06 |

RCA0-F30 -A | 385 | 8.25 | 165 | 11 | 900 | 0 | 800 | 180 | 12 | 18.84 |

RCA0-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 900 | 0 | 800 | 180 | 12 | 18.72 |

RCA0-F0-A | 550 | 8.25 | 0 | 11 | 900 | 0 | 800 | 180 | 12 | 33.52 |

RCA0-F15-A | 467.5 | 8.25 | 82.5 | 11 | 900 | 0 | 800 | 180 | 12 | 38.7855 |

RCA0-F30 -A | 385 | 8.25 | 165 | 11 | 900 | 0 | 800 | 180 | 12 | 39.9885 |

RCA0-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 900 | 0 | 800 | 180 | 12 | 39.4705 |

RCA0-F0-A | 550 | 8.25 | 0 | 11 | 900 | 0 | 800 | 180 | 12 | 44.32 |

RCA0-F15-A | 467.5 | 8.25 | 82.5 | 11 | 900 | 0 | 800 | 180 | 12 | 55.57 |

RCA0-F30 -A | 385 | 8.25 | 165 | 11 | 900 | 0 | 800 | 180 | 12 | 56.76 |

RCA0-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 900 | 0 | 800 | 180 | 12 | 56.25 |

RCA0-F0-A | 550 | 8.25 | 0 | 11 | 900 | 0 | 800 | 180 | 12 | 52.36 |

RCA0-F15-A | 467.5 | 8.25 | 82.5 | 11 | 900 | 0 | 800 | 180 | 12 | 61.35 |

RCA0-F30 -A | 385 | 8.25 | 165 | 11 | 900 | 0 | 800 | 180 | 12 | 63.17 |

RCA0-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 900 | 0 | 800 | 180 | 12 | 62.32 |

RCA0-F0-A | 550 | 8.25 | 0 | 11 | 900 | 0 | 800 | 180 | 12 | 56.34 |

RCA0-F15-A | 467.5 | 8.25 | 82.5 | 11 | 900 | 0 | 800 | 180 | 12 | 62.25 |

RCA0-F30 -A | 385 | 8.25 | 165 | 11 | 900 | 0 | 800 | 180 | 12 | 63.65 |

RCA0-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 900 | 0 | 800 | 180 | 12 | 64.19 |

RCA0-F0-A | 550 | 8.25 | 0 | 11 | 900 | 0 | 800 | 180 | 12 | 57.87 |

RCA0-F15-A | 467.5 | 8.25 | 82.5 | 11 | 900 | 0 | 800 | 180 | 12 | 63.23 |

RCA0-F30 -A | 385 | 8.25 | 165 | 11 | 900 | 0 | 800 | 180 | 12 | 64.28 |

RCA0-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 900 | 0 | 800 | 180 | 12 | 66.08 |

RCA0-F0-A | 550 | 8.25 | 0 | 11 | 900 | 0 | 800 | 180 | 12 | 58.67 |

RCA0-F15-A | 467.5 | 8.25 | 82.5 | 11 | 900 | 0 | 800 | 180 | 12 | 66.85 |

RCA0-F30 -A | 385 | 8.25 | 165 | 11 | 900 | 0 | 800 | 180 | 12 | 67.95 |

RCA0-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 900 | 0 | 800 | 180 | 12 | 68.64 |

RCA50-F0-A | 550 | 8.25 | 0 | 11 | 450 | 450 | 800 | 180 | 12 | 16.22 |

RCA50-F15-A | 467.5 | 8.25 | 82.5 | 11 | 450 | 450 | 800 | 180 | 12 | 16.16 |

RCA50-F30-A | 385 | 8.25 | 165 | 11 | 450 | 450 | 800 | 180 | 12 | 15.74 |

RCA50-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 450 | 450 | 800 | 180 | 12 | 15.38 |

RCA50-F0-A | 550 | 8.25 | 0 | 11 | 450 | 450 | 800 | 180 | 12 | 29.963 |

RCA50-F15-A | 467.5 | 8.25 | 82.5 | 11 | 450 | 450 | 800 | 180 | 12 | 30.8485 |

RCA50-F30-A | 385 | 8.25 | 165 | 11 | 450 | 450 | 800 | 180 | 12 | 32.541 |

RCA50-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 450 | 450 | 800 | 180 | 12 | 31.618 |

RCA50-F0-A | 550 | 8.25 | 0 | 11 | 450 | 450 | 800 | 180 | 12 | 43.23 |

RCA50-F15-A | 467.5 | 8.25 | 82.5 | 11 | 450 | 450 | 800 | 180 | 12 | 44.13 |

RCA50-F30-A | 385 | 8.25 | 165 | 11 | 450 | 450 | 800 | 180 | 12 | 46.51 |

RCA50-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 450 | 450 | 800 | 180 | 12 | 45.2 |

RCA50-F0-A | 550 | 8.25 | 0 | 11 | 450 | 450 | 800 | 180 | 12 | 48.82 |

RCA50-F15-A | 467.5 | 8.25 | 82.5 | 11 | 450 | 450 | 800 | 180 | 12 | 50.16 |

RCA50-F30-A | 385 | 8.25 | 165 | 11 | 450 | 450 | 800 | 180 | 12 | 51.63 |

RCA50-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 450 | 450 | 800 | 180 | 12 | 50.82 |

RCA50-F0-A | 550 | 8.25 | 0 | 11 | 450 | 450 | 800 | 180 | 12 | 50.67 |

RCA50-F15-A | 467.5 | 8.25 | 82.5 | 11 | 450 | 450 | 800 | 180 | 12 | 51.82 |

RCA50-F30-A | 385 | 8.25 | 165 | 11 | 450 | 450 | 800 | 180 | 12 | 53.22 |

RCA50-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 450 | 450 | 800 | 180 | 12 | 52.43 |

RCA50-F0-A | 550 | 8.25 | 0 | 11 | 450 | 450 | 800 | 180 | 12 | 52.54 |

RCA50-F15-A | 467.5 | 8.25 | 82.5 | 11 | 450 | 450 | 800 | 180 | 12 | 53.54 |

RCA50-F30-A | 385 | 8.25 | 165 | 11 | 450 | 450 | 800 | 180 | 12 | 54.84 |

RCA50-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 450 | 450 | 800 | 180 | 12 | 54.06 |

RCA50-F0-A | 550 | 8.25 | 0 | 11 | 450 | 450 | 800 | 180 | 12 | 55.38 |

RCA50-F15-A | 467.5 | 8.25 | 82.5 | 11 | 450 | 450 | 800 | 180 | 12 | 56.33 |

RCA50-F30-A | 385 | 8.25 | 165 | 11 | 450 | 450 | 800 | 180 | 12 | 58.17 |

RCA50-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 450 | 450 | 800 | 180 | 12 | 57.13 |

RCA75-F0-A | 550 | 8.25 | 0 | 11 | 225 | 675 | 800 | 180 | 12 | 15.28 |

RCA75-F15-A | 467.5 | 8.25 | 82.5 | 11 | 225 | 675 | 800 | 180 | 12 | 14.64 |

RCA75-F30-A | 385 | 8.25 | 165 | 11 | 225 | 675 | 800 | 180 | 12 | 14.61 |

RCA75-F45-A | 302.5 | 8.25 | 247.5 | 11 | 225 | 675 | 800 | 180 | 12 | 14.23 |

RCA75-F0-A | 550 | 8.25 | 0 | 11 | 225 | 675 | 800 | 180 | 12 | 24.936 |

RCA75-F15-A | 467.5 | 8.25 | 82.5 | 11 | 225 | 675 | 800 | 180 | 12 | 26.103 |

RCA75-F30-A | 385 | 8.25 | 165 | 11 | 225 | 675 | 800 | 180 | 12 | 26.7875 |

RCA75-F45-A | 302.5 | 8.25 | 247.5 | 11 | 225 | 675 | 800 | 180 | 12 | 28.057 |

RCA75-F0-A | 550 | 8.25 | 0 | 11 | 225 | 675 | 800 | 180 | 12 | 35.67 |

RCA75-F15-A | 467.5 | 8.25 | 82.5 | 11 | 225 | 675 | 800 | 180 | 12 | 37.26 |

RCA75-F30-A | 385 | 8.25 | 165 | 11 | 225 | 675 | 800 | 180 | 12 | 38.15 |

RCA75-F45-A | 302.5 | 8.25 | 247.5 | 11 | 225 | 675 | 800 | 180 | 12 | 39.56 |

RCA75-F0-A | 550 | 8.25 | 0 | 11 | 225 | 675 | 800 | 180 | 12 | 40.65 |

RCA75-F15-A | 467.5 | 8.25 | 82.5 | 11 | 225 | 675 | 800 | 180 | 12 | 41.81 |

RCA75-F30-A | 385 | 8.25 | 165 | 11 | 225 | 675 | 800 | 180 | 12 | 42.55 |

RCA75-F45-A | 302.5 | 8.25 | 247.5 | 11 | 225 | 675 | 800 | 180 | 12 | 44.28 |

RCA75-F0-A | 550 | 8.25 | 0 | 11 | 225 | 675 | 800 | 180 | 12 | 42.26 |

RCA75-F15-A | 467.5 | 8.25 | 82.5 | 11 | 225 | 675 | 800 | 180 | 12 | 43.79 |

RCA75-F30-A | 385 | 8.25 | 165 | 11 | 225 | 675 | 800 | 180 | 12 | 44.51 |

RCA75-F45-A | 302.5 | 8.25 | 247.5 | 11 | 225 | 675 | 800 | 180 | 12 | 46.09 |

RCA75-F0-A | 550 | 8.25 | 0 | 11 | 225 | 675 | 800 | 180 | 12 | 43.92 |

RCA75-F15-A | 467.5 | 8.25 | 82.5 | 11 | 225 | 675 | 800 | 180 | 12 | 45.78 |

RCA75-F30-A | 385 | 8.25 | 165 | 11 | 225 | 675 | 800 | 180 | 12 | 46.52 |

RCA75-F45-A | 302.5 | 8.25 | 247.5 | 11 | 225 | 675 | 800 | 180 | 12 | 47.98 |

RCA75-F0-A | 550 | 8.25 | 0 | 11 | 225 | 675 | 800 | 180 | 12 | 47.29 |

RCA75-F15-A | 467.5 | 8.25 | 82.5 | 11 | 225 | 675 | 800 | 180 | 12 | 48.99 |

RCA75-F30-A | 385 | 8.25 | 165 | 11 | 225 | 675 | 800 | 180 | 12 | 49.81 |

RCA75-F45-A | 302.5 | 8.25 | 247.5 | 11 | 225 | 675 | 800 | 180 | 12 | 51.24 |

RCA100-F0-A | 550 | 8.25 | 0 | 11 | 0 | 900 | 800 | 180 | 12 | 13.23 |

RCA100-F15-A | 467.5 | 8.25 | 82.5 | 11 | 0 | 900 | 800 | 180 | 12 | 12.28 |

RCA100-F30 -A | 385 | 8.25 | 165 | 11 | 0 | 900 | 800 | 180 | 12 | 12.07 |

RCA100-F45-A | 302.5 | 8.25 | 247.5 | 11 | 0 | 900 | 800 | 180 | 12 | 12.35 |

RCA100-F0-A | 550 | 8.25 | 0 | 11 | 0 | 900 | 800 | 180 | 12 | 20.638 |

RCA100-F15-A | 467.5 | 8.25 | 82.5 | 11 | 0 | 900 | 800 | 180 | 12 | 21.4235 |

RCA100-F30 -A | 385 | 8.25 | 165 | 11 | 0 | 900 | 800 | 180 | 12 | 22.9925 |

RCA100-F45-A | 302.5 | 8.25 | 247.5 | 11 | 0 | 900 | 800 | 180 | 12 | 22.6855 |

RCA100-F0-A | 550 | 8.25 | 0 | 11 | 0 | 900 | 800 | 180 | 12 | 29.36 |

RCA100-F15-A | 467.5 | 8.25 | 82.5 | 11 | 0 | 900 | 800 | 180 | 12 | 30.41 |

RCA100-F30 -A | 385 | 8.25 | 165 | 11 | 0 | 900 | 800 | 180 | 12 | 32.28 |

RCA100-F45-A | 302.5 | 8.25 | 247.5 | 11 | 0 | 900 | 800 | 180 | 12 | 31.72 |

RCA100-F0-A | 550 | 8.25 | 0 | 11 | 0 | 900 | 800 | 180 | 12 | 32.82 |

RCA100-F15-A | 467.5 | 8.25 | 82.5 | 11 | 0 | 900 | 800 | 180 | 12 | 34.15 |

RCA100-F30 -A | 385 | 8.25 | 165 | 11 | 0 | 900 | 800 | 180 | 12 | 35.53 |

RCA100-F45-A | 302.5 | 8.25 | 247.5 | 11 | 0 | 900 | 800 | 180 | 12 | 35.35 |

RCA100-F0-A | 550 | 8.25 | 0 | 11 | 0 | 900 | 800 | 180 | 12 | 34.51 |

RCA100-F15-A | 467.5 | 8.25 | 82.5 | 11 | 0 | 900 | 800 | 180 | 12 | 35.98 |

RCA100-F30 -A | 385 | 8.25 | 165 | 11 | 0 | 900 | 800 | 180 | 12 | 37.17 |

RCA100-F45-A | 302.5 | 8.25 | 247.5 | 11 | 0 | 900 | 800 | 180 | 12 | 36.96 |

RCA100-F0-A | 550 | 8.25 | 0 | 11 | 0 | 900 | 800 | 180 | 12 | 36.22 |

RCA100-F15-A | 467.5 | 8.25 | 82.5 | 11 | 0 | 900 | 800 | 180 | 12 | 37.86 |

RCA100-F30 -A | 385 | 8.25 | 165 | 11 | 0 | 900 | 800 | 180 | 12 | 38.84 |

RCA100-F45-A | 302.5 | 8.25 | 247.5 | 11 | 0 | 900 | 800 | 180 | 12 | 38.62 |

RCA100-F0-A | 550 | 8.25 | 0 | 11 | 0 | 900 | 800 | 180 | 12 | 40.26 |

RCA100-F15-A | 467.5 | 8.25 | 82.5 | 11 | 0 | 900 | 800 | 180 | 12 | 41.43 |

RCA100-F30 -A | 385 | 8.25 | 165 | 11 | 0 | 900 | 800 | 180 | 12 | 43.02 |

RCA100-F45-A | 302.5 | 8.25 | 247.5 | 11 | 0 | 900 | 800 | 180 | 12 | 42.67 |

Annexure-B (acid attack results)

Mix ID | Cement (kg/m3) | Nano silica (kg/m3) | Fly ash (kg/m3) | Na2SO4 (kg/m3) | NCA (kg/m3) | RCA (kg/m3) | Sand (kg/m3) | Water (kg/m3) | SP (kg/m3) | Months | Compressive strength (MPa) |

|---|---|---|---|---|---|---|---|---|---|---|---|

RCA0-F0 | 550 | 8.25 | 0 | 0 | 900 | 0 | 800 | 180 | 12 | 1 | 31.28 |

RCA0-F15 | 467.5 | 8.25 | 82.5 | 0 | 900 | 0 | 800 | 180 | 12 | 1 | 33.55 |

RCA0-F30 | 385 | 8.25 | 165 | 0 | 900 | 0 | 800 | 180 | 12 | 1 | 35.24 |

RCA0-F45 | 302.5 | 8.25 | 247.5 | 0 | 900 | 0 | 800 | 180 | 12 | 1 | 34.72 |

RCA0-F0 | 550 | 8.25 | 0 | 0 | 900 | 0 | 800 | 180 | 12 | 2 | 29.72 |

RCA0-F15 | 467.5 | 8.25 | 82.5 | 0 | 900 | 0 | 800 | 180 | 12 | 2 | 31.86 |

RCA0-F30 | 385 | 8.25 | 165 | 0 | 900 | 0 | 800 | 180 | 12 | 2 | 33.64 |

RCA0-F45 | 302.5 | 8.25 | 247.5 | 0 | 900 | 0 | 800 | 180 | 12 | 2 | 32.87 |

RCA0-F0 | 550 | 8.25 | 0 | 0 | 900 | 0 | 800 | 180 | 12 | 3 | 27.54 |

RCA0-F15 | 467.5 | 8.25 | 82.5 | 0 | 900 | 0 | 800 | 180 | 12 | 3 | 29.61 |

RCA0-F30 | 385 | 8.25 | 165 | 0 | 900 | 0 | 800 | 180 | 12 | 3 | 31.31 |

RCA0-F45 | 302.5 | 8.25 | 247.5 | 0 | 900 | 0 | 800 | 180 | 12 | 3 | 30.65 |

RCA0-F0 | 550 | 8.25 | 0 | 0 | 900 | 0 | 800 | 180 | 12 | 4 | 25.98 |

RCA0-F15 | 467.5 | 8.25 | 82.5 | 0 | 900 | 0 | 800 | 180 | 12 | 4 | 28.08 |

RCA0-F30 | 385 | 8.25 | 165 | 0 | 900 | 0 | 800 | 180 | 12 | 4 | 29.78 |

RCA0-F45 | 302.5 | 8.25 | 247.5 | 0 | 900 | 0 | 800 | 180 | 12 | 4 | 29.20 |

RCA0-F0-A | 550 | 8.25 | 0 | 11 | 900 | 0 | 800 | 180 | 12 | 1 | 31.28 |

RCA0-F15-A | 467.5 | 8.25 | 82.5 | 11 | 900 | 0 | 800 | 180 | 12 | 1 | 37.06 |

RCA0-F30 -A | 385 | 8.25 | 165 | 11 | 900 | 0 | 800 | 180 | 12 | 1 | 38.25 |

RCA0-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 900 | 0 | 800 | 180 | 12 | 1 | 37.96 |

RCA0-F0-A | 550 | 8.25 | 0 | 11 | 900 | 0 | 800 | 180 | 12 | 2 | 29.71 |

RCA0-F15-A | 467.5 | 8.25 | 82.5 | 11 | 900 | 0 | 800 | 180 | 12 | 2 | 33.82 |

RCA0-F30 -A | 385 | 8.25 | 165 | 11 | 900 | 0 | 800 | 180 | 12 | 2 | 35.53 |

RCA0-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 900 | 0 | 800 | 180 | 12 | 2 | 35.64 |

RCA0-F0-A | 550 | 8.25 | 0 | 11 | 900 | 0 | 800 | 180 | 12 | 3 | 27.54 |

RCA0-F15-A | 467.5 | 8.25 | 82.5 | 11 | 900 | 0 | 800 | 180 | 12 | 3 | 28.64 |

RCA0-F30 -A | 385 | 8.25 | 165 | 11 | 900 | 0 | 800 | 180 | 12 | 3 | 30.24 |

RCA0-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 900 | 0 | 800 | 180 | 12 | 3 | 30.73 |

RCA0-F0-A | 550 | 8.25 | 0 | 11 | 900 | 0 | 800 | 180 | 12 | 4 | 25.98 |

RCA0-F15-A | 467.5 | 8.25 | 82.5 | 11 | 900 | 0 | 800 | 180 | 12 | 4 | 22.99 |

RCA0-F30 -A | 385 | 8.25 | 165 | 11 | 900 | 0 | 800 | 180 | 12 | 4 | 24.59 |

RCA0-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 900 | 0 | 800 | 180 | 12 | 4 | 25.40 |

RCA50-F0-A | 550 | 8.25 | 0 | 11 | 450 | 450 | 800 | 180 | 12 | 1 | 28.13 |

RCA50-F15-A | 467.5 | 8.25 | 82.5 | 11 | 450 | 450 | 800 | 180 | 12 | 1 | 29.20 |

RCA50-F30-A | 385 | 8.25 | 165 | 11 | 450 | 450 | 800 | 180 | 12 | 1 | 30.85 |

RCA50-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 450 | 450 | 800 | 180 | 12 | 1 | 30.06 |

RCA50-F0-A | 550 | 8.25 | 0 | 11 | 450 | 450 | 800 | 180 | 12 | 2 | 25.26 |

RCA50-F15-A | 467.5 | 8.25 | 82.5 | 11 | 450 | 450 | 800 | 180 | 12 | 2 | 26.33 |

RCA50-F30-A | 385 | 8.25 | 165 | 11 | 450 | 450 | 800 | 180 | 12 | 2 | 28.00 |

RCA50-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 450 | 450 | 800 | 180 | 12 | 2 | 27.52 |

RCA50-F0-A | 550 | 8.25 | 0 | 11 | 450 | 450 | 800 | 180 | 12 | 3 | 20.30 |

RCA50-F15-A | 467.5 | 8.25 | 82.5 | 11 | 450 | 450 | 800 | 180 | 12 | 3 | 21.40 |

RCA50-F30-A | 385 | 8.25 | 165 | 11 | 450 | 450 | 800 | 180 | 12 | 3 | 22.92 |

RCA50-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 450 | 450 | 800 | 180 | 12 | 3 | 22.68 |

RCA50-F0-A | 550 | 8.25 | 0 | 11 | 450 | 450 | 800 | 180 | 12 | 4 | 15.70 |

RCA50-F15-A | 467.5 | 8.25 | 82.5 | 11 | 450 | 450 | 800 | 180 | 12 | 4 | 16.85 |

RCA50-F30-A | 385 | 8.25 | 165 | 11 | 450 | 450 | 800 | 180 | 12 | 4 | 18.21 |

RCA50-F45 -A | 302.5 | 8.25 | 247.5 | 11 | 450 | 450 | 800 | 180 | 12 | 4 | 18.22 |

RCA75-F0-A | 550 | 8.25 | 0 | 11 | 225 | 675 | 800 | 180 | 12 | 1 | 23.30 |

RCA75-F15-A | 467.5 | 8.25 | 82.5 | 11 | 225 | 675 | 800 | 180 | 12 | 1 | 24.59 |

RCA75-F30-A | 385 | 8.25 | 165 | 11 | 225 | 675 | 800 | 180 | 12 | 1 | 25.39 |

RCA75-F45-A | 302.5 | 8.25 | 247.5 | 11 | 225 | 675 | 800 | 180 | 12 | 1 | 26.77 |

RCA75-F0-A | 550 | 8.25 | 0 | 11 | 225 | 675 | 800 | 180 | 12 | 2 | 20.61 |

RCA75-F15-A | 467.5 | 8.25 | 82.5 | 11 | 225 | 675 | 800 | 180 | 12 | 2 | 21.93 |

RCA75-F30-A | 385 | 8.25 | 165 | 11 | 225 | 675 | 800 | 180 | 12 | 2 | 22.86 |

RCA75-F45-A | 302.5 | 8.25 | 247.5 | 11 | 225 | 675 | 800 | 180 | 12 | 2 | 24.27 |

RCA75-F0-A | 550 | 8.25 | 0 | 11 | 225 | 675 | 800 | 180 | 12 | 3 | 15.92 |

RCA75-F15-A | 467.5 | 8.25 | 82.5 | 11 | 225 | 675 | 800 | 180 | 12 | 3 | 17.13 |

RCA75-F30-A | 385 | 8.25 | 165 | 11 | 225 | 675 | 800 | 180 | 12 | 3 | 18.24 |

RCA75-F45-A | 302.5 | 8.25 | 247.5 | 11 | 225 | 675 | 800 | 180 | 12 | 3 | 19.58 |

RCA75-F0-A | 550 | 8.25 | 0 | 11 | 225 | 675 | 800 | 180 | 12 | 4 | 11.91 |

RCA75-F15-A | 467.5 | 8.25 | 82.5 | 11 | 225 | 675 | 800 | 180 | 12 | 4 | 12.90 |

RCA75-F30-A | 385 | 8.25 | 165 | 11 | 225 | 675 | 800 | 180 | 12 | 4 | 13.96 |

RCA75-F45-A | 302.5 | 8.25 | 247.5 | 11 | 225 | 675 | 800 | 180 | 12 | 4 | 15.12 |

RCA100-F0-A | 550 | 8.25 | 0 | 11 | 0 | 900 | 800 | 180 | 12 | 1 | 19.08 |

RCA100-F15-A | 467.5 | 8.25 | 82.5 | 11 | 0 | 900 | 800 | 180 | 12 | 1 | 19.97 |

RCA100-F30 -A | 385 | 8.25 | 165 | 11 | 0 | 900 | 800 | 180 | 12 | 1 | 21.53 |

RCA100-F45-A | 302.5 | 8.25 | 247.5 | 11 | 0 | 900 | 800 | 180 | 12 | 1 | 21.30 |

RCA100-F0-A | 550 | 8.25 | 0 | 11 | 0 | 900 | 800 | 180 | 12 | 2 | 16.44 |

RCA100-F15-A | 467.5 | 8.25 | 82.5 | 11 | 0 | 900 | 800 | 180 | 12 | 2 | 17.43 |

RCA100-F30 -A | 385 | 8.25 | 165 | 11 | 0 | 900 | 800 | 180 | 12 | 2 | 18.92 |

RCA100-F45-A | 302.5 | 8.25 | 247.5 | 11 | 0 | 900 | 800 | 180 | 12 | 2 | 18.88 |

RCA100-F0-A | 550 | 8.25 | 0 | 11 | 0 | 900 | 800 | 180 | 12 | 3 | 12.07 |

RCA100-F15-A | 467.5 | 8.25 | 82.5 | 11 | 0 | 900 | 800 | 180 | 12 | 3 | 12.96 |

RCA100-F30 -A | 385 | 8.25 | 165 | 11 | 0 | 900 | 800 | 180 | 12 | 3 | 14.28 |

RCA100-F45-A | 302.5 | 8.25 | 247.5 | 11 | 0 | 900 | 800 | 180 | 12 | 3 | 14.52 |

RCA100-F0-A | 550 | 8.25 | 0 | 11 | 0 | 900 | 800 | 180 | 12 | 4 | 8.38 |

RCA100-F15-A | 467.5 | 8.25 | 82.5 | 11 | 0 | 900 | 800 | 180 | 12 | 4 | 9.02 |

RCA100-F30 -A | 385 | 8.25 | 165 | 11 | 0 | 900 | 800 | 180 | 12 | 4 | 10.09 |

RCA100-F45-A | 302.5 | 8.25 | 247.5 | 11 | 0 | 900 | 800 | 180 | 12 | 4 | 10.42 |

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Khan, M.A., Ashraf, M.S., Onyelowe, K.C. et al. Machine learning predictions of high-strength RCA concrete utilizing chemically activated fly ash and nano-silica. Sci Rep 15, 10255 (2025). https://doi.org/10.1038/s41598-025-94387-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-94387-2

Keywords

This article is cited by

-

Modeling the mechanical properties of lightweight high-strength concrete incorporating supplementary cementitious materials using multi-expression programming and random forest

Scientific Reports (2026)

-

Multi-scale theoretical modeling with molecular simulation framework for fly ash-based high-performance concrete

Scientific Reports (2025)

-

Performance optimization of rigid pavement concrete using metakaolin treated RCA and silica fume with an experimental and machine learning based approach

Scientific Reports (2025)

-

Influence of colloidal nano silica on solidification mechanisms and hydration process of nano modified cement

Scientific Reports (2025)