Abstract

This study has focused on enhancing the effectiveness of supercapacitors, which are crucial for energy storage applications. Traditionally, supercapacitors have faced challenges in achieving higher energy density than batteries. This study hypothesizes that modifying the anionic structure of lithium cobalt oxide can significantly improve supercapacitors’ energy density and charge storage capability. Lithium cobalt oxide was synthesized by sol–gel method, and LiCoO2−x(F0.8Cl0.2)x with x = 0.1, 0.2, and 0.4 (F = 0.8x, Cl = 0.2x), was obtained by anion-exchange method. The structure and crystalline nature of the synthesized samples were analyzed using Fourier-transform infrared spectroscopy, powder X-ray diffraction, and X-ray photoelectron spectroscopy. To further confirm the correctness of the structures, microstructural and morphological studies were conducted using Field emission scanning electron microscopy and Transmission electron microscopy. The charge–discharge investigations showed that the electrode made of LiCoO1.6(F0.8Cl0.2)0.4 had a high specific capacitance (522.16 F g−1 at a current density of 1 A g−1) compared to the Lithium Cobalt Oxide electrode. In addition, it showed a fabulous cycle life stability with 92.04% coulombic efficiency after 4000 charge–discharge cycles.

Similar content being viewed by others

Introduction

To achieve a carbon–neutral environment, it is imperative to replace fossil fuel-based energy technologies with more stable and sustainable energy solutions1. Among the most promising innovations in energy generation and storage are supercapacitors. Supercapacitors exhibit superior capabilities, including high energy density, excellent power density, long cycle life, and rapid charging and discharging abilities2,3. These remarkable characteristics enable supercapacitors to effectively bridge the gap between conventional capacitors3,4. In the realm of energy storage, lithium cobalt oxide (LiCoO2) nanostructures play a vital role, particularly in lithium-ion batteries and supercapacitors5. LiCoO2 nanostructures are characterized by their unique atomic arrangement, which can be engineered at the nanoscale to optimize performance. By manipulating synthesis processes, such as sol–gel methods6, hydrothermal synthesis7, or electrochemical deposition8, researchers can create nanostructures with high surface area and tailored morphologies. These enhancements can significantly increase accessible surface areas compared to bulk materials. The increased surface area improves the contact between LiCoO2 and the electrolyte, facilitating better interaction with electrolyte ions essential for electrochemical reactions9. The increased surface area of LiCoO2 nanostructures directly contributes to enhanced ionic conductivity, which refers to the ability of ions to move through a material10. Although LiCoO2 demonstrates impressive performance, it is crucial to consider alternative materials in the field of supercapacitors. Other promising candidates include mesoporous dark brown TiO2 spheres, fabricated using sol–gel method, with a maximum capacitance of approximately 93 F g−1 at a scan rate of 10 mV s−1. The incorporation of Ti+3 and oxygen vacancies enhance their electrical properties, making them suitable as electrode materials11. Other transition metal oxides, such as MnO212 and NiO13, are frequently studied for their high capacitance but face challenges in terms of conductivity and stability. Conductive polymers, such as polyaniline and polypyrrole14, offer good capacitance but may lack the stability required for long-term applications. Metal-cobalt oxides, including LiCoO2, have also been recognized for their roles in perovskite solar cells, serving as functional layers that enhance charge transport15,16,17. Supercapacitors fall into two main types based on their electrochemical response and charge–discharge mechanisms. These are Electric Double-Layer Capacitors (EDLCs) in which the energy formed in the Helmholtz double layers is stored at the interface between the electrolyte and the electrode through electrochemical interactions18,19, and Pseudo-capacitors, which work through redox interactions rather than just electrostatic interactions20,21. The energy storage mechanism in pseudo-capacitors involves reversible Faradaic reactions at the electrode–electrolyte interface. The key differences between these two types of supercapacitors lie in their charge–discharge mechanisms and the underlying electrochemical processes involved in energy storage22,23. The electrochemical performance of LiCoO2 can be enhanced by modulating its electronic structure, as evidenced by studies that report improvements through partial substitution of Mg in delaminated LiCoO224, 1.0% doping of La into LiCoO29, and incorporation of Fe into LiCoO2 (LiCo0.8Fe0.2O2 as the optimized composition)10. Anion engineering, on the other hand, is a simple and applicable concept to improve the performance of supercapacitors and batteries. This technique allows for the adjustment of the electronic properties of transition metal oxides while mitigating defects in the lattice structure15,25. Anion engineering can be divided into two primary methods: doping and anion exchange. Doping involves the intentional inclusion of different anions into the host material to modify its electronic structure and improve its electrochemical properties26,27. Anion exchange, a simplified form of anion engineering, enables the partial substitution of anions in mixed metal oxides, thereby enhancing their electrochemical properties28. This method is effective in tuning the electronic nature of transition metal oxides and can help mitigate defects that may hinder performance27,29. Previously, an asymmetric supercapacitor was developed by assembling a system based on LiCoO2/Co3O4 and graphene oxide (GO) and demonstrated great performance in achieving a maximum energy density of 19.05 Wh kg−130. This is a significant improvement compared to the common energy densities of 5–8 Wh kg−1 reported for EDLCs, suggesting that LiCoO2 can enhance the energy density of supercapacitors31.

Intrigued by these reports, we considered the utilization of anion engineering technique through partial anion exchange of LiCoO2 with F− and Cl− to improve the energy density and charge storage capability in supercapacitors. As expected, the anion-exchanged LiCoO2 samples, especially LiCoO1.6(F0.8Cl0.2)0.4, exhibited remarkably high specific capacitance of 522.16 F g−1 during the cycling process, with an energy density of 93.98 Wh kg−1 and a power density of 0.3 kW kg−1 at a current density of 1 A g−1. The maximum specific capacitance reached 545 F g−1, with a capacitance retention of 93.6% at 1 A g−1 over 2000 consecutive cycles. This performance is significantly higher than many conventional supercapacitor materials, such as activated carbon, which typically offers energy densities in the range of 5–8 Wh kg−132, and even other metal oxides. For instance, recent studies have reported specific capacitances of around 300–400 F g−112,13 for various metal oxides such as MnO2 and NiO, making the performance of LiCoO1.6(F0.8Cl0.2)0.4 particularly noteworthy. This highlights its potential for applications requiring high energy and power density, such as electric vehicles and portable electronics.

Experimental

Synthesis of LiCoO2

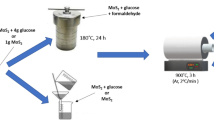

Lithium cobalt oxide (LiCoO2) was synthesized using the sol–gel method33,34. Cobalt(II) acetate tetrahydrate and lithium hydroxide (1.0 mmol of each) were first dissolved in a mixture of deionized water (10 mL) and ethanol (1.5 mL) in an Erlenmeyer flask. The flask was then placed in an ultrasonic bath for 30 min. The homogenized solution was then magnetically stirred at 50 °C, while 1.5 M acetic acid was added dropwise until a color change was observed. Then, NaOH (1.0 M) was slowly added to adjust the pH to 7.0. The solution was magnetically stirred at 90 °C to form a gel. After aging for 4 h, the suspension was filtered, washed thoroughly with deionized water, and oven-dried at 100 °C for 24 h. The dried gel was then placed into a furnace and calcined at 450 °C for 5 h (Fig. 1a).

Anion engineering via anion exchange

Sodium fluoride and ammonium chloride were used to exchange the oxide anions in LiCoO2. To obtain LiCoO2−x(F0.8Cl0.2)x with x = 0.1, 0.2, and 0.4 is also illustrated in Fig. 1b, the required amounts of sodium fluoride and ammonium chloride were independently dissolved in 5 mL of a 1:1 mixture of water and dimethylformamide (DMF), in separate beakers. The two solutions were then mixed and magnetically stirred for 20 min. Lithium cobalt oxide was then added to the mixture and stirred for 24 h at room temperature. After this time, the dispersion was transferred to test tubes, centrifuged, and dried in an oven at 80 °C for 6 h.

Characterization

Characterization of the synthesized compounds was achieved by Fourier-transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), Energy-dispersive X-ray spectroscopy (EDS), X-ray photoelectron spectroscopy (XPS), field emission scanning electron microscopy (FESEM), and transmission electron microscopy (TEM).

Electrochemical analysis

The working electrodes were prepared by blending lithium cobalt oxide and LiCoO1.6(F0.8Cl0.2)0.4 (separately), acetylene black, and polyvinylidene fluoride (PVDF) in a weight ratio of 80:10:10. This mixture was dispersed in N-methyl-2-pyrrolidone (NMP) to form a slurry, and then coated onto a nickel foam (1.0 cm × 1.0 cm) by applying pressure. The mass loading of active material was about 4.5 mg cm−2 for each electrode. The coated electrodes were dried at 85 °C for 9 h. For the electrochemical evaluations, a platinum electrode was utilized as the counter electrode, along with an Ag/AgCl reference electrode in a 2 M KOH electrolyte. The electrochemical characterization techniques included cyclic voltammetry (CV), performed at scan rates of 0.005, 0.01, 0.02 and 0.05 V s−1; galvanostatic tests, carried out at current densities of 1, 2, 5, and 10 A g−1; and electrochemical impedance spectroscopy (EIS) measurements, performed from 100 MHz to 10 kHz at the open-circuit potential, with an AC voltage amplitude of 0.005 V15.

Results and discussion

Figure 2 illustrates the FTIR spectra of LiCoO2 and LiCoO1.6(F0.8Cl0.2)0.4. In the spectrum of LiCoO2, the peaks at 555 and 600 cm−1 are attributed to the symmetric and asymmetric vibrations of O–Co–O in the octahedral sites35. The corresponding peaks of O–Li–O vibrations are expected to be seen in the far IR region, beyond the range of conventional FTIR instruments. These are in good agreement with the reported data in the literature35. In the FTIR spectrum of LiCoO1.6(F0.8Cl0.2)0.4, the symmetric O–Co–O vibrations are slightly shifted to 530, and asymmetric vibrations of O–Co–O appear at 600 cm−1. In addition, two new peaks appear at 670 and 780 cm−1, which can be attributed to the symmetric and asymmetric stretching vibrations of F–Co–F in the octahedral sites. The Cl–O–Cl counterparts are also expected to show their footprint in the far IR region, due to the higher atomic mass of chlorine.

The X-ray diffraction (XRD) patterns for the synthesized samples are presented in Fig. 3a. The diffraction peaks of LiCoO2 appeared at 2θ 19.2, 37.7, 38.7, 39.4, 45.5, 49.7, 59.9, 65.7, 66.6 and 69.9º. The peaks for LiCoO1.6(F0.8Cl0.2)0.4 appeared at 2θ 19.3, 35.4, 36.6, 39.1, 44.3, 48.3, 58.7, 64.6, 67.1 and 69.6º. In both patterns, the peaks correspond to the (003), (101), (006), (102), (015), (110), (113), (009), (201) and (202) crystallographic planes, indicating that they crystallized in a layered structure with a rhombohedral crystal system and R-3 m space group (JCPDS card No.: 01-080 for LiCoO2, and JCPDS card No.01-082 for LiCoO1.6(F0.8Cl0.2)0.4)1,34. Figure 3b represents a schematic illustration of the anticipated crystal structures. In the XRD pattern of LiCoO1.6(F0.8Cl0.2)0.4, however, a small change in the d-spacing, and a slight decrease in the peak intensities were also observed (Table 1). The X-ray photoelectron survey spectra of LiCoO2 and LiCoO1.6(F0.8Cl0.2)0.4 are shown in Fig. 3e and f. In the LiCoO1.6(F0.8Cl0.2)0.4 spectrum, peaks related to chlorine and fluorine are visible at 201.2 eV and 685.5 eV respectively, while the F 1s peak exhibits higher intensity, which can be attributed to the higher proportion of F compared to Cl 2p. The Co 2p signal (Fig. 3c) showed two notable peaks at binding energies of 779.9 eV and 795.1 eV, corresponding to the Co 2p3/2 and Co 2p1/2 states, respectively16. A significant positive shift in binding energy was observed when comparing LiCoO1.6(F0.8 Cl0.2)0.4 with unmodified LiCoO2. The higher binding energy of the Co 2p peaks in LiCoO1.6 (F0.8Cl0.2)0.4 suggests a partial reduction of Co3+ to Co2+, which is attributed to a decrease in the anion valence state and the formation of oxygen vacancies. As the cation state decreases, the bond strength between LiCoO1.6(F0.8Cl0.2)0.4 and the reaction intermediates weakens36. Figure 3d represents the O 1s XPS spectra for both LiCoO2 and LiCoO1.6(F0.8Cl0.2)0.4, showing four distinct peaks corresponding to various oxygen species: lattice oxygen (O2−, at 529.2 eV), highly oxidative oxygen (O22−/O−, at 530.1 eV), hydroxyl groups or surface-adsorbed oxygen (OH− or O2, approximately at 531.5 eV), and adsorbed water (H2O, at 533.05 eV)37. This finding is consistent with the established notion that the species O22−/O− are closely linked to oxygen vacancies, which are known to serve as active sites for enhanced supercapacitor’s electrochemical performance. The elevated concentration of O22−/O− in LiCoO1.6(F0.8Cl0.2)0.4 contributes to a significant enhancement in the supercapacitor’s performance. The incorporation of fluoride and chlorine improves both the structural and electronic characteristics of the supercapacitor, consequently, making LiCoO1.6(F0.8Cl0.2)0.4 a more efficient material for electrochemical reactions38.

(a) XRD patterns of LiCoO1.6(F0.8Cl0.2)0.4 and LiCoO2. (b) Schematic illustration of the crystal structures of LiCoO2 and anion-exchanged LiCoO2 with F− and Cl−. (c) Co 2p XPS spectra and (d) O 1 s XPS spectra of LiCoO2 and LiCoO1.6(F0.8Cl0.2)0.4. (e) and (f) XPS spectrum of LiCoO2 and LiCoO1.6(F0.8Cl0.2)0.4.

The field emission scanning electron microscopy (FESEM) micrographs are presented in Fig. 4a–f to provide insightful visualization of the morphological characteristics of the LiCoO1.6(F0.8Cl0.2)0.4 sample. The images clearly illustrate an almost-uniform arrangement of crystalline nanoparticles, indicative of a well-defined synthesis process. The observed morphology closely resembles that of LiCoO2 crystallites, suggesting that the anion exchange has not significantly altered the fundamental crystalline structure, but rather enhanced its uniformity and stability. The nanoparticles exhibit a polyhedral shape with smooth edges, which is advantageous for electrochemical applications. This morphology can facilitate efficient ion transport and enhance the electroactive surface area, thus potentially improving the charge storage capabilities of the material. The presence of smooth edges may also minimize defects that could impede ionic movement, contributing to better performance in supercapacitor applications. The energy dispersive spectroscopy (EDS) results, accompanied with elemental mapping in Fig. 4g,h, further confirm the successful synthesis of the LiCoO1.6(F0.8Cl0.2)0.4 compound. The EDS spectrum showed distinct peaks corresponding to the K and L lines of the anticipated elements, including lithium (Li), cobalt (Co), fluorine (F), and chlorine (Cl). This indicates the successful incorporation of the doped anions into the structure. The elemental mapping analysis revealed a uniform distribution of these elements throughout the sample, which is critical for ensuring consistent electrochemical properties. Homogeneous dispersion of the active elements is essential for achieving uniform charge storage and efficient energy transfer during electrochemical cycles. The absence of significant clustering or segregation of elements suggests that the anion exchange process effectively integrated the new anions, enhancing the material’s stability and performance. The histogram plot in Fig. 4i illustrates the particle size distribution for the compound LiCoO1.6(F0.8Cl0.2)0.4. The data indicates a mean particle size of 28.54 nm with a standard deviation of ± 0.46 nm. The histogram is overlaid with a normal distribution curve, suggesting that the particle sizes are approximately normally distributed around the mean. This analysis provides insight into the uniformity and consistency of the synthesized particles, which are crucial for the material’s performance in its intended applications. The transmission electron microscopy (TEM) images in Fig. 5a–d provide a detailed visualization of the LiCoO1.6(F0.8Cl0.2)0.4 nanoparticles. These images reveal the polyhedral morphology of the nanoparticles, showcasing their size distribution within the range of 10–50 nm. The high-resolution TEM images highlight the uniformity in shape and size, indicating a well-controlled synthesis process. Such homogeneity in the nanoparticle structure is crucial for ensuring consistent material properties, which can enhance the performance and reliability of the material in its applications.38,39.

Cyclic voltammetry (CV) measurements were conducted on both LiCoO1.6(F0.8Cl0.2)0.4 and LiCoO2 samples at various sweep rates. To achieve the best performance of the anion-exchanged sample, compared to the LiCoO2, three different anion exchange molar ratios (0.1, 0.2. 0.4) were considered, and the anion exchange was carried out accordingly. From Fig. 6a, it is clear that LiCoO1.6(F0.8Cl0.2)0.4 had the largest area under the CV curve. The other anion exchange ratios, also, performed better than the LiCoO2. The anion exchange process enhances the structural integrity and stability of the electrodes. The selection of x values (0.1, 0.2, and 0.4) was driven by the desire to systematically explore the effect of anion substitution on the material’s properties. These specific values allow for a parametric study to assess how varying degrees of fluoride and chloride substitution influence the structural integrity, electronic properties, and overall performance of the material. The limiting factor for x was primarily the structural stability of the lithium cobalt oxide matrix. Excessive substitution disrupted the crystal lattice, leading to degradation of the desired properties. Therefore, x values beyond 0.4 might compromise the stability and functionality of the compound, making it essential to maintain a balance between substitution and structural integrity. The 0.4 ratio likely leads to a more favorable arrangement of active sites, allowing for greater interaction with hydroxide ions (OH−) in the KOH electrolyte. At the 0.4 molar ratio, the nanostructured material potentially exhibits a greater surface area, which enhances the electrochemical interface. This increase allows for more active sites to be available for charge storage, leading to a larger integrated current response during the CV measurement. Consequently, 0.4 was selected as the optimal ratio and was used for further studies. The CV curves showed redox peaks, likely attributed to the quasi-reversible conversion of cobalt(III) to cobalt (II) due to the presence of hydroxide ions (OH−) in the basic KOH electrolyte. This quasi-capacitive behavior was observed for both materials40,41. However, the LiCoO1.6(F0.8Cl0.2)0.4 sample exhibited a larger area under the CV curve and distinct redox peaks, which collectively highlight its potential for high-performance energy storage applications compared to LiCoO2, which is further corroborated by the galvanostatic charge–discharge curves (Fig. 6b)42,43. In Fig. 6c, the pure nickel foam serves as a conductive support for the active materials, facilitating electron transfer during the electrochemical processes. Its high surface area and porous structure allow for increased accessibility to the electrolyte, which is essential for efficient ion transport. This property is particularly beneficial when assessing the performance of the nanostructured electrodes. In the CV curves, the LiCoO1.6(F0.8Cl0.2)0.4 sample shows a significantly larger area under the curve compared to both the LiCoO2 and the nickel foam. This indicates superior charge storage capacity and enhanced capacitive performance attributed to the optimized anion exchange ratio of 0.4. The distinct redox peaks observed in this sample suggest effective Faradaic reactions, which are crucial for energy storage applications. The LiCoO2, while exhibiting redox activity, shows a lower area under the CV curve, indicating its comparatively moderate capacitive performance. The presence of pure nickel foam, on the other hand, is characterized with minimal capacitance, emphasizing its role primarily as a conductive substrate rather than an energy-storing electrode. The capacitive performance of LiCoO2 is moderately low, but the nanostructured LiCoO1.6(F0.8Cl0.2)0.4 gave a steady and symmetric CV curve, proposing a progressed capacitive behavior compared to the LiCoO244. The redox peaks observed in the cyclic voltammograms of the LiCoO1.6(F0.8Cl0.2)0.4 nanoparticles are due to the Faradaic nature of the test. The rectangular-like shape of the CV curves was preserved at higher scanning rates, showing the near-ideal capacitive behavior of the fabricated nanostructures45. On the other hand, as the scanning rate increased, the area under the curves increased, but the stored charge and consequently the capacity of capacitance declined46. The reason can be that at higher scan rates, the particles do not have sufficient time to enter the electrode structure, and the surface is unchanged, whereas at lower scan rates, both the surface and the bulk of the electrode take part in the reaction47,48,49. The specific capacitance values of LiCoO1.6(F0.8Cl0.2)0.4 electrode estimated from the CV curves were 278, 270, 293.16, 131, 101.31 and 87 F g−1 at scanning rates of 0.005, 0.01, 0.02, 0.05, 0.1 and 0.2 V s−1, calculated from the following equation (Fig. 6d,e)50:

where ν is the scan rate, (Vc–Va) is the potential window, w is the mass of the dynamic fabric, and I is the current.

The galvanostatic charge–discharge (GCD) tests were performed within the potential range of 0–0.6 V to observe the oxidation peak at a constant current density of 1 A g−1 in Fig. 7a and b, and at diverse current densities of 1, 2, 5, and 10 A g−1 in Fig. 7c–e. These results are comparable to the previously reported specific capacitance values for LiCoO2 (Table 2). These results confirm the supercapacitor behavior observed in the CV measurements, and clearly illustrate the enhanced performance of the LiCoO1.6(F0.8Cl0.2)0.4 electrode compared to the LiCoO2 electrode. The nonlinear behavior in the GCD curves is credited to the quasi-reversible Faradaic responses. The LiCoO1.6(F0.8Cl0.2)0.4 electrode showed the longest release time, demonstrating a higher specific capacity compared to the LiCoO2 electrode under the same conditions. This is in good agreement with the results obtained from the CV curves49,51.

The initial charge–discharge curves of the LiCoO1.6(F0.8Cl0.2)0.4 (a), and LiCoO2 (b) at 1 A g−1, the charge–discharge curves of LiCoO1.6(F0.8Cl0.2)0.4 (c), and LiCoO2 (d) at distinct current densities. The discharge curves of LiCoO1.6(F0.8Cl0.2)0.4 at distinct current densities (e). The energy density and power density as a Ragone plot for the LiCoO1.6(F0.8Cl0.2)0.4 electrode (f).

Two critical parameters in the performance of a supercapacitor are energy density and power density. The Ragone plot, which plots power density against energy density, is presented in Fig. 7f. As illustrated, for the LiCoO1.6(F0.8Cl0.2)0.4 electrode, as the current density increases, the power density increases, and the energy density decreases. This implies that at higher current densities, less energy is accessible in a shorter time, which can be rationalized by the fact that at lower current densities, the electrode has more time, and the electrolyte can enter the electrode structure more easily. For the LiCoO1.6(F0.8Cl0.2)0.4 electrode, the energy density and power density were 70.2 Wh kg1 and 2800 W kg−1, respectively, at a current density of 10 A g−1. In comparison, LiCoO2 in a nano-flake structure has a power density of 2262 W kg−1 at an energy density of 41.0 Wh kg−1 at a current density of 6 A g−155. The Co3O4/graphene composite has an energy density of 43.1 Wh kg−1 and a power density of 4000 W kg−1 at a current density of 10 A g−157. The CuCo2S4 NRAs//AC ASC showed an energy density of 26.259 Wh kg−1 and a power density of 4800 W kg−1 at a current density of 15 mA cm−238. The Co3O4 nanocubes-NiO composite exhibited an energy density of 42.0 Wh kg−1 and a power density of 1483 W kg−1 at a current density of 5 A g−113. The values of energy density and power density were also obtained from the following equations (Table 3)52,53:

where C is the specific capacitance, ΔV is the potential window, and Rm is the equivalent series resistance (ESR). At lower scanning rates, the particles have sufficient time to enter the electrode structure, and both the surface and the bulk of the electrode take part in the charge–discharge process. However, at higher scanning rates, the particles do not have sufficient time to diffuse into the electrode network. As a result, only the surface participates in the charge–discharge process, leading to a lower capacity.

The electrochemical performance of LiCoO2 and LiCoO1.6(F0.8Cl0.2)0.4 electrodes was assessed by conducting nonstop charge–discharge cycles at preferable current densities, as presented in Fig. 8. The specific capacitance of the samples was calculated utilizing the following equation50:

where, I is the applied charge–discharge current, m is the mass of the LiCoO2, Δt is the evacuation time, and ΔV is the operating potential window. The LiCoO1.6(F0.8Cl0.2)0.4 sample exhibited high capacitance and good electrochemical behavior, indicating its superior potential for supercapacitor usages. Compared to the LiCoO1.6(F0.8Cl0.2)0.4 sample, the unmodified LiCoO2 electrode, showed a slightly lower specific capacitance, which could be attributed to the presence of the PVDF binder and potential structural changes. However, the LiCoO1.6(F0.8Cl0.2)0.4 electrodes exhibited extraordinary cycling stability, with a capacity retention rate outperforming of 93.6% after 2000 cycles at a current density of 1 A g−1 that is comparable to the previously reported specific capacitance values for the LiCoO2 (Table 2) (Fig. 8a). This transcendent performance reveals a synergistic affect between the carbon material and the energetic LiCoO1.6(F0.8Cl0.2)0.4 component46,54.

(a) The electrochemical capacitance of LiCoO1.6(F0.8Cl0.2)0.4 and LCO at 1 A g−1. (b) The rate performance of LiCoO1.6(F0.8Cl0.2)0.4 and LCO at various discharge current densities. (c) The discharge specific capacitance and coulombic efficiency of LiCoO1.6(F0.8Cl0.2)0.4 electrode (4000 cycles) at 2 A g−1. (d) The charge–discharge profiles of LiCoO1.6(F0.8Cl0.2)0.4 at 2 A g−1.

The coulombic efficiency (η) of the charge storage process is a criterion of the efficiency of ion-charge transfer during an electrochemical reaction. It is calculated as the proportion of the discharge time (tD) to the charge time (tC), using the following equation58,59:

The coulombic efficiency values for the first cycle at different current densities (1, 2, 5, and 10 A g−1) for the LiCoO1.6(F0.8Cl0.2)0.4 electrode was found to be 86.7%, 88.4%, 90.6%, and 92.5%, respectively and also, specific capacitances of 522.16, 503.3, 431.6, and 390 F g−1 were obtained at current densities of 1, 2, 5, and 10 A g−1, respectively (Fig. 8b). The decline in capacitance with growing current density was attributed to the higher potential drop and limited Faradaic reactions at higher discharge rates47. The cycling performance and energy efficiency of the LiCoO1.6(F0.8Cl0.2)0.4 electrode was also evaluated. The sample exhibited a maximum capacitance of 512 F g−1, and an excellent coulombic efficiency of 92.04% after 4000 cycles at a current density of 2 A g−1 (Fig. 8c). The high coulombic efficiency indicated the outstanding long-term electrochemical stability of the electrode48. The galvanostatic charge–discharge curves of the LiCoO1.6(F0.8Cl0.2)0.4 confirmed its highly reversible C-DC action and great electrochemical capacitive characteristics (Fig. 8d).

Electrochemical impedance spectroscopy is a valuable and effective strategy for exploring the electrochemical behavior of supercapacitors and calculating the active parameters of the framework5. The Nyquist plot of the electrodes (Fig. 9a) was obtained in the frequency range of 100 mHz–10 kHz at the open-course potential and with the application of a 5 mV AC potential. The impedance characteristics were analyzed utilizing the Complex Nonlinear Least Squares fitting technique based on a Randles equivalent circuit (Fig. 9a)59. In this circuit, Rs and Rct are solution and charge-transfer resistances, and Cdl and Cps indicate double layer and pseudo-capacitance, respectively. The interfacial diffusive resistance, known as the Warburg impedance, is described as “W”. Two distinct characteristic features in the high and low-frequency regions are attributed to the resistance phenomenon during interfacial processes in Faradaic reaction60. The semicircle at the high-frequency region is characteristic of the resistance at the solid oxide/liquid electrolyte interface61. The linear change observed in the Nyquist plot of LiCoO1.6=(F0.8Cl0.2)0.4 compared to LiCoO2 can be attributed to the enhanced electrochemical kinetics and improved ionic conductivity resulting from anion exchange. The introduction of fluoride and chloride ions alters the electronic and ionic properties of the material, facilitating faster charge transfer at the electrode/electrolyte interface. This is reflected in the nearly vertical line observed in the low-frequency region, indicating ideal capacitive behavior and suggesting that the material can effectively store and release energy with minimal resistance at high current densities. The semicircle at high frequencies corresponds to charge transfer resistance (Rct) and interfacial resistance, with a smaller semicircle for LiCoO1.6(F0.8Cl0.2)0.4 indicating lower resistance compared to LiCoO262,63. The LiCoO1.6(F0.8Cl0.2)0.4 electrode has an ohmic resistance (RS) of 0.04 Ω and a charge transfer resistance (Rct) of 0.135 Ω, which are lower than those of LiCoO2, which has an ohmic resistance of 0.05 Ω and a charge transfer resistance of 0.15 Ω, indicating better electrical performance. The LiCoO1.6(F0.8Cl0.2)0.4 electrode also showed a lower charge transfer resistance than Co3O4 (0.06 Ω)56 and Co3O4/Graphene (0.25 Ω)57. The values of the diffusion coefficient (D) and Warburg coefficient (σw), as well as the double-layer capacitance (Cdl), were obtained from Eqs. 6, 7, 8, and 965, which are given in Table 4. Overall, these characteristics highlight LiCoO1.6(F0.8Cl0.2)0.4 as a more efficient electrode material for supercapacitor applications, demonstrating superior energy storage capabilities. The observed low charge transfer resistance for the electrode is due to the fast Faradaic kinetics and the quick electrical charge exchange facilitated. The low charge transfer resistance value confirms the fast reaction of the supercapacitor and the support of capacity at high current densities64.

Cdl is determined with the angular frequency "w" at medium frequency within maximum value of imaginary impedance "Z″".

Where Rct is charge transfer resistance, Re is electrolyte resistance, ω is angular frequency in the low-frequency region for diffusion, D is diffusion coefficient, A is the area of the electrode surface, T is the area of the absolute temperature, R is the gas constant, and C is molar concentration of KOH.

The exploratory impedance information of the LiCoO1.6(F0.8Cl0.2)0.4 test was changed over to specific capacitance (Cs) utilizing the taking after condition, and plotted against frequency f30:

The specific capacitance values decrease over the whole frequency range. The LiCoO1.6(F0.8Cl0.2)0.4 electrode showed specific capacitance values of 144 F g−1 and 121 F g−1 at 100 mHz and 1 Hz, respectively (Fig. 9b).

Conclusions

In summary, the lithium cobalt oxide was modified to LiCoO1.6(F0.8Cl0.2)0.4 and used as a high-performance pseudocapacitive material for the first time. This modified material exhibited impressive performance characteristics, indicating the great potential of LiCoO2 materials for supercapacitor applications. The LiCoO1.6(F0.8Cl0.2)0.4 sample showed a prominent specific capacitance of 512 F g−1 and a coulombic efficiency of 92.04% (after 4000 cycles) at a current density of 2 A g−1. The LiCoO1.6(F0.8Cl0.2)0.4 electrode had appropriate values of ohmic resistance of 0.04 Ω and charge transfer resistance of 0.135 Ω. Its electrochemical stability at elevated current rates and low equivalent series resistance highlights its suitability for various supercapacitor applications. Overall, the exceptional performance of LiCoO1.6(F0.8Cl0.2)0.4 positions it as a significant candidate for future advancements in supercapacitor technology.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Gui, L. et al. Anion engineering in LiCoO2 for highly efficient oxygen electrocatalysis and rechargeable Zn-air batteries. Appl. Surf. Sci. 15(613), 156039 (2023).

Yu, A., Chabot, V. & Zhang, J. Electrochemical Supercapacitors for Energy Storage and Delivery: Fundamentals and Applications (CRC Press, 2013).

Packiaraj, R., Devendran, P., Venkatesh, K. & Nallamuthu, N. Investigation on the structural, morphological and electrochemical properties of nickel tungstate for energy storage application. Inorg. Chem. Commun. 126, 108490 (2021).

Pandolfo, A. G. & Hollenkamp, A. F. Carbon properties and their role in supercapacitors. J. Power Sources 157(1), 11–27 (2006).

Kim, B. K. et al. Electrochemical supercapacitors for energy storage and conversion. In Handbook of Clean Energy Systems (ed. Yan, J.) 1–25 (Wiley, 2015).

Smith, L., Maloney, R. & Dunn, B. Sol-gel materials for energy storage. In The Sol-Gel Handbook (eds Zayat, M. & Levy, D.) 1119–1144 (Wiley, 2015).

Gopi, C. V., Somasekha, A., Reddy, A. E., Kim, S. K. & Kim, H. J. One-step facile hydrothermal synthesis of Fe2O3@ LiCoO2 composite as excellent supercapacitor electrode materials. Appl. Surf. Sci. 30(435), 462–467 (2018).

Velmurugan, R. & Subramanian, B. Physicochemical approaches for thin film energy storage devices through PVD techniques. In Management and Applications of Energy Storage Devices (ed. Okedu, K. E.) (IntechOpen, 2021).

Zhang, Z. et al. Breaking the local symmetry of LiCoO2 via atomic doping for efficient oxygen evolution. Nano Lett. 19, 8774–8779 (2019).

Zhu, Y. et al. A high-performance Electrocatalyst for oxygen evolution reaction: LiCo0.8Fe0.2O2. Adv. Mater. 27, 7150–7155 (2015).

Singh, J., Palsaniya, S. & Soni, R. K. Mesoporous dark brown TiO2 spheres for pollutant removal and energy storage applications. Appl. Surf. Sci. 15(527), 146796 (2020).

Zheng, X. et al. D interpenetrating networks of MnO2/Carbon-CNTs composites derived from ZIF-67 MOF and their application to supercapacitors. Colloids Surf. A 20(623), 126686 (2021).

Reddy, N. R. et al. Synthesis of novel Co3O4 nanocubes-NiO octahedral hybrids for electrochemical energy storage supercapacitors. J. Environ. Manage. 15(298), 113484 (2021).

Tian, D. et al. The ordered polyaniline nanowires wrapped on the polypyrrole nanotubes as electrode materials for electrochemical energy storage. Electrochim. Acta 1(398), 139328 (2021).

You, M. et al. Electronic tuning of SrIrO3 perovskite nanosheets by sulfur incorporation to induce highlyefficient and long-lasting oxygen evolution in acidic media. Appl. Catal. B Environ. 298, 120562 (2021).

Ede, S. R. et al. Intermediate Sr2Co1.5Fe0.5O6−δ tetragonal structure between perovskite and brownmillerite as a model catalyst with layered oxygen deficiency for enhanced electrochemical water oxidation. ACS Catal. 11(7), 4327–4337 (2021).

Gaurav, A. et al. Could halide perovskites revolutionalise batteries and supercapacitors: A leap in energy storage. J. Energy Storage 30(88), 111468 (2024).

Papageorgiou, D. G., Kinloch, I. A. & Young, R. J. Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater Sci. 1(90), 75–127 (2017).

Durga, I. K., Rao, S. S., Kalla, R. M., Ahn, J. W. & Kim, H. J. Facile synthesis of FeS2/PVP composite as high-performance electrodes for supercapacitors. J. Energy Storage 1(28), 101216 (2020).

Ganfoud, N. et al. Effect of the carbon microporous structure on the capacitance of aqueous supercapacitors. Energy Storage Mater. 1(21), 190–195 (2019).

Pandey, K. & Jeong, H. K. Time-dependent synthesis of tungsten disulfide for flexible supercapacitors. J. Energy Storage 15(90), 111756 (2024).

Ojha, G. P., Pant, B., Acharya, J., Lohani, P. C. & Park, M. Solvothermal-localized selenylation transformation of cobalt nickel MOFs templated heterointerfaces enriched monoclinic Co3Se4/CoNi2Se4@ activated knitted carbon cloth for flexible and bi-axial stretchable supercapacitors. Chem. Eng. J. 15(464), 142621 (2023).

Choudhary, N. et al. Directly deposited MoS 2 thin film electrodes for high performance supercapacitors. J. Mater. Chem. A 3(47), 24049–24054 (2015).

Zheng, X. et al. Electronic structure engineering of LiCoO2 toward enhanced oxygen electrocatalysis. Adv. Energy Mater. 9, 1803482 (2019).

Peng, S. et al. Electronic and defective engineering of electrospun CaMnO3 nanotubes for enhanced oxygen Electrocatalysis in rechargeable zinc-air batteries. Adv. Energy Mater. 8, 1800612 (2018).

Nowroozi, M. A. et al. Fluoride ion batteries–past, present, and future. J. Mater. Chem. A. 9(10), 5980–6012 (2021).

Druffel, D. L. et al. First-principles prediction of electrochemical electron-anion exchange: ion insertion without redox. J. Phys. Chem. Lett. 11, 9210–9214 (2020).

Wu, R., Deng, L., Huang, H., Kubota, M. & Kobayashi, N. Exploration of LiCoO2-doped cobalt oxide composite for thermochemical energy storage at high temperature. J. Energy Storage 30(55), 105774 (2022).

Li, Z. et al. Anion exchange strategy to synthesis of porous NiS hexagonal nanoplates for supercapacitors. Nanotechnology 28(6), 065406 (2017).

Béguin, F., Presser, V., Balducci, A. & Frackowiak, E. Carbons and electrolytes for advanced supercapacitors. Adv. Mater. 26(14), 2219–2251 (2014).

Dighe, A. B., Dubal, D. P. & Holze, R. Screen printed asymmetric supercapacitors based on LiCoO2 and graphene oxide. Z. Anorg. Allg. Chem. 640(14), 2852–2857 (2014).

Zhang, W. et al. Supramolecule-assisted synthesis of cyclodextrin polymer functionalized polyaniline/carbon nanotube with core-shell nanostructure as high-performance supercapacitor material. Electrochim. Acta 20(331), 135345 (2020).

Koike, S. & Tatsumi, K. Preparation and performances of highly porous layered LiCoO2 films for lithium batteries. J. Power Sources 174(2), 976–980 (2007).

Liang, G. & MacNeil, D. D. State-of-the-art production technology of cathode and anode materials for lithium-ion batteries. In Lithium-ion Batteries. Advanced Materials and Technologies 327–402 (CRC Press, 2012).

Sharma, R., Rahul, R., Sharma, M. & Goswamy, J. K. Li-ion battery: Lithium cobalt oxide as cathode material. In AIP Conference Proceedings, Vol. 2265, No. 1 (AIP Publishing, 2020).

Zheng, X. et al. Multifunctional active-center-transferable platinum/lithium cobalt oxide heterostructured electrocatalysts towards superior water splitting. Angew. Chem. Int. Ed. 59(34), 14533–14540 (2020).

Gui, L. et al. In situ exsolved Co nanoparticles coupled on LiCoO2 nanofibers to induce oxygen electrocatalysis for rechargeable Zn–air batteries. J. Mater. Chem. A. 8(38), 19946–19953 (2020).

Cheng, S. et al. Construction of porous CuCo2S4 nanorod arrays via anion exchange for high-performance asymmetric supercapacitor. Sci. Rep. 7(1), 6681 (2017).

Bluth, G. J., Doiron, S. D., Schnetzler, C. C., Krueger, A. J. & Walter, L. S. Global tracking of the SO2 clouds from the June, 1991 Mount Pinatubo eruptions. Geophys. Res. Lett. 19(2), 151–154 (1992).

Xu, Y. et al. Novel application of LiCoO2 as a high-performance candidate material for supercapacitor. J. Energy Chem. 24(2), 193–198 (2015).

Cao, W. et al. Synthesis of zeolitic imidazolate framework-67 nanocube wrapped by graphene oxide and its application for supercapacitors. J. Solid-State Electrochem. 19(23), 325–334 (2019).

Kaliyappan, K., Li, G., Yang, L., Bai, Z. & Chen, Z. An ion conductive polyimide encapsulation: New insight and significant performance enhancement of sodium based P2 layered cathodes. Energy Storage Mater. 1(22), 168–178 (2019).

Dang, R., Li, Q., Chen, M., Hu, Z. & Xiao, X. CuO-Coated and Cu2+-doped Co-modified P2-type Na2/3[Ni1/3Mn2/3] O2 for sodium-ion batteries. Phys. Chem. Chem. Phys. 21(1), 314–321 (2019).

Wang, Q. C. et al. Tuning P2-structured cathode material by Na-site Mg substitution for Na-ion batteries. J. Am. Chem. Soc. 141(2), 840–848 (2018).

Luo, R. et al. Habit plane-driven P2-type manganese-based layered oxide as long cycling cathode for Na-ion batteries. J. Power Sources 15(383), 80–86 (2018).

Wu, Z. S. et al. Graphene/metal oxide composite electrode materials for energy storage. Nano Energy 1(1), 107–131 (2012).

Gabriel, F., Benitez, J., Jorge, A., Peruzzi, B. & Faria, R. N. Jr. Mathematical expressions for simulation of supercapacitor voltammetry curves and capacitance dependence on scan rate. J. Energy Storage 15(87), 111267 (2024).

Raut, K., Shendge, A., Chaudhari, J., Lamba, R. & Alshammari, N. F. Modeling and simulation of photovoltaic powered battery-supercapacitor hybrid energy storage system for electric vehicles. J. Energy Storage 30(82), 110324 (2024).

Shi, Y. et al. Probing the structural transition kinetics and charge compensation of the P2-Na0.78Al0.05Ni0.33Mn0.60O2 cathode for sodium ion batteries. ACS Appl. Mater. Interfaces 11(27), 24122–24131 (2019).

Chen, T. et al. An inactive metal supported oxide cathode material with high-rate capability for sodium ion batteries. Energy Storage Mater. 1(20), 263–268 (2019).

Zheng, X. et al. New insights into understanding the exceptional electrochemical performance of P2-type manganese-based layered oxide cathode for sodium ion batteries. Energy Storage Mater. 1(15), 257–265 (2018).

Dong, W., Xie, M., Zhao, S., Qin, Q. & Huang, F. Materials design and preparation for high energy density and high-power density electrochemical supercapacitors. Mater. Sci. Eng. R. Rep. 1(152), 100713 (2023).

Fan, X. et al. High power-and energy-density supercapacitors through the chlorine respiration mechanism. Angew. Chem. 135(2), e202215342 (2023).

Xin, S., Guo, Y. G. & Wan, L. J. Nanocarbon networks for advanced rechargeable lithium batteries. Acc. Chem. Res. 45(10), 1759–1769 (2012).

Liu, Q. et al. Promoting power density by cleaving LiCoO2 into nano-flake structure for high performance supercapacitor. Nanoscale 9(17), 5509–5516 (2017).

Aboelazm, E. A. et al. Magnetic electrodeposition of the hierarchical cobalt oxide nanostructure from spent lithium-ion batteries: Its application as a supercapacitor electrode. J. Phys. Chem. C. 122(23), 12200–12206 (2018).

Yang, S. et al. Oxygen-vacancy abundant ultrafine Co3O4/graphene composites for high-rate supercapacitor electrodes. Adv. Sci. 5(4), 1700659 (2018).

Meher, S. K., Justin, P. & Rao, G. R. Nanoscale morphology dependent pseudocapacitance of NiO: Influence of intercalating anions during synthesis. Nanoscale 3(2), 683–692 (2011).

Hsu, Y. K., Chen, Y. C., Lin, Y. G., Chen, L. C. & Chen, K. H. Reversible phase transformation of MnO2 nanosheets in an electrochemical capacitor investigated by in situ Raman spectroscopy. Chem. Commun. 47(4), 1252–1254 (2011).

Zhu, X., Zhang, X., Li, Y. & Liu, Y. Exploring transition metal oxide-based oxygen vacancy supercapacitors: A review. J. Energy Storage 1(80), 110350 (2024).

Lin, K. M., Chang, K. H., Hu, C. C. & Li, Y. Y. Mesoporous RuO2 for the next generation supercapacitors with an ultrahigh power density. Electrochim. Acta 54(19), 4574–4581 (2009).

Grey, C. P. & Dupré, N. NMR studies of cathode materials for lithium-ion rechargeable batteries. Chem. Rev. 104(10), 4493–4512 (2004).

Wagemaker, M., van de Krol, R., Kentgens, A. P., Van Well, A. A. & Mulder, F. M. Two phase morphology limits lithium diffusion in TiO2 (anatase): A 7Li MAS NMR study. J. Am. Chem. Soc. 123(46), 11454–11461 (2001).

Ramesh, S. et al. Nanostructurally fabrication of nickel oxide-interfaced carbon nanotubes for supercapacitors and exploration of electrochemical correlation via computer vision techniques and artificial intelligence. J. Energy Storage. 30(82), 110429 (2024).

Eraky, M. S., El-Sadek, M., Shenouda, A. Y. & Sanad, M. M. Fabrication of new Mn-based MXene structure from MnO2 for electrochemical energy storage applications. Monatshefte für Chemie-Chemical Monthly 155(3), 289–297 (2024).

Acknowledgements

Partial support for this study from the research council of the University of Guilan is gratefully acknowledged.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

S. M. Hashemzadeh performed the experiments and contributed to the preparation of the initial manuscript draft. A. Khorshidi conceptualized and supervised the research and edited the manuscript. M. Arvand contributed to the electrochemical data analyses and edited the manuscript draft.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hashemzadeh, S.M., Khorshidi, A. & Arvand, M. Anion engineering in lithium cobalt oxide for application in high-performance supercapacitors. Sci Rep 15, 10064 (2025). https://doi.org/10.1038/s41598-025-95338-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-95338-7

Keywords

This article is cited by

-

Assessing carbon–neutral supercapacitors in renewable energy systems with self-improving agent-based molecular fuzzy intelligent algorithms

Scientific Reports (2025)

-

A Comprehensive Review on Synthesis of Nanocomposites for Supercapacitor

Journal of Inorganic and Organometallic Polymers and Materials (2025)